troubleshooting SUZUKI SWIFT 2008 2.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2008, Model line: SWIFT, Model: SUZUKI SWIFT 2008 2.GPages: 1496, PDF Size: 34.44 MB

Page 891 of 1496

Downloaded from www.Manualslib.com manuals search engine Power Assisted Steering System: 6C-9

3) Start engine.

4) Read DTC according to the instructions displayed on

SUZUKI scan tool. For further details, refer to

operator’s manual for SUZUKI scan tool.

NOTE

• If communication between SUZUKI scan tool and the vehicle can not be

established, perform “Serial Data Link

Circuit Check”.

• DTC C1122 (engine speed signal failure) is indicated when ignition switch is at ON

position and engine is not running, but it

means there is nothing abnormal if

indication changes to a normal one when

engine is started.

5) After completing the check, turn ignition switch to

OFF position and disconnect SUZUKI scan tool from

DLC.

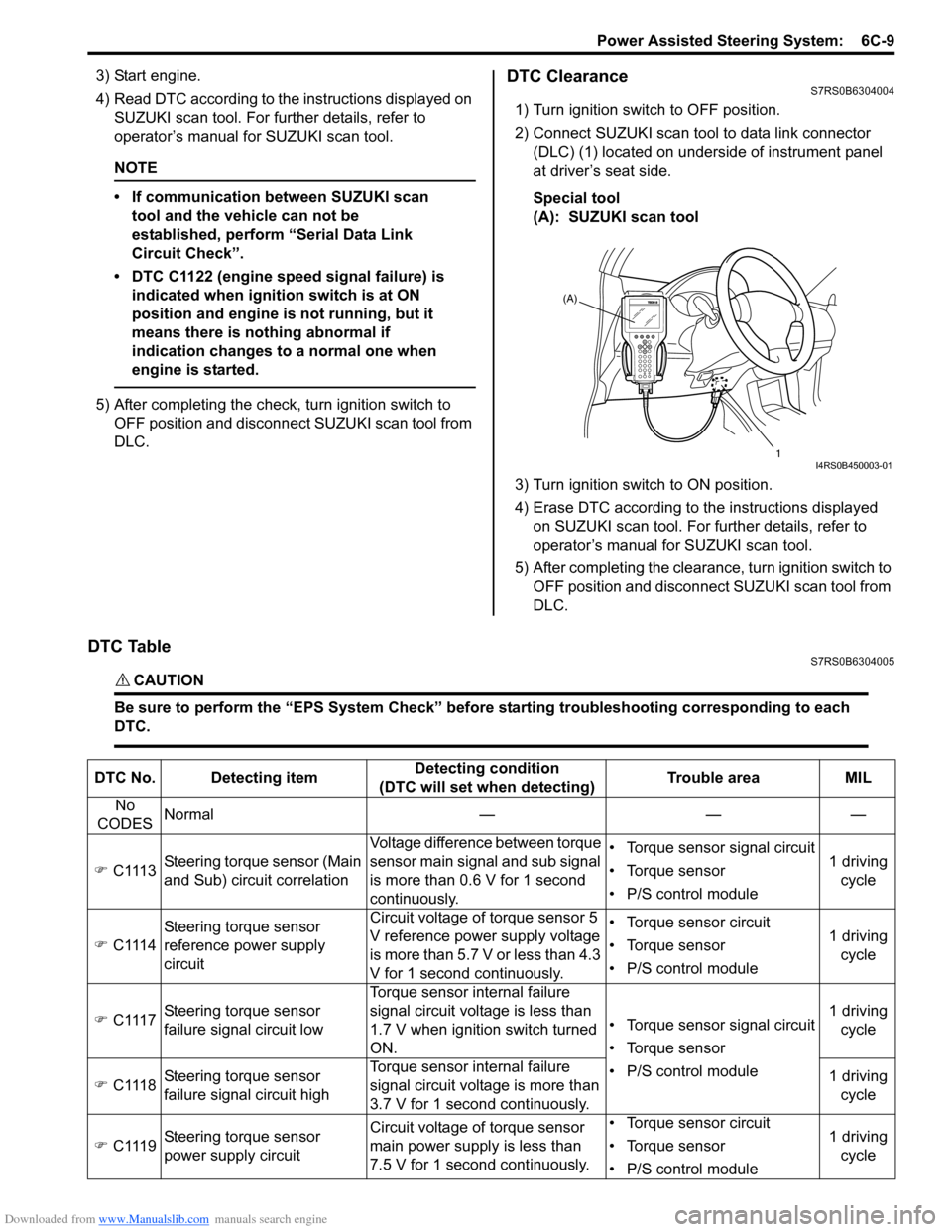

DTC ClearanceS7RS0B6304004

1) Turn ignition switch to OFF position.

2) Connect SUZUKI scan tool to data link connector (DLC) (1) located on underside of instrument panel

at driver’s seat side.

Special tool

(A): SUZUKI scan tool

3) Turn ignition switch to ON position.

4) Erase DTC according to the instructions displayed on SUZUKI scan tool. For further details, refer to

operator’s manual for SUZUKI scan tool.

5) After completing the clearance, turn ignition switch to OFF position and disconnect SUZUKI scan tool from

DLC.

DTC TableS7RS0B6304005

CAUTION!

Be sure to perform the “EPS Syst em Check” before starting troubleshooting corresponding to each

DTC.

(A)

1

I4RS0B450003-01

DTC No. Detecting item Detecting condition

(DTC will set when detecting) Trouble area MIL

No

CODES Normal — — —

�) C1113 Steering torque sensor (Main

and Sub) circuit correlation Voltage difference between torque

sensor main signal and sub signal

is more than 0.6 V for 1 second

continuously. • Torque sensor signal circuit

• Torque sensor

• P/S control module

1 driving

cycle

�) C1114 Steering torque sensor

reference power supply

circuit Circuit voltage of torque sensor 5

V reference power supply voltage

is more than 5.7 V or less than 4.3

V for 1 second continuously. • Torque sensor circuit

• Torque sensor

• P/S control module

1 driving

cycle

�) C1117 Steering torque sensor

failure signal circuit low Torque sensor internal failure

signal circuit voltage is less than

1.7 V when ignition switch turned

ON.

• Torque sensor signal circuit

• Torque sensor

• P/S control module1 driving

cycle

�) C1118 Steering torque sensor

failure signal circuit high Torque sensor internal failure

signal circuit voltage is more than

3.7 V for 1 second continuously. 1 driving

cycle

�) C1119 Steering torque sensor

power supply circuit Circuit voltage of torque sensor

main power supply

is less than

7.5 V for 1 second continuously. • Torque sensor circuit

• Torque sensor

• P/S control module

1 driving

cycle

Page 895 of 1496

Downloaded from www.Manualslib.com manuals search engine Power Assisted Steering System: 6C-13

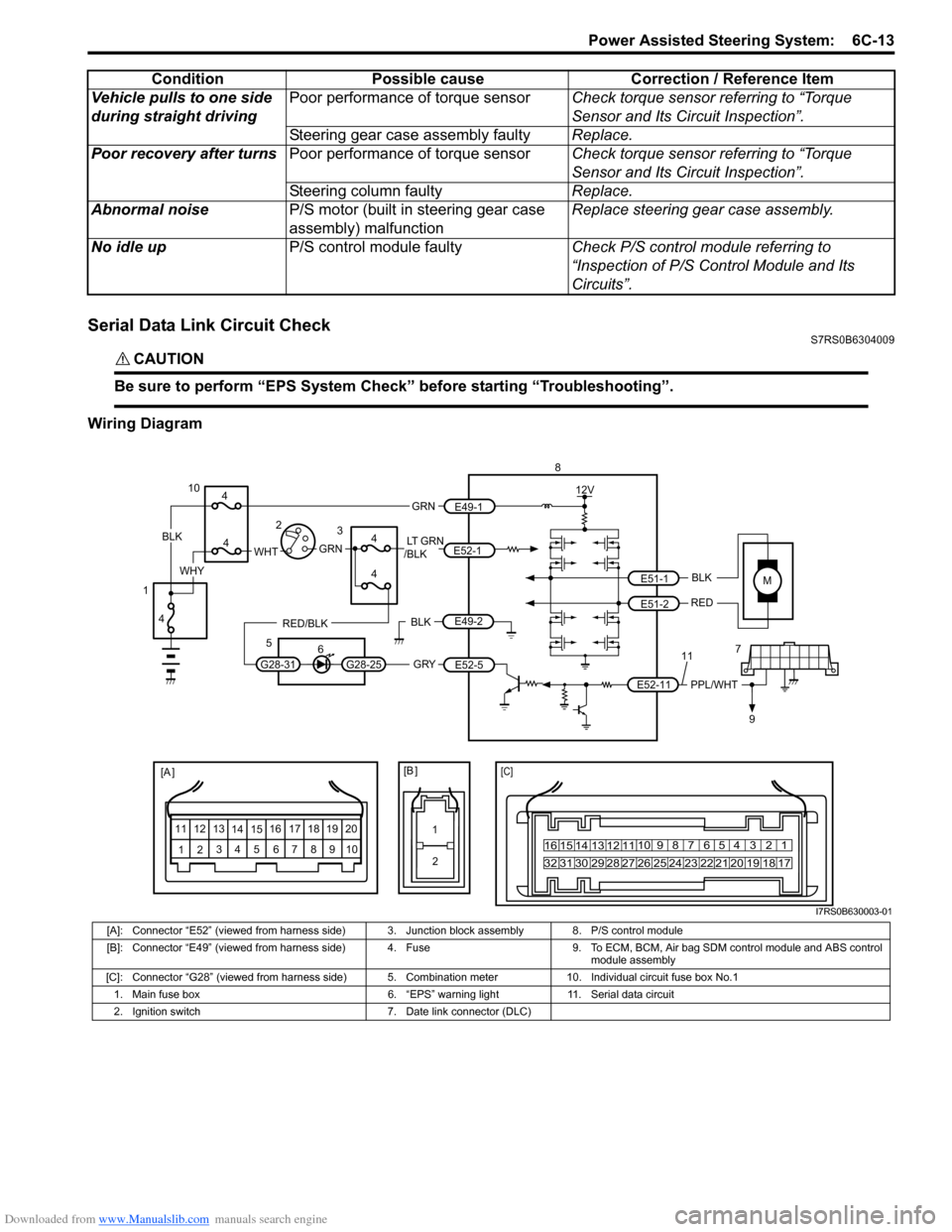

Serial Data Link Circuit CheckS7RS0B6304009

CAUTION!

Be sure to perform “EPS System Check” before starting “Troubleshooting”.

Wiring DiagramVehicle pulls to one side

during straight driving

Poor performance of torque sensor

Check torque sensor referring to “Torque

Sensor and Its Circuit Inspection”.

Steering gear case assembly faulty Replace.

Poor recovery after turns Poor performance of torque sensor Check torque sensor referring to “Torque

Sensor and Its Circuit Inspection”.

Steering column faulty Replace.

Abnormal noise P/S motor (built in steering gear case

assembly) malfunction Replace steering gear case assembly.

No idle up P/S control module faulty Check P/S control module referring to

“Inspection of P/S Control Module and Its

Circuits”.

Condition Possible cause Correction / Reference Item

MBLK

RED

E52-11 E51-1

E51-2PPL/WHT

[A ]

12

3

4 5 67

89

11

10

12 13

141516

17 18 19 2010 9 8 7654 3 21

16 15 14 13 12 11

26 25 24 2322 21 20 19 18 17

32 31 30 29 28 27

[C]

8

79

12V

[B ]

11

12

GRY

LT GRN

/BLK

E52-1

E52-5

E49-1

GRNGRNWHTBLK

WHY

G28-25G28-31

RED/BLK

10

3

4

4

5 6

4

4

1 2

4

E49-2BLK

I7RS0B630003-01

[A]: Connector “E52” (viewed from harness side) 3. Junction block assembly 8. P/S control module

[B]: Connector “E49” (viewed from harness side) 4. Fuse 9. T o ECM, BCM, Air bag SDM control module and ABS control

module assembly

[C]: Connector “G28” (viewed from harness side) 5. Comb ination meter 10. Individual circuit fuse box No.1

1. Main fuse box 6. “EPS” warning light 11. Serial data circuit

2. Ignition switch 7. Date link connector (DLC)

Page 896 of 1496

Downloaded from www.Manualslib.com manuals search engine 6C-14 Power Assisted Steering System:

TroubleshootingStep Action Yes No 1 Was “EPS System Check” performed? Go to Step 2. Go to “EPS System

Check”.

2 1) Make sure that SUZUKI scan tool is free from malfunction and that correct program card (software) for

P/S system is used.

2) Turn ignition switch to OFF position.

3) Check proper connection of SUZUKI scan tool to DLC.

Is connection in good condition? Go to Step 3. Connect SUZUKI scan

tool to DLC properly.

3 1) Check if communication is possible by making communication with other controllers (ECM, BCM, ABS

or SDM) or other vehicles.

Is it possible to communic ate with the other controllers? Go to Step 4. Repair open in common

section of “serial data

circuit” (“PPL/WHT” wire

circuit) used by all

controllers or short to

ground or power circuit

which has occurred

somewhere in serial

data circuit (“PPL/WHT”

wire circuit).

4 1) Check power supply circuit and ground circuit for P/S control module referring to “P/S Control Module Power

Supply and Ground Circuit Check”.

Is check result in good condition? Go to Step 5. Repair or replace

defective circuit.

5 1) With ignition switch turned OFF, disconnect “E52” connector from P/S control module and check for

terminal to P/S control module connector.

2) If connections are OK, check t hat “Serial data circuit” is

as following.

• Insulation resistance of “Serial data circuit” wire is infinity between its terminal and other terminals at P/S

control module connector.

• Wiring resistance of “Seria l data circuit” wire is less

than 1 Ω.

• Insulation resistance of “Serial data circuit” wire is infinity between its terminal and vehicle body ground.

Is circuit in good condition? Substitute a known-

good P/S control

module and recheck.

Repair or replace

defective circuit.

Page 897 of 1496

Downloaded from www.Manualslib.com manuals search engine Power Assisted Steering System: 6C-15

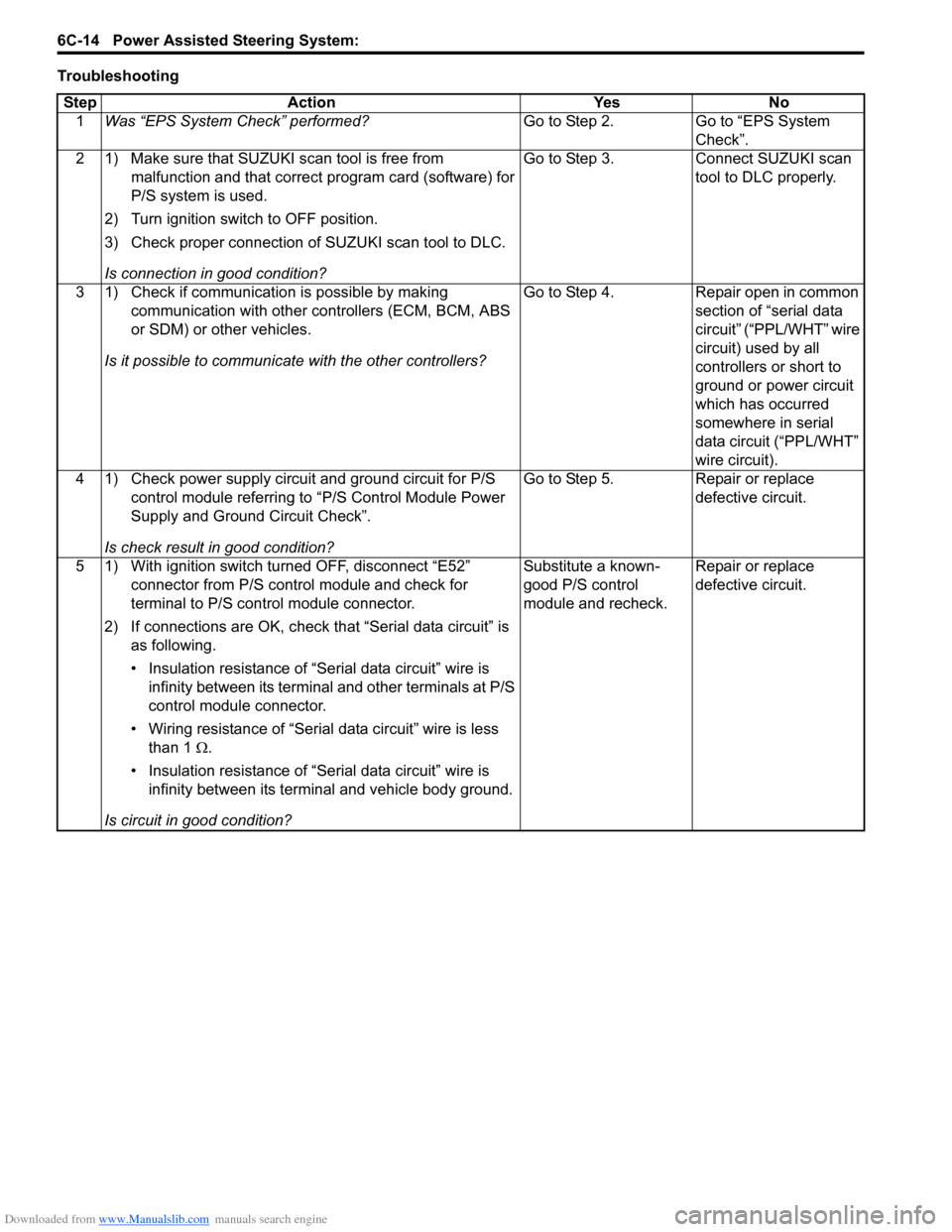

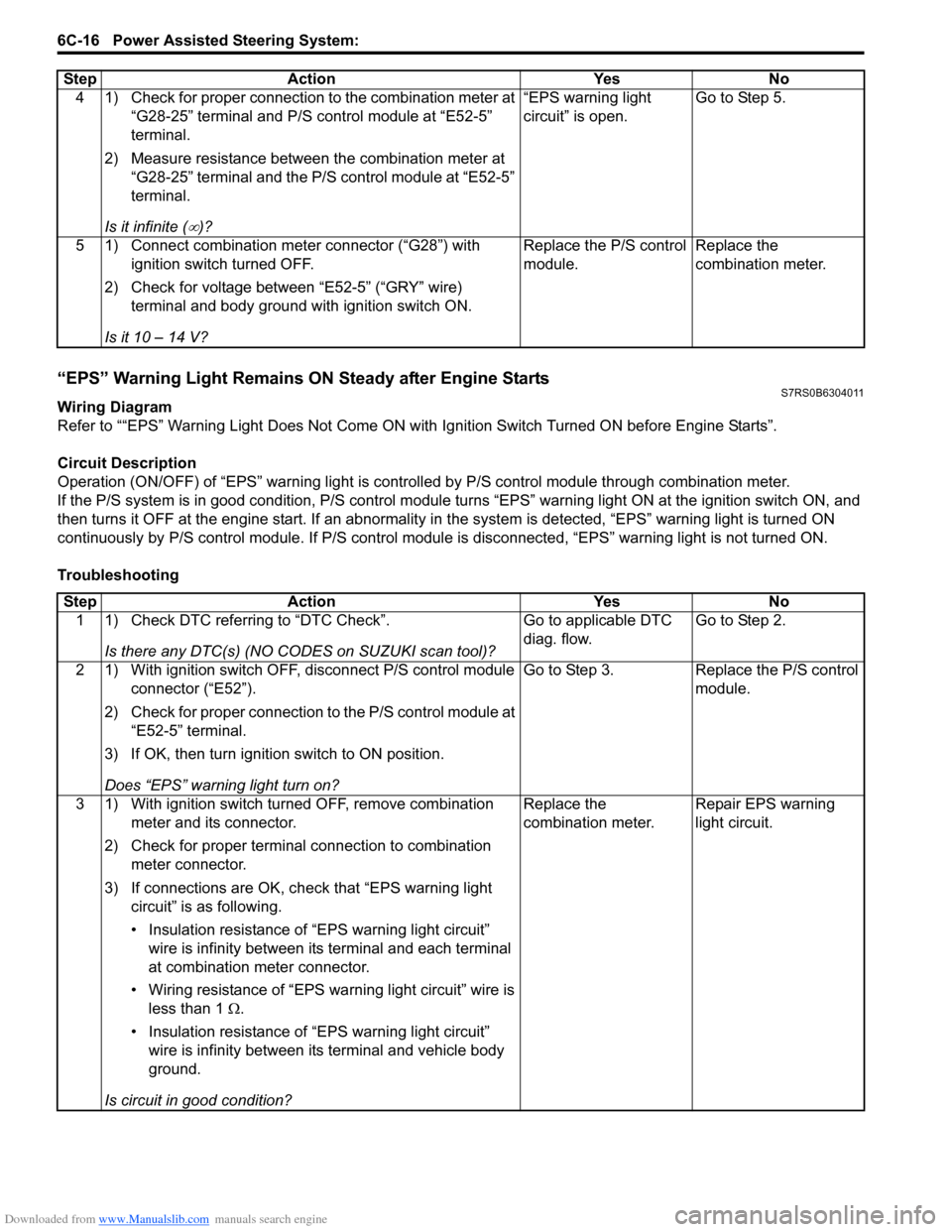

“EPS” Warning Light Does Not Come ON with Ignition Switch Turned ON before Engine StartsS7RS0B6304010

Wiring Diagram

Circuit Description

Operation (ON/OFF) of “EPS” warning light is controlled by P/S control module through combination meter.

If the P/S system is in good condition, P/S control module turns “ EPS” warning light ON at the ignition switch ON, and

then turns it OFF at the engine start. If an abnormality in the system is detected, “EPS” warning light is turned ON

continuously by P/S control module. If P/S control module is disconnected, “EPS” warning light is not turned ON.

Troubleshooting

MBLK

REDE51-1

E51-2

[A ]

12 3

4 5 67

89

11

10

12 13

141516

17 18 19 2010 9 8 7654 3 21

16 15 14 13 12 11

26 25 24 2322 21 20 19 18 17

32 31 30 29 28 27

[C]

7

12V

E49-2BLK

[B ]

1 2

GRY

LT GRN

/BLK

E52-1

E52-5

E49-1

GRNGRNWHTBLK

WHY

G28-25G28-31

RED/BLK

8

3

4

4

5 6

4

4

1 2

4

9

I7RS0B630004-01

[A]: Connector “E52” (viewed from harness side) 2. Ignition switch6. “EPS” warning light

[B]: Connector “E49” (viewed from harness side) 3. Junction block assembly7. P/S control module

[C]: Connector “G28” (viewed from harness si de)4. Fuse 8. Individual circuit fuse box No.1

1. Main fuse box 5. Combination meter9. “EPS” warning light circuit

StepAction YesNo

1 1) Turn ignition switch ON.

Do the other warning lights come on? Go to Step 2.

“GRN”, “RED/BLK” wire

circuit or circuit fuse for

combination meter open

or short to ground.

2 1) Check power supply circuit and ground circuit for P/S control module referring to “P/S Control Module Power

Supply and Ground Circuit Check”.

Is check result in good condition? Go to Step 3.

Repair or replace

defective circuit.

3 1) Remove combination meter and disconnect combination meter connector (“G28”) with ignition switch turned OFF.

2) Check for proper connection to the combination meter at “G28-31” terminal.

3) If OK, check voltage between “G28-31” (“RED/BLK” wire) terminal and body ground with ignition switch ON.

Is it 10 – 14 V? Go to Step 4.

“RED/BLK” wire circuit

open or short to ground.

Page 898 of 1496

Downloaded from www.Manualslib.com manuals search engine 6C-16 Power Assisted Steering System:

“EPS” Warning Light Remains ON Steady after Engine StartsS7RS0B6304011

Wiring Diagram

Refer to ““EPS” Warning Light Does Not Come ON with Ignition Switch Turned ON before Engine Starts”.

Circuit Description

Operation (ON/OFF) of “EPS” warning light is controlled by P/S c ontrol module through combination meter.

If the P/S system is in good condition, P/S control module tu rns “EPS” warning light ON at the ignition switch ON, and

then turns it OFF at the engine start. If an abnormality in the system is detected, “EPS” warning light is turned ON

continuously by P/S control module. If P/S control module is disconnected, “EPS” warning light is not turned ON.

Troubleshooting 4 1) Check for proper connection to the combination meter at

“G28-25” terminal and P/S control module at “E52-5”

terminal.

2) Measure resistance between the combination meter at “G28-25” terminal and the P/S control module at “E52-5”

terminal.

Is it infinite (

∞)? “EPS warning light

circuit” is open.

Go to Step 5.

5 1) Connect combination meter connector (“G28”) with ignition switch turned OFF.

2) Check for voltage between “E52-5” (“GRY” wire) terminal and body ground with ignition switch ON.

Is it 10 – 14 V? Replace the P/S control

module.

Replace the

combination meter.

Step

Action YesNo

Step Action YesNo

1 1) Check DTC referring to “DTC Check”.

Is there any DTC(s) (NO CODES on SUZUKI scan tool)? Go to applicable DTC

diag. flow.

Go to Step 2.

2 1) With ignition switch OFF, disconnect P/S control module connector (“E52”).

2) Check for proper connection to the P/S control module at “E52-5” terminal.

3) If OK, then turn ignition switch to ON position.

Does “EPS” warning light turn on? Go to Step 3.

Replace the P/S control

module.

3 1) With ignition switch turned OFF, remove combination meter and its connector.

2) Check for proper terminal connection to combination meter connector.

3) If connections are OK, ch eck that “EPS warning light

circuit” is as following.

• Insulation resistance of “EPS warning light circuit” wire is infinity between its terminal and each terminal

at combination meter connector.

• Wiring resistance of “EPS wa rning light circuit” wire is

less than 1 Ω.

• Insulation resistance of “EPS warning light circuit” wire is infinity between its terminal and vehicle body

ground.

Is circuit in good condition? Replace the

combination meter.

Repair EPS warning

light circuit.

Page 899 of 1496

Downloaded from www.Manualslib.com manuals search engine Power Assisted Steering System: 6C-17

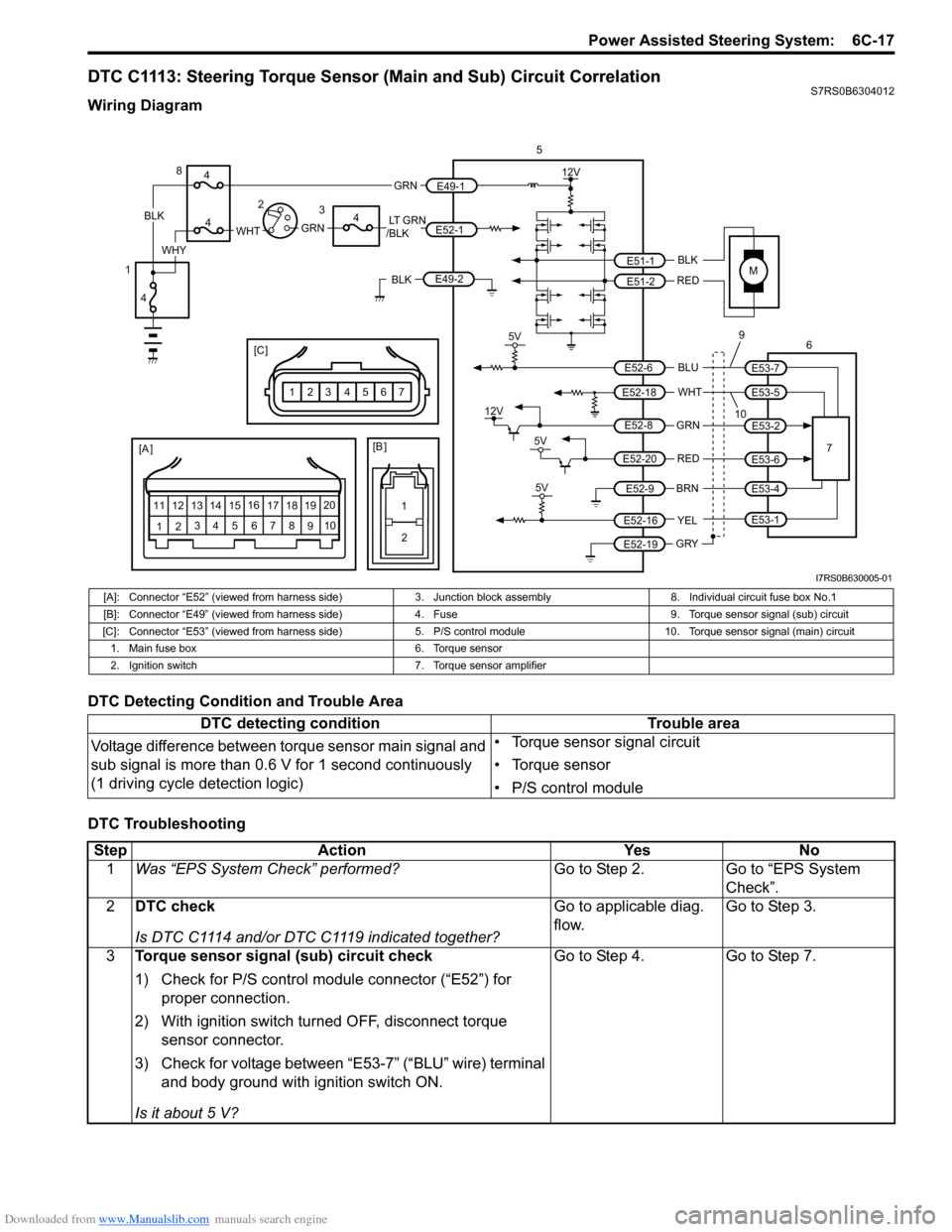

DTC C1113: Steering Torque Sensor (Main and Sub) Circuit CorrelationS7RS0B6304012

Wiring Diagram

DTC Detecting Condition and Trouble Area

DTC Troubleshooting

M

5V

BLK

RED

WHT BLU

GRN

BRN YEL

E51-1

E51-2

E52-18

E53-5

E53-7

E52-6

E52-8

E53-2

E52-9

E52-16

E52-19

GRY

[A ]

12 3

4 5 67

89

11

10

12 13

141516

17 18 19 20

5

67

12V

5V

5V

12V

REDE52-20E53-6

E53-4

E53-1

109

1

2

[B ]

[C ]

7654321

LT GRN

/BLKE52-1 E49-1

GRNGRNWHTBLK

WHY

8

3

4

4

4

4

1 2

E49-2BLK

I7RS0B630005-01

[A]: Connector “E52” (viewed from harness side)

3. Junction block assembly 8. Individual circuit fuse box No.1

[B]: Connector “E49” (viewed from harness side )4. Fuse 9. Torque sensor signal (sub) circuit

[C]: Connector “E53” (viewed from harness side) 5. P/S control module 10. Torque sensor signal (main) circuit

1. Main fuse box 6. Torque sensor

2. Ignition switch 7. Torque sensor amplifier

DTC detecting condition Trouble area

Voltage difference between torque sensor main signal and

sub signal is more than 0.6 V for 1 second continuously

(1 driving cycle detection logic) • Torque sensor signal circuit

• Torque sensor

• P/S control module

Step

Action YesNo

1 Was “EPS System Check” performed? Go to Step 2.Go to “EPS System

Check”.

2 DTC check

Is DTC C1114 and/or DTC C1119 indicated together? Go to applicable diag.

flow.

Go to Step 3.

3 Torque sensor signal (sub) circuit check

1) Check for P/S control module connector (“E52”) for

proper connection.

2) With ignition switch turned OFF, disconnect torque sensor connector.

3) Check for voltage between “E53-7” (“BLU” wire) terminal and body ground with ignition switch ON.

Is it about 5 V? Go to Step 4.

Go to Step 7.

Page 902 of 1496

Downloaded from www.Manualslib.com manuals search engine 6C-20 Power Assisted Steering System:

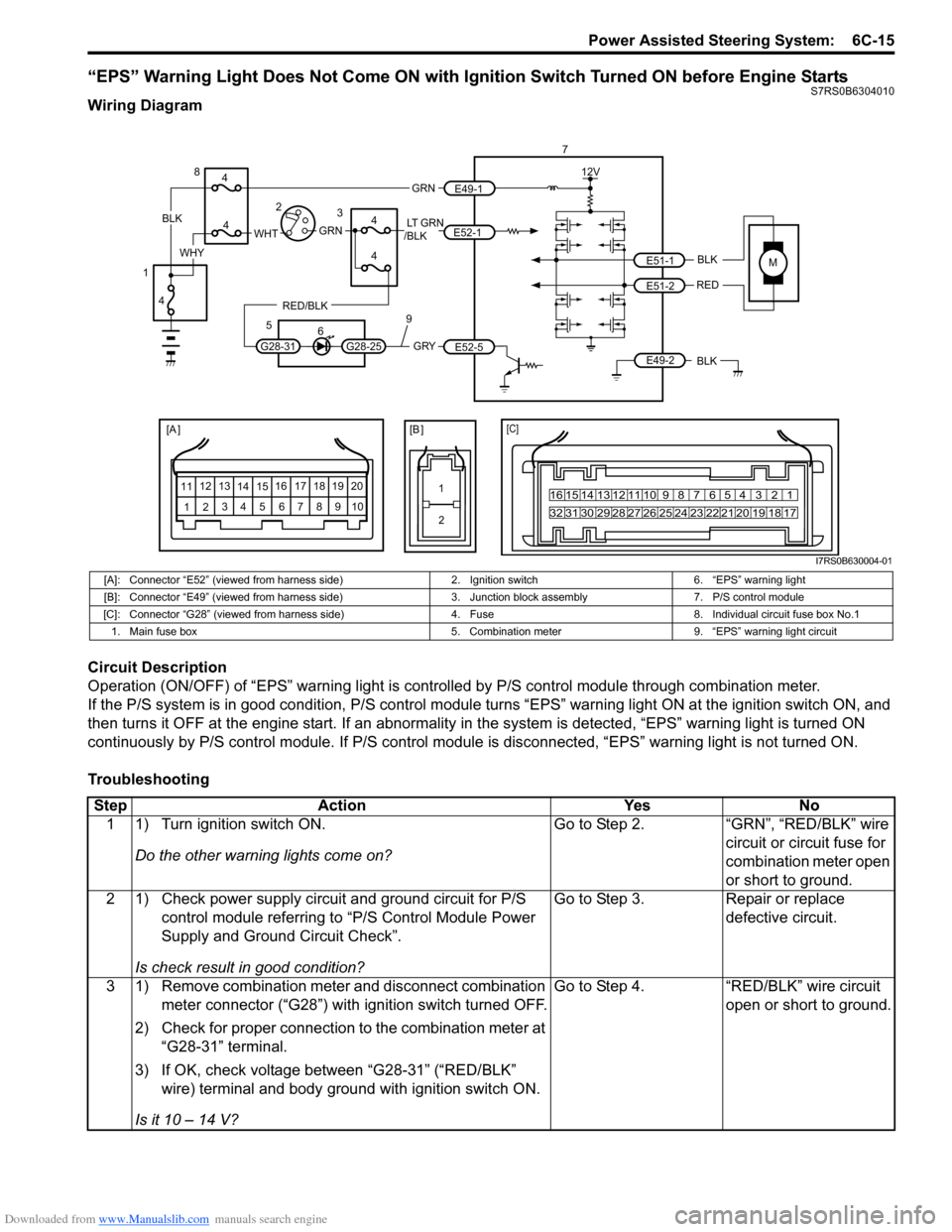

DTC TroubleshootingStep Action Yes No 1 Was “EPS System Check” performed? Go to Step 2. Go to “EPS System

Check”.

2 DTC check

Is DTC C1153 and/or DTC C1155 indicated together? Go to applicable DTC

diag. flow.

Go to Step 3.

3 Torque sensor 5 V reference power supply circuit

voltage check

1) With ignition switch turned OFF, disconnect torque

sensor connector and check for proper terminal

connection to torque sensor connector.

2) If connections are OK, check for voltage between “E53- 6” (“RED” wire) terminal and body ground with ignition

switch ON.

Is it approx. 5 V? Go to Step 4. Go to Step 5.

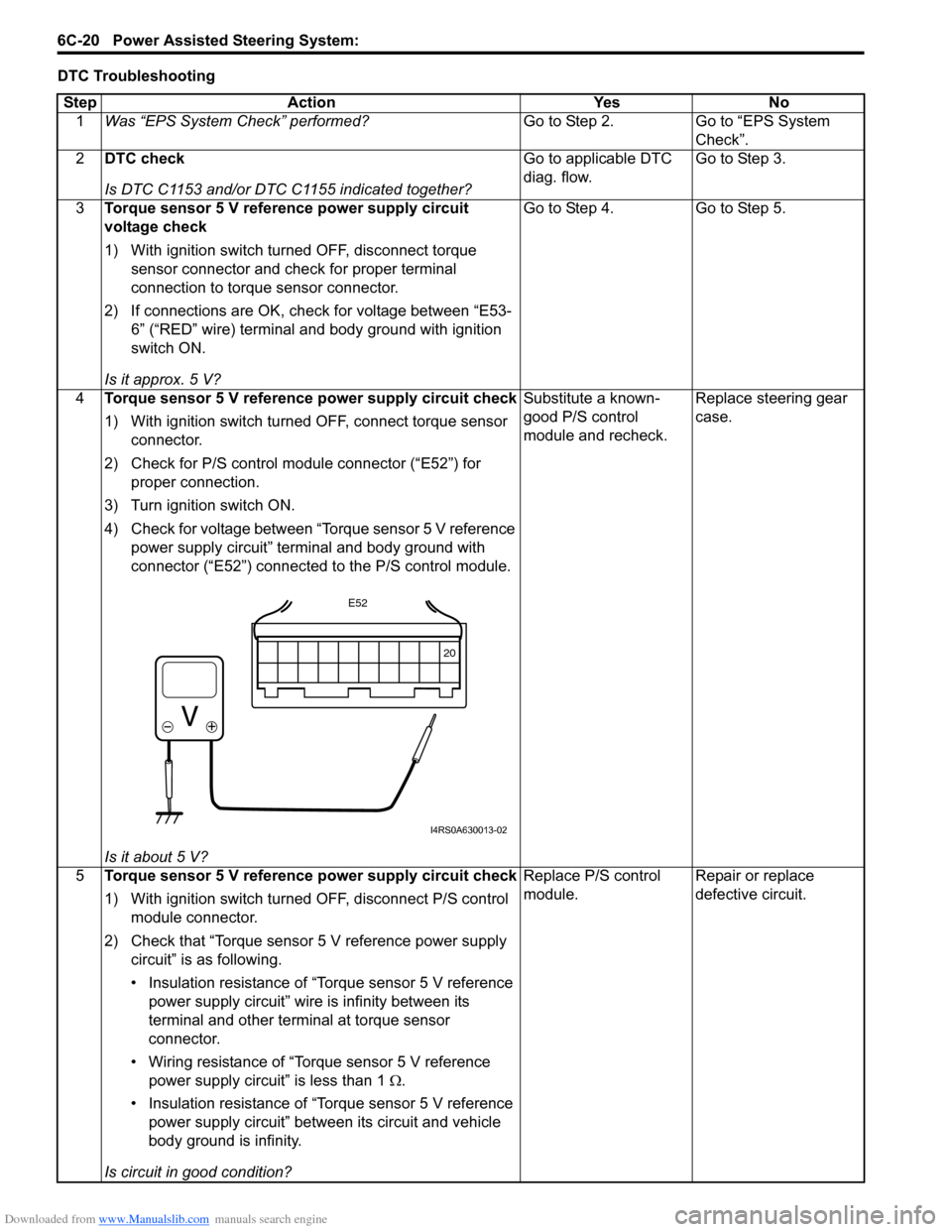

4 Torque sensor 5 V reference power supply circuit check

1) With ignition switch turned OFF, connect torque sensor

connector.

2) Check for P/S control module connector (“E52”) for proper connection.

3) Turn ignition switch ON.

4) Check for voltage between “Torque sensor 5 V reference power supply circuit” terminal and body ground with

connector (“E52”) connected to the P/S control module.

Is it about 5 V? Substitute a known-

good P/S control

module and recheck.

Replace steering gear

case.

5 Torque sensor 5 V reference power supply circuit check

1) With ignition switch turned OFF, disconnect P/S control

module connector.

2) Check that “Torque sensor 5 V reference power supply circuit” is as following.

• Insulation resistance of “Torque sensor 5 V reference power supply circuit” wire is infinity between its

terminal and other terminal at torque sensor

connector.

• Wiring resistance of “Torque sensor 5 V reference power supply circuit” is less than 1 Ω.

• Insulation resistance of “Torque sensor 5 V reference power supply circuit” between its circuit and vehicle

body ground is infinity.

Is circuit in good condition? Replace P/S control

module.

Repair or replace

defective circuit.

20

E52

I4RS0A630013-02

Page 904 of 1496

Downloaded from www.Manualslib.com manuals search engine 6C-22 Power Assisted Steering System:

DTC Troubleshooting

DTC C1118: Steering Torque Sensor Failure Signal Circuit HighS7RS0B6304015

Wiring Diagram

Refer to “DTC C1117: Steering Torque Sensor Failure Signal Circuit Low”.

DTC Detecting Condition and Trouble AreaStep Action Yes No

1 Was “EPS System Check” performed? Go to Step 2. Go to “EPS System

Check”.

2 DTC check

Is DTC C1113, C1114 and/or DTC C1119 indicated together? Go to applicable diag.

flow.

Go to Step 3.

3 Torque sensor internal failure signal circuit check

1) Check for P/S control module connector (“E52”) for

proper connection.

2) With ignition switch turned OFF, disconnect torque sensor connector.

3) Check for voltage between “E53-1” (“YEL” wire) terminal and body ground with ignition switch ON.

Is it about 5 V? Go to Step 4. Go to Step 5.

4 Torque sensor internal failure signal circuit check

1) With ignition switch turned OFF, connect torque sensor

connector.

2) Check that voltage between “E52-16” (“YEL” wire) terminal and body ground is about 5V at the moment of

ignition switch turned ON.

Is it about 5 V? Substitute a known-

good P/S control

module and recheck.

Replace steering gear

case.

5 Torque sensor internal failure signal circuit wire check

1) Disconnect P/S control module.

2) Check that torque sensor failure signal circuit is as

follows.

• Insulation resistance of wire harness is infinity between “Torque sensor internal failure signal circuit”

terminal and other terminal at torque sensor

connector.

• Insulation resistance between “Torque sensor internal failure signal circuit” and vehicle body ground is

infinity.

Is circuit in good condition? Substitute a known-

good P/S control

module and recheck.

Repair or replace

defective circuit.

DTC detecting condition

Trouble area

Torque sensor internal failure signal circuit voltage is more

than 3.7 V for 1 second continuously

(1 driving cycle detection logic) • Torque sensor signal circuit

• Torque sensor internal failure signal circuit

• Torque sensor

• P/S control module

Page 905 of 1496

Downloaded from www.Manualslib.com manuals search engine Power Assisted Steering System: 6C-23

DTC TroubleshootingStep Action Yes No 1 Was “EPS System Check” performed? Go to Step 2. Go to “EPS System

Check”.

2 DTC check

Is DTC C1113, C1114 and/or DTC C1119 indicated together? Go to applicable diag.

flow.

Go to Step 3.

3 Torque sensor internal failure signal voltage check

1) Check for P/S control module connector (“E52”) for

proper connection.

2) Check for voltage between “E52-16” (“YEL” wire) terminal and body ground with ignition switch ON.

Is voltage 0 – 1 V? Substitute a known-

good P/S control

module and recheck.

Go to Step 4.

4 Torque sensor internal failure signal circuit check

1) With ignition switch turned OFF, disconnect torque

sensor connector.

2) Check for voltage between “E53-1” (“YEL” wire) terminal and body ground with ignition switch ON.

Is it about 5 V? Go to Step 5. Go to Step 6.

5 Torque sensor internal failure signal circuit check

1) Disconnect P/S control module connector.

2) Check that torque sensor failure signal circuit is as

follows.

• Insulation resistance of wire harness is infinity between “Torque sensor internal failure signal circuit”

terminal and other terminal at torque sensor

connector.

Is circuit in good condition? Go to Step 7. Repair or replace

defective circuit.

6 Torque sensor internal failure signal circuit check

1) Disconnect P/S control module connector.

2) Check that torque sensor failure signal circuit is as

follows.

• Insulation resistance of wire harness is infinity between “Torque sensor internal failure signal circuit”

terminal and other terminal at torque sensor

connector.

• Wiring harness resistance of “Torque sensor internal failure signal circuit” is less than 1 Ω.

Is circuit in good condition? Substitute a known-

good P/S control

module and recheck.

Repair or replace

defective circuit.

7 Torque sensor signal circuit check

1) Check for torque sensor signal circuit referring to Step 3)

– 8) of “DTC C1113: Steering Torque Sensor (Main and

Sub) Circuit Correlation”.

Is torque sensor and its circuit in good condition? Replace steering gear

case.

Repair or replace

defective parts.

Page 907 of 1496

Downloaded from www.Manualslib.com manuals search engine Power Assisted Steering System: 6C-25

DTC TroubleshootingStep Action Yes No 1 Was “EPS System Check” performed? Go to Step 2. Go to “EPS System

Check”.

2 DTC check

Is DTC C1153 indicated together? Go to DTC C1153 diag.

flow.

Go to Step 3.

3 Torque sensor main power supply voltage check

1) With ignition switch turned OFF, disconnect torque

sensor connector.

2) Check for P/S control module connector (“E52”) for proper connection.

3) If connections are OK, check for voltage between “E52- 8” (“GRN” wire) terminal and body ground with ignition

switch ON.

Is it approx. 12 V? Go to Step 4. Go to Step 5.

4 Torque sensor main power supply voltage check

1) With ignition switch turned OFF, connect torque sensor

connector.

2) Check for P/S control module connector (“E52”) for proper connection.

3) Turn ignition switch ON.

4) Check for voltage between “Main power supply for torque sensor circuit” terminal and body ground with

connector (“E52”) connected to the P/S control module.

Is it about 12 V? Substitute a known-

good P/S control

module and recheck.

Replace steering gear

case assembly and

recheck.

5 Torque sensor main power supply circuit check

1) With ignition switch turned OFF, disconnect P/S control

module connector.

2) Check that “Main power supply for torque sensor circuit” is as following.

• Insulation resistance of “Main power supply for torque sensor circuit” wire is infinity between its terminal and

other terminal at torque sensor connector.

• Wiring resistance of “Main power supply for torque sensor circuit” is less than 1 Ω .

• Insulation resistance of “Main power supply for torque sensor circuit” between its circuit and vehicle body

ground is infinity.

Is circuit in good condition? Replace P/S control

module.

Repair or replace

defective circuit.

8

E52

I4RS0A630021-02