shaft SUZUKI SWIFT 2000 1.G Transmission Service Manual Online

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2000, Model line: SWIFT, Model: SUZUKI SWIFT 2000 1.GPages: 447, PDF Size: 10.54 MB

Page 169 of 447

AUTOMATIC TRANSMISSION (4 A/T) 7B-127

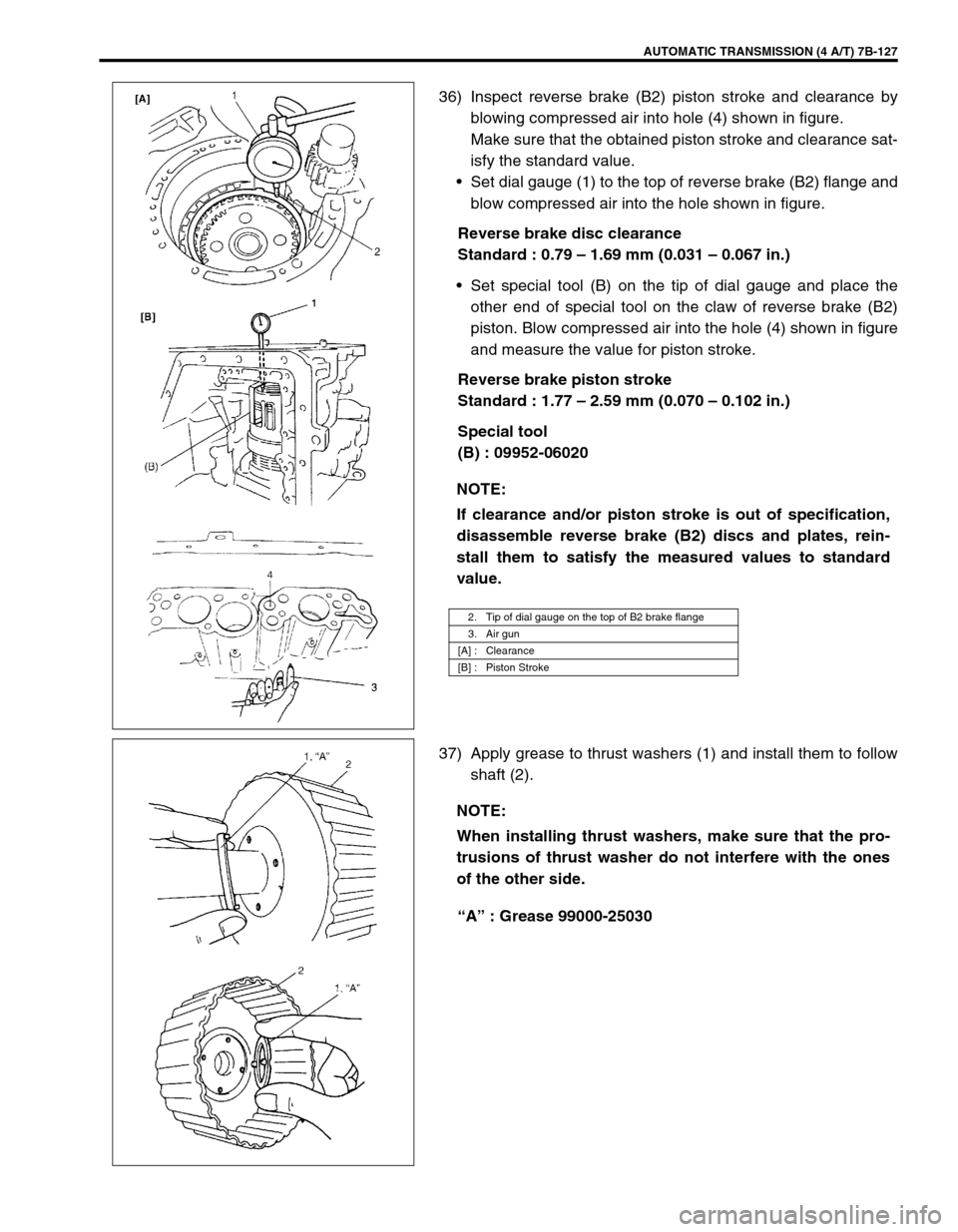

36) Inspect reverse brake (B2) piston stroke and clearance by

blowing compressed air into hole (4) shown in figure.

Make sure that the obtained piston stroke and clearance sat-

isfy the standard value.

Set dial gauge (1) to the top of reverse brake (B2) flange and

blow compressed air into the hole shown in figure.

Reverse brake disc clearance

Standard : 0.79 – 1.69 mm (0.031 – 0.067 in.)

Set special tool (B) on the tip of dial gauge and place the

other end of special tool on the claw of reverse brake (B2)

piston. Blow compressed air into the hole (4) shown in figure

and measure the value for piston stroke.

Reverse brake piston stroke

Standard : 1.77 – 2.59 mm (0.070 – 0.102 in.)

Special tool

(B) : 09952-06020

37) Apply grease to thrust washers (1) and install them to follow

shaft (2).

“A” : Grease 99000-25030 NOTE:

If clearance and/or piston stroke is out of specification,

disassemble reverse brake (B2) discs and plates, rein-

stall them to satisfy the measured values to standard

value.

2. Tip of dial gauge on the top of B2 brake flange

3. Air gun

[A] : Clearance

[B] : Piston Stroke

NOTE:

When installing thrust washers, make sure that the pro-

trusions of thrust washer do not interfere with the ones

of the other side.

Page 170 of 447

7B-128 AUTOMATIC TRANSMISSION (4 A/T)

38) Install follow shaft (1) to transmission case.

Turn it right and left to match the reverse brake (B2) discs

and the spline of follow shaft.

39) Install thrust needle roller bearing (1) to intermediate shaft

(2).

40) Install intermediate shaft (1) to transmission case.

41) Install rear clutch assembly (1) by turning it right and left to

match the clutch disc of rear clutch assembly and the spline

of intermediate shaft.

42) Install thrust bearing race (2).

“A” : Grease 99000-25030

43) Install front clutch assembly (1) by turning it right and left to

match the clutch of disc clutch assembly and the spline of

follow shaft. NOTE:

When installing follow shaft, do not let the thrust washer

fall off from follow shaft.

Page 171 of 447

AUTOMATIC TRANSMISSION (4 A/T) 7B-129

44) Apply grease to thrust needle roller bearing (1) and install it.

“A” : Grease 99000-25030

45) Apply grease to clutch drum thrust washer (1) and install it to

oil pump assembly (2).

“A” : Grease 99000-25030

46) Install new gasket to transmission case and install oil pump

assembly (1) to transmission case.

Tightening torque

Oil pump assembly bolts (a) : 12 N·m (1.2 kg-m, 9.0 lb-ft)

47) Measure input shaft end (2) play.

Set dial gauge (1) as shown in figure and measure the play

of the input shaft.

Input shaft end Play

Standard : 0.3 – 0.7 mm (0.012 – 0.028 in.)

48) If the obtained value is out of standard value, select thrust

bearing race (installed in step 41)) of different thickness

shown in table below and adjust the play.

Available thrust bearing race size (thickness)

1.3 mm (0.051 in.), 1.7 mm (0.067 in.) or 2.1 mm (0.083 in.)

3. Oil pump

Page 174 of 447

7B-132 AUTOMATIC TRANSMISSION (4 A/T)

56) Install valve body assembly (1) to transmission case.

First match the pin of the manual valve to the slot of the

manual shift shaft.

To fix valve body assembly (1) to transmission case, first

tighten bolt B (3), then tighten other bolts.

Tightening torque

Valve body to transmission case bolts

: 10 N·m (1.0 kg-m, 7.5 lb-ft)

57) Connect couplers of wire-to-solenoid to solenoid valves.Bolt Length “a”Pieces

A 30 mm (1.20 in.) 7

B 31 mm (1.22 in.) 2

C 25 mm (0.98 in.) 2

2. Bolt A

4. Bolt C

5. Manual valve pin

6. Slot of manual shift shaft

Solenoid Valve Wire Color

A (No.1) White

B (No.2) Black

C (No.3) Red

D (No.4) Yellow

E (No.5) Brown

TCC (Lock-up) Orange

1. Solenoid valve No.1

2. Solenoid valve No.2

3. Solenoid valve No.3

4. Solenoid valve No.4

5. Solenoid valve No.5

6. Lock-up solenoid

Page 176 of 447

7B-134 AUTOMATIC TRANSMISSION (4 A/T)

63) Install vehicle speed sensor (for speedometer) (1), shift

cable bracket (2) and connector clamp bracket (3).

Tightening torque

Vehicle speed sensor bolt

(a) : 5.5 N·m (0.55 kg-m, 4.0 lb-ft)

Shift cable bracket bolts

(b) : 13 N·m (1.3 kg-m, 9.5 lb-ft)

Connector clamp bracket bolt : 8 N·m (0.8 kg-m, 6.0 lb-ft)

64) Install A/T fluid filler tube (2) and level gauge (1).

Tightening torque

A/T fluid filler tube bolt (a) : 19.5 N·m (1.95 kg-m, 14.5 lb-ft)

65) Install output shaft speed sensor (1) and input shaft speed

sensor (2).

Apply grease to O-ring of each sensor.

Tightening torque

Output shaft speed sensor bolt

(a) : 8 N·m (0.8 kg-m, 6.0 lb-ft)

Input shaft speed sensor bolt

(b) : 8 N·m (0.8 kg-m, 6.0 Ib-ft)

Grease : 99000-25030

66) Install engine mounting LH bracket.

Tightening torque

Engine mounting LH bracket bolts

(a) : 55 N·m (5.5 kg-m, 40.0 lb-ft)

Page 177 of 447

AUTOMATIC TRANSMISSION (4 A/T) 7B-135

67) Install breather sensor hose (1).

68) Install transmission range sensor (2).

Install it temporarily so that the adjustment can be done after

installing assembly back to the vehicle.

Tightening torque

Transmission range sensor bolt

(a) : 18 N·m (1.8 kg-m, 13.0 lb-ft)

69) Install torque converter (1) to input shaft.

Install torque converter, using care not to damage oil seal of

oil pump.

After installing torque converter, check to make sure that dis-

tance “a” is within specification.

Torque converter installing position

“a” : More than 19.9 mm (0.783 in.)

Check torque converter for smooth rotation.

Apply grease around cup at the center of torque converter.

“C” : Grease 99000-25010

CAUTION:

Before installing converter, make sure that its pump

hub portion is free from nicks, burrs or damage which

may cause oil seal to leak.

Be very careful not to drop converter on oil pump gear.

Damage in gear, should it occur, may cause a critical

trouble.

2. Flange nut

3. Torque converter housing

4. Cup

Page 178 of 447

7B-136 AUTOMATIC TRANSMISSION (4 A/T)

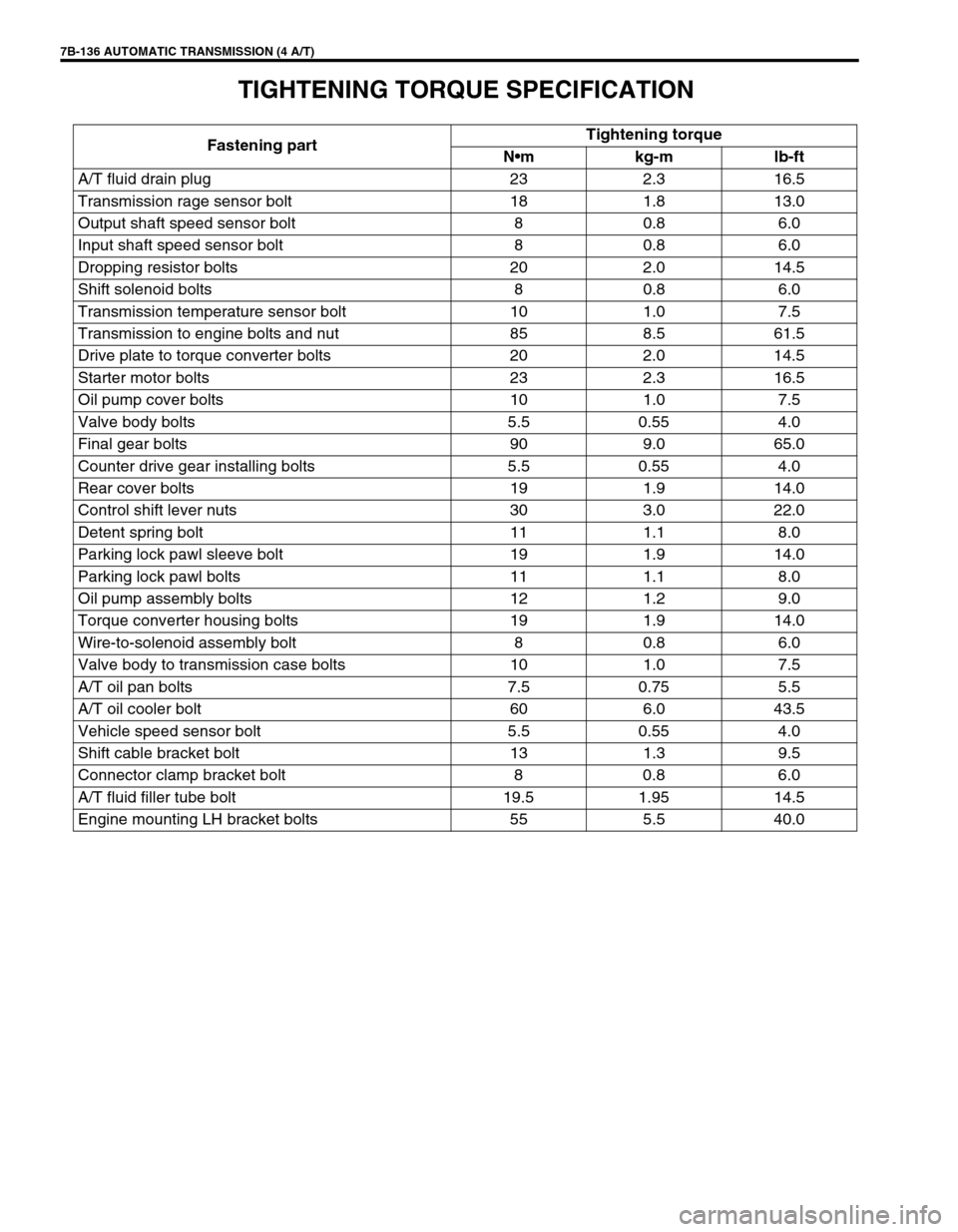

TIGHTENING TORQUE SPECIFICATION

Fastening partTightening torque

Nm kg-m lb-ft

A/T fluid drain plug 23 2.3 16.5

Transmission rage sensor bolt 18 1.8 13.0

Output shaft speed sensor bolt 8 0.8 6.0

Input shaft speed sensor bolt 8 0.8 6.0

Dropping resistor bolts 20 2.0 14.5

Shift solenoid bolts 8 0.8 6.0

Transmission temperature sensor bolt 10 1.0 7.5

Transmission to engine bolts and nut 85 8.5 61.5

Drive plate to torque converter bolts 20 2.0 14.5

Starter motor bolts 23 2.3 16.5

Oil pump cover bolts 10 1.0 7.5

Valve body bolts 5.5 0.55 4.0

Final gear bolts 90 9.0 65.0

Counter drive gear installing bolts 5.5 0.55 4.0

Rear cover bolts 19 1.9 14.0

Control shift lever nuts 30 3.0 22.0

Detent spring bolt 11 1.1 8.0

Parking lock pawl sleeve bolt 19 1.9 14.0

Parking lock pawl bolts 11 1.1 8.0

Oil pump assembly bolts 12 1.2 9.0

Torque converter housing bolts 19 1.9 14.0

Wire-to-solenoid assembly bolt 8 0.8 6.0

Valve body to transmission case bolts 10 1.0 7.5

A/T oil pan bolts 7.5 0.75 5.5

A/T oil cooler bolt 60 6.0 43.5

Vehicle speed sensor bolt 5.5 0.55 4.0

Shift cable bracket bolt 13 1.3 9.5

Connector clamp bracket bolt 8 0.8 6.0

A/T fluid filler tube bolt 19.5 1.95 14.5

Engine mounting LH bracket bolts 55 5.5 40.0

Page 180 of 447

7B-138 AUTOMATIC TRANSMISSION (4 A/T)

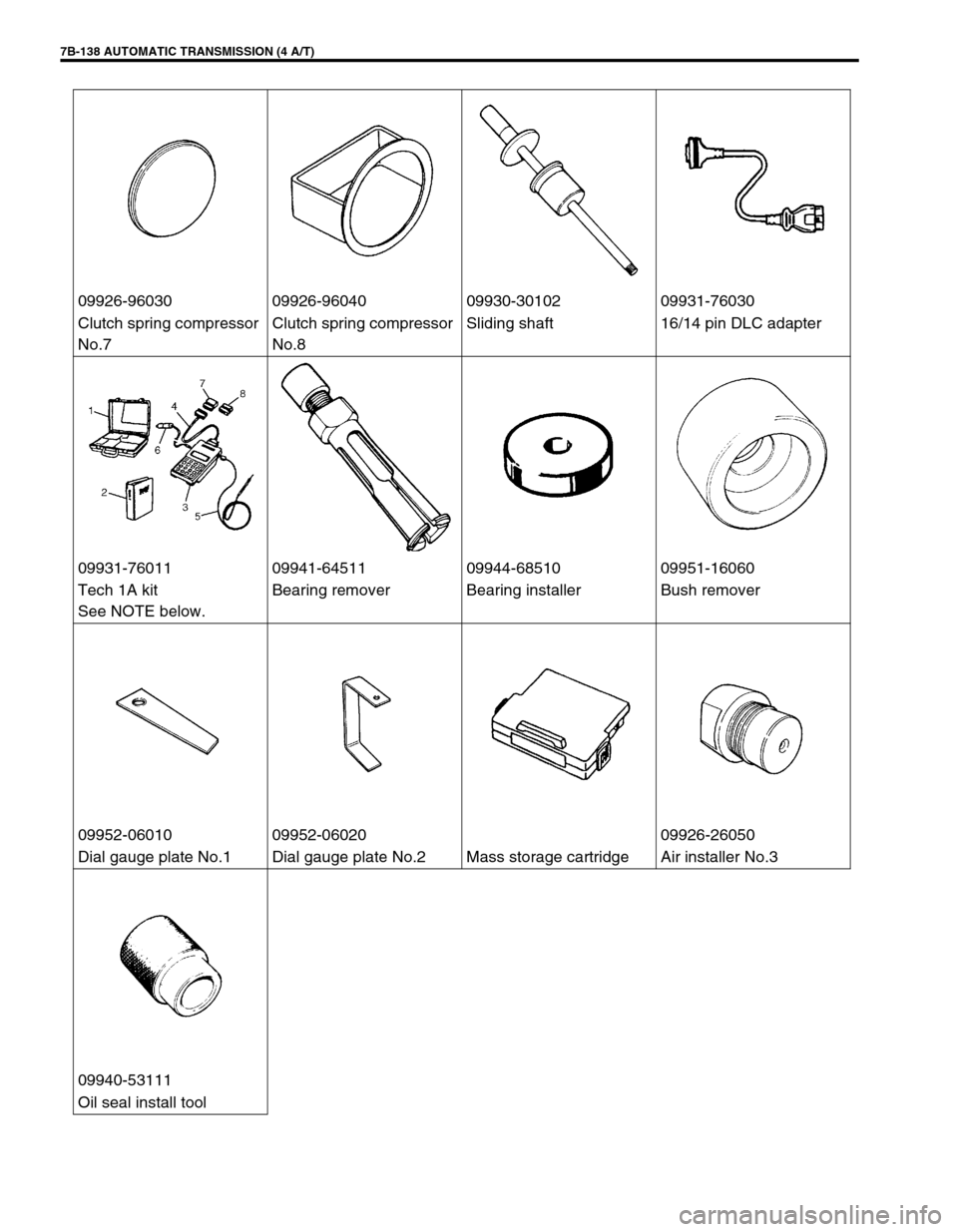

09926-96030 09926-96040 09930-30102 09931-76030

Clutch spring compressor

No.7Clutch spring compressor

No.8Sliding shaft 16/14 pin DLC adapter

09931-76011 09941-64511 09944-68510 09951-16060

Tech 1A kit

See NOTE below.Bearing remover Bearing installer Bush remover

09952-06010 09952-06020 09926-26050

Dial gauge plate No.1 Dial gauge plate No.2 Mass storage cartridge Air installer No.3

09940-53111

Oil seal install tool

Page 184 of 447

7C-2 CLUTCH

GENERAL DESCRIPTION

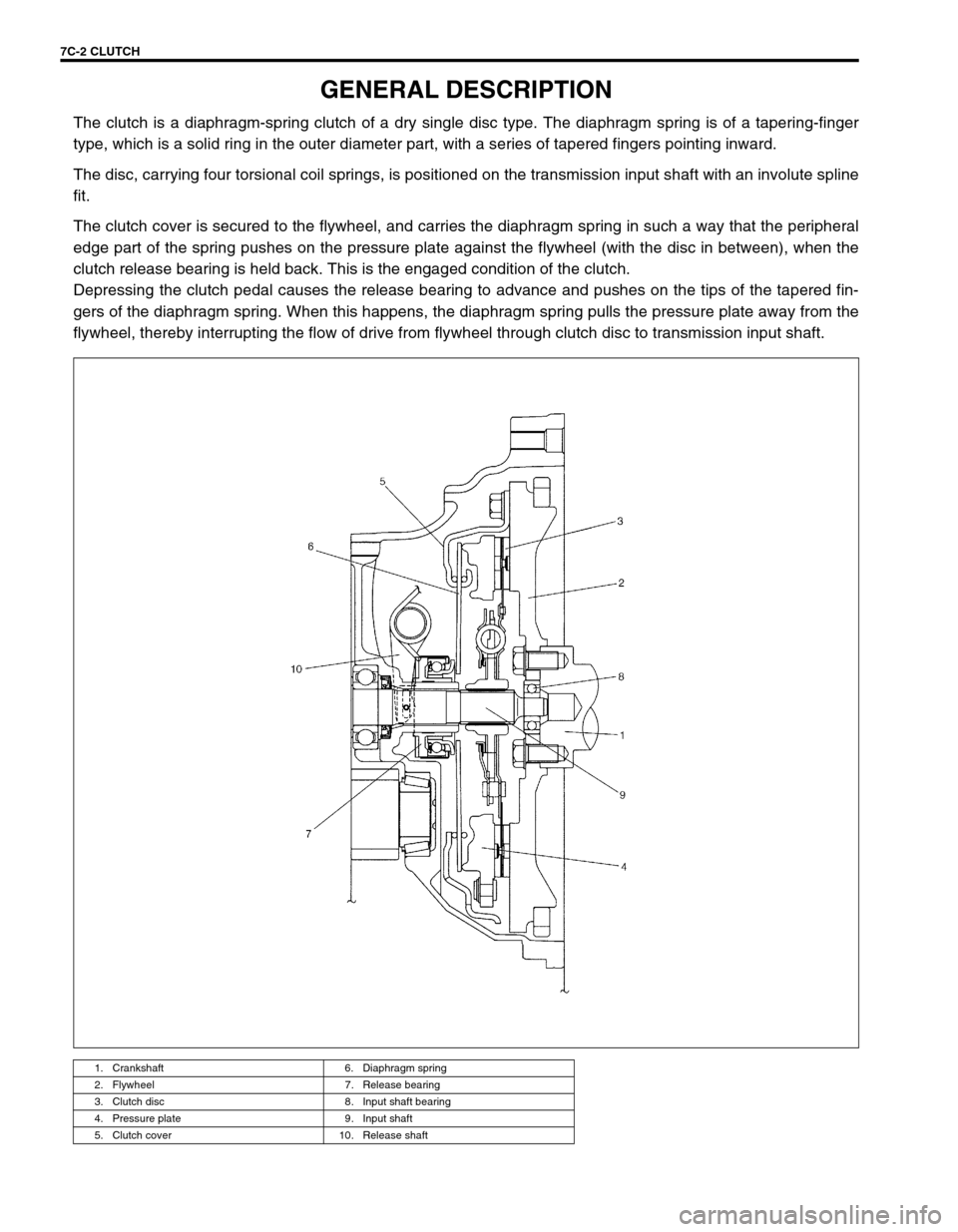

The clutch is a diaphragm-spring clutch of a dry single disc type. The diaphragm spring is of a tapering-finger

type, which is a solid ring in the outer diameter part, with a series of tapered fingers pointing inward.

The disc, carrying four torsional coil springs, is positioned on the transmission input shaft with an involute spline

fit.

The clutch cover is secured to the flywheel, and carries the diaphragm spring in such a way that the peripheral

edge part of the spring pushes on the pressure plate against the flywheel (with the disc in between), when the

clutch release bearing is held back. This is the engaged condition of the clutch.

Depressing the clutch pedal causes the release bearing to advance and pushes on the tips of the tapered fin-

gers of the diaphragm spring. When this happens, the diaphragm spring pulls the pressure plate away from the

flywheel, thereby interrupting the flow of drive from flywheel through clutch disc to transmission input shaft.

1. Crankshaft 6. Diaphragm spring

2. Flywheel 7. Release bearing

3. Clutch disc 8. Input shaft bearing

4. Pressure plate 9. Input shaft

5. Clutch cover 10. Release shaft

Page 185 of 447

CLUTCH 7C-3

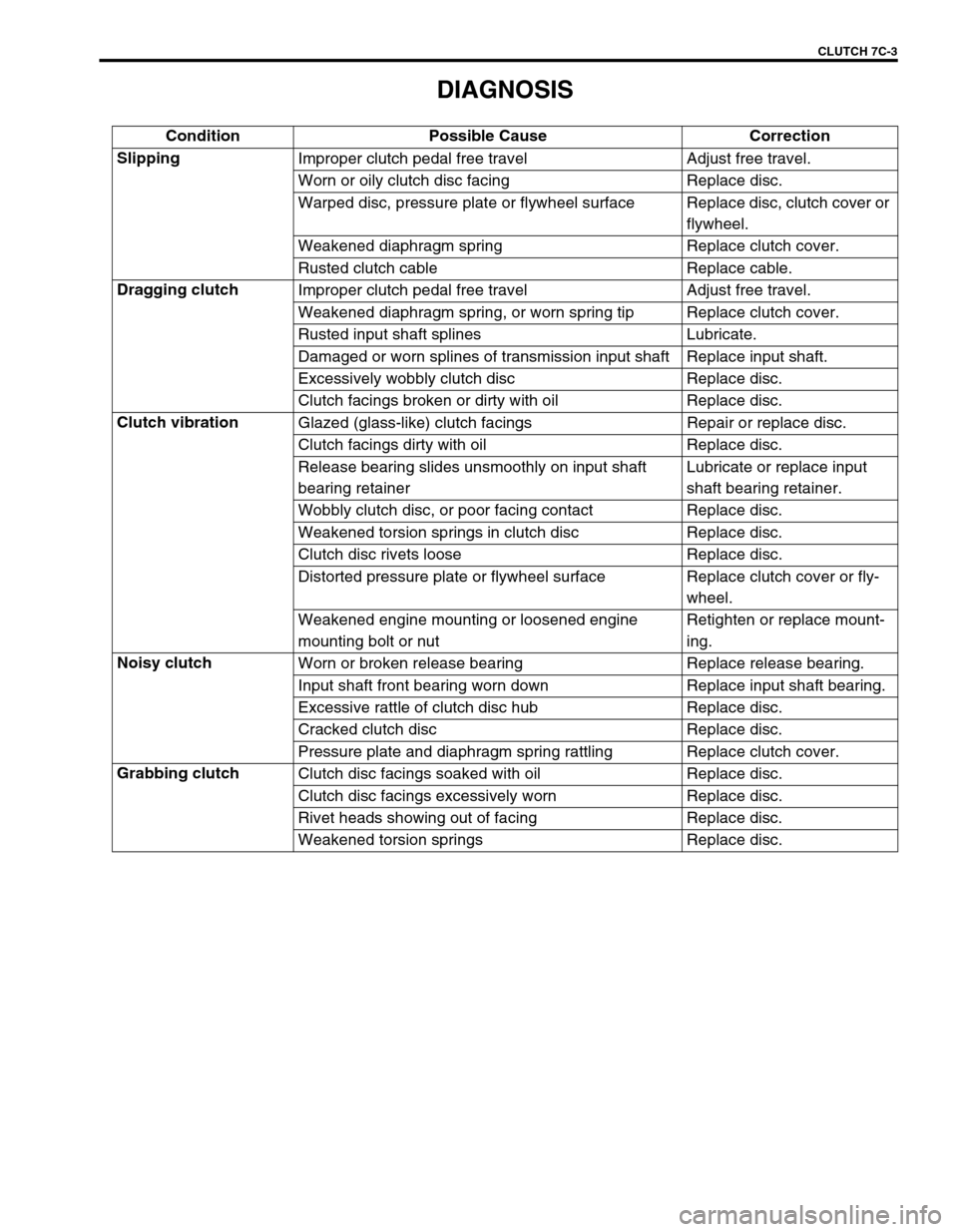

DIAGNOSIS

Condition Possible Cause Correction

Slipping

Improper clutch pedal free travel Adjust free travel.

Worn or oily clutch disc facing Replace disc.

Warped disc, pressure plate or flywheel surface Replace disc, clutch cover or

flywheel.

Weakened diaphragm spring Replace clutch cover.

Rusted clutch cable Replace cable.

Dragging clutch

Improper clutch pedal free travel Adjust free travel.

Weakened diaphragm spring, or worn spring tip Replace clutch cover.

Rusted input shaft splines Lubricate.

Damaged or worn splines of transmission input shaft Replace input shaft.

Excessively wobbly clutch disc Replace disc.

Clutch facings broken or dirty with oil Replace disc.

Clutch vibration

Glazed (glass-like) clutch facings Repair or replace disc.

Clutch facings dirty with oil Replace disc.

Release bearing slides unsmoothly on input shaft

bearing retainerLubricate or replace input

shaft bearing retainer.

Wobbly clutch disc, or poor facing contact Replace disc.

Weakened torsion springs in clutch disc Replace disc.

Clutch disc rivets loose Replace disc.

Distorted pressure plate or flywheel surface Replace clutch cover or fly-

wheel.

Weakened engine mounting or loosened engine

mounting bolt or nutRetighten or replace mount-

ing.

Noisy clutch

Worn or broken release bearing Replace release bearing.

Input shaft front bearing worn down Replace input shaft bearing.

Excessive rattle of clutch disc hub Replace disc.

Cracked clutch disc Replace disc.

Pressure plate and diaphragm spring rattling Replace clutch cover.

Grabbing clutch

Clutch disc facings soaked with oil Replace disc.

Clutch disc facings excessively worn Replace disc.

Rivet heads showing out of facing Replace disc.

Weakened torsion springs Replace disc.