troubleshooting SUZUKI SWIFT 2008 2.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2008, Model line: SWIFT, Model: SUZUKI SWIFT 2008 2.GPages: 1496, PDF Size: 34.44 MB

Page 909 of 1496

Downloaded from www.Manualslib.com manuals search engine Power Assisted Steering System: 6C-27

DTC TroubleshootingStep Action Yes No 1 Was “EPS System Check” performed? Go to Step 2. Go to “EPS System

Check”.

2 DTC check

DTC Check for ECM referring to “DTC Check in Section 1A”.

Is there any DTC detected? Go to applicable DTC

diag. flow.

Go to Step 3.

3 DTC check

1) Check ABS control module for DTC referring to “DTC

Check in Section 4E”.

Is there any DTC detected? Go to applicable DTC

diag. flow.

Go to Step 4.

4 Vehicle speed signal circuit check

1) With ignition switch turned OFF, disconnect connectors

from ECM.

2) Check ECM connector for proper connection.

3) If OK, turn ON ignition switch, measure voltage between “E23-25” wire terminal of ECM connector and body

ground.

Is voltage 4 – 5 V? Go to Step 6.

Go to Step 5.

5 Vehicle speed signal circuit check

1) With ignition switch turned OFF, disconnect P/S control

module connector “E52”.

2) Check for proper terminal connection to P/S control module connector and ECM connector.

3) If connections are OK, chec k that “Vehicle speed signal

circuit” is as following.

• Insulation resistance of “Vehicle speed signal circuit” wire harness is infinity between its terminal and other

terminals at ECM and P/S control module connector.

• Wiring resistance of “Vehicle speed signal circuit” is less than 1 Ω.

• Insulation resistance of “Vehicle speed signal circuit” between its circuit and vehicle body ground is infinity.

• Circuit voltage between “Vehicle speed signal” circuit and ground circuit is 0 – 1 V with ignition switch turned

ON.

Is circuit in good condition? Replace P/S control

module.

Repair or replace

defective circuit.

6 ECM voltage check

1) Connect P/S control mo dule and ECM connectors.

2) Check ECM for vehicle speed signal output referring to “Inspection of ECM and Its Circuits in Section 1A”.

Is check result in good condition? Replace P/S control

module.

Replace ECM.

Page 911 of 1496

Downloaded from www.Manualslib.com manuals search engine Power Assisted Steering System: 6C-29

DTC TroubleshootingStep Action Yes No 1 Was “EPS System Check” performed? Go to Step 2. Go to “EPS System

Check”.

2 DTC check

1) Clear DTC(s) referring to “DTC Clearance”.

2) Run engine at idle speed.

3) Check if any DTC is detecte d referring to “DTC Check”.

Is DTC C1122 still detected? Go to Step 3. Check intermittent

trouble referring to

“Intermittent and Poor

Connection Inspection

in Section 00”.

3 DTC check

1) Check ECM for DTC referring to “DTC Check in Section

1A”.

Is there any DTC related to engine speed? Go to applicable DTC

diag. flow.

Go to Step 4.

4 Engine speed signal circuit check

1) With ignition switch turned OFF, disconnect P/S control

module connector.

2) Check P/S control module connector for proper connection.

3) If OK, turn ON ignition switch, measure voltage between “E52-12” wire terminal of P/S control module connector

and vehicle body ground.

Is voltage 10 – 14 V? Go to Step 6.

Go to Step 5.

5 1) With ignition switch turned OFF, disconnect ECM connector.

2) Check for proper connection to the P/S control module and ECM at each “Engine speed signal circuit” terminal.

3) If connections are OK, chec k that “Engine speed signal

circuit” is as following.

• Insulation resistance of “Engine speed signal circuit” wire is infinity between its terminal and other terminals

at ECM and P/S control module connector.

• Wiring resistance of “Engine speed signal circuit” terminal are less than 1 Ω.

• Insulation resistance of “Engine speed signal circuit” between its terminal and vehicle body ground is

infinity.

• Circuit voltage between “Engine speed signal circuit” and ground circuit is 0 – 1 V with ignition switch turned

ON.

Is circuit in good condition? Go to Step 6.

Repair engine speed

signal circuit.

6 ECM voltage check

1) Connect P/S control mo dule and ECM connectors.

2) Check ECM for engine speed signal and vehicle speed signal output voltage to P/S control module referring to

“Inspection of ECM and Its Circuits in Section 1A”.

Is check result in good condition? Substitute a known-

good P/S control

module and recheck.

Substitute a known-

good ECM and recheck.

Page 913 of 1496

Downloaded from www.Manualslib.com manuals search engine Power Assisted Steering System: 6C-31

DTC Detecting Condition and Trouble Area

DTC TroubleshootingDTC detecting condition Trouble area

DTC C1141:

Voltage between both motor drive circuits is more than 8.5

V or less than 0.2 V for 0.5 seconds continuously while

motor is not drived

(1 driving cycle detection logic)

DTC C1142:

Measured motor drive current is more than 10 A as

compared with target motor drive current.

(1 driving cycle detection logic)

DTC C1143:

Measured motor drive current is more than 50 A.

(1 driving cycle detection logic)

DTC C1145:

Measured motor drive current is less than 2 A

continuously for more than 3 seconds even though target

motor drive current is more than 4 A.

or

Measured motor drive current is less than 0.8 A for total 1

second even though motor cont rol duty is more than 90%

while target motor drive current is less than 8 A.

(1 driving cycle detection logic) • P/S motor circuit

• P/S motor

• P/S control module

Step

Action YesNo

1 Was “EPS System Check” performed? Go to Step 2.Go to “EPS System

Check”.

2 DTC check

Is DTC C1153 and/or DTC C1155 indicated together? Go to applicable DTC

diag. flow.

Go to Step 3.

3 Power supply and ground circuit check

1) Check P/S control module power supply and ground

circuit referring to “P/S Control Module Power Supply

and Ground Circuit Check”.

Is it in good condition? Go to Step 4.

Repair or replace

defective circuit.

4 Motor circuit check

1) With ignition switch tuned OFF, disconnect P/S motor

connector (“E51”).

2) Check that P/S motor circuit is as follows. • Insulation resistance of wire harness is infinity between each “P/S motor circuit” terminal and other

terminal at P/S motor connector.

• Wiring harness resistance of each “P/S motor circuit”

is less than 1 Ω.

• Insulation resistance between each “P/S motor circuit” and vehicle body ground is infinity.

• Circuit voltage between each “P/S motor circuit” and ground circuit is 0 – 1 V with ignition switch turned

ON.

Is circuit in good condition? Go to Step 5.

Repair or replace

defective circuit.

5 P/S motor check

1) Check motor and its circuit referring to “P/S Motor and Its

Circuit Inspection”.

Is motor in good condition? Substitute a known-

good P/S control

module, and recheck.

Replace the steering

gear case assembly.

Page 914 of 1496

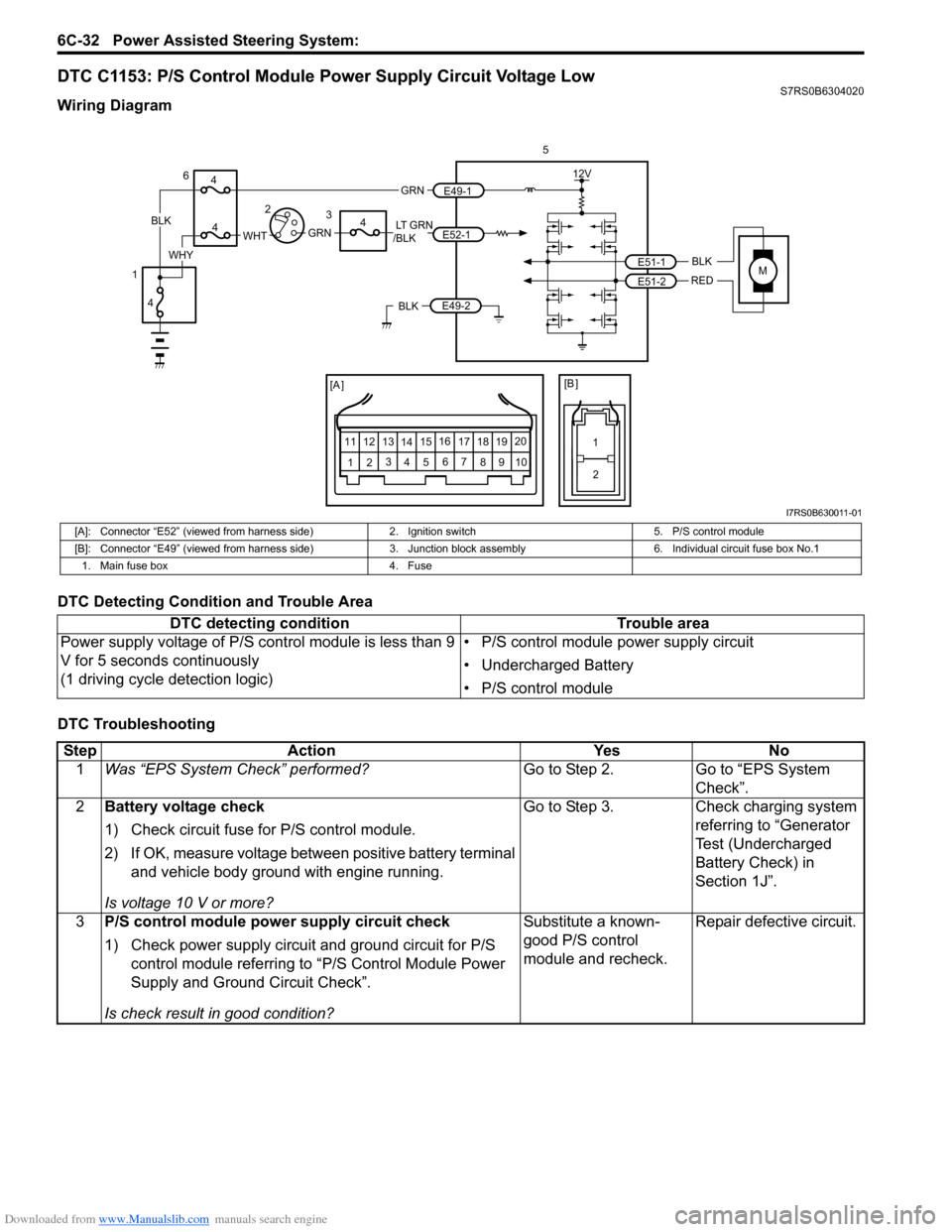

Downloaded from www.Manualslib.com manuals search engine 6C-32 Power Assisted Steering System:

DTC C1153: P/S Control Module Power Supply Circuit Voltage LowS7RS0B6304020

Wiring Diagram

DTC Detecting Condition and Trouble Area

DTC Troubleshooting

MBLK

REDE51-1

E51-2

12V

5

[A ]

12 3

4 5 67

89

11

10

12 13

141516

17 18 19 20

[B ]

1

2

LT GRN

/BLKE52-1 E49-1

GRNGRNWHTBLK

WHY

6

3

4

4

4

4

1 2

E49-2BLK

I7RS0B630011-01

[A]: Connector “E52” (viewed from harness side)

2. Ignition switch5. P/S control module

[B]: Connector “E49” (viewed from harness side) 3. Junction block assembly 6. Individual circuit fuse box No.1

1. Main fuse box 4. Fuse

DTC detecting condition Trouble area

Power supply voltage of P/S control module is less than 9

V for 5 seconds continuously

(1 driving cycle detection logic) • P/S control module power supply circuit

• Undercharged Battery

• P/S control module

Step

Action YesNo

1 Was “EPS System Check” performed? Go to Step 2.Go to “EPS System

Check”.

2 Battery voltage check

1) Check circuit fuse for P/S control module.

2) If OK, measure voltage between positive battery terminal

and vehicle body ground with engine running.

Is voltage 10 V or more? Go to Step 3.

Check charging system

referring to “Generator

Test (Undercharged

Battery Check) in

Section 1J”.

3 P/S control module power supply circuit check

1) Check power supply circuit and ground circuit for P/S

control module referring to “P/S Control Module Power

Supply and Ground Circuit Check”.

Is check result in good condition? Substitute a known-

good P/S control

module and recheck.

Repair defective circuit.

Page 915 of 1496

Downloaded from www.Manualslib.com manuals search engine Power Assisted Steering System: 6C-33

DTC C1155: P/S Control Module FailureS7RS0B6304021

Wiring Diagram

Refer to “DTC C1153: P/S Control Module Power Supply Circuit Voltage Low”.

DTC Detecting Condition and Trouble Area

DTC Troubleshooting DTC detecting condition Trouble area

Internal memory (EEPROM) is data error.

(In this case, MIL does not light up)

or

Internal circuit is faulty.

or

Power supply voltage of P/S control module exceeded

17.5 V.

(1 driving cycle detection logic) • Overcharged Battery

• P/S control module

Step

Action YesNo

1 Was “EPS System Check” performed? Go to Step 2.Go to “EPS System

Check”.

2 P/S control module power supply and ground circuit

check

Check power supply circuit and ground circuit for P/S control

module referring to “P/S Control Module Power Supply and

Ground Circuit Check”.

Is check result in good condition? Go to Step 3.

Repair or replace

defective circuit.

3 Battery voltage check

1) Check voltage between positive (+) battery terminal and

vehicle body ground with engine speed at 3000 rpm.

Is voltage 15.5 V or less? Replace P/S control

module.

Check charging system

referring to “Generator

Test (Overcharged

Battery Check) in

Section 1J”.

Page 982 of 1496

Downloaded from www.Manualslib.com manuals search engine 7B-34 Air Conditioning System: Automatic Type

Automatic Type

Precautions

A/C System CautionS7RS0B7220001

Refer to “A/C System Caution”.

Precautions in Diagnosing TroubleS7RS0B7220002

• Do not disconnect couplers from HVAC control module, battery cable from battery, HVAC control module ground

wire harness from body or main fuse before confirming diagnostic information (diagnostic trouble code) stored in

HVAC control module memory.

• Diagnostic information (diagnostic trouble code) stored in HVAC control module can be checked by display of HVAC

control module. Also, it can be checked by using SU ZUKI scan tool. Before checking diagnostic information

(diagnostic trouble code), read this manual and operator's manual for SUZUKI scan tool to know how to read

diagnostic information (diagnostic trouble code).

• When trouble is diagnosed using diagnostic information (diagnostic trouble code) on display of HVAC control

module, keep in your mind that each diagnostic inform ation (diagnostic trouble code) has priority, and only

diagnostic information (diagnostic troub le code) which has the highest priority is indicated. Therefore, after

troubleshooting the malfunction, make sure if there exists any other diagnostic information (diagnostic trouble

code).

• Be sure to read “Precautions for Electrical Circuit Service in Section 00” before inspection.

Precautions on Servicing A/C SystemS7RS0B7220003

Refer to “Precautions on Servicing A/C System”.

General Description

Auto A/C System DescriptionS7RS0B7221001

The automatic type air conditioning system (auto A/C) is pr ovided with the function to automatically control the inside

air temperature, fan speed, air flow outl et direction and air intake position by HVAC control module in addition to

functions of the manual type air conditioning system (manua l A/C). Once the inside air temperature is set using the

temperature selector, HVAC control module automatically controls the inside air temperature at the constant level at all

times based on the inside air temperature, outside ai r temperature, amount of sunlight and engine coolant

temperature detected respectively by the inside air te mperature sensor, outside air temperature sensor, sunload

sensor and ECT sensor. At this time, “FULL AUTO A/ C” appears on the display of HVAC control module.

With the air intake selector pushed in the above state, it is possible to select any position of the air intake actuator.

Then, “FULL AUTO A/C” on the display changes to “AUTO A/C”.

Page 991 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Conditioning System: Automatic Type 7B-43

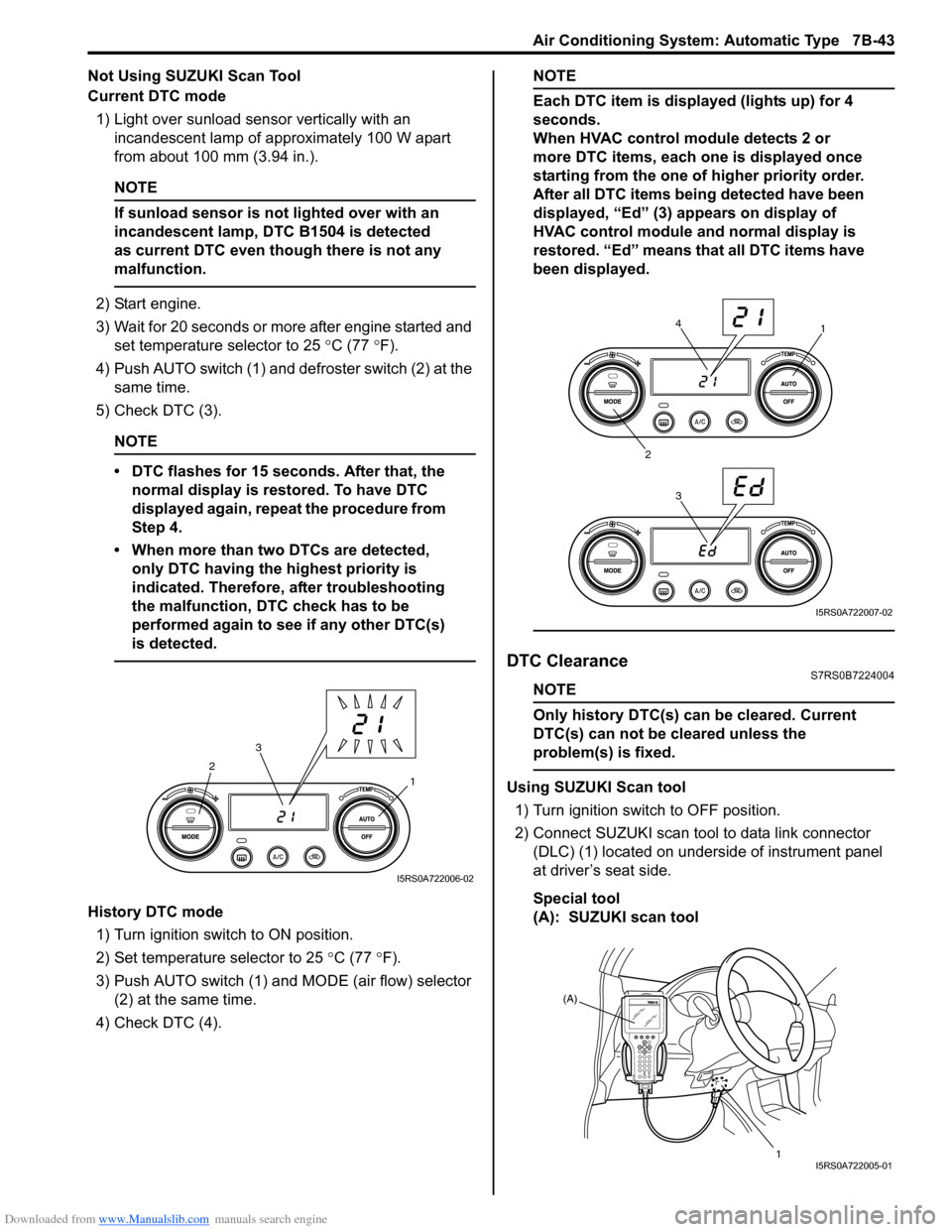

Not Using SUZUKI Scan Tool

Current DTC mode1) Light over sunload sensor vertically with an incandescent lamp of approximately 100 W apart

from about 100 mm (3.94 in.).

NOTE

If sunload sensor is not lighted over with an

incandescent lamp, DTC B1504 is detected

as current DTC even though there is not any

malfunction.

2) Start engine.

3) Wait for 20 seconds or more after engine started and set temperature selector to 25 °C (77 °F).

4) Push AUTO switch (1) and defroster switch (2) at the same time.

5) Check DTC (3).

NOTE

• DTC flashes for 15 seconds. After that, the normal display is rest ored. To have DTC

displayed again, repeat the procedure from

Step 4.

• When more than two DTCs are detected, only DTC having the highest priority is

indicated. Therefore, after troubleshooting

the malfunction, DTC check has to be

performed again to see if any other DTC(s)

is detected.

History DTC mode

1) Turn ignition switch to ON position.

2) Set temperature selector to 25 °C (77 °F).

3) Push AUTO switch (1) and MODE (air flow) selector

(2) at the same time.

4) Check DTC (4).

NOTE

Each DTC item is displayed (lights up) for 4

seconds.

When HVAC control module detects 2 or

more DTC items, each one is displayed once

starting from the one of higher priority order.

After all DTC items being detected have been

displayed, “Ed” (3) appears on display of

HVAC control module and normal display is

restored. “Ed” means that all DTC items have

been displayed.

DTC ClearanceS7RS0B7224004

NOTE

Only history DTC(s) can be cleared. Current

DTC(s) can not be cleared unless the

problem(s) is fixed.

Using SUZUKI Scan tool

1) Turn ignition switch to OFF position.

2) Connect SUZUKI scan tool to data link connector (DLC) (1) located on underside of instrument panel

at driver’s seat side.

Special tool

(A): SUZUKI scan tool1

2

3

I5RS0A722006-02

1

2 34

I5RS0A722007-02

(A)

1

I5RS0A722005-01

Page 995 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Conditioning System: Automatic Type 7B-47

Scan Tool Data Definitions

TEMP CONT SWITCH (TEMPERATURE SELECTOR): Position of temperature control

selector of HVAC control module

CABIN TEMPERATURE: In-car temperature detected

by inside air temperature sensor installed in HVAC

control module

OUTSIDE AIR TEMP (OUTSIDE AIR TEMPERATURE): Outside air temperature

detected by outside air temperature sensor installed

in front bumper member

EVAPORATOR TEMP (EVAPORATOR TEMPERATURE): Temperature of air passed

through evaporator

COOLANT TEMP (ENGINE COOLANT TEMPERATURE): Engine coolant temperature

detected by engine coolant temperature sensor

SUN LOAD: Amount of sunlight detected by sunload

sensor installed on the driver side on the dashboard

MODE CONT SWITCH (MODE (AIR FLOW) SELECTOR): Position of air flow selector of HVAC

control module

FAN CONT SWITCH (BLOWER SPEED SELECTOR): Position of blower speed selector of HVAC control

module

FAN DESIRED VOLT: Voltage for blower motor AIR MIX POS SEN (TEMPERATURE CONTROL

ACTUATOR POSITI ON SENSOR): Input signal

from position sensor in temperature control actuator

MODE POS SENSOR (AIR FLOW CONTROL ACTUATOR POSITI ON SENSOR): Input signal

from position sensor in air flow control actuator

A/C CONT SIG (A/C SWITCH SIGNAL, ON or OFF): State of A/C switch

BLOWER LOAD SIG (BLO WER FAN LOAD SIGNAL,

ON or OFF): ON: Position of blower speed selector

is 1st position or more / OFF: Position of blower

speed selector is OFF position.

AIR INTAKE MODE (AUTO, FRE or REC): State of air

intake mode

REFRIGERANT PRESSURE (A/C REFRIGERANT ABSOLUTE PRESSURE): This parameter

indicates A/C refrigerant absolute pressure

calculated by ECM

A/C COMP CLUTCH (A/C COMPRESSOR MAGNET CLUTCH, ON or OFF): This parameter indicates

the state of the A/C switch

DFR INDICATOR (DEFROSTER INDICATOR LAMP, ON or OFF): State of defroster indicator lamp

VEHICLE SPEED: It is computed based on pulse

signals from vehicle speed sensor

Air Conditioning System CheckS7RS0B7224008

Step Action YesNo

1 Customer complaint analysis

1) Perform �)”Customer complaint analysis”.

Was customer complaint analysis performed? Go to Step 2.

Perform customer

complaint analysis.

2 Visual inspection

1) Perform �)“Visual inspection”.

Is there any faulty condition? Repair or replace

malfunction part.

Go to Step 3.

3 DTC check

1) Perform �)“DTC check”.

Is there any DTC code? Go to Step 4.

Go to Step 5.

4 Troubleshooting malfunction

1) Perform �) “Troubleshooting malfunction”.

Is there any faulty condition? Repair or replace

malfunction part, and go

to Step 7.

Go to Step 5.

5 Perform A/C system symptom diagnosis

1) Inspect and repair referri ng to “A/C System Symptom

Diagnosis”.

Is there any faulty condition? Repair or replace

malfunction part, and go

to Step 7.

Go to Step 6.

6 Check for intermittent problem

1) Check for intermittent troubles referring to “Intermittent

and Poor Connection Inspection in Section 00”.

Is there any faulty condition? Repair or replace

malfunction part, and go

to Step 7.

Go to Step 7.

7 Final confirmation test

1) Perform �) “Final confirmation test”.

Is there any malfunction code? Go to Step 4.

End.

Page 996 of 1496

Downloaded from www.Manualslib.com manuals search engine 7B-48 Air Conditioning System: Automatic Type

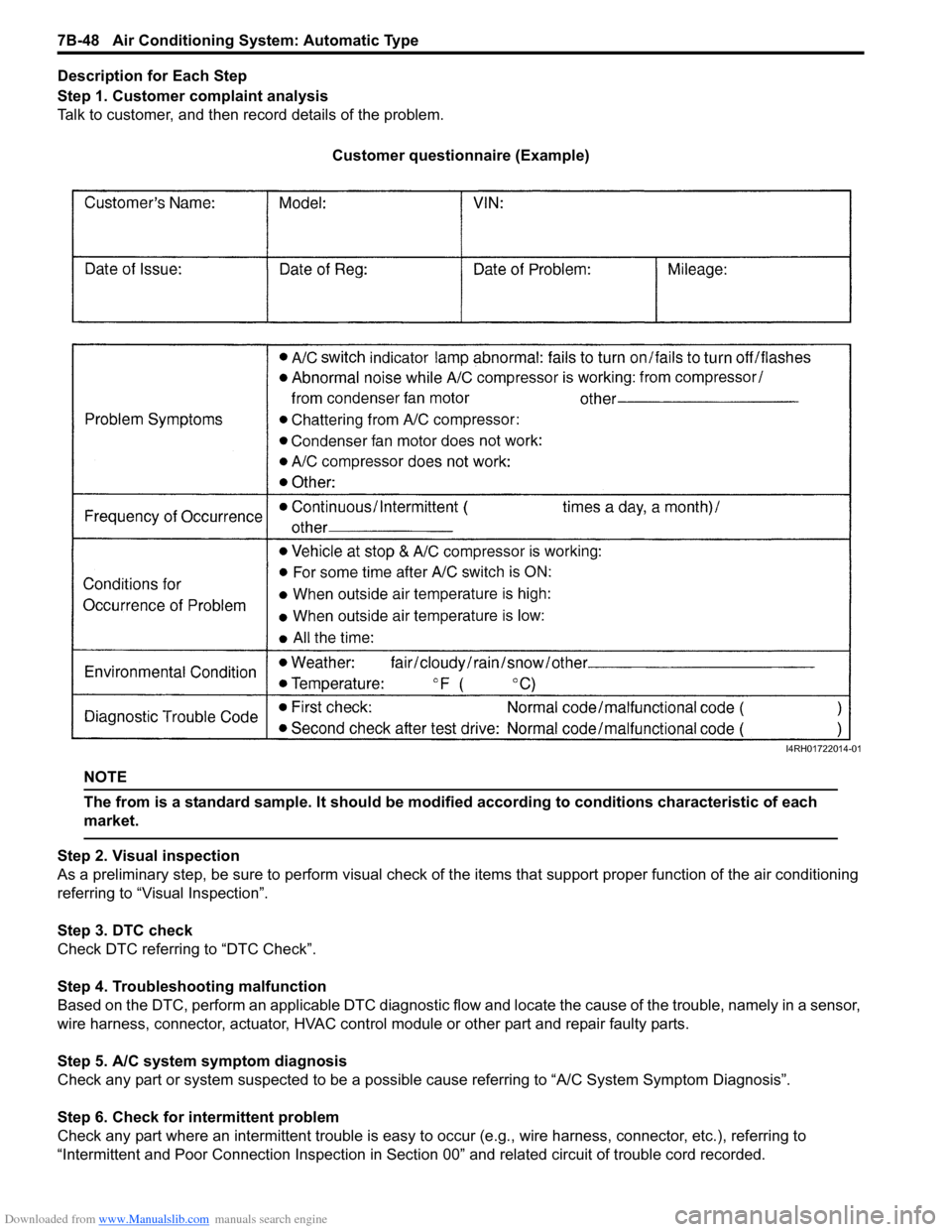

Description for Each Step

Step 1. Customer complaint analysis

Talk to customer, and then record details of the problem.

Customer questionnaire (Example)

NOTE

The from is a standard sample. It should be modified according to conditions characteristic of each

market.

Step 2. Visual inspection

As a preliminary step, be sure to perform visual check of th e items that support proper function of the air conditioning

referring to “Visual Inspection”.

Step 3. DTC check

Check DTC referring to “DTC Check”.

Step 4. Troubleshooting malfunction

Based on the DTC, perform an applicable DTC diagnostic flow and locate the cause of the trouble, namely in a sensor,

wire harness, connector, actuat or, HVAC control module or other part and repair faulty parts.

Step 5. A/C system symptom diagnosis

Check any part or system suspected to be a possible cause referring to “A/C System Symptom Diagnosis”.

Step 6. Check for intermittent problem

Check any part where an intermittent trouble is easy to oc cur (e.g., wire harness, connector, etc.), referring to

“Intermittent and Poor Connection Inspection in Sect ion 00” and related circuit of trouble cord recorded.

I4RH01722014-01

Page 997 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Conditioning System: Automatic Type 7B-49

Step 7. Final confirmation test

Confirm if the problem symptom is troubleshoot and the A/C system is free from any abnormal conditions. If there

existed DTC, clear the DTC. Then , check if the DTC is still detected and if there is any other DTC.

Visual InspectionS7RS0B7224009

Check visually the following parts and systems.

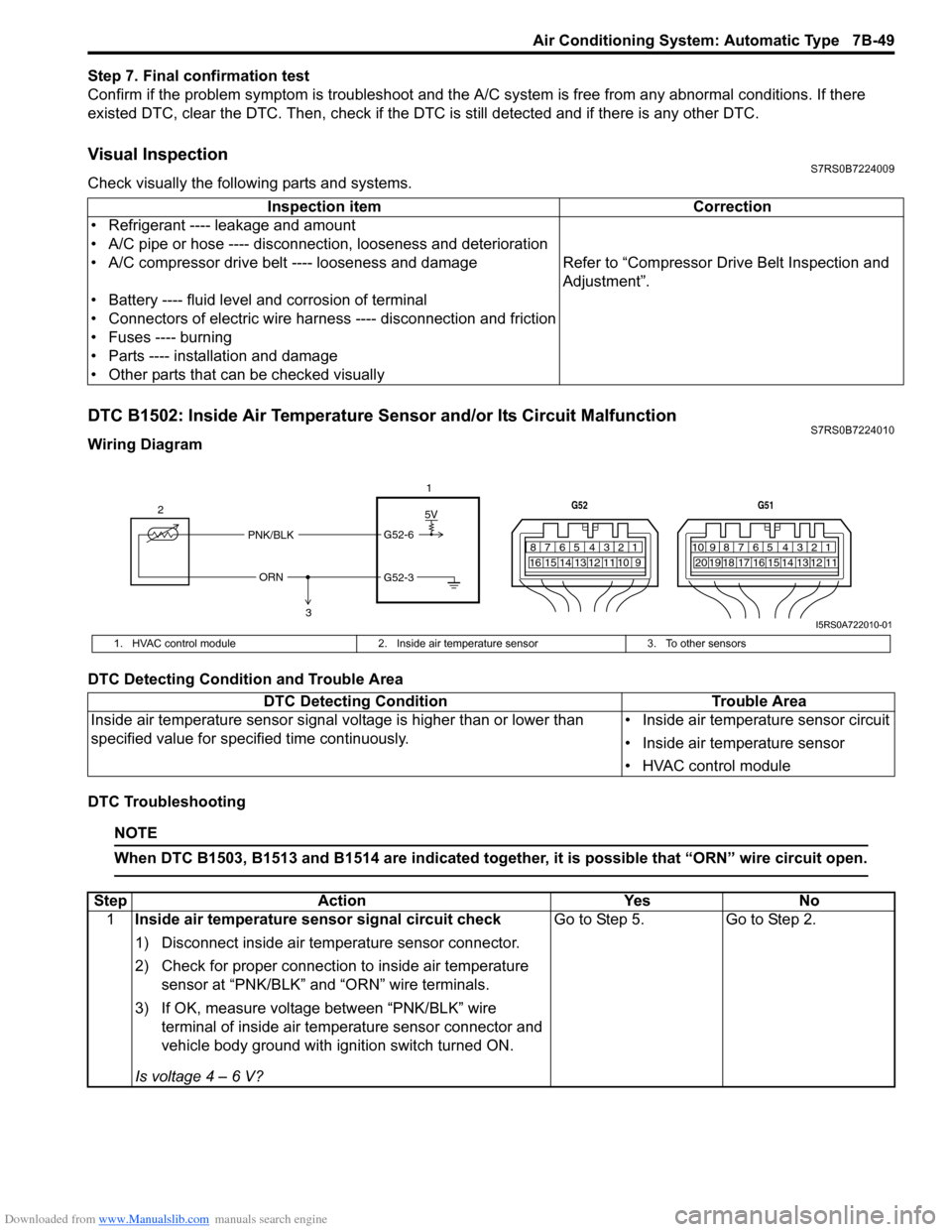

DTC B1502: Inside Air Temperature Sensor and/or Its Circuit MalfunctionS7RS0B7224010

Wiring Diagram

DTC Detecting Condition and Trouble Area

DTC Troubleshooting

NOTE

When DTC B1503, B1513 and B1514 are indicated together, it is possible that “ORN” wire circuit open.

Inspection item Correction

• Refrigerant ---- leakage and amount

• A/C pipe or hose ---- disconnection, looseness and deterioration

• A/C compressor drive belt ---- looseness and damage Refer to “Compressor Drive Belt Inspection and

Adjustment”.

• Battery ---- fluid level and corrosion of terminal

• Connectors of electric wire harn ess ---- disconnection and friction

• Fuses ---- burning

• Parts ---- installation and damage

• Other parts that can be checked visually

5V

PNK/BLK

ORN G52-6

G52-3

2

1

3

7812910

65 431516 14 13 12 11

G52

789101920121112

65 431718 16 15 14 13

G51

I5RS0A722010-01

1. HVAC control module

2. Inside air temperature sensor 3. To other sensors

DTC Detecting Condition Trouble Area

Inside air temperature sensor signal voltage is higher than or lower than

specified value for specified time continuously. • Inside air temperature sensor circuit

• Inside air temperature sensor

• HVAC control module

Step

Action YesNo

1 Inside air temperature sensor signal circuit check

1) Disconnect inside air temperature sensor connector.

2) Check for proper connection to inside air temperature

sensor at “PNK/BLK” and “ORN” wire terminals.

3) If OK, measure voltage between “PNK/BLK” wire terminal of inside air temp erature sensor connector and

vehicle body ground with ignition switch turned ON.

Is voltage 4 – 6 V? Go to Step 5.

Go to Step 2.