engine mount SUZUKI SX4 2006 1.G Service Owners Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2006, Model line: SX4, Model: SUZUKI SX4 2006 1.GPages: 1556, PDF Size: 37.31 MB

Page 492 of 1556

Downloaded from www.Manualslib.com manuals search engine 3A-13 Drive Shaft / Axle: Front

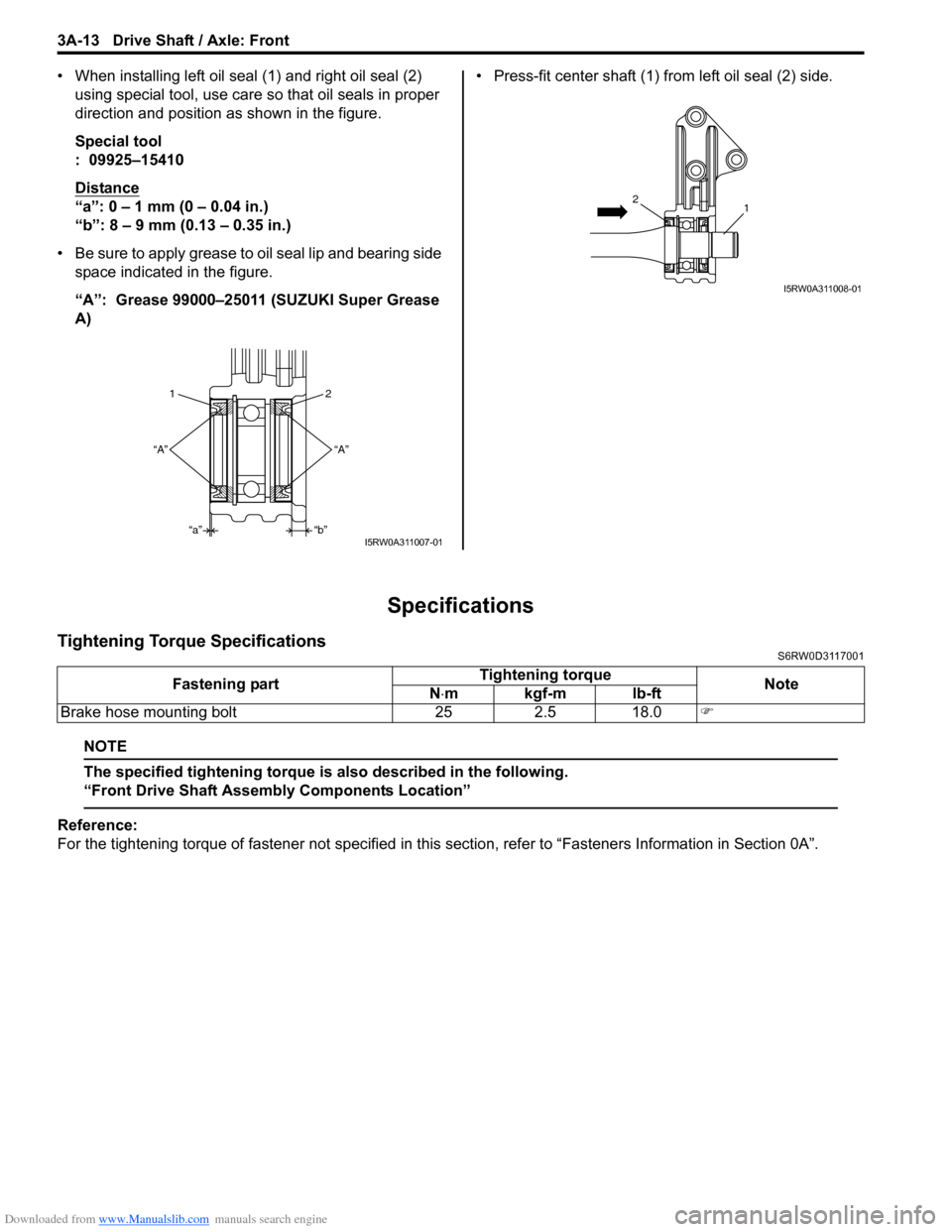

• When installing left oil seal (1) and right oil seal (2)

using special tool, use care so that oil seals in proper

direction and position as shown in the figure.

Special tool

: 09925–15410

Distance

“a”: 0 – 1 mm (0 – 0.04 in.)

“b”: 8 – 9 mm (0.13 – 0.35 in.)

• Be sure to apply grease to oil seal lip and bearing side

space indicated in the figure.

“A”: Grease 99000–25011 (SUZUKI Super Grease

A) • Press-fit center shaft (1) from left oil seal (2) side.

Specifications

Tightening Torque SpecificationsS6RW0D3117001

NOTE

The specified tightening torque is also described in the following.

“Front Drive Shaft Assembly Components Location”

Reference:

For the tightening torque of fastener not specified in this section, refer to “Fasteners Information in Section 0A”.

2 1

“A”

“b”

“a” “A”

I5RW0A311007-01

12

I5RW0A311008-01

Fastening partTightening torque

Note

N⋅mkgf-mlb-ft

Brake hose mounting bolt 25 2.5 18.0�)

Page 496 of 1556

Downloaded from www.Manualslib.com manuals search engine 3A-17 Drive Shaft / Axle: Rear

Reassembly

Refer to “Front Drive Shaft Disassembly and

Reassembly” note the following points which is different

from the front drive shaft is described.

• Apply grease to each joint.

Grease color

Wheel side: Black

Differential side: Dark gray

Amount

Wheel side: 50 – 70 g (1.8 – 2.5 oz)

Differential side: 70 – 90 g (2.5 – 3.2 oz)

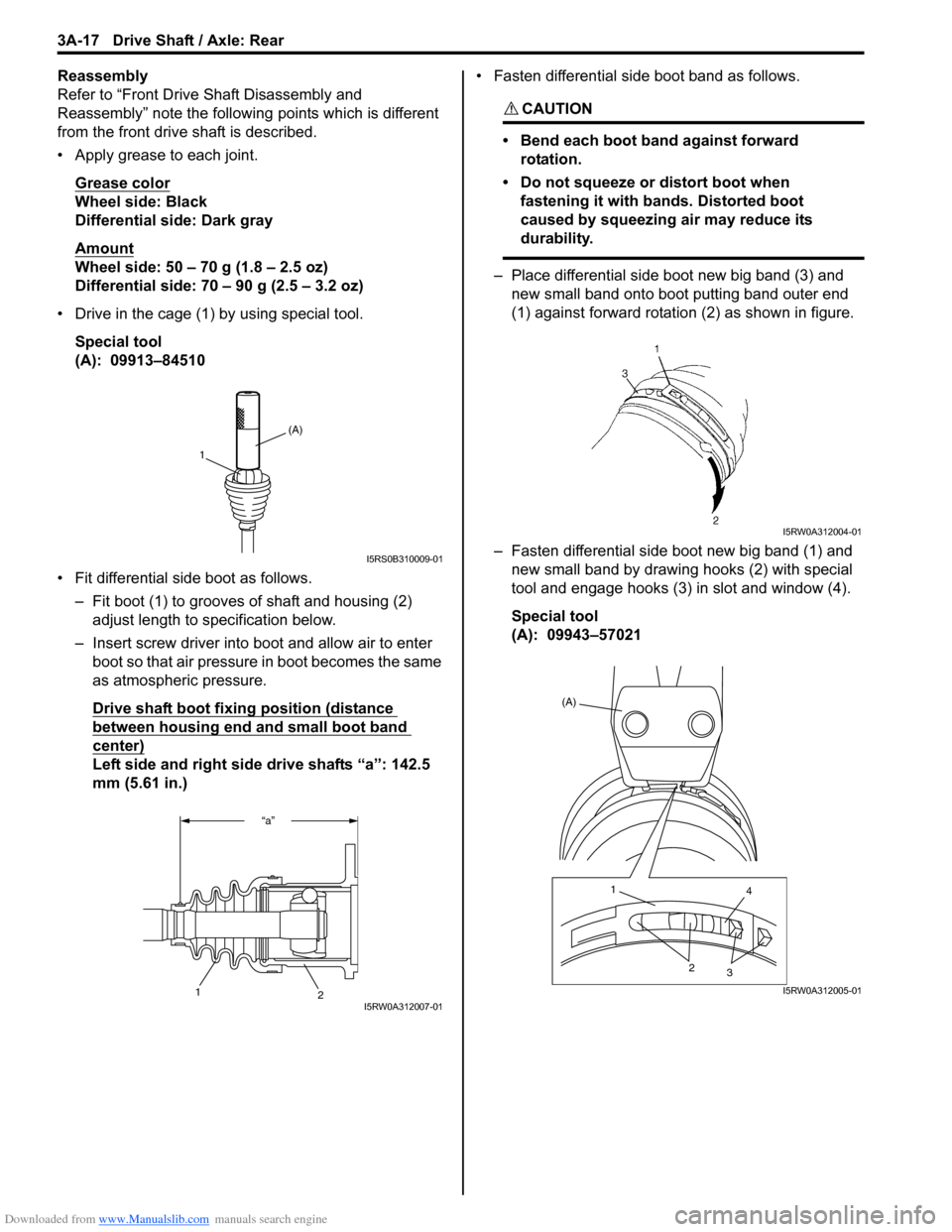

• Drive in the cage (1) by using special tool.

Special tool

(A): 09913–84510

• Fit differential side boot as follows.

– Fit boot (1) to grooves of shaft and housing (2)

adjust length to specification below.

– Insert screw driver into boot and allow air to enter

boot so that air pressure in boot becomes the same

as atmospheric pressure.

Drive shaft boot fixing position (distance

between housing end and small boot band

center)

Left side and right side drive shafts “a”: 142.5

mm (5.61 in.)• Fasten differential side boot band as follows.

CAUTION!

• Bend each boot band against forward

rotation.

• Do not squeeze or distort boot when

fastening it with bands. Distorted boot

caused by squeezing air may reduce its

durability.

– Place differential side boot new big band (3) and

new small band onto boot putting band outer end

(1) against forward rotation (2) as shown in figure.

– Fasten differential side boot new big band (1) and

new small band by drawing hooks (2) with special

tool and engage hooks (3) in slot and window (4).

Special tool

(A): 09943–57021

(A)

1

I5RS0B310009-01

“a”

2

1I5RW0A312007-01

I5RW0A312004-01

(A)

1

4

2

3

I5RW0A312005-01

Page 508 of 1556

Downloaded from www.Manualslib.com manuals search engine 3B-11 Differential:

Visual InspectionS6RW0D3204004

Check the following parts and systems visually.

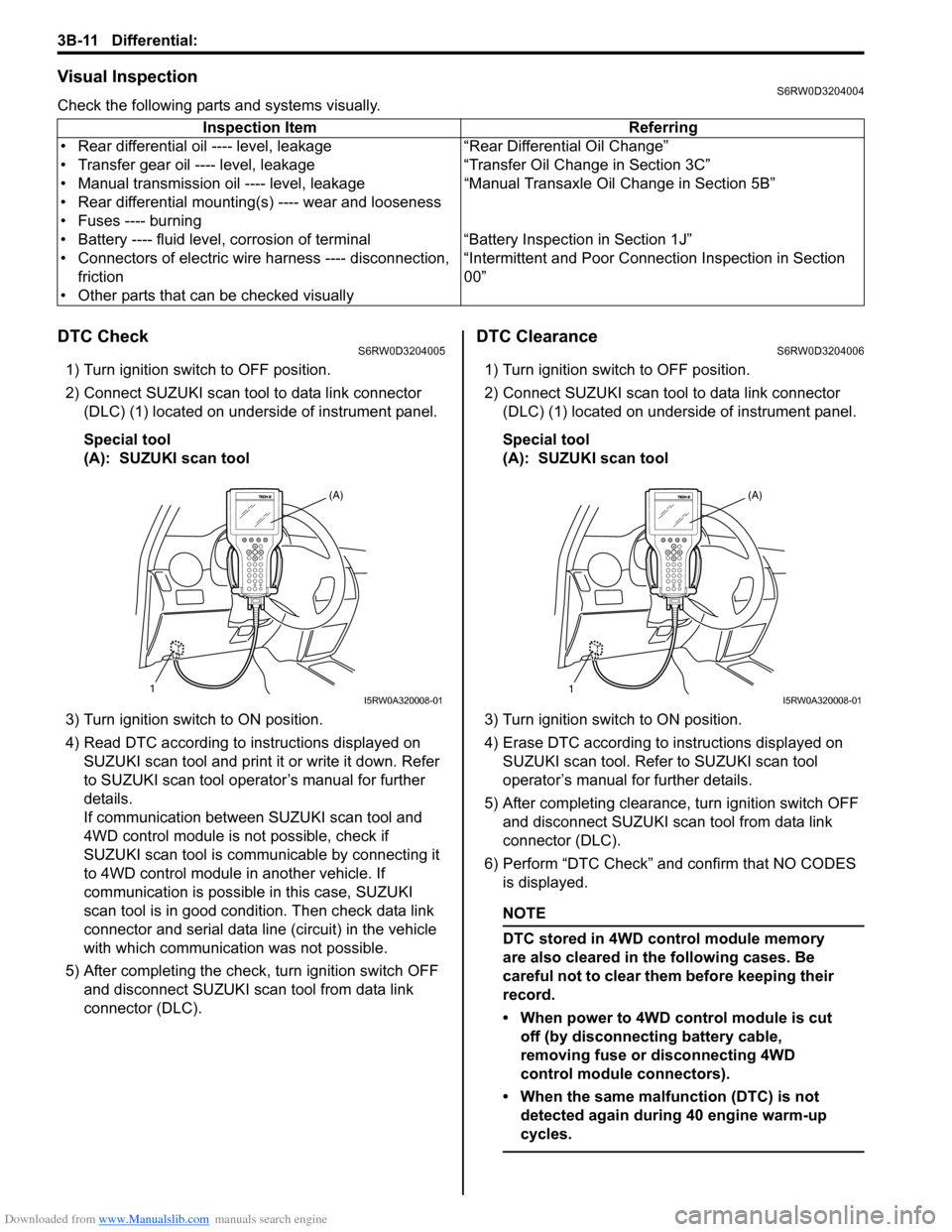

DTC CheckS6RW0D3204005

1) Turn ignition switch to OFF position.

2) Connect SUZUKI scan tool to data link connector

(DLC) (1) located on underside of instrument panel.

Special tool

(A): SUZUKI scan tool

3) Turn ignition switch to ON position.

4) Read DTC according to instructions displayed on

SUZUKI scan tool and print it or write it down. Refer

to SUZUKI scan tool operator’s manual for further

details.

If communication between SUZUKI scan tool and

4WD control module is not possible, check if

SUZUKI scan tool is communicable by connecting it

to 4WD control module in another vehicle. If

communication is possible in this case, SUZUKI

scan tool is in good condition. Then check data link

connector and serial data line (circuit) in the vehicle

with which communication was not possible.

5) After completing the check, turn ignition switch OFF

and disconnect SUZUKI scan tool from data link

connector (DLC).

DTC ClearanceS6RW0D3204006

1) Turn ignition switch to OFF position.

2) Connect SUZUKI scan tool to data link connector

(DLC) (1) located on underside of instrument panel.

Special tool

(A): SUZUKI scan tool

3) Turn ignition switch to ON position.

4) Erase DTC according to instructions displayed on

SUZUKI scan tool. Refer to SUZUKI scan tool

operator’s manual for further details.

5) After completing clearance, turn ignition switch OFF

and disconnect SUZUKI scan tool from data link

connector (DLC).

6) Perform “DTC Check” and confirm that NO CODES

is displayed.

NOTE

DTC stored in 4WD control module memory

are also cleared in the following cases. Be

careful not to clear them before keeping their

record.

• When power to 4WD control module is cut

off (by disconnecting battery cable,

removing fuse or disconnecting 4WD

control module connectors).

• When the same malfunction (DTC) is not

detected again during 40 engine warm-up

cycles.

Inspection Item Referring

• Rear differential oil ---- level, leakage “Rear Differential Oil Change”

• Transfer gear oil ---- level, leakage “Transfer Oil Change in Section 3C”

• Manual transmission oil ---- level, leakage “Manual Transaxle Oil Change in Section 5B”

• Rear differential mounting(s) ---- wear and looseness

• Fuses ---- burning

• Battery ---- fluid level, corrosion of terminal “Battery Inspection in Section 1J”

• Connectors of electric wire harness ---- disconnection,

friction“Intermittent and Poor Connection Inspection in Section

00”

• Other parts that can be checked visually

1(A)I5RW0A320008-011(A)I5RW0A320008-01

Page 528 of 1556

Downloaded from www.Manualslib.com manuals search engine 3B-31 Differential:

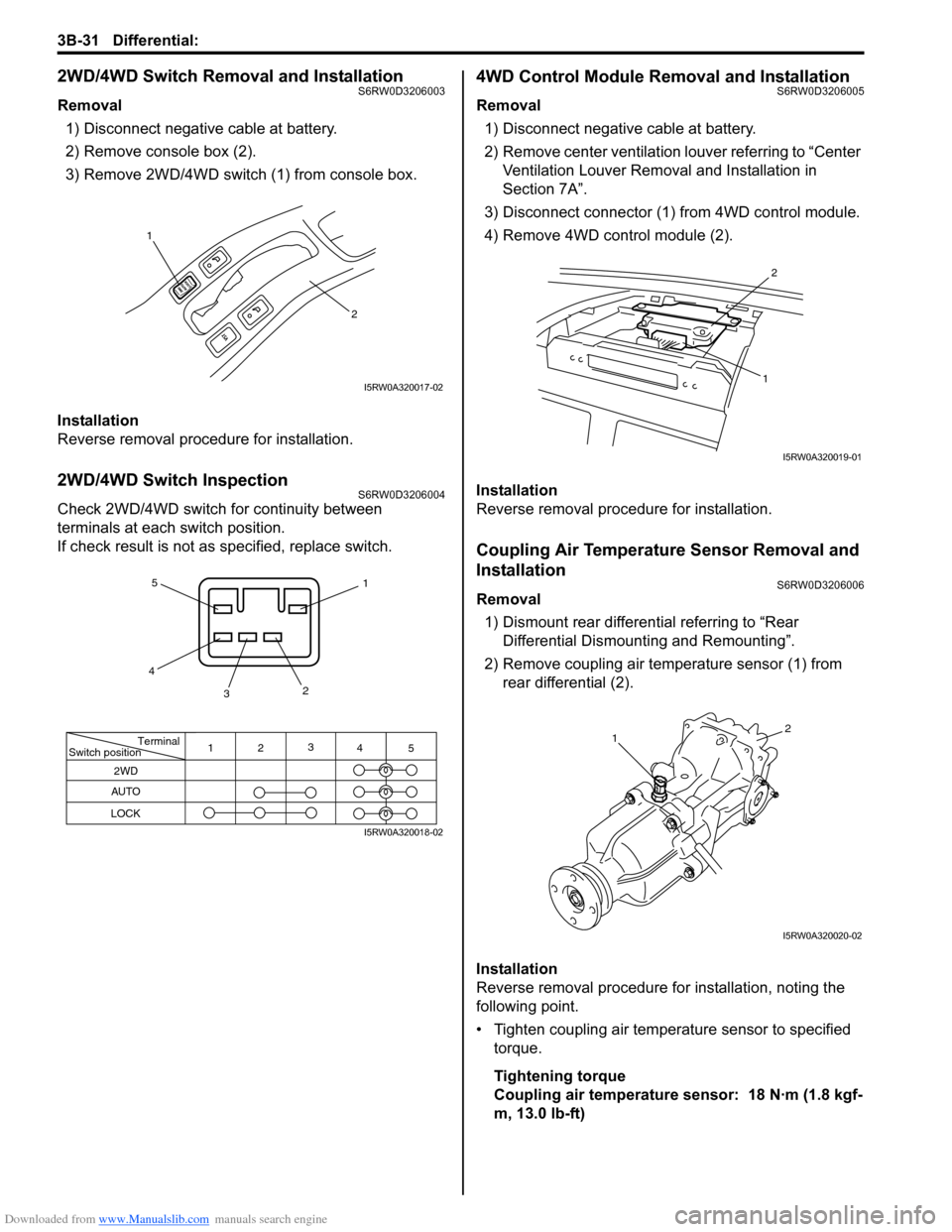

2WD/4WD Switch Removal and InstallationS6RW0D3206003

Removal

1) Disconnect negative cable at battery.

2) Remove console box (2).

3) Remove 2WD/4WD switch (1) from console box.

Installation

Reverse removal procedure for installation.

2WD/4WD Switch InspectionS6RW0D3206004

Check 2WD/4WD switch for continuity between

terminals at each switch position.

If check result is not as specified, replace switch.

4WD Control Module Removal and InstallationS6RW0D3206005

Removal

1) Disconnect negative cable at battery.

2) Remove center ventilation louver referring to “Center

Ventilation Louver Removal and Installation in

Section 7A”.

3) Disconnect connector (1) from 4WD control module.

4) Remove 4WD control module (2).

Installation

Reverse removal procedure for installation.

Coupling Air Temperature Sensor Removal and

Installation

S6RW0D3206006

Removal

1) Dismount rear differential referring to “Rear

Differential Dismounting and Remounting”.

2) Remove coupling air temperature sensor (1) from

rear differential (2).

Installation

Reverse removal procedure for installation, noting the

following point.

• Tighten coupling air temperature sensor to specified

torque.

Tightening torque

Coupling air temperature sensor: 18 N·m (1.8 kgf-

m, 13.0 lb-ft)

1

2

I5RW0A320017-02

Terminal

Switch position

2WD

AUTO

LOCK

11

22

3 3

4 4

5 5

I5RW0A320018-02

2

1

I5RW0A320019-01

12

I5RW0A320020-02

Page 530 of 1556

Downloaded from www.Manualslib.com manuals search engine 3B-33 Differential:

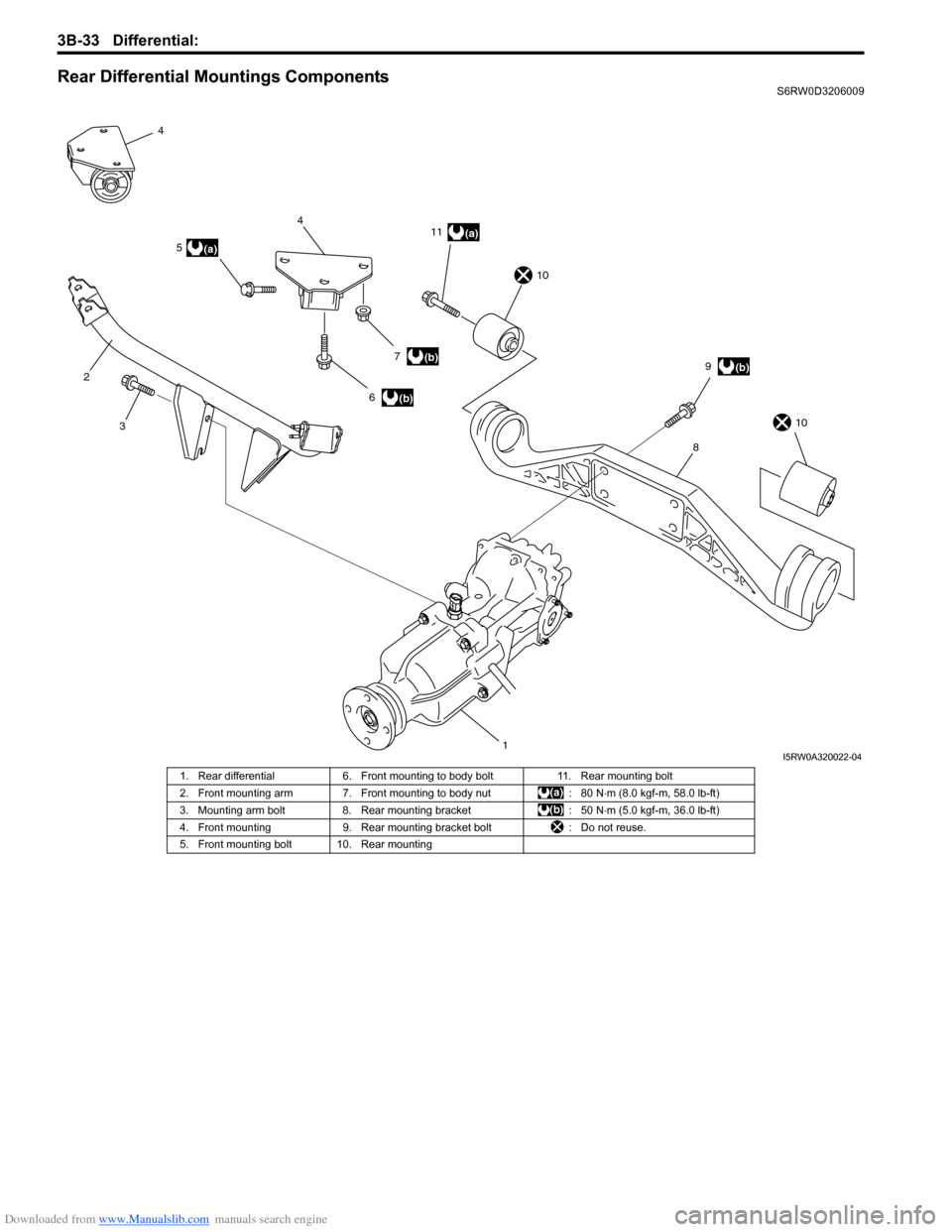

Rear Differential Mountings ComponentsS6RW0D3206009

18

10

10

3

24

54

6

(a)11

(a)

(b)9

(b) 7(b)

I5RW0A320022-04

1. Rear differential 6. Front mounting to body bolt 11. Rear mounting bolt

2. Front mounting arm 7. Front mounting to body nut : 80 N⋅m (8.0 kgf-m, 58.0 lb-ft)

3. Mounting arm bolt 8. Rear mounting bracket : 50 N⋅m (5.0 kgf-m, 36.0 lb-ft)

4. Front mounting 9. Rear mounting bracket bolt : Do not reuse.

5. Front mounting bolt 10. Rear mounting

Page 531 of 1556

Downloaded from www.Manualslib.com manuals search engine Differential: 3B-34

Front Mounting Arm and/or Rear Mounting

Bracket Assembly Removal and Installation

S6RW0D3206010

Remove and install front mounting arm and/or rear

mounting bracket after rear differential removed.

For tightening torque of each bolt and nut, refer to “Rear

Differential Mountings Components”.

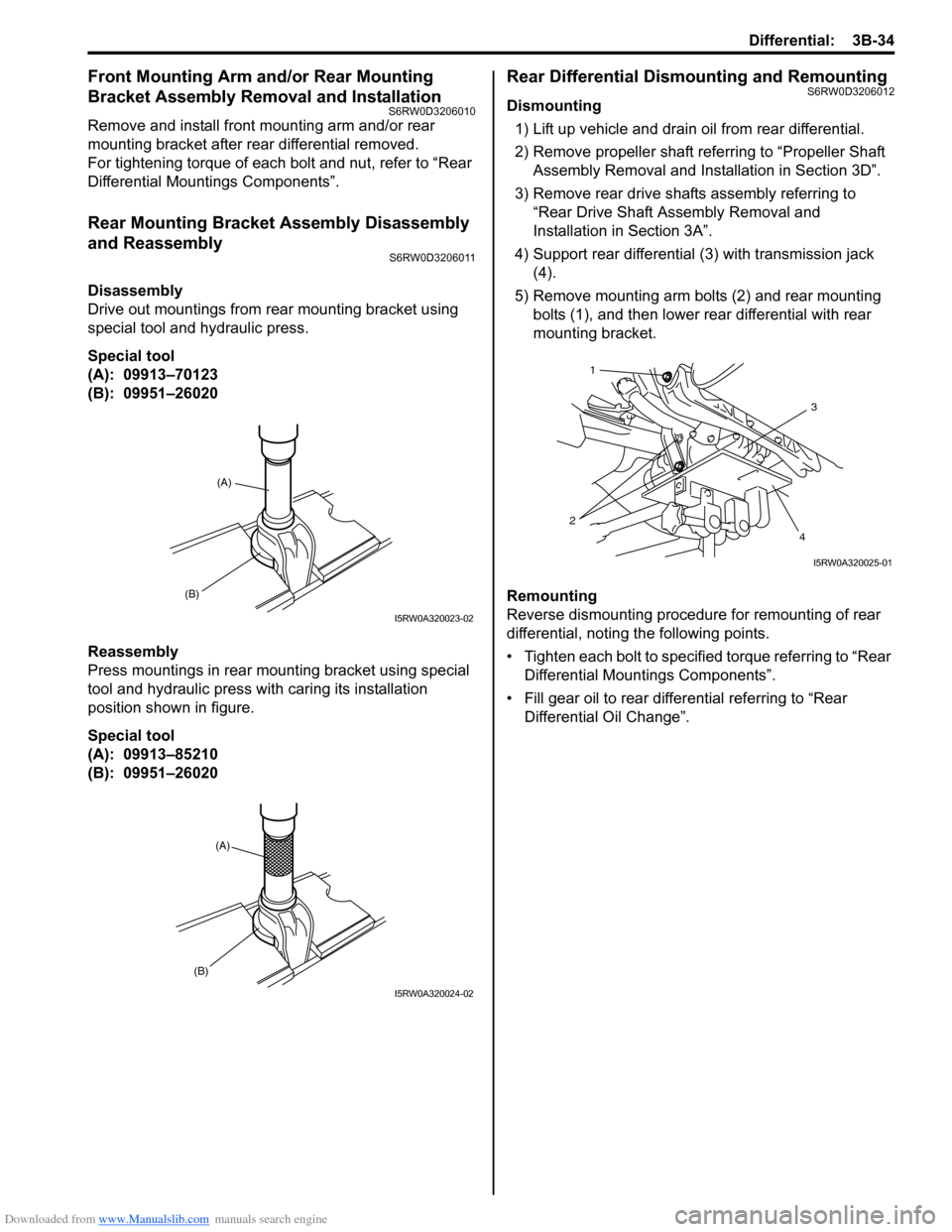

Rear Mounting Bracket Assembly Disassembly

and Reassembly

S6RW0D3206011

Disassembly

Drive out mountings from rear mounting bracket using

special tool and hydraulic press.

Special tool

(A): 09913–70123

(B): 09951–26020

Reassembly

Press mountings in rear mounting bracket using special

tool and hydraulic press with caring its installation

position shown in figure.

Special tool

(A): 09913–85210

(B): 09951–26020

Rear Differential Dismounting and RemountingS6RW0D3206012

Dismounting

1) Lift up vehicle and drain oil from rear differential.

2) Remove propeller shaft referring to “Propeller Shaft

Assembly Removal and Installation in Section 3D”.

3) Remove rear drive shafts assembly referring to

“Rear Drive Shaft Assembly Removal and

Installation in Section 3A”.

4) Support rear differential (3) with transmission jack

(4).

5) Remove mounting arm bolts (2) and rear mounting

bolts (1), and then lower rear differential with rear

mounting bracket.

Remounting

Reverse dismounting procedure for remounting of rear

differential, noting the following points.

• Tighten each bolt to specified torque referring to “Rear

Differential Mountings Components”.

• Fill gear oil to rear differential referring to “Rear

Differential Oil Change”.

(B)

(A)

I5RW0A320023-02

(A)

(B)

I5RW0A320024-02

3

4 21

I5RW0A320025-01

Page 533 of 1556

Downloaded from www.Manualslib.com manuals search engine Differential: 3B-36

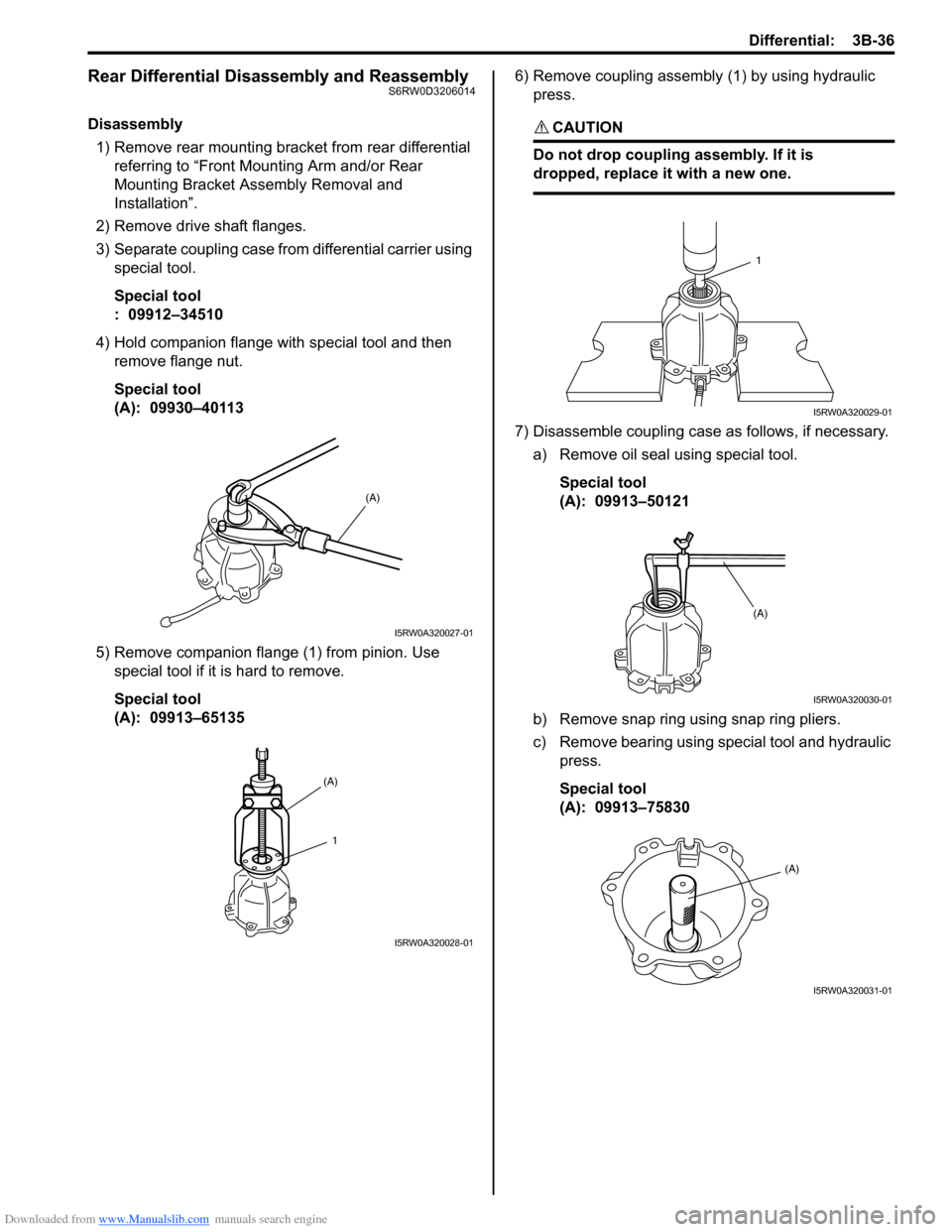

Rear Differential Disassembly and ReassemblyS6RW0D3206014

Disassembly

1) Remove rear mounting bracket from rear differential

referring to “Front Mounting Arm and/or Rear

Mounting Bracket Assembly Removal and

Installation”.

2) Remove drive shaft flanges.

3) Separate coupling case from differential carrier using

special tool.

Special tool

: 09912–34510

4) Hold companion flange with special tool and then

remove flange nut.

Special tool

(A): 09930–40113

5) Remove companion flange (1) from pinion. Use

special tool if it is hard to remove.

Special tool

(A): 09913–651356) Remove coupling assembly (1) by using hydraulic

press.CAUTION!

Do not drop coupling assembly. If it is

dropped, replace it with a new one.

7) Disassemble coupling case as follows, if necessary.

a) Remove oil seal using special tool.

Special tool

(A): 09913–50121

b) Remove snap ring using snap ring pliers.

c) Remove bearing using special tool and hydraulic

press.

Special tool

(A): 09913–75830

(A)

I5RW0A320027-01

(A)

1

I5RW0A320028-01

1

I5RW0A320029-01

(A)

I5RW0A320030-01

(A)

I5RW0A320031-01

Page 537 of 1556

Downloaded from www.Manualslib.com manuals search engine Differential: 3B-40

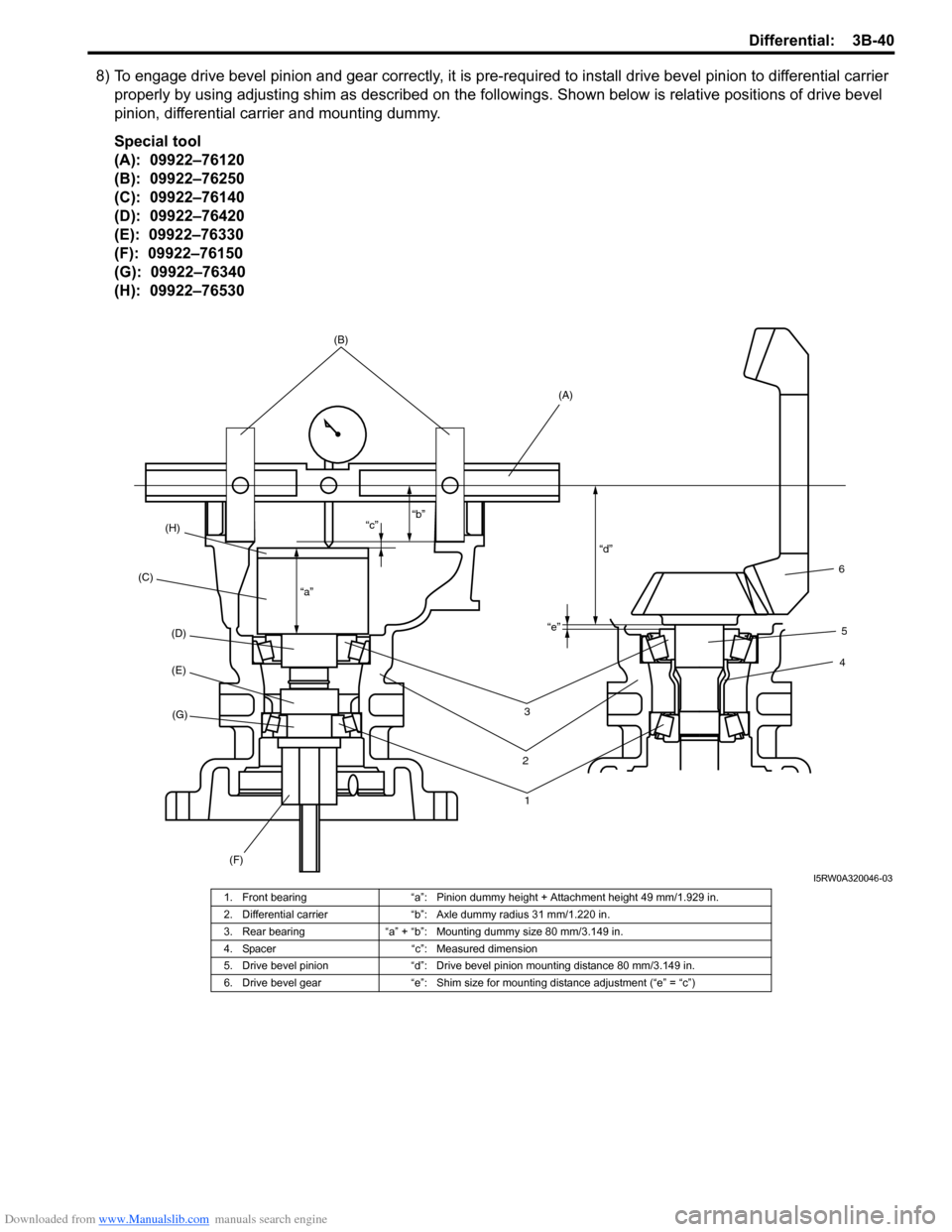

8) To engage drive bevel pinion and gear correctly, it is pre-required to install drive bevel pinion to differential carrier

properly by using adjusting shim as described on the followings. Shown below is relative positions of drive bevel

pinion, differential carrier and mounting dummy.

Special tool

(A): 09922–76120

(B): 09922–76250

(C): 09922–76140

(D): 09922–76420

(E): 09922–76330

(F): 09922–76150

(G): 09922–76340

(H): 09922–76530

3

2

14

5

6

(H)(B)

(A)

(C)

(D)

(E)

(G)

(F)

“a”“c”“b”

“d”

“e”

I5RW0A320046-03

1. Front bearing “a”: Pinion dummy height + Attachment height 49 mm/1.929 in.

2. Differential carrier “b”: Axle dummy radius 31 mm/1.220 in.

3. Rear bearing “a” + “b”: Mounting dummy size 80 mm/3.149 in.

4. Spacer “c”: Measured dimension

5. Drive bevel pinion “d”: Drive bevel pinion mounting distance 80 mm/3.149 in.

6. Drive bevel gear “e”: Shim size for mounting distance adjustment (“e” = “c”)

Page 538 of 1556

Downloaded from www.Manualslib.com manuals search engine 3B-41 Differential:

9) Set special tools and make drive bevel pinion

mounting dummy.

Special tool

(A): 09922–76120

(B): 09922–76250

10) Install dial gauge (1) to mounting dummy as shown

in figure.

Special tool set distance

“a”: 38.0 mm (1.496 in.)

“b”: 0 mm (0.000 in.)

11) Set special tools and make drive bevel pinion

dummy.

Special tool

(A): 09922–76140

(B): 09922–76420

(C): 09922–76330

(D): 09922–7634012) Apply gear oil to drive bevel pinion bearings, install

special tools with bearings to differential carrier as

shown in figure.

Special tool

(A): 09922–76140

(B): 09922–76420

(C): 09922–76330

(D): 09922–76340

(E): 09922–76150

(F): 09922–76530

NOTE

This installation requires no spacer or oil

seal.

13) Tighten bevel pinion nut (special tool) (1) so that

specified bearing preload is obtained.

NOTE

Before taking measurement, check for

rotation by hand more than 15 revolutions.

Pinion bearing preload (at 50 r/min)

: 1.3 – 2.6 N⋅m (13.0 – 26.0 kgf-cm, 11.3 – 22.6 lb-

in.)

I5RW0A320047-01

(C)

(D)

(A)

(A)(B)I5RW0A320048-01

(E) (D) (C)(B) (A) (F)I5RW0A320049-01

1

I5RW0A320050-01

Page 539 of 1556

Downloaded from www.Manualslib.com manuals search engine Differential: 3B-42

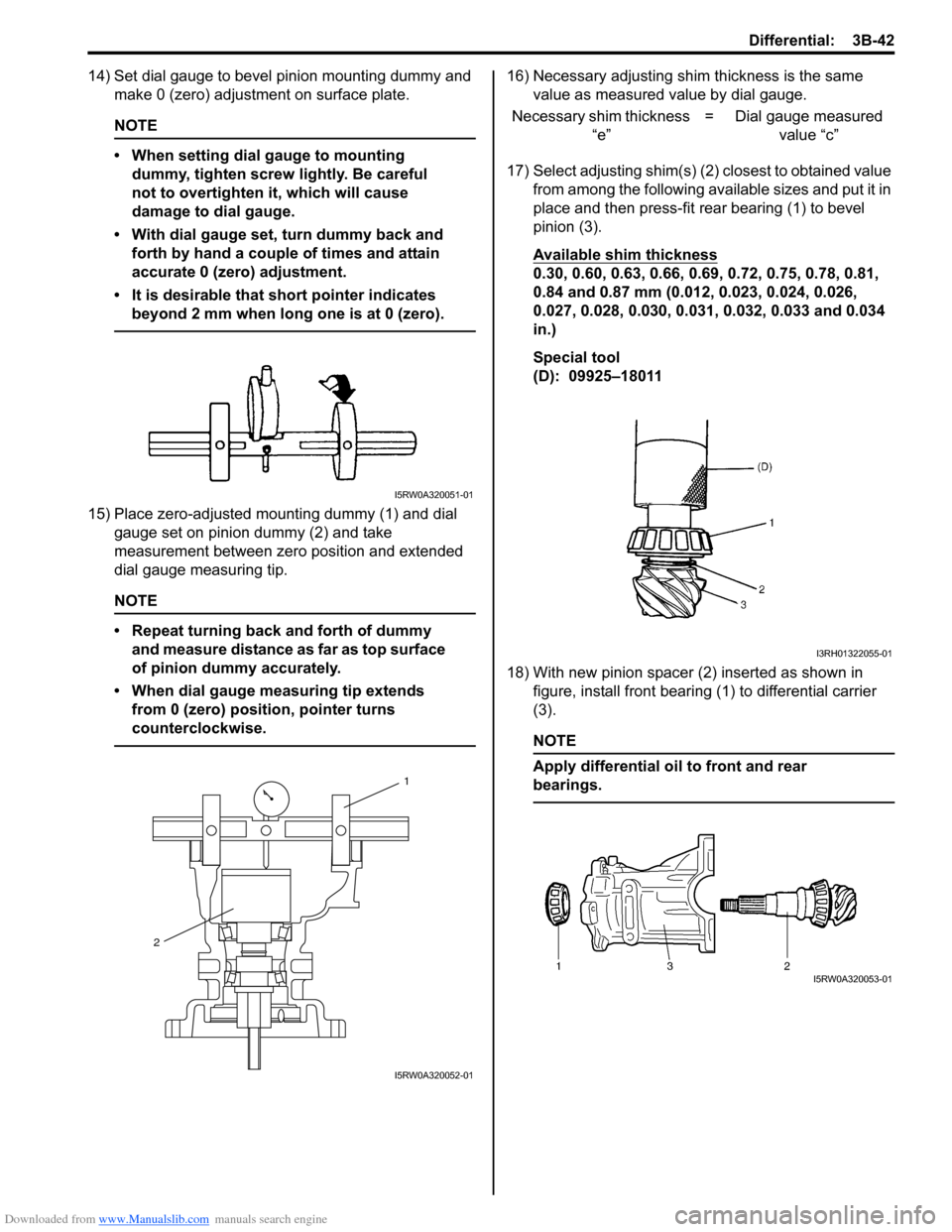

14) Set dial gauge to bevel pinion mounting dummy and

make 0 (zero) adjustment on surface plate.

NOTE

• When setting dial gauge to mounting

dummy, tighten screw lightly. Be careful

not to overtighten it, which will cause

damage to dial gauge.

• With dial gauge set, turn dummy back and

forth by hand a couple of times and attain

accurate 0 (zero) adjustment.

• It is desirable that short pointer indicates

beyond 2 mm when long one is at 0 (zero).

15) Place zero-adjusted mounting dummy (1) and dial

gauge set on pinion dummy (2) and take

measurement between zero position and extended

dial gauge measuring tip.

NOTE

• Repeat turning back and forth of dummy

and measure distance as far as top surface

of pinion dummy accurately.

• When dial gauge measuring tip extends

from 0 (zero) position, pointer turns

counterclockwise.

16) Necessary adjusting shim thickness is the same

value as measured value by dial gauge.

17) Select adjusting shim(s) (2) closest to obtained value

from among the following available sizes and put it in

place and then press-fit rear bearing (1) to bevel

pinion (3).

Available shim thickness

0.30, 0.60, 0.63, 0.66, 0.69, 0.72, 0.75, 0.78, 0.81,

0.84 and 0.87 mm (0.012, 0.023, 0.024, 0.026,

0.027, 0.028, 0.030, 0.031, 0.032, 0.033 and 0.034

in.)

Special tool

(D): 09925–18011

18) With new pinion spacer (2) inserted as shown in

figure, install front bearing (1) to differential carrier

(3).

NOTE

Apply differential oil to front and rear

bearings.

I5RW0A320051-01

1

2

I5RW0A320052-01

Necessary shim thickness

“e”= Dial gauge measured

value “c”

I3RH01322055-01

I5RW0A320053-01