SUZUKI SWIFT 2000 1.G Transmission Service Workshop Manual

Manufacturer: SUZUKI, Model Year: 2000, Model line: SWIFT, Model: SUZUKI SWIFT 2000 1.GPages: 447, PDF Size: 10.54 MB

Page 271 of 447

BODY ELECTRICAL SYSTEM 8-27

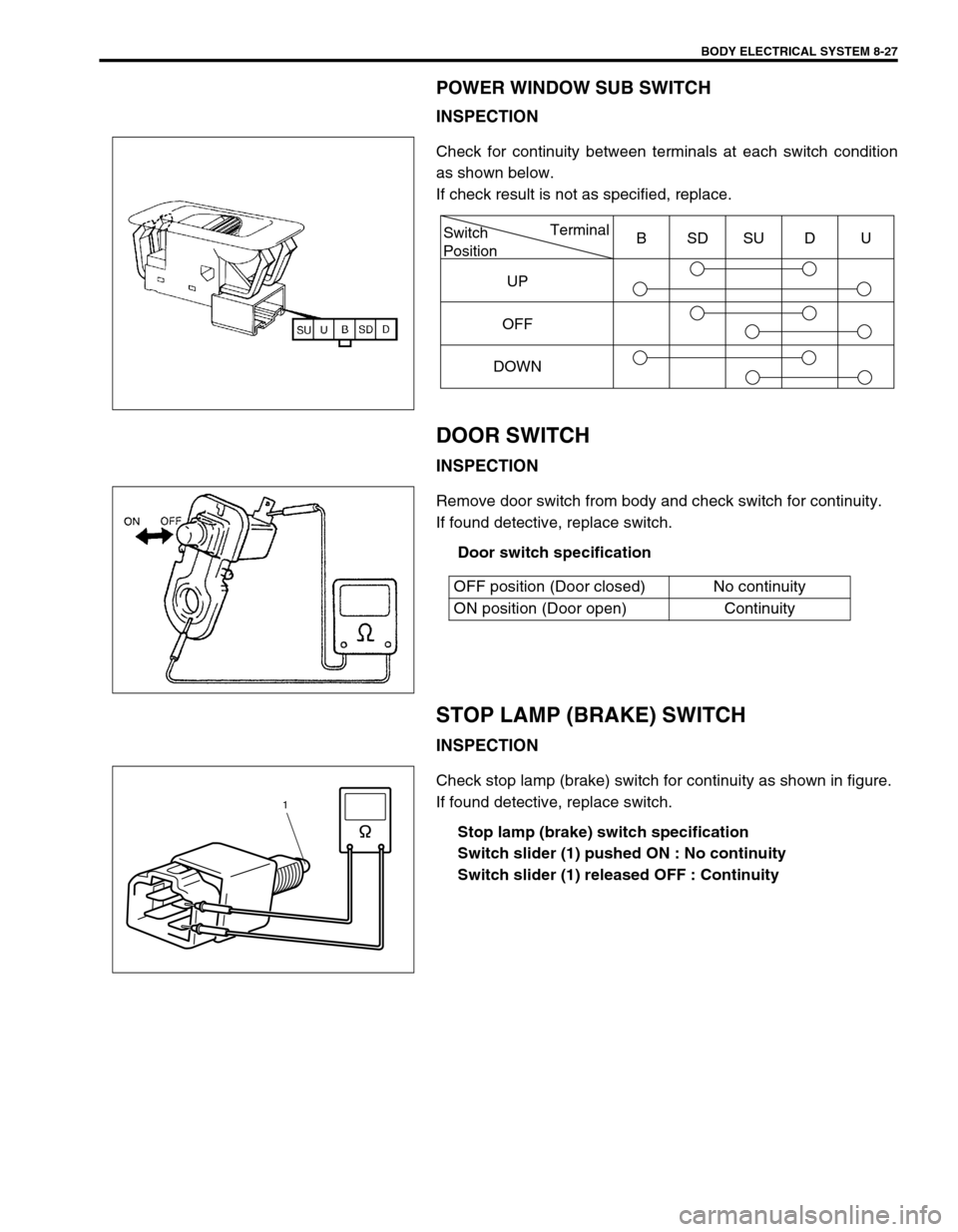

POWER WINDOW SUB SWITCH

INSPECTION

Check for continuity between terminals at each switch condition

as shown below.

If check result is not as specified, replace.

DOOR SWITCH

INSPECTION

Remove door switch from body and check switch for continuity.

If found detective, replace switch.

Door switch specification

STOP LAMP (BRAKE) SWITCH

INSPECTION

Check stop lamp (brake) switch for continuity as shown in figure.

If found detective, replace switch.

Stop lamp (brake) switch specification

Switch slider (1) pushed ON : No continuity

Switch slider (1) released OFF : Continuity

Terminal

Switch

Position

UPBSDSUD U

OFF

DOWN

OFF position (Door closed) No continuity

ON position (Door open) Continuity

1

Page 272 of 447

8-28 BODY ELECTRICAL SYSTEM

POWER DOOR LOCK SYSTEM (IF

EQUIPPED)

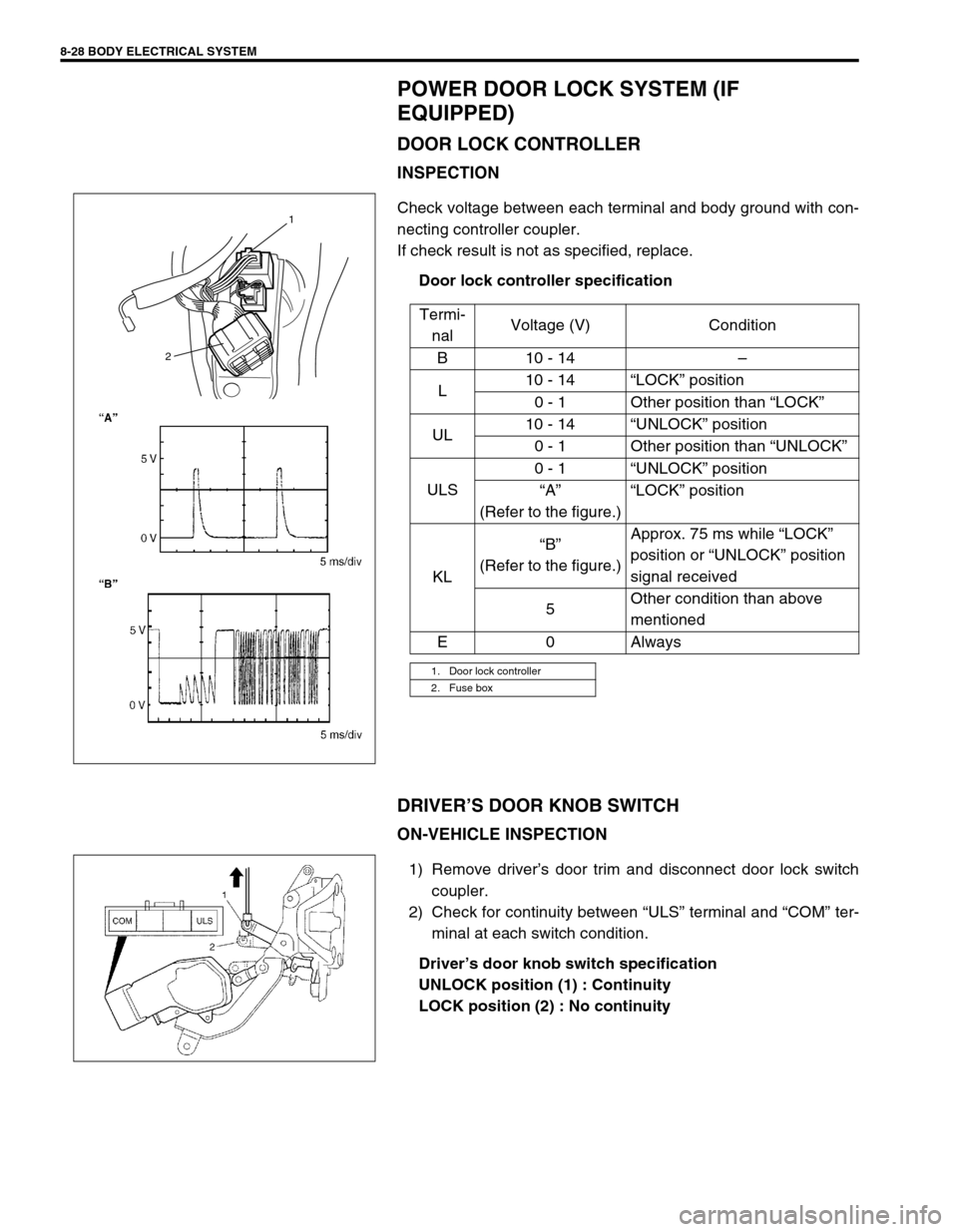

DOOR LOCK CONTROLLER

INSPECTION

Check voltage between each terminal and body ground with con-

necting controller coupler.

If check result is not as specified, replace.

Door lock controller specification

DRIVER’S DOOR KNOB SWITCH

ON-VEHICLE INSPECTION

1) Remove driver’s door trim and disconnect door lock switch

coupler.

2) Check for continuity between “ULS” terminal and “COM” ter-

minal at each switch condition.

Driver’s door knob switch specification

UNLOCK position (1) : Continuity

LOCK position (2) : No continuityTermi-

nalVoltage (V) Condition

B10 - 14–

L10 - 14“LOCK” position

0 - 1 Other position than “LOCK”

UL10 - 14“UNLOCK” position

0 - 1 Other position than “UNLOCK”

ULS0 - 1“UNLOCK” position

“A”

(Refer to the figure.)“LOCK” position

KL“B”

(Refer to the figure.)Approx. 75 ms while “LOCK”

position or “UNLOCK” position

signal received

5Other condition than above

mentioned

E0Always

1. Door lock controller

2. Fuse box

1

2

Page 273 of 447

BODY ELECTRICAL SYSTEM 8-29

DOOR LOCK ACTUATOR

ON-VEHICLE INSPECTION

1) Remove door trim (front, rear or back) and disconnect door

lock actuator (3) coupler.

2) Connect battery (+) terminal to terminal “L” and (-) terminal

to terminal “UL”. Check that door lock actuator (3) is on

“LOCK” position.

If check result is not satisfied, replace.

3) Connect battery (+) terminal to terminal “UL” and (-) terminal

to terminal “L”. Check that door lock actuator (3) is on

“UNLOCK” position.

If check result is not satisfied, replace.

KEYLESS ENTRY SYSTEM (IF EQUIPPED)

DOOR LOCK CONTROLLER

INSPECTION

Refer to DOOR LOCK CONTROLLER of POWER DOOR LOCK

SYSTEM (IF EQUIPPED) in this section.

DOOR LOCK ACTUATOR

INSPECTION

Refer to DOOR LOCK ACTUATOR of POWER DOOR LOCK

SYSTEM (IF EQUIPPED) in this section.

[A] : FRONT DOOR

[B] : REAR DOOR

[C] : BACK DOOR

Page 274 of 447

8-30 BODY ELECTRICAL SYSTEM

RECEIVER

INSPECTION

Check voltage between each terminal and body ground with con-

necting controller coupler. If check result is not as specified,

replace.

Receiver specification

Reference :

TRANSMITTER

REPLACEMEMT OF THE BATTERY

If the transmitter becomes unreliable, replace the battery.

As the battery power is consumed, the operation distance will be

shorter.

1) Remove screw.

2) Use a small coin or flat blade screwdriver to separate the

bottom half from the top half of the transmitter.

3) Replace the battery with the new one. Make sure the posi-

tive (+) side of battery faces up. For battery replacement,

use type CR2032 or equivalent.

4) Put the two halves back together and install a screw.

5) Make sure the door locks can be operated with the transmit-

ter. Terminal Voltage (V) Condition

B10 - 14Always

SIG“A”

(Refer to the figure)Approx. 75 ms while trans-

mitter signal received

5Other condition than above

mentioned

GND 0 Always

1. Receiver

2. Receiver coupler (receiver side)

Page 275 of 447

BODY ELECTRICAL SYSTEM 8-31

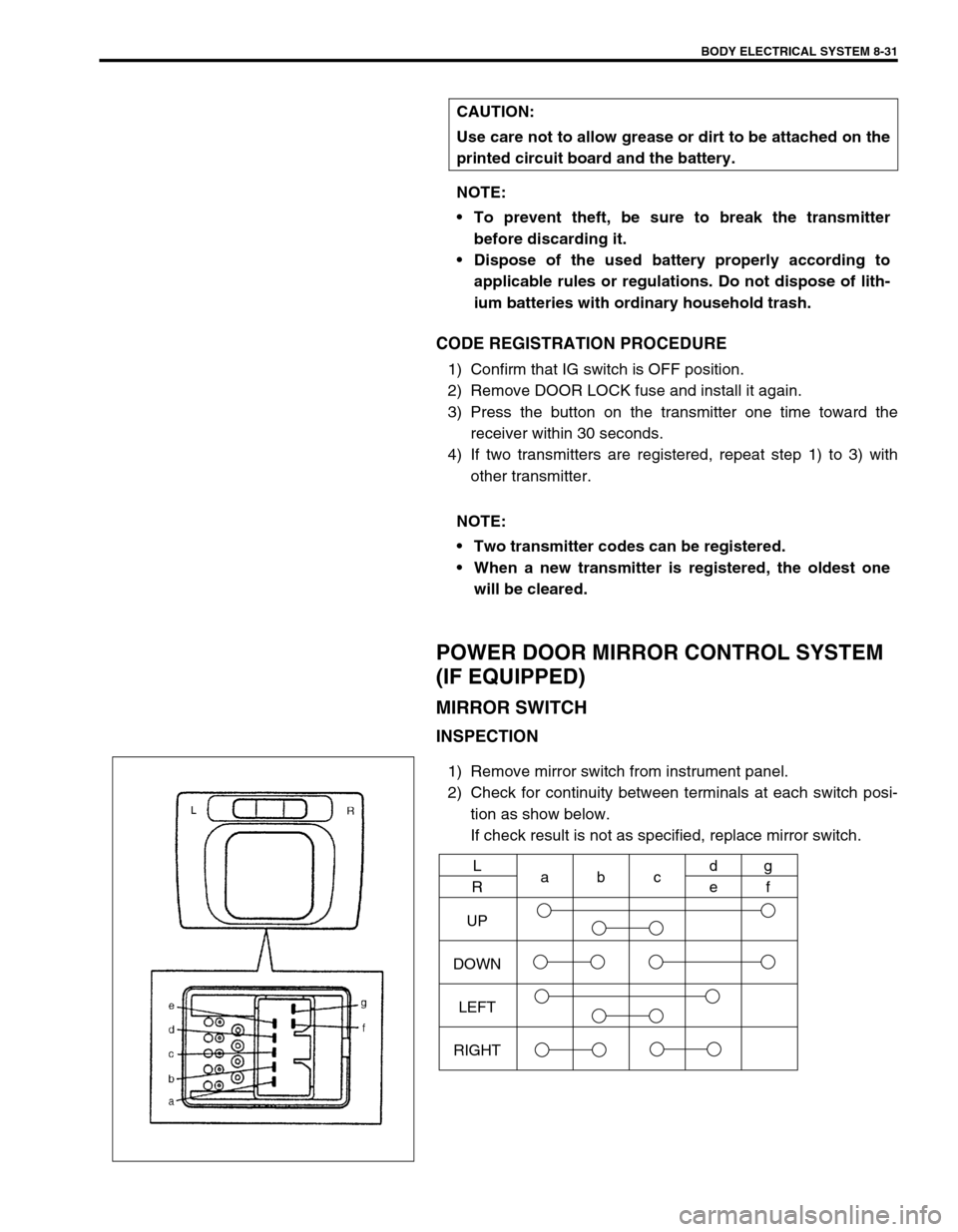

CODE REGISTRATION PROCEDURE

1) Confirm that IG switch is OFF position.

2) Remove DOOR LOCK fuse and install it again.

3) Press the button on the transmitter one time toward the

receiver within 30 seconds.

4) If two transmitters are registered, repeat step 1) to 3) with

other transmitter.

POWER DOOR MIRROR CONTROL SYSTEM

(IF EQUIPPED)

MIRROR SWITCH

INSPECTION

1) Remove mirror switch from instrument panel.

2) Check for continuity between terminals at each switch posi-

tion as show below.

If check result is not as specified, replace mirror switch. CAUTION:

Use care not to allow grease or dirt to be attached on the

printed circuit board and the battery.

NOTE:

To prevent theft, be sure to break the transmitter

before discarding it.

Dispose of the used battery properly according to

applicable rules or regulations. Do not dispose of lith-

ium batteries with ordinary household trash.

NOTE:

Two transmitter codes can be registered.

When a new transmitter is registered, the oldest one

will be cleared.

UP

DOWN

LEFT

RIGHTL

Rabcd

eg

f

Page 276 of 447

8-32 BODY ELECTRICAL SYSTEM

DOOR MIRROR ACTUATOR

INSPECTION

1) Remove garnish from door.

2) Pull out door mirror coupler at bracket.

3) Disconnect door mirror coupler.

4) Check that door mirror operates properly when battery volt-

age is applied to connector terminals.

Connect battery positive and negative terminal to the door

mirror terminal shown below.

If it does not follow the table’s operation, replace door mirror

assembly.

FRONT SEAT HEATER (IF EQUIPPED)

SEAT HEATER SWITCH (DRIVER AND PASSENGER

SIDE)

INSPECTION

1) Confirm that ignition switch is OFF position.

2) Pull out seat heater switch from front center console box.

3) Disconnect seat heater switch coupler.

4) Check for continuity between terminals at each switch posi-

tion as show below. If check result is not as specified,

replace. NOTE:

When installing door mirror to door, be careful not to

pinch harness between door and door mirror.

M2COMM1

Terminal

Operation

UpCOM M1 M2

Down

Left

Right

Terminal

Switch

Position

OFF

LO

HIIG LOAD1 LOAD2 E

Page 277 of 447

BODY ELECTRICAL SYSTEM 8-33

SEAT HEATER WIRE

INSPECTION

1) Confirm that seat heater switch is OFF position.

2) Disconnect two couplers of seat heater under the seat cush-

ion.

3) Check for continuity between terminals as show below.

If not continuity, replace faulty seat heater.

Seat heater circuit in seat back

Between “a” and “b”

Between “b” and “d”

Between “c” and “e”

Seat heater circuit in seat cushion

Between “f” and “g”

1. Heater wire

2. Thermostat

Page 278 of 447

8-34 BODY ELECTRICAL SYSTEM

Page 279 of 447

IMMOBILIZER CONTROL SYSTEM 8G-1

6F1

6F2

6G

6H

6K

7A

7A1

7B1

7C1

7D

7E

7F

8A

8B

8C

8D

8G

9

10

10A

10B

SECTION 8G

IMMOBILIZER CONTROL SYSTEM

CONTENTS

GENERAL DESCRIPTION ............................. 8G-2

WIRING CIRCUIT ....................................... 8G-3

ON-BOARD DIAGNOSTIC SYSTEM

(SELF-DIAGNOSIS FUNCTION) ................ 8G-4

DIAGNOSIS .................................................... 8G-5

PRECAUTIONS IN DIAGNOSING

TROUBLES ................................................. 8G-5

PRECAUTIONS IN IDENTIFYING

DIAGNOSTIC TROUBLE CODE............. 8G-5

DIAGNOSTIC FLOW TABLE ...................... 8G-6

DIAGNOSTIC TROUBLE CODE (DTC)

CHECK

(IMMOBILIZER CONTROL MODULE)........ 8G-7

DIAGNOSTIC TROUBLE CODE (DTC)

CHECK (ECM) ............................................ 8G-8

DIAGNOSTIC TROUBLE CODE TABLE .... 8G-9

TABLE A - IMMOBILIZER INDICATOR

LAMP CHECK (IMMOBILIZER INDICATOR

LAMP DOES NOT LIGHT AT IGNITION

SWITCH ON) ............................................ 8G-10

TABLE B - IMMOBILIZER INDICATOR

LAMP CHECK (IMMOBILIZER INDICATOR

LAMP REMAINS ON AFTER ENGINE

STARTS) ................................................... 8G-11

TABLE C - DTC IS NOT OUTPUT FROM

IMMOBILIZER CONTROL MODULE ........ 8G-12

DTC11/32 TRANSPONDER CODE NOT

MATCHED ................................................ 8G-13

DTC31 TRANSPONDER CODE NOT

REGISTERED ........................................... 8G-14

DTC12 FAULT IN IMMOBILIZER

CONTROL MODULE ................................ 8G-14DTC13 NO TRANSPONDER CODE

TRANSMITTED OR COIL ANTENNA

OPENED/SHORTED ................................. 8G-15

DTC21 ECM/IMMOBILIZER CONTROL

MODULE CODE NOT MATCHED

(IMMOBILIZER CONTROL MODULE

SIDE) ......................................................... 8G-16

DTC P1623 ECM/IMMOBILIZER CONTROL

MODULE CODE NOT MATCHED (ECM

SIDE) ......................................................... 8G-16

DTC P1620 ECM/IMMOBILIZER CONTROL

MODULE CODE NOT REGISTERED ....... 8G-16

DTC P1622 FAULT IN ECM ...................... 8G-16

DTC22 IGNITION SWITCH CIRCUIT

OPEN/SHORT ........................................... 8G-17

DTC23 NO ECM/IMMOBILIZER CONTROL

MODULE CODE TRANSMITTED FROM

ECM OR DLC CIRCUIT OPENED/

SHORTED ................................................. 8G-18

DTC P1621 NO ECM/IMMOBILIZER

CONTROL MODULE CODE TRANSMITTED

FROM IMMOBILIZER CONTROL

MODULE OR DLC CIRCUIT OPENED/

SHORTED ................................................. 8G-18

INSPECTION OF ECM, IMMOBILIZER

CONTROL MODULE AND ITS CIRCUIT .. 8G-20

ON-VEHICLE SERVICE ................................ 8G-21

PRECAUTIONS IN HANDLING

IMMOBILIZER CONTROL SYSTEM ......... 8G-21

IMMOBILIZER CONTROL MODULE ......... 8G-22

HOW TO REGISTER IGNITION KEY ........... 8G-23 WARNING:

For vehicles equipped with Supplemental Restraint (Air Bag) System

Service on and around the air bag system components or wiring must be performed only by an

authorized SUZUKI dealer. Refer to “Air Bag System Components and Wiring Location View” under

“General Description” in air bag system section in order to confirm whether you are performing ser-

vice on or near the air bag system components or wiring. Please observe all WARNINGS and “Ser-

vice Precautions” under “On-Vehicle Service” in air bag system section before performing service

on or around the air bag system components or wiring. Failure to follow WARNINGS could result in

unintentional activation of the system or could render the system inoperative. Either of these two

conditions may result in severe injury.

Technical service work must be started at least 90 seconds after the ignition switch is turned to the

“LOCK” position and the negative cable is disconnected from the battery. Otherwise, the system

may be activated by reserve energy in the Sensing and Diagnostic Module (SDM).

Page 280 of 447

8G-2 IMMOBILIZER CONTROL SYSTEM

PROCEDURE AFTER IMMOBILIZER CONTROL

MODULE REPLACEMENT ........................... 8G-24

PROCEDURE AFTER ECM

REPLACEMENT............................................ 8G-25SPECIAL TOOL ............................................ 8G-25

GENERAL DESCRIPTION

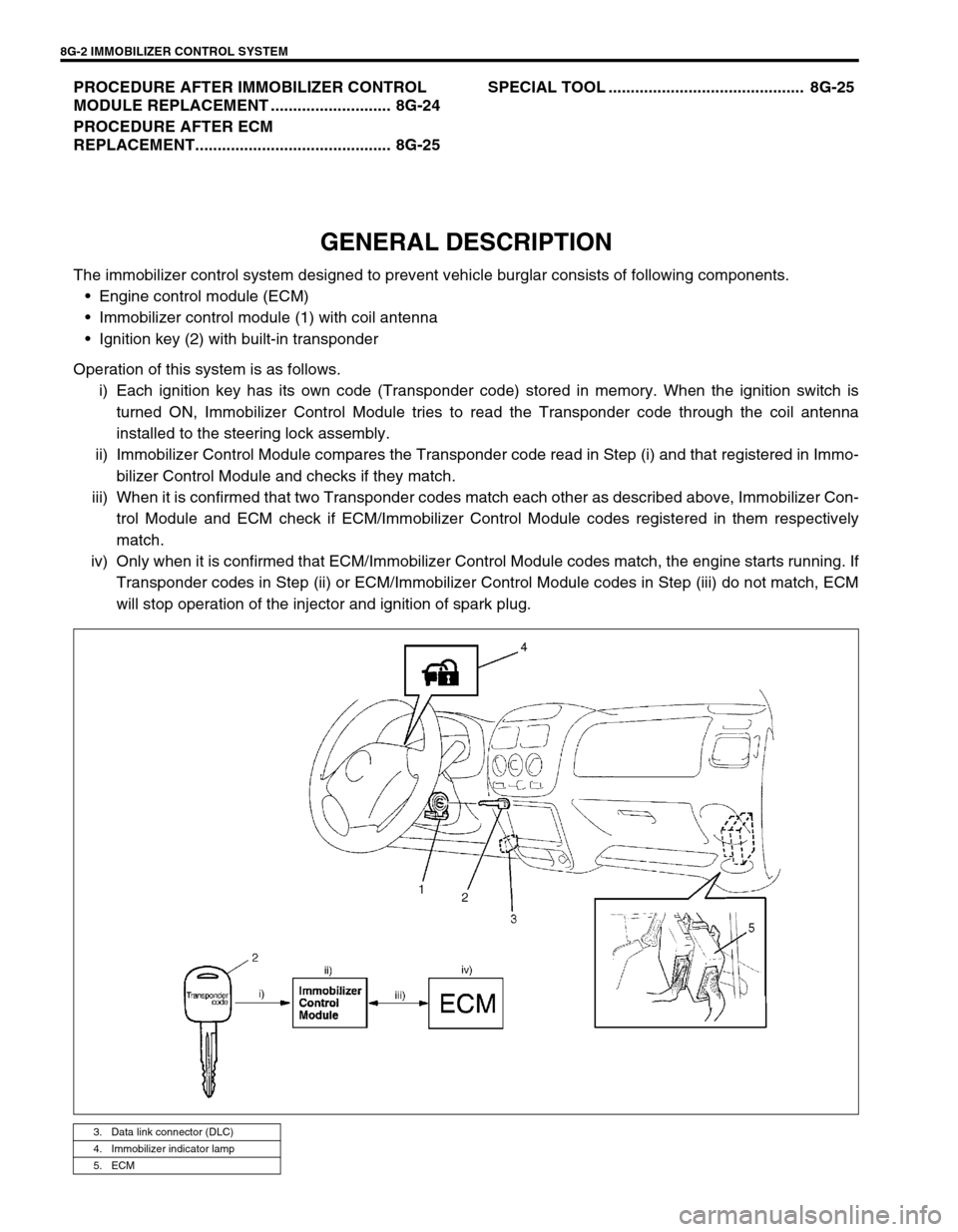

The immobilizer control system designed to prevent vehicle burglar consists of following components.

Engine control module (ECM)

Immobilizer control module (1) with coil antenna

Ignition key (2) with built-in transponder

Operation of this system is as follows.

i) Each ignition key has its own code (Transponder code) stored in memory. When the ignition switch is

turned ON, Immobilizer Control Module tries to read the Transponder code through the coil antenna

installed to the steering lock assembly.

ii) Immobilizer Control Module compares the Transponder code read in Step (i) and that registered in Immo-

bilizer Control Module and checks if they match.

iii) When it is confirmed that two Transponder codes match each other as described above, Immobilizer Con-

trol Module and ECM check if ECM/Immobilizer Control Module codes registered in them respectively

match.

iv) Only when it is confirmed that ECM/Immobilizer Control Module codes match, the engine starts running. If

Transponder codes in Step (ii) or ECM/Immobilizer Control Module codes in Step (iii) do not match, ECM

will stop operation of the injector and ignition of spark plug.

3. Data link connector (DLC)

4. Immobilizer indicator lamp

5. ECM