SUZUKI SWIFT 2000 1.G Transmission Service Workshop Manual

Manufacturer: SUZUKI, Model Year: 2000, Model line: SWIFT, Model: SUZUKI SWIFT 2000 1.GPages: 447, PDF Size: 10.54 MB

Page 251 of 447

BODY ELECTRICAL SYSTEM 8-7

POWER WINDOW CONTROL SYSTEM (IF EQUIPPED)

CIGARETTE LIGHTER

POWER DOOR LOCK CONTROL SYSTEM (IF EQUIPPED)

KEYLESS ENTRY SYSTEM (IF EQUIPPED)

Condition Possible Cause Correction

All power windows do

not operate“POWER WINDOW” fuse blown Replace fuse to check for short.

Ignition switch faulty Check ignition switch.

Power window main switch faulty Check power window main switch.

Wiring or grounding faulty Repair circuit.

Only one power win-

dow does not operateWiring and/or coupler faulty Check wiring and/or coupler.

Power window switch (main or sub) faulty Check power window switch.

Window actuator faulty Check window actuator.

Grounding faulty Repair.

Condition Possible Cause Correction

Cigarette lighter

shows no operation“CIGAR” fuse blown Replace fuse to check for short.

Ignition switch faulty Check ignition switch.

Cigarette lighter faulty Check cigarette lighter.

Wiring or grounding faulty Repair circuit.

Condition Possible Cause Correction

Power door(s) is (are)

not locked/unlocked

by driver side door

key switch“DOOR LOCK” fuse blown Replace fuse to check for short.

Ignition switch faulty Check ignition switch.

Driver’s door knob switch faulty Check driver’s door knob switch.

Door lock actuator faulty Check door lock actuator.

Wiring or grounding faulty Repair circuit.

Door lock controller faulty Check controller.

Condition Possible Cause Correction

Power door(s) is (are)

not locked/unlocked

by keyless entry trans-

mitter“DOOR LOCK” fuse blown Replace fuse to check for short.

Ignition switch faulty Check ignition switch.

Code registration error Register code.

Transmitter battery dead Replace battery.

Transmitter faulty Check transmitter.

Receiver faulty Check receiver.

Door lock controller faulty Check controller.

Wiring or grounding faulty Repair circuit.

Page 252 of 447

8-8 BODY ELECTRICAL SYSTEM

POWER DOOR MIRROR CONTROL SYSTEM (IF EQUIPPED)

INTERIOR LIGHT

HORN

IGNITION KEY REMAINDER (IF EQUIPPED) AND LIGHT REMAINDER WARN-

ING BUZZER

SEAT BELT WARNING LIGHT (IF EQUIPPED)

Condition Possible Cause Correction

All power mirrors do

not operate“CIGAR” fuse blown Replace fuse to check for short.

Power door mirror switch faulty Check switch.

Wiring or grounding faulty Repair circuit.

One power mirror

does not operatePower door mirror switch faulty Check switch.

Actuator (power door mirror motor) faulty Check actuator.

Wiring or grounding faulty Repair circuit.

Condition Possible Cause Correction

Interior lights do not

light upBulbs blown Replace bulbs.

“RADIO/DOME” fuse blown Replace fuse to check for short.

Interior light switch faulty Check switch.

Door switch faulty Check switch.

Wiring or grounding Repair circuit.

One of interior light

does not light upBulb blown Replace bulb.

Interior light switch faulty Check switch.

Door switch faulty Check switch.

Wiring or grounding Repair circuit.

Condition Possible Cause Correction

Horn does not operate

“HORN/HAZARD” fuse blown Replace fuse to check for short.

Horn switch faulty Check horn switch.

Horn relay faulty Check horn relay.

Horn faulty Replace horn.

Condition Possible Cause Correction

Ignition key remain-

der and light remain-

der warning buzzer

shows no soundingBuzzer faulty Replace buzzer.

Wiring or grounding faulty Repair circuit.

Driver side door switch faulty Check door switch.

Ignition switch faulty Check ignition switch.

Condition Possible Cause Correction

Seat belt warning light

does not light upBulb in combination meter blown Replace bulb.

“IG/METER” fuse blown Replace fuse to check for short.

Seat belt switch faulty Check seat belt switch.

Wiring or grounding faulty Repair circuit.

Page 253 of 447

BODY ELECTRICAL SYSTEM 8-9

FRONT SEAT HEATER (IF EQUIPPED)

ON-VEHICLE SERVICE

CAUTIONS IN SERVICING

When performing works related to electric systems, observe the cautions described in GENERAL INFORMA-

TION (Section 0A) of this manual for the purpose of protection of electrical parts and prevention of a fire from

occurrence.

HEADLIGHT

HEADLIGHT SWITCH

REMOVAL AND INSTALLATION

Refer to “CONTACT COIL AND COMBINATION SWITCH ASSEMBLY” in Section 3C. Condition Possible Cause Correction

Both seat back and

cushion do not

become hot although

seat heater switch is

LO/HI position“SEAT HTR” fuse blown Replace fuse to check for short.

Seat heater switch faulty Check switch.

Seat heater circuit in seat back and/or seat

cushion faultyCheck heater front back and/or

heater front cushion.

Wiring or grounding faulty Repair circuit.

Only seat back does

not become hot

although seat heater

switch is HI positionSeat heater circuit in seat back faulty Check heater front back.

Seat heater switch faulty Check switch.

Wiring faulty Repair.

Only seat cushion

does not become hot

although seat heater

switch is HI positionSeat heater circuit in seat back and/or seat

cushion faultyCheck heater front back and/or

heater front cushion.

Seat heater switch faulty Check switch.

Wiring faulty Repair.

Page 254 of 447

8-10 BODY ELECTRICAL SYSTEM

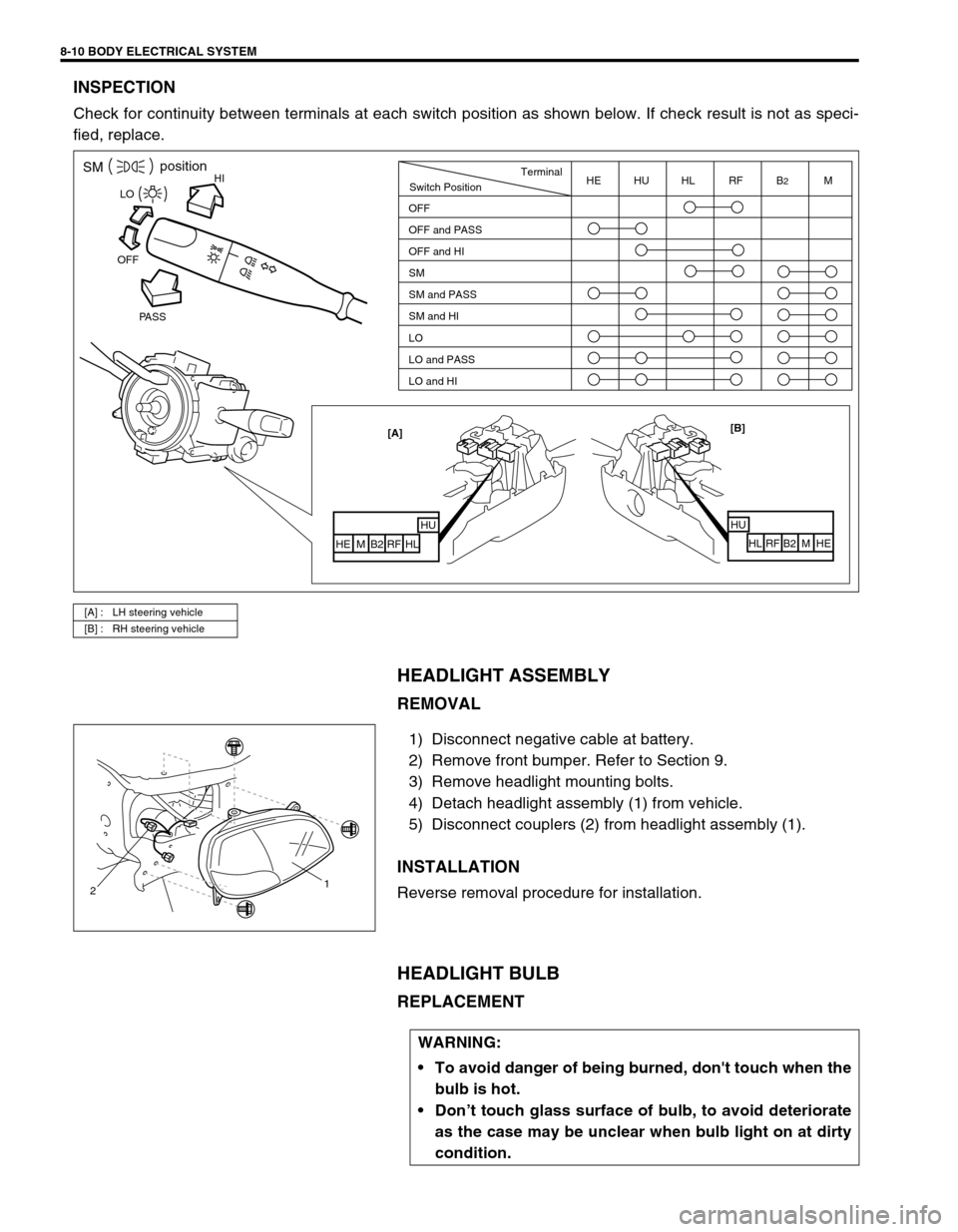

INSPECTION

Check for continuity between terminals at each switch position as shown below. If check result is not as speci-

fied, replace.

HEADLIGHT ASSEMBLY

REMOVAL

1) Disconnect negative cable at battery.

2) Remove front bumper. Refer to Section 9.

3) Remove headlight mounting bolts.

4) Detach headlight assembly (1) from vehicle.

5) Disconnect couplers (2) from headlight assembly (1).

INSTALLATION

Reverse removal procedure for installation.

HEADLIGHT BULB

REPLACEMENT

[A] : LH steering vehicle

[B] : RH steering vehicle

HISMposition

PASS OFFLO

[B]

HU

HL RF B2 M HE [A]

HUHL

RF B2 M HE

Switch PositionTerminal

OFF

OFF and PASS

OFF and HI

SM

SM and PASS

SM and HI

LO

LO and PASS

LO and HIHE HU HL RF B2M

21

WARNING:

To avoid danger of being burned, don't touch when the

bulb is hot.

Don’t touch glass surface of bulb, to avoid deteriorate

as the case may be unclear when bulb light on at dirty

condition.

Page 255 of 447

BODY ELECTRICAL SYSTEM 8-11

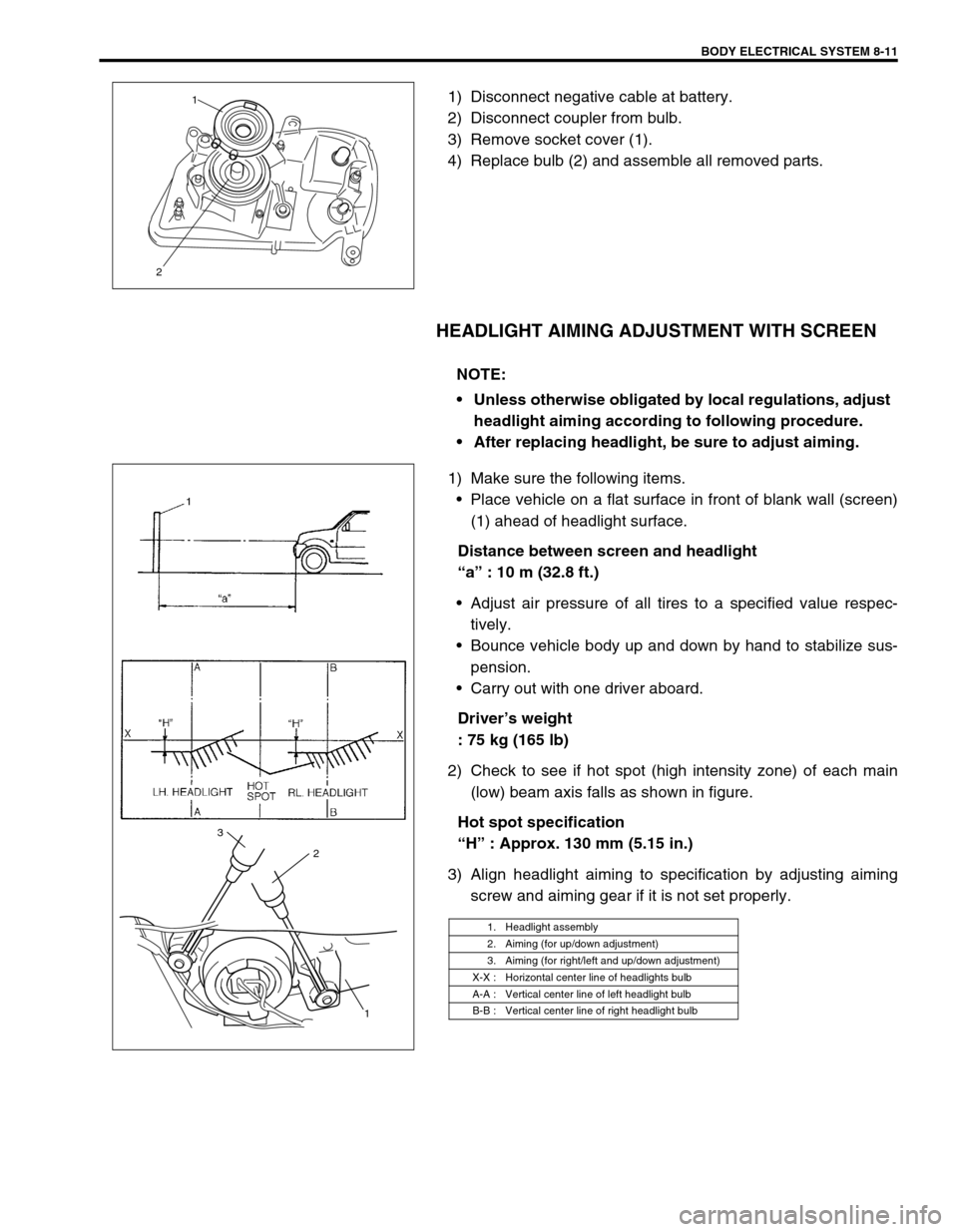

1) Disconnect negative cable at battery.

2) Disconnect coupler from bulb.

3) Remove socket cover (1).

4) Replace bulb (2) and assemble all removed parts.

HEADLIGHT AIMING ADJUSTMENT WITH SCREEN

1) Make sure the following items.

Place vehicle on a flat surface in front of blank wall (screen)

(1) ahead of headlight surface.

Distance between screen and headlight

“a” : 10 m (32.8 ft.)

Adjust air pressure of all tires to a specified value respec-

tively.

Bounce vehicle body up and down by hand to stabilize sus-

pension.

Carry out with one driver aboard.

Driver’s weight

: 75 kg (165 lb)

2) Check to see if hot spot (high intensity zone) of each main

(low) beam axis falls as shown in figure.

Hot spot specification

“H” : Approx. 130 mm (5.15 in.)

3) Align headlight aiming to specification by adjusting aiming

screw and aiming gear if it is not set properly.

21

NOTE:

Unless otherwise obligated by local regulations, adjust

headlight aiming according to following procedure.

After replacing headlight, be sure to adjust aiming.

1. Headlight assembly

2. Aiming (for up/down adjustment)

3. Aiming (for right/left and up/down adjustment)

X-X : Horizontal center line of headlights bulb

A-A : Vertical center line of left headlight bulb

B-B : Vertical center line of right headlight bulb

1 2 3

Page 256 of 447

8-12 BODY ELECTRICAL SYSTEM

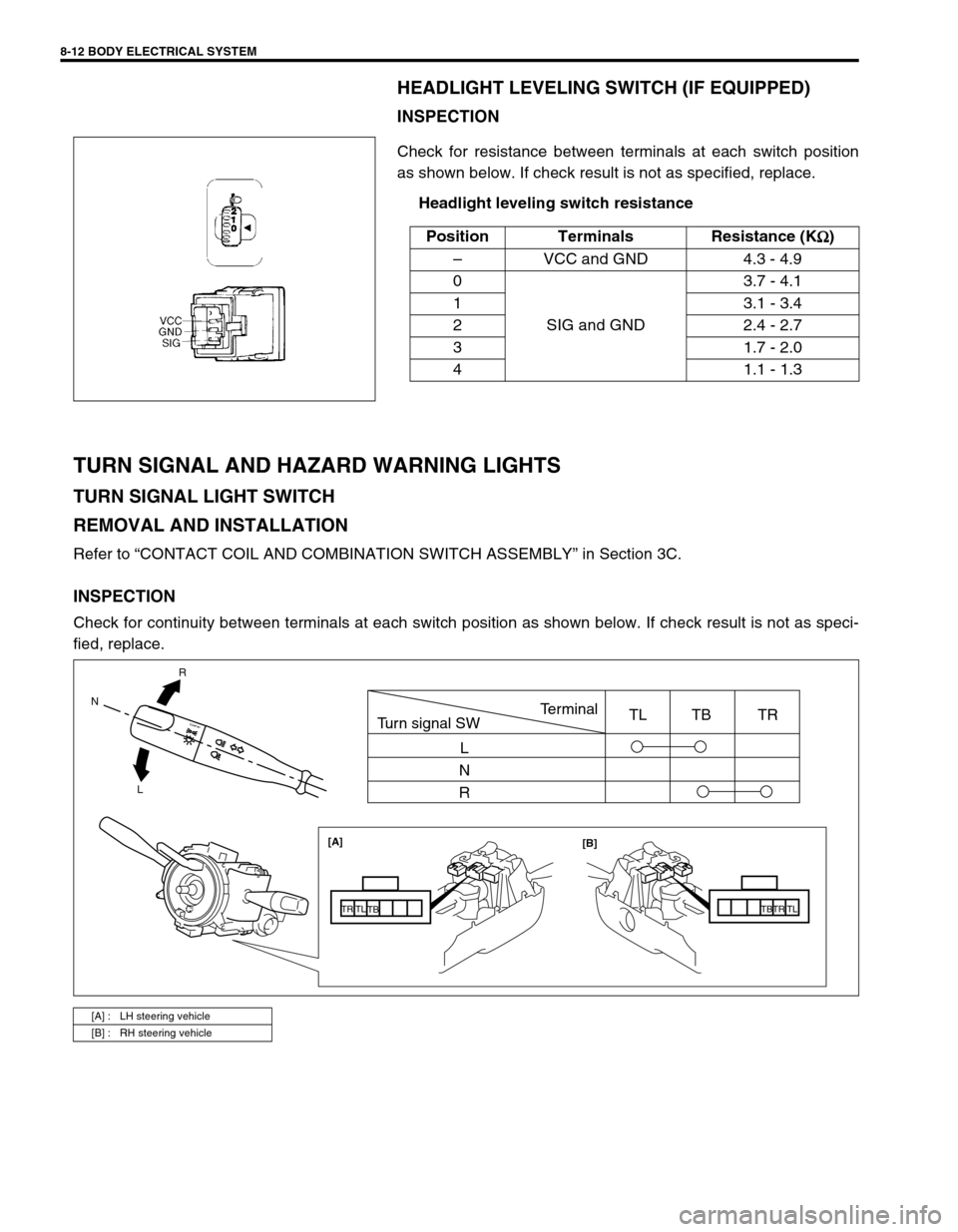

HEADLIGHT LEVELING SWITCH (IF EQUIPPED)

INSPECTION

Check for resistance between terminals at each switch position

as shown below. If check result is not as specified, replace.

Headlight leveling switch resistance

TURN SIGNAL AND HAZARD WARNING LIGHTS

TURN SIGNAL LIGHT SWITCH

REMOVAL AND INSTALLATION

Refer to “CONTACT COIL AND COMBINATION SWITCH ASSEMBLY” in Section 3C.

INSPECTION

Check for continuity between terminals at each switch position as shown below. If check result is not as speci-

fied, replace.Position Terminals Resistance (K

Ω

ΩΩ Ω)

–VCC and GND 4.3 - 4.9

0

SIG and GND3.7 - 4.1

1 3.1 - 3.4

2 2.4 - 2.7

3 1.7 - 2.0

4 1.1 - 1.3

[A] : LH steering vehicle

[B] : RH steering vehicle

R

L N

[A]

[B]

TB

TBTR TR

TL TL

Turn signal SWTerminal

L

N

RTL TB TR

Page 257 of 447

BODY ELECTRICAL SYSTEM 8-13

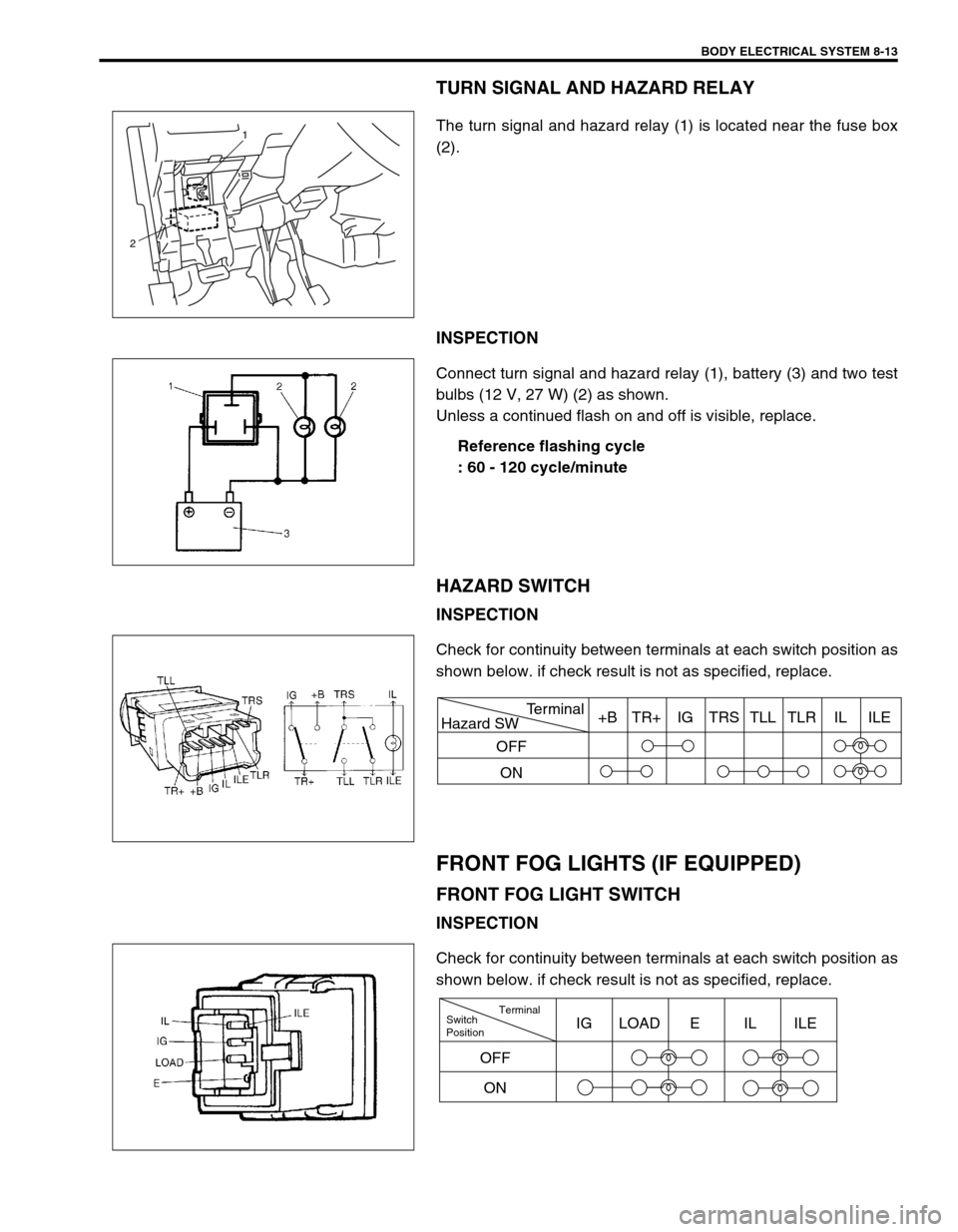

TURN SIGNAL AND HAZARD RELAY

The turn signal and hazard relay (1) is located near the fuse box

(2).

INSPECTION

Connect turn signal and hazard relay (1), battery (3) and two test

bulbs (12 V, 27 W) (2) as shown.

Unless a continued flash on and off is visible, replace.

Reference flashing cycle

: 60 - 120 cycle/minute

HAZARD SWITCH

INSPECTION

Check for continuity between terminals at each switch position as

shown below. if check result is not as specified, replace.

FRONT FOG LIGHTS (IF EQUIPPED)

FRONT FOG LIGHT SWITCH

INSPECTION

Check for continuity between terminals at each switch position as

shown below. if check result is not as specified, replace.

1

2

Hazard SWTerminal

OFF

ON+B TR+ IG TRS TLL TLR IL ILE

Switch

PositionTerminal

ONIG LOAD E IL ILE

OFF

Page 258 of 447

8-14 BODY ELECTRICAL SYSTEM

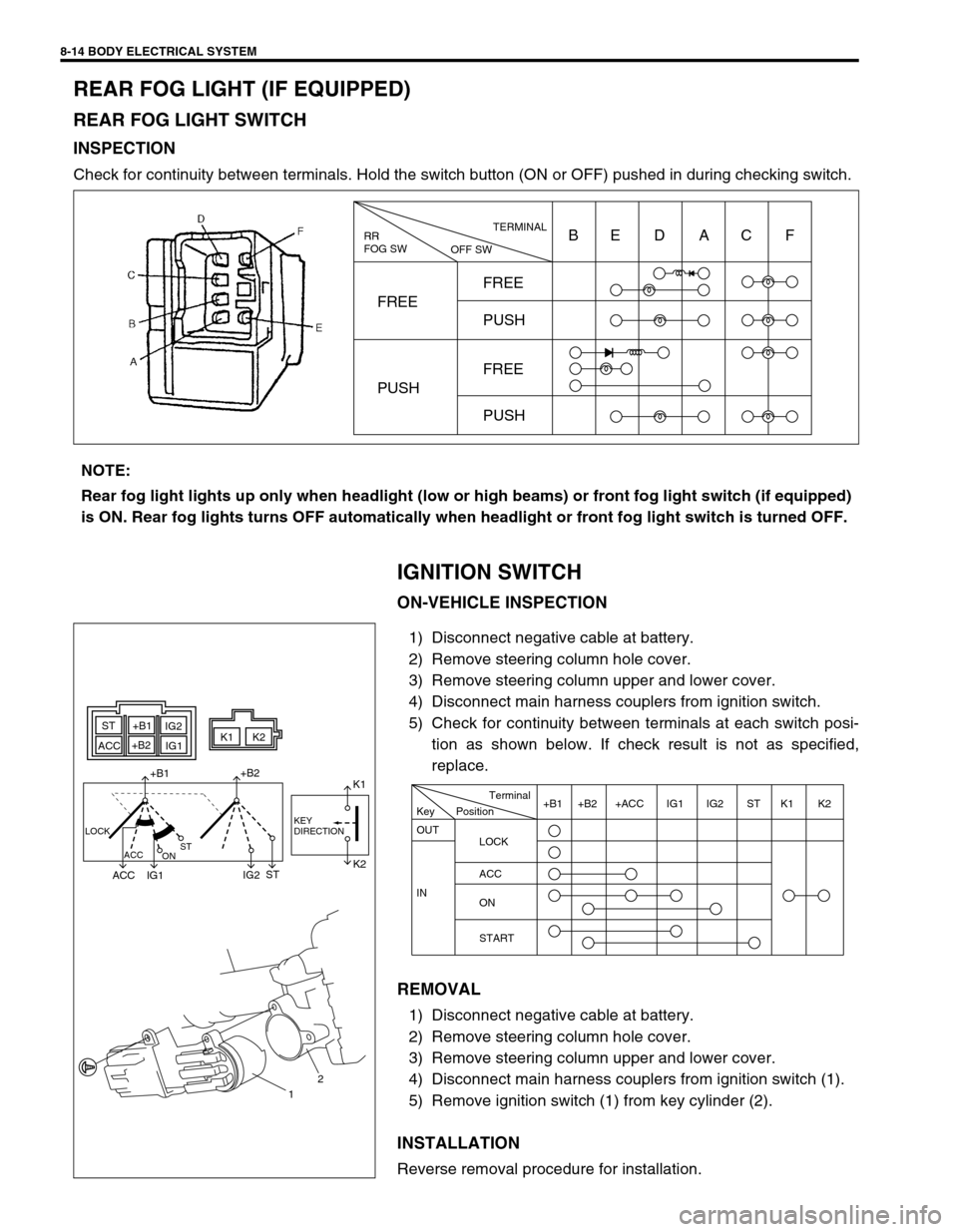

REAR FOG LIGHT (IF EQUIPPED)

REAR FOG LIGHT SWITCH

INSPECTION

Check for continuity between terminals. Hold the switch button (ON or OFF) pushed in during checking switch.

IGNITION SWITCH

ON-VEHICLE INSPECTION

1) Disconnect negative cable at battery.

2) Remove steering column hole cover.

3) Remove steering column upper and lower cover.

4) Disconnect main harness couplers from ignition switch.

5) Check for continuity between terminals at each switch posi-

tion as shown below. If check result is not as specified,

replace.

REMOVAL

1) Disconnect negative cable at battery.

2) Remove steering column hole cover.

3) Remove steering column upper and lower cover.

4) Disconnect main harness couplers from ignition switch (1).

5) Remove ignition switch (1) from key cylinder (2).

INSTALLATION

Reverse removal procedure for installation.

RR

FOG SW

OFF SWTERMINAL

FREEFREE

PUSH

FREE

PUSH PUSHBE D AC F

NOTE:

Rear fog light lights up only when headlight (low or high beams) or front fog light switch (if equipped)

is ON. Rear fog lights turns OFF automatically when headlight or front fog light switch is turned OFF.

ST+B1

+B2

ACCIG2

IG1K1K2

+B1+B2

ACC IG1IG2STK1

K2

LOCK

ACC

ONSTKEY

DIRECTION

12

Position Key

OUT

LOCK

ACC

ON

START IN+B1 +B2 +ACC IG1 IG2 ST K1 K2 Terminal

Page 259 of 447

BODY ELECTRICAL SYSTEM 8-15

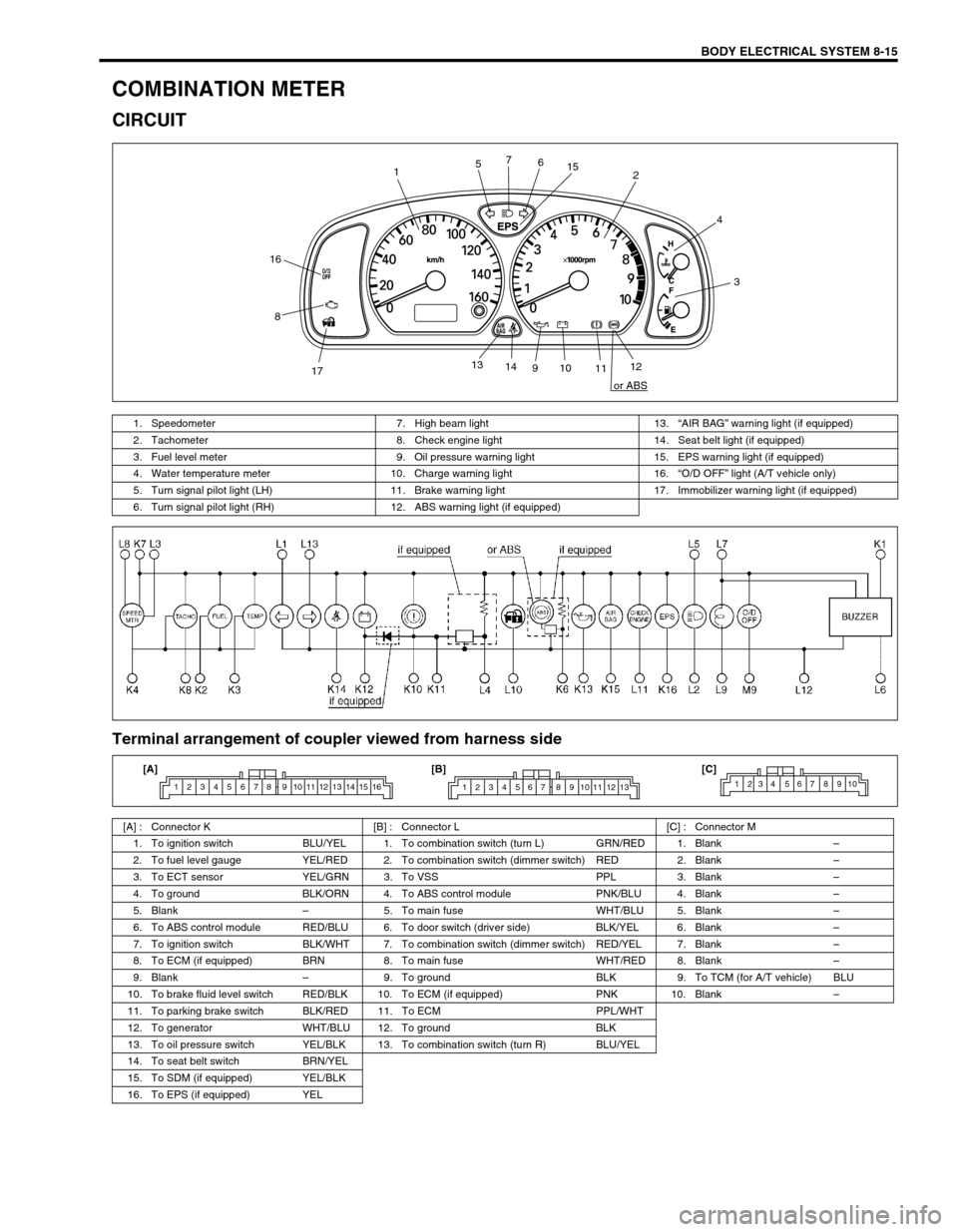

COMBINATION METER

CIRCUIT

Terminal arrangement of coupler viewed from harness side

12

3 4

56 7

8

910

1112 13

14

1715

16

or ABS

1. Speedometer 7. High beam light 13.“AIR BAG” warning light (if equipped)

2. Tachometer 8. Check engine light 14. Seat belt light (if equipped)

3. Fuel level meter 9. Oil pressure warning light 15. EPS warning light (if equipped)

4. Water temperature meter 10. Charge warning light 16.“O/D OFF” light (A/T vehicle only)

5. Turn signal pilot light (LH) 11. Brake warning light 17. Immobilizer warning light (if equipped)

6. Turn signal pilot light (RH) 12. ABS warning light (if equipped)

[A] : Connector K [B] : Connector L [C] : Connector M

1. To ignition switch BLU/YEL 1. To combination switch (turn L) GRN/RED 1. Blank–

2. To fuel level gauge YEL/RED 2. To combination switch (dimmer switch) RED 2. Blank–

3. To ECT sensor YEL/GRN 3. To VSS PPL 3. Blank–

4. To ground BLK/ORN 4. To ABS control module PNK/BLU 4. Blank–

5. Blank–5. To main fuse WHT/BLU 5. Blank–

6. To ABS control module RED/BLU 6. To door switch (driver side) BLK/YEL 6. Blank–

7. To ignition switch BLK/WHT 7. To combination switch (dimmer switch) RED/YEL 7. Blank–

8. To ECM (if equipped) BRN 8. To main fuse WHT/RED 8. Blank–

9. Blank–9. To ground BLK 9. To TCM (for A/T vehicle) BLU

10. To brake fluid level switch RED/BLK 10. To ECM (if equipped) PNK 10. Blank–

11. To parking brake switch BLK/RED 11. To ECM PPL/WHT

12. To generator WHT/BLU 12. To ground BLK

13. To oil pressure switch YEL/BLK 13. To combination switch (turn R) BLU/YEL

14. To seat belt switch BRN/YEL

15. To SDM (if equipped) YEL/BLK

16. To EPS (if equipped) YEL

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 161 2 3 4 5 6 7 8 9 10 11 12 131234 567 8910[A] [B] [C]

Page 260 of 447

8-16 BODY ELECTRICAL SYSTEM

REMOVAL

1) Disconnect negative cable at battery.

2) Loosen steering column mounting nuts. Refer to Section 3C.

3) Remove meter cluster panel (1).

4) Disconnect all couplers from combination meter, then

remove combination meter (2).

INSTALLATION

Reverse removal procedure for installation.

INSPECTION

Check printed plate (1) visually for scratch, crack and discolora-

tion.

If any of such faulty conditions is found, replace the printed plate

(1).

FUEL METER AND FUEL LEVEL SENSOR

(GAUGE UNIT)

FUEL LEVEL METER

INSPECTION

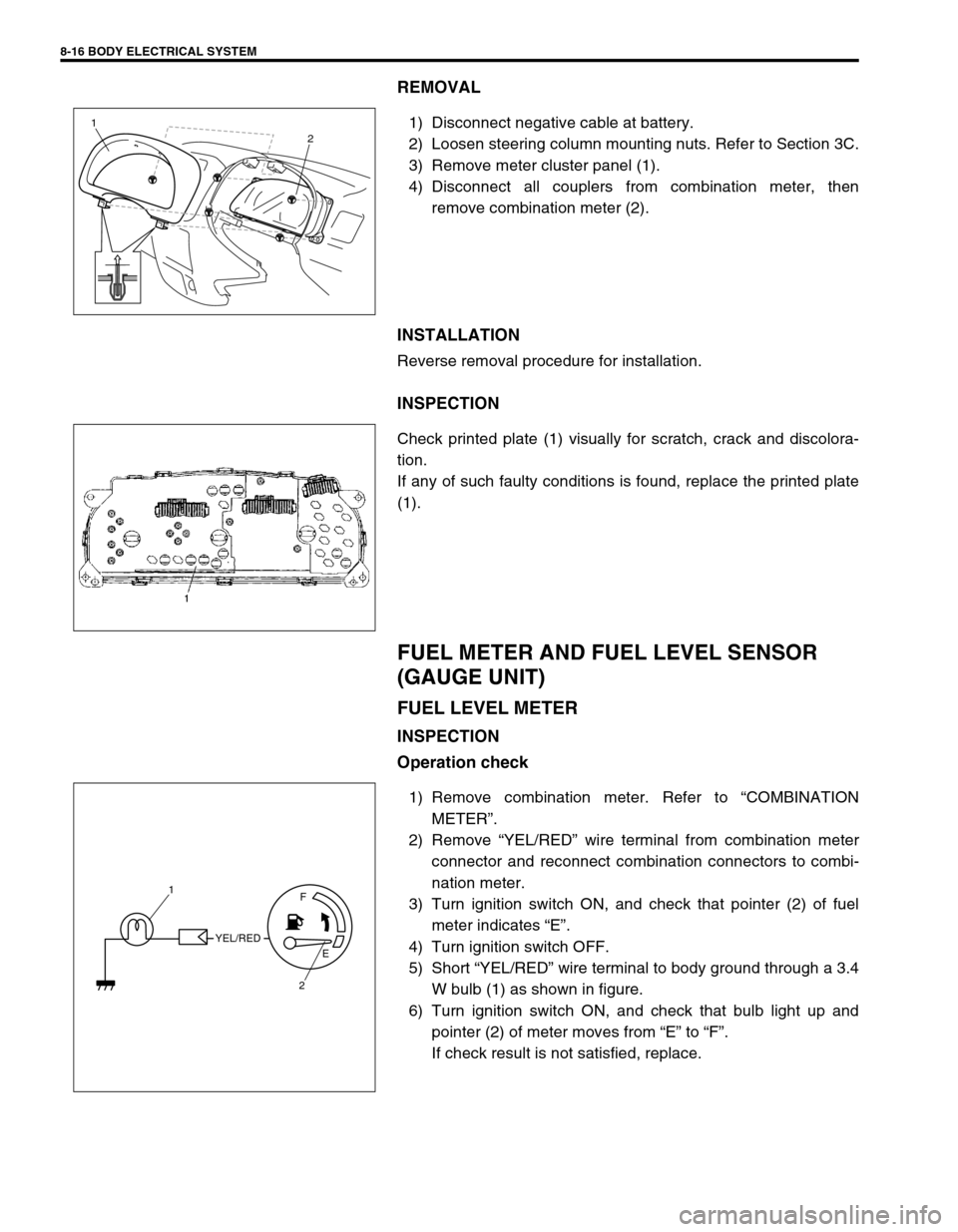

Operation check

1) Remove combination meter. Refer to “COMBINATION

METER”.

2) Remove “YEL/RED” wire terminal from combination meter

connector and reconnect combination connectors to combi-

nation meter.

3) Turn ignition switch ON, and check that pointer (2) of fuel

meter indicates “E”.

4) Turn ignition switch OFF.

5) Short “YEL/RED” wire terminal to body ground through a 3.4

W bulb (1) as shown in figure.

6) Turn ignition switch ON, and check that bulb light up and

pointer (2) of meter moves from “E” to “F”.

If check result is not satisfied, replace.

1

2

YEL/REDF

E

2 1