engine mount SUZUKI SX4 2006 1.G Service Repair Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2006, Model line: SX4, Model: SUZUKI SX4 2006 1.GPages: 1556, PDF Size: 37.31 MB

Page 428 of 1556

Downloaded from www.Manualslib.com manuals search engine 1K-1 Exhaust System:

Engine

Exhaust System

General Description

Exhaust System DescriptionS6RW0D1B01001

The exhaust system consists of an exhaust manifold, three-way catalytic converter (TWC) in catalyst case, exhaust

pipes, a muffler and seals, gasket and etc.

The three-way catalytic converter is an emission control device added to the exhaust system to lower the levels of

Hydrocarbon (HC), Carbon Monoxide (CO), and Oxides of Nitrogen (NOx) pollutants in the exhaust gas.

Diagnostic Information and Procedures

Exhaust System CheckS6RW0D1B04001

WARNING!

To avoid the danger of being burned, do not touch the exhaust system when the system is hot. Any

service on the exhaust system should be performed when the system is cool.

At every interval of periodic maintenance service, and when vehicle is raised for other service, check exhaust system

as follows:

• Check rubber mountings for damage, deterioration, and out of position.

• Check exhaust system for leakage, loose connection, dent and damage.

• If bolts or nuts are loosened, tighten them to specified torque referring to “Exhaust System Components”.

• Check nearby body areas damaged, missing, or mispositioned part, open seam, hole connection or any other

defect which could permit exhaust fumes to seep into vehicle.

• Make sure that exhaust system components have enough clearance from underbody to avoid overheating and

possible damage to vehicle underbody.

• Any defect should be fixed at once.

IYSY011B0003-01

Page 429 of 1556

Downloaded from www.Manualslib.com manuals search engine Exhaust System: 1K-2

Repair Instructions

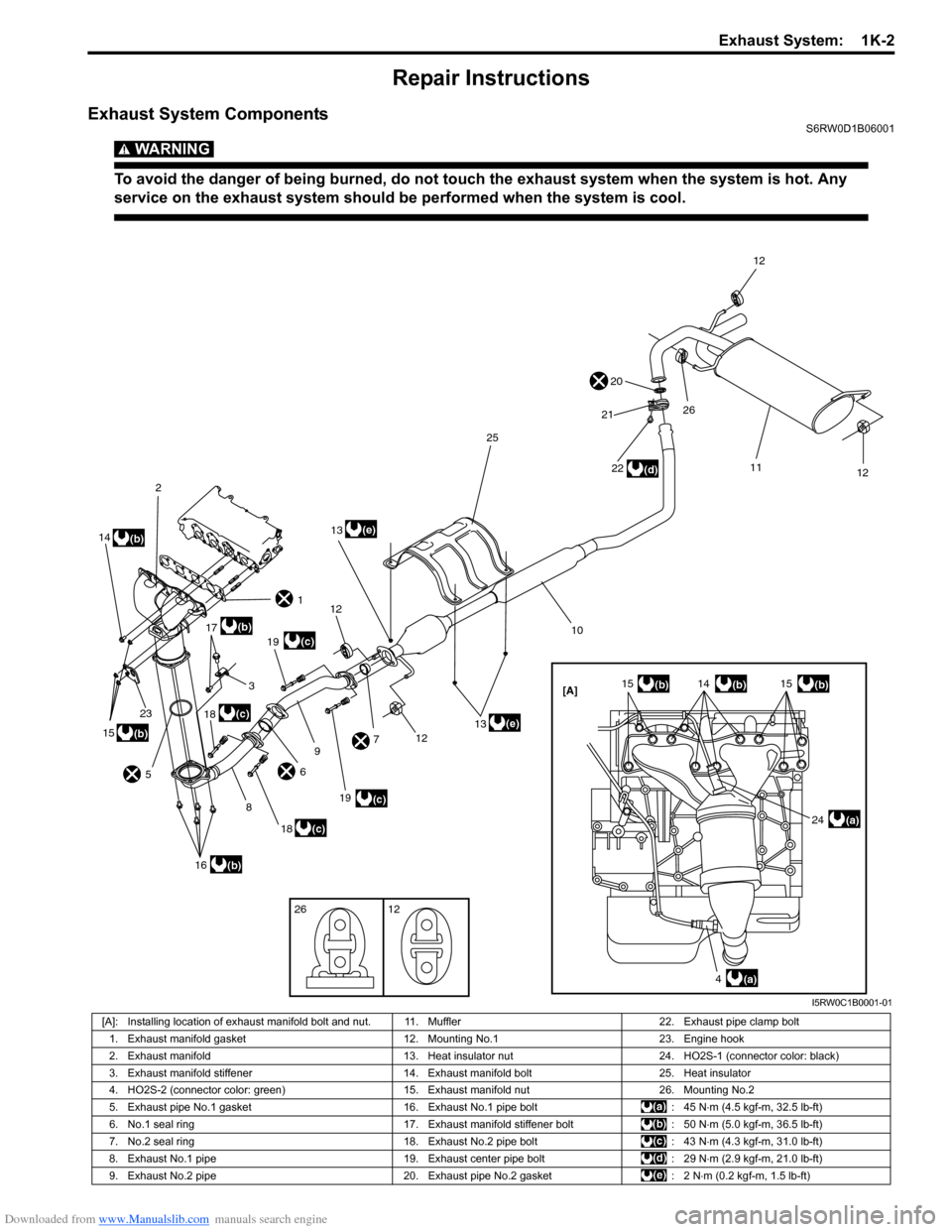

Exhaust System ComponentsS6RW0D1B06001

WARNING!

To avoid the danger of being burned, do not touch the exhaust system when the system is hot. Any

service on the exhaust system should be performed when the system is cool.

[A]

1

2

3

4

56

7

8

9

10

11

12

12

26

12

12

141515

16

26 12

17

18

18

19

19

20

21

23

22

24

25

(a)(c)

(c)

(d)

(e)

(b)

(a)

(b)(b)

(c)

(c)

(b)

(b)

14(b)

15(b)13

(e)

13

I5RW0C1B0001-01

[A]: Installing location of exhaust manifold bolt and nut. 11. Muffler 22. Exhaust pipe clamp bolt

1. Exhaust manifold gasket 12. Mounting No.1 23. Engine hook

2. Exhaust manifold 13. Heat insulator nut 24. HO2S-1 (connector color: black)

3. Exhaust manifold stiffener 14. Exhaust manifold bolt 25. Heat insulator

4. HO2S-2 (connector color: green) 15. Exhaust manifold nut 26. Mounting No.2

5. Exhaust pipe No.1 gasket 16. Exhaust No.1 pipe bolt : 45 N⋅m (4.5 kgf-m, 32.5 lb-ft)

6. No.1 seal ring 17. Exhaust manifold stiffener bolt : 50 N⋅m (5.0 kgf-m, 36.5 lb-ft)

7. No.2 seal ring 18. Exhaust No.2 pipe bolt : 43 N⋅m (4.3 kgf-m, 31.0 lb-ft)

8. Exhaust No.1 pipe 19. Exhaust center pipe bolt : 29 N⋅m (2.9 kgf-m, 21.0 lb-ft)

9. Exhaust No.2 pipe 20. Exhaust pipe No.2 gasket : 2 N⋅m (0.2 kgf-m, 1.5 lb-ft)

Page 433 of 1556

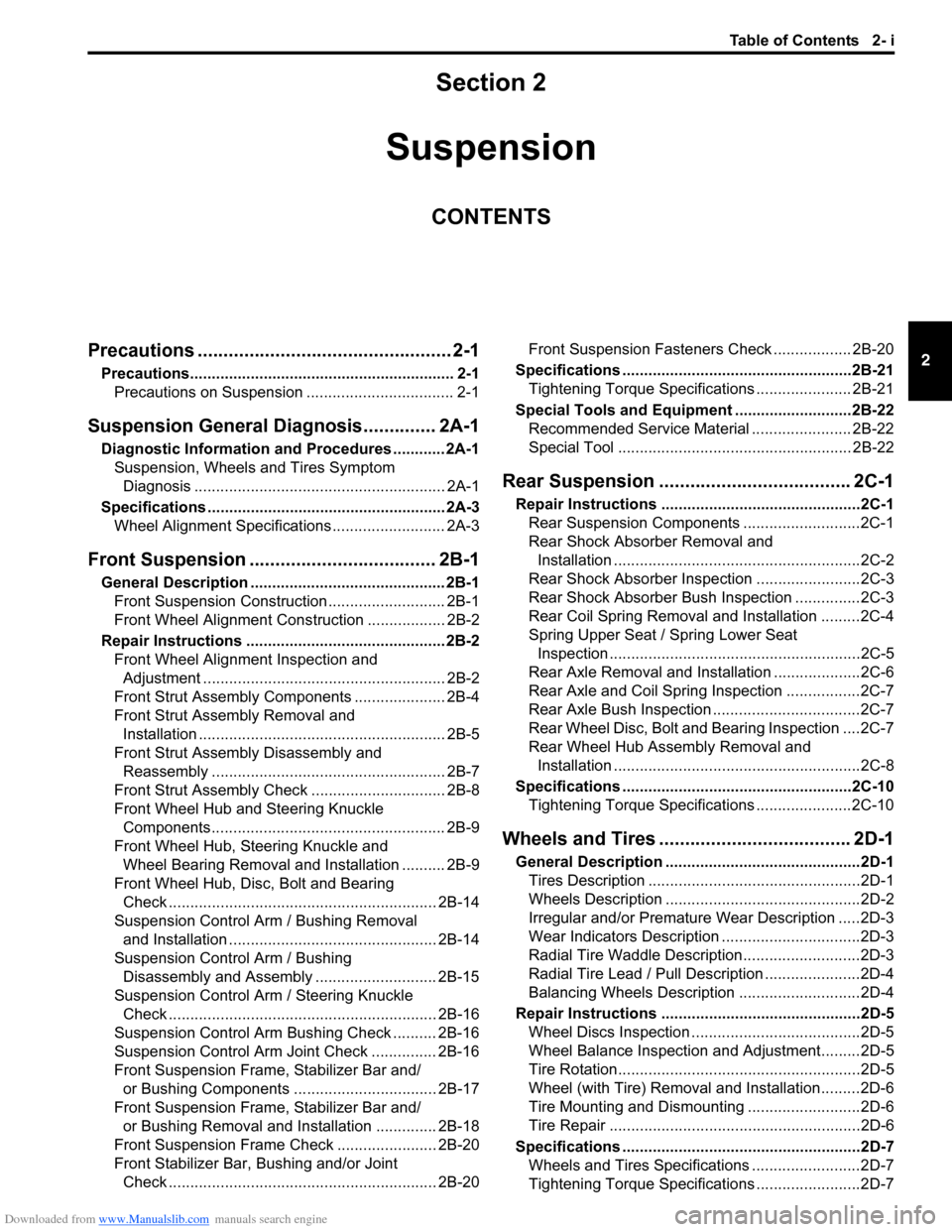

Downloaded from www.Manualslib.com manuals search engine Table of Contents 2- i

2

Section 2

CONTENTS

Suspension

Precautions ................................................. 2-1

Precautions............................................................. 2-1

Precautions on Suspension .................................. 2-1

Suspension General Diagnosis.............. 2A-1

Diagnostic Information and Procedures ............ 2A-1

Suspension, Wheels and Tires Symptom

Diagnosis .......................................................... 2A-1

Specifications....................................................... 2A-3

Wheel Alignment Specifications .......................... 2A-3

Front Suspension .................................... 2B-1

General Description ............................................. 2B-1

Front Suspension Construction ........................... 2B-1

Front Wheel Alignment Construction .................. 2B-2

Repair Instructions .............................................. 2B-2

Front Wheel Alignment Inspection and

Adjustment ........................................................ 2B-2

Front Strut Assembly Components ..................... 2B-4

Front Strut Assembly Removal and

Installation ......................................................... 2B-5

Front Strut Assembly Disassembly and

Reassembly ...................................................... 2B-7

Front Strut Assembly Check ............................... 2B-8

Front Wheel Hub and Steering Knuckle

Components...................................................... 2B-9

Front Wheel Hub, Steering Knuckle and

Wheel Bearing Removal and Installation .......... 2B-9

Front Wheel Hub, Disc, Bolt and Bearing

Check .............................................................. 2B-14

Suspension Control Arm / Bushing Removal

and Installation ................................................ 2B-14

Suspension Control Arm / Bushing

Disassembly and Assembly ............................ 2B-15

Suspension Control Arm / Steering Knuckle

Check .............................................................. 2B-16

Suspension Control Arm Bushing Check .......... 2B-16

Suspension Control Arm Joint Check ............... 2B-16

Front Suspension Frame, Stabilizer Bar and/

or Bushing Components ................................. 2B-17

Front Suspension Frame, Stabilizer Bar and/

or Bushing Removal and Installation .............. 2B-18

Front Suspension Frame Check ....................... 2B-20

Front Stabilizer Bar, Bushing and/or Joint

Check .............................................................. 2B-20Front Suspension Fasteners Check .................. 2B-20

Specifications .....................................................2B-21

Tightening Torque Specifications ...................... 2B-21

Special Tools and Equipment ...........................2B-22

Recommended Service Material ....................... 2B-22

Special Tool ...................................................... 2B-22

Rear Suspension ..................................... 2C-1

Repair Instructions ..............................................2C-1

Rear Suspension Components ...........................2C-1

Rear Shock Absorber Removal and

Installation .........................................................2C-2

Rear Shock Absorber Inspection ........................2C-3

Rear Shock Absorber Bush Inspection ...............2C-3

Rear Coil Spring Removal and Installation .........2C-4

Spring Upper Seat / Spring Lower Seat

Inspection ..........................................................2C-5

Rear Axle Removal and Installation ....................2C-6

Rear Axle and Coil Spring Inspection .................2C-7

Rear Axle Bush Inspection ..................................2C-7

Rear Wheel Disc, Bolt and Bearing Inspection ....2C-7

Rear Wheel Hub Assembly Removal and

Installation .........................................................2C-8

Specifications .....................................................2C-10

Tightening Torque Specifications ......................2C-10

Wheels and Tires ..................................... 2D-1

General Description .............................................2D-1

Tires Description .................................................2D-1

Wheels Description .............................................2D-2

Irregular and/or Premature Wear Description .....2D-3

Wear Indicators Description ................................2D-3

Radial Tire Waddle Description...........................2D-3

Radial Tire Lead / Pull Description ......................2D-4

Balancing Wheels Description ............................2D-4

Repair Instructions ..............................................2D-5

Wheel Discs Inspection .......................................2D-5

Wheel Balance Inspection and Adjustment.........2D-5

Tire Rotation........................................................2D-5

Wheel (with Tire) Removal and Installation.........2D-6

Tire Mounting and Dismounting ..........................2D-6

Tire Repair ..........................................................2D-6

Specifications .......................................................2D-7

Wheels and Tires Specifications .........................2D-7

Tightening Torque Specifications ........................2D-7

Page 435 of 1556

Downloaded from www.Manualslib.com manuals search engine Suspension General Diagnosis: 2A-1

Suspension

Suspension General Diagnosis

Diagnostic Information and Procedures

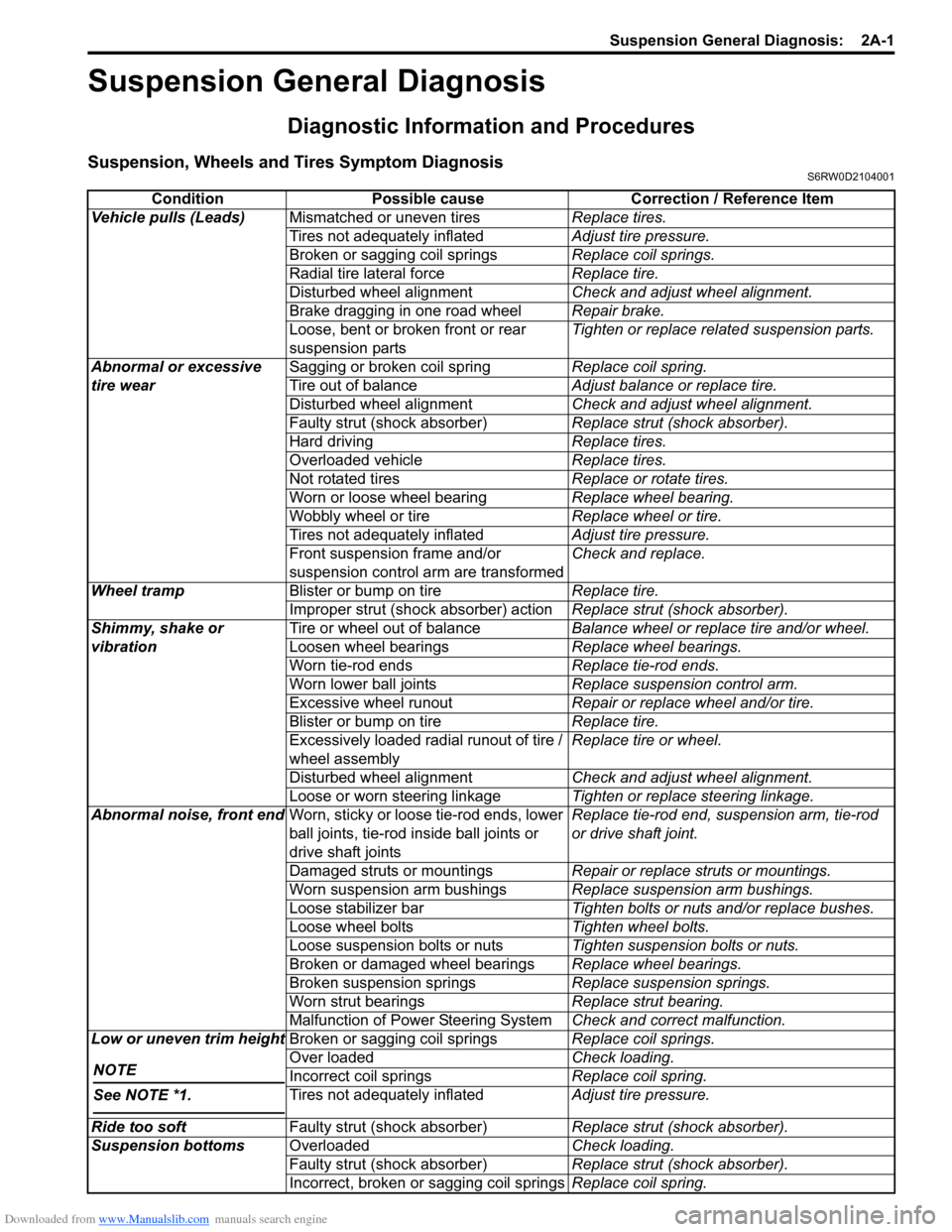

Suspension, Wheels and Tires Symptom DiagnosisS6RW0D2104001

Condition Possible cause Correction / Reference Item

Vehicle pulls (Leads)Mismatched or uneven tiresReplace tires.

Tires not adequately inflatedAdjust tire pressure.

Broken or sagging coil springsReplace coil springs.

Radial tire lateral forceReplace tire.

Disturbed wheel alignmentCheck and adjust wheel alignment.

Brake dragging in one road wheelRepair brake.

Loose, bent or broken front or rear

suspension partsTighten or replace related suspension parts.

Abnormal or excessive

tire wearSagging or broken coil springReplace coil spring.

Tire out of balanceAdjust balance or replace tire.

Disturbed wheel alignmentCheck and adjust wheel alignment.

Faulty strut (shock absorber)Replace strut (shock absorber).

Hard drivingReplace tires.

Overloaded vehicleReplace tires.

Not rotated tiresReplace or rotate tires.

Worn or loose wheel bearingReplace wheel bearing.

Wobbly wheel or tireReplace wheel or tire.

Tires not adequately inflatedAdjust tire pressure.

Front suspension frame and/or

suspension control arm are transformedCheck and replace.

Wheel trampBlister or bump on tireReplace tire.

Improper strut (shock absorber) actionReplace strut (shock absorber).

Shimmy, shake or

vibrationTire or wheel out of balanceBalance wheel or replace tire and/or wheel.

Loosen wheel bearingsReplace wheel bearings.

Worn tie-rod endsReplace tie-rod ends.

Worn lower ball jointsReplace suspension control arm.

Excessive wheel runoutRepair or replace wheel and/or tire.

Blister or bump on tireReplace tire.

Excessively loaded radial runout of tire /

wheel assemblyReplace tire or wheel.

Disturbed wheel alignmentCheck and adjust wheel alignment.

Loose or worn steering linkageTighten or replace steering linkage.

Abnormal noise, front endWorn, sticky or loose tie-rod ends, lower

ball joints, tie-rod inside ball joints or

drive shaft jointsReplace tie-rod end, suspension arm, tie-rod

or drive shaft joint.

Damaged struts or mountingsRepair or replace struts or mountings.

Worn suspension arm bushingsReplace suspension arm bushings.

Loose stabilizer barTighten bolts or nuts and/or replace bushes.

Loose wheel boltsTighten wheel bolts.

Loose suspension bolts or nutsTighten suspension bolts or nuts.

Broken or damaged wheel bearingsReplace wheel bearings.

Broken suspension springsReplace suspension springs.

Worn strut bearingsReplace strut bearing.

Malfunction of Power Steering SystemCheck and correct malfunction.

Low or uneven trim height

NOTE

See NOTE *1.

Broken or sagging coil springsReplace coil springs.

Over loadedCheck loading.

Incorrect coil springsReplace coil spring.

Tires not adequately inflatedAdjust tire pressure.

Ride too softFaulty strut (shock absorber)Replace strut (shock absorber).

Suspension bottomsOverloadedCheck loading.

Faulty strut (shock absorber)Replace strut (shock absorber).

Incorrect, broken or sagging coil springsReplace coil spring.

Page 436 of 1556

Downloaded from www.Manualslib.com manuals search engine 2A-2 Suspension General Diagnosis:

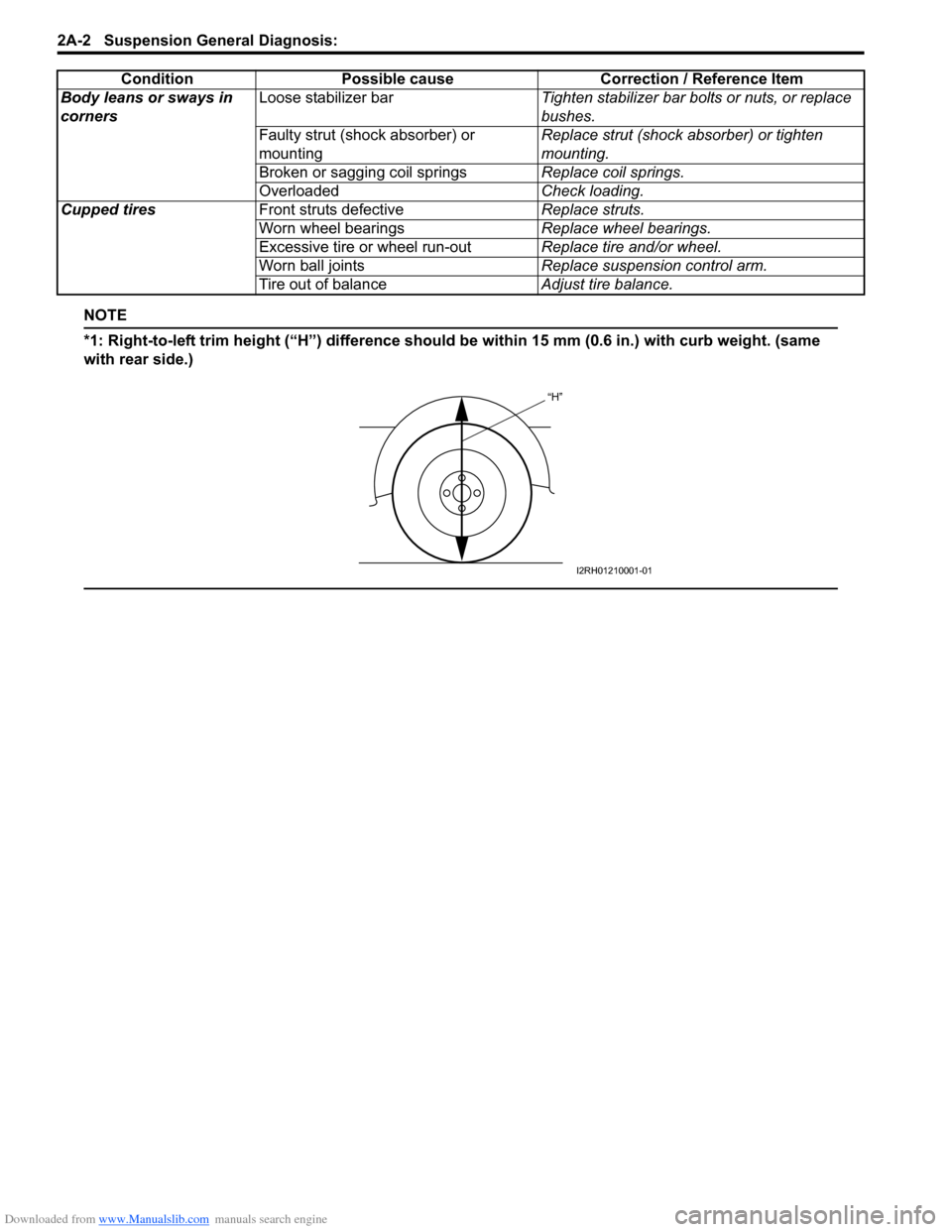

NOTE

*1: Right-to-left trim height (“H”) difference should be within 15 mm (0.6 in.) with curb weight. (same

with rear side.)

Body leans or sways in

cornersLoose stabilizer barTighten stabilizer bar bolts or nuts, or replace

bushes.

Faulty strut (shock absorber) or

mountingReplace strut (shock absorber) or tighten

mounting.

Broken or sagging coil springsReplace coil springs.

OverloadedCheck loading.

Cupped tiresFront struts defectiveReplace struts.

Worn wheel bearingsReplace wheel bearings.

Excessive tire or wheel run-outReplace tire and/or wheel.

Worn ball jointsReplace suspension control arm.

Tire out of balanceAdjust tire balance. Condition Possible cause Correction / Reference Item

“H”

I2RH01210001-01

Page 440 of 1556

Downloaded from www.Manualslib.com manuals search engine 2B-3 Front Suspension:

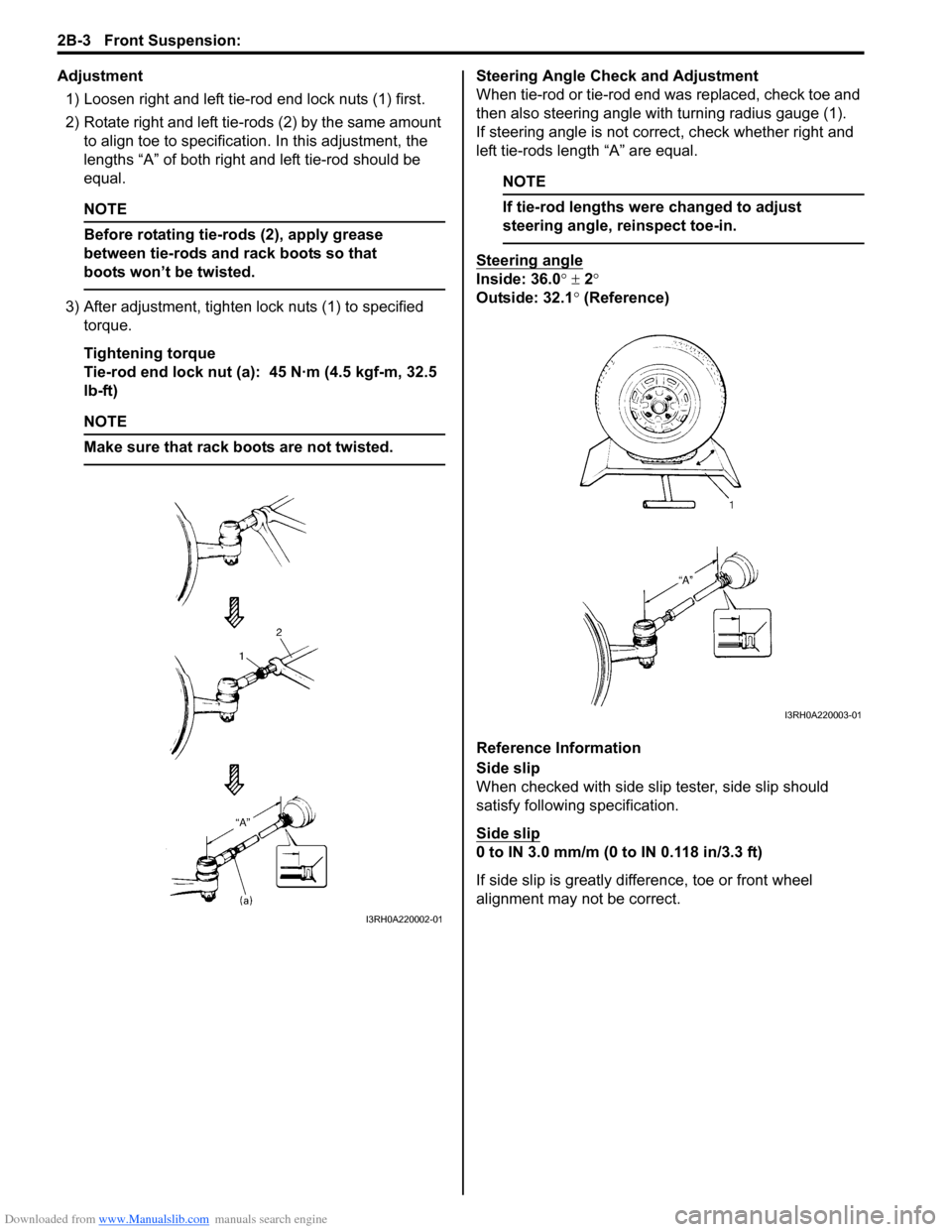

Adjustment

1) Loosen right and left tie-rod end lock nuts (1) first.

2) Rotate right and left tie-rods (2) by the same amount

to align toe to specification. In this adjustment, the

lengths “A” of both right and left tie-rod should be

equal.

NOTE

Before rotating tie-rods (2), apply grease

between tie-rods and rack boots so that

boots won’t be twisted.

3) After adjustment, tighten lock nuts (1) to specified

torque.

Tightening torque

Tie-rod end lock nut (a): 45 N·m (4.5 kgf-m, 32.5

lb-ft)

NOTE

Make sure that rack boots are not twisted.

Steering Angle Check and Adjustment

When tie-rod or tie-rod end was replaced, check toe and

then also steering angle with turning radius gauge (1).

If steering angle is not correct, check whether right and

left tie-rods length “A” are equal.

NOTE

If tie-rod lengths were changed to adjust

steering angle, reinspect toe-in.

Steering angle

Inside: 36.0° ± 2°

Outside: 32.1° (Reference)

Reference Information

Side slip

When checked with side slip tester, side slip should

satisfy following specification.

Side slip

0 to IN 3.0 mm/m (0 to IN 0.118 in/3.3 ft)

If side slip is greatly difference, toe or front wheel

alignment may not be correct.

I3RH0A220002-01

I3RH0A220003-01

Page 442 of 1556

Downloaded from www.Manualslib.com manuals search engine 2B-5 Front Suspension:

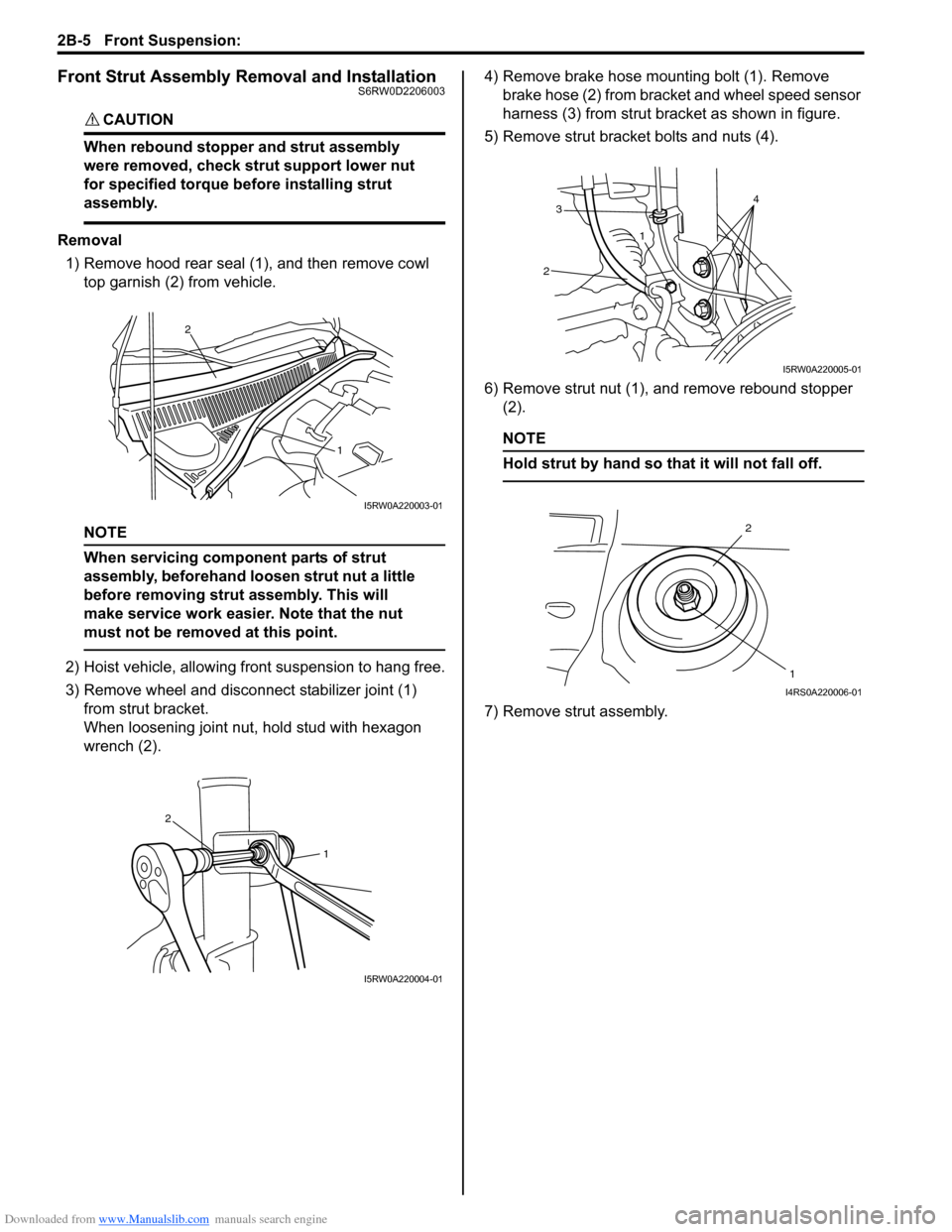

Front Strut Assembly Removal and InstallationS6RW0D2206003

CAUTION!

When rebound stopper and strut assembly

were removed, check strut support lower nut

for specified torque before installing strut

assembly.

Removal

1) Remove hood rear seal (1), and then remove cowl

top garnish (2) from vehicle.

NOTE

When servicing component parts of strut

assembly, beforehand loosen strut nut a little

before removing strut assembly. This will

make service work easier. Note that the nut

must not be removed at this point.

2) Hoist vehicle, allowing front suspension to hang free.

3) Remove wheel and disconnect stabilizer joint (1)

from strut bracket.

When loosening joint nut, hold stud with hexagon

wrench (2).4) Remove brake hose mounting bolt (1). Remove

brake hose (2) from bracket and wheel speed sensor

harness (3) from strut bracket as shown in figure.

5) Remove strut bracket bolts and nuts (4).

6) Remove strut nut (1), and remove rebound stopper

(2).

NOTE

Hold strut by hand so that it will not fall off.

7) Remove strut assembly.

2

1

I5RW0A220003-01

1

2

I5RW0A220004-01

3

214

I5RW0A220005-01

2

1

I4RS0A220006-01

Page 443 of 1556

Downloaded from www.Manualslib.com manuals search engine Front Suspension: 2B-6

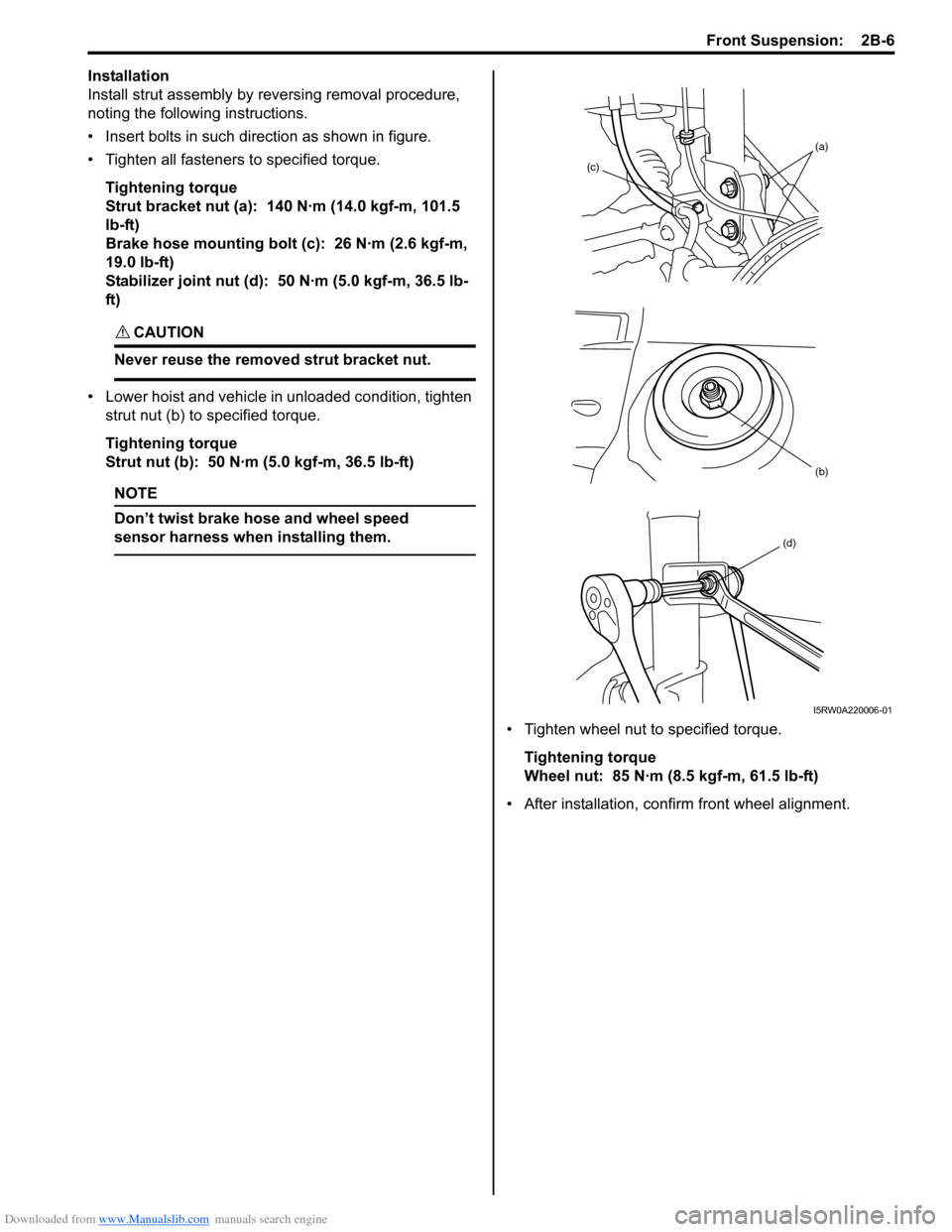

Installation

Install strut assembly by reversing removal procedure,

noting the following instructions.

• Insert bolts in such direction as shown in figure.

• Tighten all fasteners to specified torque.

Tightening torque

Strut bracket nut (a): 140 N·m (14.0 kgf-m, 101.5

lb-ft)

Brake hose mounting bolt (c): 26 N·m (2.6 kgf-m,

19.0 lb-ft)

Stabilizer joint nut (d): 50 N·m (5.0 kgf-m, 36.5 lb-

ft)

CAUTION!

Never reuse the removed strut bracket nut.

• Lower hoist and vehicle in unloaded condition, tighten

strut nut (b) to specified torque.

Tightening torque

Strut nut (b): 50 N·m (5.0 kgf-m, 36.5 lb-ft)

NOTE

Don’t twist brake hose and wheel speed

sensor harness when installing them.

• Tighten wheel nut to specified torque.

Tightening torque

Wheel nut: 85 N·m (8.5 kgf-m, 61.5 lb-ft)

• After installation, confirm front wheel alignment.

(b)

(a)

(c)

(d)

I5RW0A220006-01

Page 445 of 1556

Downloaded from www.Manualslib.com manuals search engine Front Suspension: 2B-8

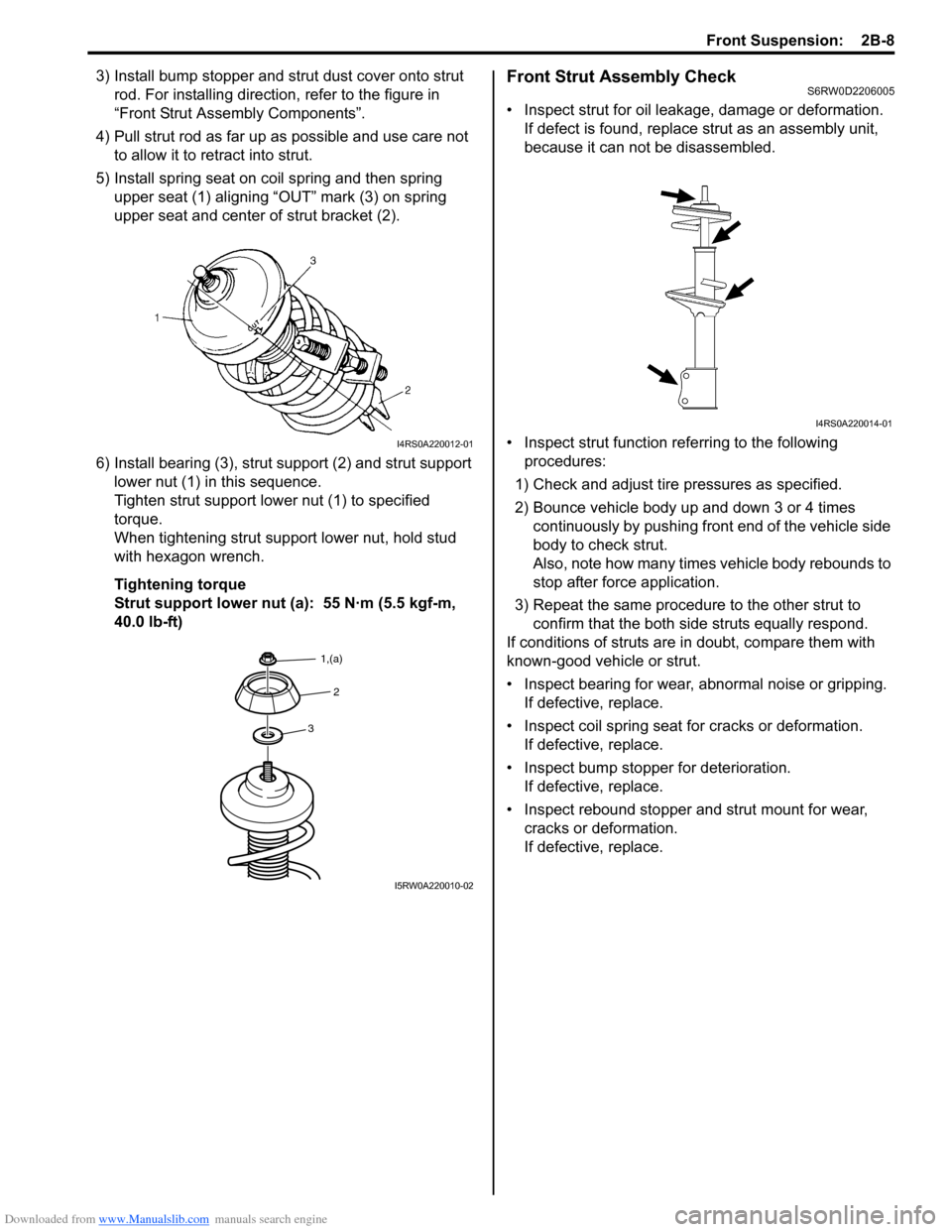

3) Install bump stopper and strut dust cover onto strut

rod. For installing direction, refer to the figure in

“Front Strut Assembly Components”.

4) Pull strut rod as far up as possible and use care not

to allow it to retract into strut.

5) Install spring seat on coil spring and then spring

upper seat (1) aligning “OUT” mark (3) on spring

upper seat and center of strut bracket (2).

6) Install bearing (3), strut support (2) and strut support

lower nut (1) in this sequence.

Tighten strut support lower nut (1) to specified

torque.

When tightening strut support lower nut, hold stud

with hexagon wrench.

Tightening torque

Strut support lower nut (a): 55 N·m (5.5 kgf-m,

40.0 lb-ft)Front Strut Assembly CheckS6RW0D2206005

• Inspect strut for oil leakage, damage or deformation.

If defect is found, replace strut as an assembly unit,

because it can not be disassembled.

• Inspect strut function referring to the following

procedures:

1) Check and adjust tire pressures as specified.

2) Bounce vehicle body up and down 3 or 4 times

continuously by pushing front end of the vehicle side

body to check strut.

Also, note how many times vehicle body rebounds to

stop after force application.

3) Repeat the same procedure to the other strut to

confirm that the both side struts equally respond.

If conditions of struts are in doubt, compare them with

known-good vehicle or strut.

• Inspect bearing for wear, abnormal noise or gripping.

If defective, replace.

• Inspect coil spring seat for cracks or deformation.

If defective, replace.

• Inspect bump stopper for deterioration.

If defective, replace.

• Inspect rebound stopper and strut mount for wear,

cracks or deformation.

If defective, replace.

I4RS0A220012-01

3

2

1,(a)

I5RW0A220010-02

I4RS0A220014-01

Page 450 of 1556

Downloaded from www.Manualslib.com manuals search engine 2B-13 Front Suspension:

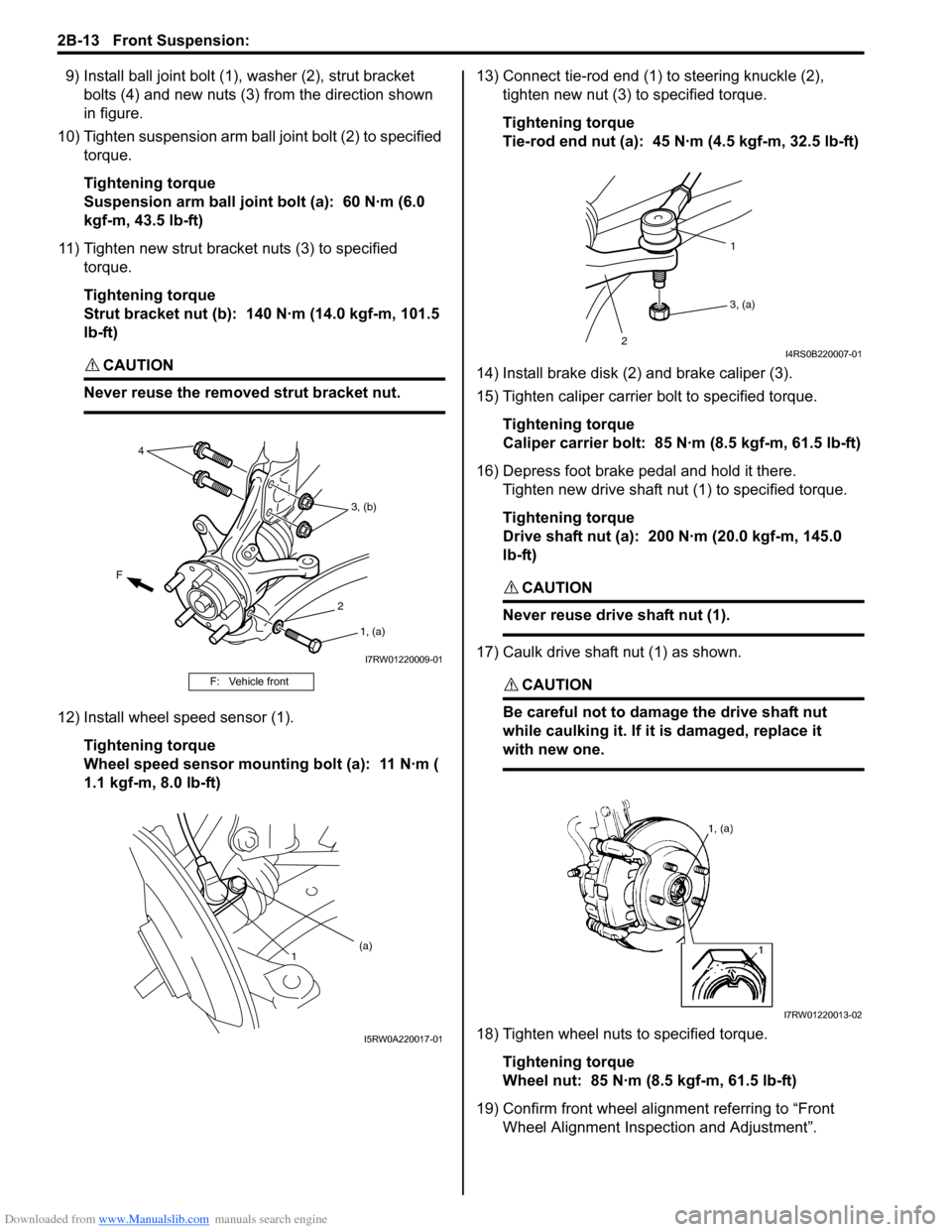

9) Install ball joint bolt (1), washer (2), strut bracket

bolts (4) and new nuts (3) from the direction shown

in figure.

10) Tighten suspension arm ball joint bolt (2) to specified

torque.

Tightening torque

Suspension arm ball joint bolt (a): 60 N·m (6.0

kgf-m, 43.5 lb-ft)

11) Tighten new strut bracket nuts (3) to specified

torque.

Tightening torque

Strut bracket nut (b): 140 N·m (14.0 kgf-m, 101.5

lb-ft)

CAUTION!

Never reuse the removed strut bracket nut.

12) Install wheel speed sensor (1).

Tightening torque

Wheel speed sensor mounting bolt (a): 11 N·m (

1.1 kgf-m, 8.0 lb-ft)13) Connect tie-rod end (1) to steering knuckle (2),

tighten new nut (3) to specified torque.

Tightening torque

Tie-rod end nut (a): 45 N·m (4.5 kgf-m, 32.5 lb-ft)

14) Install brake disk (2) and brake caliper (3).

15) Tighten caliper carrier bolt to specified torque.

Tightening torque

Caliper carrier bolt: 85 N·m (8.5 kgf-m, 61.5 lb-ft)

16) Depress foot brake pedal and hold it there.

Tighten new drive shaft nut (1) to specified torque.

Tightening torque

Drive shaft nut (a): 200 N·m (20.0 kgf-m, 145.0

lb-ft)

CAUTION!

Never reuse drive shaft nut (1).

17) Caulk drive shaft nut (1) as shown.

CAUTION!

Be careful not to damage the drive shaft nut

while caulking it. If it is damaged, replace it

with new one.

18) Tighten wheel nuts to specified torque.

Tightening torque

Wheel nut: 85 N·m (8.5 kgf-m, 61.5 lb-ft)

19) Confirm front wheel alignment referring to “Front

Wheel Alignment Inspection and Adjustment”.

F: Vehicle front

F

4

3, (b)

2

1, (a)

I7RW01220009-01

1(a)

I5RW0A220017-01

1

3, (a)

2I4RS0B220007-01

I7RW01220013-02