Ignition system SUZUKI SX4 2006 1.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2006, Model line: SX4, Model: SUZUKI SX4 2006 1.GPages: 1556, PDF Size: 37.31 MB

Page 211 of 1556

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-161

DTC Detecting Condition and Trouble Area

DTC Confirmation Procedure

1) With ignition switch turned OFF, connect scan tool.

2) Turn ON ignition switch and clear DTC using scan tool.

3) Keep the accelerator pedal at idle position for 2 seconds.

4) Keep the accelerator pedal at fully depressed position for 2 seconds.

5) Repeat Step 3) and 4) for 3 times.

6) Check DTC.

DTC Troubleshooting

NOTE

Before this troubleshooting is performed, read the precautions for DTC troubleshooting referring to

“Precautions for DTC Troubleshooting”.

DTC detecting condition Trouble area

Difference between the opening angle based on throttle position

sensor (main) and the opening angle based on throttle position

sensor (sub) is more than specification for specified time.

(1 driving detection logic)• Throttle position sensor (main) and (sub) circuit

• Electric throttle body assembly

•ECM

Step Action Yes No

1Was “Engine and Emission Control System Check”

performed?Go to Step 2. Go to “Engine and

Emission Control

System Check”.

2Throttle position sensor and its circuit check

1) Connect scan tool to DLC with ignition switch turned

OFF.

2) Turn ON ignition switch, check each voltage of “TP

Sensor 1 Volt” and “TP Sensor 2 Volt” displayed on scan

tool when accelerator pedal is idle position and fully

depressed.

Is each TP sensor voltage within specified value in the table

“Scan Tool Data”?Intermittent trouble.

Check for intermittent

referring to “Intermittent

and Poor Connection

Inspection in Section

00”.Go to Step 3.

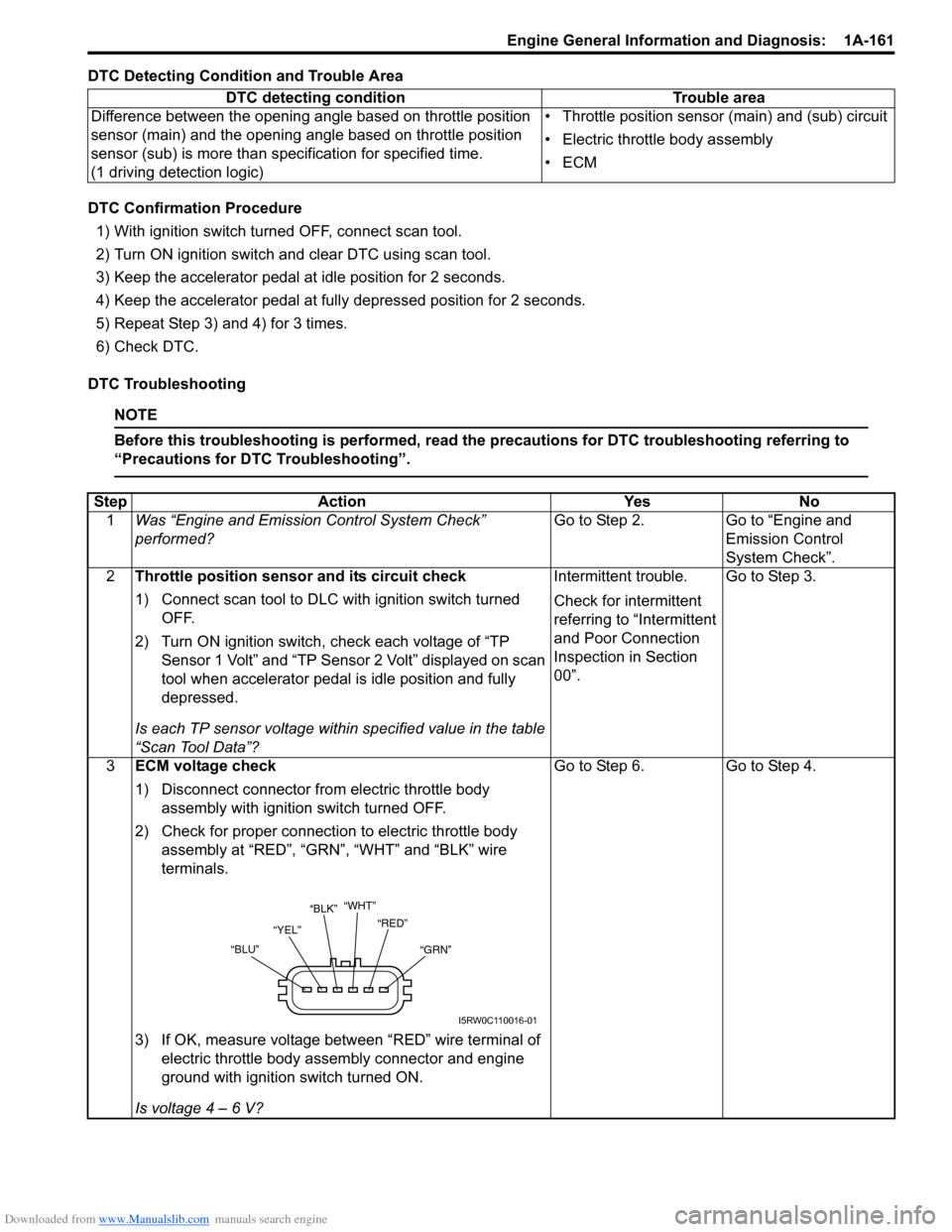

3ECM voltage check

1) Disconnect connector from electric throttle body

assembly with ignition switch turned OFF.

2) Check for proper connection to electric throttle body

assembly at “RED”, “GRN”, “WHT” and “BLK” wire

terminals.

3) If OK, measure voltage between “RED” wire terminal of

electric throttle body assembly connector and engine

ground with ignition switch turned ON.

Is voltage 4 – 6 V?Go to Step 6. Go to Step 4.

“WHT”

“YEL”“RED”

“GRN” “BLU”“BLK”

I5RW0C110016-01

Page 214 of 1556

Downloaded from www.Manualslib.com manuals search engine 1A-164 Engine General Information and Diagnosis:

DTC Troubleshooting

NOTE

Before this troubleshooting is performed, read the precautions for DTC troubleshooting referring to

“Precautions for DTC Troubleshooting”.

Step Action Yes No

1Was “Engine and Emission Control System Check”

performed?Go to Step 2. Go to “Engine and

Emission Control

System Check”.

2APP sensor and its circuit check

1) Connect scan tool to DLC with ignition switch turned

OFF.

2) Turn ON ignition switch.

3) Check each voltage of “APP Sensor 1 Volt” and “APP

Sensor 2 Volt” displayed on scan tool when accelerator

pedal is idle position and fully depressed.

Is each APP sensor voltage within specified value in the

table “Scan Tool Data”?Intermittent trouble.

Check for intermittent

referring to “Intermittent

and Poor Connection

Inspection in Section

00”.Go to Step 3.

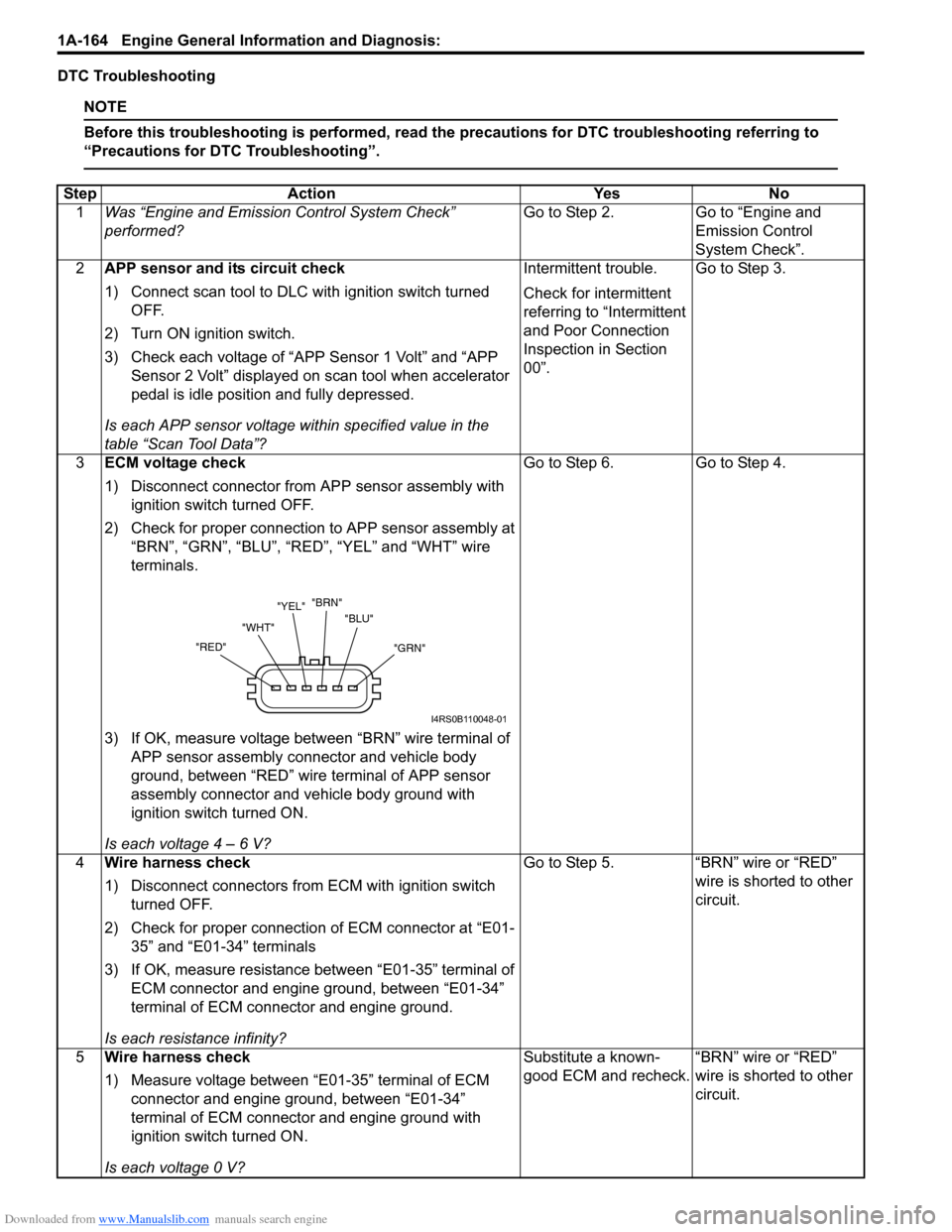

3ECM voltage check

1) Disconnect connector from APP sensor assembly with

ignition switch turned OFF.

2) Check for proper connection to APP sensor assembly at

“BRN”, “GRN”, “BLU”, “RED”, “YEL” and “WHT” wire

terminals.

3) If OK, measure voltage between “BRN” wire terminal of

APP sensor assembly connector and vehicle body

ground, between “RED” wire terminal of APP sensor

assembly connector and vehicle body ground with

ignition switch turned ON.

Is each voltage 4 – 6 V?Go to Step 6. Go to Step 4.

4Wire harness check

1) Disconnect connectors from ECM with ignition switch

turned OFF.

2) Check for proper connection of ECM connector at “E01-

35” and “E01-34” terminals

3) If OK, measure resistance between “E01-35” terminal of

ECM connector and engine ground, between “E01-34”

terminal of ECM connector and engine ground.

Is each resistance infinity?Go to Step 5. “BRN” wire or “RED”

wire is shorted to other

circuit.

5Wire harness check

1) Measure voltage between “E01-35” terminal of ECM

connector and engine ground, between “E01-34”

terminal of ECM connector and engine ground with

ignition switch turned ON.

Is each voltage 0 V?Substitute a known-

good ECM and recheck.“BRN” wire or “RED”

wire is shorted to other

circuit.

"GRN" "BLU" "BRN"

"YEL"

"WHT"

"RED"

I4RS0B110048-01

Page 215 of 1556

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-165

DTC P2227 / P2228 / P2229: Barometric Pressure Circuit MalfunctionS6RW0D1104068

DTC P2227: Barometric Pressure Circuit Range / Performance

DTC P2228: Barometric Pressure Circuit Low

DTC P2229: Barometric Pressure Circuit High

System Description

Barometric pressure sensor is installed in ECM.

DTC Detecting Condition and Trouble Area6Wire harness check

1) Disconnect connectors from ECM with ignition switch

turned OFF.

2) Check for proper connection of ECM connector at “E01-

37”, “E01-52”, “E01-36” and “E01-51” terminals.

3) If OK, measure resistance between “GRN” wire terminal

of APP sensor assembly connector and vehicle body

ground, between “YEL” wire terminal of APP sensor

assembly connector and vehicle body ground.

Is each resistance infinity?Go to Step 7. “GRN” wire or “YEL”

wire is shorted to other

circuit.

7Wire harness check

1) Turn ON ignition switch.

2) Measure voltage between “E01-37” terminal of ECM

connector and engine ground, between “E01-36”

terminal of ECM connector and engine ground.

Is each voltage 0 V?Go to Step 8. “GRN” wire or “YEL”

wire is shorted to other

circuit.

8APP sensor assembly check

1) 1)Check APP sensor referring to “Accelerator Pedal

Position (APP) Sensor Assembly Inspection in Section

1C”.

Is output voltage within specified value?Substitute a known-

good ECM and recheck.Replace APP sensor

assembly. Step Action Yes No

DTC detecting condition Trouble area

DTC P2227:

Difference of barometric pressure value and intake manifold pressure value

is more than specified value while engine cranking.

(2 driving cycle detection logic)• Manifold absolute pressure sensor

performance problem

• Barometric pressure sensor in ECM

DTC P2228:

Barometric pressure signal is lower than specified value.

(1 driving cycle detection logic)• Barometric pressure sensor in ECM

DTC P2229:

Barometric pressure signal is higher than specified value.

(1 driving cycle detection logic)

Page 216 of 1556

Downloaded from www.Manualslib.com manuals search engine 1A-166 Engine General Information and Diagnosis:

DTC Confirmation Procedure

DTC P2227:

WARNING!

• When performing a road test, select a place where there is no traffic or possibility of a traffic

accident and be very careful during testing to avoid occurrence of an accident.

• Road test should be carried out by 2 persons, a driver and a tester, on a level road.

1) Connect scan tool to DLC with ignition switch turned OFF.

2) Turn ON ignition switch and clear DTC, pending DTC and freeze frame data by using scan tool and warm up

engine to normal operating temperature.

3) Check DTC and pending DTC by using scan tool.

DTC P2228 / P2229:

1) Connect scan tool to DLC with ignition switch turned OFF.

2) Turn ON ignition switch, clear DTC by using scan tool and run engine for 1 min.

3) Check DTC and pending DTC by using scan tool.

DTC Troubleshooting

NOTE

Before this troubleshooting is performed, read the precautions for DTC troubleshooting referring to

“Precautions for DTC Troubleshooting”.

DTC U0073: Control Module Communication Bus OffS6RW0D1104069

Refer to “Troubleshooting for CAN-DTC”.

DTC U0101: Lost Communication with TCMS6RW0D1104082

Refer to “Troubleshooting for CAN-DTC”.

DTC U0121: Lost Communication with ABS Control ModuleS6RW0D1104070

Refer to“Troubleshooting for CAN-DTC”.

DTC U0140: Lost Communication with Body Control ModuleS6RW0D1104071

Refer to“Troubleshooting for CAN-DTC”.Step Action Yes No

1Was “Engine and Emission Control System Check”

performed?Go to Step 2. Go to “Engine and

Emission Control

System Check”.

2Is DTC P2227 set?Go to Step 3. Substitute a known-

good ECM and recheck.

3MAP sensor check

1) Check MAP sensor and its circuit referring to “DTC

P0107: Manifold Absolute Pressure Circuit Low

Input”and/or “DTC P0108: Manifold Absolute Pressure

Circuit High Input”.

Is check result satisfactory?Substitute a known-

good ECM and recheck.MAP sensor or its circuit

malfunction.

Page 227 of 1556

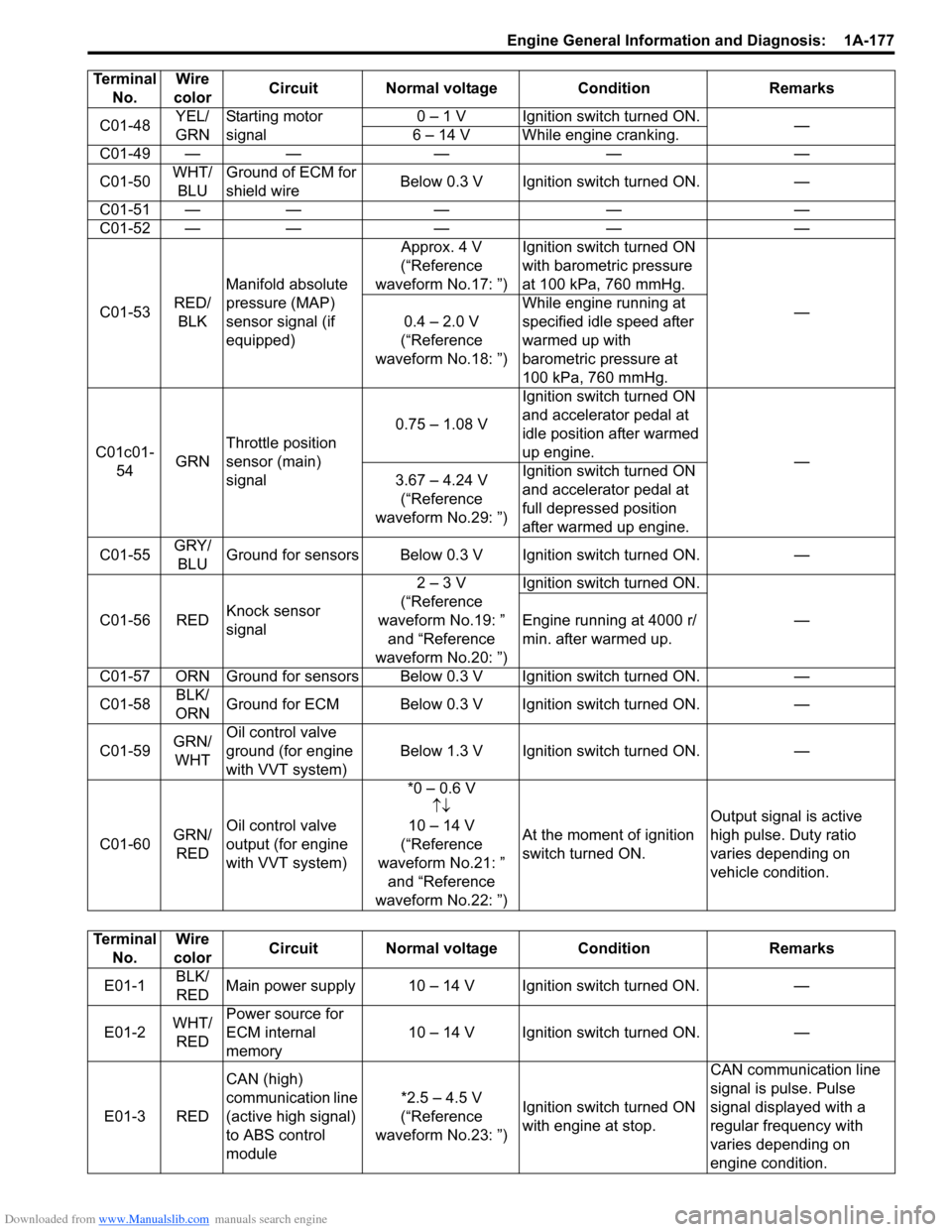

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-177

C01-48YEL/

GRNStarting motor

signal0 – 1 V Ignition switch turned ON.

—

6 – 14 V While engine cranking.

C01-49 — — — — —

C01-50WHT/

BLUGround of ECM for

shield wireBelow 0.3 V Ignition switch turned ON. —

C01-51 — — — — —

C01-52 — — — — —

C01-53RED/

BLKManifold absolute

pressure (MAP)

sensor signal (if

equipped)Approx. 4 V

(“Reference

waveform No.17: ”)Ignition switch turned ON

with barometric pressure

at 100 kPa, 760 mmHg.

—

0.4 – 2.0 V

(“Reference

waveform No.18: ”)While engine running at

specified idle speed after

warmed up with

barometric pressure at

100 kPa, 760 mmHg.

C01c01-

54GRNThrottle position

sensor (main)

signal0.75 – 1.08 VIgnition switch turned ON

and accelerator pedal at

idle position after warmed

up engine.

—

3.67 – 4.24 V

(“Reference

waveform No.29: ”)Ignition switch turned ON

and accelerator pedal at

full depressed position

after warmed up engine.

C01-55GRY/

BLUGround for sensors Below 0.3 V Ignition switch turned ON. —

C01-56 REDKnock sensor

signal2 – 3 V

(“Reference

waveform No.19: ”

and “Reference

waveform No.20: ”)Ignition switch turned ON.

— Engine running at 4000 r/

min. after warmed up.

C01-57 ORN Ground for sensors Below 0.3 V Ignition switch turned ON. —

C01-58BLK/

ORNGround for ECM Below 0.3 V Ignition switch turned ON. —

C01-59GRN/

WHTOil control valve

ground (for engine

with VVT system)Below 1.3 V Ignition switch turned ON. —

C01-60GRN/

REDOil control valve

output (for engine

with VVT system)*0 – 0.6 V

↑↓

10 – 14 V

(“Reference

waveform No.21: ”

and “Reference

waveform No.22: ”)At the moment of ignition

switch turned ON.Output signal is active

high pulse. Duty ratio

varies depending on

vehicle condition. Terminal

No.Wire

colorCircuit Normal voltage Condition Remarks

Terminal

No.Wire

colorCircuit Normal voltage Condition Remarks

E01-1BLK/

REDMain power supply 10 – 14 V Ignition switch turned ON. —

E01-2WHT/

REDPower source for

ECM internal

memory10 – 14 V Ignition switch turned ON. —

E01-3 REDCAN (high)

communication line

(active high signal)

to ABS control

module*2.5 – 4.5 V

(“Reference

waveform No.23: ”)Ignition switch turned ON

with engine at stop.CAN communication line

signal is pulse. Pulse

signal displayed with a

regular frequency with

varies depending on

engine condition.

Page 238 of 1556

Downloaded from www.Manualslib.com manuals search engine 1A-188 Engine General Information and Diagnosis:

Reference waveform No.19

Knock sensor signal at engine speed 4000 r/min.

Reference waveform No.20

Knock sensor signal at engine speed 4000 r/min.Reference waveform No.21

Oil control valve signal with engine idling (for engine with

VVT system)

Reference waveform No.22

Oil control valve signal with engine racing (for engine

with VVT system) Measurement

terminalCH1: “C01-56” to “C01-58”

Oscilloscope

settingCH1: 1 V/DIV

TIME: 10 ms/DIV

Measurement

condition• After warmed up to normal

operating temperature

• Engine running at 4000 r/min.

Measurement

terminalCH1: “C01-56” to “C01-58”

Oscilloscope

settingCH1: 1 V/DIV

TIME: 200 µs/DIV

Measurement

condition• After warmed up to normal

operating temperature

• Engine running at 4000 r/min.

I4RS0B110072-01

I4RS0B110073-01

Measurement

terminalCH1: “C01-60” to “C01-59”

Oscilloscope

settingCH1: 5 V/DIV

TIME: 2 ms/DIV

Measurement

conditionAt the moment of the ignition switch

turned on

1. ON signal 3. Only duty cycle

2. OFF signal

Measurement

terminalCH1: “C01-60” to “C01-59”

Oscilloscope

settingCH1: 5 V/DIV

TIME: 400 µs/DIV

Measurement

condition• After warmed up to normal

operating temperature

• Vehicle running at 20 km/h (12

mph) and depress accelerator

pedal fully

1. Accelerator pedal depressed fully 4. ON signal

2. Accelerator pedal depressed partially 5. OFF signal

3. Oil control valve signal

I4RS0B110074-01

I4RS0B110075-01

Page 242 of 1556

Downloaded from www.Manualslib.com manuals search engine 1A-192 Engine General Information and Diagnosis:

Resistance Check

1) Remove ECM from its bracket referring to “Engine Control Module (ECM) Removal and Installation in Section 1C”.

CAUTION!

Never touch terminals of ECM itself or connect voltmeter or ohmmeter (2).

2) Connect special tool to ECM connectors (1) securely.

NOTE

Do not connect the other connector of special tool to ECM.

Special tool

(A): 09933–06320

3) Check resistance between each pair of terminals of special tool connectors (1) as listed in the following table.

CAUTION!

• Be sure to connect ohmmeter probe from wire harness side of coupler.

• Be sure to turn OFF ignition switch for this check.

• Resistance in the following table represents that measured when parts temperature is 20 °C (68 °F).

1

(A)

2

3

I7RW01110032-02

Terminals Circuit Standard resistance Condition

C01-47 to E01-29 Heater of HO2S-2 4 – 15 Ω—

E01-46 to E01-1/16 Radiator cooling fan relay No.1 160 – 240 Ω—

E01-60 to E01-29 Main relay 160 – 240 ΩBattery disconnected and

ignition switch turned ON

E01-15 to E01-29 Fuel pump relay 160 – 240 Ω—

C01-16 to E01-1/16No.3 fuel injector

10.8 – 18.2 Ω—

C01-17 to E01-1/16No.4 fuel injector

C01-4 to E01-1/16EGR valve (stepping motor No.1 coil) (if

equipped)20 – 31 Ω—

C01-29 to E01-1/16 EVAP canister purge valve 28 – 35 Ω—

C01-2 to E01-1/16 No.2 fuel injector 10.8 – 18.2 Ω—

C01-3 to E01-1/16EGR valve (stepping motor No.2 coil) (if

equipped)

20 – 31 Ω— C01-18 to E01-1/16EGR valve (stepping motor No.4 coil) (if

equipped)

C01-19 to E01-1/16EGR valve (stepping motor No.3 coil) (if

equipped)

C01-46 to E01-29 Heater of HO2S-1 2 – 11 Ω—

C01-1 to E01-1/16 No.1 fuel injector 10.8 – 18.2 Ω—

E01-29 to E01-47 A/C compressor relay (if equipped with A/C) 160 – 240 Ω—

E01-58 to E01-1/16A/C condenser cooling fan relay

(if equipped with A/C)160 – 240 Ω—

C01-60 to C01-59 Oil control valve (for engine with VVT system) 6 – 15 Ω—

E01-45 to E01-1/16 Throttle actuator control relay 160 – 240 Ω—

Page 249 of 1556

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-199

Troubleshooting

NOTE

• Before performed trouble shooting, be sure to read the “Precautions of ECM Circuit Inspection”.

• When measuring circuit voltage, resistance and/or pulse signal at ECM connector, connect the

special tool to ECM and/or the ECM connectors referring to “Inspection of ECM and Its Circuits”.

Step Action Yes No

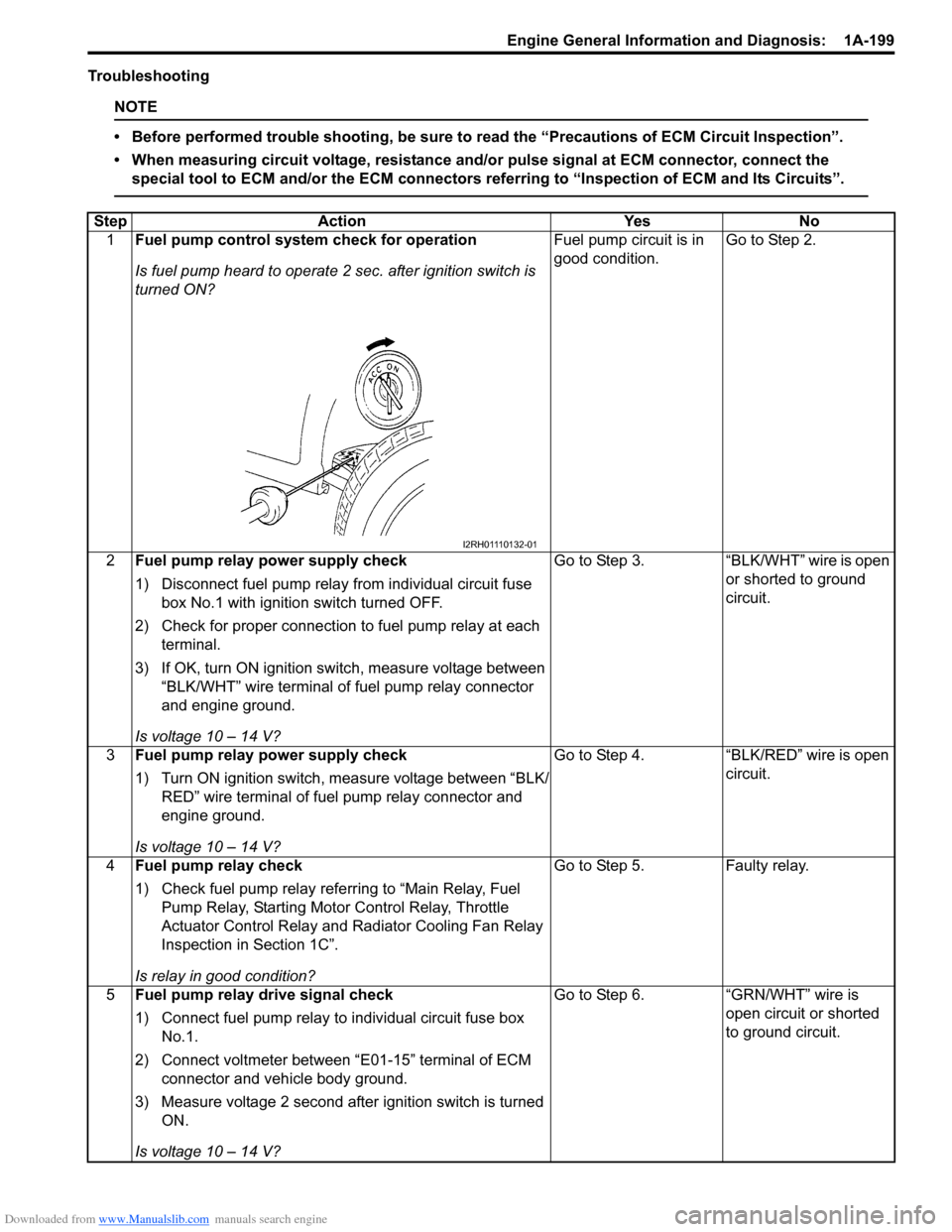

1Fuel pump control system check for operation

Is fuel pump heard to operate 2 sec. after ignition switch is

turned ON?Fuel pump circuit is in

good condition.Go to Step 2.

2Fuel pump relay power supply check

1) Disconnect fuel pump relay from individual circuit fuse

box No.1 with ignition switch turned OFF.

2) Check for proper connection to fuel pump relay at each

terminal.

3) If OK, turn ON ignition switch, measure voltage between

“BLK/WHT” wire terminal of fuel pump relay connector

and engine ground.

Is voltage 10 – 14 V?Go to Step 3. “BLK/WHT” wire is open

or shorted to ground

circuit.

3Fuel pump relay power supply check

1) Turn ON ignition switch, measure voltage between “BLK/

RED” wire terminal of fuel pump relay connector and

engine ground.

Is voltage 10 – 14 V?Go to Step 4. “BLK/RED” wire is open

circuit.

4Fuel pump relay check

1) Check fuel pump relay referring to “Main Relay, Fuel

Pump Relay, Starting Motor Control Relay, Throttle

Actuator Control Relay and Radiator Cooling Fan Relay

Inspection in Section 1C”.

Is relay in good condition?Go to Step 5. Faulty relay.

5Fuel pump relay drive signal check

1) Connect fuel pump relay to individual circuit fuse box

No.1.

2) Connect voltmeter between “E01-15” terminal of ECM

connector and vehicle body ground.

3) Measure voltage 2 second after ignition switch is turned

ON.

Is voltage 10 – 14 V?Go to Step 6. “GRN/WHT” wire is

open circuit or shorted

to ground circuit.

I2RH01110132-01

Page 252 of 1556

Downloaded from www.Manualslib.com manuals search engine 1A-202 Engine General Information and Diagnosis:

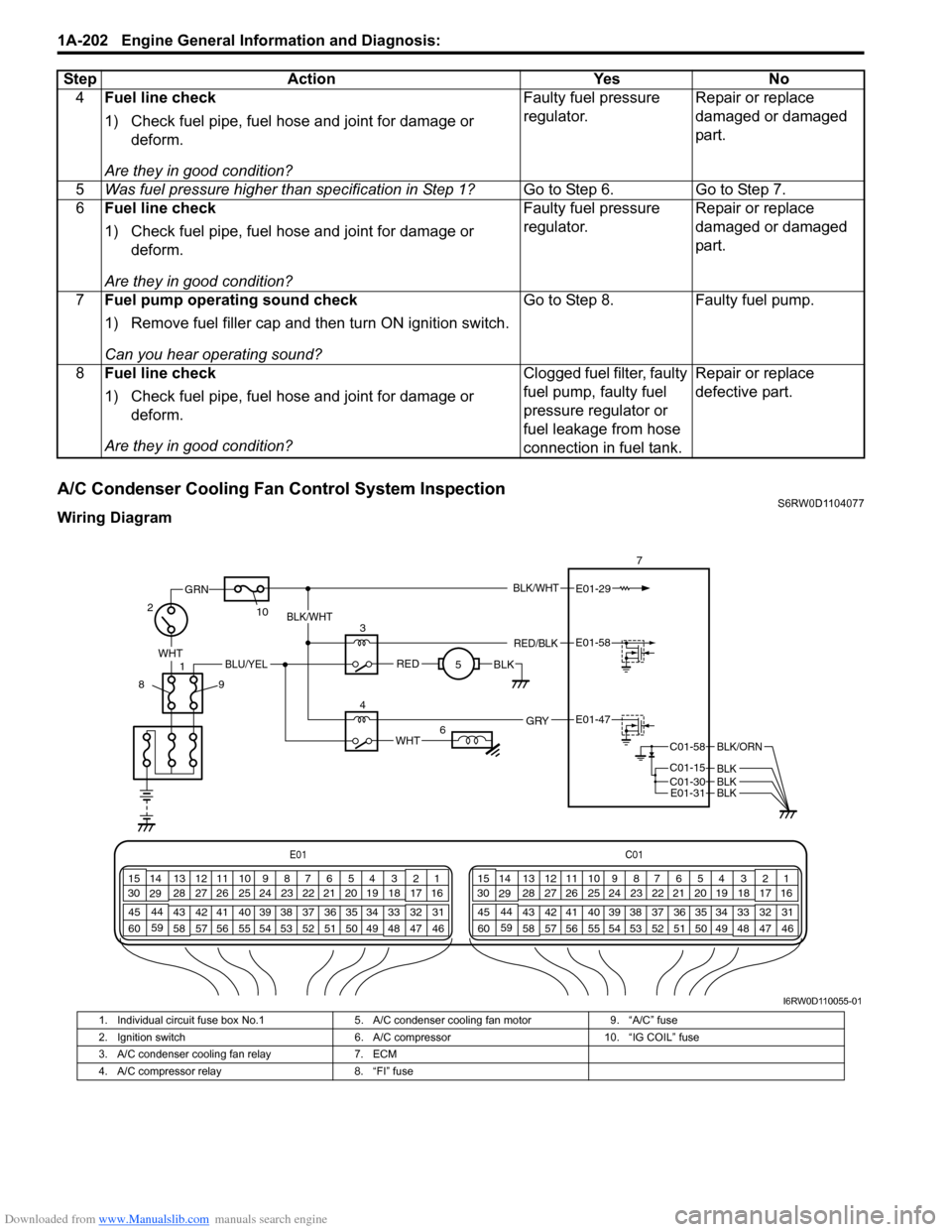

A/C Condenser Cooling Fan Control System InspectionS6RW0D1104077

Wiring Diagram4Fuel line check

1) Check fuel pipe, fuel hose and joint for damage or

deform.

Are they in good condition?Faulty fuel pressure

regulator.Repair or replace

damaged or damaged

part.

5Was fuel pressure higher than specification in Step 1?Go to Step 6. Go to Step 7.

6Fuel line check

1) Check fuel pipe, fuel hose and joint for damage or

deform.

Are they in good condition?Faulty fuel pressure

regulator.Repair or replace

damaged or damaged

part.

7Fuel pump operating sound check

1) Remove fuel filler cap and then turn ON ignition switch.

Can you hear operating sound?Go to Step 8. Faulty fuel pump.

8Fuel line check

1) Check fuel pipe, fuel hose and joint for damage or

deform.

Are they in good condition?Clogged fuel filter, faulty

fuel pump, faulty fuel

pressure regulator or

fuel leakage from hose

connection in fuel tank.Repair or replace

defective part. Step Action Yes No

E01C01

3 4

18 19 5 6 7 10 11

17 20

47 46 49 50 51 21 22

5216 259

24 14

29

55 57 54 53 59

60 582

26 27 28 15

30

56 4832 31 34 35 36 37 40 42 39 38 44

45 43 41 331 12 13

238 3 4

18 19 5 6 7 10 11

17 20

47 46 49 50 51 21 22

5216 259

24 14

29

55 57 54 53 59

60 582

26 27 28 15

30

56 4832 31 34 35 36 37 40 42 39 38 44

45 43 41 331 12 13

238

BLK/WHT

WHT

1

GRN

27

E01-29

10

89

REDBLK

3

5BLK/WHT

RED/BLKE01-58

WHT

4E01-47 GRY

BLU/YEL

6

C01-58

C01-15 C01-30

BLK/ORN

BLKBLKE01-31BLK

I6RW0D110055-01

1. Individual circuit fuse box No.1 5. A/C condenser cooling fan motor 9. “A/C” fuse

2. Ignition switch 6. A/C compressor 10. “IG COIL” fuse

3. A/C condenser cooling fan relay 7. ECM

4. A/C compressor relay 8. “FI” fuse

Page 253 of 1556

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-203

Troubleshooting

Step Action Yes No

1Check A/C condenser fan control system

Is A/C condenser fan started when A/C is operating?Intermittent trouble.

Check for intermittent

referring to “Intermittent

and Poor Connection

Inspection in Section

00”.Go to Step 2.

2Check A/C condenser fan relay and its circuit

1) Connect scan tool to DLC with ignition switch OFF.

2) Check pending DTC and DTC with scan tool.

Is DTC P0481 displayed?Go to “DTC P0481:

Cooling Fan 2 (A/C

Condenser Fan) Control

Circuit”.Go to Step 3.

3Check A/C refrigerant

1) Check amount of A/C refrigerant referring to “A/C

System Performance Inspection in Section 7B”.

Is it good condition?Go to Step 4. Recharge refrigerant.

4Check wire circuit

1) Disconnect A/C condenser cooling fan control relay from

individual circuit fuse box No.1 with ignition switch

turned OFF.

2) Turn ON ignition switch, measure voltage between

engine ground and “BLU/YEL” wire terminal of A/C

condenser cooling fan control relay connector.

Is voltage 10 – 14V?Go to Step 7. Go to Step 5.

5Check wire circuit

1) Disconnect A/C compressor control relay from individual

circuit fuse box No.1 with ignition switch turn OFF.

2) Turn ON ignition switch, measure voltage between

engine ground and “BLU/YEL” wire terminal of A/C

compressor control relay connector.

Is voltage 10 – 14 V?Faulty A/C compressor

control relay.Go to Step 6.

6Check wire circuit

1) Remove “A/C” fuse “20 A” from individual circuit fuse box

No.1 with ignition switch turned OFF.

2) Measure resistance between “BLU/YEL” wire terminal of

main fuse connector and engine ground.

Is resistance infinity?Open wire in “BLU/YEL”

circuit. If OK, go to Step

7.“BLU/YEL” wire shorted

to ground circuit.

7Check wire circuit

1) Disconnect connector from A/C condenser cooling fan

with ignition switch tun OFF.

2) Measure resistance between engine ground and “RED”

wire terminal of A/C condenser fan connector.

Is resistance infinity?Go to Step 8. “RED” wire shorted to

ground circuit.

8Check A/C condenser cooling fan control relay

1) Check A/C condenser cooling fan control relay referring

to “A/C System Relay Inspection in Section 7B”.

Is result in good condition?Go to Step 9. Replace relay.