Ignition system SUZUKI SX4 2006 1.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2006, Model line: SX4, Model: SUZUKI SX4 2006 1.GPages: 1556, PDF Size: 37.31 MB

Page 255 of 1556

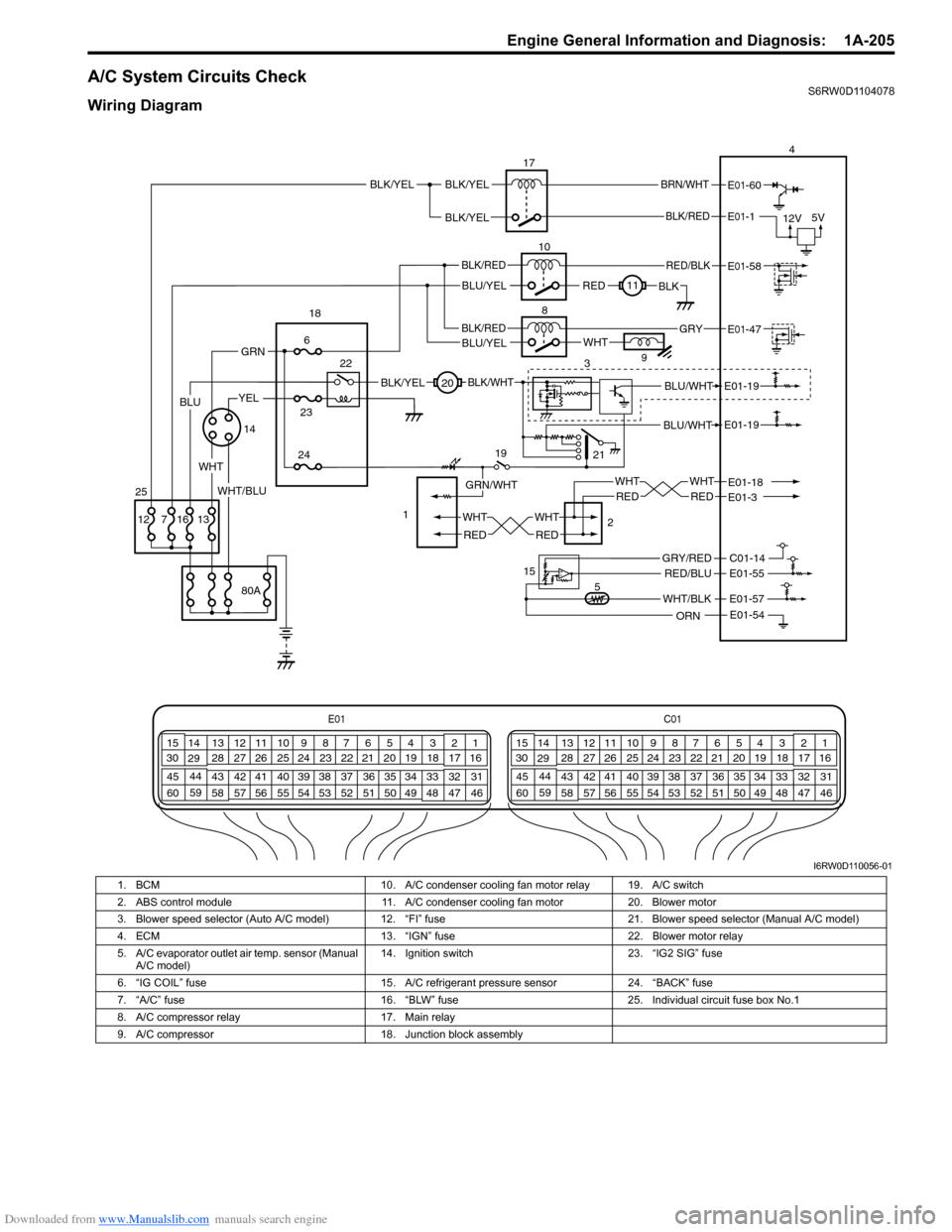

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-205

A/C System Circuits CheckS6RW0D1104078

Wiring Diagram

BLU/WHT

BLU/WHTE01-19

E01-19

21

E01C01

3 4

18 19 5 6 7 10 11

17 20

47 46 49 50 51 21 22

5216 259

24 14

29

55 57 54 53 59

60 582

26 27 28 15

30

56 4832 31 34 35 36 37 40 42 39 38 44

45 43 41 331 12 13

238 3 4

18 19 5 6 7 10 11

17 20

47 46 49 50 51 21 22

5216 259

24 14

29

55 57 54 53 59

60 582

26 27 28 15

30

56 4832 31 34 35 36 37 40 42 39 38 44

45 43 41 331 12 13

238

BLK/RED

BRN/WHT

12V5V

17

10

8

E01-1

E01-60

BLK/YEL

REDBLK11

WHT9

34

RED/BLK

BLK/REDE01-47

E01-58

BLU/YELGRY

19

2 1

20

5 15

WHT

RED

WHT

RED

WHT

RED

WHT

RED

E01-18E01-3

WHT/BLK

C01-14

E01-57

E01-54

E01-55RED/BLU

ORN

GRY/RED

BLK/YEL

GRN/WHT

BLK/WHT

WHT

1423

24

6

22 18

80A

1316 7 12

GRN

25

BLK/RED

BLU/YEL

YEL

WHT/BLU

BLK/YELBLK/YEL

BLU

I6RW0D110056-01

1. BCM 10. A/C condenser cooling fan motor relay 19. A/C switch

2. ABS control module 11. A/C condenser cooling fan motor 20. Blower motor

3. Blower speed selector (Auto A/C model) 12. “FI” fuse 21. Blower speed selector (Manual A/C model)

4. ECM 13. “IGN” fuse 22. Blower motor relay

5. A/C evaporator outlet air temp. sensor (Manual

A/C model)14. Ignition switch 23. “IG2 SIG” fuse

6. “IG COIL” fuse 15. A/C refrigerant pressure sensor 24. “BACK” fuse

7. “A/C” fuse 16. “BLW” fuse 25. Individual circuit fuse box No.1

8. A/C compressor relay 17. Main relay

9. A/C compressor 18. Junction block assembly

Page 256 of 1556

Downloaded from www.Manualslib.com manuals search engine 1A-206 Engine General Information and Diagnosis:

Troubleshooting

NOTE

• Before performed trouble shooting, be sure to read the “Precautions of ECM Circuit Inspection”.

• When measuring circuit voltage, resistance and/or pulse signal at ECM connector, connect the

special tool to ECM and/or the ECM connectors referring to “Inspection of ECM and Its Circuits”.

• When A/C evaporator outlet air temp. is below 2.5 °C (36.5 °F), A/C remains OFF (“E01-47” terminal

voltage becomes 10 – 14 V). This condition is not abnormal.

Step Action Yes No

1Reception data check from BCM

1) Connect scan tool to DLC with ignition switch turned

OFF.

2) Turn ON ignition switch.

3) Check DTC for CAN-DTC.

Is there CAN-DTC?Go to “Troubleshooting

for CAN-DTC”.Go to Step 2.

2A/C switch signal circuit check

1) Start engine and select “Data List” mode on scan tool.

2) Check A/C switch signal under following conditions

respectively.

A/C switch signal

Engine running, A/C switch OFF: OFF

Engine running, A/C switch ON and blower speed

selector turned 1st position or more: ON

Is check result satisfactory?Go to Step 3. Check A/C switch

circuit.

3DTC check of ECT sensor circuit

1) Check ECM for DTC of ECT sensor circuit.

Is there DTC P0116, DTC P0117 or DTC P0118?Go to applicable DTC

diag. flow.Go to Step 4.

4A/C condenser cooling fan control system check

Is A/C condenser cooling fan started when A/C and blower

speed selector switch are turned ON with engine running?Go to Step 10. Go to Step 5.

5A/C condenser cooling fan control circuit check

1) Check DTC with scan tool.

Is DTC P0481 displayed?Go to “DTC P0481:

Cooling Fan 2 (A/C

Condenser Fan) Control

Circuit”.Go to Step 6.

Page 257 of 1556

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-207

6A/C evaporator outlet air temp. sensor check

1) Disconnect connectors from ECM with ignition switch

turned OFF.

2) Check for proper connection to “E01-57” and “E01-54”

wire terminals of ECM connector.

3) If OK, measure resistance between “E01-57” and “E01-

54” wire terminals of ECM connector.

Evaporator temp. sensor resistance

At 0 °C: 6.3 – 6.9 kΩ

At 25 °C: 1.8 – 2.2 kΩ

Is resistance within specification?Go to Step 7. Faulty A/C evaporator

outlet air temp. sensor

or its circuit.

7DTC check of A/C refrigerant pressure sensor circuit

1) Connect scan tool to DLC with ignition switch turned

OFF.

2) Turn ON ignition switch.

3) Check ECM for DTC of A/C refrigerant pressure sensor

circuit.

Is there DTC P0532 or DTC P0533?Go to applicable DTC

diag. flow.Go to Step 8.

8A/C refrigerant pressure sensor voltage check

1) Check A/C refrigerant pressure sensor voltage referring

to “Inspection of ECM and Its Circuits”.

Is voltage within specified value?Go to Step 9. Check amount of

refrigerant. If OK,

replace A/C refrigerant

pressure sensor.

9A/C condenser cooling fan check

1) Check A/C condenser cooling fan referring to

“Condenser Cooling Fan Inspection in Section 7B”.

Is check result satisfactory?A/C condenser cooling

fan drive circuit

malfunction. If circuit is

OK, go to Step 6.Replace A/C condenser

cooling fan motor.

10A/C compressor control system check

Is A/C compressor started when A/C and blower speed

selector switch are turned ON with engine running?A/C system is in good

condition.Go to Step 11. Step Action Yes No

7

6

5

4

3

2

1

10

20

30

4050 010

2030

60 70

80 ResistanceTemperatureI3RB0A110053-01

Page 261 of 1556

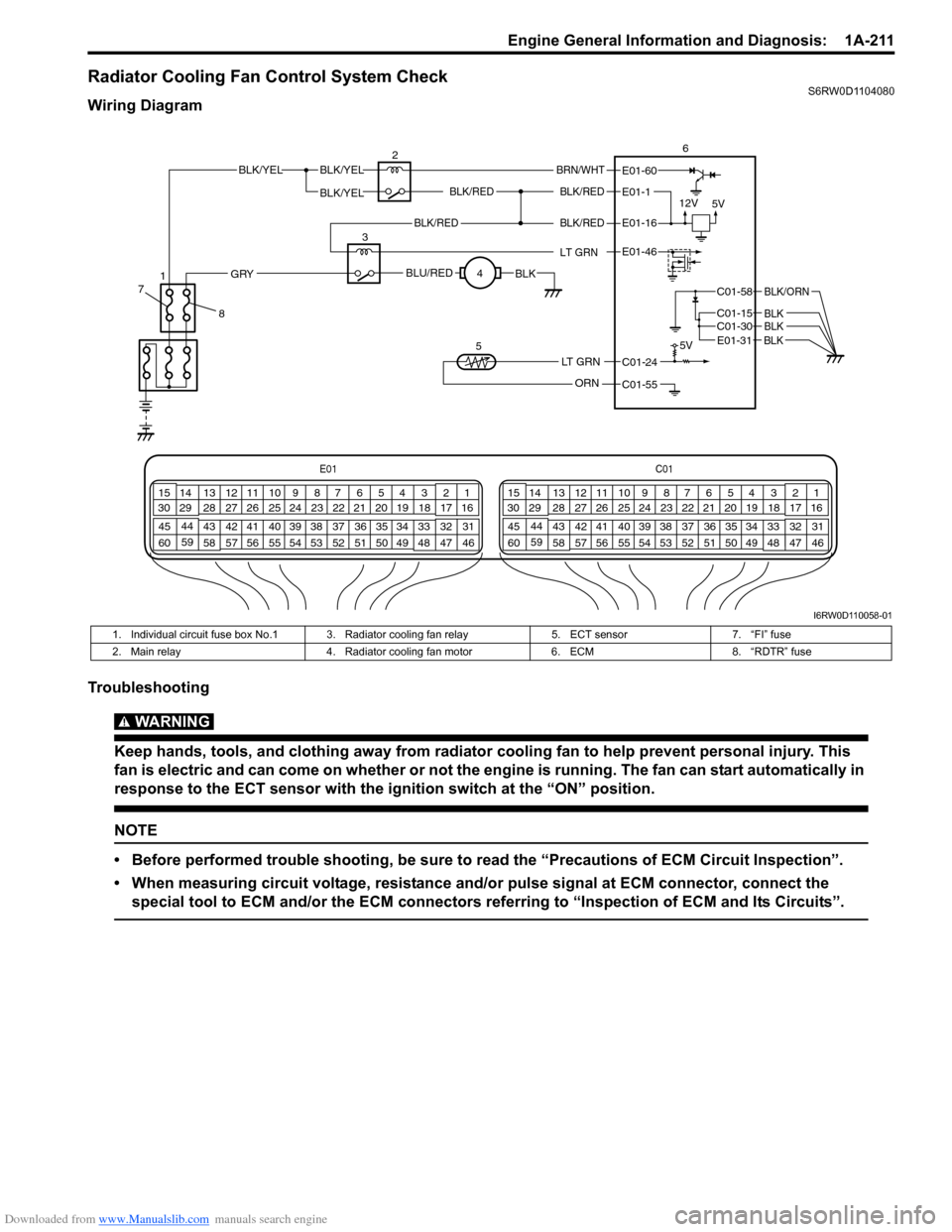

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-211

Radiator Cooling Fan Control System CheckS6RW0D1104080

Wiring Diagram

Troubleshooting

WARNING!

Keep hands, tools, and clothing away from radiator cooling fan to help prevent personal injury. This

fan is electric and can come on whether or not the engine is running. The fan can start automatically in

response to the ECT sensor with the ignition switch at the “ON” position.

NOTE

• Before performed trouble shooting, be sure to read the “Precautions of ECM Circuit Inspection”.

• When measuring circuit voltage, resistance and/or pulse signal at ECM connector, connect the

special tool to ECM and/or the ECM connectors referring to “Inspection of ECM and Its Circuits”.

E01C01

3 4

18 19 5 6 7 10 11

17 20

47 46 49 50 51 21 22

5216 259

24 14

29

55 57 54 53 59

60 582

26 27 28 15

30

56 4832 31 34 35 36 37 40 42 39 38 44

45 43 41 331 12 13

238 3 4

18 19 5 6 7 10 11

17 20

47 46 49 50 51 21 22

5216 259

24 14

29

55 57 54 53 59

60 582

26 27 28 15

30

56 4832 31 34 35 36 37 40 42 39 38 44

45 43 41 331 12 13

238

BLK/REDBLK/RED

BLK/YELBLK/YEL

BLK/YEL

BRN/WHT

12V

5V5V

26

E01-1

E01-60

C01-58

C01-15 C01-30

BLK/ORN

BLKBLK

BLK/RED

LT GRN

BLK/REDE01-16

E01-46

BLU/REDBLKGRY

LT GRN

ORN

C01-24

C01-55 3

4

5

E01-31 BLK

8 71

I6RW0D110058-01

1. Individual circuit fuse box No.1 3. Radiator cooling fan relay 5. ECT sensor 7. “FI” fuse

2. Main relay 4. Radiator cooling fan motor 6. ECM 8. “RDTR” fuse

Page 262 of 1556

Downloaded from www.Manualslib.com manuals search engine 1A-212 Engine General Information and Diagnosis:

Repair Instructions

Idle Speed and IAC Throttle Valve Opening

Inspection

S6RW0D1106001

Before idle speed check, make sure of the following.

• Lead wires and hoses of electronic fuel injection and

engine and emission control systems are connected

securely.

• Valve lash is checked according to maintenance

schedule.

• Ignition timing is within specification.

• All accessories (wipers, heater, lights, A/C, etc.) are

out of service.

• Air cleaner has been properly installed and is in good

condition.

• No abnormal air drawn in from air intake system.After all items are confirmed, check idle speed and IAC

throttle opening as follows.NOTE

Before starting engine, place transmission

gear shift lever in “Neutral”, and set parking

brake and block drive wheels.

Step Action Yes No

1Is there DTC(s) of ECT sensor circuit (DTC P0116 / P0117 /

P0118) and/or radiator cooling fan circuit (DTC P0480)?Go to corresponding

DTC flow.Go to Step 2.

2Radiator cooling fan control circuit check

1) Connect scan tool to DLC with ignition switch turned

OFF.

2) Start engine and select “Data List” on scan tool.

3) Warm up engine until coolant temp. is 100 °C, 212 °F or

higher and A/C switch turns OFF (if equipped with A/C).

(If engine coolant temp. dose not rise, check engine

cooling system or ECT sensor.)

Is radiator cooling fan started when engine coolant temp.

reached above temp.?Radiator cooling fan

control system is in

good condition.Perform from Step 2 to

Step 7 in DTC P0480

diag. flow. If OK, Go to

Ste p 3.

3Radiator cooling fan control check

1) Disconnect radiator cooling fan motor connector with

ignition switch turned OFF.

2) Run engine when ECT is over 100 °C, 212 °F.

3) Measure voltage between vehicle body ground and

“BLU/RED” wire terminal of disconnected radiator

cooling fan motor connector.

Is voltage 10 – 14 V?Go to Step 4. “BLU/RED” wire is open

or high resistance

circuit.

4Check radiator cooling fan wire circuit check

1) Turn ignition switch to OFF position.

2) Measure resistance between “BLK” wire terminal of

disconnected radiator cooling fan motor connector and

vehicle body ground.

Is resistance below 1

Ω?Go to Step 5. “BLK” wire is open or

high resistance circuit.

5Radiator cooling fan check

1) Check radiator cooling fan referring to “Radiator Cooling

Fan Assembly On-Vehicle Inspection in Section 1F”.

Is it in good condition?Substitute a known-

good ECM and recheck.Faulty radiator cooling

fan.

Page 263 of 1556

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-213

1) Connect SUZUKI scan tool to DLC (1) with ignition

switch turned OFF.

Special tool

(A): SUZUKI scan tool (SUZUKI-SDT)2) Warm up engine to normal operating temperature.

3) Check engine idle speed and “IAC throttle opening”

by using “Data List” mode on scan tool to check “IAC

throttle opening”.

4) If check result is out of specification, inspect electric

throttle body assembly referring to “Electric Throttle

Body Assembly On-Vehicle Inspection in Section

1C”.

Engine idle speed

A/C OFF: 700 ± 50 rpm (IAC duty: 5 – 25%)

A/C ON: 750 ± 50 rpm

5) Check that specified engine idle speed is obtained

with A/C turned ON if vehicle is equipped with A/C.

If not, check A/C system referring to “A/C System

Circuits Check”.

Special Tools and Equipment

Special ToolS6RW0D1108001

(A) 1I5RW0C110011-01

09912–58432 09912–58442

Fuel pressure gauge hose Fuel pressure gauge

This tool is included in fuel

pressure gauge set (09912-

58413). �)This tool is included in fuel

pressure gauge set (09912-

58413). �)

09912–58490 09933–06320

3-way joint & hose ECM check harness (120P)

�)�) / �)

SUZUKI scan tool (SUZUKI-

SDT)

—

This kit includes following

items. 1. SUZUKI-SDT 2.

DLC3 cable 3. USB cable 4.

AC/DC power supply 5.

Voltage meter probe 6.

Storage case �) / �)

1

2

34

56

Page 264 of 1556

Downloaded from www.Manualslib.com manuals search engine 1B-1 Aux. Emission Control Devices:

Engine

Aux. Emission Control Devices

Diagnostic Information and Procedures

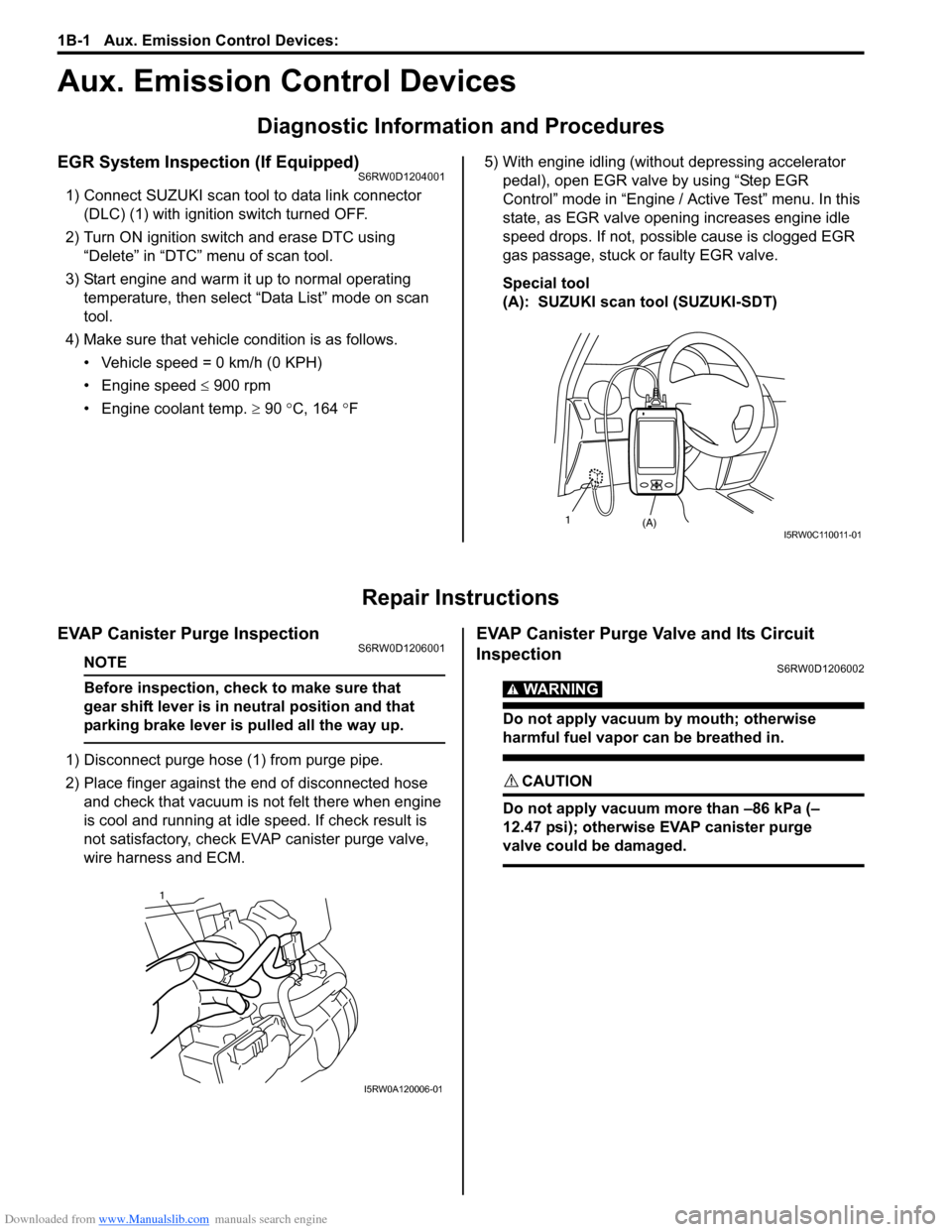

EGR System Inspection (If Equipped)S6RW0D1204001

1) Connect SUZUKI scan tool to data link connector

(DLC) (1) with ignition switch turned OFF.

2) Turn ON ignition switch and erase DTC using

“Delete” in “DTC” menu of scan tool.

3) Start engine and warm it up to normal operating

temperature, then select “Data List” mode on scan

tool.

4) Make sure that vehicle condition is as follows.

• Vehicle speed = 0 km/h (0 KPH)

• Engine speed ≤ 900 rpm

• Engine coolant temp. ≥ 90 °C, 164 °F5) With engine idling (without depressing accelerator

pedal), open EGR valve by using “Step EGR

Control” mode in “Engine / Active Test” menu. In this

state, as EGR valve opening increases engine idle

speed drops. If not, possible cause is clogged EGR

gas passage, stuck or faulty EGR valve.

Special tool

(A): SUZUKI scan tool (SUZUKI-SDT)

Repair Instructions

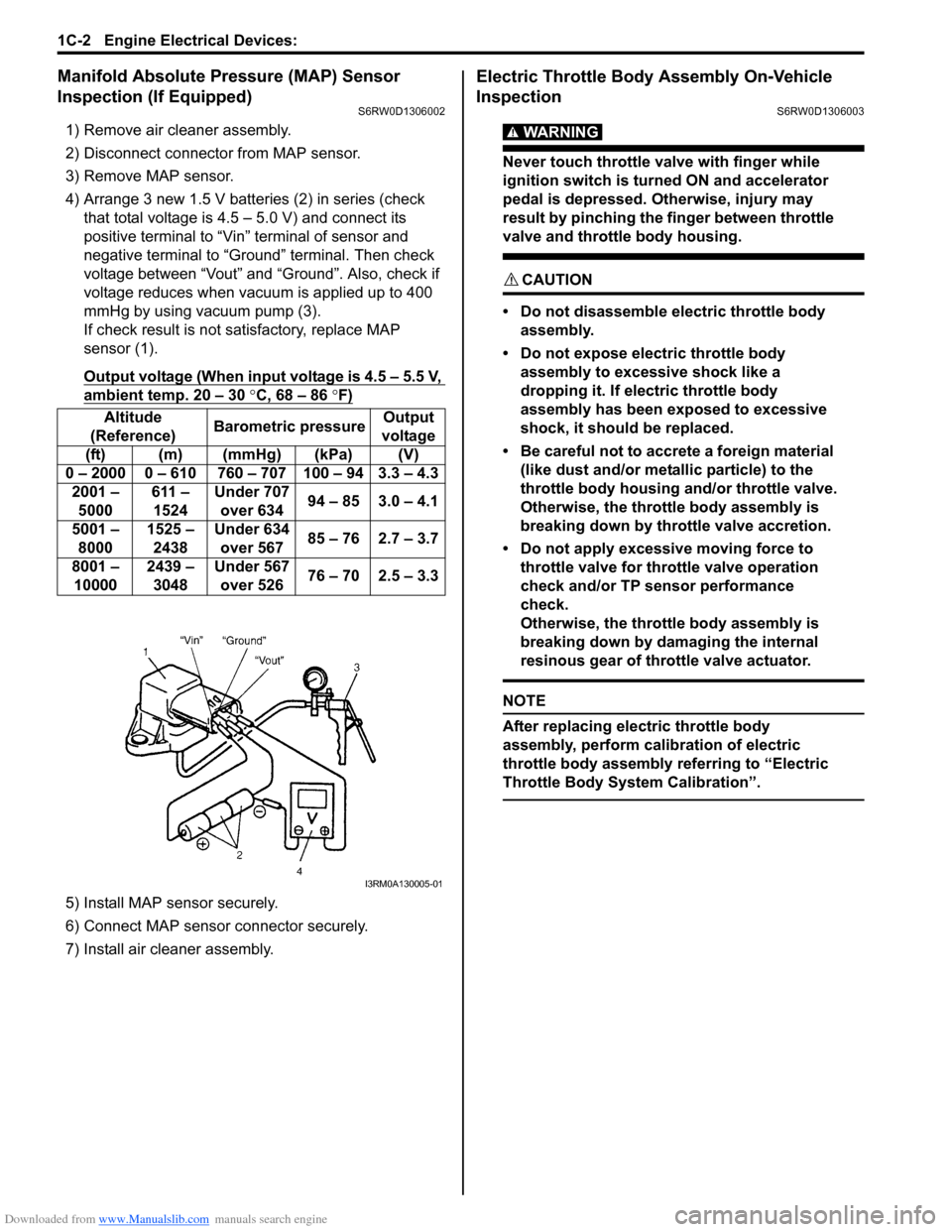

EVAP Canister Purge InspectionS6RW0D1206001

NOTE

Before inspection, check to make sure that

gear shift lever is in neutral position and that

parking brake lever is pulled all the way up.

1) Disconnect purge hose (1) from purge pipe.

2) Place finger against the end of disconnected hose

and check that vacuum is not felt there when engine

is cool and running at idle speed. If check result is

not satisfactory, check EVAP canister purge valve,

wire harness and ECM.

EVAP Canister Purge Valve and Its Circuit

Inspection

S6RW0D1206002

WARNING!

Do not apply vacuum by mouth; otherwise

harmful fuel vapor can be breathed in.

CAUTION!

Do not apply vacuum more than –86 kPa (–

12.47 psi); otherwise EVAP canister purge

valve could be damaged.

(A) 1I5RW0C110011-01

1

I5RW0A120006-01

Page 270 of 1556

Downloaded from www.Manualslib.com manuals search engine 1C-2 Engine Electrical Devices:

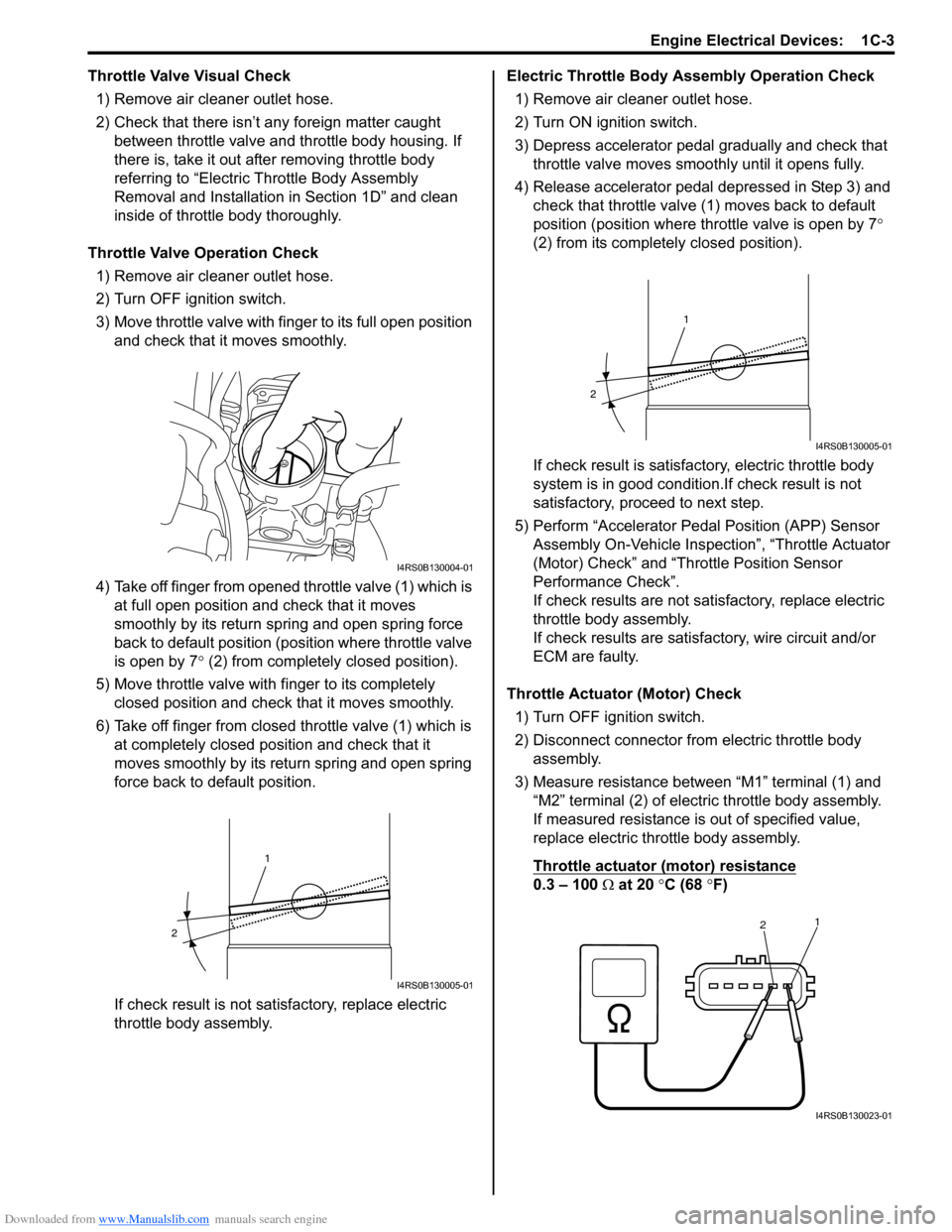

Manifold Absolute Pressure (MAP) Sensor

Inspection (If Equipped)

S6RW0D1306002

1) Remove air cleaner assembly.

2) Disconnect connector from MAP sensor.

3) Remove MAP sensor.

4) Arrange 3 new 1.5 V batteries (2) in series (check

that total voltage is 4.5 – 5.0 V) and connect its

positive terminal to “Vin” terminal of sensor and

negative terminal to “Ground” terminal. Then check

voltage between “Vout” and “Ground”. Also, check if

voltage reduces when vacuum is applied up to 400

mmHg by using vacuum pump (3).

If check result is not satisfactory, replace MAP

sensor (1).

Output voltage (When input voltage is 4.5 – 5.5 V,

ambient temp. 20 – 30 °C, 68 – 86 °F)

5) Install MAP sensor securely.

6) Connect MAP sensor connector securely.

7) Install air cleaner assembly.

Electric Throttle Body Assembly On-Vehicle

Inspection

S6RW0D1306003

WARNING!

Never touch throttle valve with finger while

ignition switch is turned ON and accelerator

pedal is depressed. Otherwise, injury may

result by pinching the finger between throttle

valve and throttle body housing.

CAUTION!

• Do not disassemble electric throttle body

assembly.

• Do not expose electric throttle body

assembly to excessive shock like a

dropping it. If electric throttle body

assembly has been exposed to excessive

shock, it should be replaced.

• Be careful not to accrete a foreign material

(like dust and/or metallic particle) to the

throttle body housing and/or throttle valve.

Otherwise, the throttle body assembly is

breaking down by throttle valve accretion.

• Do not apply excessive moving force to

throttle valve for throttle valve operation

check and/or TP sensor performance

check.

Otherwise, the throttle body assembly is

breaking down by damaging the internal

resinous gear of throttle valve actuator.

NOTE

After replacing electric throttle body

assembly, perform calibration of electric

throttle body assembly referring to “Electric

Throttle Body System Calibration”.

Altitude

(Reference)Barometric pressureOutput

voltage

(ft) (m) (mmHg) (kPa) (V)

0 – 2000 0 – 610 760 – 707 100 – 94 3.3 – 4.3

2001 –

5000611 –

1524Under 707

over 63494 – 85 3.0 – 4.1

5001 –

80001525 –

2438Under 634

over 56785 – 76 2.7 – 3.7

8001 –

100002439 –

3048Under 567

over 52676 – 70 2.5 – 3.3

I3RM0A130005-01

Page 271 of 1556

Downloaded from www.Manualslib.com manuals search engine Engine Electrical Devices: 1C-3

Throttle Valve Visual Check

1) Remove air cleaner outlet hose.

2) Check that there isn’t any foreign matter caught

between throttle valve and throttle body housing. If

there is, take it out after removing throttle body

referring to “Electric Throttle Body Assembly

Removal and Installation in Section 1D” and clean

inside of throttle body thoroughly.

Throttle Valve Operation Check

1) Remove air cleaner outlet hose.

2) Turn OFF ignition switch.

3) Move throttle valve with finger to its full open position

and check that it moves smoothly.

4) Take off finger from opened throttle valve (1) which is

at full open position and check that it moves

smoothly by its return spring and open spring force

back to default position (position where throttle valve

is open by 7° (2) from completely closed position).

5) Move throttle valve with finger to its completely

closed position and check that it moves smoothly.

6) Take off finger from closed throttle valve (1) which is

at completely closed position and check that it

moves smoothly by its return spring and open spring

force back to default position.

If check result is not satisfactory, replace electric

throttle body assembly.Electric Throttle Body Assembly Operation Check

1) Remove air cleaner outlet hose.

2) Turn ON ignition switch.

3) Depress accelerator pedal gradually and check that

throttle valve moves smoothly until it opens fully.

4) Release accelerator pedal depressed in Step 3) and

check that throttle valve (1) moves back to default

position (position where throttle valve is open by 7°

(2) from its completely closed position).

If check result is satisfactory, electric throttle body

system is in good condition.If check result is not

satisfactory, proceed to next step.

5) Perform “Accelerator Pedal Position (APP) Sensor

Assembly On-Vehicle Inspection”, “Throttle Actuator

(Motor) Check” and “Throttle Position Sensor

Performance Check”.

If check results are not satisfactory, replace electric

throttle body assembly.

If check results are satisfactory, wire circuit and/or

ECM are faulty.

Throttle Actuator (Motor) Check

1) Turn OFF ignition switch.

2) Disconnect connector from electric throttle body

assembly.

3) Measure resistance between “M1” terminal (1) and

“M2” terminal (2) of electric throttle body assembly.

If measured resistance is out of specified value,

replace electric throttle body assembly.

Throttle actuator (motor) resistance

0.3 – 100 Ω at 20 °C (68 °F)

I4RS0B130004-01

1

2

I4RS0B130005-01

1

2

I4RS0B130005-01

21

I4RS0B130023-01

Page 273 of 1556

Downloaded from www.Manualslib.com manuals search engine Engine Electrical Devices: 1C-5

Electric Throttle Body System CalibrationS6RW0D1306004

NOTE

If the service described under the

“Precautions of Electric Throttle Body

System Calibration in Section 1A” is

performed, calibrate electric throttle body

system as follows.

1) If electric throttle body assembly and/or accelerator

pedal position (APP) sensor assembly are replaced,

perform following steps.

a) Disconnect negative cable at battery for 20

seconds or more for the purpose of clearing

calibration data of closed throttle position from

memory in ECM.

b) Connect negative cable to battery.

2) Keep ignition switch at ON position for 5 seconds or

more without running engine.

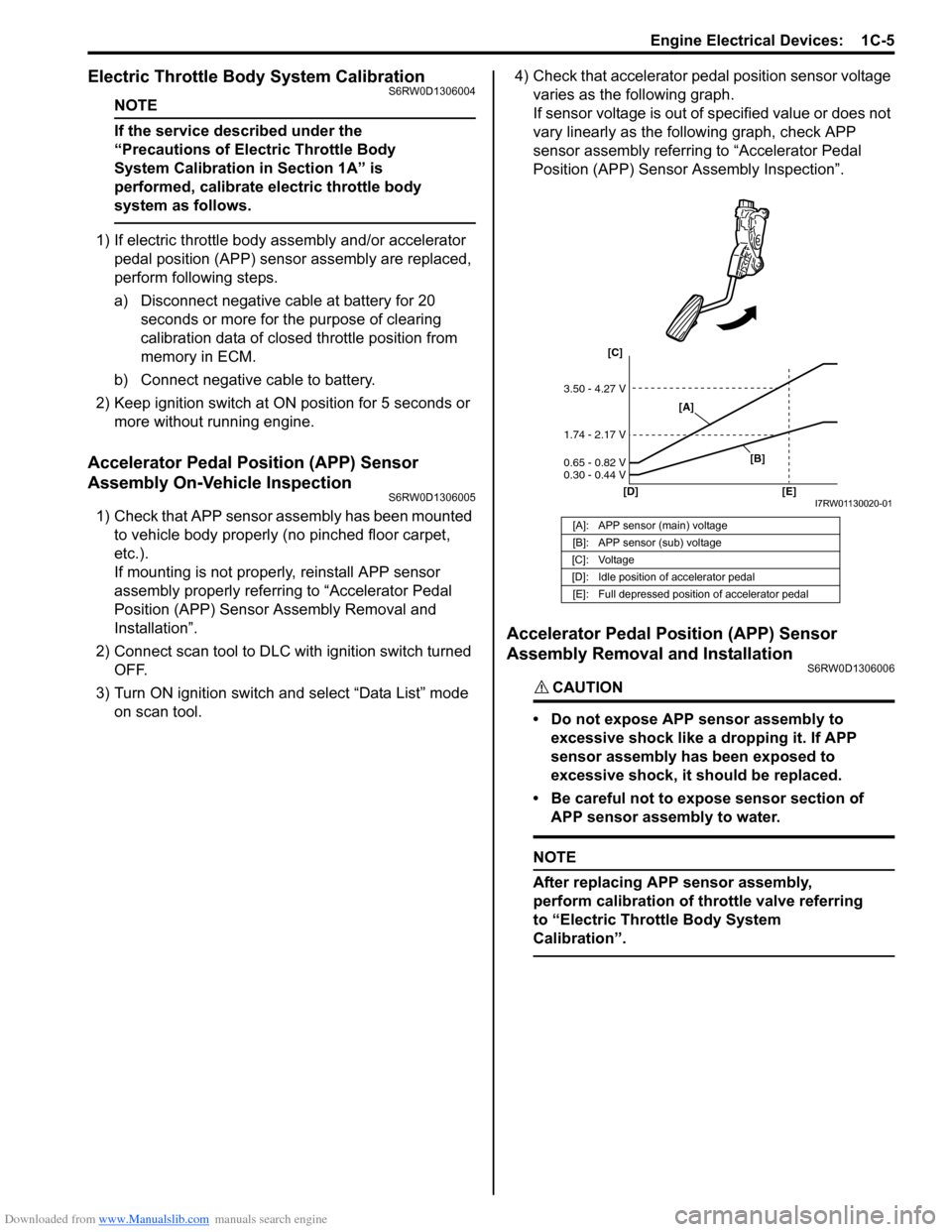

Accelerator Pedal Position (APP) Sensor

Assembly On-Vehicle Inspection

S6RW0D1306005

1) Check that APP sensor assembly has been mounted

to vehicle body properly (no pinched floor carpet,

etc.).

If mounting is not properly, reinstall APP sensor

assembly properly referring to “Accelerator Pedal

Position (APP) Sensor Assembly Removal and

Installation”.

2) Connect scan tool to DLC with ignition switch turned

OFF.

3) Turn ON ignition switch and select “Data List” mode

on scan tool.4) Check that accelerator pedal position sensor voltage

varies as the following graph.

If sensor voltage is out of specified value or does not

vary linearly as the following graph, check APP

sensor assembly referring to “Accelerator Pedal

Position (APP) Sensor Assembly Inspection”.

Accelerator Pedal Position (APP) Sensor

Assembly Removal and Installation

S6RW0D1306006

CAUTION!

• Do not expose APP sensor assembly to

excessive shock like a dropping it. If APP

sensor assembly has been exposed to

excessive shock, it should be replaced.

• Be careful not to expose sensor section of

APP sensor assembly to water.

NOTE

After replacing APP sensor assembly,

perform calibration of throttle valve referring

to “Electric Throttle Body System

Calibration”.

[A]: APP sensor (main) voltage

[B]: APP sensor (sub) voltage

[C]: Voltage

[D]: Idle position of accelerator pedal

[E]: Full depressed position of accelerator pedal

[C]

[D] [E]

3.50 - 4.27 V

1.74 - 2.17 V

0.65 - 0.82 V

0.30 - 0.44 V

[A]

[B]

I7RW01130020-01