300 SUZUKI SX4 2006 1.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2006, Model line: SX4, Model: SUZUKI SX4 2006 1.GPages: 1556, PDF Size: 37.31 MB

Page 1318 of 1556

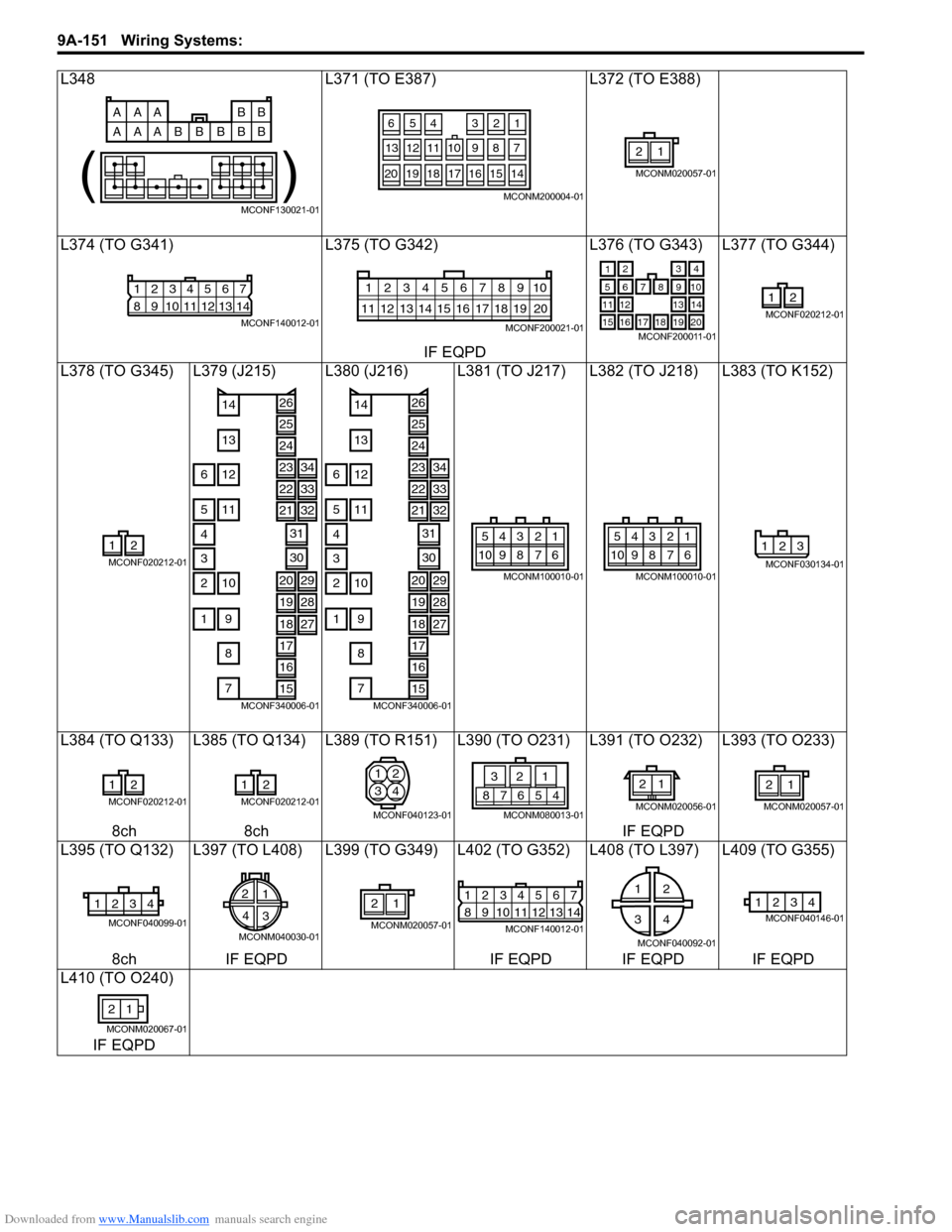

Downloaded from www.Manualslib.com manuals search engine 9A-151 Wiring Systems:

L348 L371 (TO E387) L372 (TO E388)

L374 (TO G341) L375 (TO G342) L376 (TO G343) L377 (TO G344)

IF EQPD

L378 (TO G345) L379 (J215) L380 (J216) L381 (TO J217) L382 (TO J218) L383 (TO K152)

L384 (TO Q133) L385 (TO Q134) L389 (TO R151) L390 (TO O231) L391 (TO O232) L393 (TO O233)

8ch 8ch IF EQPD

L395 (TO Q132) L397 (TO L408) L399 (TO G349) L402 (TO G352) L408 (TO L397) L409 (TO G355)

8ch IF EQPD IF EQPD IF EQPD IF EQPD

L410 (TO O240)

IF EQPD

AAA BB

AAA BB B BB

( )

MCONF130021-01

4

521

108

11

127

36

20191817161514

9 13

MCONM200004-01

21

MCONM020057-01

12567

8

9 1011121314

34

MCONF140012-01

10

11 12 13 14 15 16 17 18 19123456789

20

MCONF200021-01

21

8

3

9765

131211

1819

4

10

14

20171615MCONF200011-01

12

MCONF020212-01

12

MCONF020212-01

26

25

24

2334

2233

21

31

14

13

126

115

10

7

8

2

91

4

330

32

2029

1928

18

17

16

15

27

MCONF340006-01

26

25

24

2334

2233

21

31

14

13

126

115

10

7

8

2

91

4

330

32

2029

1928

18

17

16

15

27

MCONF340006-01

543 21

10 9 8 7 6

MCONM100010-01

543 21

10 9 8 7 6

MCONM100010-01

123

MCONF030134-01

12

MCONF020212-01

12

MCONF020212-01

1

32

4

MCONF040123-01

4 5 6 7 8

21 3

MCONM080013-01

1 2

MCONM020056-01

21

MCONM020057-01

4 3 2 1

MCONF040099-01

2

1

4

3

MCONM040030-01

21

MCONM020057-01

12567

8

9 1011121314

34

MCONF140012-01

12

34

MCONF040092-01

4 3 12MCONF040146-01

21

MCONM020067-01

Page 1325 of 1556

Downloaded from www.Manualslib.com manuals search engine Lighting Systems: 9B-6

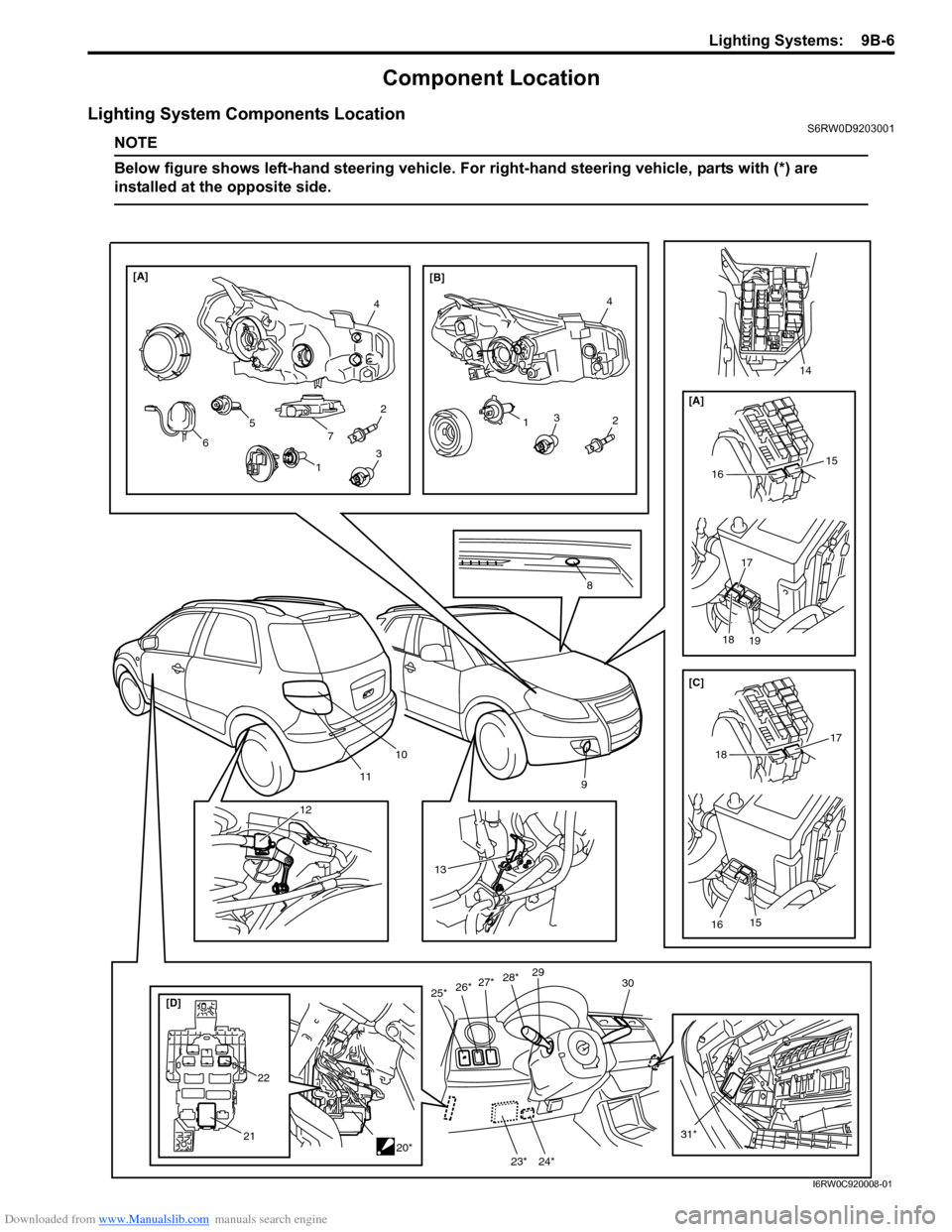

Component Location

Lighting System Components LocationS6RW0D9203001

NOTE

Below figure shows left-hand steering vehicle. For right-hand steering vehicle, parts with (*) are

installed at the opposite side.

10

119

[D]25*30

21

27*26*29

31*20*

13

4

2

4

[A]

[B]

8

132

7 5

6

12

13

22

28*

15

16

[A]

17

18

19

15

16

17

18 [C]

14

23* 24*

I6RW0C920008-01

Page 1326 of 1556

Downloaded from www.Manualslib.com manuals search engine 9B-7 Lighting Systems:

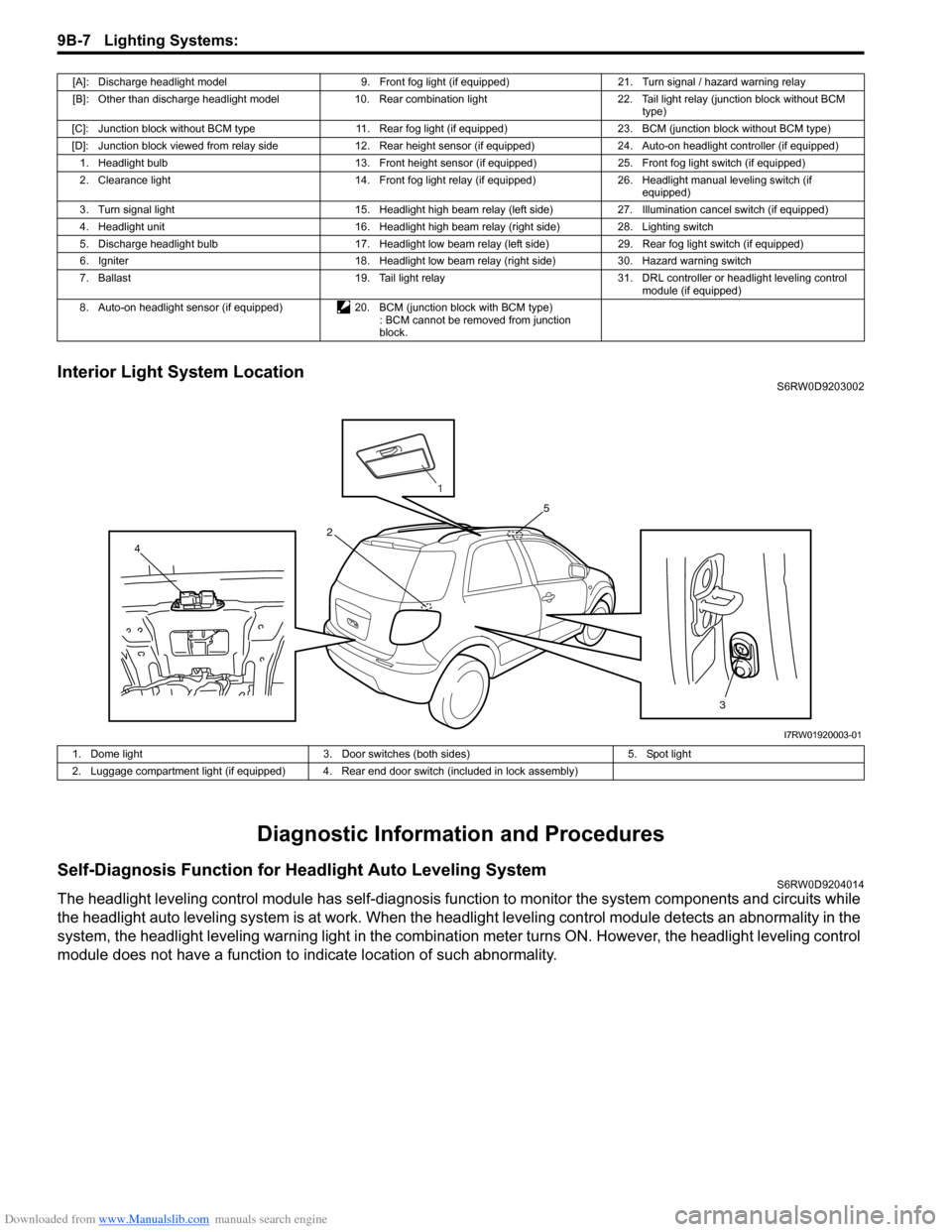

Interior Light System LocationS6RW0D9203002

Diagnostic Information and Procedures

Self-Diagnosis Function for Headlight Auto Leveling SystemS6RW0D9204014

The headlight leveling control module has self-diagnosis function to monitor the system components and circuits while

the headlight auto leveling system is at work. When the headlight leveling control module detects an abnormality in the

system, the headlight leveling warning light in the combination meter turns ON. However, the headlight leveling control

module does not have a function to indicate location of such abnormality.

[A]: Discharge headlight model 9. Front fog light (if equipped) 21. Turn signal / hazard warning relay

[B]: Other than discharge headlight model 10. Rear combination light 22. Tail light relay (junction block without BCM

type)

[C]: Junction block without BCM type 11. Rear fog light (if equipped) 23. BCM (junction block without BCM type)

[D]: Junction block viewed from relay side 12. Rear height sensor (if equipped) 24. Auto-on headlight controller (if equipped)

1. Headlight bulb 13. Front height sensor (if equipped) 25. Front fog light switch (if equipped)

2. Clearance light 14. Front fog light relay (if equipped) 26. Headlight manual leveling switch (if

equipped)

3. Turn signal light 15. Headlight high beam relay (left side) 27. Illumination cancel switch (if equipped)

4. Headlight unit 16. Headlight high beam relay (right side) 28. Lighting switch

5. Discharge headlight bulb 17. Headlight low beam relay (left side) 29. Rear fog light switch (if equipped)

6. Igniter 18. Headlight low beam relay (right side) 30. Hazard warning switch

7. Ballast 19. Tail light relay 31. DRL controller or headlight leveling control

module (if equipped)

8. Auto-on headlight sensor (if equipped) 20. BCM (junction block with BCM type)

: BCM cannot be removed from junction

block.

3 4

5

2

1

I7RW01920003-01

1. Dome light 3. Door switches (both sides) 5. Spot light

2. Luggage compartment light (if equipped) 4. Rear end door switch (included in lock assembly)

Page 1353 of 1556

Downloaded from www.Manualslib.com manuals search engine Instrumentation / Driver Info. / Horn: 9C-1

Body, Cab and Accessories

Instrumentation / Driver Info. / Horn

Precautions

Precautions in Diagnosing Troubles for Combination MeterS6RW0D9300001

Combination meter uses signals (information) from each control module by CAN communication to control

speedometer, tachometer, fuel meter, engine coolant temp meter, warning light and indicator light (other than air bag

warning light, EPS warning light, headlight leveling warning light (if equipped), rear fog light indicator light (if

equipped), high beam indicator light and turn signal indicator light). Therefor, check that no DTC is detected in each

module before performing combination meter symptom diagnosis. If any DTC is detected, correct trouble indicated by

that DTC troubleshooting first.

General Description

CAN Communication System DescriptionS6RW0D9301001

Refer to “CAN Communication System Description in Section 1A” for CAN communication system description.

Combination meter communicates control data with each control module as follows.

Combination Meter Transmission Data

BCM

Combination

meterDATA

TransmitCombination meter spec signal

I5RW0A930001-02

Page 1354 of 1556

Downloaded from www.Manualslib.com manuals search engine 9C-2 Instrumentation / Driver Info. / Horn:

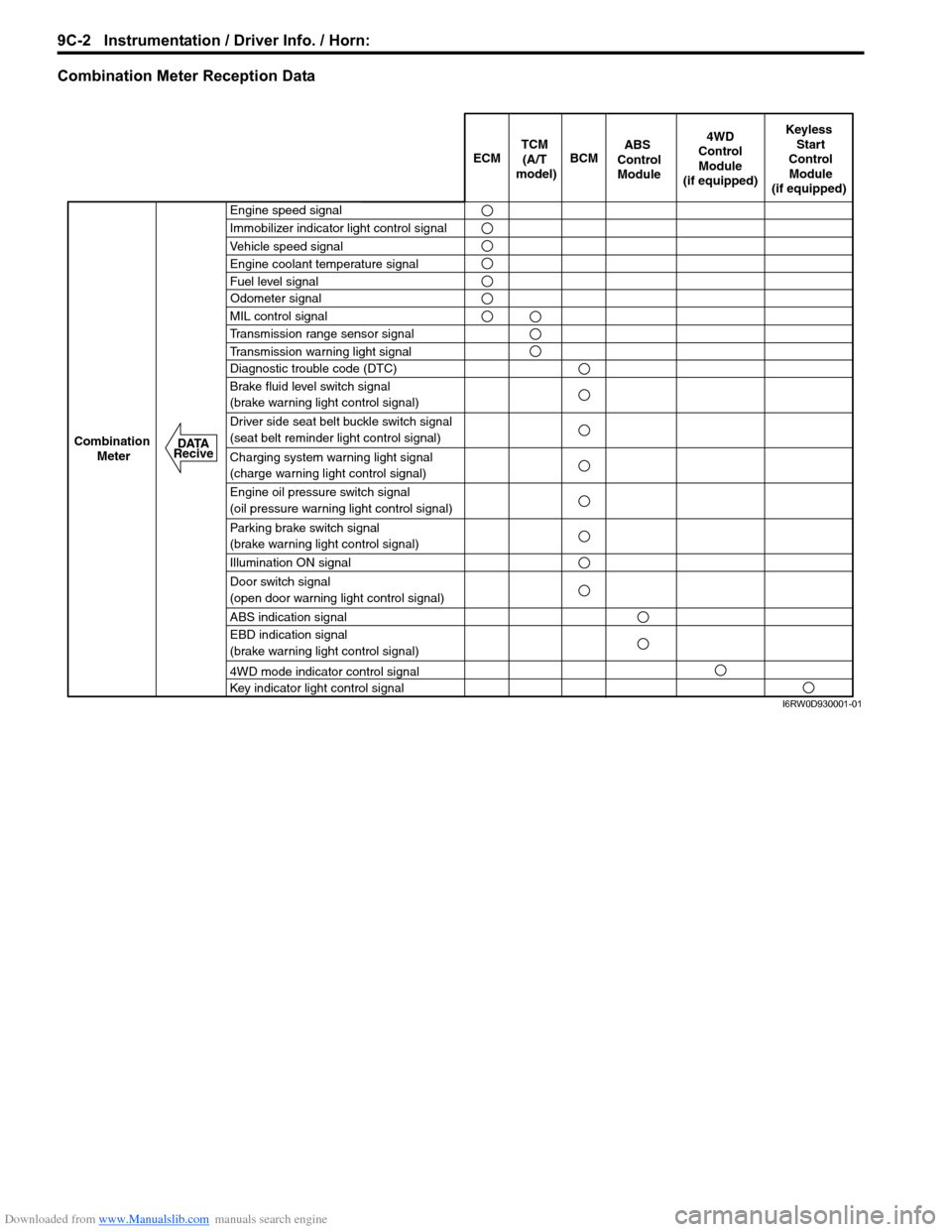

Combination Meter Reception Data

ECM BCM

Keyless

Start

Control

Module

(if equipped)

Combination

Meter4WD

Control

Module

(if equipped)TCM

(A/T

model)

Engine speed signal

Immobilizer indicator light control signal

Vehicle speed signal

Engine coolant temperature signal

Fuel level signal

MIL control signal

Transmission range sensor signal

Transmission warning light signal

Diagnostic trouble code (DTC)

Brake fluid level switch signal

(brake warning light control signal)

Driver side seat belt buckle switch signal

(seat belt reminder light control signal)

Charging system warning light signal

(charge warning light control signal)

Engine oil pressure switch signal

(oil pressure warning light control signal)

Parking brake switch signal

(brake warning light control signal)

Illumination ON signal

Door switch signal

(open door warning light control signal)

ABS indication signal

EBD indication signal

(brake warning light control signal)

4WD mode indicator control signal

Key indicator light control signal

ABS

Control

Module

Odometer signal

DATA

Recive

I6RW0D930001-01

Page 1355 of 1556

Downloaded from www.Manualslib.com manuals search engine Instrumentation / Driver Info. / Horn: 9C-3

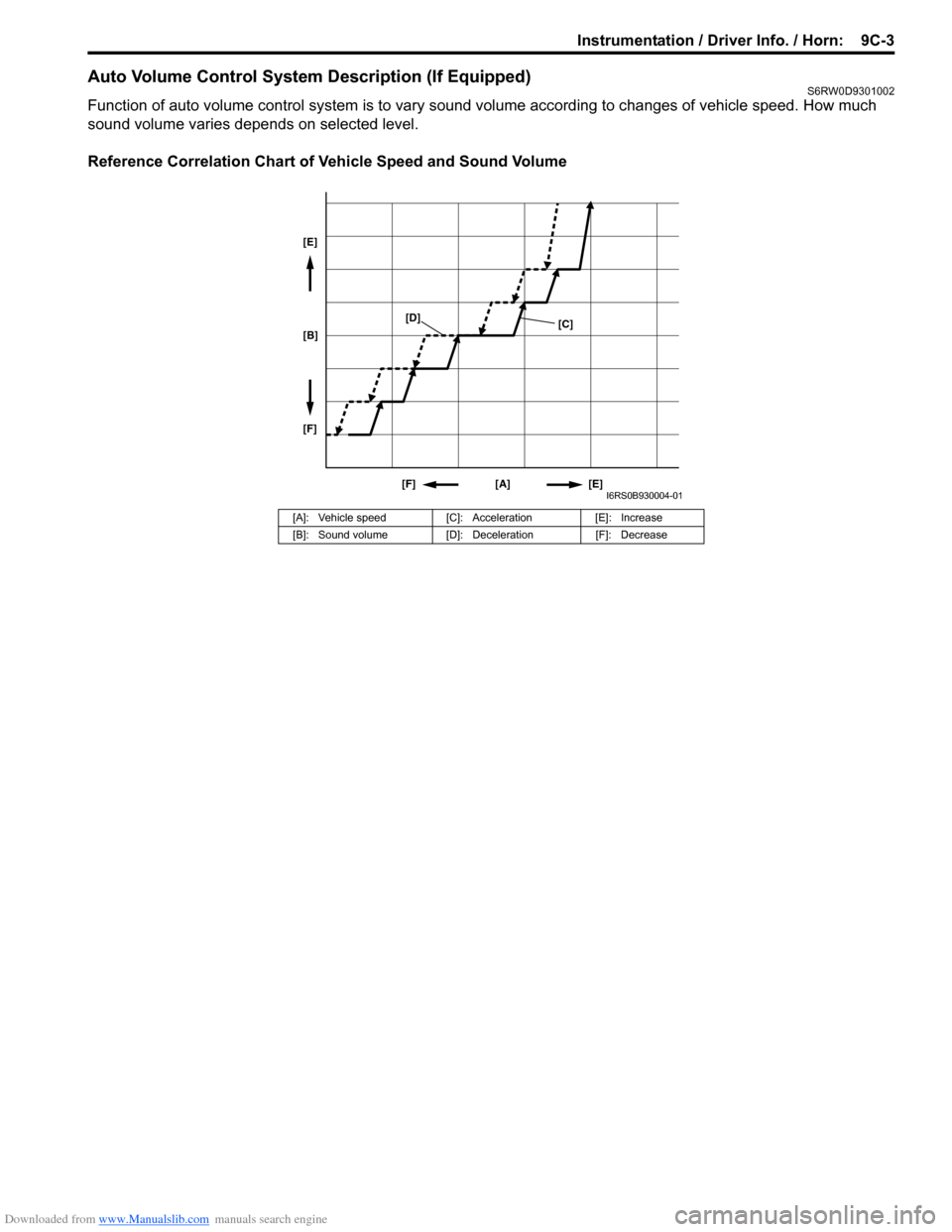

Auto Volume Control System Description (If Equipped)S6RW0D9301002

Function of auto volume control system is to vary sound volume according to changes of vehicle speed. How much

sound volume varies depends on selected level.

Reference Correlation Chart of Vehicle Speed and Sound Volume

[A]: Vehicle speed [C]: Acceleration [E]: Increase

[B]: Sound volume [D]: Deceleration [F]: Decrease

[A] [E] [F] [B] [E]

[F][C]

[D]

I6RS0B930004-01

Page 1356 of 1556

Downloaded from www.Manualslib.com manuals search engine 9C-4 Instrumentation / Driver Info. / Horn:

Schematic and Routing Diagram

Combination Meter Circuit DiagramS6RW0D9302001

7

6

5

4G241-99

G241-5

1

2

11

G241-1323

G241-31

G241-263

G241-16

G241-2212

G241-2513

G241-13

8 17

1514

20

G241-32

G241-69

16

18

19

G241-2121

G241-7 G241-10 10

10

G241-1922

I6RW0D930002-01

1. DOME fuse 9. 4WD control module (if equipped) 17. CAN driver

2. METER fuse 10. CAN junction connector 18. Stepper motor and LED output driver

3. Combination switch 11. SDM 19. A/T shift position indicator (“P”, “R”, “N”, “D”, “3”, “2” and “L”)

4. Tachometer 12. Combination switch (high beam) 20. Combination meter

5. Speedometer 13. P/S control module 21. Combination switch (rear fog light)

6. Fuel meter 14. CPU 22. Headlight leveling control module (if equipped)

7. ECT meter 15. Power supply 23. Illumination cancel switch (if equipped)

8. ODO-TRIP 16. Interface circuit

Page 1357 of 1556

Downloaded from www.Manualslib.com manuals search engine Instrumentation / Driver Info. / Horn: 9C-5

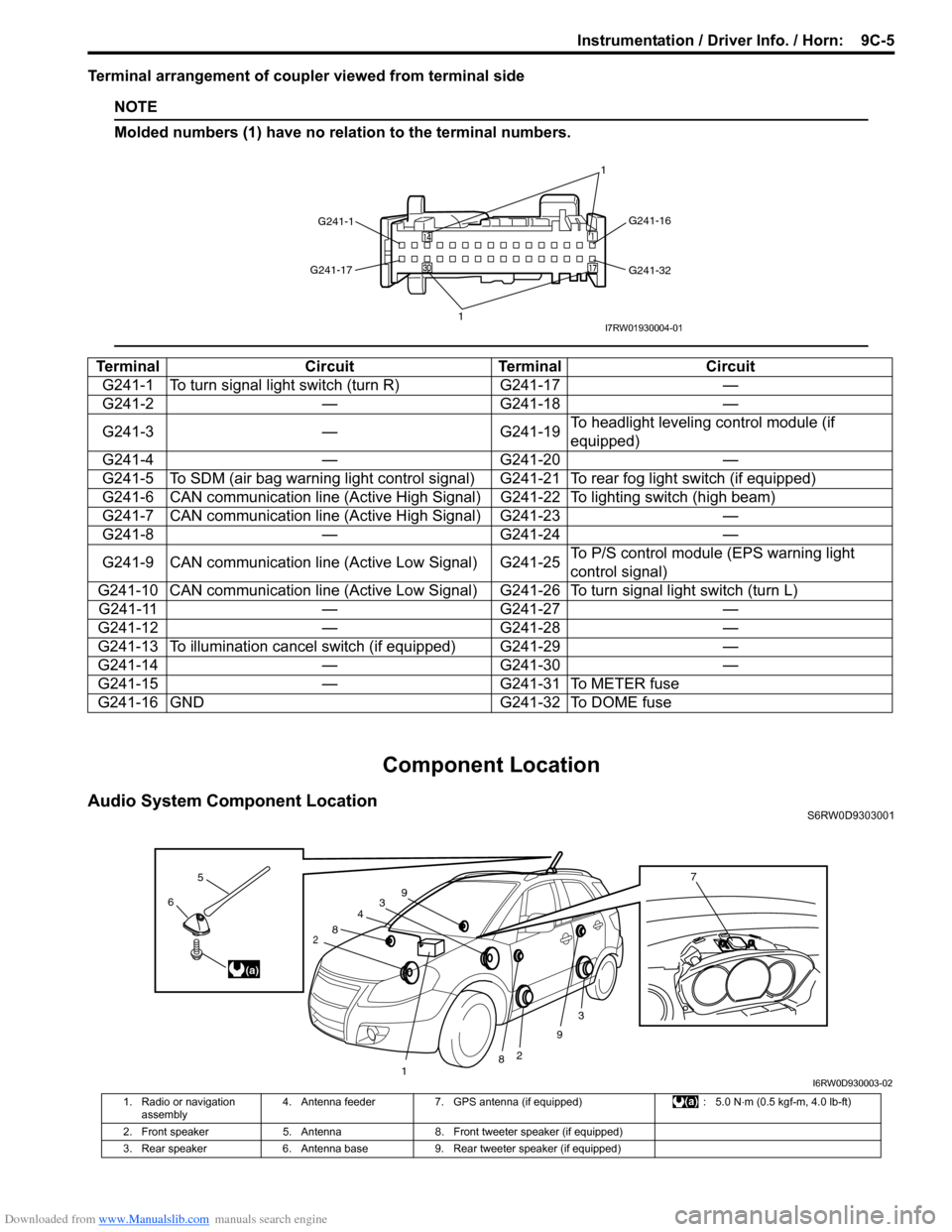

Terminal arrangement of coupler viewed from terminal side

NOTE

Molded numbers (1) have no relation to the terminal numbers.

Component Location

Audio System Component LocationS6RW0D9303001

Terminal Circuit Terminal Circuit

G241-1 To turn signal light switch (turn R) G241-17 —

G241-2 — G241-18 —

G241-3 — G241-19To headlight leveling control module (if

equipped)

G241-4 — G241-20 —

G241-5 To SDM (air bag warning light control signal) G241-21 To rear fog light switch (if equipped)

G241-6 CAN communication line (Active High Signal) G241-22 To lighting switch (high beam)

G241-7 CAN communication line (Active High Signal) G241-23 —

G241-8 — G241-24 —

G241-9 CAN communication line (Active Low Signal) G241-25To P/S control module (EPS warning light

control signal)

G241-10 CAN communication line (Active Low Signal) G241-26 To turn signal light switch (turn L)

G241-11 — G241-27 —

G241-12 — G241-28 —

G241-13 To illumination cancel switch (if equipped) G241-29 —

G241-14 — G241-30 —

G241-15 — G241-31 To METER fuse

G241-16 GND G241-32 To DOME fuse

G241-1G241-16

G241-32 G241-17

11I7RW01930004-01

3

2

3

2

1

4

8

8

9

96

5

(a)

7

I6RW0D930003-02

1. Radio or navigation

assembly4. Antenna feeder 7. GPS antenna (if equipped) : 5.0 N⋅m (0.5 kgf-m, 4.0 lb-ft)

2. Front speaker 5. Antenna 8. Front tweeter speaker (if equipped)

3. Rear speaker 6. Antenna base 9. Rear tweeter speaker (if equipped)

Page 1366 of 1556

Downloaded from www.Manualslib.com manuals search engine 9C-14 Instrumentation / Driver Info. / Horn:

Repair Instructions

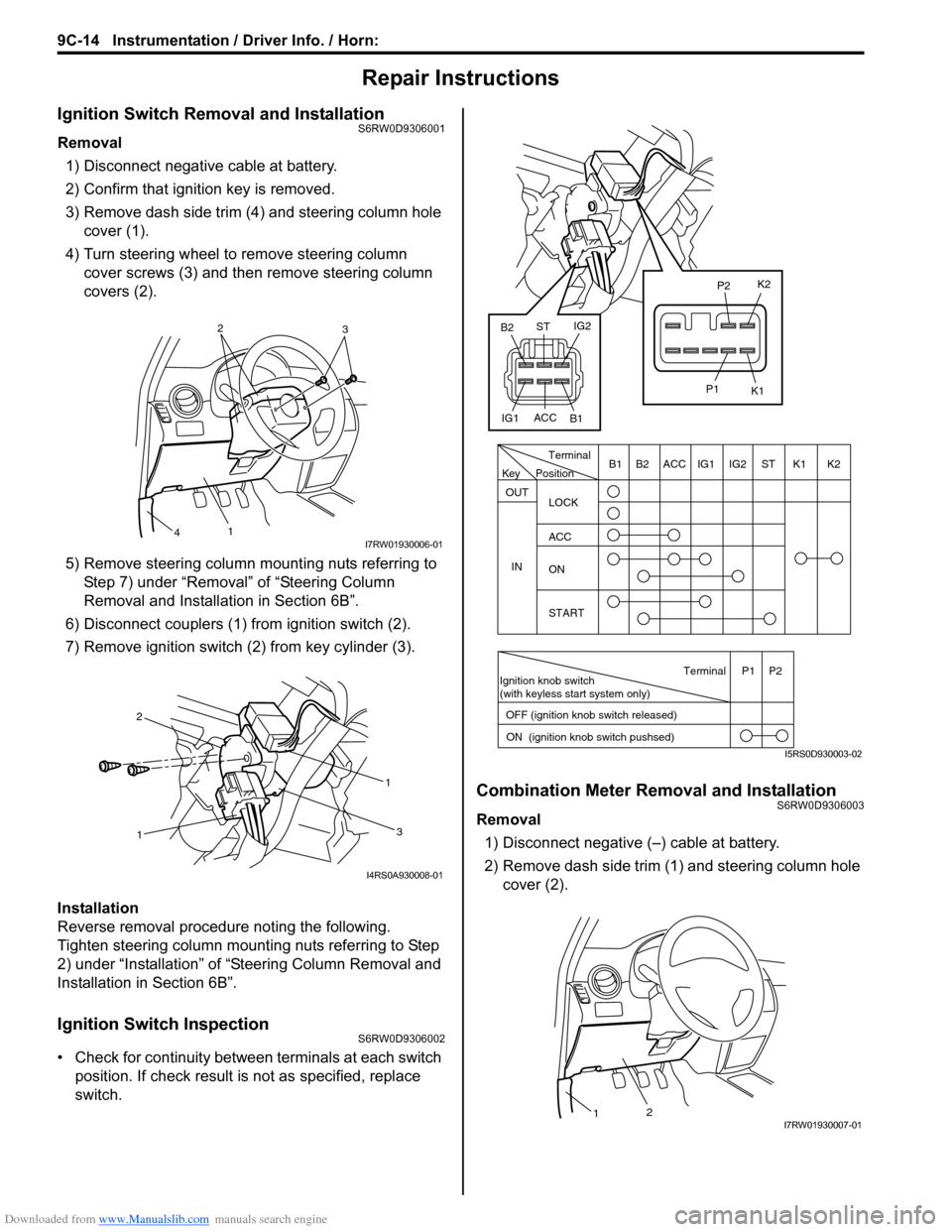

Ignition Switch Removal and InstallationS6RW0D9306001

Removal

1) Disconnect negative cable at battery.

2) Confirm that ignition key is removed.

3) Remove dash side trim (4) and steering column hole

cover (1).

4) Turn steering wheel to remove steering column

cover screws (3) and then remove steering column

covers (2).

5) Remove steering column mounting nuts referring to

Step 7) under “Removal” of “Steering Column

Removal and Installation in Section 6B”.

6) Disconnect couplers (1) from ignition switch (2).

7) Remove ignition switch (2) from key cylinder (3).

Installation

Reverse removal procedure noting the following.

Tighten steering column mounting nuts referring to Step

2) under “Installation” of “Steering Column Removal and

Installation in Section 6B”.

Ignition Switch InspectionS6RW0D9306002

• Check for continuity between terminals at each switch

position. If check result is not as specified, replace

switch.

Combination Meter Removal and InstallationS6RW0D9306003

Removal

1) Disconnect negative (–) cable at battery.

2) Remove dash side trim (1) and steering column hole

cover (2).

2

3

1

4I7RW01930006-01

11

2

3

I4RS0A930008-01

PositionTerminal

LOCK

ACC

ON

START OUT

INK2 K1 ST IG2 IG1 ACC B1 B2

Ignition knob switch

(with keyless start system only)

ACC

IG1IG2

ST

B2

B1K2

K1

P2

P1

Terminal

OFF (ignition knob switch released)

ON (ignition knob switch pushsed)P1 P2

Key

I5RS0D930003-02

21I7RW01930007-01

Page 1367 of 1556

Downloaded from www.Manualslib.com manuals search engine Instrumentation / Driver Info. / Horn: 9C-15

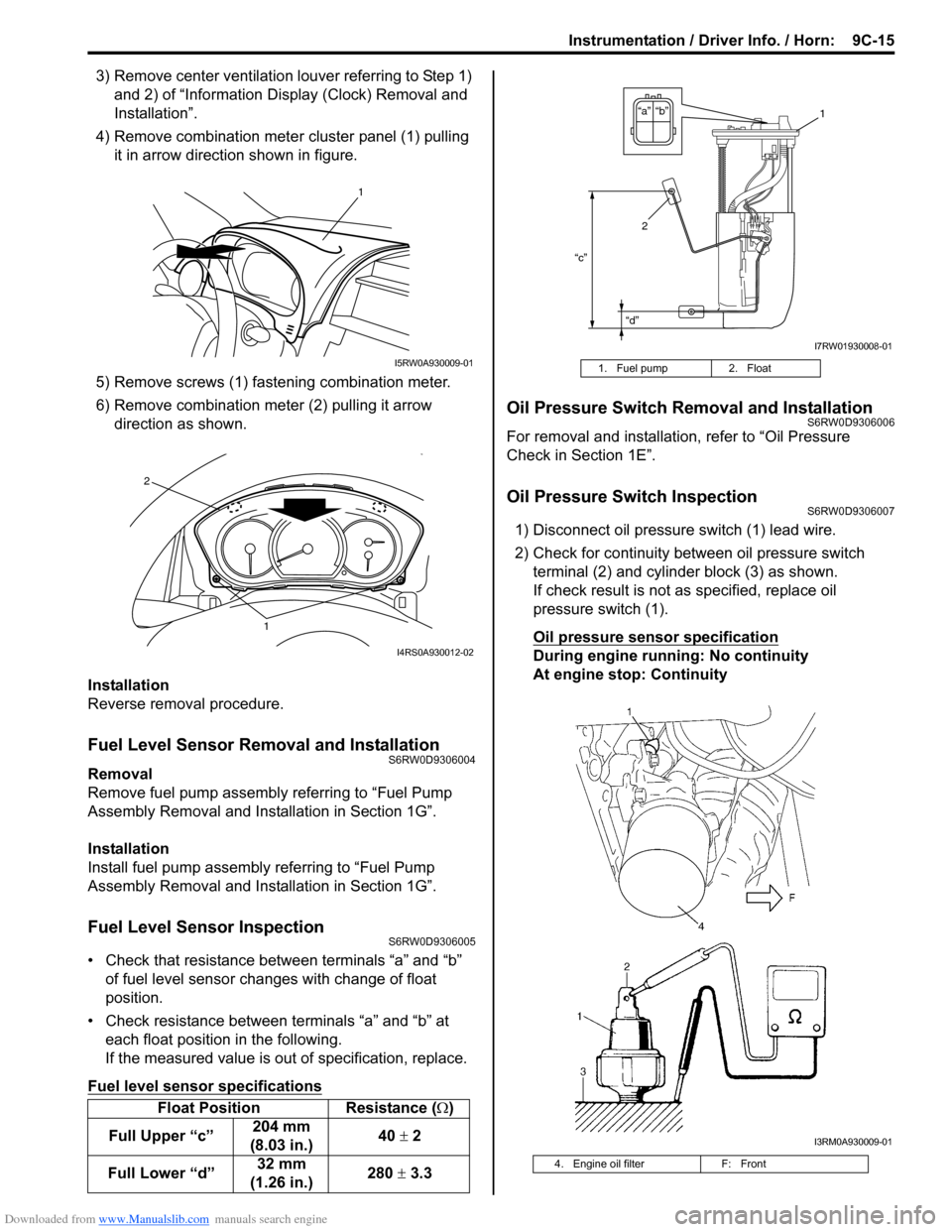

3) Remove center ventilation louver referring to Step 1)

and 2) of “Information Display (Clock) Removal and

Installation”.

4) Remove combination meter cluster panel (1) pulling

it in arrow direction shown in figure.

5) Remove screws (1) fastening combination meter.

6) Remove combination meter (2) pulling it arrow

direction as shown.

Installation

Reverse removal procedure.

Fuel Level Sensor Removal and InstallationS6RW0D9306004

Removal

Remove fuel pump assembly referring to “Fuel Pump

Assembly Removal and Installation in Section 1G”.

Installation

Install fuel pump assembly referring to “Fuel Pump

Assembly Removal and Installation in Section 1G”.

Fuel Level Sensor InspectionS6RW0D9306005

• Check that resistance between terminals “a” and “b”

of fuel level sensor changes with change of float

position.

• Check resistance between terminals “a” and “b” at

each float position in the following.

If the measured value is out of specification, replace.

Fuel level sensor specifications

Oil Pressure Switch Removal and InstallationS6RW0D9306006

For removal and installation, refer to “Oil Pressure

Check in Section 1E”.

Oil Pressure Switch InspectionS6RW0D9306007

1) Disconnect oil pressure switch (1) lead wire.

2) Check for continuity between oil pressure switch

terminal (2) and cylinder block (3) as shown.

If check result is not as specified, replace oil

pressure switch (1).

Oil pressure sensor specification

During engine running: No continuity

At engine stop: Continuity

Float Position Resistance (Ω)

Full Upper “c”204 mm

(8.03 in.)40 ± 2

Full Lower “d”32 mm

(1.26 in.)280 ± 3.3

1

I5RW0A930009-01

1

2

I4RS0A930012-02

1. Fuel pump 2. Float

4. Engine oil filter F: Front

“c”

“d”

“b” “a”1

2

I7RW01930008-01

I3RM0A930009-01