SUZUKI SWIFT 2000 1.G Transmission Service Workshop Manual

SWIFT 2000 1.G

SUZUKI

SUZUKI

https://www.carmanualsonline.info/img/20/7605/w960_7605-0.png

SUZUKI SWIFT 2000 1.G Transmission Service Workshop Manual

Trending: wheel bolt torque, wiper fluid, ABS, door lock, fuel pump, change time, oil viscosity

Page 191 of 447

CLUTCH 7C-9

3) Pull out input shaft bearing (1) by using special tool (B), and

wrench.

Special tool

(B) : 09921-26020

09930-30104

INSPECTION

Input Shaft Bearing

Check bearing (1) for smooth rotation and replace it if abnormality

is found.

Clutch Disc

Measure depth of rivet head depression, i.e. distance between

rivet head and facing surface. If depression is found to have

reached service limit at any of holes, replace disc assembly.

Rivet head depth

Standard : 1.65 – 2.25 mm (0.06 – 0.09 in.)

Service limit : 0.5 mm (0.02 in.)

Clutch Cover

1) Check diaphragm spring (1) for abnormal wear or damage.

2) Inspect pressure plate (2) for wear or heat spots.

3) If abnormality is found, replace it as assembly. Do not disas-

semble it into diaphragm and pressure plate.

Flywheel

Check surface contacting clutch disc for abnormal wear or heat

spots. Replace or repair as required.

Page 192 of 447

7C-10 CLUTCH

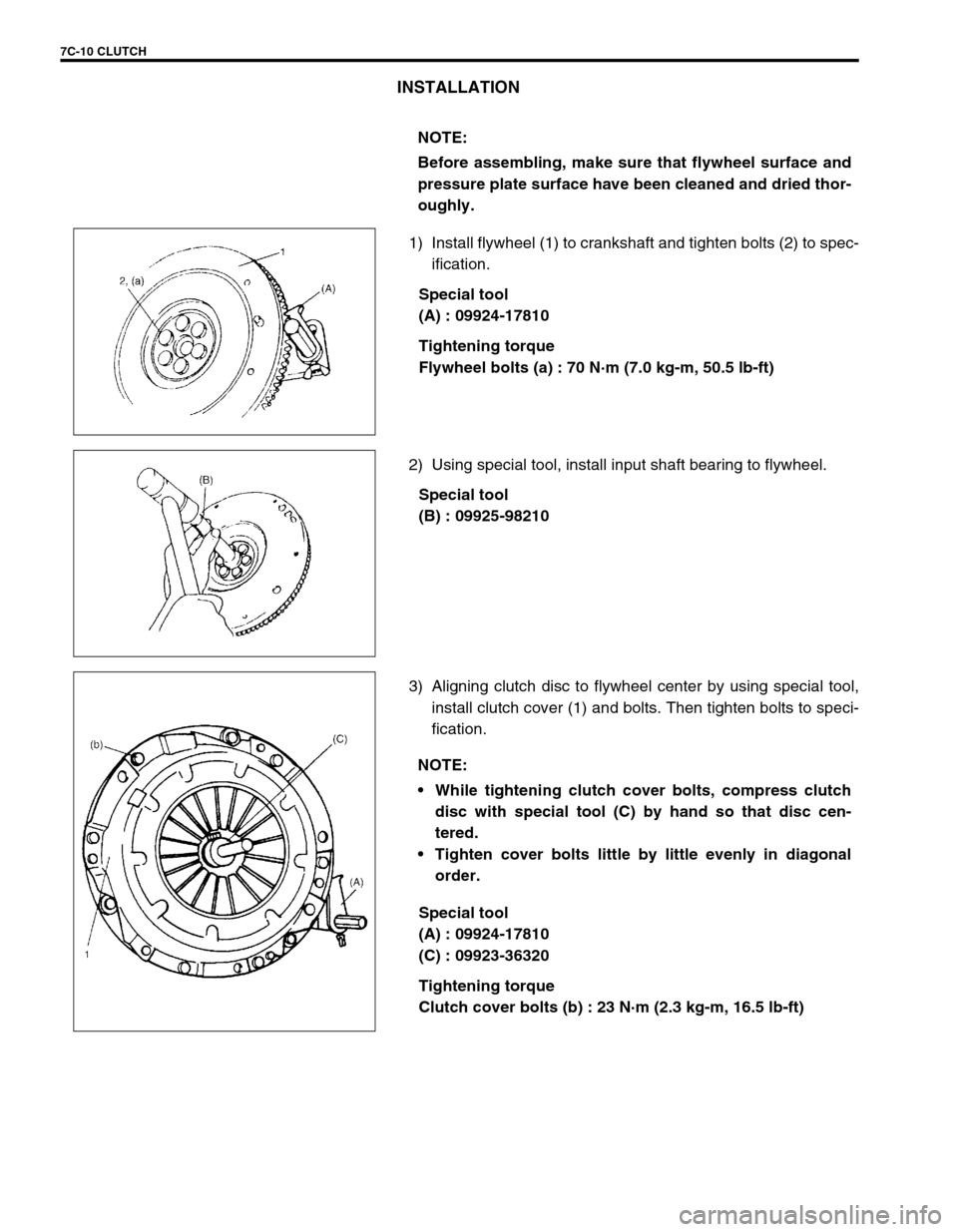

INSTALLATION

1) Install flywheel (1) to crankshaft and tighten bolts (2) to spec-

ification.

Special tool

(A) : 09924-17810

Tightening torque

Flywheel bolts (a) : 70 N·m (7.0 kg-m, 50.5 lb-ft)

2) Using special tool, install input shaft bearing to flywheel.

Special tool

(B) : 09925-98210

3) Aligning clutch disc to flywheel center by using special tool,

install clutch cover (1) and bolts. Then tighten bolts to speci-

fication.

Special tool

(A) : 09924-17810

(C) : 09923-36320

Tightening torque

Clutch cover bolts (b) : 23 N·m (2.3 kg-m, 16.5 lb-ft) NOTE:

Before assembling, make sure that flywheel surface and

pressure plate surface have been cleaned and dried thor-

oughly.

NOTE:

While tightening clutch cover bolts, compress clutch

disc with special tool (C) by hand so that disc cen-

tered.

Tighten cover bolts little by little evenly in diagonal

order.

Page 193 of 447

CLUTCH 7C-11

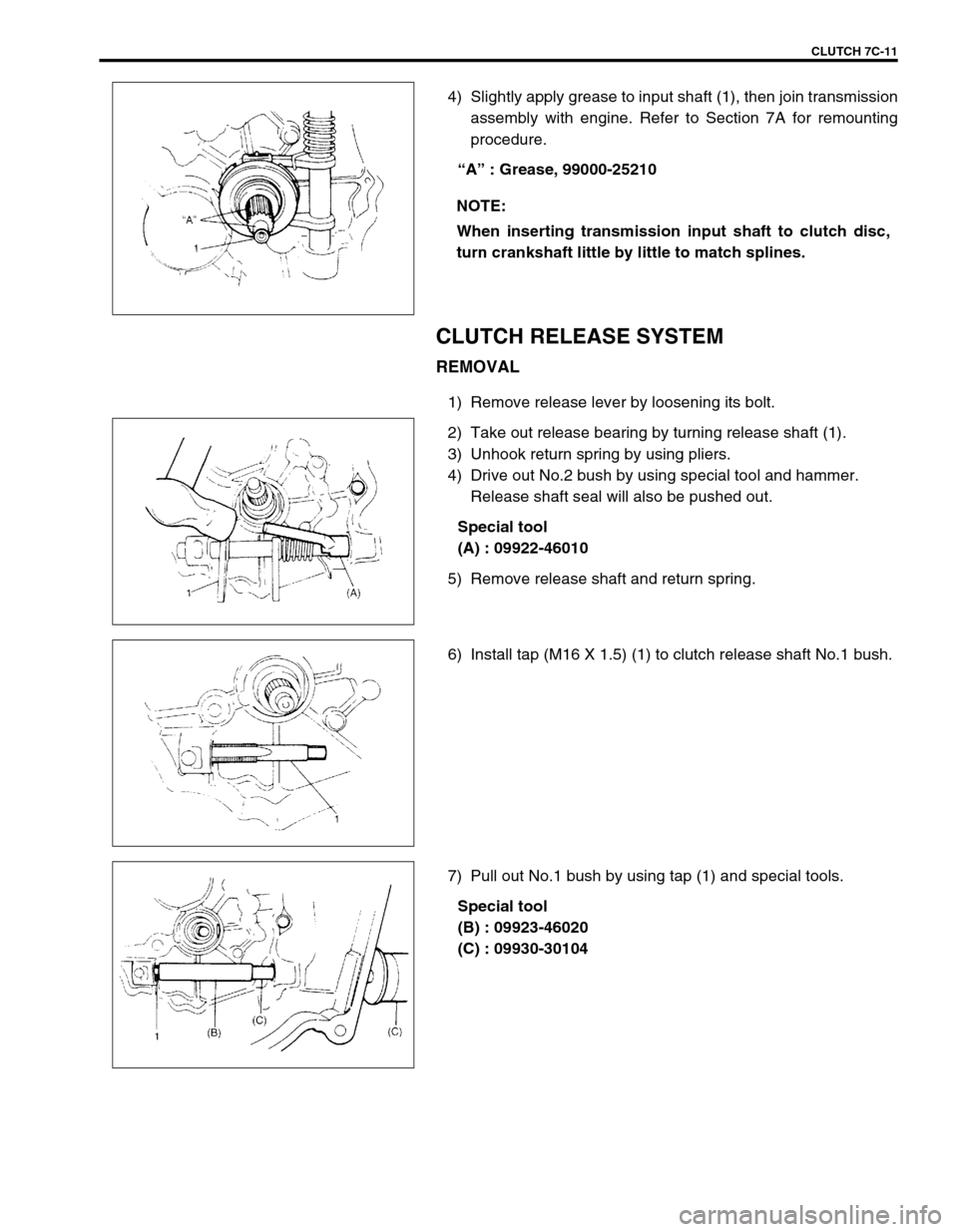

4) Slightly apply grease to input shaft (1), then join transmission

assembly with engine. Refer to Section 7A for remounting

procedure.

“A” : Grease, 99000-25210

CLUTCH RELEASE SYSTEM

REMOVAL

1) Remove release lever by loosening its bolt.

2) Take out release bearing by turning release shaft (1).

3) Unhook return spring by using pliers.

4) Drive out No.2 bush by using special tool and hammer.

Release shaft seal will also be pushed out.

Special tool

(A) : 09922-46010

5) Remove release shaft and return spring.

6) Install tap (M16 X 1.5) (1) to clutch release shaft No.1 bush.

7) Pull out No.1 bush by using tap (1) and special tools.

Special tool

(B) : 09923-46020

(C) : 09930-30104 NOTE:

When inserting transmission input shaft to clutch disc,

turn crankshaft little by little to match splines.

Page 194 of 447

7C-12 CLUTCH

INSPECTION

Clutch release bearing

Check clutch release bearing for smooth rotation.

If abnormality is found, replace it.

Clutch release shaft

Check clutch release shaft and its pin for deflection or damage.

If abnormality is found, replace it.

INSTALLATION

1) Drive in a new No.1 bush by using special tools and then

apply grease to bush inside.

Special tool

(A) : 09930-30104

(B) : 09923-46030

“A” : Grease 99000-25010

2) Install release shaft with return spring applied to it.CAUTION:

Do not wash release bearing. Washing may cause grease

leakage and consequential bearing damage.

Page 195 of 447

CLUTCH 7C-13

3) Apply grease to No.2 bush (1) inside and press-fit it by using

the same special tool as in removal.

“A” : Grease 99000-25010

Special tool

(C) : 09922-46010

4) Coat grease to shaft seal (2) lip and then install it till it is flush

with case surface. Use special tool for this installation and

face seal lip downward (inside).

“A” : Grease 99000-25010

Special tool

(D) : 09925-98221

5) Caulk seal at A by using caulking tool and hammer.

6) Hook return spring.

7) Apply grease to release bearing (1) inside and release shaft

arm (2), then set bearing.

“A” : Grease 99000-25010

8) Apply small amount of grease to input shaft (3) spline (0.3 g)

and front end (0.15 g) as well.

“B” : Grease 99000-25210

9) Set release lever to release shaft aligning their punch marks

(1), then tighten bolt.

Tightening torque

Release lever bolt (a) : 23 N·m (2.3 kg-m, 16.5 lb-ft)

Page 196 of 447

7C-14 CLUTCH

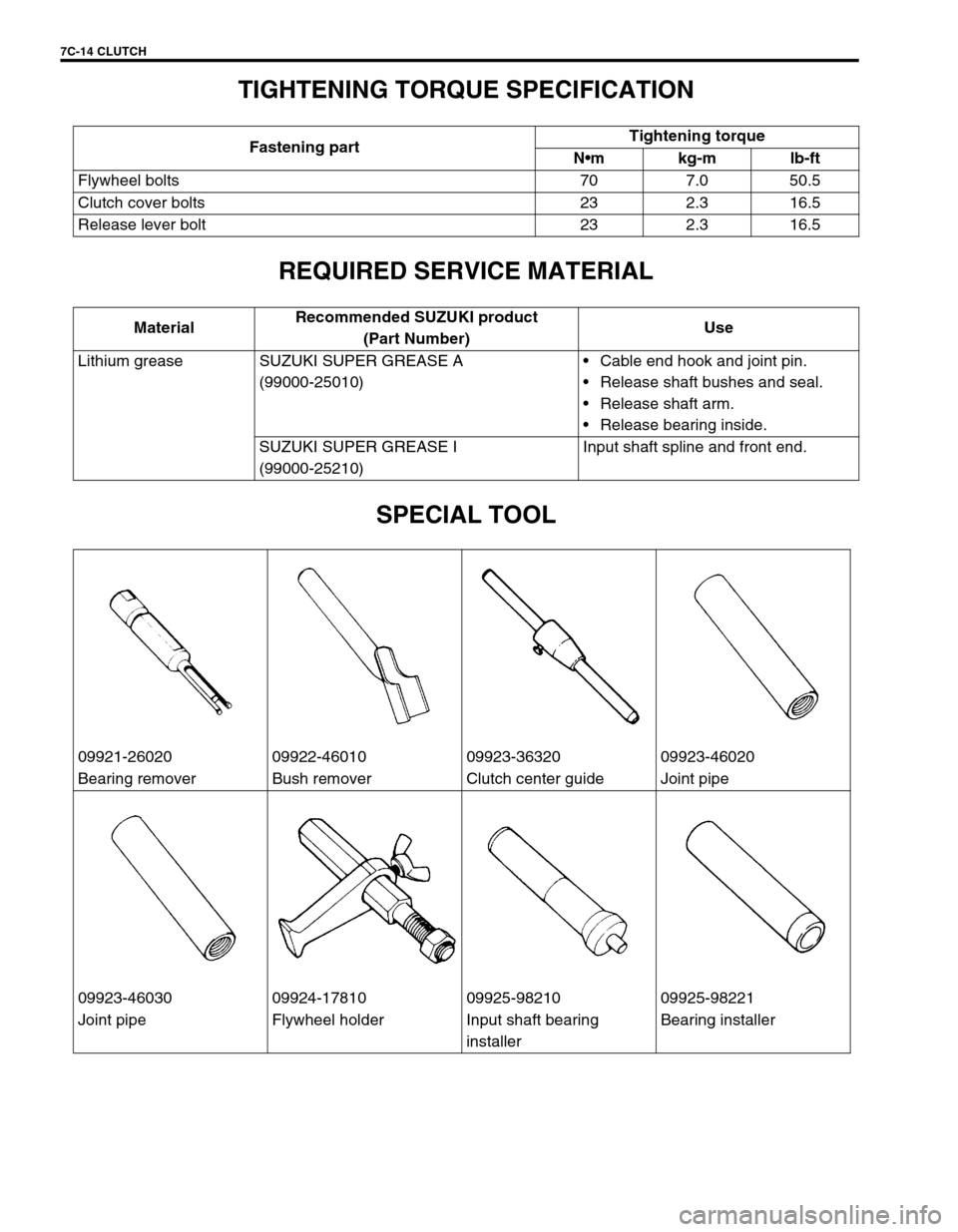

TIGHTENING TORQUE SPECIFICATION

REQUIRED SERVICE MATERIAL

SPECIAL TOOL

Fastening partTightening torque

Nm kg-m lb-ft

Flywheel bolts 70 7.0 50.5

Clutch cover bolts 23 2.3 16.5

Release lever bolt 23 2.3 16.5

MaterialRecommended SUZUKI product

(Part Number)Use

Lithium grease SUZUKI SUPER GREASE A

(99000-25010)Cable end hook and joint pin.

Release shaft bushes and seal.

Release shaft arm.

Release bearing inside.

SUZUKI SUPER GREASE I

(99000-25210)Input shaft spline and front end.

09921-26020 09922-46010 09923-36320 09923-46020

Bearing remover Bush remover Clutch center guide Joint pipe

09923-46030 09924-17810 09925-98210 09925-98221

Joint pipe Flywheel holder Input shaft bearing

installerBearing installer

Page 197 of 447

CLUTCH 7C-15

09930-30104

Sliding shaft

Page 198 of 447

Page 199 of 447

TRANSFER 7D-1

6F1

6F2

6G

6H

6K

7A

7A1

7B1

7C1

7E

7F

7D

8A

8B

8C

8D

8E

9

10

10A

10B

SECTION 7D

TRANSFER

CONTENTS

GENERAL DESCRIPTION ...............................7D-2

DIAGNOSIS ......................................................7D-2

ON-VEHICLE SERVICE ...................................7D-3

UNIT REPAIR OVERHAUL ..............................7D-4

UNIT DISMOUNTING ...................................7D-5

UNIT DISASSEMBLY ...................................7D-6

TRANSFER ASSEMBLY...........................7D-6

REDUCTION DRIVEN GEAR ...................7D-7

INTERMEDIATE SHAFT ...........................7D-8

TRANSFER OUTPUT RETAINER ............7D-9

COMPONENT INSPECTION ......................7D-10

UNIT ASSEMBLY .......................................7D-10REDUCTION DRIVEN GEAR ................. 7D-10

BEVEL GEAR SHIM ............................... 7D-11

TRANSFER OUTPUT RETAINER .......... 7D-12

RIGHT CASE .......................................... 7D-16

LEFT CASE............................................. 7D-17

TRANSFER ASSEMBLY ........................ 7D-17

BEVEL GEAR BACK LASH .................... 7D-18

UNIT INSTALLATION ................................. 7D-20

TIGHTENING TORQUE SPECIFICATION..... 7D-22

REQUIRED SERVICE MATERIAL................. 7D-22

SPECIAL TOOL ............................................. 7D-22

Page 200 of 447

7D-2 TRANSFER

GENERAL DESCRIPTION

The transfer consists of parts as shown in figure.

DIAGNOSIS

1. Intermediate shaft 6. Shim 11. Transfer output retainer

2. Left case 7. Reduction driven gear 12. Flange

3. Reduction drive gear 8. Bevel gear✱

:Forward

4. Circlip 9. Bevel pinion shaft

5. Right case 10. Pinion shaft spacer

Condition Possible Cause Correction

Noise

Inadequate or insufficient lubricant Replenish.

Damaged or worn bearing(s) Replace.

Damaged or worn gear(s) Replace.

Damaged or worn chamfered tooth on sleeve or

gearReplace.

Preload of taper roller bearing is reduced Adjust.

Trending: steering wheel, wheel, sensor, fuel pump, lug pattern, window, drain bolt