troubleshooting SUZUKI SWIFT 2008 2.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2008, Model line: SWIFT, Model: SUZUKI SWIFT 2008 2.GPages: 1496, PDF Size: 34.44 MB

Page 716 of 1496

Downloaded from www.Manualslib.com manuals search engine 5A-72 Automatic Transmission/Transaxle:

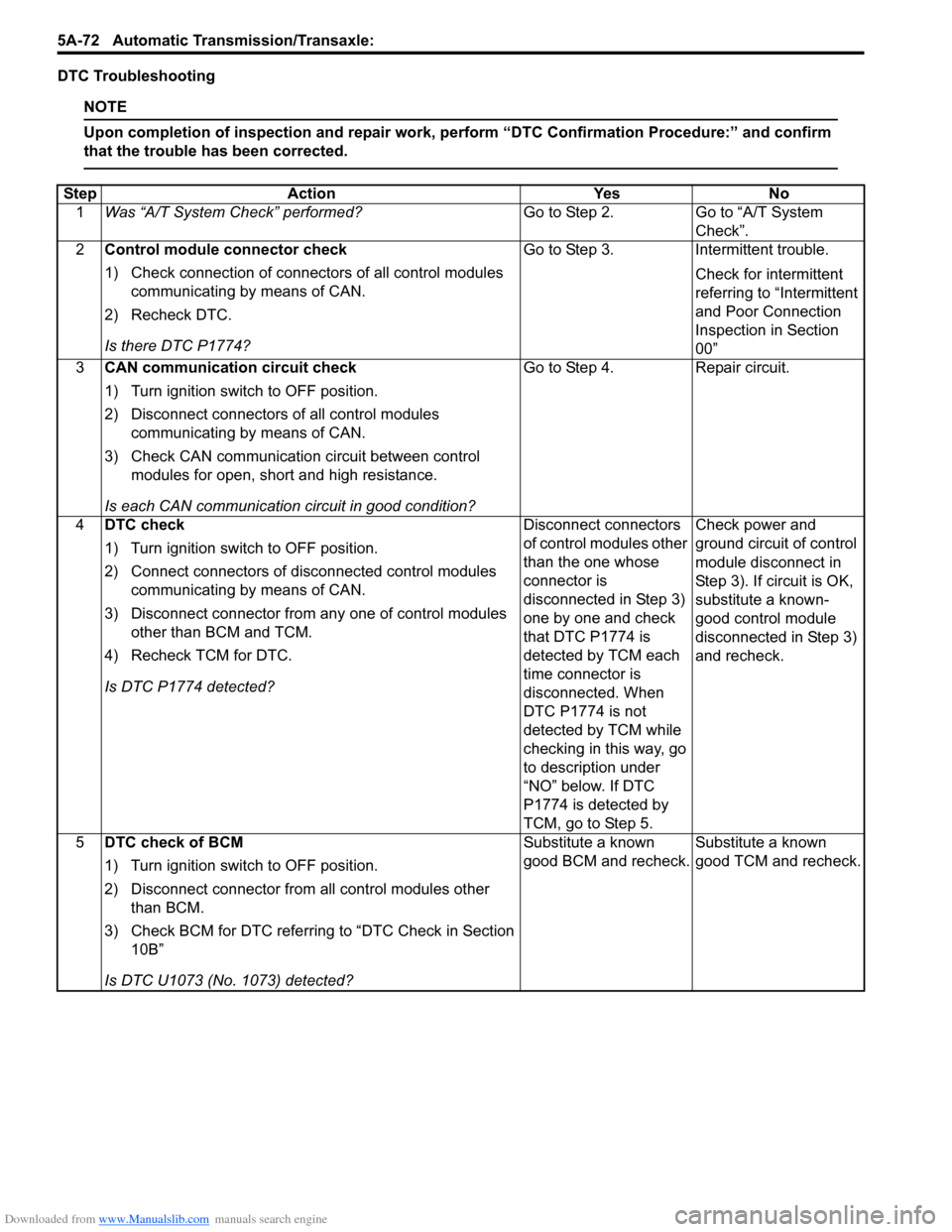

DTC Troubleshooting

NOTE

Upon completion of inspection and repair work, perform “DTC Confirmation Procedure:” and confirm

that the trouble has been corrected.

Step Action YesNo

1 Was “A/T System Check” performed? Go to Step 2.Go to “A/T System

Check”.

2 Control module connector check

1) Check connection of connectors of all control modules

communicating by means of CAN.

2) Recheck DTC.

Is there DTC P1774? Go to Step 3.

Intermittent trouble.

Check for intermittent

referring to “Intermittent

and Poor Connection

Inspection in Section

00”

3 CAN communication circuit check

1) Turn ignition switch to OFF position.

2) Disconnect connectors of all control modules

communicating by means of CAN.

3) Check CAN communication circuit between control modules for open, short and high resistance.

Is each CAN communication circuit in good condition? Go to Step 4.

Repair circuit.

4 DTC check

1) Turn ignition switch to OFF position.

2) Connect connectors of disconnected control modules

communicating by means of CAN.

3) Disconnect connector from any one of control modules other than BCM and TCM.

4) Recheck TCM for DTC.

Is DTC P1774 detected? Disconnect connectors

of control modules other

than the one whose

connector is

disconnected in Step 3)

one by one and check

that DTC P1774 is

detected by TCM each

time connector is

disconnected. When

DTC P1774 is not

detected by TCM while

checking in this way, go

to description under

“NO” below. If DTC

P1774 is detected by

TCM, go to Step 5.Check power and

ground circuit of control

module disconnect in

Step 3). If circuit is OK,

substitute a known-

good control module

disconnected in Step 3)

and recheck.

5 DTC check of BCM

1) Turn ignition switch to OFF position.

2) Disconnect connector from all control modules other

than BCM.

3) Check BCM for DTC referring to “DTC Check in Section 10B”

Is DTC U1073 (No. 1073) detected? Substitute a known

good BCM and recheck.

Substitute a known

good TCM and recheck.

Page 717 of 1496

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-73

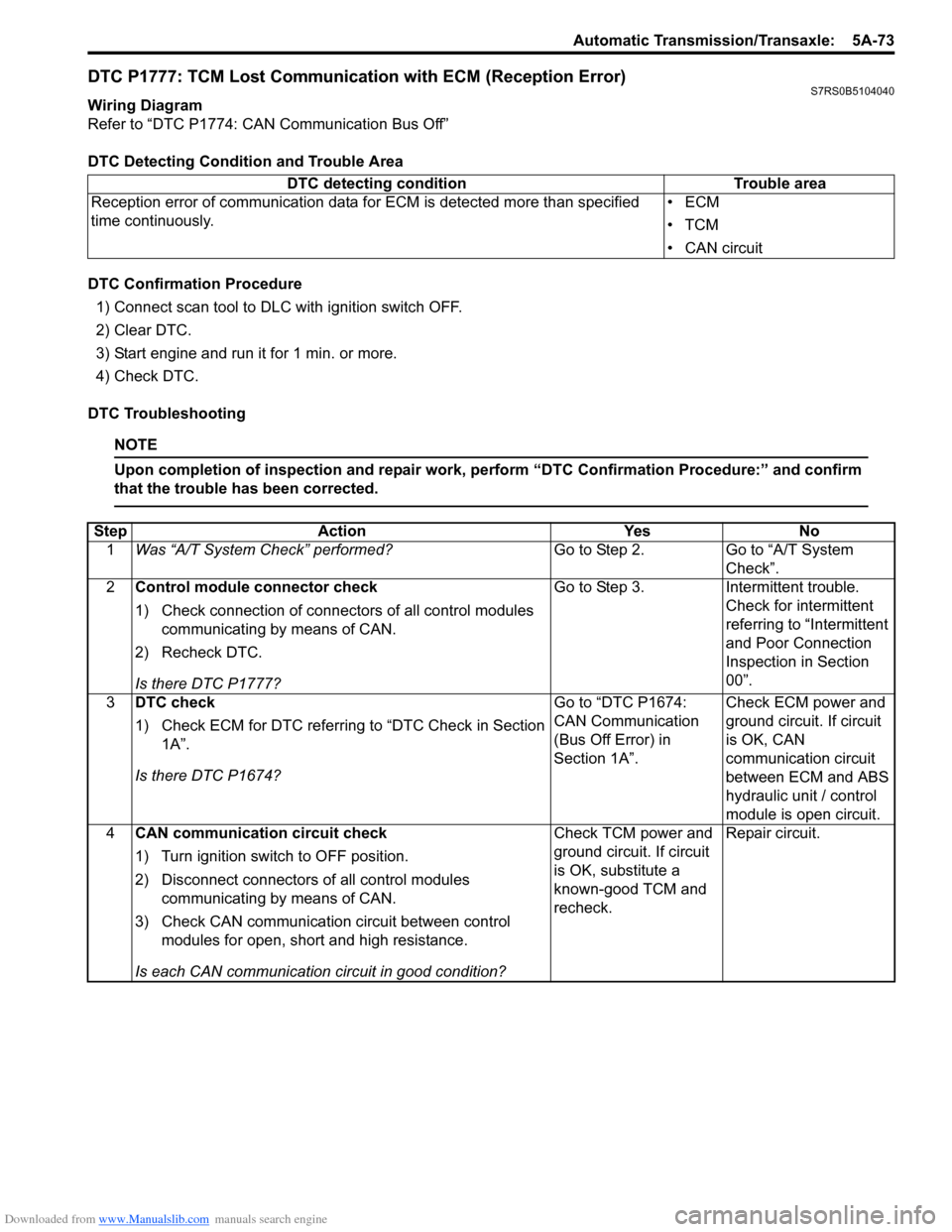

DTC P1777: TCM Lost Communication with ECM (Reception Error)S7RS0B5104040

Wiring Diagram

Refer to “DTC P1774: CAN Communication Bus Off”

DTC Detecting Condition and Trouble Area

DTC Confirmation Procedure1) Connect scan tool to DLC with ignition switch OFF.

2) Clear DTC.

3) Start engine and run it for 1 min. or more.

4) Check DTC.

DTC Troubleshooting

NOTE

Upon completion of inspection and repair work, perform “DTC Confirmation Procedure:” and confirm

that the trouble has been corrected.

DTC detecting condition Trouble area

Reception error of communication data fo r ECM is detected more than specified

time continuously. •ECM

•TCM

• CAN circuit

Step

Action YesNo

1 Was “A/T System Check” performed? Go to Step 2.Go to “A/T System

Check”.

2 Control module connector check

1) Check connection of connectors of all control modules

communicating by means of CAN.

2) Recheck DTC.

Is there DTC P1777? Go to Step 3.

Intermittent trouble.

Check for intermittent

referring to “Intermittent

and Poor Connection

Inspection in Section

00”.

3 DTC check

1) Check ECM for DTC referring to “DTC Check in Section

1A”.

Is there DTC P1674? Go to “DTC P1674:

CAN Communication

(Bus Off Error) in

Section 1A”.

Check ECM power and

ground circuit. If circuit

is OK, CAN

communication circuit

between ECM and ABS

hydraulic unit / control

module is open circuit.

4 CAN communication circuit check

1) Turn ignition switch to OFF position.

2) Disconnect connectors of all control modules

communicating by means of CAN.

3) Check CAN communication circuit between control modules for open, short and high resistance.

Is each CAN communication circuit in good condition? Check TCM power and

ground circuit. If circuit

is OK, substitute a

known-good TCM and

recheck.

Repair circuit.

Page 718 of 1496

Downloaded from www.Manualslib.com manuals search engine 5A-74 Automatic Transmission/Transaxle:

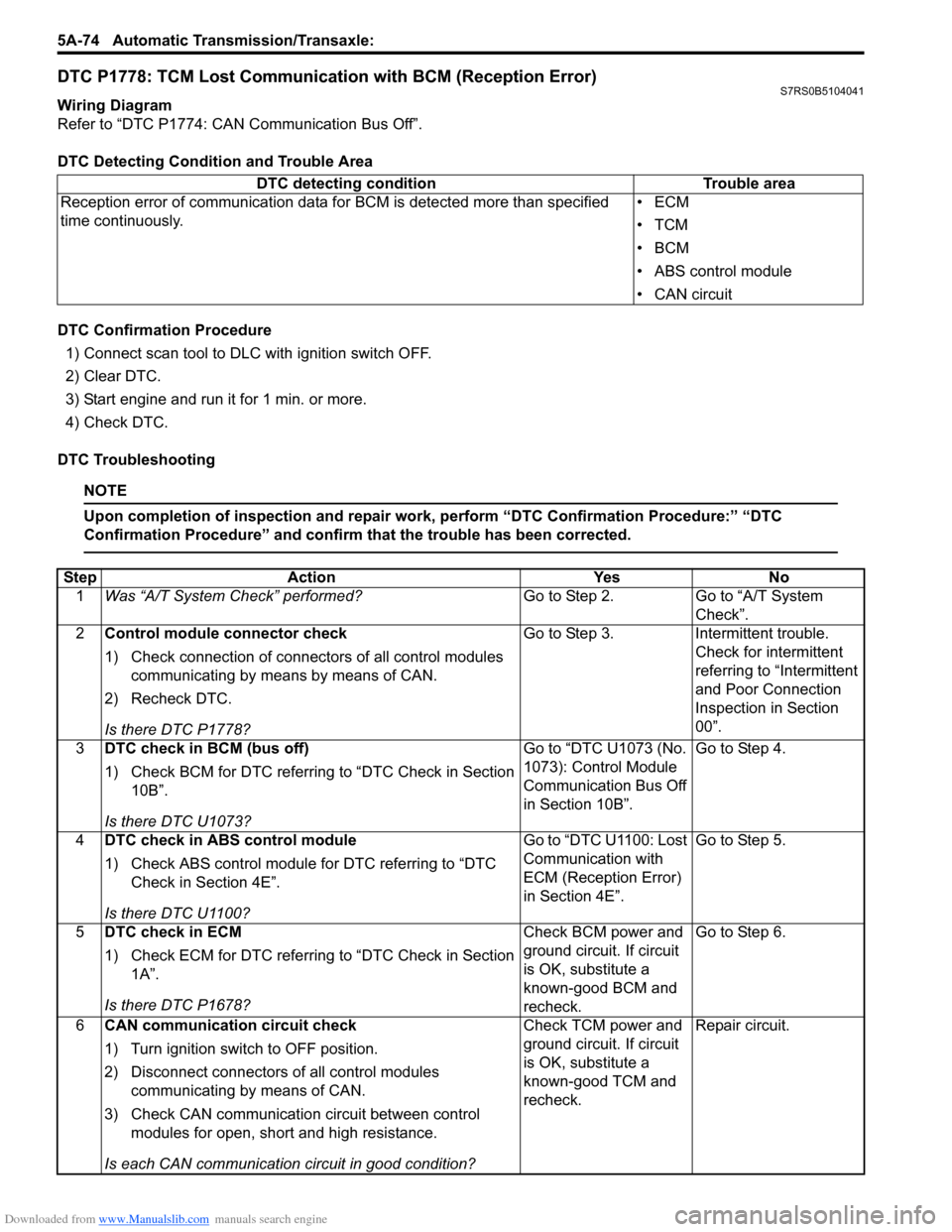

DTC P1778: TCM Lost Communication with BCM (Reception Error)S7RS0B5104041

Wiring Diagram

Refer to “DTC P1774: CAN Communication Bus Off”.

DTC Detecting Condition and Trouble Area

DTC Confirmation Procedure

1) Connect scan tool to DLC with ignition switch OFF.

2) Clear DTC.

3) Start engine and run it for 1 min. or more.

4) Check DTC.

DTC Troubleshooting

NOTE

Upon completion of inspection and repair work, perform “DTC Confirmation Procedure:” “DTC

Confirmation Procedure” and confirm that the trouble has been corrected.

DTC detecting condition Trouble area

Reception error of communication data fo r BCM is detected more than specified

time continuously. •ECM

•TCM

•BCM

• ABS control module

• CAN circuit

Step

Action YesNo

1 Was “A/T System Check” performed? Go to Step 2.Go to “A/T System

Check”.

2 Control module connector check

1) Check connection of connectors of all control modules

communicating by means by means of CAN.

2) Recheck DTC.

Is there DTC P1778? Go to Step 3.

Intermittent trouble.

Check for intermittent

referring to “Intermittent

and Poor Connection

Inspection in Section

00”.

3 DTC check in BCM (bus off)

1) Check BCM for DTC referring to “DTC Check in Section

10B”.

Is there DTC U1073? Go to “DTC U1073 (No.

1073): Control Module

Communication Bus Off

in Section 10B”.

Go to Step 4.

4 DTC check in ABS control module

1) Check ABS control module for DTC referring to “DTC

Check in Section 4E”.

Is there DTC U1100? Go to “DTC U1100: Lost

Communication with

ECM (Reception Error)

in Section 4E”.

Go to Step 5.

5 DTC check in ECM

1) Check ECM for DTC referring to “DTC Check in Section

1A”.

Is there DTC P1678? Check BCM power and

ground circuit. If circuit

is OK, substitute a

known-good BCM and

recheck.Go to Step 6.

6 CAN communication circuit check

1) Turn ignition switch to OFF position.

2) Disconnect connectors of all control modules

communicating by means of CAN.

3) Check CAN communication circuit between control modules for open, short and high resistance.

Is each CAN communication circuit in good condition? Check TCM power and

ground circuit. If circuit

is OK, substitute a

known-good TCM and

recheck.

Repair circuit.

Page 719 of 1496

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-75

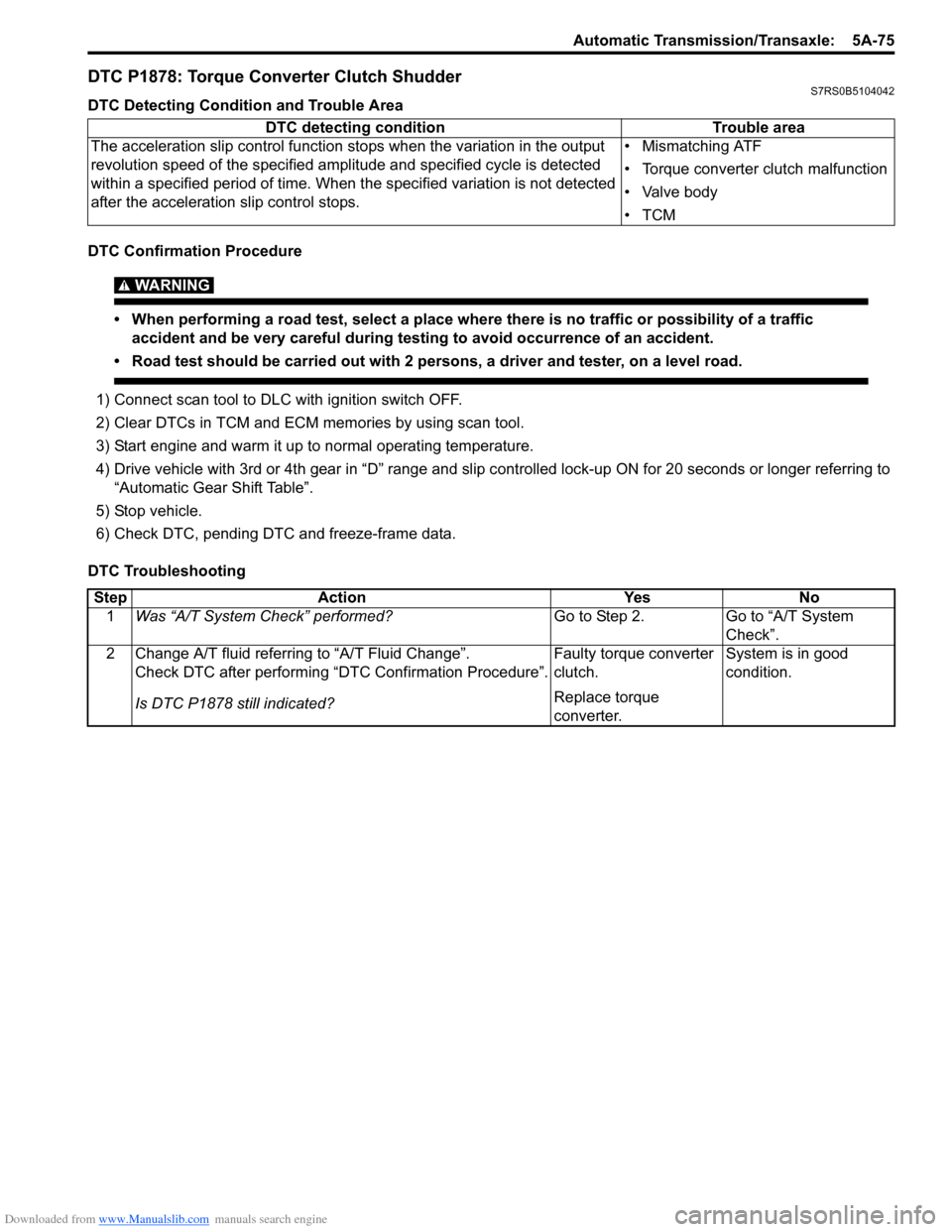

DTC P1878: Torque Converter Clutch ShudderS7RS0B5104042

DTC Detecting Condition and Trouble Area

DTC Confirmation Procedure

WARNING!

• When performing a road test, select a place where there is no traffic or possibility of a traffic accident and be very careful during testing to avoid occurrence of an accident.

• Road test should be carried out with 2 persons, a driver and tester, on a level road.

1) Connect scan tool to DLC with ignition switch OFF.

2) Clear DTCs in TCM and ECM memories by using scan tool.

3) Start engine and warm it up to normal operating temperature.

4) Drive vehicle with 3rd or 4th gear in “D” range and slip c ontrolled lock-up ON for 20 seconds or longer referring to

“Automatic Gear Shift Table”.

5) Stop vehicle.

6) Check DTC, pending DTC and freeze-frame data.

DTC Troubleshooting DTC detecting condition

Trouble area

The acceleration slip control function stops when the variation in the output

revolution speed of the specified amp litude and specified cycle is detected

within a specified period of time. When t he specified variation is not detected

after the acceleration slip control stops. • Mismatching ATF

• Torque converter clutch malfunction

• Valve body

•TCM

Step

Action YesNo

1 Was “A/T System Check” performed? Go to Step 2.Go to “A/T System

Check”.

2 Change A/T fluid referring to “A/T Fluid Change”. Check DTC after performing “DTC Confirmation Procedure”.

Is DTC P1878 still indicated? Faulty torque converter

clutch.

Replace torque

converter.System is in good

condition.

Page 721 of 1496

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-77

DTC TroubleshootingStep Action Yes No 1 Was “A/T System Check” performed? Go to Step 2. Go to “A/T System

Check”.

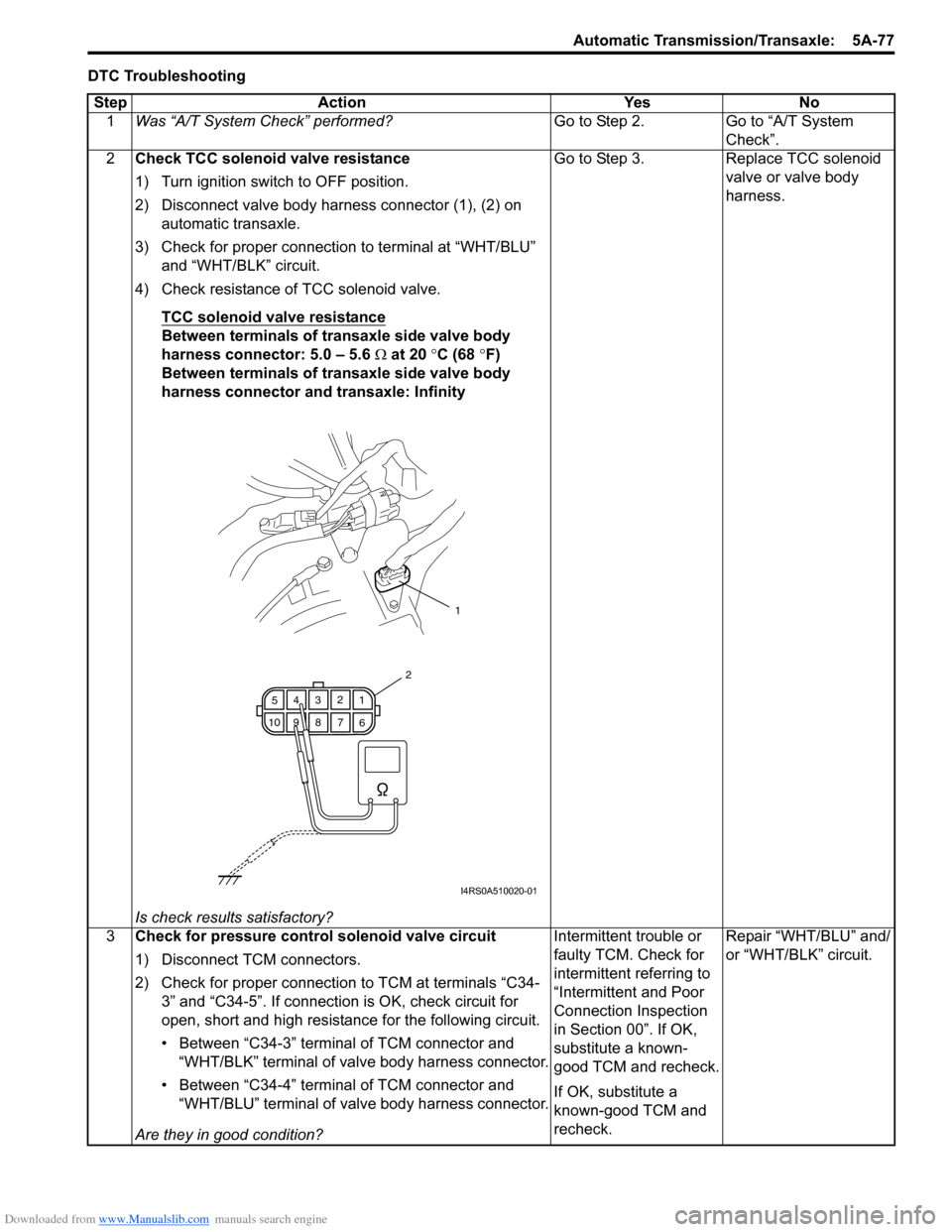

2 Check TCC solenoid valve resistance

1) Turn ignition switch to OFF position.

2) Disconnect valve body harness connector (1), (2) on

automatic transaxle.

3) Check for proper connection to terminal at “WHT/BLU” and “WHT/BLK” circuit.

4) Check resistance of TCC solenoid valve.

TCC solenoid valve resistance

Between terminals of transaxle side valve body

harness connector: 5.0 – 5.6 Ω at 20 °C (68 °F)

Between terminals of transaxle side valve body

harness connector and transaxle: Infinity

Is check results satisfactory? Go to Step 3. Replace TCC solenoid

valve or valve body

harness.

3 Check for pressure control solenoid valve circuit

1) Disconnect TCM connectors.

2) Check for proper connection to TCM at terminals “C34-

3” and “C34-5”. If connection is OK, check circuit for

open, short and high resistance for the following circuit.

• Between “C34-3” terminal of TCM connector and “WHT/BLK” terminal of valve body harness connector.

• Between “C34-4” terminal of TCM connector and “WHT/BLU” terminal of valve body harness connector.

Are they in good condition? Intermittent trouble or

faulty TCM. Check for

intermittent referring to

“Intermittent and Poor

Connection Inspection

in Section 00”. If OK,

substitute a known-

good TCM and recheck.

If OK, substitute a

known-good TCM and

recheck.

Repair “WHT/BLU” and/

or “WHT/BLK” circuit.

1

6

7

89

10 5

43 2

1

2

I4RS0A510020-01

Page 722 of 1496

Downloaded from www.Manualslib.com manuals search engine 5A-78 Automatic Transmission/Transaxle:

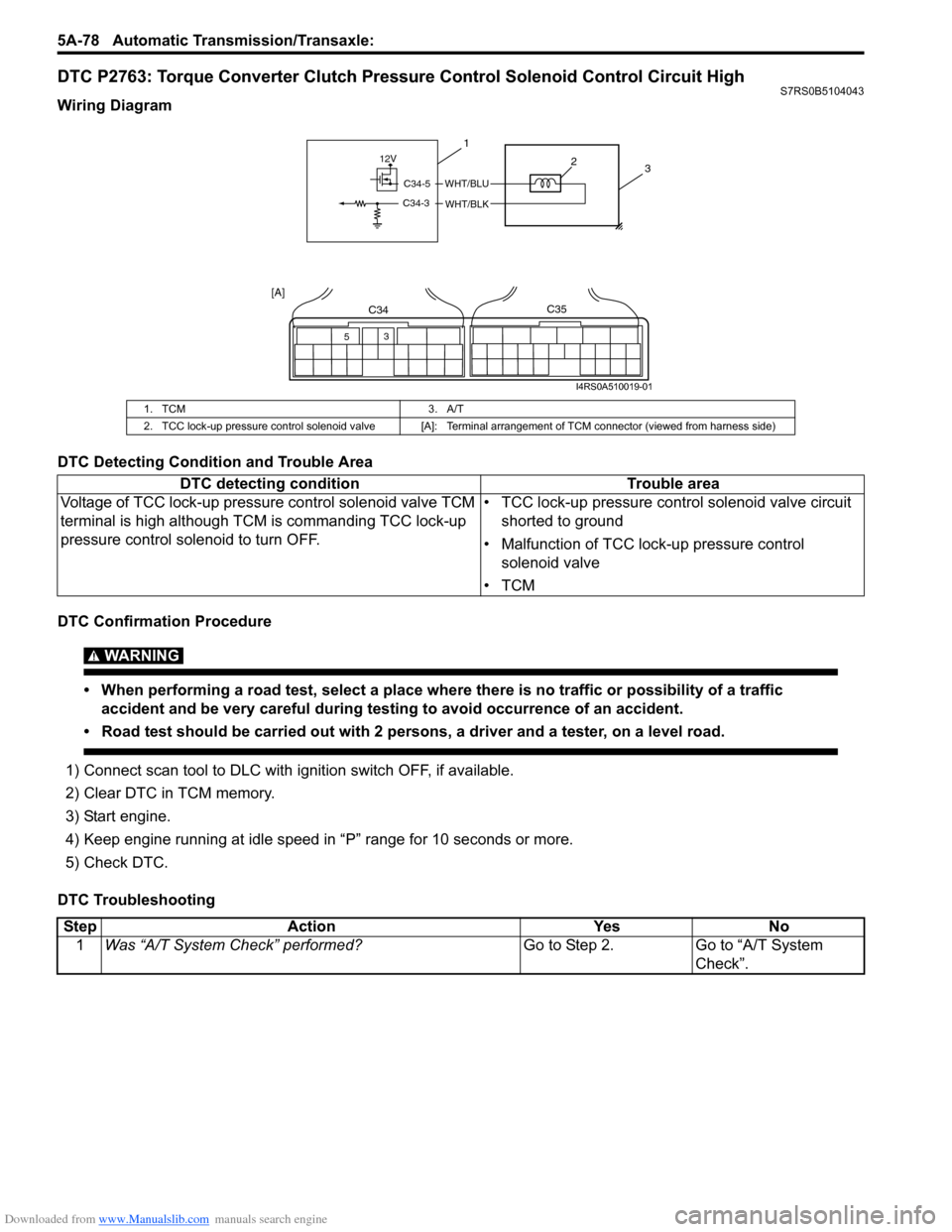

DTC P2763: Torque Converter Clutch Pressure Control Solenoid Control Circuit HighS7RS0B5104043

Wiring Diagram

DTC Detecting Condition and Trouble Area

DTC Confirmation Procedure

WARNING!

• When performing a road test, select a place where there is no traffic or possibility of a traffic

accident and be very careful during testing to avoid occurrence of an accident.

• Road test should be carried out with 2 persons, a driver and a tester, on a level road.

1) Connect scan tool to DLC with ig nition switch OFF, if available.

2) Clear DTC in TCM memory.

3) Start engine.

4) Keep engine running at idle speed in “P” range for 10 seconds or more.

5) Check DTC.

DTC Troubleshooting

1. TCM 3. A/T

2. TCC lock-up pressure control solenoid valve [A]: Terminal arrangement of TCM connector (viewed from harness side)

DTC detecting conditionTrouble area

Voltage of TCC lock-up pressure control solenoid valve TCM

terminal is high although TCM is commanding TCC lock-up

pressure control sole noid to turn OFF. • TCC lock-up pressure contro

l solenoid valve circuit

shorted to ground

• Malfunction of TCC lock-up pressure control solenoid valve

•TCM

12V

C34-5

C34-3

WHT/BLU

WHT/BLK

3

1

2

53

C34C35

[A]

I4RS0A510019-01

Step

Action YesNo

1 Was “A/T System Check” performed? Go to Step 2.Go to “A/T System

Check”.

Page 724 of 1496

Downloaded from www.Manualslib.com manuals search engine 5A-80 Automatic Transmission/Transaxle:

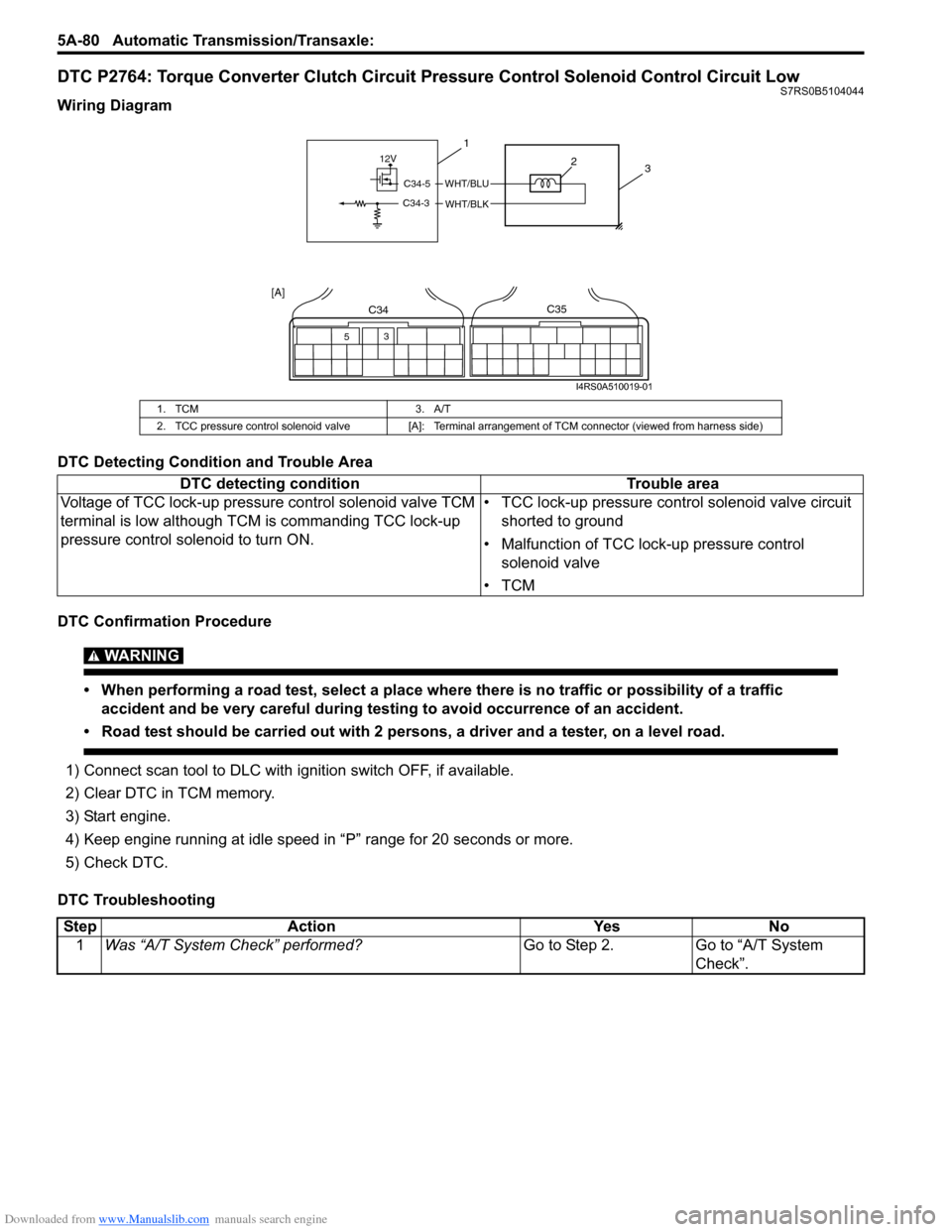

DTC P2764: Torque Converter Clutch Circuit Pressure Control Solenoid Control Circuit LowS7RS0B5104044

Wiring Diagram

DTC Detecting Condition and Trouble Area

DTC Confirmation Procedure

WARNING!

• When performing a road test, select a place where there is no traffic or possibility of a traffic

accident and be very careful during testing to avoid occurrence of an accident.

• Road test should be carried out with 2 persons, a driver and a tester, on a level road.

1) Connect scan tool to DLC with ig nition switch OFF, if available.

2) Clear DTC in TCM memory.

3) Start engine.

4) Keep engine running at idle speed in “P” range for 20 seconds or more.

5) Check DTC.

DTC Troubleshooting

1. TCM 3. A/T

2. TCC pressure control solenoid valve [A]: Terminal arrangement of TCM connector (viewed from harness side)

DTC detecting condition Trouble area

Voltage of TCC lock-up pressure control solenoid valve TCM

terminal is low although TCM is commanding TCC lock-up

pressure control sole noid to turn ON. • TCC lock-up pressure contro

l solenoid valve circuit

shorted to ground

• Malfunction of TCC lock-up pressure control solenoid valve

•TCM

12V

C34-5

C34-3

WHT/BLU

WHT/BLK

3

1

2

53

C34C35

[A]

I4RS0A510019-01

Step

Action YesNo

1 Was “A/T System Check” performed? Go to Step 2.Go to “A/T System

Check”.

Page 731 of 1496

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-87

Troubleshooting

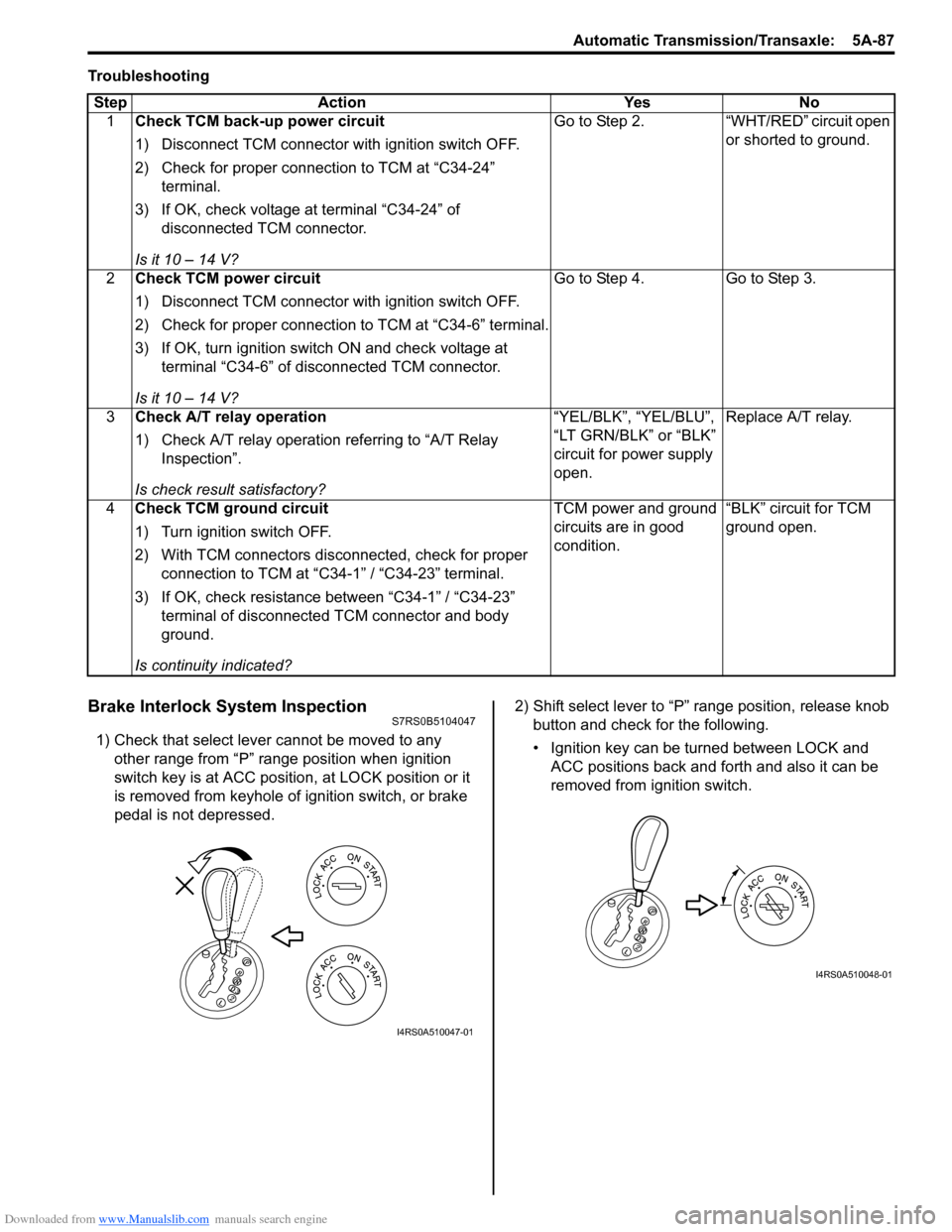

Brake Interlock System InspectionS7RS0B5104047

1) Check that select lever cannot be moved to any other range from “P” range position when ignition

switch key is at ACC position, at LOCK position or it

is removed from keyhole of ignition switch, or brake

pedal is not depressed. 2) Shift select lever to “P” range position, release knob

button and check for the following.

• Ignition key can be turned between LOCK and ACC positions back and forth and also it can be

removed from ignition switch.

Step Action Yes No

1 Check TCM back-up power circuit

1) Disconnect TCM connector with ignition switch OFF.

2) Check for proper connection to TCM at “C34-24”

terminal.

3) If OK, check voltage at terminal “C34-24” of disconnected TCM connector.

Is it 10 – 14 V? Go to Step 2. “WHT/RED” circuit open

or shorted to ground.

2 Check TCM power circuit

1) Disconnect TCM connector with ignition switch OFF.

2) Check for proper connection to TCM at “C34-6” terminal.

3) If OK, turn ignition switch ON and check voltage at

terminal “C34-6” of disconnected TCM connector.

Is it 10 – 14 V? Go to Step 4. Go to Step 3.

3 Check A/T relay operation

1) Check A/T relay operation referring to “A/T Relay

Inspection”.

Is check result satisfactory? “YEL/BLK”, “YEL/BLU”,

“LT GRN/BLK” or “BLK”

circuit for power supply

open.

Replace A/T relay.

4 Check TCM ground circuit

1) Turn ignition switch OFF.

2) With TCM connectors disconnected, check for proper

connection to TCM at “C34-1” / “C34-23” terminal.

3) If OK, check resistance between “C34-1” / “C34-23” terminal of disconnected TCM connector and body

ground.

Is continuity indicated? TCM power and ground

circuits are in good

condition.

“BLK” circuit for TCM

ground open.

I4RS0A510047-01

I4RS0A510048-01

Page 888 of 1496

Downloaded from www.Manualslib.com manuals search engine 6C-6 Power Assisted Steering System:

NOTE

• As execution of “DTC Clearance” will clear all DTCs, be sure to record all DTCs before service.

• DTC C1122 is indicated when ignition switch is at ON position and engine is not running, it means

that nothing is abnormal.

• Current DTC and history DTC ca n be identified by condition of the “EPS” warning light.

“EPS” warning light operates as follows.

7 �) Rechecking and record of DTC

1) Recheck for DTC referring to “DTC Check”.

Is there any DTC(s)? Go to Step 9. Go to Step 10.

8 �) Steering symptom diagnosis and P/S system

symptom diagnosis

1) Check and repair according to “Steering Symptom Diagnosis in Section 6A” and “P/S System Symptom

Diagnosis”.

Are check and repair complete? Go to Step 11. Check and repair

malfunction part(s), and

go to Step 11.

9 �) Troubleshooting for DTC

1) Check and repair according to applicable DTC diag. flow.

Are check and repair complete? Go to Step 11. Check and repair

malfunction part(s), and

go to Step 11.

10 �) Intermittent problems check

1) Check for intermittent problems referring to “Intermittent Problems Check”.

Is there any faulty condition? Repair or replace

malfunction part(s), and

go to Step 11.

Go to Step 11.

11 �) Final confirmation test

1) Clear DTC if any.

2) Perform final confirmation test referring to “Final Confirmation Test”.

Is there any problem symptom, DTC or abnormal condition? Go to Step 6. End.

Step Action Yes No

Current DTC is set.

(Abnormality exists at

present.)

Only history DTC is set.

(Faulty condition occurred once

in the past, but normal condition

is detected at present.)

Current and history DTC

exist.

“EPS” warning light

after engine started Remains ON. Turns OFF. Remains ON.

Page 890 of 1496

Downloaded from www.Manualslib.com manuals search engine 6C-8 Power Assisted Steering System:

Step 2: DTC Check, Record and Clearance

First, check DTC, referring to “DTC Check”. If DTC is

indicated, print it or write them down and then clear them

by referring to “DTC Clearance”. DTC indicates

malfunction that occurred in the system but does not

indicate whether it exists now or it occurred in the past

and the normal condition has been restored now. To

check which case applies, check the symptom in

question according to Step 5 and recheck DTC

according to Step 6 and 7.

Attempt to diagnose a trouble based on DTC in this step

only or failure to clear the DTC in this step will lead to

incorrect diagnosis, trouble diagnosis of a normal circuit

or difficulty in troubleshooting.

Step 3 and 4: Visual Inspection

As a preliminary step, be sure to perform visual check of

the items that support proper function of the P/S system

referring to “Visual Inspection”.

Step 5: Trouble Symptom Confirmation

Based on information obtained in “Step 1: Customer

Complaint Analysis: ” and “S tep 2: DTC Check, Record

and Clearance: ”, confirm trouble symptoms. Also,

reconfirm trouble symptom by performing test drive and

turning steering wheel fully to right and left at stopped

vehicle.

Step 6 and 7: Rechecking and Record of DTC

Refer to “DTC Check” for checking procedure.

Step 8: Steering Symptom Diagnosis and P/S

System Symptom Diagnosis

Perform basic steering system check according to

“Steering Symptom Diagnosis in Section 6A” first. When

the end of the flow has been reached, check the parts of

the system suspected as a possible cause referring to

“P/S System Symptom Diagnosis” and based on

symptoms appearing on the vehicle (symptoms obtained

through steps of customer complaint analysis, trouble

symptom confirmation and/or basic P/S system check)

and repair or replace faulty parts, if any.

Step 9: Troubleshooting for DTC (See each DTC

Diag. Flow)

Based on the DTC indicated in Step 6 or 7 and referring

to the applicable DTC diag. flow, locate the cause of the

trouble, namely in a sensor, switch, wire harness,

connector, actuator, P/S control module or other part and

repair or replace faulty parts.

Step 10: Intermittent Problems Check

Check parts where an intermittent trouble is easy to

occur (e.g., wire harness, connector, etc.), referring to

“Intermittent and Poor Connection Inspection in Section

00” and related circuit of DTC recorded in Step 2. Step 11: Final Confirmation Test

Confirm that the problem symptom has gone and the P/

S system is free from any abnormal conditions. If what

has been repaired is related to the DTC, clear the DTC

once, perform DTC confirmation procedure and confirm

that no DTC is indicated.

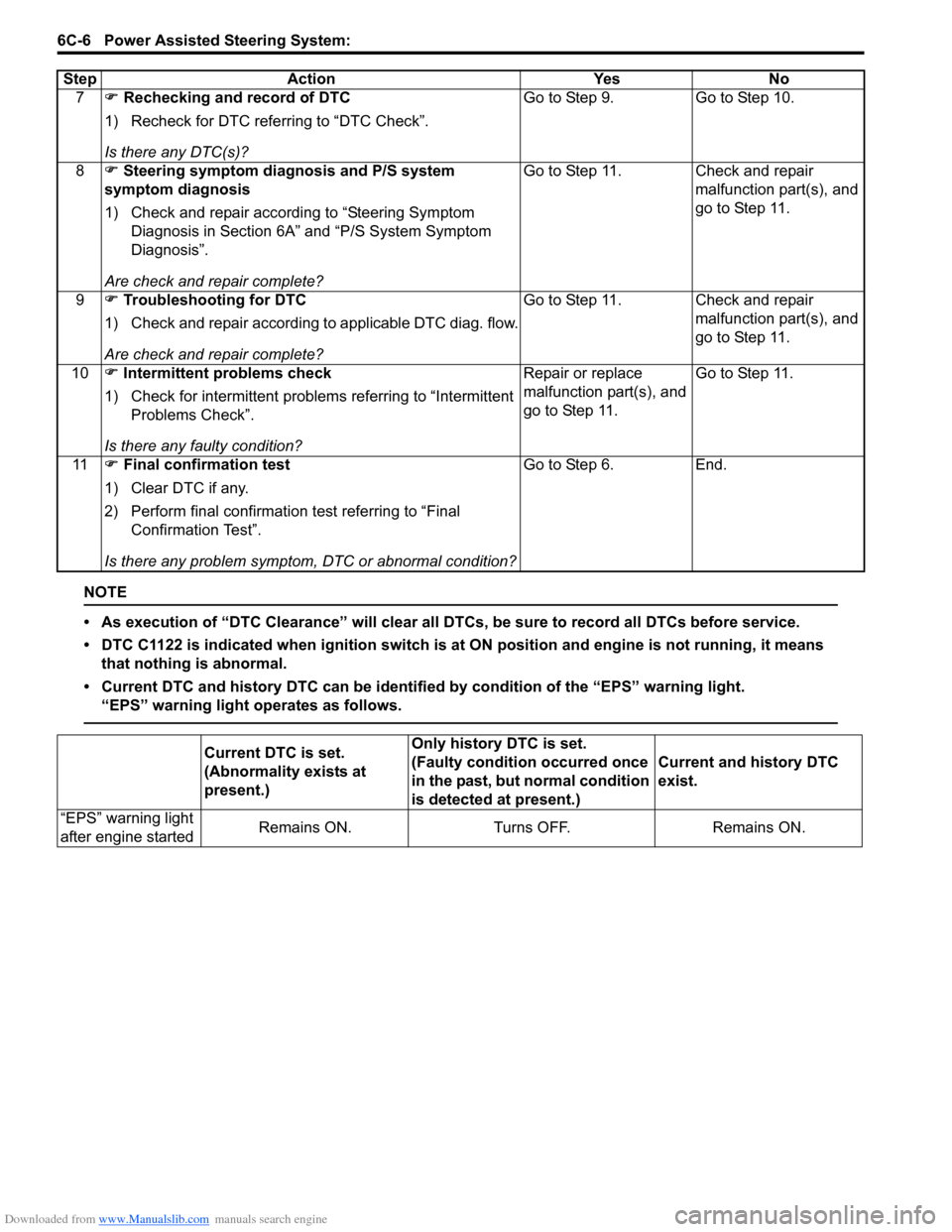

“EPS” Warning Light CheckS7RS0B6304002

1) Turn ignition switch to ON position (without engine

running) and chec k if the “EPS” warning light (1)

lights up. If the light dose not light up, go to ““EPS”

Warning Light Does Not Come ON with Ignition

Switch Turned ON before Engine Starts” of the

diagnostic flows.

2) Start engine and check if the “EPS” warning light turns OFF. If light remains ON and no DTC is stored

in P/S control module, go to ““EPS” Warning Light

Remains ON Steady after Engine Starts” for

troubleshooting.

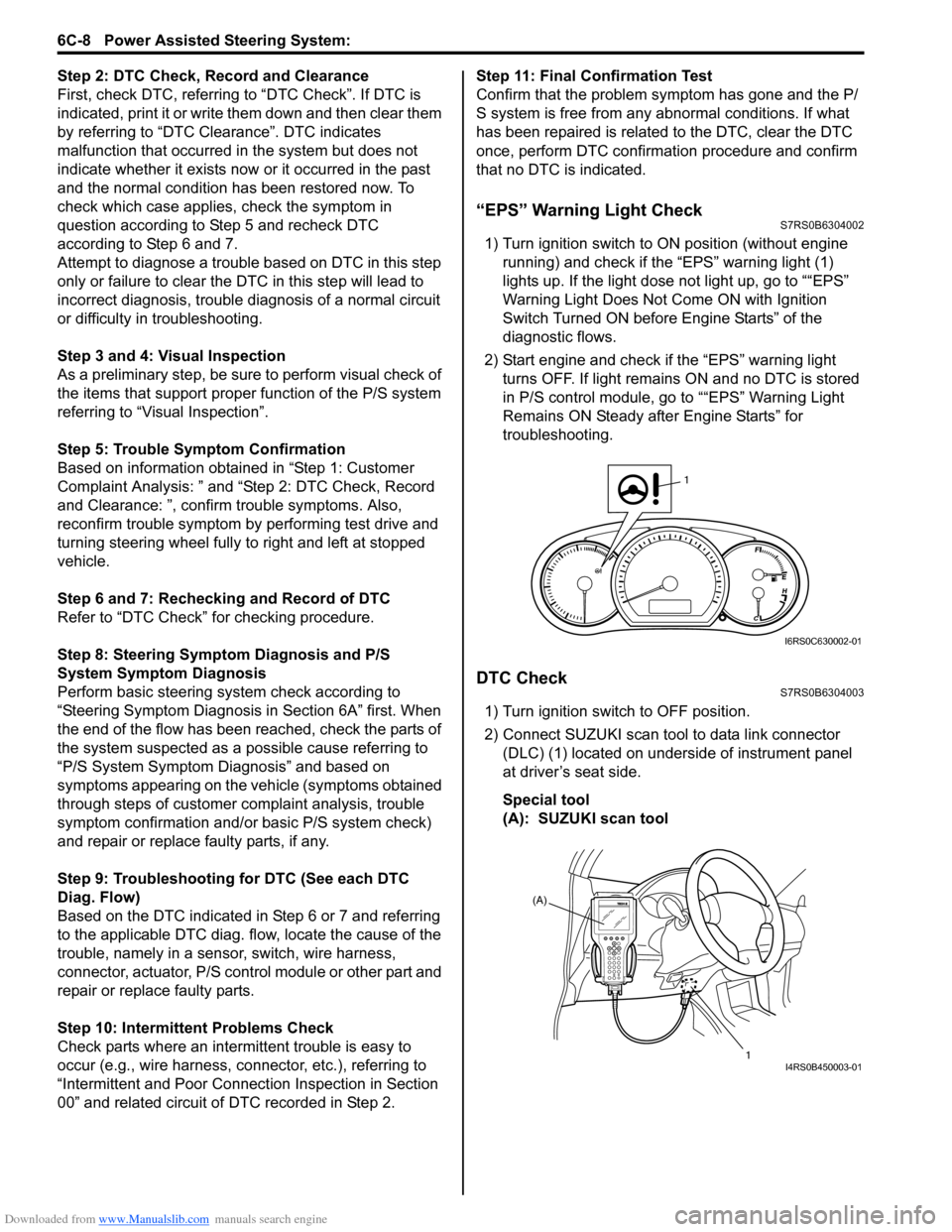

DTC CheckS7RS0B6304003

1) Turn ignition switch to OFF position.

2) Connect SUZUKI scan tool to data link connector (DLC) (1) located on underside of instrument panel

at driver’s seat side.

Special tool

(A): SUZUKI scan tool

1

I6RS0C630002-01

(A)

1

I4RS0B450003-01