300 SUZUKI SX4 2006 1.G Service Manual Online

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2006, Model line: SX4, Model: SUZUKI SX4 2006 1.GPages: 1556, PDF Size: 37.31 MB

Page 862 of 1556

Downloaded from www.Manualslib.com manuals search engine 5C-9 Clutch:

Clutch Disc

Measure depth of rivet head depression, i.e. distance

between rivet head and facing surface.

If depression is found to have reached service limit at

any of rivet holes (2), replace clutch disc assembly (1).

Rivet head depth

Standard: 1.65 – 2.25 mm (0.06 – 0.09 in.)

Limit: 0.5 mm (0.02 in.)Clutch Cover

1) Check diaphragm spring (1) for abnormal wear or

damage.

2) Inspect pressure plate (2) for wear or heat spots.

3) If abnormality is found, replace clutch cover.

Do not disassemble it into diaphragm spring and

pressure plate.

Flywheel

Check surface contacting clutch disc for abnormal wear

or heat spots. Replace or repair as required.

Specifications

Tightening Torque SpecificationsS6RW0D5307001

NOTE

The specified tightening torque is also described in the following.

“Clutch Cover, Clutch Disc and Flywheel Components”

Reference:

For the tightening torque of fastener not specified in this section, refer to “Fasteners Information in Section 0A”.

I4RS0A530019-01

I3RM0A530015-01

Fastening partTightening torque

Note

N⋅mkgf-mlb-ft

Clutch master cylinder nut 13 1.3 9.5�)

Clutch operating cylinder assembly mounting

bolt10 1.0 7.5�)

Clutch fluid pipe flare nut 16 1.6 11.5�)

Flywheel bolt 70 7.0 51.0�)

Clutch cover bolt 23 2.3 17.0�)

Page 881 of 1556

Downloaded from www.Manualslib.com manuals search engine Power Assisted Steering System: 6C-1

Ste eri ng

Power Assisted Steering System

Precautions

P/S System NoteS6RW0D6300001

NOTE

All steering gear fasteners are important attaching parts in that they could affect the performance of

vital parts and systems, and/or could result in major repair expense. They must be replaced with one of

the same part number or with an equivalent part if replacement becomes necessary. Do not use a

replacement part of lesser quality or substitute design. Torque values must be used as specified

during reassembly to assure proper retention of these parts.

Precautions in Diagnosing TroublesS6RW0D6300002

• Take a note of DTC indicated on the SUZUKI scan tool.

• Before inspection, be sure to read “Precautions for Electrical Circuit Service in Section 00” and understand what is

written there.

• DTC C1122 (engine speed signal failure) is indicated when ignition switch is at ON position and engine is not

running, but it means there is nothing abnormal if indication changes to a normal one when engine is started.

• As DTC is stored in memory of the P/S control module, be sure to clear memory after repair by performing the

procedure described in “DTC Clearance”.

Page 884 of 1556

![SUZUKI SX4 2006 1.G Service Manual Online Downloaded from www.Manualslib.com manuals search engine 6C-4 Power Assisted Steering System:

Schematic and Routing Diagram

EPS System Wiring Circuit DiagramS6RW0D6302001

[A]

123

45

3 21

4

567

8

9 11 SUZUKI SX4 2006 1.G Service Manual Online Downloaded from www.Manualslib.com manuals search engine 6C-4 Power Assisted Steering System:

Schematic and Routing Diagram

EPS System Wiring Circuit DiagramS6RW0D6302001

[A]

123

45

3 21

4

567

8

9 11](/img/20/7612/w960_7612-883.png)

Downloaded from www.Manualslib.com manuals search engine 6C-4 Power Assisted Steering System:

Schematic and Routing Diagram

EPS System Wiring Circuit DiagramS6RW0D6302001

[A]

123

45

3 21

4

567

8

9 11

10 12 13

141516

17 18 19201

2

[B]

1

2

[C] [D]

10 9 8 7654 3 21

16 15 14 13 12 11

26 25 24 2322 21 20 19 18 17

32 31 30 29 28 27

[F][E]

12

BRN RED/

BLU GRY LT GRN/

BLK

BLK

RED

WHT GRN

BLK

E11-1

E11-5

E11-14

E11-12

[J]:E01-44E01-4

[J]:E01-27E01-26

E12-1

E12-2

E11-10E11-8

E11-9

E11-19

E13-1 GRN

GRY

GRN

WHT

G241-25G241-31

RED/BLK

11

12

1314 3 18

20

21

7 19

4 12

22

12V

E13-2BLK

9V

REDE11-20

12V

12V

E61-2

E61-1

610

55

5V

8

E11-115V

PPL

E11-4

9

23

+BB

BLU/

WHTE04-9

1524YELE11-18E31-5

E31-2

E31-39V

3V

E31-4

E31-1IG11617

C07-25

[H]

[G]

G04-15

[I]:G04-22

25L313-3

[I]

I6RW0D630001-01

[A]: P/S control module connector No.1 “E11” (viewed from harness side) 3. Junction block assembly 15. BCM

[B]: P/S control module connector No.2 “E13” (viewed from harness side) 4. Main fuse 16. Output shaft speed sensor

[C]: P/S control module connector No.3 “E12” (viewed from harness side) 5. Front (left/right) wheel speed sensor 17. TCM

[D]: Combination meter connector “G241” (viewed from harness side) 6. ABS control module 18. Individual circuit fuse box No.1

[E]: Torque sensor connector “E31” (viewed from harness side) 7. Combination meter 19. “IGN” fuse

[F]: Motor connector “E61” (viewed from harness side) 8. “EPS” warning light 20. “P/S” fuse

[G]: M/T model 9. Data link connector (DLC) 21. “IG1 SIG” fuse

[H]: A/T model 10. ECM 22. “MTR” fuse

[I]: Junction block without BCM model (Taiwan model) 11. P/S control module 23. To ABS control module

[J]: M15A engine with 4A/T equipped with slip control model (Hong Kong

model)12. P/S motor 24. To HVAC control module

1. Main fuse box 13. Shield 25. To SDM

2. Ignition switch 14. Torque sensor (built into steering gear case)

Page 888 of 1556

Downloaded from www.Manualslib.com manuals search engine 6C-8 Power Assisted Steering System:

Step 8: Steering Symptom Diagnosis and P/S

System Symptom Diagnosis

Perform basic steering system check according to

“Steering Symptom Diagnosis in Section 6A” first. When

the end of the flow has been reached, check the parts of

the system suspected as a possible cause referring to

“P/S System Symptom Diagnosis” and based on

symptoms appearing on the vehicle (symptoms obtained

through steps of customer complaint analysis, trouble

symptom confirmation and/or basic P/S system check)

and repair or replace faulty parts, if any.

Step 9: Troubleshooting for DTC (See each DTC

Diag. Flow)

Based on the DTC indicated in Step 6 or 7 and referring

to the applicable DTC diag. flow, locate the cause of the

trouble, namely in a sensor, switch, wire harness,

connector, actuator, P/S control module or other part and

repair or replace faulty parts.

Step 10: Intermittent Problems Check

Check parts where an intermittent trouble is easy to

occur (e.g., wire harness, connector, etc.), referring to

“Intermittent and Poor Connection Inspection in Section

00” and related circuit of DTC recorded in Step 2.

Step 11: Final Confirmation Test

Confirm that the problem symptom has gone and the P/

S system is free from any abnormal conditions. If what

has been repaired is related to the DTC, clear the DTC

once, perform DTC confirmation procedure and confirm

that no DTC is indicated.

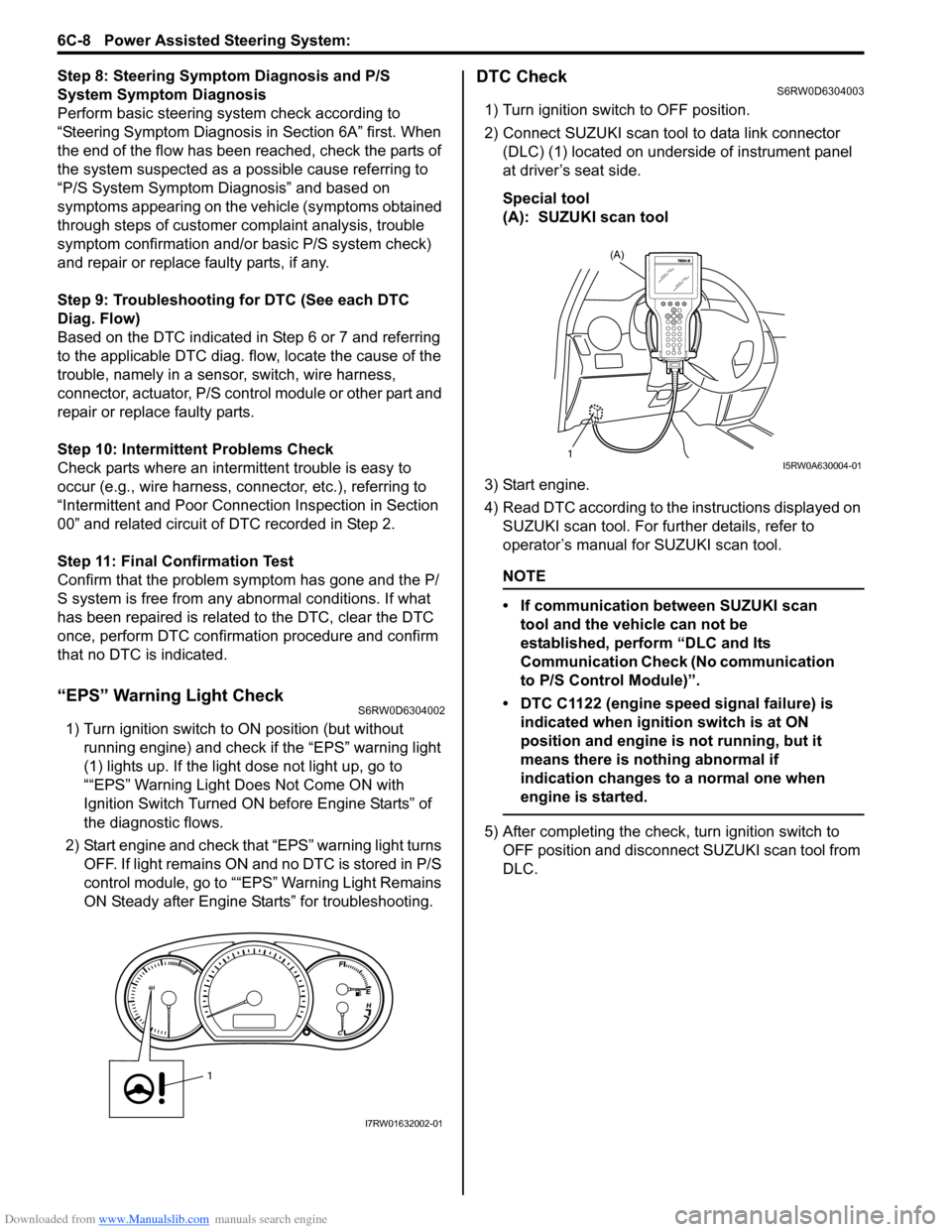

“EPS” Warning Light CheckS6RW0D6304002

1) Turn ignition switch to ON position (but without

running engine) and check if the “EPS” warning light

(1) lights up. If the light dose not light up, go to

““EPS” Warning Light Does Not Come ON with

Ignition Switch Turned ON before Engine Starts” of

the diagnostic flows.

2) Start engine and check that “EPS” warning light turns

OFF. If light remains ON and no DTC is stored in P/S

control module, go to ““EPS” Warning Light Remains

ON Steady after Engine Starts” for troubleshooting.

DTC CheckS6RW0D6304003

1) Turn ignition switch to OFF position.

2) Connect SUZUKI scan tool to data link connector

(DLC) (1) located on underside of instrument panel

at driver’s seat side.

Special tool

(A): SUZUKI scan tool

3) Start engine.

4) Read DTC according to the instructions displayed on

SUZUKI scan tool. For further details, refer to

operator’s manual for SUZUKI scan tool.

NOTE

• If communication between SUZUKI scan

tool and the vehicle can not be

established, perform “DLC and Its

Communication Check (No communication

to P/S Control Module)”.

• DTC C1122 (engine speed signal failure) is

indicated when ignition switch is at ON

position and engine is not running, but it

means there is nothing abnormal if

indication changes to a normal one when

engine is started.

5) After completing the check, turn ignition switch to

OFF position and disconnect SUZUKI scan tool from

DLC.

1

I7RW01632002-01

(A)

1I5RW0A630004-01

Page 889 of 1556

Downloaded from www.Manualslib.com manuals search engine Power Assisted Steering System: 6C-9

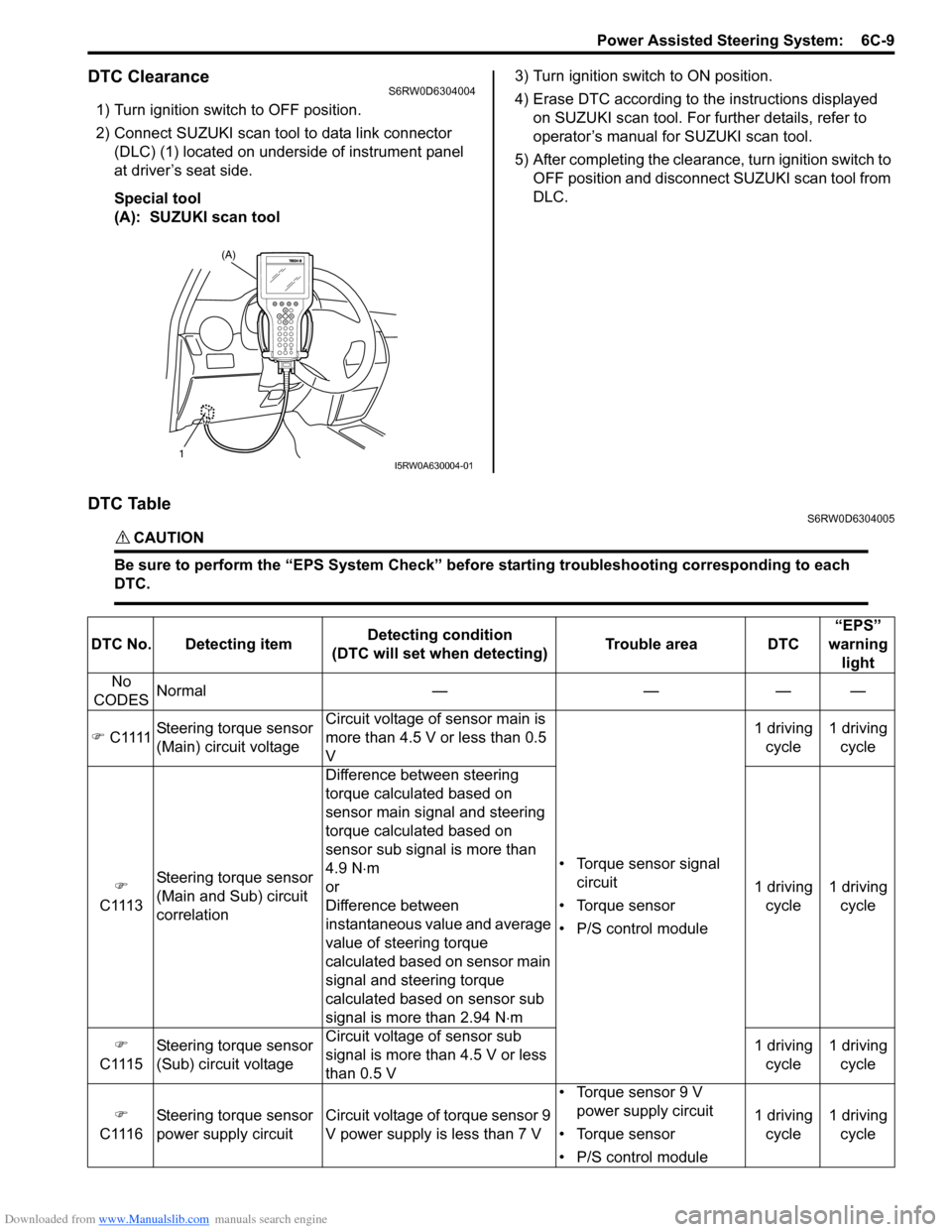

DTC ClearanceS6RW0D6304004

1) Turn ignition switch to OFF position.

2) Connect SUZUKI scan tool to data link connector

(DLC) (1) located on underside of instrument panel

at driver’s seat side.

Special tool

(A): SUZUKI scan tool3) Turn ignition switch to ON position.

4) Erase DTC according to the instructions displayed

on SUZUKI scan tool. For further details, refer to

operator’s manual for SUZUKI scan tool.

5) After completing the clearance, turn ignition switch to

OFF position and disconnect SUZUKI scan tool from

DLC.

DTC TableS6RW0D6304005

CAUTION!

Be sure to perform the “EPS System Check” before starting troubleshooting corresponding to each

DTC.

(A)

1I5RW0A630004-01

DTC No. Detecting itemDetecting condition

(DTC will set when detecting)Trouble area DTC“EPS”

warning

light

No

CODESNormal — — — —

�) C1111Steering torque sensor

(Main) circuit voltageCircuit voltage of sensor main is

more than 4.5 V or less than 0.5

V

• Torque sensor signal

circuit

• Torque sensor

• P/S control module1 driving

cycle1 driving

cycle

�)

C1113Steering torque sensor

(Main and Sub) circuit

correlationDifference between steering

torque calculated based on

sensor main signal and steering

torque calculated based on

sensor sub signal is more than

4.9 N⋅m

or

Difference between

instantaneous value and average

value of steering torque

calculated based on sensor main

signal and steering torque

calculated based on sensor sub

signal is more than 2.94 N⋅m1 driving

cycle1 driving

cycle

�)

C1115Steering torque sensor

(Sub) circuit voltageCircuit voltage of sensor sub

signal is more than 4.5 V or less

than 0.5 V1 driving

cycle1 driving

cycle

�)

C1116Steering torque sensor

power supply circuit Circuit voltage of torque sensor 9

V power supply is less than 7 V• Torque sensor 9 V

power supply circuit

• Torque sensor

• P/S control module1 driving

cycle1 driving

cycle

Page 894 of 1556

Downloaded from www.Manualslib.com manuals search engine 6C-14 Power Assisted Steering System:

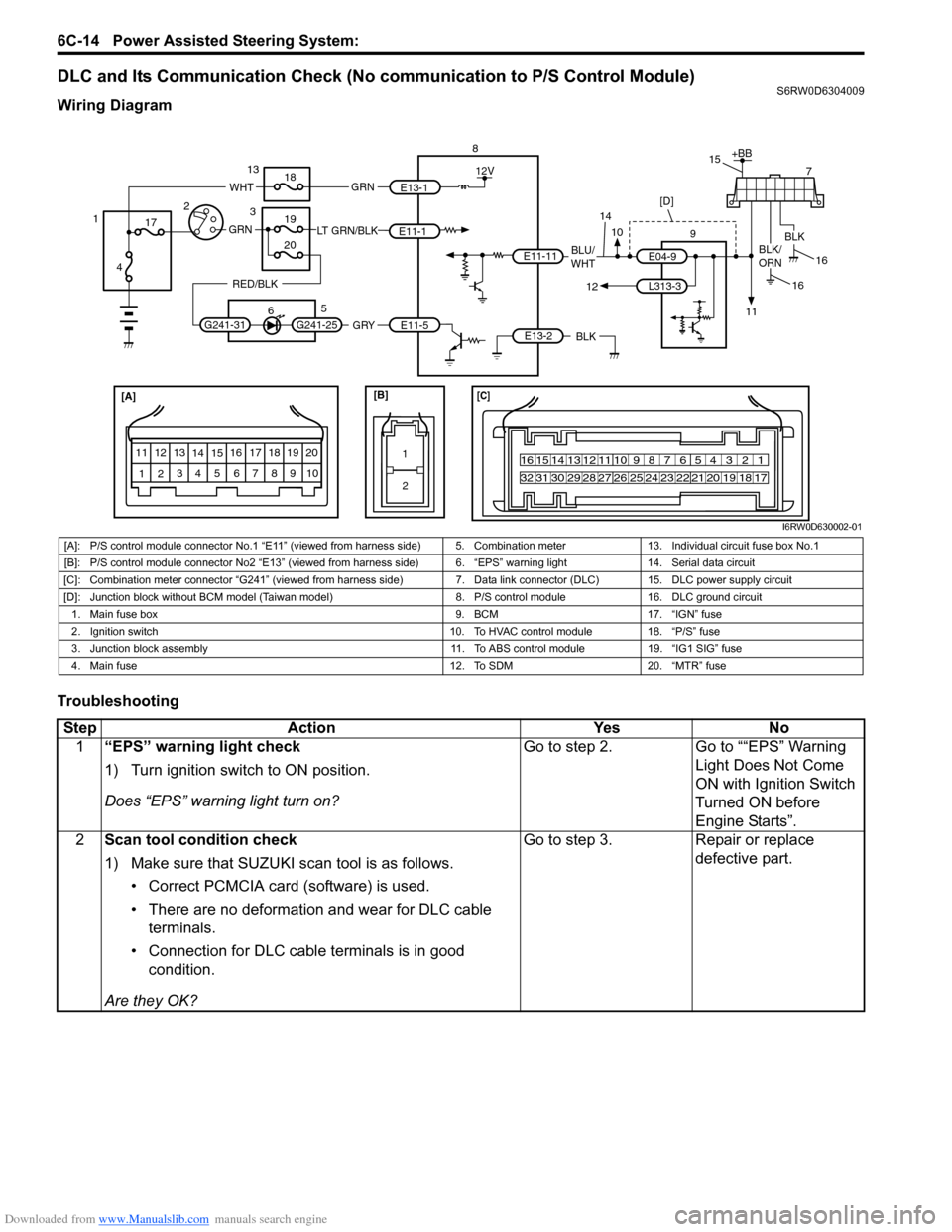

DLC and Its Communication Check (No communication to P/S Control Module)S6RW0D6304009

Wiring Diagram

Troubleshooting

[A]

123

4567

8

9 11

10 12 13

141516

17 18 1920

1

2

[B]

10 9 8 7654 3 21

16 15 14 13 12 11

26 25 24 2322 21 20 19 18 17

32 31 30 29 28 27

[C]

LT GRN/BLKE11-1

E11-11

E13-1 GRN

GRN

WHT

8

13

318

19

20

5

6 17

4

12

712V

E13-2BLK

9

G241-31

+BB

BLU/

WHTE04-9

10

11

RED/BLK

G241-25E11-5GRY

L313-312

BLKBLK/

ORN

16

16

15

14[D]

I6RW0D630002-01

[A]: P/S control module connector No.1 “E11” (viewed from harness side) 5. Combination meter 13. Individual circuit fuse box No.1

[B]: P/S control module connector No2 “E13” (viewed from harness side) 6. “EPS” warning light 14. Serial data circuit

[C]: Combination meter connector “G241” (viewed from harness side) 7. Data link connector (DLC) 15. DLC power supply circuit

[D]: Junction block without BCM model (Taiwan model) 8. P/S control module 16. DLC ground circuit

1. Main fuse box 9. BCM 17. “IGN” fuse

2. Ignition switch 10. To HVAC control module 18. “P/S” fuse

3. Junction block assembly 11. To ABS control module 19. “IG1 SIG” fuse

4. Main fuse 12. To SDM 20. “MTR” fuse

Step Action Yes No

1“EPS” warning light check

1) Turn ignition switch to ON position.

Does “EPS” warning light turn on?Go to step 2. Go to ““EPS” Warning

Light Does Not Come

ON with Ignition Switch

Turned ON before

Engine Starts”.

2Scan tool condition check

1) Make sure that SUZUKI scan tool is as follows.

• Correct PCMCIA card (software) is used.

• There are no deformation and wear for DLC cable

terminals.

• Connection for DLC cable terminals is in good

condition.

Are they OK?Go to step 3. Repair or replace

defective part.

Page 896 of 1556

Downloaded from www.Manualslib.com manuals search engine 6C-16 Power Assisted Steering System:

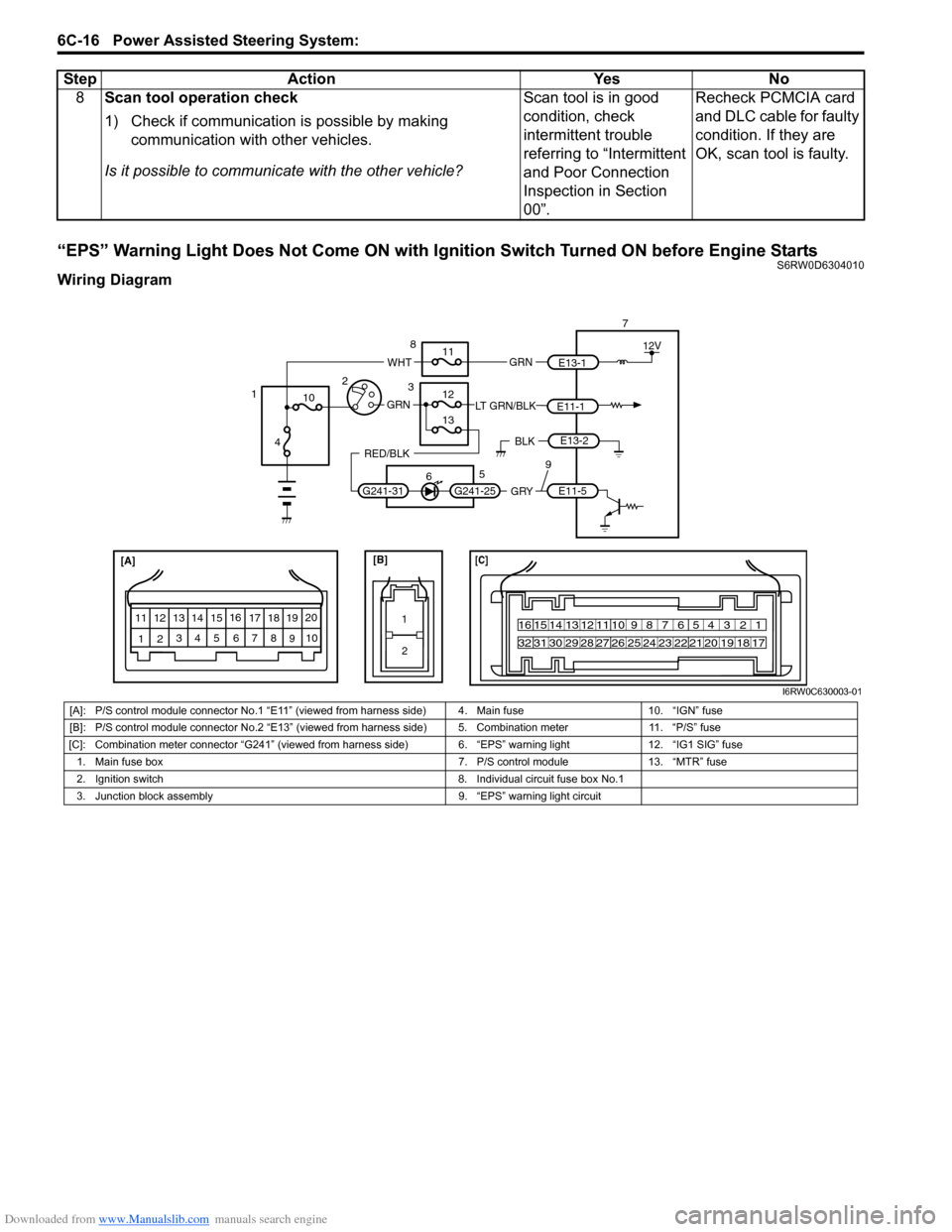

“EPS” Warning Light Does Not Come ON with Ignition Switch Turned ON before Engine StartsS6RW0D6304010

Wiring Diagram8Scan tool operation check

1) Check if communication is possible by making

communication with other vehicles.

Is it possible to communicate with the other vehicle?Scan tool is in good

condition, check

intermittent trouble

referring to “Intermittent

and Poor Connection

Inspection in Section

00”.Recheck PCMCIA card

and DLC cable for faulty

condition. If they are

OK, scan tool is faulty. Step Action Yes No

[A]

123

4567

8

9 11

10 12 13

141516

17 18 1920

1

2

[B]

10 9 8 7654 3 21

16 15 14 13 12 11

26 25 24 2322 21 20 19 18 17

32 31 30 29 28 27

[C]

LT GRN/BLKE11-1E13-1 GRNGRN

WHT

7

8

311

12

13

5

6 10

4 12

12V

E13-2BLK

G241-31

RED/BLK

G241-25E11-5GRY

9

I6RW0C630003-01

[A]: P/S control module connector No.1 “E11” (viewed from harness side) 4. Main fuse 10. “IGN” fuse

[B]: P/S control module connector No.2 “E13” (viewed from harness side) 5. Combination meter 11. “P/S” fuse

[C]: Combination meter connector “G241” (viewed from harness side) 6. “EPS” warning light 12. “IG1 SIG” fuse

1. Main fuse box 7. P/S control module 13. “MTR” fuse

2. Ignition switch 8. Individual circuit fuse box No.1

3. Junction block assembly 9. “EPS” warning light circuit

Page 899 of 1556

Downloaded from www.Manualslib.com manuals search engine Power Assisted Steering System: 6C-19

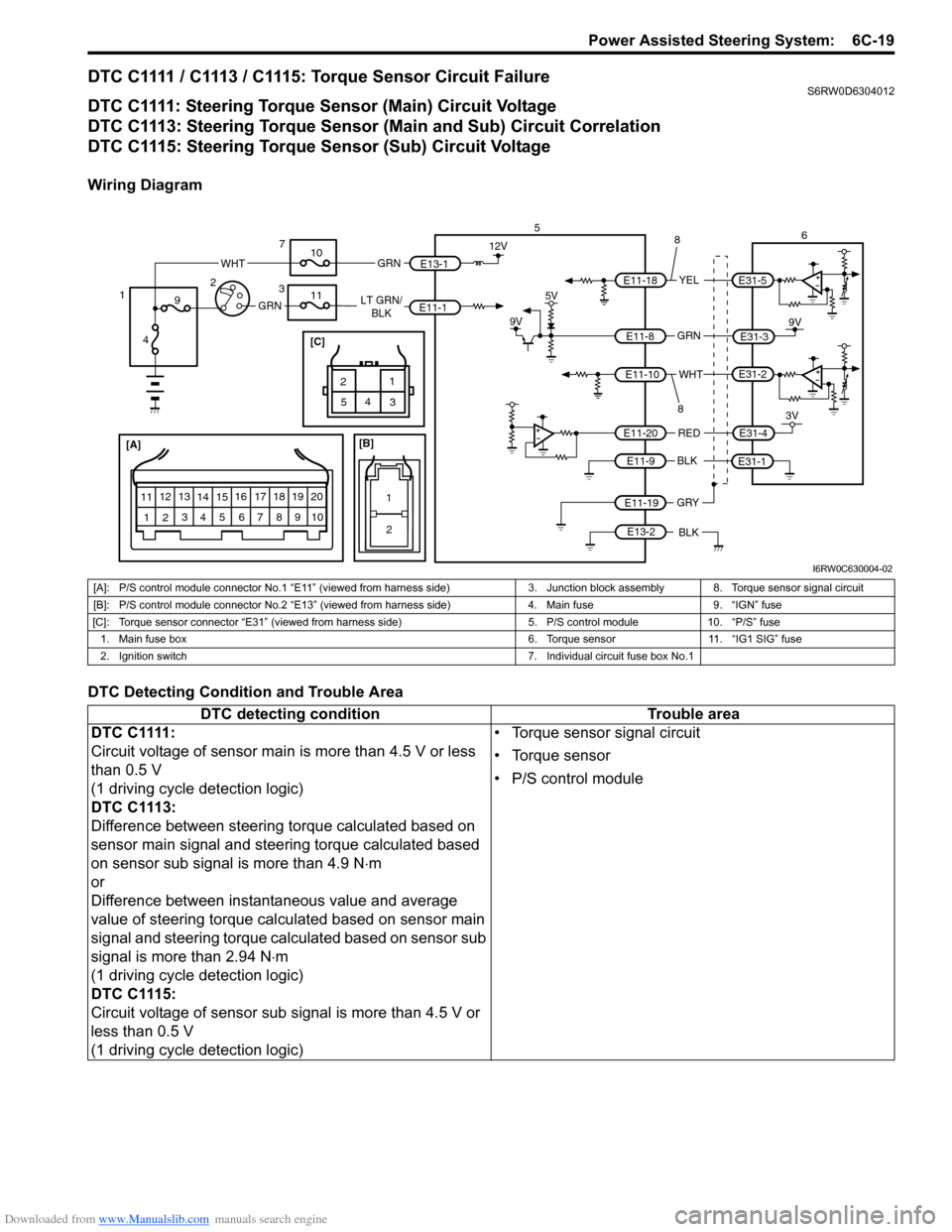

DTC C1111 / C1113 / C1115: Torque Sensor Circuit FailureS6RW0D6304012

DTC C1111: Steering Torque Sensor (Main) Circuit Voltage

DTC C1113: Steering Torque Sensor (Main and Sub) Circuit Correlation

DTC C1115: Steering Torque Sensor (Sub) Circuit Voltage

Wiring Diagram

DTC Detecting Condition and Trouble Area

[A]

123

453 21

4

5

67

8

9 11

10 12 13

141516

17 18 1920

1

2

[B]

[C]

LT GRN/

BLK

WHT GRN

BLK

E11-1

E11-10E11-8

E11-9

E11-19

E13-1 GRN

GRY

GRN

WHT

5

6

37

10

11

9

4 12

12V

E13-2BLK

9V

REDE11-20

5VYELE11-18E31-5

E31-2

E31-39V

E31-43V

E31-1

8

8

I6RW0C630004-02

[A]: P/S control module connector No.1 “E11” (viewed from harness side) 3. Junction block assembly 8. Torque sensor signal circuit

[B]: P/S control module connector No.2 “E13” (viewed from harness side) 4. Main fuse 9. “IGN” fuse

[C]: Torque sensor connector “E31” (viewed from harness side) 5. P/S control module 10. “P/S” fuse

1. Main fuse box 6. Torque sensor 11. “IG1 SIG” fuse

2. Ignition switch 7. Individual circuit fuse box No.1

DTC detecting condition Trouble area

DTC C1111:

Circuit voltage of sensor main is more than 4.5 V or less

than 0.5 V

(1 driving cycle detection logic)

DTC C1113:

Difference between steering torque calculated based on

sensor main signal and steering torque calculated based

on sensor sub signal is more than 4.9 N⋅m

or

Difference between instantaneous value and average

value of steering torque calculated based on sensor main

signal and steering torque calculated based on sensor sub

signal is more than 2.94 N⋅m

(1 driving cycle detection logic)

DTC C1115:

Circuit voltage of sensor sub signal is more than 4.5 V or

less than 0.5 V

(1 driving cycle detection logic)• Torque sensor signal circuit

• Torque sensor

• P/S control module

Page 901 of 1556

Downloaded from www.Manualslib.com manuals search engine Power Assisted Steering System: 6C-21

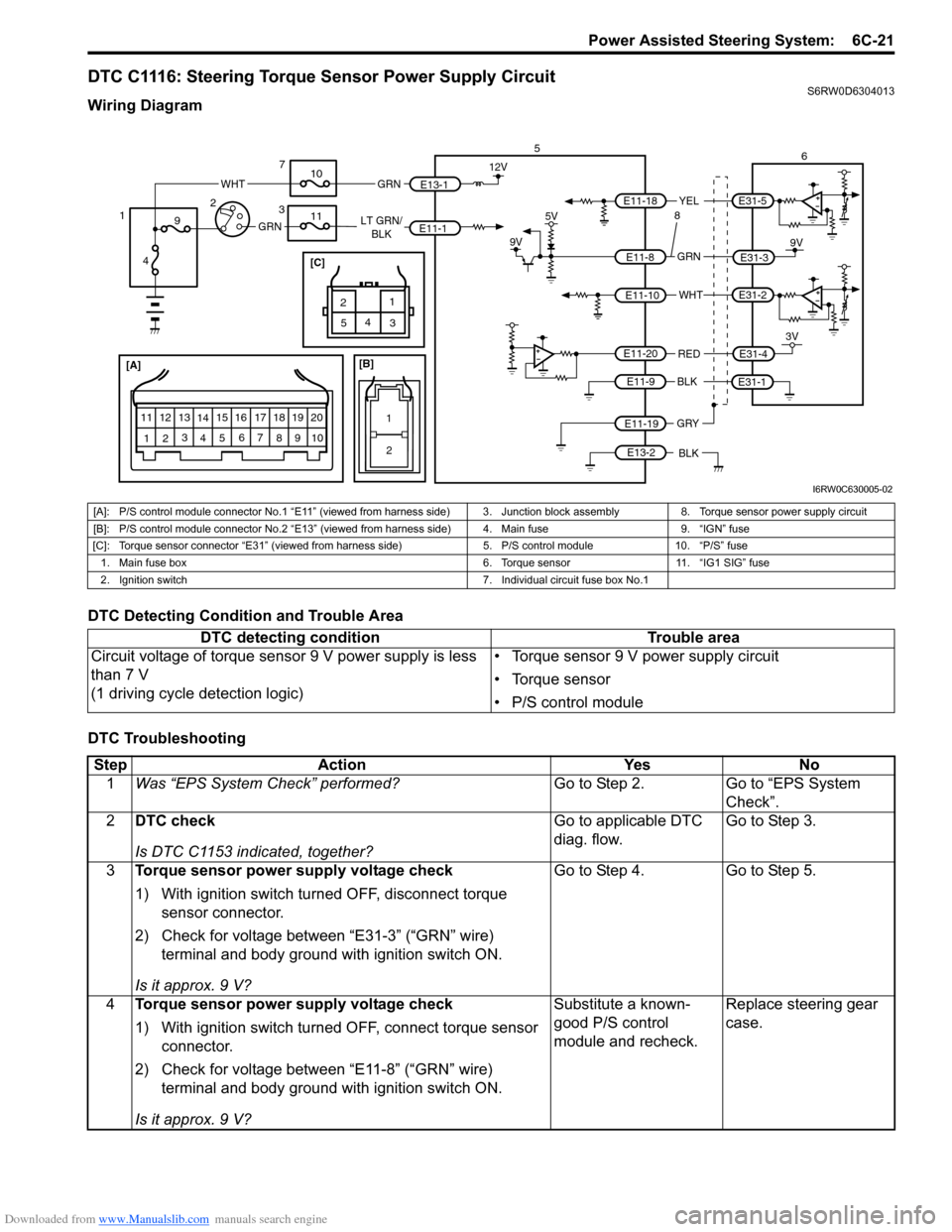

DTC C1116: Steering Torque Sensor Power Supply CircuitS6RW0D6304013

Wiring Diagram

DTC Detecting Condition and Trouble Area

DTC Troubleshooting

[A]

123

453 21

4

5

67

8

9 11

10 12 13

141516

17 18 1920

1

2

[B]

[C]

LT GRN/

BLK

WHT GRN

BLK

E11-1

E11-10E11-8

E11-9

E11-19

E13-1 GRN

GRY

GRN

WHT

5

6

37

10

11

9

4 12

12V

E13-2BLK

9V

REDE11-20

5VYELE11-18E31-5

E31-2

E31-39V

E31-43V

E31-1

8

I6RW0C630005-02

[A]: P/S control module connector No.1 “E11” (viewed from harness side) 3. Junction block assembly 8. Torque sensor power supply circuit

[B]: P/S control module connector No.2 “E13” (viewed from harness side) 4. Main fuse 9. “IGN” fuse

[C]: Torque sensor connector “E31” (viewed from harness side) 5. P/S control module 10. “P/S” fuse

1. Main fuse box 6. Torque sensor 11. “IG1 SIG” fuse

2. Ignition switch 7. Individual circuit fuse box No.1

DTC detecting condition Trouble area

Circuit voltage of torque sensor 9 V power supply is less

than 7 V

(1 driving cycle detection logic)• Torque sensor 9 V power supply circuit

• Torque sensor

• P/S control module

Step Action Yes No

1Was “EPS System Check” performed?Go to Step 2. Go to “EPS System

Check”.

2DTC check

Is DTC C1153 indicated, together?Go to applicable DTC

diag. flow.Go to Step 3.

3Torque sensor power supply voltage check

1) With ignition switch turned OFF, disconnect torque

sensor connector.

2) Check for voltage between “E31-3” (“GRN” wire)

terminal and body ground with ignition switch ON.

Is it approx. 9 V?Go to Step 4. Go to Step 5.

4Torque sensor power supply voltage check

1) With ignition switch turned OFF, connect torque sensor

connector.

2) Check for voltage between “E11-8” (“GRN” wire)

terminal and body ground with ignition switch ON.

Is it approx. 9 V?Substitute a known-

good P/S control

module and recheck.Replace steering gear

case.

Page 902 of 1556

Downloaded from www.Manualslib.com manuals search engine 6C-22 Power Assisted Steering System:

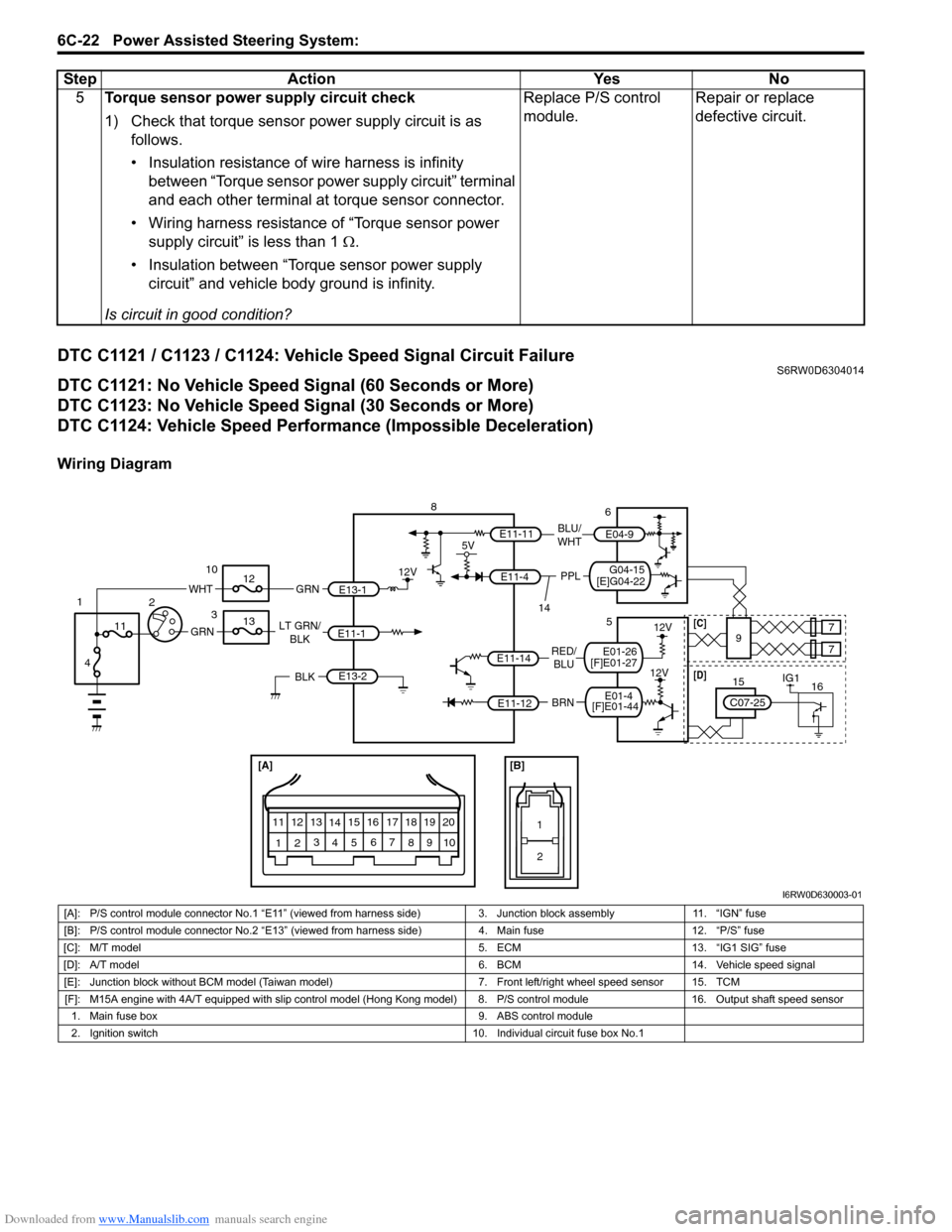

DTC C1121 / C1123 / C1124: Vehicle Speed Signal Circuit FailureS6RW0D6304014

DTC C1121: No Vehicle Speed Signal (60 Seconds or More)

DTC C1123: No Vehicle Speed Signal (30 Seconds or More)

DTC C1124: Vehicle Speed Performance (Impossible Deceleration)

Wiring Diagram5Torque sensor power supply circuit check

1) Check that torque sensor power supply circuit is as

follows.

• Insulation resistance of wire harness is infinity

between “Torque sensor power supply circuit” terminal

and each other terminal at torque sensor connector.

• Wiring harness resistance of “Torque sensor power

supply circuit” is less than 1 Ω.

• Insulation between “Torque sensor power supply

circuit” and vehicle body ground is infinity.

Is circuit in good condition?Replace P/S control

module.Repair or replace

defective circuit. Step Action Yes No

[A]

123

4567

8

9 11

10 12 13

141516

17 18 1920

1

2

[B]

BRN RED/

BLU LT GRN/

BLK

E11-1

E11-14

E11-12

E13-1 GRN

GRN

WHT

8

3 10

12

13

11

4 1

2

12V

E13-2BLK

12V

12V

9 5

77

E11-11

G04-15

[E]G04-22

5V

PPL

E11-4

BLU/

WHTE04-9

6

14

IG11615

C07-25

[D][C]

[F]E01-44E01-4

[F]E01-27E01-26

I6RW0D630003-01

[A]: P/S control module connector No.1 “E11” (viewed from harness side) 3. Junction block assembly 11. “IGN” fuse

[B]: P/S control module connector No.2 “E13” (viewed from harness side) 4. Main fuse 12. “P/S” fuse

[C]: M/T model 5. ECM 13. “IG1 SIG” fuse

[D]: A/T model 6. BCM 14. Vehicle speed signal

[E]: Junction block without BCM model (Taiwan model) 7. Front left/right wheel speed sensor 15. TCM

[F]: M15A engine with 4A/T equipped with slip control model (Hong Kong model) 8. P/S control module 16. Output shaft speed sensor

1. Main fuse box 9. ABS control module

2. Ignition switch 10. Individual circuit fuse box No.1