ecm terminal SUZUKI SX4 2006 1.G Service Owners Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2006, Model line: SX4, Model: SUZUKI SX4 2006 1.GPages: 1556, PDF Size: 37.31 MB

Page 245 of 1556

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-195

6ECM ground circuit check

1) Turn ignition switch to OFF position.

2) Disconnect connectors from ECM.

3) Measure resistance between each “E01-31”, “C01-58”,

“C01-15” and “C01-30” terminals of ECM connector and

body ground.

Is resistance 1

Ω or less?Substitute a known-

good ECM and recheck.“BLK/ORN” or “BLK”

wire is open or high

resistance circuit.

7Main relay circuit check

1) Disconnect connectors from ECM with ignition switch

turned OFF.

2) Using service wire, ground “E01-60” terminal of ECM

connector and measure voltage between each “E01-1”

and “E01-16” terminals of ECM connector and body

ground.

Is voltage 10 – 14 V?Go to Step 11. Go to Step 8.

8Main relay circuit check

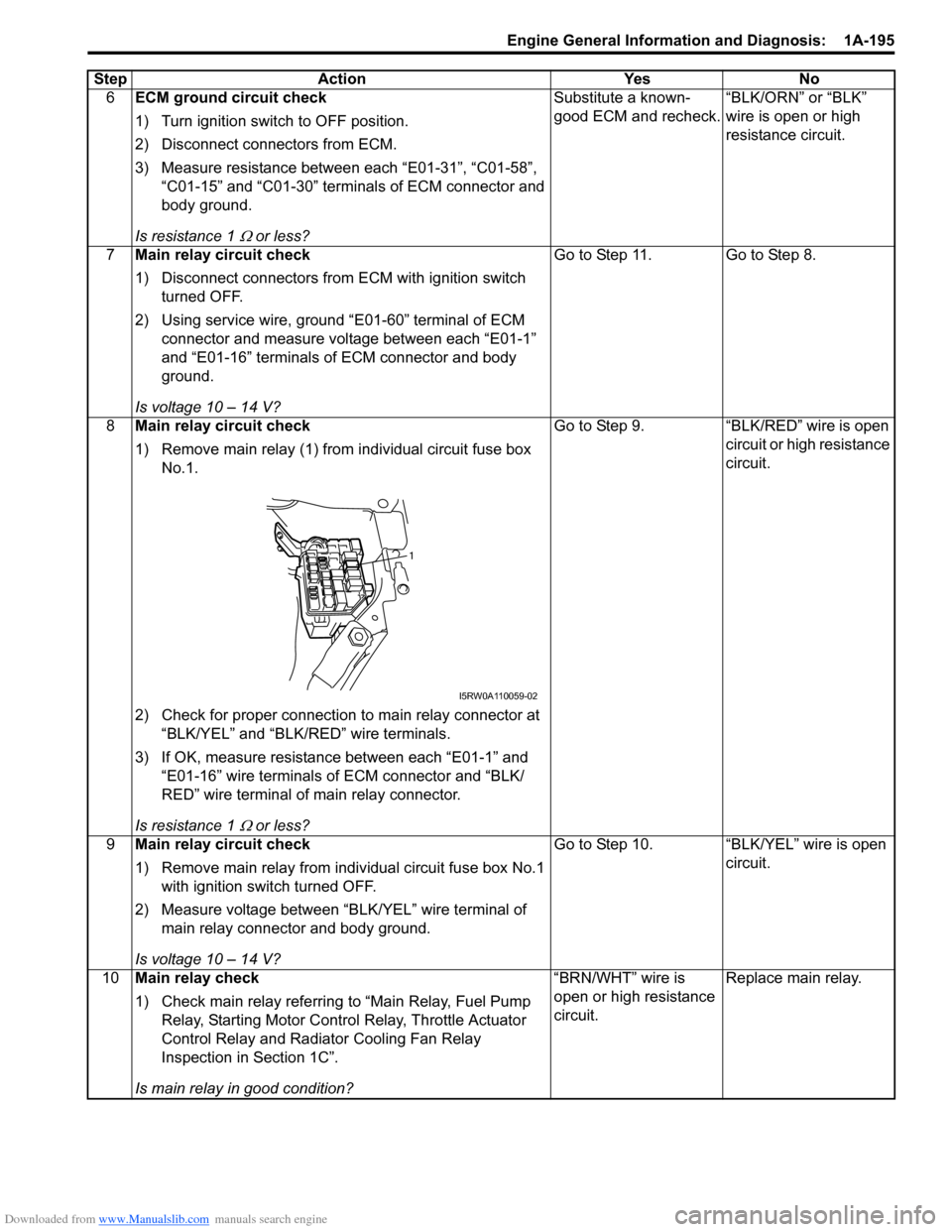

1) Remove main relay (1) from individual circuit fuse box

No.1.

2) Check for proper connection to main relay connector at

“BLK/YEL” and “BLK/RED” wire terminals.

3) If OK, measure resistance between each “E01-1” and

“E01-16” wire terminals of ECM connector and “BLK/

RED” wire terminal of main relay connector.

Is resistance 1

Ω or less?Go to Step 9. “BLK/RED” wire is open

circuit or high resistance

circuit.

9Main relay circuit check

1) Remove main relay from individual circuit fuse box No.1

with ignition switch turned OFF.

2) Measure voltage between “BLK/YEL” wire terminal of

main relay connector and body ground.

Is voltage 10 – 14 V?Go to Step 10. “BLK/YEL” wire is open

circuit.

10Main relay check

1) Check main relay referring to “Main Relay, Fuel Pump

Relay, Starting Motor Control Relay, Throttle Actuator

Control Relay and Radiator Cooling Fan Relay

Inspection in Section 1C”.

Is main relay in good condition?“BRN/WHT” wire is

open or high resistance

circuit.Replace main relay. Step Action Yes No

1

I5RW0A110059-02

Page 246 of 1556

Downloaded from www.Manualslib.com manuals search engine 1A-196 Engine General Information and Diagnosis:

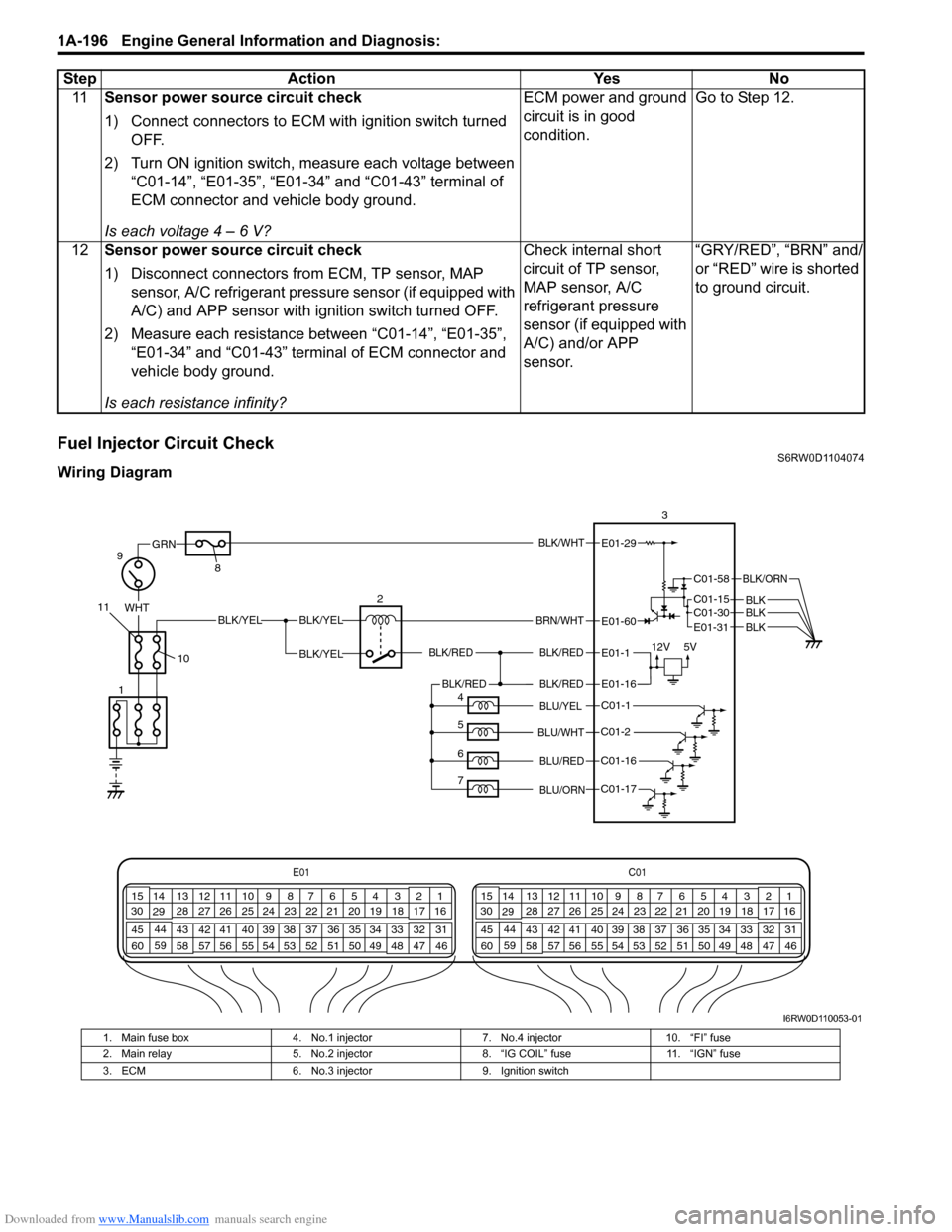

Fuel Injector Circuit CheckS6RW0D1104074

Wiring Diagram11Sensor power source circuit check

1) Connect connectors to ECM with ignition switch turned

OFF.

2) Turn ON ignition switch, measure each voltage between

“C01-14”, “E01-35”, “E01-34” and “C01-43” terminal of

ECM connector and vehicle body ground.

Is each voltage 4 – 6 V?ECM power and ground

circuit is in good

condition.Go to Step 12.

12Sensor power source circuit check

1) Disconnect connectors from ECM, TP sensor, MAP

sensor, A/C refrigerant pressure sensor (if equipped with

A/C) and APP sensor with ignition switch turned OFF.

2) Measure each resistance between “C01-14”, “E01-35”,

“E01-34” and “C01-43” terminal of ECM connector and

vehicle body ground.

Is each resistance infinity?Check internal short

circuit of TP sensor,

MAP sensor, A/C

refrigerant pressure

sensor (if equipped with

A/C) and/or APP

sensor.“GRY/RED”, “BRN” and/

or “RED” wire is shorted

to ground circuit. Step Action Yes No

BLK/WHT

BLK/RED

BLK/RED

WHTBLK/YELBLK/YEL

BLK/YEL

GRN

BRN/WHT

12V5V

9

2 83E01-29

E01-1

E01-60

10 11

E01C01

3 4

18 19 5 6 7 10 11

17 20

47 46 49 50 51 21 22

5216 259

24 14

29

55 57 54 53 59

60 582

26 27 28 15

30

56 4832 31 34 35 36 37 40 42 39 38 44

45 43 41 331 12 13

238 3 4

18 19 5 6 7 10 11

17 20

47 46 49 50 51 21 22

5216 259

24 14

29

55 57 54 53 59

60 582

26 27 28 15

30

56 4832 31 34 35 36 37 40 42 39 38 44

45 43 41 331 12 13

238

C01-1

C01-2

C01-16

C01-17

BLK/REDBLK/RED

BLU/YEL

BLU/RED

BLU/ORN

BLU/WHT

E01-16

4

5

6

71

C01-58

C01-15 C01-30

BLK/ORN

BLKBLKBLKE01-31

I6RW0D110053-01

1. Main fuse box 4. No.1 injector 7. No.4 injector 10. “FI” fuse

2. Main relay 5. No.2 injector 8. “IG COIL” fuse 11. “IGN” fuse

3. ECM 6. No.3 injector 9. Ignition switch

Page 247 of 1556

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-197

Troubleshooting

NOTE

• Before performed trouble shooting, be sure to read the “Precautions of ECM Circuit Inspection”.

• When measuring circuit voltage, resistance and/or pulse signal at ECM connector, connect the

special tool to ECM and/or the ECM connectors referring to “Inspection of ECM and Its Circuits”.

Step Action Yes No

1Fuel injector check for operating sound

1) Using sound scope, check each injector for operating

sound at engine cranking.

Do all 4 injector make operating sound?Fuel injectors circuit is

in good condition.Go to Step 2.

2Fuel injector resistance check

1) Disconnect connectors from fuel injectors with ignition

switch turned OFF.

2) Check for proper connection to fuel injector at each

terminals.

3) If OK, check all 4 fuel injectors for resistance referring to

“Fuel Injector On-Vehicle Inspection in Section 1G”.

Are all injectors in good condition?Go to Step 3. Faulty fuel injector.

3Fuel injector insulation resistance check

1) Check that there is insulation between each fuel injector

terminal and engine ground.

Is there insulation?Go to Step 4. Faulty fuel injector.

4Fuel injector power supply check

1) Measure voltage between each “BLK/RED” wire terminal

of fuel injector connector and engine ground with ignition

switch turned ON.

Is voltage 10 – 14 V?Go to Step 5. “BLK/RED” wire is open

or shorted to ground

circuit.

If it is in good condition,

go to “ECM Power and

Ground Circuit Check”.

5Wire circuit check

1) Turn OFF ignition switch.

2) Disconnect connectors from ECM.

3) Measure resistance between each “BLU/YEL”, “BLU/

WHT”, “BLU/RED”, “BLU/ORN” wire terminal of fuel

injector connector and vehicle body ground.

Is resistance infinity?Go to Step 6. “BLU/YEL”, “BLU/WHT”,

“BLU/RED” and/or

“BLU/ORN” wire(s) are

shorted to ground.

6Wire circuit check

1) Measure voltage between each “BLU/YEL”, “BLU/WHT”,

“BLU/RED”, “BLU/ORN” wire terminal of fuel injector

connector and vehicle body ground with ignition switch

turned ON.

Is voltage 0 V?Go to Step 7. “BLU/YEL”, “BLU/WHT”,

“BLU/RED” and/or

“BLU/ORN” wire(s) are

shorted to power supply

circuit.

7Fuel injector drive signal check

1) Connect connectors to each fuel injector and ECM with

ignition switch turned OFF.

2) Turn ON ignition switch.

3) Measure voltage between each “C01-1”, “C01-2”, “C01-

16”, “C01-17” terminal of ECM connector and vehicle

body ground.

Is voltage 10 – 14 V?Check fuel injector

referring to “Fuel

Injector Inspection in

Section 1G”.

If check result is

satisfactory, substitute a

known-good ECM and

recheck.“BLU/YEL”, “BLU/WHT”,

“BLU/RED” and/or

“BLU/ORN” wire(s) are

open circuit.

Page 249 of 1556

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-199

Troubleshooting

NOTE

• Before performed trouble shooting, be sure to read the “Precautions of ECM Circuit Inspection”.

• When measuring circuit voltage, resistance and/or pulse signal at ECM connector, connect the

special tool to ECM and/or the ECM connectors referring to “Inspection of ECM and Its Circuits”.

Step Action Yes No

1Fuel pump control system check for operation

Is fuel pump heard to operate 2 sec. after ignition switch is

turned ON?Fuel pump circuit is in

good condition.Go to Step 2.

2Fuel pump relay power supply check

1) Disconnect fuel pump relay from individual circuit fuse

box No.1 with ignition switch turned OFF.

2) Check for proper connection to fuel pump relay at each

terminal.

3) If OK, turn ON ignition switch, measure voltage between

“BLK/WHT” wire terminal of fuel pump relay connector

and engine ground.

Is voltage 10 – 14 V?Go to Step 3. “BLK/WHT” wire is open

or shorted to ground

circuit.

3Fuel pump relay power supply check

1) Turn ON ignition switch, measure voltage between “BLK/

RED” wire terminal of fuel pump relay connector and

engine ground.

Is voltage 10 – 14 V?Go to Step 4. “BLK/RED” wire is open

circuit.

4Fuel pump relay check

1) Check fuel pump relay referring to “Main Relay, Fuel

Pump Relay, Starting Motor Control Relay, Throttle

Actuator Control Relay and Radiator Cooling Fan Relay

Inspection in Section 1C”.

Is relay in good condition?Go to Step 5. Faulty relay.

5Fuel pump relay drive signal check

1) Connect fuel pump relay to individual circuit fuse box

No.1.

2) Connect voltmeter between “E01-15” terminal of ECM

connector and vehicle body ground.

3) Measure voltage 2 second after ignition switch is turned

ON.

Is voltage 10 – 14 V?Go to Step 6. “GRN/WHT” wire is

open circuit or shorted

to ground circuit.

I2RH01110132-01

Page 250 of 1556

Downloaded from www.Manualslib.com manuals search engine 1A-200 Engine General Information and Diagnosis:

6Fuel pump relay drive signal check

1) Measure voltage within 2 second after ignition switch is

turned ON.

Is voltage 0 – 1 V?Go to Step 7. Substitute a known-

good ECM and recheck.

7Wire circuit check

1) Turn OFF ignition switch.

2) Detach fuel tank referring to “Fuel Tank Removal and

Installation in Section 1G”.

3) Disconnect connector from fuel pump.

4) Measure resistance between “PNK” wire terminal of fuel

pump connector and vehicle body ground.

Is resistance infinity?Go to Step 8. “PNK” wire is shorted to

ground.

8Fuel pump circuit check

1) Connect service wire between “E01-15” terminal of ECM

connector and vehicle body ground.

2) Turn ON ignition switch, measure voltage between

“PNK” terminal at fuel pump connector and vehicle body

ground.

Is voltage 10 – 14 V?Go to Step 9. “PNK” wire is open

circuit.

9Fuel pump circuit check

1) Turn OFF ignition switch.

2) Measure resistance between “BLK” wire terminal at fuel

pump connector and vehicle body ground.

Is resistance less than 5

Ω?Faulty fuel pump. “BLK” wire is open

circuit. Step Action Yes No

Page 254 of 1556

Downloaded from www.Manualslib.com manuals search engine 1A-204 Engine General Information and Diagnosis:

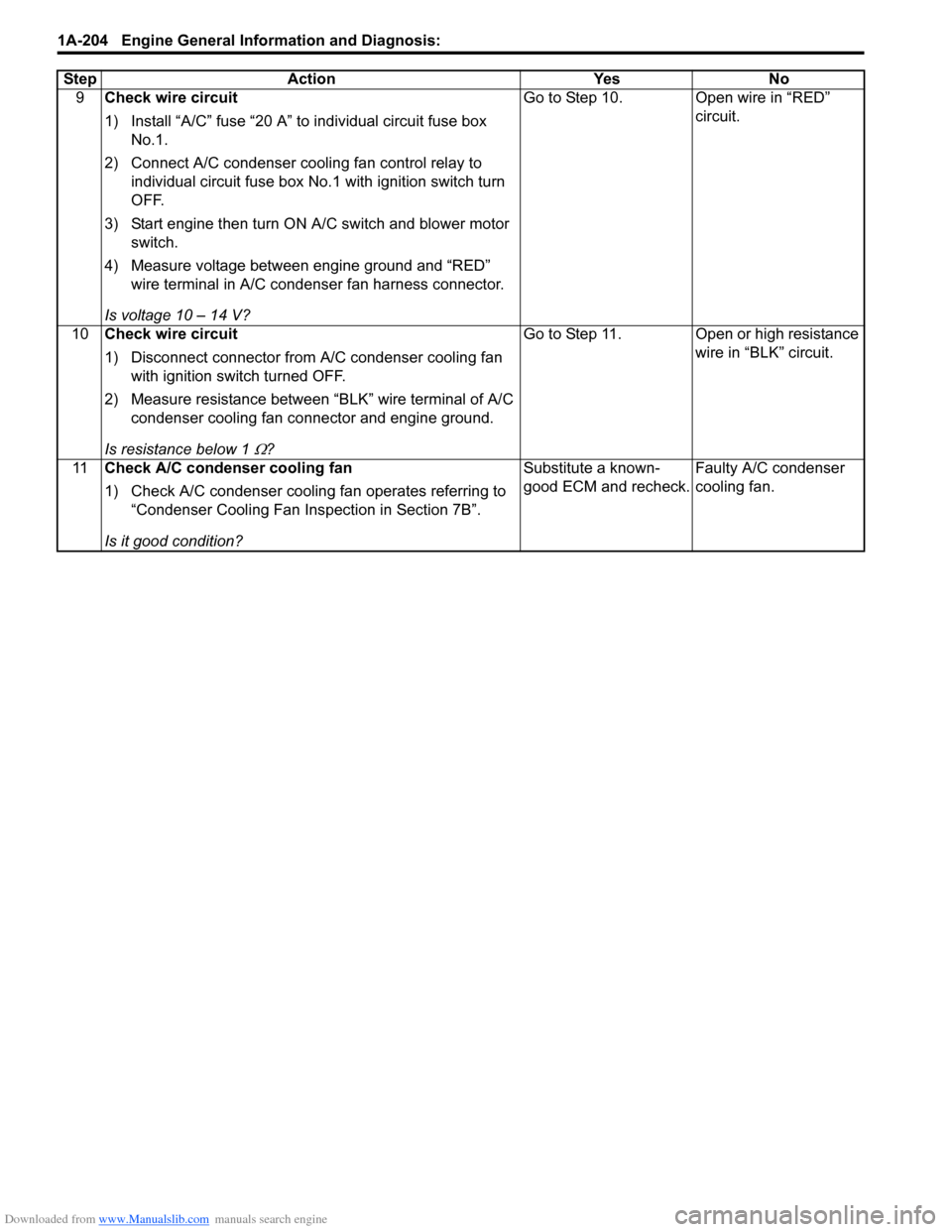

9Check wire circuit

1) Install “A/C” fuse “20 A” to individual circuit fuse box

No.1.

2) Connect A/C condenser cooling fan control relay to

individual circuit fuse box No.1 with ignition switch turn

OFF.

3) Start engine then turn ON A/C switch and blower motor

switch.

4) Measure voltage between engine ground and “RED”

wire terminal in A/C condenser fan harness connector.

Is voltage 10 – 14 V?Go to Step 10. Open wire in “RED”

circuit.

10Check wire circuit

1) Disconnect connector from A/C condenser cooling fan

with ignition switch turned OFF.

2) Measure resistance between “BLK” wire terminal of A/C

condenser cooling fan connector and engine ground.

Is resistance below 1

Ω?Go to Step 11. Open or high resistance

wire in “BLK” circuit.

11Check A/C condenser cooling fan

1) Check A/C condenser cooling fan operates referring to

“Condenser Cooling Fan Inspection in Section 7B”.

Is it good condition?Substitute a known-

good ECM and recheck.Faulty A/C condenser

cooling fan. Step Action Yes No

Page 256 of 1556

Downloaded from www.Manualslib.com manuals search engine 1A-206 Engine General Information and Diagnosis:

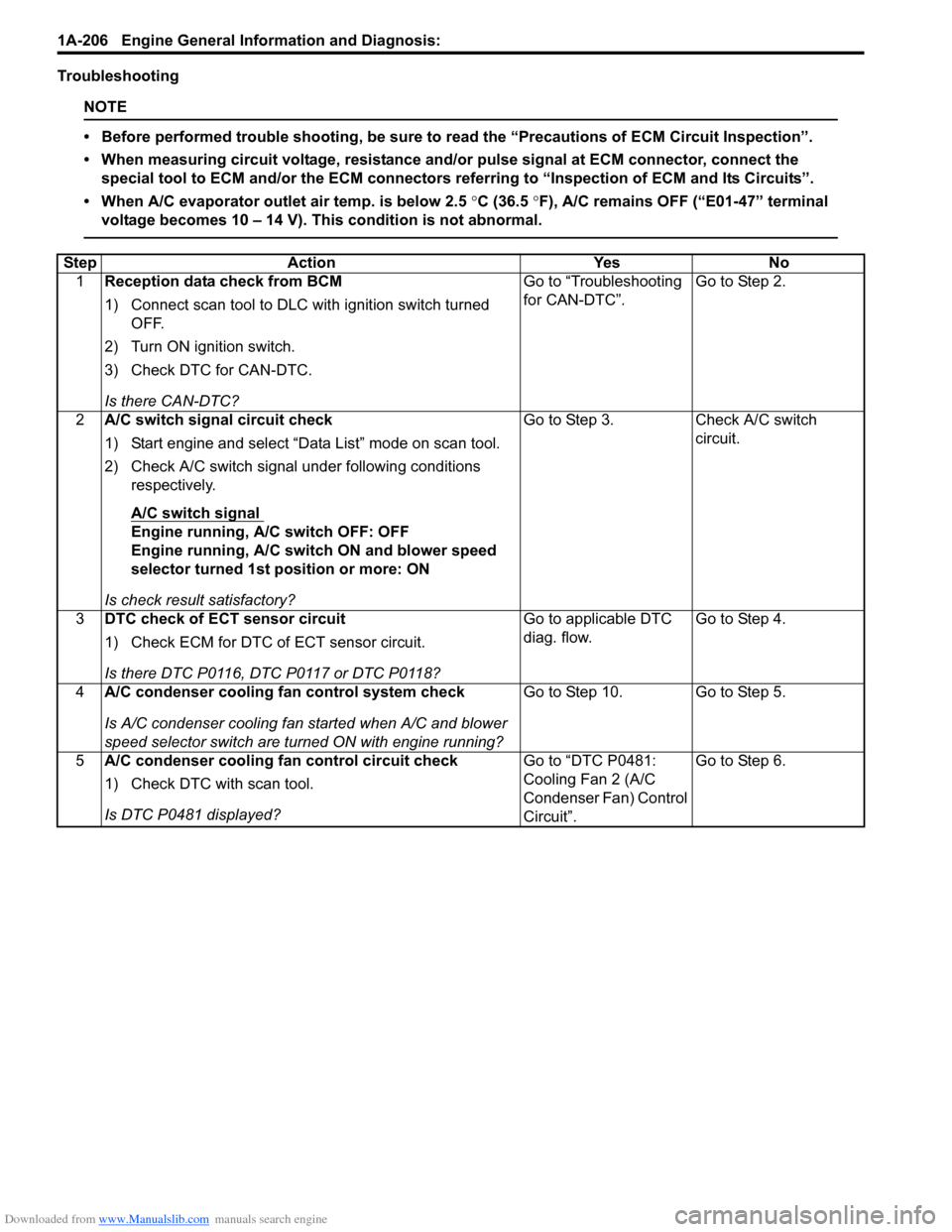

Troubleshooting

NOTE

• Before performed trouble shooting, be sure to read the “Precautions of ECM Circuit Inspection”.

• When measuring circuit voltage, resistance and/or pulse signal at ECM connector, connect the

special tool to ECM and/or the ECM connectors referring to “Inspection of ECM and Its Circuits”.

• When A/C evaporator outlet air temp. is below 2.5 °C (36.5 °F), A/C remains OFF (“E01-47” terminal

voltage becomes 10 – 14 V). This condition is not abnormal.

Step Action Yes No

1Reception data check from BCM

1) Connect scan tool to DLC with ignition switch turned

OFF.

2) Turn ON ignition switch.

3) Check DTC for CAN-DTC.

Is there CAN-DTC?Go to “Troubleshooting

for CAN-DTC”.Go to Step 2.

2A/C switch signal circuit check

1) Start engine and select “Data List” mode on scan tool.

2) Check A/C switch signal under following conditions

respectively.

A/C switch signal

Engine running, A/C switch OFF: OFF

Engine running, A/C switch ON and blower speed

selector turned 1st position or more: ON

Is check result satisfactory?Go to Step 3. Check A/C switch

circuit.

3DTC check of ECT sensor circuit

1) Check ECM for DTC of ECT sensor circuit.

Is there DTC P0116, DTC P0117 or DTC P0118?Go to applicable DTC

diag. flow.Go to Step 4.

4A/C condenser cooling fan control system check

Is A/C condenser cooling fan started when A/C and blower

speed selector switch are turned ON with engine running?Go to Step 10. Go to Step 5.

5A/C condenser cooling fan control circuit check

1) Check DTC with scan tool.

Is DTC P0481 displayed?Go to “DTC P0481:

Cooling Fan 2 (A/C

Condenser Fan) Control

Circuit”.Go to Step 6.

Page 257 of 1556

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-207

6A/C evaporator outlet air temp. sensor check

1) Disconnect connectors from ECM with ignition switch

turned OFF.

2) Check for proper connection to “E01-57” and “E01-54”

wire terminals of ECM connector.

3) If OK, measure resistance between “E01-57” and “E01-

54” wire terminals of ECM connector.

Evaporator temp. sensor resistance

At 0 °C: 6.3 – 6.9 kΩ

At 25 °C: 1.8 – 2.2 kΩ

Is resistance within specification?Go to Step 7. Faulty A/C evaporator

outlet air temp. sensor

or its circuit.

7DTC check of A/C refrigerant pressure sensor circuit

1) Connect scan tool to DLC with ignition switch turned

OFF.

2) Turn ON ignition switch.

3) Check ECM for DTC of A/C refrigerant pressure sensor

circuit.

Is there DTC P0532 or DTC P0533?Go to applicable DTC

diag. flow.Go to Step 8.

8A/C refrigerant pressure sensor voltage check

1) Check A/C refrigerant pressure sensor voltage referring

to “Inspection of ECM and Its Circuits”.

Is voltage within specified value?Go to Step 9. Check amount of

refrigerant. If OK,

replace A/C refrigerant

pressure sensor.

9A/C condenser cooling fan check

1) Check A/C condenser cooling fan referring to

“Condenser Cooling Fan Inspection in Section 7B”.

Is check result satisfactory?A/C condenser cooling

fan drive circuit

malfunction. If circuit is

OK, go to Step 6.Replace A/C condenser

cooling fan motor.

10A/C compressor control system check

Is A/C compressor started when A/C and blower speed

selector switch are turned ON with engine running?A/C system is in good

condition.Go to Step 11. Step Action Yes No

7

6

5

4

3

2

1

10

20

30

4050 010

2030

60 70

80 ResistanceTemperatureI3RB0A110053-01

Page 258 of 1556

Downloaded from www.Manualslib.com manuals search engine 1A-208 Engine General Information and Diagnosis:

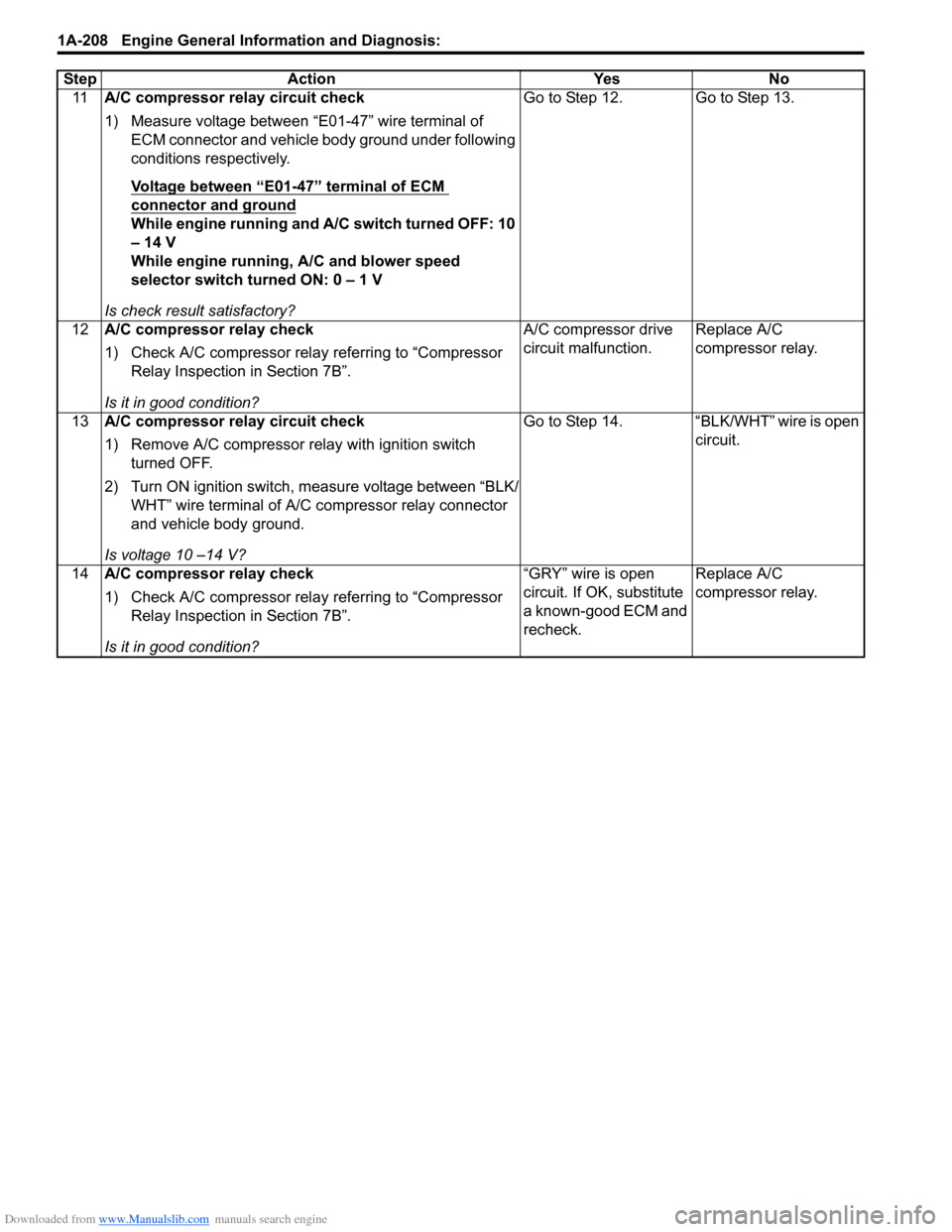

11A/C compressor relay circuit check

1) Measure voltage between “E01-47” wire terminal of

ECM connector and vehicle body ground under following

conditions respectively.

Voltage between “E01-47” terminal of ECM

connector and ground

While engine running and A/C switch turned OFF: 10

– 14 V

While engine running, A/C and blower speed

selector switch turned ON: 0 – 1 V

Is check result satisfactory?Go to Step 12. Go to Step 13.

12A/C compressor relay check

1) Check A/C compressor relay referring to “Compressor

Relay Inspection in Section 7B”.

Is it in good condition?A/C compressor drive

circuit malfunction.Replace A/C

compressor relay.

13A/C compressor relay circuit check

1) Remove A/C compressor relay with ignition switch

turned OFF.

2) Turn ON ignition switch, measure voltage between “BLK/

WHT” wire terminal of A/C compressor relay connector

and vehicle body ground.

Is voltage 10 –14 V?Go to Step 14. “BLK/WHT” wire is open

circuit.

14A/C compressor relay check

1) Check A/C compressor relay referring to “Compressor

Relay Inspection in Section 7B”.

Is it in good condition?“GRY” wire is open

circuit. If OK, substitute

a known-good ECM and

recheck.Replace A/C

compressor relay. Step Action Yes No

Page 262 of 1556

Downloaded from www.Manualslib.com manuals search engine 1A-212 Engine General Information and Diagnosis:

Repair Instructions

Idle Speed and IAC Throttle Valve Opening

Inspection

S6RW0D1106001

Before idle speed check, make sure of the following.

• Lead wires and hoses of electronic fuel injection and

engine and emission control systems are connected

securely.

• Valve lash is checked according to maintenance

schedule.

• Ignition timing is within specification.

• All accessories (wipers, heater, lights, A/C, etc.) are

out of service.

• Air cleaner has been properly installed and is in good

condition.

• No abnormal air drawn in from air intake system.After all items are confirmed, check idle speed and IAC

throttle opening as follows.NOTE

Before starting engine, place transmission

gear shift lever in “Neutral”, and set parking

brake and block drive wheels.

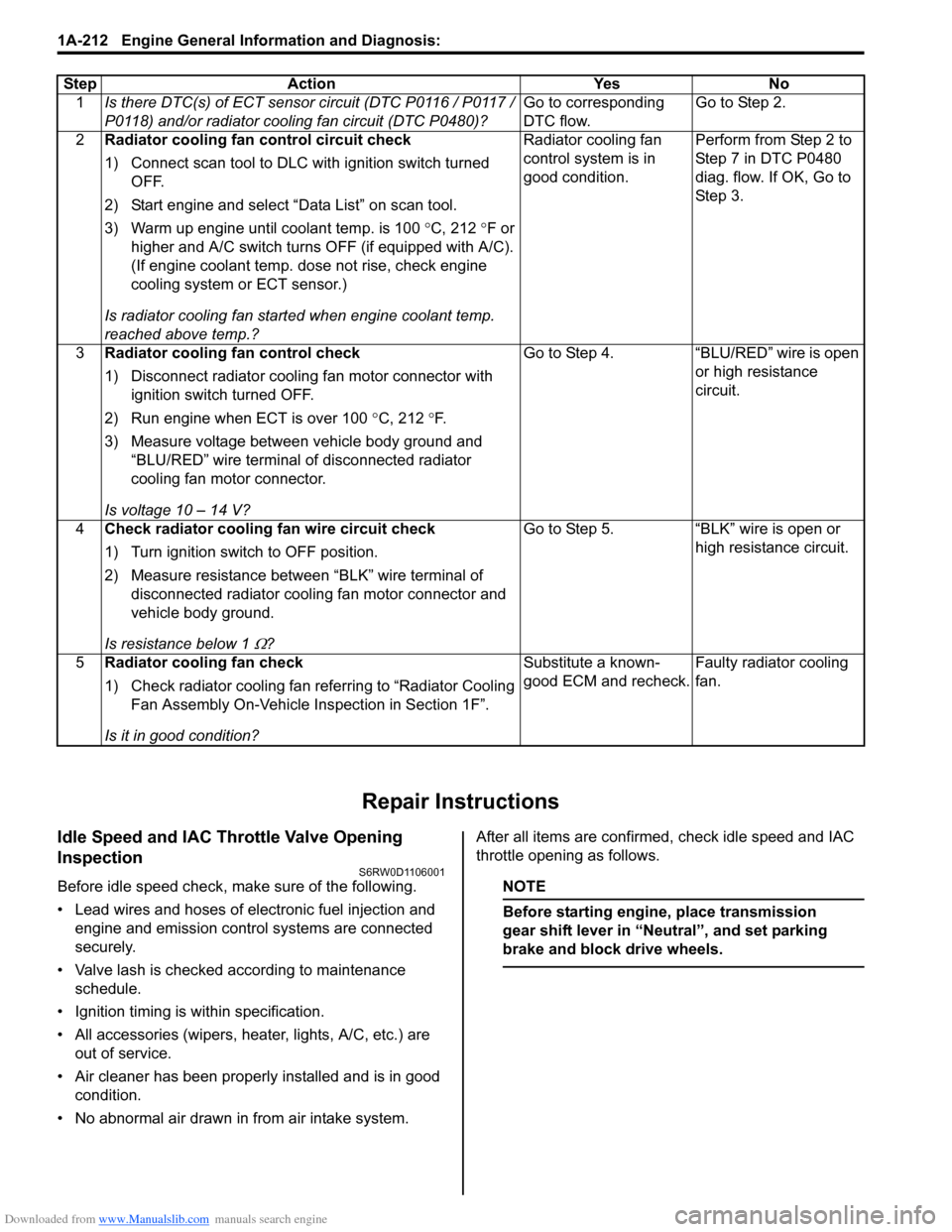

Step Action Yes No

1Is there DTC(s) of ECT sensor circuit (DTC P0116 / P0117 /

P0118) and/or radiator cooling fan circuit (DTC P0480)?Go to corresponding

DTC flow.Go to Step 2.

2Radiator cooling fan control circuit check

1) Connect scan tool to DLC with ignition switch turned

OFF.

2) Start engine and select “Data List” on scan tool.

3) Warm up engine until coolant temp. is 100 °C, 212 °F or

higher and A/C switch turns OFF (if equipped with A/C).

(If engine coolant temp. dose not rise, check engine

cooling system or ECT sensor.)

Is radiator cooling fan started when engine coolant temp.

reached above temp.?Radiator cooling fan

control system is in

good condition.Perform from Step 2 to

Step 7 in DTC P0480

diag. flow. If OK, Go to

Ste p 3.

3Radiator cooling fan control check

1) Disconnect radiator cooling fan motor connector with

ignition switch turned OFF.

2) Run engine when ECT is over 100 °C, 212 °F.

3) Measure voltage between vehicle body ground and

“BLU/RED” wire terminal of disconnected radiator

cooling fan motor connector.

Is voltage 10 – 14 V?Go to Step 4. “BLU/RED” wire is open

or high resistance

circuit.

4Check radiator cooling fan wire circuit check

1) Turn ignition switch to OFF position.

2) Measure resistance between “BLK” wire terminal of

disconnected radiator cooling fan motor connector and

vehicle body ground.

Is resistance below 1

Ω?Go to Step 5. “BLK” wire is open or

high resistance circuit.

5Radiator cooling fan check

1) Check radiator cooling fan referring to “Radiator Cooling

Fan Assembly On-Vehicle Inspection in Section 1F”.

Is it in good condition?Substitute a known-

good ECM and recheck.Faulty radiator cooling

fan.