Water SUZUKI SX4 2006 1.G Service Owner's Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2006, Model line: SX4, Model: SUZUKI SX4 2006 1.GPages: 1556, PDF Size: 37.31 MB

Page 306 of 1556

Downloaded from www.Manualslib.com manuals search engine 1D-24 Engine Mechanical:

Installation

1) Clean sealing surface on timing chain cover, cylinder

block and cylinder head.

Remove oil, old sealant and dust from sealing

surface.

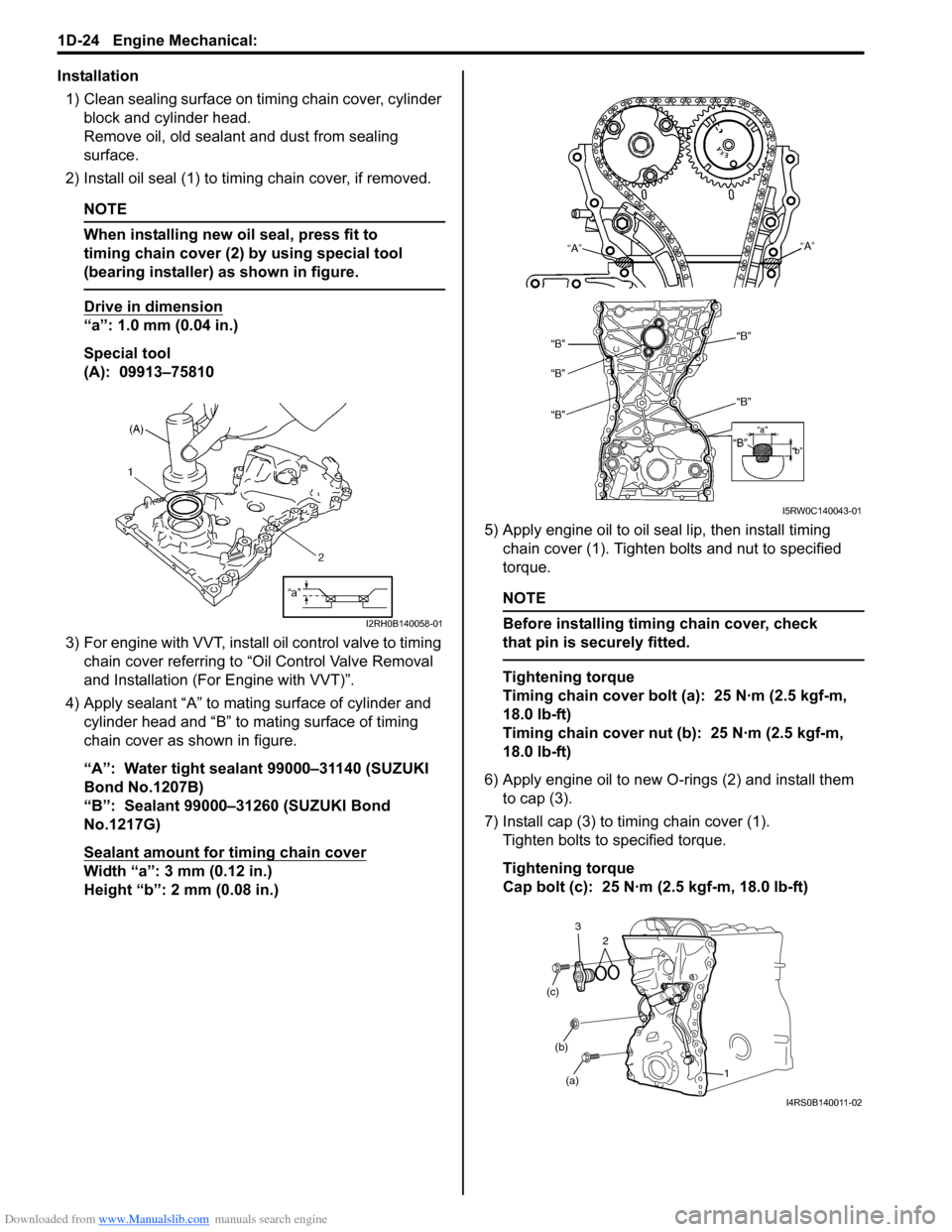

2) Install oil seal (1) to timing chain cover, if removed.

NOTE

When installing new oil seal, press fit to

timing chain cover (2) by using special tool

(bearing installer) as shown in figure.

Drive in dimension

“a”: 1.0 mm (0.04 in.)

Special tool

(A): 09913–75810

3) For engine with VVT, install oil control valve to timing

chain cover referring to “Oil Control Valve Removal

and Installation (For Engine with VVT)”.

4) Apply sealant “A” to mating surface of cylinder and

cylinder head and “B” to mating surface of timing

chain cover as shown in figure.

“A”: Water tight sealant 99000–31140 (SUZUKI

Bond No.1207B)

“B”: Sealant 99000–31260 (SUZUKI Bond

No.1217G)

Sealant amount for timing chain cover

Width “a”: 3 mm (0.12 in.)

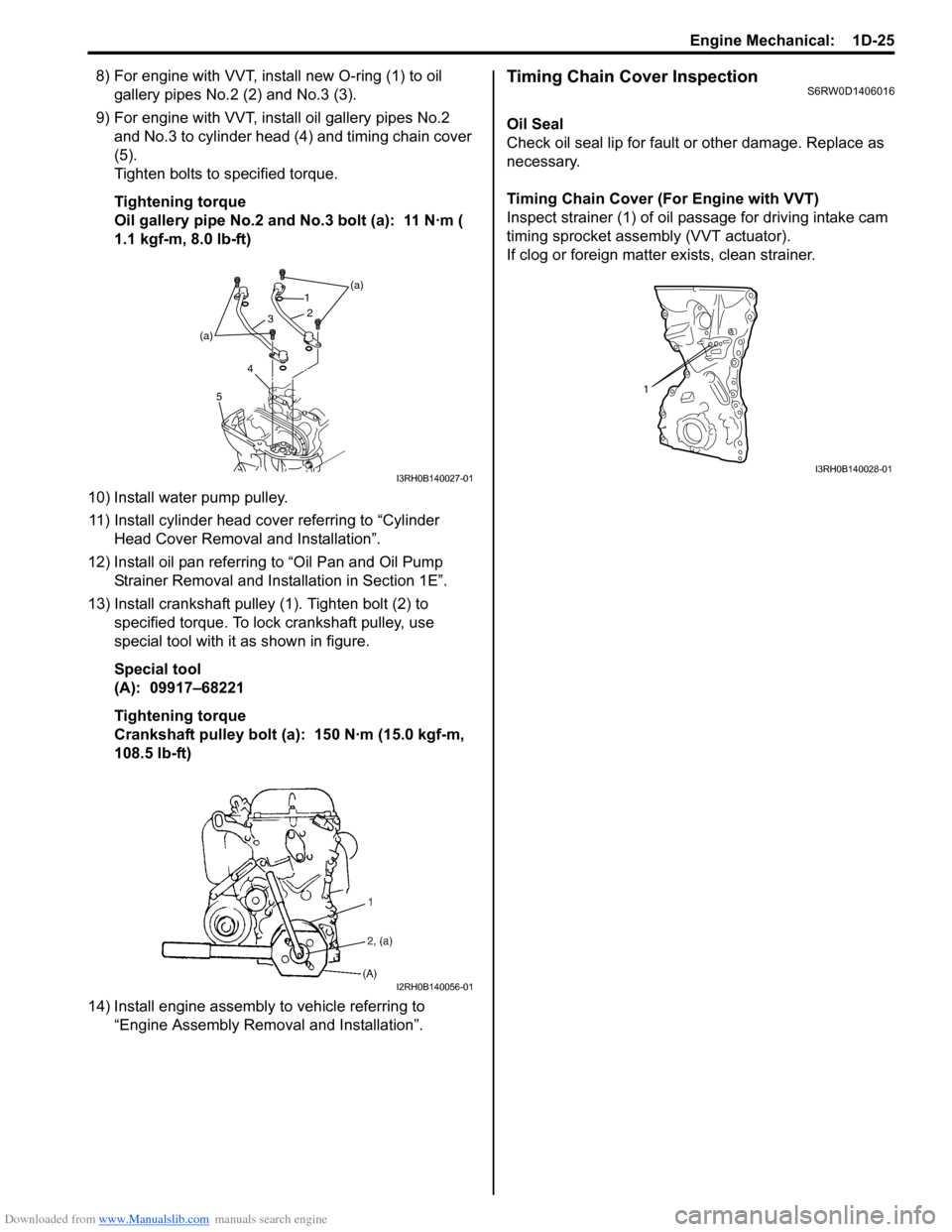

Height “b”: 2 mm (0.08 in.)5) Apply engine oil to oil seal lip, then install timing

chain cover (1). Tighten bolts and nut to specified

torque.

NOTE

Before installing timing chain cover, check

that pin is securely fitted.

Tightening torque

Timing chain cover bolt (a): 25 N·m (2.5 kgf-m,

18.0 lb-ft)

Timing chain cover nut (b): 25 N·m (2.5 kgf-m,

18.0 lb-ft)

6) Apply engine oil to new O-rings (2) and install them

to cap (3).

7) Install cap (3) to timing chain cover (1).

Tighten bolts to specified torque.

Tightening torque

Cap bolt (c): 25 N·m (2.5 kgf-m, 18.0 lb-ft)

I2RH0B140058-01

I5RW0C140043-01

(a) (b) (c)

1 2 3

I4RS0B140011-02

Page 307 of 1556

Downloaded from www.Manualslib.com manuals search engine Engine Mechanical: 1D-25

8) For engine with VVT, install new O-ring (1) to oil

gallery pipes No.2 (2) and No.3 (3).

9) For engine with VVT, install oil gallery pipes No.2

and No.3 to cylinder head (4) and timing chain cover

(5).

Tighten bolts to specified torque.

Tightening torque

Oil gallery pipe No.2 and No.3 bolt (a): 11 N·m (

1.1 kgf-m, 8.0 lb-ft)

10) Install water pump pulley.

11) Install cylinder head cover referring to “Cylinder

Head Cover Removal and Installation”.

12) Install oil pan referring to “Oil Pan and Oil Pump

Strainer Removal and Installation in Section 1E”.

13) Install crankshaft pulley (1). Tighten bolt (2) to

specified torque. To lock crankshaft pulley, use

special tool with it as shown in figure.

Special tool

(A): 09917–68221

Tightening torque

Crankshaft pulley bolt (a): 150 N·m (15.0 kgf-m,

108.5 lb-ft)

14) Install engine assembly to vehicle referring to

“Engine Assembly Removal and Installation”.Timing Chain Cover InspectionS6RW0D1406016

Oil Seal

Check oil seal lip for fault or other damage. Replace as

necessary.

Timing Chain Cover (For Engine with VVT)

Inspect strainer (1) of oil passage for driving intake cam

timing sprocket assembly (VVT actuator).

If clog or foreign matter exists, clean strainer.

(a)

(a)1

2

3

4

5

I3RH0B140027-01

I2RH0B140056-01

1

I3RH0B140028-01

Page 329 of 1556

Downloaded from www.Manualslib.com manuals search engine Engine Mechanical: 1D-47

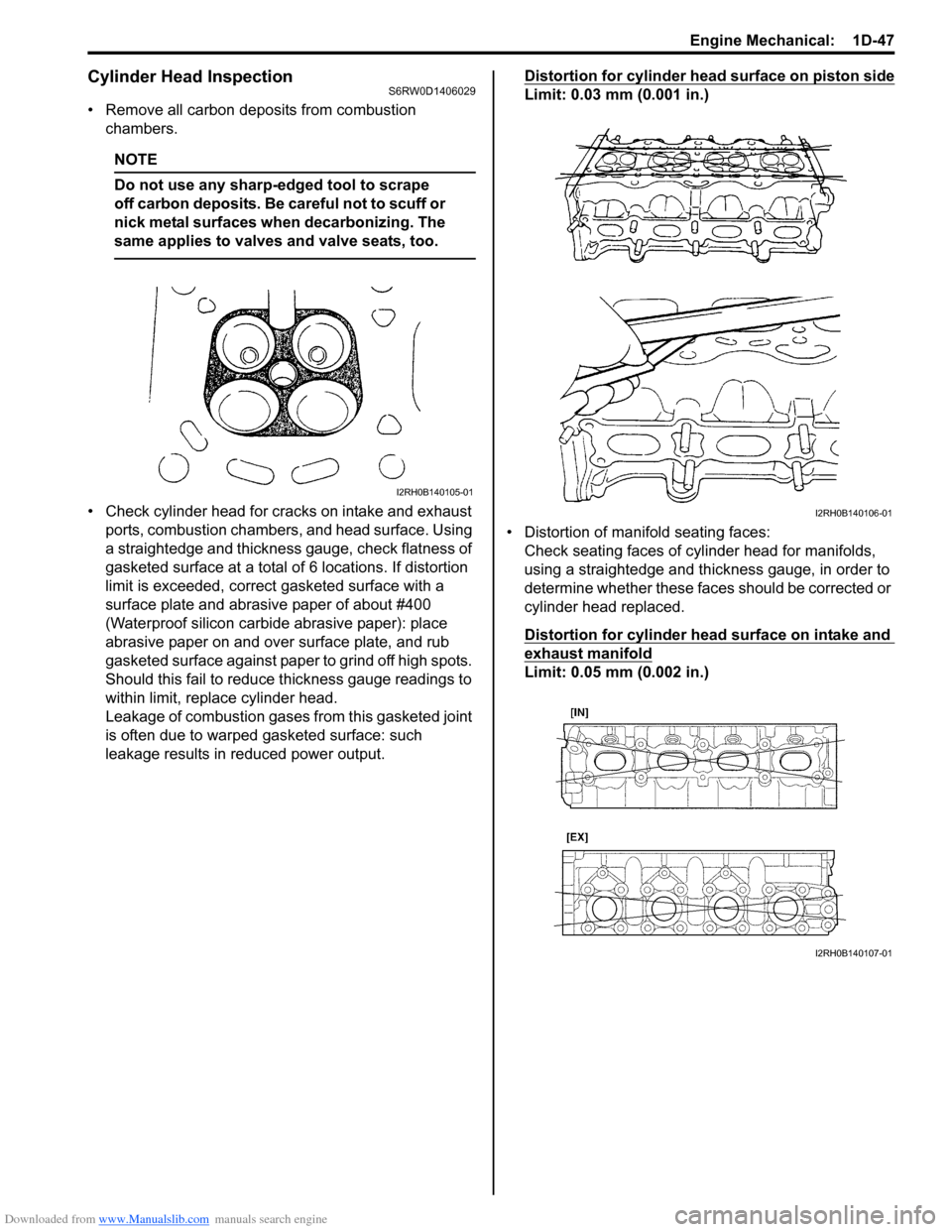

Cylinder Head InspectionS6RW0D1406029

• Remove all carbon deposits from combustion

chambers.

NOTE

Do not use any sharp-edged tool to scrape

off carbon deposits. Be careful not to scuff or

nick metal surfaces when decarbonizing. The

same applies to valves and valve seats, too.

• Check cylinder head for cracks on intake and exhaust

ports, combustion chambers, and head surface. Using

a straightedge and thickness gauge, check flatness of

gasketed surface at a total of 6 locations. If distortion

limit is exceeded, correct gasketed surface with a

surface plate and abrasive paper of about #400

(Waterproof silicon carbide abrasive paper): place

abrasive paper on and over surface plate, and rub

gasketed surface against paper to grind off high spots.

Should this fail to reduce thickness gauge readings to

within limit, replace cylinder head.

Leakage of combustion gases from this gasketed joint

is often due to warped gasketed surface: such

leakage results in reduced power output.Distortion for cylinder head surface on piston side

Limit: 0.03 mm (0.001 in.)

• Distortion of manifold seating faces:

Check seating faces of cylinder head for manifolds,

using a straightedge and thickness gauge, in order to

determine whether these faces should be corrected or

cylinder head replaced.

Distortion for cylinder head surface on intake and

exhaust manifold

Limit: 0.05 mm (0.002 in.)

I2RH0B140105-01

I2RH0B140106-01

I2RH0B140107-01

Page 344 of 1556

Downloaded from www.Manualslib.com manuals search engine 1D-62 Engine Mechanical:

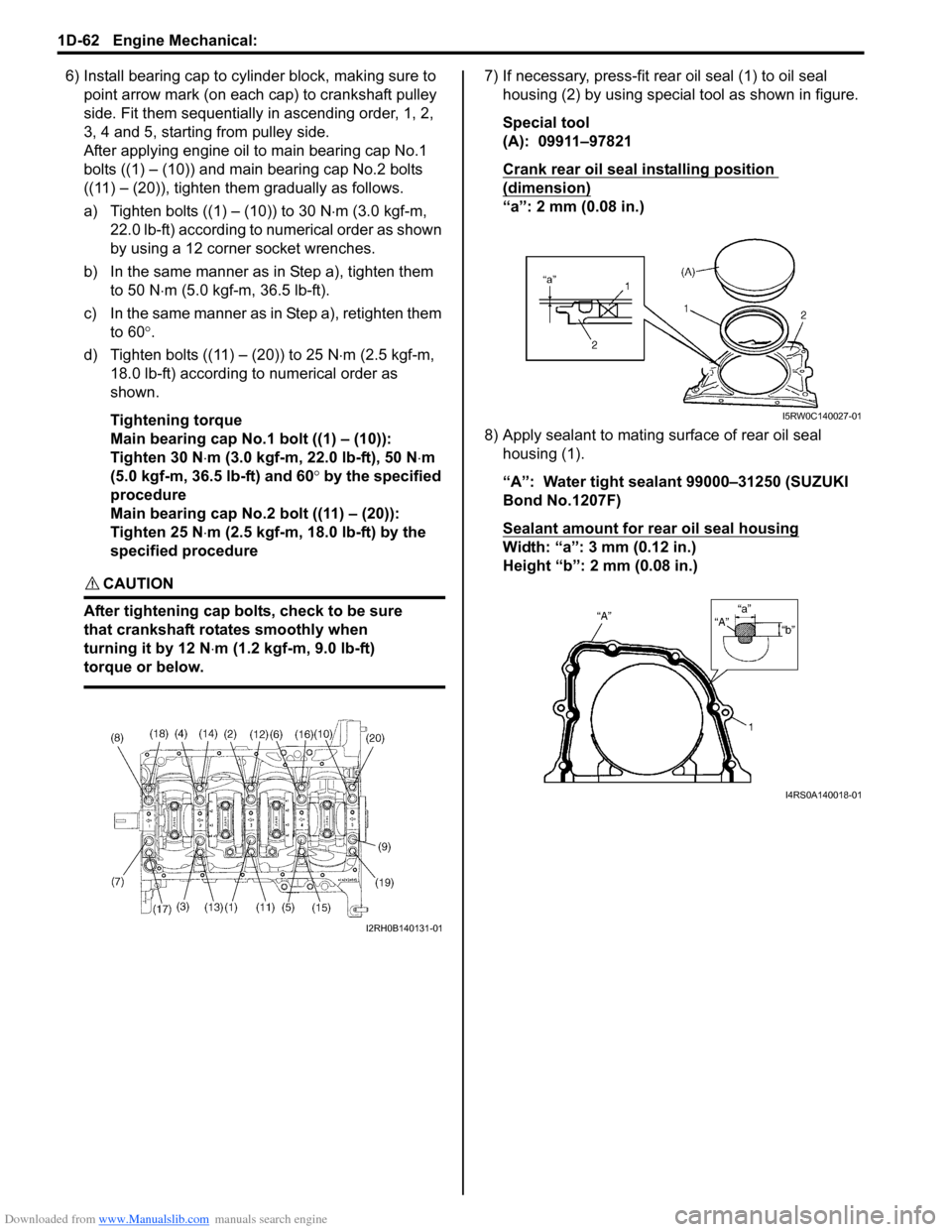

6) Install bearing cap to cylinder block, making sure to

point arrow mark (on each cap) to crankshaft pulley

side. Fit them sequentially in ascending order, 1, 2,

3, 4 and 5, starting from pulley side.

After applying engine oil to main bearing cap No.1

bolts ((1) – (10)) and main bearing cap No.2 bolts

((11) – (20)), tighten them gradually as follows.

a) Tighten bolts ((1) – (10)) to 30 N⋅m (3.0 kgf-m,

22.0 lb-ft) according to numerical order as shown

by using a 12 corner socket wrenches.

b) In the same manner as in Step a), tighten them

to 50 N⋅m (5.0 kgf-m, 36.5 lb-ft).

c) In the same manner as in Step a), retighten them

to 60°.

d) Tighten bolts ((11) – (20)) to 25 N⋅m (2.5 kgf-m,

18.0 lb-ft) according to numerical order as

shown.

Tightening torque

Main bearing cap No.1 bolt ((1) – (10)):

Tighten 30 N⋅m (3.0 kgf-m, 22.0 lb-ft), 50 N⋅m

(5.0 kgf-m, 36.5 lb-ft) and 60° by the specified

procedure

Main bearing cap No.2 bolt ((11) – (20)):

Tighten 25 N⋅m (2.5 kgf-m, 18.0 lb-ft) by the

specified procedure

CAUTION!

After tightening cap bolts, check to be sure

that crankshaft rotates smoothly when

turning it by 12 N⋅m (1.2 kgf-m, 9.0 lb-ft)

torque or below.

7) If necessary, press-fit rear oil seal (1) to oil seal

housing (2) by using special tool as shown in figure.

Special tool

(A): 09911–97821

Crank rear oil seal installing position

(dimension)

“a”: 2 mm (0.08 in.)

8) Apply sealant to mating surface of rear oil seal

housing (1).

“A”: Water tight sealant 99000–31250 (SUZUKI

Bond No.1207F)

Sealant amount for rear oil seal housing

Width: “a”: 3 mm (0.12 in.)

Height “b”: 2 mm (0.08 in.)

I2RH0B140131-01

I5RW0C140027-01

I4RS0A140018-01

Page 355 of 1556

Downloaded from www.Manualslib.com manuals search engine Engine Mechanical: 1D-73

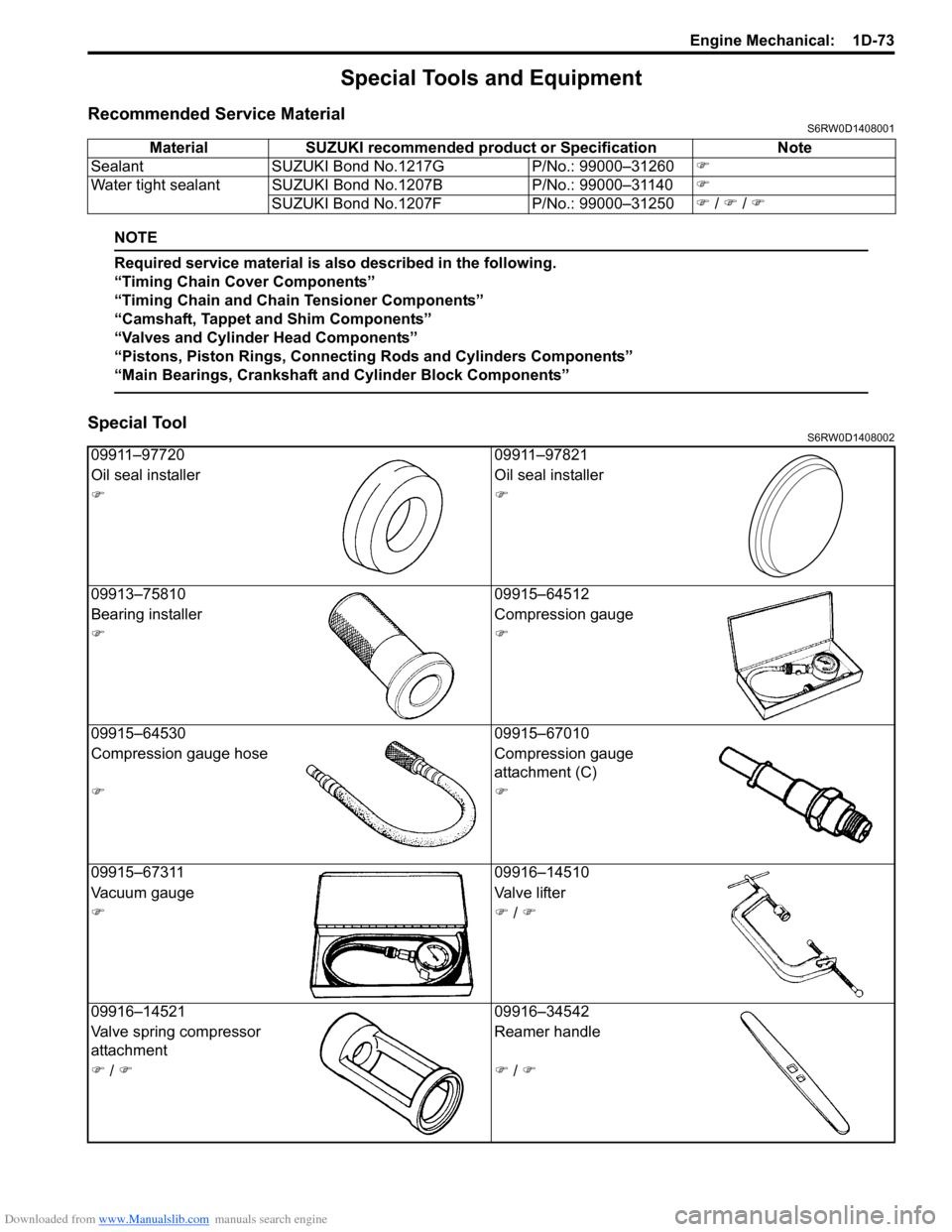

Special Tools and Equipment

Recommended Service MaterialS6RW0D1408001

NOTE

Required service material is also described in the following.

“Timing Chain Cover Components”

“Timing Chain and Chain Tensioner Components”

“Camshaft, Tappet and Shim Components”

“Valves and Cylinder Head Components”

“Pistons, Piston Rings, Connecting Rods and Cylinders Components”

“Main Bearings, Crankshaft and Cylinder Block Components”

Special ToolS6RW0D1408002

Material SUZUKI recommended product or Specification Note

Sealant SUZUKI Bond No.1217G P/No.: 99000–31260�)

Water tight sealant SUZUKI Bond No.1207B P/No.: 99000–31140�)

SUZUKI Bond No.1207F P/No.: 99000–31250�) / �) / �)

09911–97720 09911–97821

Oil seal installer Oil seal installer

�)�)

09913–75810 09915–64512

Bearing installer Compression gauge

�)�)

09915–64530 09915–67010

Compression gauge hose Compression gauge

attachment (C)

�)�)

09915–67311 09916–14510

Vacuum gauge Valve lifter

�)�) / �)

09916–14521 09916–34542

Valve spring compressor

attachmentReamer handle

�) / �)�) / �)

Page 366 of 1556

Downloaded from www.Manualslib.com manuals search engine 1F-1 Engine Cooling System:

Engine

Engine Cooling System

General Description

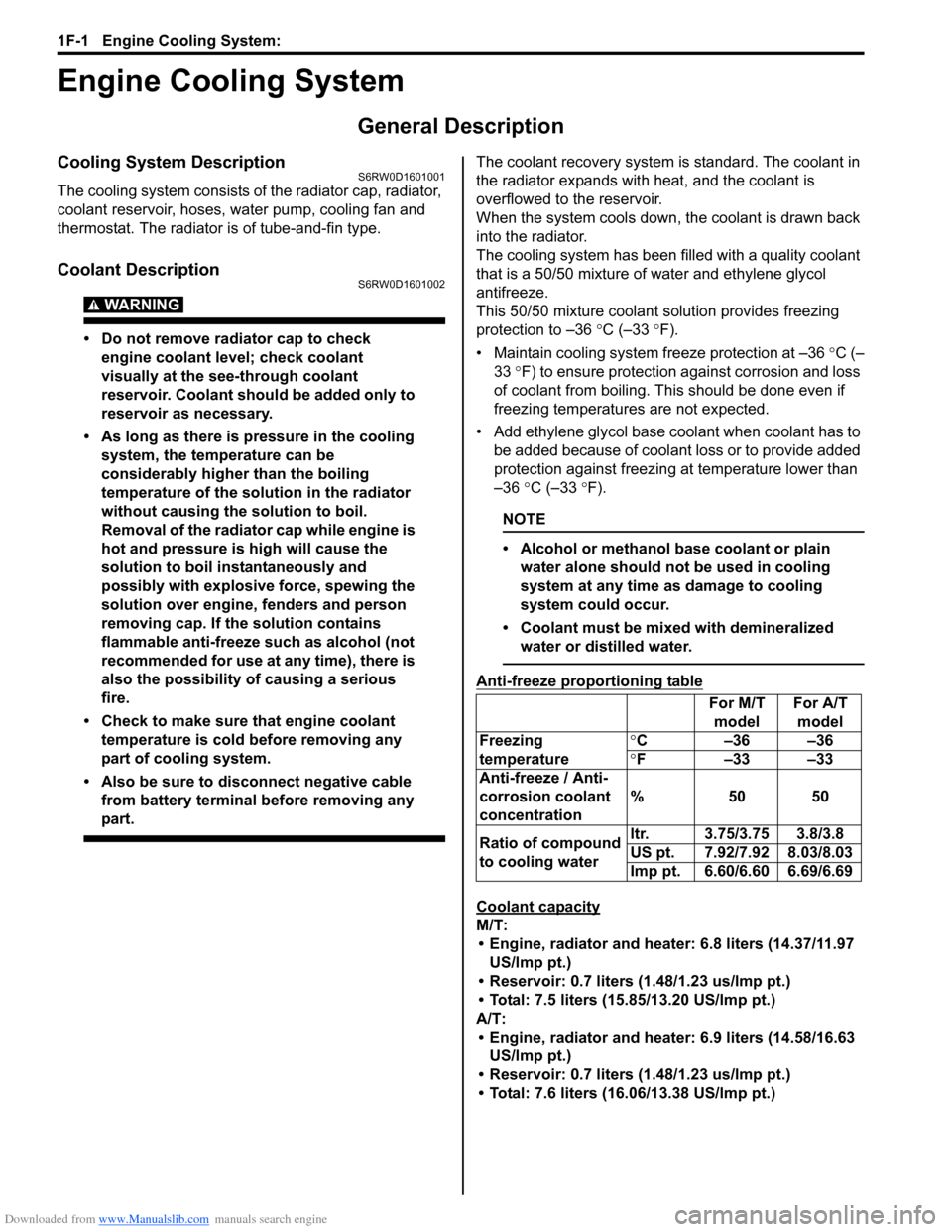

Cooling System DescriptionS6RW0D1601001

The cooling system consists of the radiator cap, radiator,

coolant reservoir, hoses, water pump, cooling fan and

thermostat. The radiator is of tube-and-fin type.

Coolant DescriptionS6RW0D1601002

WARNING!

• Do not remove radiator cap to check

engine coolant level; check coolant

visually at the see-through coolant

reservoir. Coolant should be added only to

reservoir as necessary.

• As long as there is pressure in the cooling

system, the temperature can be

considerably higher than the boiling

temperature of the solution in the radiator

without causing the solution to boil.

Removal of the radiator cap while engine is

hot and pressure is high will cause the

solution to boil instantaneously and

possibly with explosive force, spewing the

solution over engine, fenders and person

removing cap. If the solution contains

flammable anti-freeze such as alcohol (not

recommended for use at any time), there is

also the possibility of causing a serious

fire.

• Check to make sure that engine coolant

temperature is cold before removing any

part of cooling system.

• Also be sure to disconnect negative cable

from battery terminal before removing any

part.

The coolant recovery system is standard. The coolant in

the radiator expands with heat, and the coolant is

overflowed to the reservoir.

When the system cools down, the coolant is drawn back

into the radiator.

The cooling system has been filled with a quality coolant

that is a 50/50 mixture of water and ethylene glycol

antifreeze.

This 50/50 mixture coolant solution provides freezing

protection to –36 °C (–33 °F).

• Maintain cooling system freeze protection at –36 °C (–

33 °F) to ensure protection against corrosion and loss

of coolant from boiling. This should be done even if

freezing temperatures are not expected.

• Add ethylene glycol base coolant when coolant has to

be added because of coolant loss or to provide added

protection against freezing at temperature lower than

–36 °C (–33 °F).

NOTE

• Alcohol or methanol base coolant or plain

water alone should not be used in cooling

system at any time as damage to cooling

system could occur.

• Coolant must be mixed with demineralized

water or distilled water.

Anti-freeze proportioning table

Coolant capacity

M/T:

• Engine, radiator and heater: 6.8 liters (14.37/11.97

US/lmp pt.)

• Reservoir: 0.7 liters (1.48/1.23 us/lmp pt.)

• Total: 7.5 liters (15.85/13.20 US/lmp pt.)

A/T:

• Engine, radiator and heater: 6.9 liters (14.58/16.63

US/lmp pt.)

• Reservoir: 0.7 liters (1.48/1.23 us/lmp pt.)

• Total: 7.6 liters (16.06/13.38 US/lmp pt.)For M/T

modelFor A/T

model

Freezing

temperature°C–36–36

°F–33–33

Anti-freeze / Anti-

corrosion coolant

concentration%5050

Ratio of compound

to cooling waterltr. 3.75/3.75 3.8/3.8

US pt. 7.92/7.92 8.03/8.03

Imp pt. 6.60/6.60 6.69/6.69

Page 367 of 1556

Downloaded from www.Manualslib.com manuals search engine Engine Cooling System: 1F-2

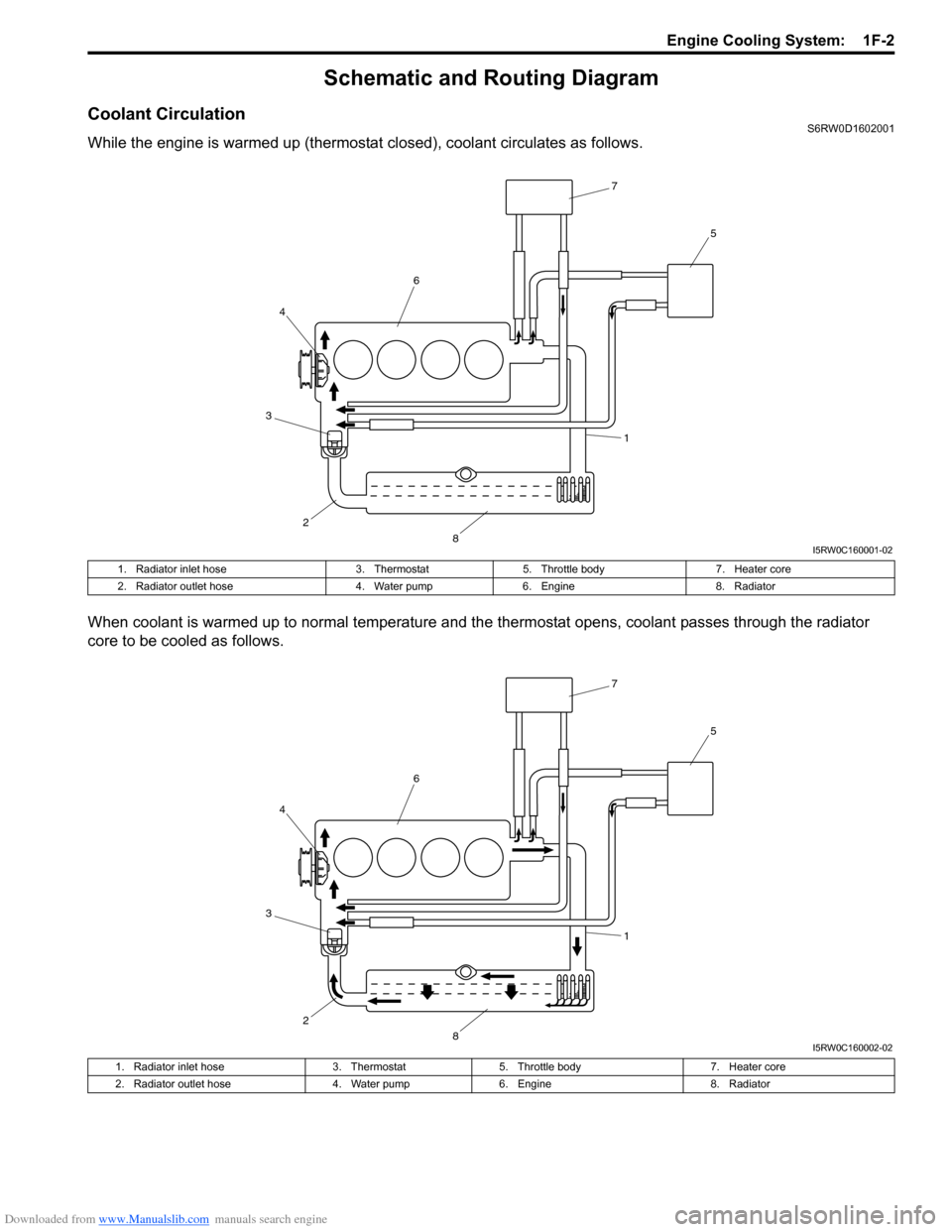

Schematic and Routing Diagram

Coolant CirculationS6RW0D1602001

While the engine is warmed up (thermostat closed), coolant circulates as follows.

When coolant is warmed up to normal temperature and the thermostat opens, coolant passes through the radiator

core to be cooled as follows.

7

5

6

4

3

2

81

I5RW0C160001-02

1. Radiator inlet hose 3. Thermostat 5. Throttle body 7. Heater core

2. Radiator outlet hose 4. Water pump 6. Engine 8. Radiator

7

5

6

4

3

2

81

I5RW0C160002-02

1. Radiator inlet hose 3. Thermostat 5. Throttle body 7. Heater core

2. Radiator outlet hose 4. Water pump 6. Engine 8. Radiator

Page 368 of 1556

Downloaded from www.Manualslib.com manuals search engine 1F-3 Engine Cooling System:

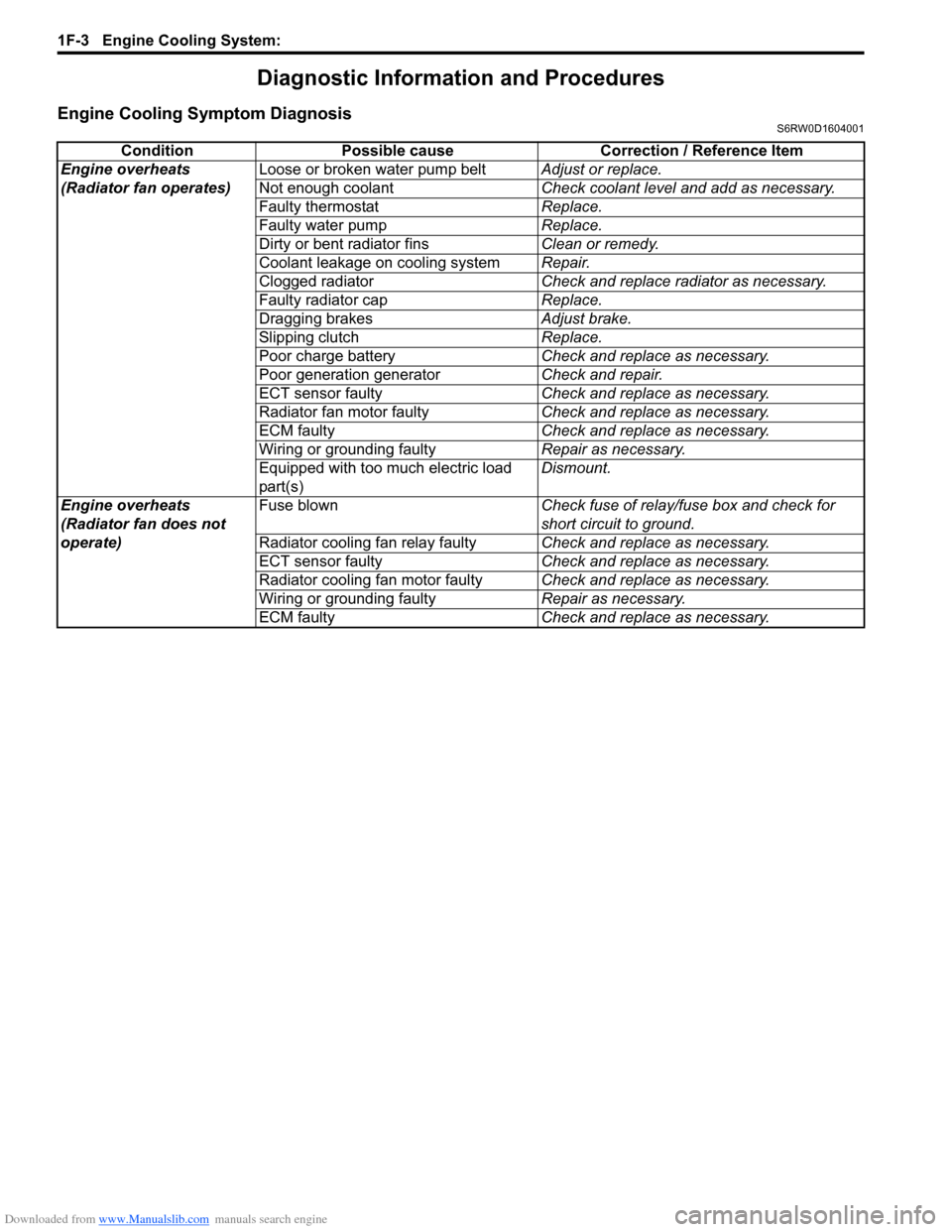

Diagnostic Information and Procedures

Engine Cooling Symptom DiagnosisS6RW0D1604001

Condition Possible cause Correction / Reference Item

Engine overheats

(Radiator fan operates)Loose or broken water pump beltAdjust or replace.

Not enough coolantCheck coolant level and add as necessary.

Faulty thermostatReplace.

Faulty water pumpReplace.

Dirty or bent radiator finsClean or remedy.

Coolant leakage on cooling systemRepair.

Clogged radiatorCheck and replace radiator as necessary.

Faulty radiator capReplace.

Dragging brakesAdjust brake.

Slipping clutchReplace.

Poor charge batteryCheck and replace as necessary.

Poor generation generatorCheck and repair.

ECT sensor faultyCheck and replace as necessary.

Radiator fan motor faultyCheck and replace as necessary.

ECM faultyCheck and replace as necessary.

Wiring or grounding faultyRepair as necessary.

Equipped with too much electric load

part(s)Dismount.

Engine overheats

(Radiator fan does not

operate)Fuse blownCheck fuse of relay/fuse box and check for

short circuit to ground.

Radiator cooling fan relay faultyCheck and replace as necessary.

ECT sensor faultyCheck and replace as necessary.

Radiator cooling fan motor faultyCheck and replace as necessary.

Wiring or grounding faultyRepair as necessary.

ECM faultyCheck and replace as necessary.

Page 369 of 1556

Downloaded from www.Manualslib.com manuals search engine Engine Cooling System: 1F-4

Repair Instructions

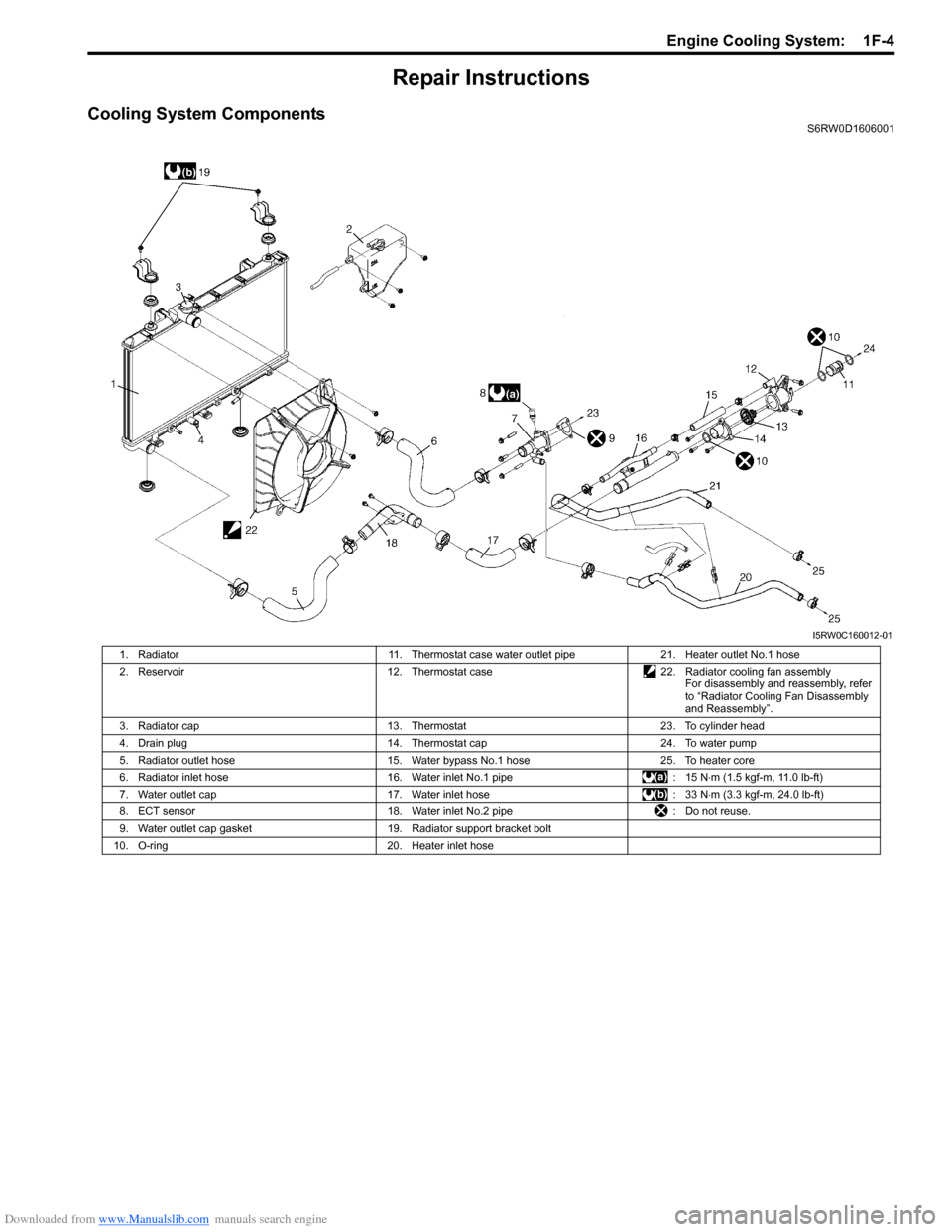

Cooling System ComponentsS6RW0D1606001

I5RW0C160012-01

1. Radiator 11. Thermostat case water outlet pipe 21. Heater outlet No.1 hose

2. Reservoir 12. Thermostat case 22. Radiator cooling fan assembly

For disassembly and reassembly, refer

to “Radiator Cooling Fan Disassembly

and Reassembly”.

3. Radiator cap 13. Thermostat 23. To cylinder head

4. Drain plug 14. Thermostat cap 24. To water pump

5. Radiator outlet hose 15. Water bypass No.1 hose 25. To heater core

6. Radiator inlet hose 16. Water inlet No.1 pipe : 15 N⋅m (1.5 kgf-m, 11.0 lb-ft)

7. Water outlet cap 17. Water inlet hose : 33 N⋅m (3.3 kgf-m, 24.0 lb-ft)

8. ECT sensor 18. Water inlet No.2 pipe : Do not reuse.

9. Water outlet cap gasket 19. Radiator support bracket bolt

10. O-ring 20. Heater inlet hose

Page 370 of 1556

Downloaded from www.Manualslib.com manuals search engine 1F-5 Engine Cooling System:

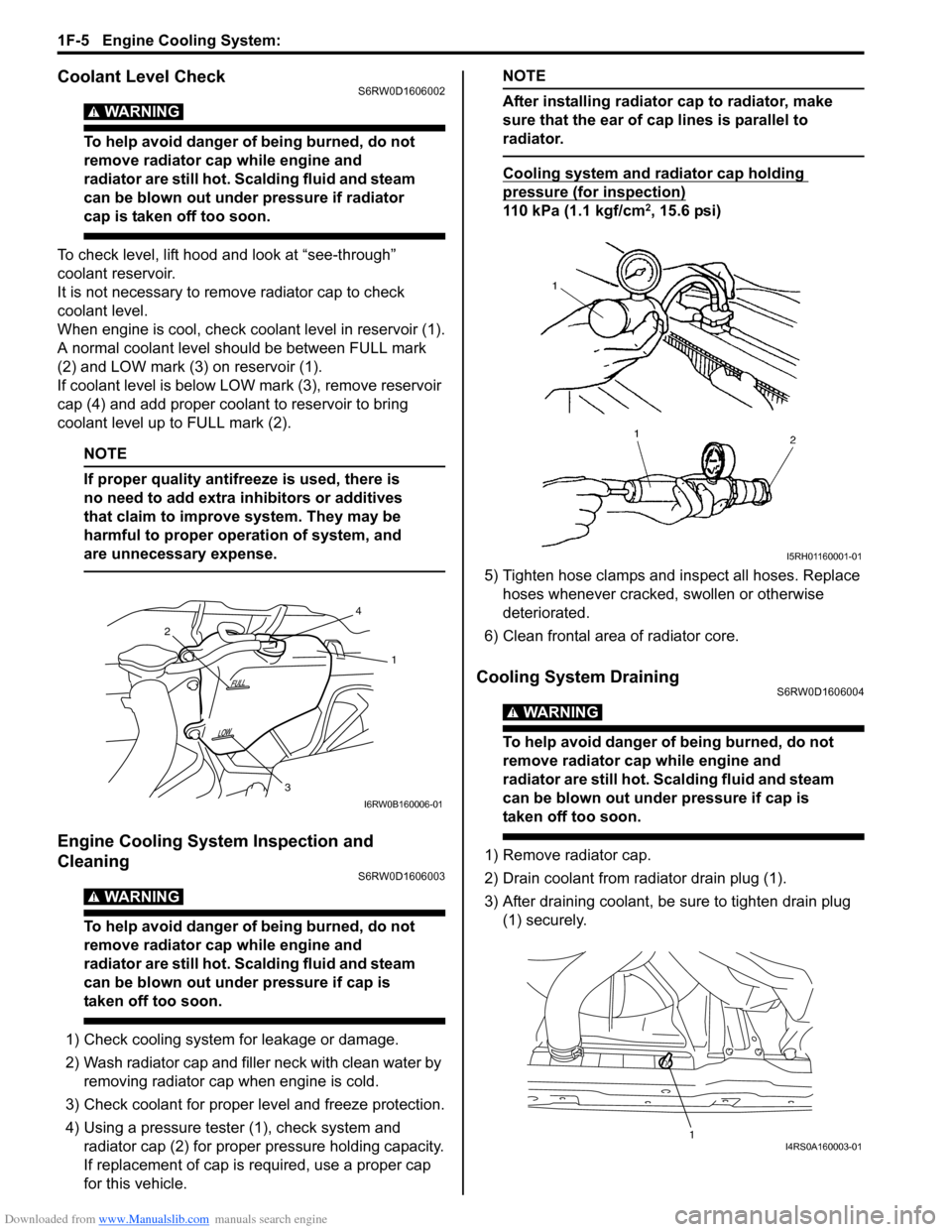

Coolant Level CheckS6RW0D1606002

WARNING!

To help avoid danger of being burned, do not

remove radiator cap while engine and

radiator are still hot. Scalding fluid and steam

can be blown out under pressure if radiator

cap is taken off too soon.

To check level, lift hood and look at “see-through”

coolant reservoir.

It is not necessary to remove radiator cap to check

coolant level.

When engine is cool, check coolant level in reservoir (1).

A normal coolant level should be between FULL mark

(2) and LOW mark (3) on reservoir (1).

If coolant level is below LOW mark (3), remove reservoir

cap (4) and add proper coolant to reservoir to bring

coolant level up to FULL mark (2).

NOTE

If proper quality antifreeze is used, there is

no need to add extra inhibitors or additives

that claim to improve system. They may be

harmful to proper operation of system, and

are unnecessary expense.

Engine Cooling System Inspection and

Cleaning

S6RW0D1606003

WARNING!

To help avoid danger of being burned, do not

remove radiator cap while engine and

radiator are still hot. Scalding fluid and steam

can be blown out under pressure if cap is

taken off too soon.

1) Check cooling system for leakage or damage.

2) Wash radiator cap and filler neck with clean water by

removing radiator cap when engine is cold.

3) Check coolant for proper level and freeze protection.

4) Using a pressure tester (1), check system and

radiator cap (2) for proper pressure holding capacity.

If replacement of cap is required, use a proper cap

for this vehicle.

NOTE

After installing radiator cap to radiator, make

sure that the ear of cap lines is parallel to

radiator.

Cooling system and radiator cap holding

pressure (for inspection)

110 kPa (1.1 kgf/cm2, 15.6 psi)

5) Tighten hose clamps and inspect all hoses. Replace

hoses whenever cracked, swollen or otherwise

deteriorated.

6) Clean frontal area of radiator core.

Cooling System DrainingS6RW0D1606004

WARNING!

To help avoid danger of being burned, do not

remove radiator cap while engine and

radiator are still hot. Scalding fluid and steam

can be blown out under pressure if cap is

taken off too soon.

1) Remove radiator cap.

2) Drain coolant from radiator drain plug (1).

3) After draining coolant, be sure to tighten drain plug

(1) securely.

4

1

2

3

I6RW0B160006-01

I5RH01160001-01

1I4RS0A160003-01