Ignition system SUZUKI SX4 2006 1.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2006, Model line: SX4, Model: SUZUKI SX4 2006 1.GPages: 1556, PDF Size: 37.31 MB

Page 398 of 1556

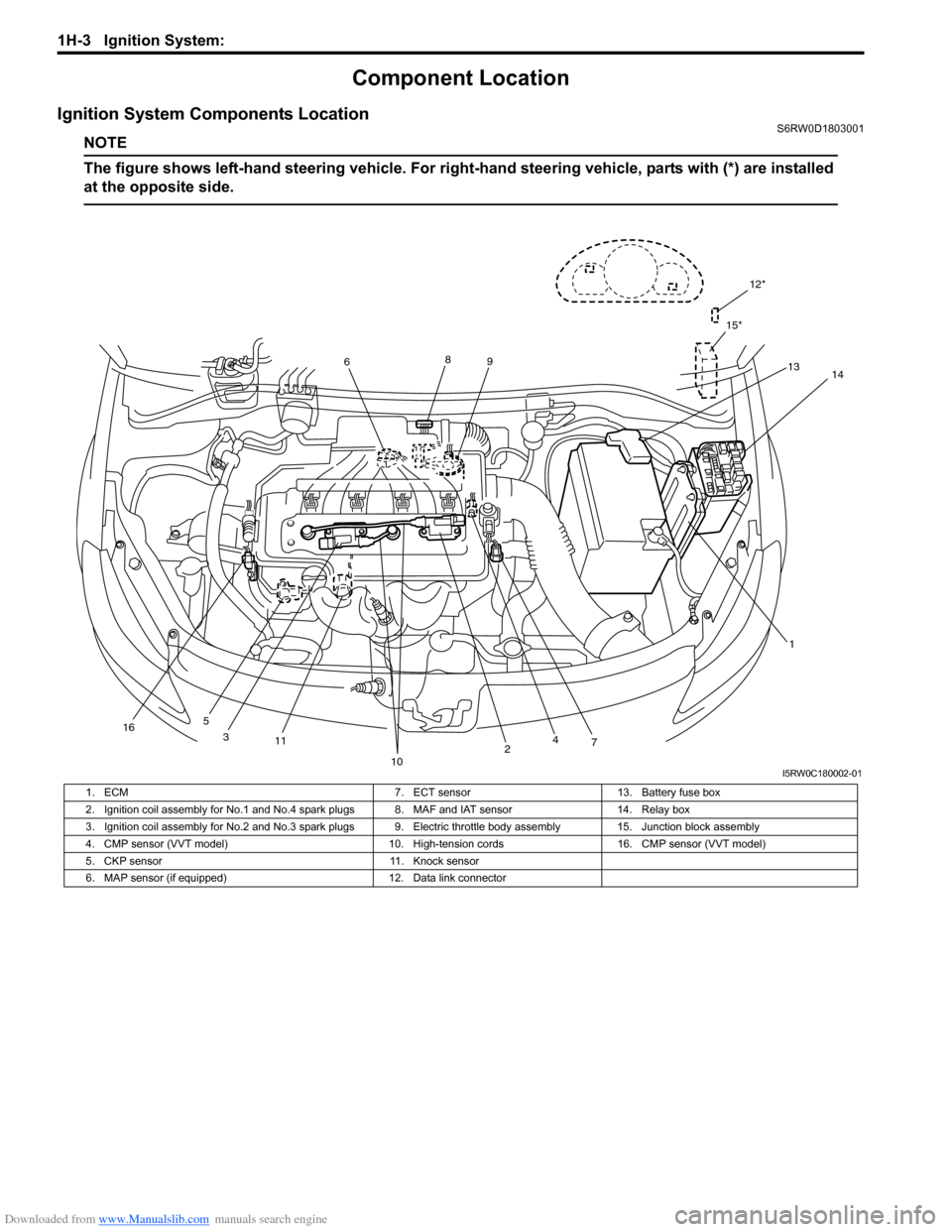

Downloaded from www.Manualslib.com manuals search engine 1H-3 Ignition System:

Component Location

Ignition System Components LocationS6RW0D1803001

NOTE

The figure shows left-hand steering vehicle. For right-hand steering vehicle, parts with (*) are installed

at the opposite side.

12*

15*

13

1 689

11

10

74

5

14

2 3

16

I5RW0C180002-01

1. ECM 7. ECT sensor 13. Battery fuse box

2. Ignition coil assembly for No.1 and No.4 spark plugs 8. MAF and IAT sensor 14. Relay box

3. Ignition coil assembly for No.2 and No.3 spark plugs 9. Electric throttle body assembly 15. Junction block assembly

4. CMP sensor (VVT model) 10. High-tension cords 16. CMP sensor (VVT model)

5. CKP sensor 11. Knock sensor

6. MAP sensor (if equipped) 12. Data link connector

Page 399 of 1556

Downloaded from www.Manualslib.com manuals search engine Ignition System: 1H-4

Diagnostic Information and Procedures

Ignition System Symptom DiagnosisS6RW0D1804001

Reference Waveform of Ignition SystemS6RW0D1804002

Refer to “Reference waveform No.5”, “Reference waveform No.6” and “Reference waveform No.7” under “Inspection

of ECM and Its Circuits in Section 1A” for waveform of Ignition trigger signal.

Ignition System CheckS6RW0D1804003

Condition Possible cause Correction / Reference Item

Engine cranks, but will

not start or hard to start

(No spark)Blown fuse for ignition coilReplace.

Loose connection or disconnection of

lead wire or high-tension cord(s)Connect securely.

Faulty high-tension cord(s)Replace.

Faulty spark plug(s)Replace.

Faulty ignition coilReplace ignition coil assembly.

Faulty CKP sensor or CKP sensor plateClean, tighten or replace.

Faulty CMP sensor or sensor rotor tooth

of camshaftClean, tighten or replace.

Faulty ECMReplace.

Poor fuel economy or

engine performanceIncorrect ignition timingCheck related sensors and CKP sensor plate.

Faulty spark plug(s) or high-tension

cord(s)Adjust, clean or replace.

Faulty ignition coil assemblyReplace.

Faulty CKP sensor or CKP sensor plateClean, tighten or replace.

Faulty CMP sensor or sensor rotor tooth

of camshaftClean, tighten or replace.

Faulty knock sensorReplace.

Faulty ECMReplace.

Step Action Yes No

1Was “Engine and Emission Control System Check”

performed?Go to Step 2. Go to “Engine and

Emission Control

System Check in

Section 1A”.

2Ignition spark test

1) Check all spark plugs for condition and type referring to

“Spark Plug Inspection”.

2) If OK, perform ignition spark test referring to “Ignition

Spar k Tes t”.

Is spark emitted from all spark plugs?Go to Step 12. Go to Step 3.

3DTC check

1) Perform DTC check referring to “DTC Check in Section

1A”.

Is DTC stored in ECM?Go to applicable DTC

diag. flow.Go to Step 4.

4Electrical connection check

1) Check ignition coil assemblies and high-tension cords

for electrical connection.

Are they connected securely?Go to Step 5. Connect securely.

5High-tension cords check

1) Check high-tension cord for resistance referring to

“High-Tension Cord Inspection”.

Is check result satisfactory?Go to Step 6. Replace high-tension

cord(s).

Page 400 of 1556

Downloaded from www.Manualslib.com manuals search engine 1H-5 Ignition System:

6Ignition coil assembly power supply and ground circuit

check

1) Check ignition coil assembly power supply and ground

circuits for open and short.

Are circuits in good condition?Go to Step 7. Repair or replace.

7Ignition coil assembly check

1) Check ignition coil for resistance referring to “Ignition

Coil Assembly (Including Ignitor) Inspection”.

Is check result satisfactory?Go to Step 8. Replace ignition coil

assembly.

8CKP sensor check

1) Check CKP sensor referring to “Crankshaft Position

(CKP) Sensor Inspection in Section 1C”.

Is check result satisfactory?Go to Step 9. Tighten CKP sensor

bolt, replace CKP

sensor or CKP sensor

plate.

9CMP sensor check

1) Check CMP sensor referring to “Camshaft Position

(CMP) Sensor Inspection in Section 1C”.

Is check result satisfactory?Go to Step 10. Tighten CMP sensor

bolt, replace CMP

sensor or intake

camshaft.

10Ignition trigger signal circuit check

1) Check ignition trigger signal wire for open, short and

poor connection.

Is circuit in good condition?Go to Step 11. Repair or replace.

11A known-good ignition coil assembly substitution

1) Substitute a known-good ignition coil assembly and then

repeat Step 2.

Is check result of Step 2 satisfactory?Go to Step 12. Substitute a known-

good ECM and then

repeat Step 2.

12Ignition timing check

1) Check initial ignition timing and ignition timing advance

referring to “Ignition Timing Inspection”.

Is check result satisfactory?System is in good

condition.Go to Step 13.

13Knock sensor check

1) Confirm that knock sensor circuit is in good condition

referring to “DTC P0327 / P0328: Knock Sensor Circuit

Low / High in Section 1A”.

2) Check oscilloscope waveform of knock sensor signal

referring to “Reference waveform No.19” and

“Reference waveform No.20” under “Inspection of ECM

and Its Circuits in Section 1A”.

Is check result satisfactory?Check CMP sensor,

CMP sensor rotor tooth

of camshaft, CKP

sensor, CKP sensor

plate and/or input

signals related to this

system.Substitute a known-

good knock sensor and

recheck. Step Action Yes No

Page 401 of 1556

Downloaded from www.Manualslib.com manuals search engine Ignition System: 1H-6

Ignition Spark TestS6RW0D1804004

1) Remove air cleaner assembly with air intake pipe.

2) Disconnect all injector couplers from injectors.

WARNING!

Without disconnection of injector couplers,

combustible gas may come out from spark

plug holes during this test and may get

ignited in engine room.

3) Remove spark plug and check it for condition and

type referring to “Spark Plug Inspection”.

4) If OK, connect ignition coil coupler to ignition coil

assembly and connect spark plug to ignition coil

assembly or high-tension cord. Ground spark plug.5) Crank engine and check if each spark plug sparks.

6) If no spark is emitted, inspect the related parts as

described in “Ignition System Symptom Diagnosis”.

Repair Instructions

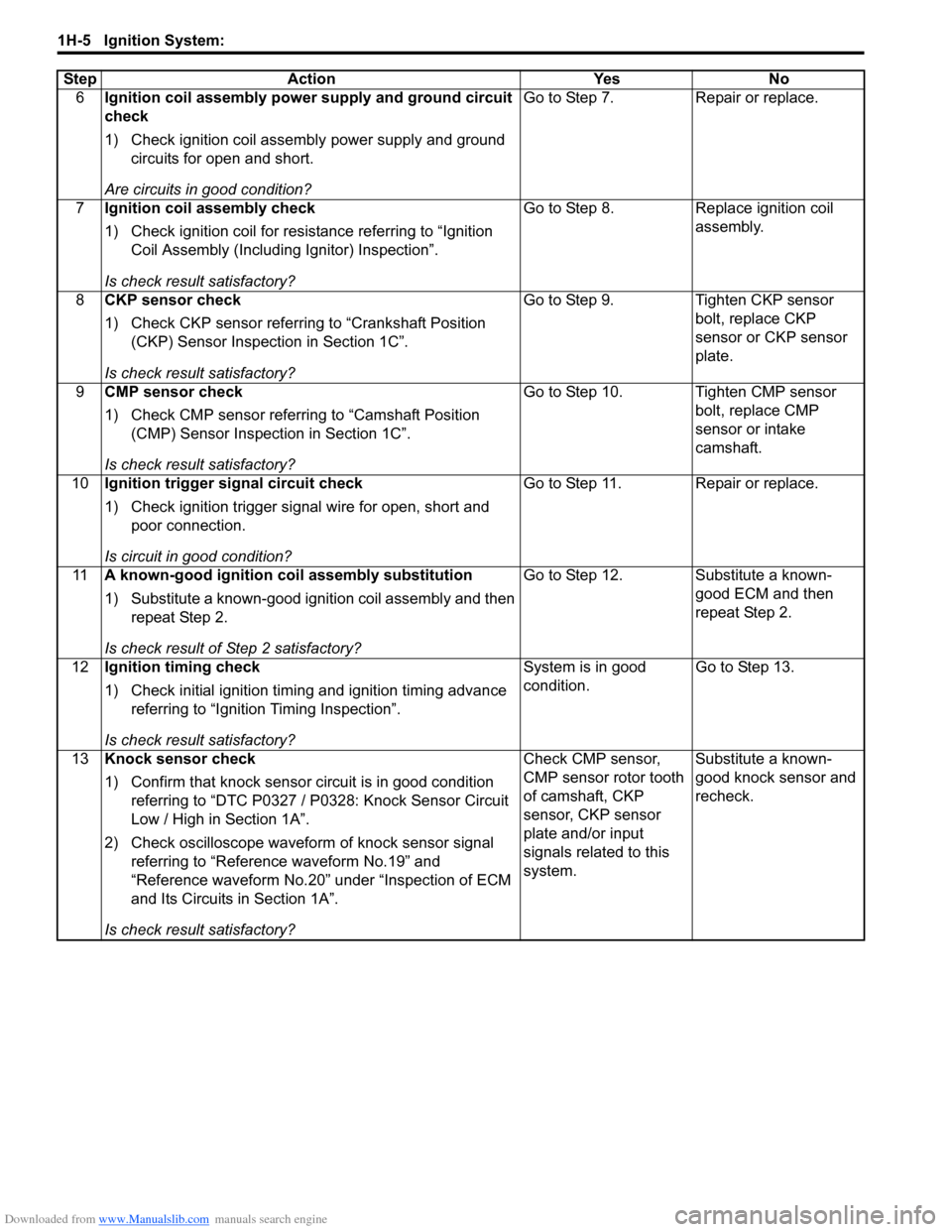

High-Tension Cord Removal and InstallationS6RW0D1806001

Removal

1) Remove air cleaner assembly with air intake pipe

and cylinder head upper cover.

2) Disconnect No.1 cylinder (2) and No.3 cylinder (3)

high-tension cords from ignition coil assemblies (1)

while gripping each cap.

3) Pull out high-tension cords from spark plugs while

gripping each cap.

CAUTION!

• Removal of high-tension cords together

with clamps will be recommended so as

not to damage their inside wire (resistive

conductor).

• For the same reason, pull out each

connection by gripping cap portion.

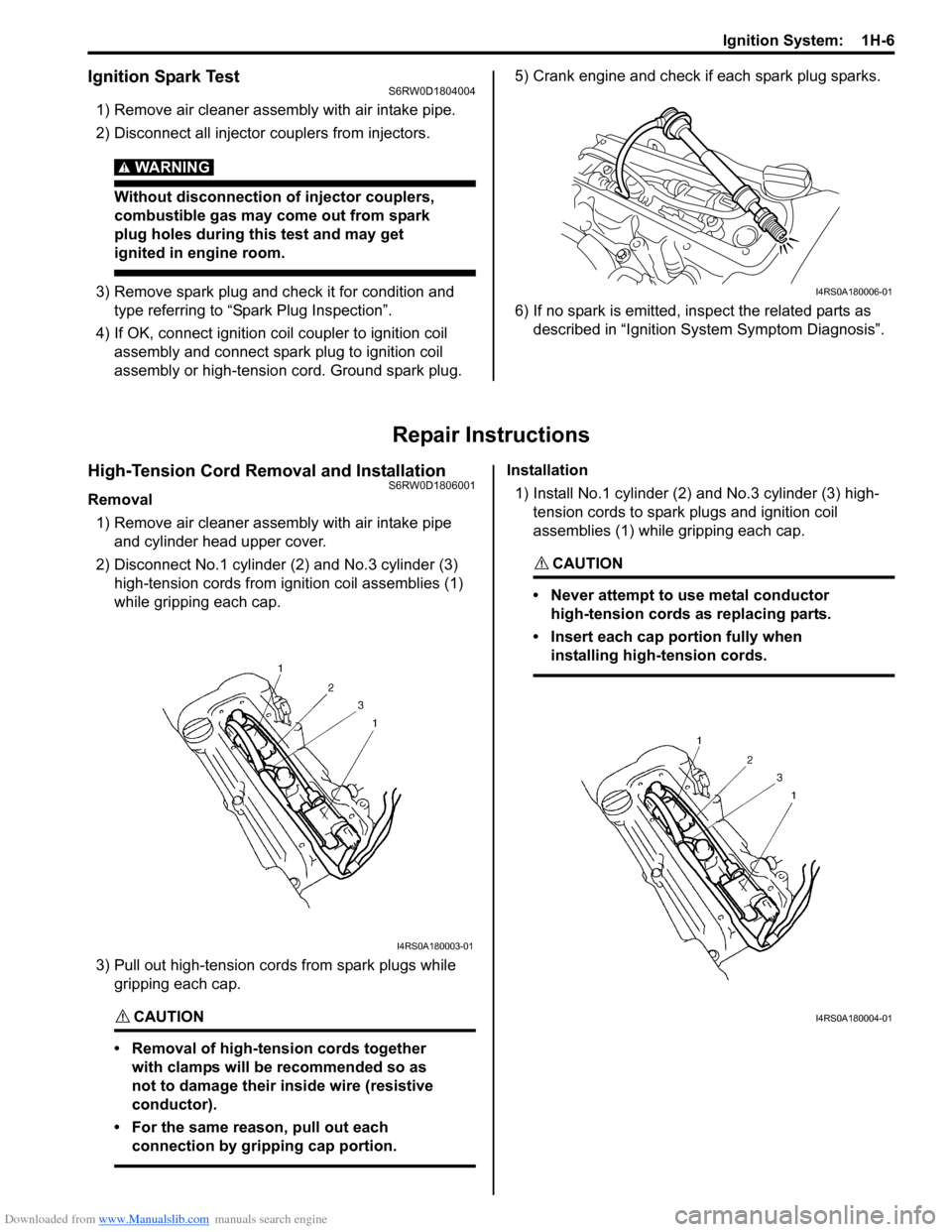

Installation

1) Install No.1 cylinder (2) and No.3 cylinder (3) high-

tension cords to spark plugs and ignition coil

assemblies (1) while gripping each cap.

CAUTION!

• Never attempt to use metal conductor

high-tension cords as replacing parts.

• Insert each cap portion fully when

installing high-tension cords.

I4RS0A180006-01

I4RS0A180003-01

I4RS0A180004-01

Page 402 of 1556

Downloaded from www.Manualslib.com manuals search engine 1H-7 Ignition System:

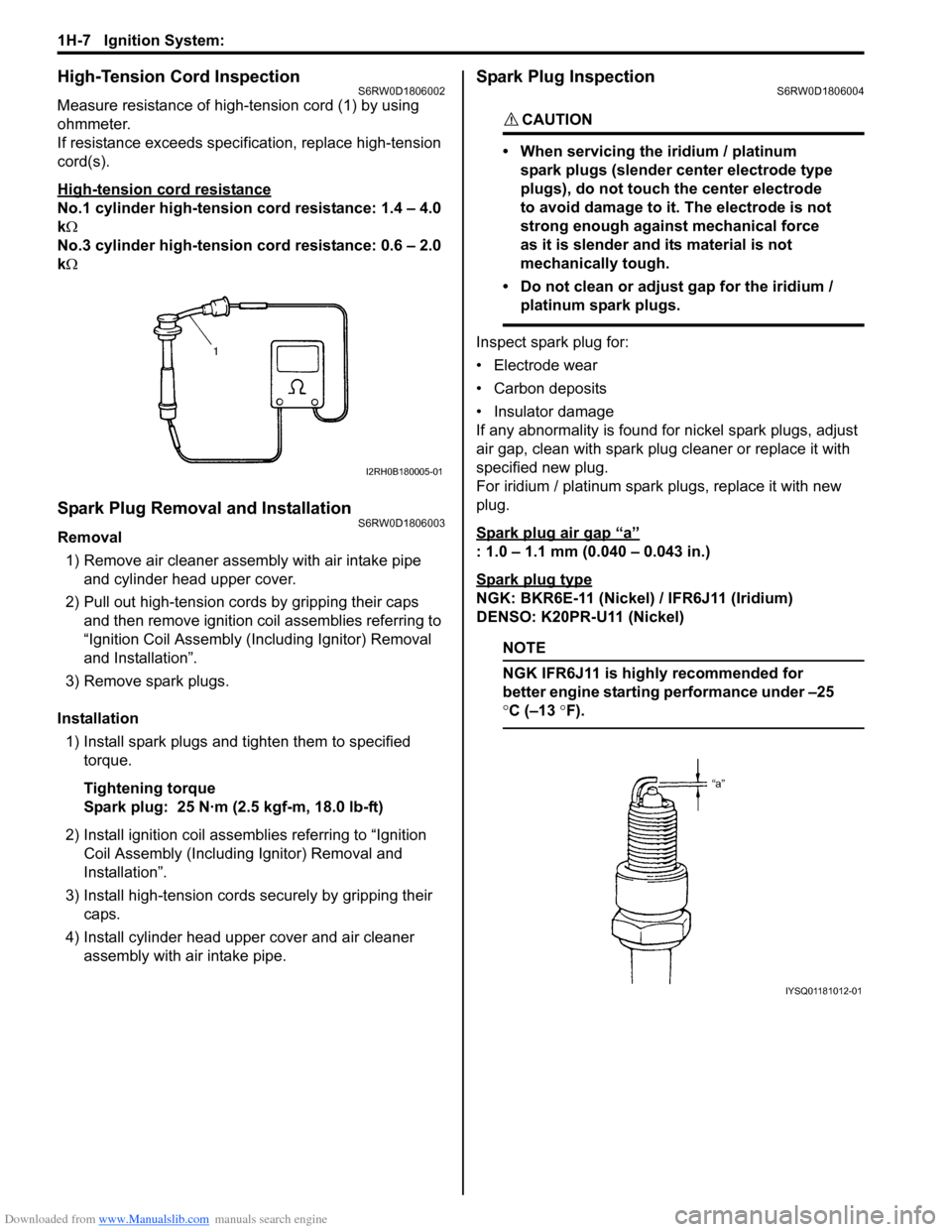

High-Tension Cord InspectionS6RW0D1806002

Measure resistance of high-tension cord (1) by using

ohmmeter.

If resistance exceeds specification, replace high-tension

cord(s).

High-tension cord resistance

No.1 cylinder high-tension cord resistance: 1.4 – 4.0

kΩ

No.3 cylinder high-tension cord resistance: 0.6 – 2.0

kΩ

Spark Plug Removal and InstallationS6RW0D1806003

Removal

1) Remove air cleaner assembly with air intake pipe

and cylinder head upper cover.

2) Pull out high-tension cords by gripping their caps

and then remove ignition coil assemblies referring to

“Ignition Coil Assembly (Including Ignitor) Removal

and Installation”.

3) Remove spark plugs.

Installation

1) Install spark plugs and tighten them to specified

torque.

Tightening torque

Spark plug: 25 N·m (2.5 kgf-m, 18.0 lb-ft)

2) Install ignition coil assemblies referring to “Ignition

Coil Assembly (Including Ignitor) Removal and

Installation”.

3) Install high-tension cords securely by gripping their

caps.

4) Install cylinder head upper cover and air cleaner

assembly with air intake pipe.

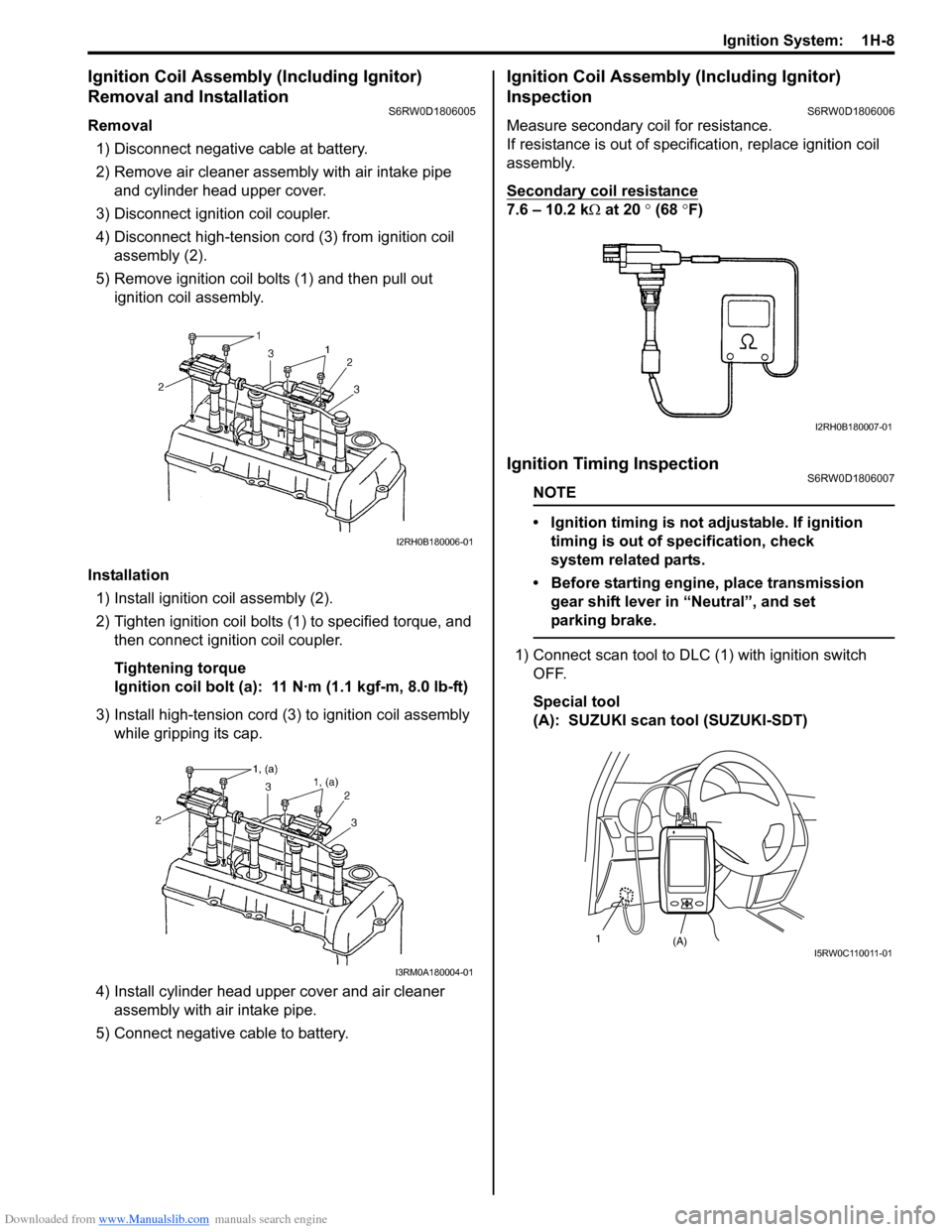

Spark Plug InspectionS6RW0D1806004

CAUTION!

• When servicing the iridium / platinum

spark plugs (slender center electrode type

plugs), do not touch the center electrode

to avoid damage to it. The electrode is not

strong enough against mechanical force

as it is slender and its material is not

mechanically tough.

• Do not clean or adjust gap for the iridium /

platinum spark plugs.

Inspect spark plug for:

• Electrode wear

• Carbon deposits

• Insulator damage

If any abnormality is found for nickel spark plugs, adjust

air gap, clean with spark plug cleaner or replace it with

specified new plug.

For iridium / platinum spark plugs, replace it with new

plug.

Spark plug air gap

“a”

: 1.0 – 1.1 mm (0.040 – 0.043 in.)

Spark plug type

NGK: BKR6E-11 (Nickel) / IFR6J11 (Iridium)

DENSO: K20PR-U11 (Nickel)

NOTE

NGK IFR6J11 is highly recommended for

better engine starting performance under –25

°C (–13 °F).

I2RH0B180005-01

IYSQ01181012-01

Page 403 of 1556

Downloaded from www.Manualslib.com manuals search engine Ignition System: 1H-8

Ignition Coil Assembly (Including Ignitor)

Removal and Installation

S6RW0D1806005

Removal

1) Disconnect negative cable at battery.

2) Remove air cleaner assembly with air intake pipe

and cylinder head upper cover.

3) Disconnect ignition coil coupler.

4) Disconnect high-tension cord (3) from ignition coil

assembly (2).

5) Remove ignition coil bolts (1) and then pull out

ignition coil assembly.

Installation

1) Install ignition coil assembly (2).

2) Tighten ignition coil bolts (1) to specified torque, and

then connect ignition coil coupler.

Tightening torque

Ignition coil bolt (a): 11 N·m (1.1 kgf-m, 8.0 lb-ft)

3) Install high-tension cord (3) to ignition coil assembly

while gripping its cap.

4) Install cylinder head upper cover and air cleaner

assembly with air intake pipe.

5) Connect negative cable to battery.

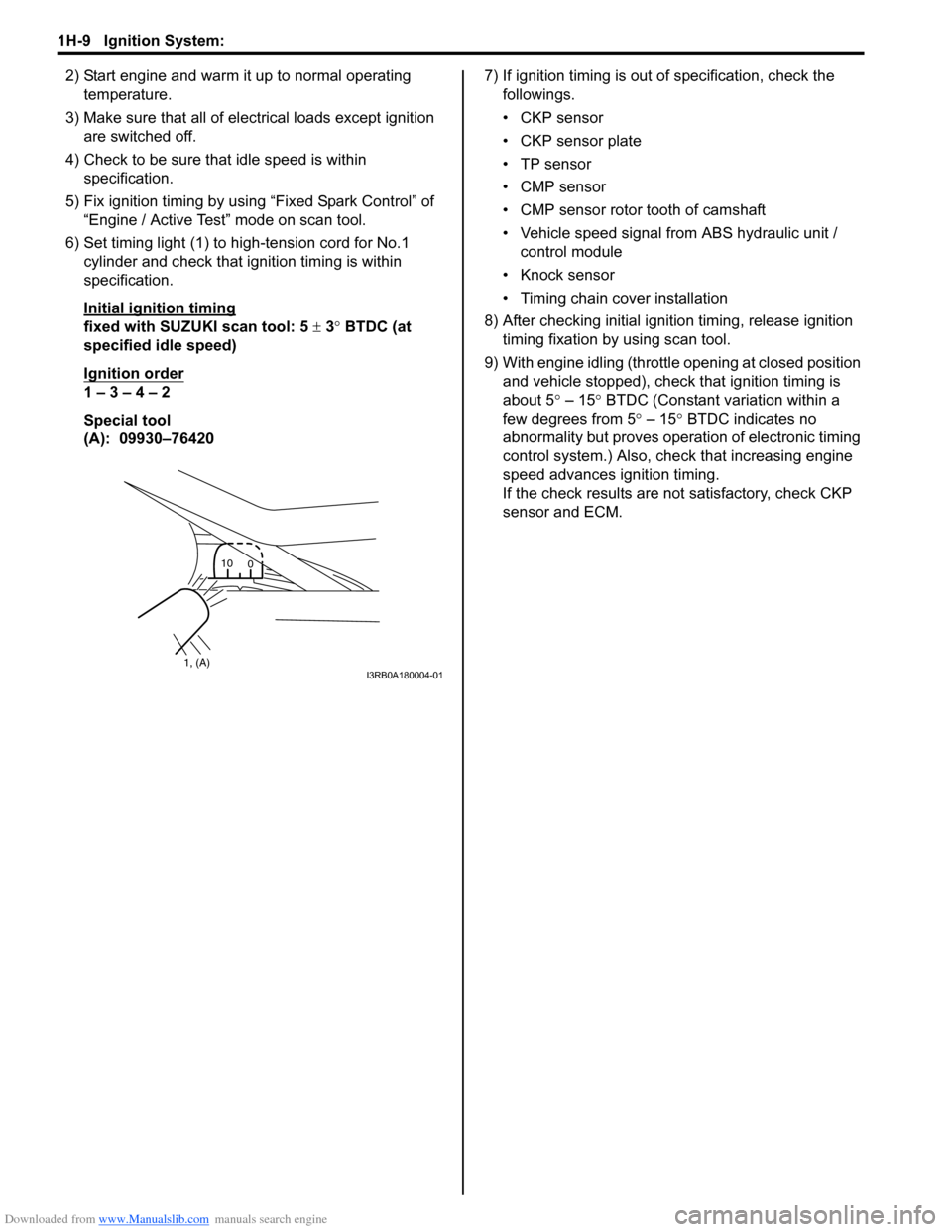

Ignition Coil Assembly (Including Ignitor)

Inspection

S6RW0D1806006

Measure secondary coil for resistance.

If resistance is out of specification, replace ignition coil

assembly.

Secondary coil resistance

7.6 – 10.2 kΩ at 20 ° (68 °F)

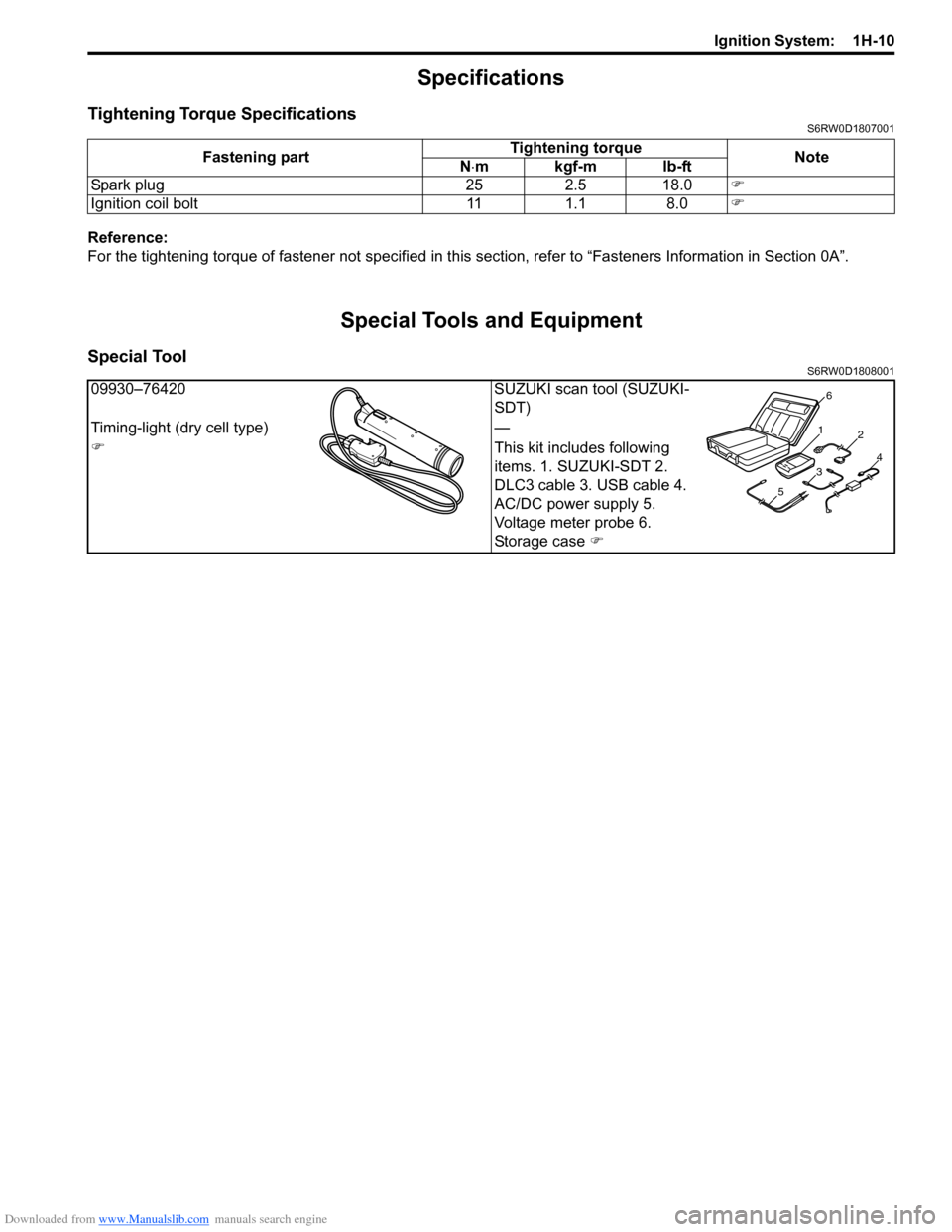

Ignition Timing InspectionS6RW0D1806007

NOTE

• Ignition timing is not adjustable. If ignition

timing is out of specification, check

system related parts.

• Before starting engine, place transmission

gear shift lever in “Neutral”, and set

parking brake.

1) Connect scan tool to DLC (1) with ignition switch

OFF.

Special tool

(A): SUZUKI scan tool (SUZUKI-SDT)

I2RH0B180006-01

I3RM0A180004-01

I2RH0B180007-01

(A) 1I 5 R W 0 C 11 0 0 11 - 0 1

Page 404 of 1556

Downloaded from www.Manualslib.com manuals search engine 1H-9 Ignition System:

2) Start engine and warm it up to normal operating

temperature.

3) Make sure that all of electrical loads except ignition

are switched off.

4) Check to be sure that idle speed is within

specification.

5) Fix ignition timing by using “Fixed Spark Control” of

“Engine / Active Test” mode on scan tool.

6) Set timing light (1) to high-tension cord for No.1

cylinder and check that ignition timing is within

specification.

Initial ignition timing

fixed with SUZUKI scan tool: 5 ± 3° BTDC (at

specified idle speed)

Ignition order

1 – 3 – 4 – 2

Special tool

(A): 09930–764207) If ignition timing is out of specification, check the

followings.

• CKP sensor

• CKP sensor plate

• TP sensor

• CMP sensor

• CMP sensor rotor tooth of camshaft

• Vehicle speed signal from ABS hydraulic unit /

control module

• Knock sensor

• Timing chain cover installation

8) After checking initial ignition timing, release ignition

timing fixation by using scan tool.

9) With engine idling (throttle opening at closed position

and vehicle stopped), check that ignition timing is

about 5° – 15° BTDC (Constant variation within a

few degrees from 5° – 15° BTDC indicates no

abnormality but proves operation of electronic timing

control system.) Also, check that increasing engine

speed advances ignition timing.

If the check results are not satisfactory, check CKP

sensor and ECM.

1, (A)10

0I3RB0A180004-01

Page 405 of 1556

Downloaded from www.Manualslib.com manuals search engine Ignition System: 1H-10

Specifications

Tightening Torque SpecificationsS6RW0D1807001

Reference:

For the tightening torque of fastener not specified in this section, refer to “Fasteners Information in Section 0A”.

Special Tools and Equipment

Special ToolS6RW0D1808001

Fastening partTightening torque

Note

N⋅mkgf-mlb-ft

Spark plug 25 2.5 18.0�)

Ignition coil bolt 11 1.1 8.0�)

09930–76420 SUZUKI scan tool (SUZUKI-

SDT)

Timing-light (dry cell type) —

�)This kit includes following

items. 1. SUZUKI-SDT 2.

DLC3 cable 3. USB cable 4.

AC/DC power supply 5.

Voltage meter probe 6.

Storage case �)

1

2

34

56

Page 406 of 1556

Downloaded from www.Manualslib.com manuals search engine 1I-1 Starting System:

Engine

Starting System

Schematic and Routing Diagram

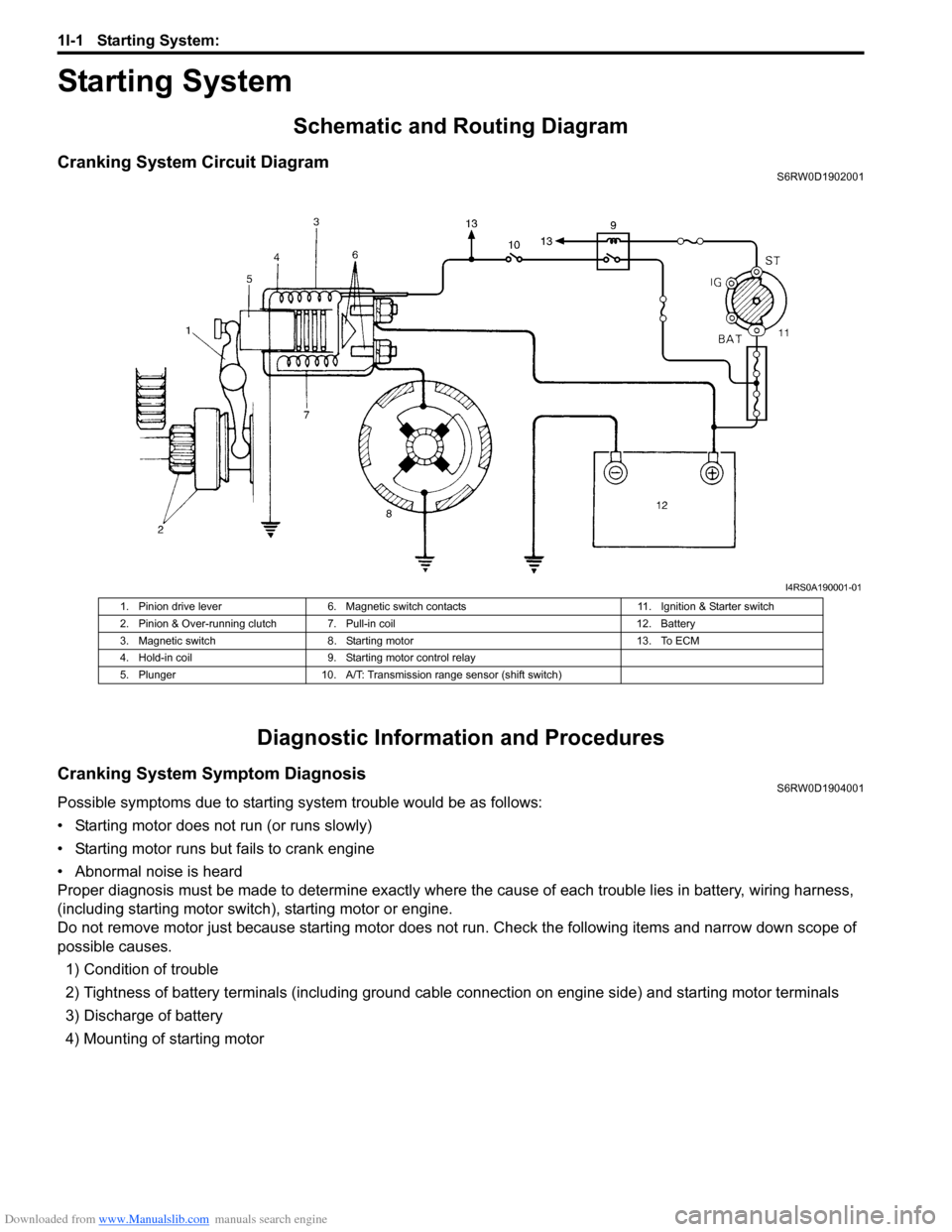

Cranking System Circuit DiagramS6RW0D1902001

Diagnostic Information and Procedures

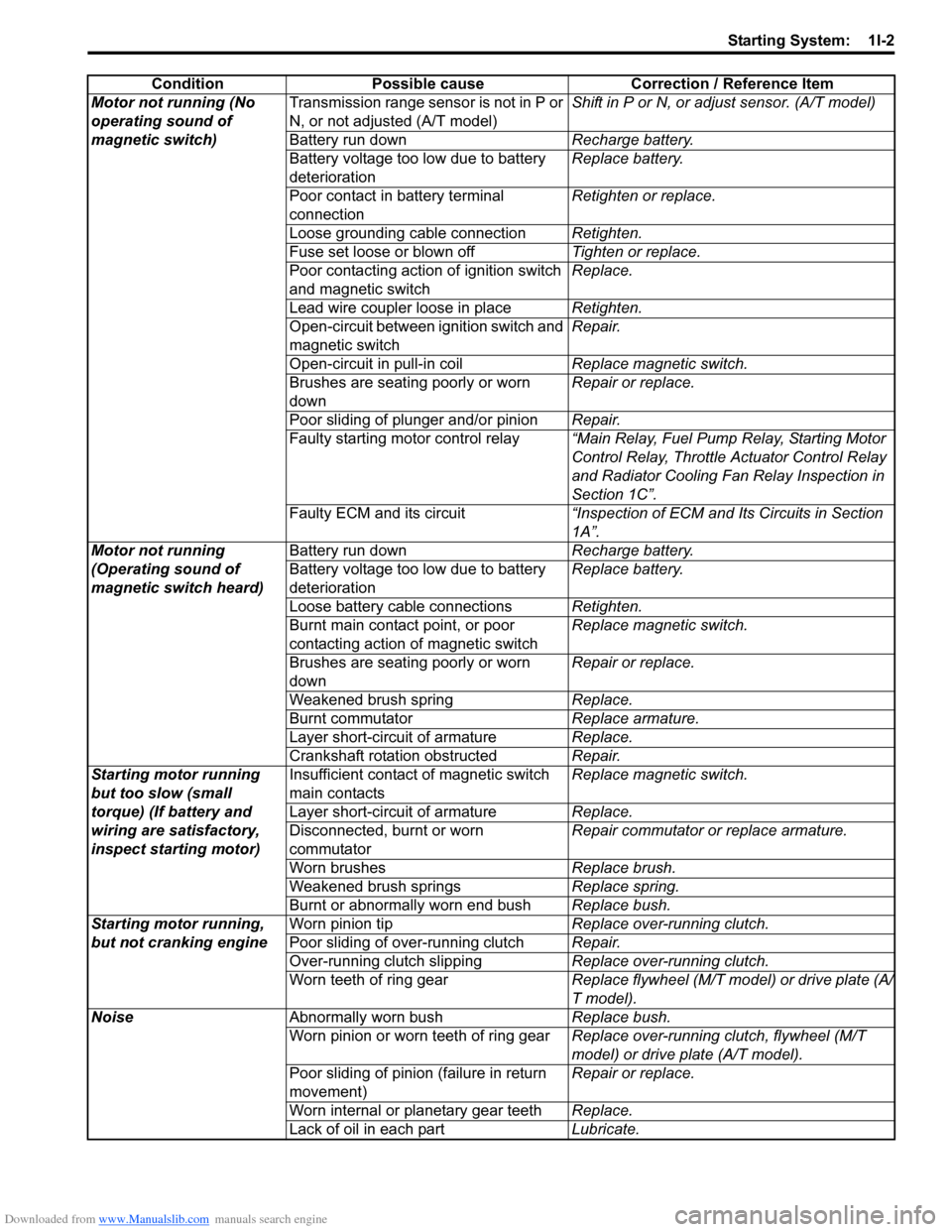

Cranking System Symptom DiagnosisS6RW0D1904001

Possible symptoms due to starting system trouble would be as follows:

• Starting motor does not run (or runs slowly)

• Starting motor runs but fails to crank engine

• Abnormal noise is heard

Proper diagnosis must be made to determine exactly where the cause of each trouble lies in battery, wiring harness,

(including starting motor switch), starting motor or engine.

Do not remove motor just because starting motor does not run. Check the following items and narrow down scope of

possible causes.

1) Condition of trouble

2) Tightness of battery terminals (including ground cable connection on engine side) and starting motor terminals

3) Discharge of battery

4) Mounting of starting motor

I4RS0A190001-01

1. Pinion drive lever 6. Magnetic switch contacts 11. Ignition & Starter switch

2. Pinion & Over-running clutch 7. Pull-in coil 12. Battery

3. Magnetic switch 8. Starting motor 13. To ECM

4. Hold-in coil 9. Starting motor control relay

5. Plunger 10. A/T: Transmission range sensor (shift switch)

Page 407 of 1556

Downloaded from www.Manualslib.com manuals search engine Starting System: 1I-2

Condition Possible cause Correction / Reference Item

Motor not running (No

operating sound of

magnetic switch)Transmission range sensor is not in P or

N, or not adjusted (A/T model)Shift in P or N, or adjust sensor. (A/T model)

Battery run downRecharge battery.

Battery voltage too low due to battery

deteriorationReplace battery.

Poor contact in battery terminal

connectionRetighten or replace.

Loose grounding cable connectionRetighten.

Fuse set loose or blown offTighten or replace.

Poor contacting action of ignition switch

and magnetic switchReplace.

Lead wire coupler loose in placeRetighten.

Open-circuit between ignition switch and

magnetic switchRepair.

Open-circuit in pull-in coilReplace magnetic switch.

Brushes are seating poorly or worn

downRepair or replace.

Poor sliding of plunger and/or pinionRepair.

Faulty starting motor control relay“Main Relay, Fuel Pump Relay, Starting Motor

Control Relay, Throttle Actuator Control Relay

and Radiator Cooling Fan Relay Inspection in

Section 1C”.

Faulty ECM and its circuit“Inspection of ECM and Its Circuits in Section

1A”.

Motor not running

(Operating sound of

magnetic switch heard)Battery run downRecharge battery.

Battery voltage too low due to battery

deteriorationReplace battery.

Loose battery cable connectionsRetighten.

Burnt main contact point, or poor

contacting action of magnetic switchReplace magnetic switch.

Brushes are seating poorly or worn

downRepair or replace.

Weakened brush springReplace.

Burnt commutatorReplace armature.

Layer short-circuit of armatureReplace.

Crankshaft rotation obstructedRepair.

Starting motor running

but too slow (small

torque) (If battery and

wiring are satisfactory,

inspect starting motor)Insufficient contact of magnetic switch

main contactsReplace magnetic switch.

Layer short-circuit of armatureReplace.

Disconnected, burnt or worn

commutatorRepair commutator or replace armature.

Worn brushesReplace brush.

Weakened brush springsReplace spring.

Burnt or abnormally worn end bushReplace bush.

Starting motor running,

but not cranking engineWorn pinion tipReplace over-running clutch.

Poor sliding of over-running clutchRepair.

Over-running clutch slippingReplace over-running clutch.

Worn teeth of ring gearReplace flywheel (M/T model) or drive plate (A/

T model).

NoiseAbnormally worn bushReplace bush.

Worn pinion or worn teeth of ring gearReplace over-running clutch, flywheel (M/T

model) or drive plate (A/T model).

Poor sliding of pinion (failure in return

movement)Repair or replace.

Worn internal or planetary gear teethReplace.

Lack of oil in each partLubricate.