brake SUZUKI XL7 2007 2.G Service Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2007, Model line: XL7, Model: SUZUKI XL7 2007 2.GPages: 274, PDF Size: 6.12 MB

Page 222 of 274

5-38 SERVICE AND APPEARANCE CARE

78J00-03E

If a front tire fails, the flat tire will create a

drag that pulls the vehicle toward that side.

Take your foot off the accelerator pedal

and grip the steering wheel firmly. Steer to

maintain lane position, and then gently

brake to a stop well out of the traffic lane.

A rear blowout, particularly on a curve,

acts much like a skid and may require the

same correction you would use in a skid. In

any rear blowout remove your foot from

the accelerator pedal. Get the vehicle

under control by steering the way you want

the vehicle to go. It may be very bumpy

and noisy, but you can still steer. Gently

brake to a stop, well off the road if possi-

ble.

If a tire goes flat, the next part shows how

to use the jacking equipment to change a

flat tire safely.

Changing a Flat TireIf a tire goes flat, avoid further tire and

wheel damage by driving slowly to a level

place. Turn on your vehicle’s hazard warn-

ing flashers. Refer to “Hazard Warning

Flashers” in “Instrument Panel Overview”

in the “Instrument Panel” section for more

information.

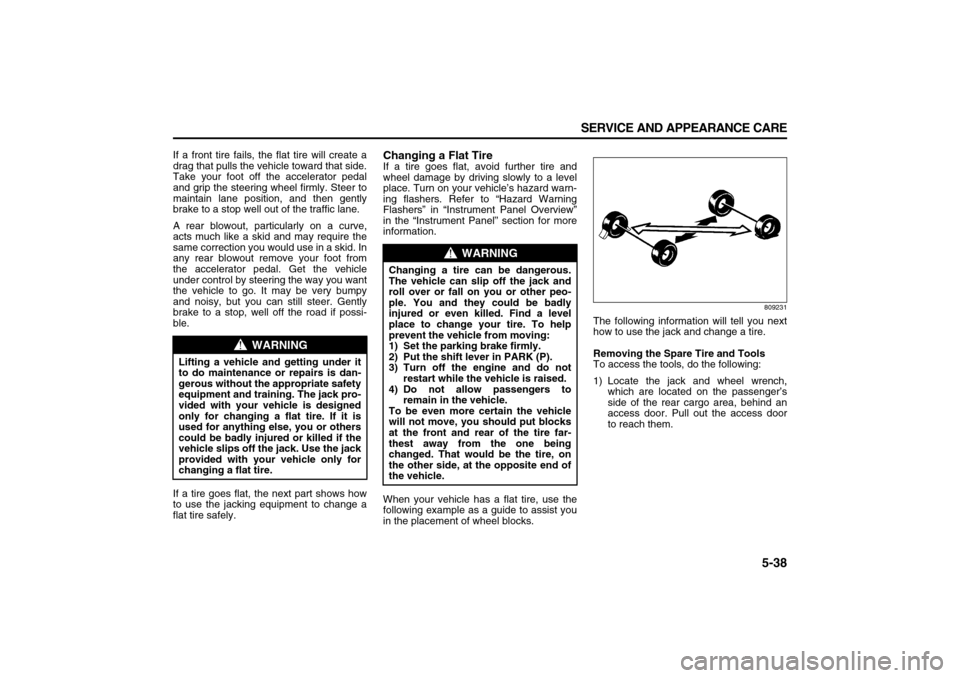

When your vehicle has a flat tire, use the

following example as a guide to assist you

in the placement of wheel blocks.

809231

The following information will tell you next

how to use the jack and change a tire.

Removing the Spare Tire and Tools

To access the tools, do the following:

1) Locate the jack and wheel wrench,

which are located on the passenger’s

side of the rear cargo area, behind an

access door. Pull out the access door

to reach them.

WARNING

Lifting a vehicle and getting under it

to do maintenance or repairs is dan-

gerous without the appropriate safety

equipment and training. The jack pro-

vided with your vehicle is designed

only for changing a flat tire. If it is

used for anything else, you or others

could be badly injured or killed if the

vehicle slips off the jack. Use the jack

provided with your vehicle only for

changing a flat tire.

WARNING

Changing a tire can be dangerous.

The vehicle can slip off the jack and

roll over or fall on you or other peo-

ple. You and they could be badly

injured or even killed. Find a level

place to change your tire. To help

prevent the vehicle from moving:

1) Set the parking brake firmly.

2) Put the shift lever in PARK (P).

3) Turn off the engine and do not

restart while the vehicle is raised.

4) Do not allow passengers to

remain in the vehicle.

To be even more certain the vehicle

will not move, you should put blocks

at the front and rear of the tire far-

thest away from the one being

changed. That would be the tire, on

the other side, at the opposite end of

the vehicle.

Page 226 of 274

5-42 SERVICE AND APPEARANCE CARE

78J00-03E

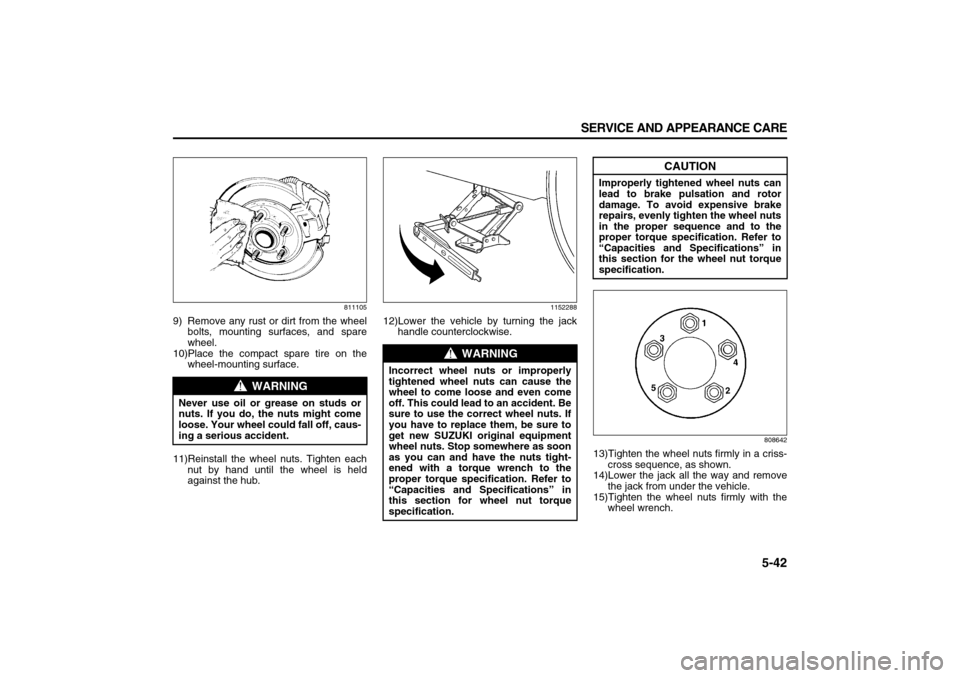

811105

9) Remove any rust or dirt from the wheel

bolts, mounting surfaces, and spare

wheel.

10)Place the compact spare tire on the

wheel-mounting surface.

11)Reinstall the wheel nuts. Tighten each

nut by hand until the wheel is held

against the hub.

1152288

12)Lower the vehicle by turning the jack

handle counterclockwise.

808642

13)Tighten the wheel nuts firmly in a criss-

cross sequence, as shown.

14)Lower the jack all the way and remove

the jack from under the vehicle.

15)Tighten the wheel nuts firmly with the

wheel wrench.

WARNING

Never use oil or grease on studs or

nuts. If you do, the nuts might come

loose. Your wheel could fall off, caus-

ing a serious accident.

WARNING

Incorrect wheel nuts or improperly

tightened wheel nuts can cause the

wheel to come loose and even come

off. This could lead to an accident. Be

sure to use the correct wheel nuts. If

you have to replace them, be sure to

get new SUZUKI original equipment

wheel nuts. Stop somewhere as soon

as you can and have the nuts tight-

ened with a torque wrench to the

proper torque specification. Refer to

“Capacities and Specifications” in

this section for wheel nut torque

specification.

CAUTION

Improperly tightened wheel nuts can

lead to brake pulsation and rotor

damage. To avoid expensive brake

repairs, evenly tighten the wheel nuts

in the proper sequence and to the

proper torque specification. Refer to

“Capacities and Specifications” in

this section for the wheel nut torque

specification.

Page 239 of 274

5-55 SERVICE AND APPEARANCE CARE

78J00-03E

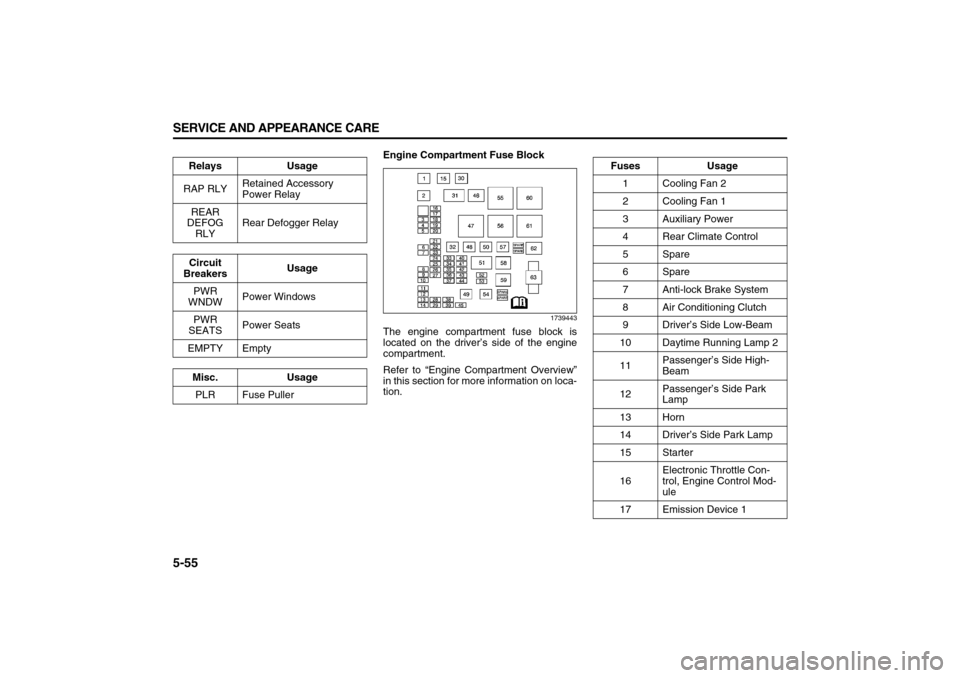

Engine Compartment Fuse Block

1739443

The engine compartment fuse block is

located on the driver’s side of the engine

compartment.

Refer to “Engine Compartment Overview”

in this section for more information on loca-

tion. Relays Usage

RAP RLYRetained Accessory

Power Relay

REAR

DEFOG

RLYRear Defogger Relay

Circuit

BreakersUsage

PWR

WNDWPower Windows

PWR

SEATSPower Seats

EMPTY Empty

Misc. Usage

PLR Fuse Puller

Fuses Usage

1 Cooling Fan 2

2 Cooling Fan 1

3 Auxiliary Power

4 Rear Climate Control

5 Spare

6 Spare

7 Anti-lock Brake System

8 Air Conditioning Clutch

9 Driver’s Side Low-Beam

10 Daytime Running Lamp 2

11Passenger’s Side High-

Beam

12Passenger’s Side Park

Lamp

13 Horn

14 Driver’s Side Park Lamp

15 Starter

16Electronic Throttle Con-

trol, Engine Control Mod-

ule

17 Emission Device 1

Page 240 of 274

5-56 SERVICE AND APPEARANCE CARE

78J00-03E

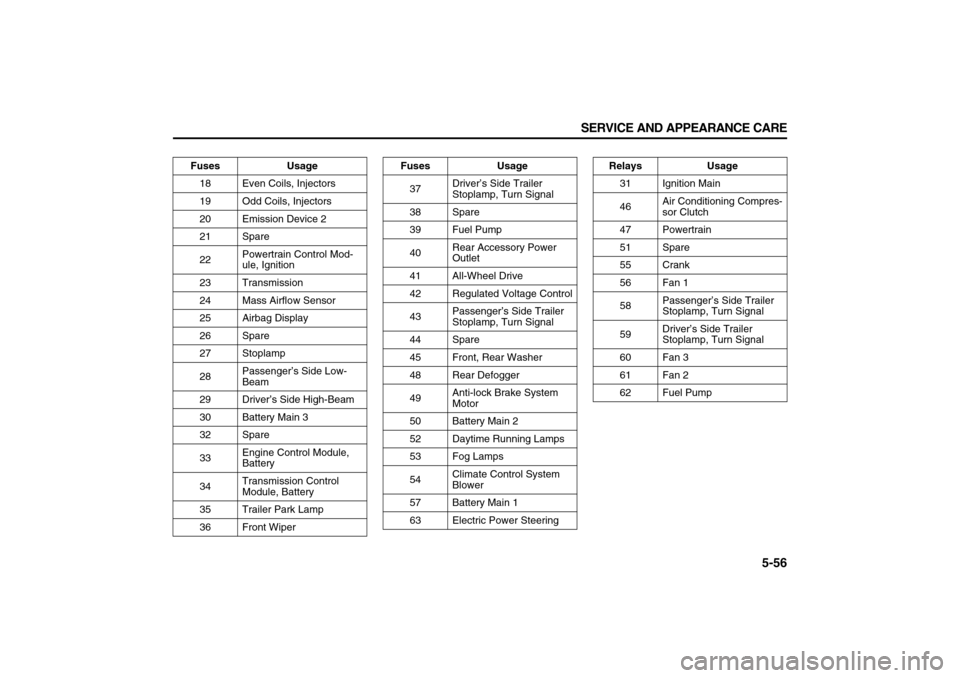

Fuses Usage

18 Even Coils, Injectors

19 Odd Coils, Injectors

20 Emission Device 2

21 Spare

22Powertrain Control Mod-

ule, Ignition

23 Transmission

24 Mass Airflow Sensor

25 Airbag Display

26 Spare

27 Stoplamp

28Passenger’s Side Low-

Beam

29 Driver’s Side High-Beam

30 Battery Main 3

32 Spare

33Engine Control Module,

Battery

34Transmission Control

Module, Battery

35 Trailer Park Lamp

36 Front Wiper

Fuses Usage

37Driver’s Side Trailer

Stoplamp, Turn Signal

38 Spare

39 Fuel Pump

40Rear Accessory Power

Outlet

41 All-Wheel Drive

42 Regulated Voltage Control

43Passenger’s Side Trailer

Stoplamp, Turn Signal

44 Spare

45 Front, Rear Washer

48 Rear Defogger

49Anti-lock Brake System

Motor

50 Battery Main 2

52 Daytime Running Lamps

53 Fog Lamps

54Climate Control System

Blower

57 Battery Main 1

63 Electric Power Steering

Relays Usage

31 Ignition Main

46Air Conditioning Compres-

sor Clutch

47 Powertrain

51 Spare

55 Crank

56 Fan 1

58Passenger’s Side Trailer

Stoplamp, Turn Signal

59Driver’s Side Trailer

Stoplamp, Turn Signal

60 Fan 3

61 Fan 2

62 Fuel Pump

Page 245 of 274

6-3 MAINTENANCE SCHEDULE

78J00-03E

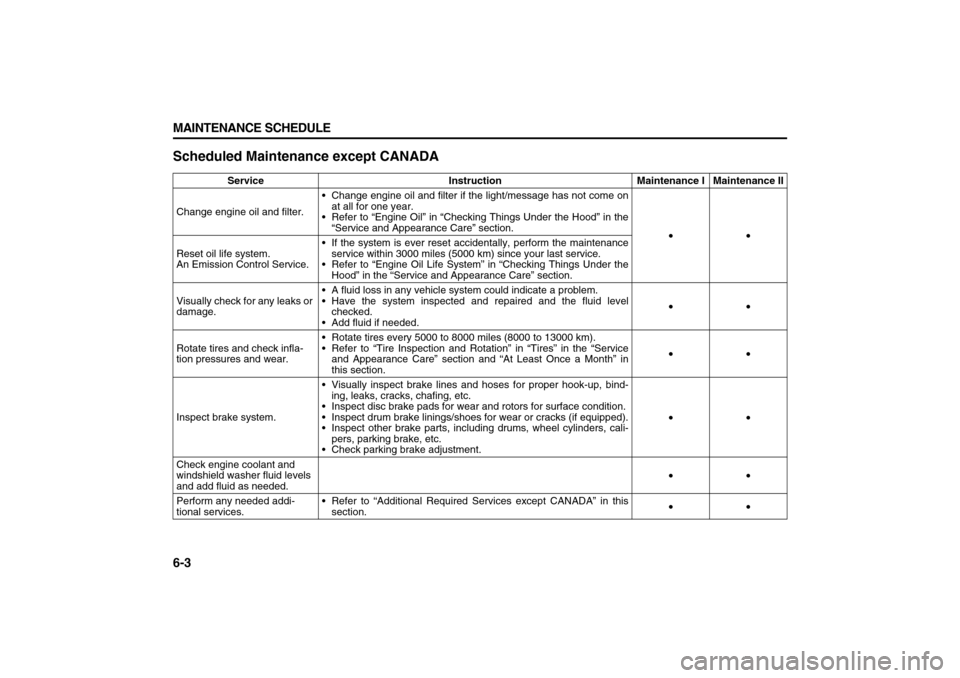

Scheduled Maintenance except CANADA

Service Instruction Maintenance I Maintenance II

Change engine oil and filter. Change engine oil and filter if the light/message has not come on

at all for one year.

Refer to “Engine Oil” in “Checking Things Under the Hood” in the

“Service and Appearance Care” section.

••

Reset oil life system.

An Emission Control Service. If the system is ever reset accidentally, perform the maintenance

service within 3000 miles (5000 km) since your last service.

Refer to “Engine Oil Life System” in “Checking Things Under the

Hood” in the “Service and Appearance Care” section.

Visually check for any leaks or

damage. A fluid loss in any vehicle system could indicate a problem.

Have the system inspected and repaired and the fluid level

checked.

Add fluid if needed.••

Rotate tires and check infla-

tion pressures and wear. Rotate tires every 5000 to 8000 miles (8000 to 13000 km).

Refer to “Tire Inspection and Rotation” in “Tires” in the “Service

and Appearance Care” section and “At Least Once a Month” in

this section.••

Inspect brake system. Visually inspect brake lines and hoses for proper hook-up, bind-

ing, leaks, cracks, chafing, etc.

Inspect disc brake pads for wear and rotors for surface condition.

Inspect drum brake linings/shoes for wear or cracks (if equipped).

Inspect other brake parts, including drums, wheel cylinders, cali-

pers, parking brake, etc.

Check parking brake adjustment.••

Check engine coolant and

windshield washer fluid levels

and add fluid as needed.••

Perform any needed addi-

tional services. Refer to “Additional Required Services except CANADA” in this

section.••

Page 250 of 274

6-8 MAINTENANCE SCHEDULE

78J00-03E

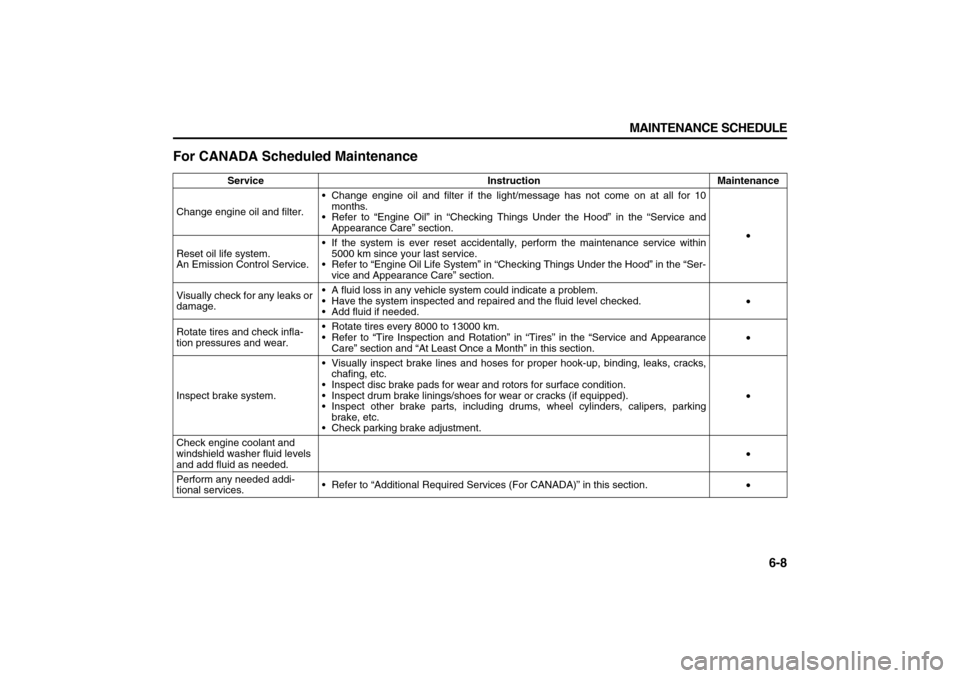

For CANADA Scheduled Maintenance

Service Instruction Maintenance

Change engine oil and filter. Change engine oil and filter if the light/message has not come on at all for 10

months.

Refer to “Engine Oil” in “Checking Things Under the Hood” in the “Service and

Appearance Care” section.

•

Reset oil life system.

An Emission Control Service. If the system is ever reset accidentally, perform the maintenance service within

5000 km since your last service.

Refer to “Engine Oil Life System” in “Checking Things Under the Hood” in the “Ser-

vice and Appearance Care” section.

Visually check for any leaks or

damage. A fluid loss in any vehicle system could indicate a problem.

Have the system inspected and repaired and the fluid level checked.

Add fluid if needed.•

Rotate tires and check infla-

tion pressures and wear. Rotate tires every 8000 to 13000 km.

Refer to “Tire Inspection and Rotation” in “Tires” in the “Service and Appearance

Care” section and “At Least Once a Month” in this section.•

Inspect brake system. Visually inspect brake lines and hoses for proper hook-up, binding, leaks, cracks,

chafing, etc.

Inspect disc brake pads for wear and rotors for surface condition.

Inspect drum brake linings/shoes for wear or cracks (if equipped).

Inspect other brake parts, including drums, wheel cylinders, calipers, parking

brake, etc.

Check parking brake adjustment.•

Check engine coolant and

windshield washer fluid levels

and add fluid as needed.•

Perform any needed addi-

tional services. Refer to “Additional Required Services (For CANADA)” in this section.•

Page 255 of 274

6-13 MAINTENANCE SCHEDULE

78J00-03E

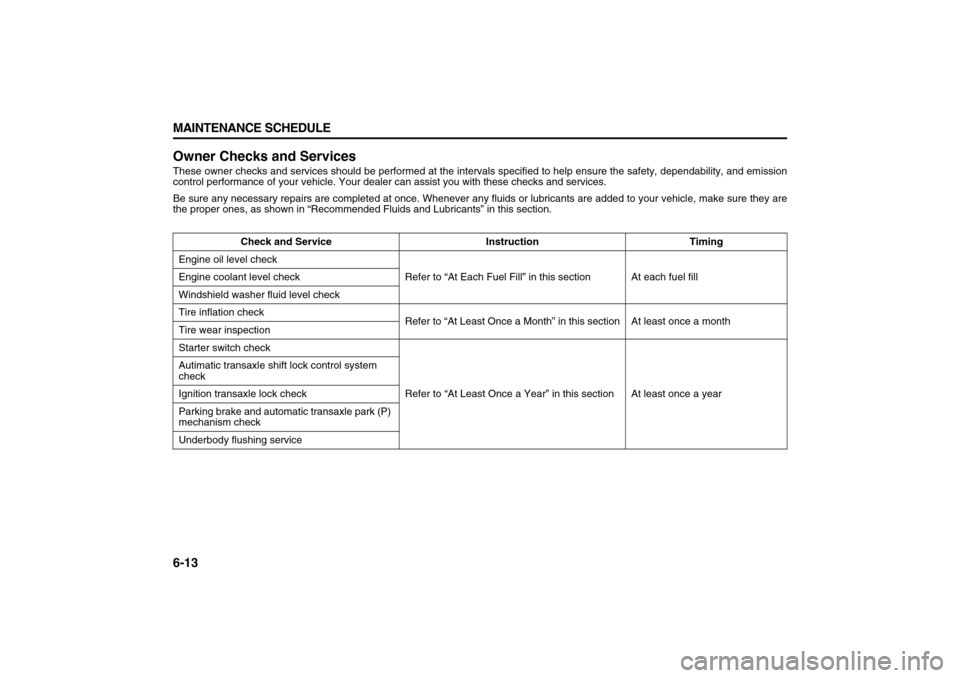

Owner Checks and ServicesThese owner checks and services should be performed at the intervals specified to help ensure the safety, dependability, and emission

control performance of your vehicle. Your dealer can assist you with these checks and services.

Be sure any necessary repairs are completed at once. Whenever any fluids or lubricants are added to your vehicle, make sure they are

the proper ones, as shown in “Recommended Fluids and Lubricants” in this section.

Check and Service Instruction Timing

Engine oil level check

Refer to “At Each Fuel Fill” in this section At each fuel fill Engine coolant level check

Windshield washer fluid level check

Tire inflation check

Refer to “At Least Once a Month” in this section At least once a month

Tire wear inspection

Starter switch check

Refer to “At Least Once a Year” in this section At least once a year Autimatic transaxle shift lock control system

check

Ignition transaxle lock check

Parking brake and automatic transaxle park (P)

mechanism check

Underbody flushing service

Page 256 of 274

6-14 MAINTENANCE SCHEDULE

78J00-03E

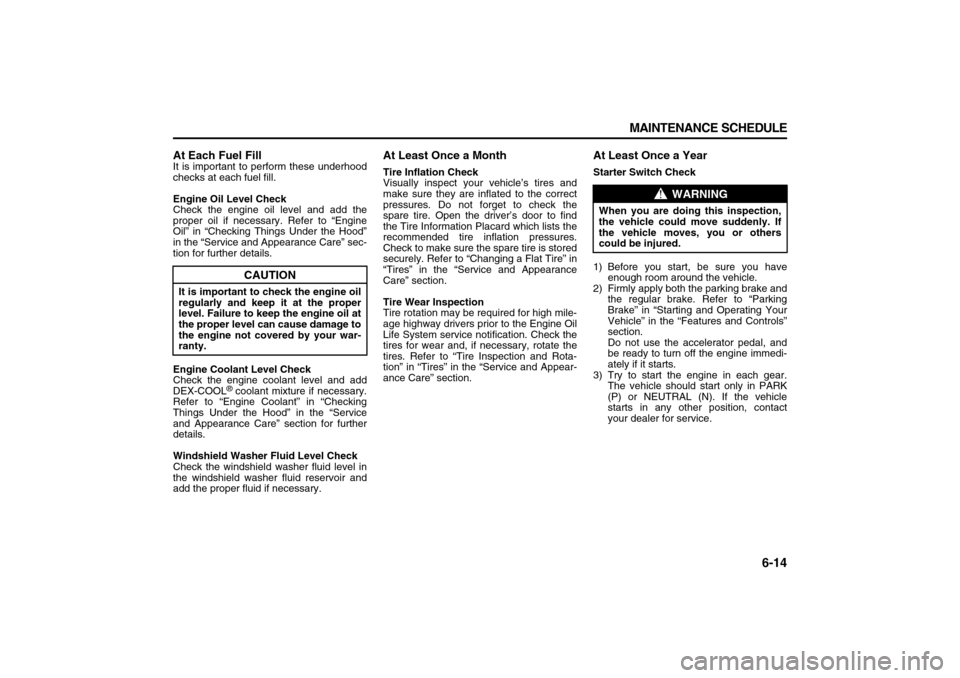

At Each Fuel FillIt is important to perform these underhood

checks at each fuel fill.

Engine Oil Level Check

Check the engine oil level and add the

proper oil if necessary. Refer to “Engine

Oil” in “Checking Things Under the Hood”

in the “Service and Appearance Care” sec-

tion for further details.

Engine Coolant Level Check

Check the engine coolant level and add

DEX-COOL

® coolant mixture if necessary.

Refer to “Engine Coolant” in “Checking

Things Under the Hood” in the “Service

and Appearance Care” section for further

details.

Windshield Washer Fluid Level Check

Check the windshield washer fluid level in

the windshield washer fluid reservoir and

add the proper fluid if necessary.

At Least Once a MonthTire Inflation Check

Visually inspect your vehicle’s tires and

make sure they are inflated to the correct

pressures. Do not forget to check the

spare tire. Open the driver’s door to find

the Tire Information Placard which lists the

recommended tire inflation pressures.

Check to make sure the spare tire is stored

securely. Refer to “Changing a Flat Tire” in

“Tires” in the “Service and Appearance

Care” section.

Tire Wear Inspection

Tire rotation may be required for high mile-

age highway drivers prior to the Engine Oil

Life System service notification. Check the

tires for wear and, if necessary, rotate the

tires. Refer to “Tire Inspection and Rota-

tion” in “Tires” in the “Service and Appear-

ance Care” section.

At Least Once a YearStarter Switch Check

1) Before you start, be sure you have

enough room around the vehicle.

2) Firmly apply both the parking brake and

the regular brake. Refer to “Parking

Brake” in “Starting and Operating Your

Vehicle” in the “Features and Controls”

section.

Do not use the accelerator pedal, and

be ready to turn off the engine immedi-

ately if it starts.

3) Try to start the engine in each gear.

The vehicle should start only in PARK

(P) or NEUTRAL (N). If the vehicle

starts in any other position, contact

your dealer for service.

CAUTION

It is important to check the engine oil

regularly and keep it at the proper

level. Failure to keep the engine oil at

the proper level can cause damage to

the engine not covered by your war-

ranty.

WARNING

When you are doing this inspection,

the vehicle could move suddenly. If

the vehicle moves, you or others

could be injured.

Page 257 of 274

6-15 MAINTENANCE SCHEDULE

78J00-03E

Automatic Transaxle Shift Lock Control

System Check

1) Before you start, be sure you have

enough room around the vehicle. It

should be parked on a level surface.

2) Firmly apply the parking brake. Refer to

“Parking Brake” in “Starting and Oper-

ating Your Vehicle” in the “Features

and Controls” section.

Be ready to apply the regular brake

immediately if the vehicle begins to

move.

3) With the engine off, turn the ignition to

RUN, but do not start the engine. With-

out applying the regular brake, try to

move the shift lever out of PARK (P)

with normal effort. If the shift lever

moves out of PARK (P), contact your

dealer for service.Ignition Transaxle Lock Check

While parked, and with the parking brake

set, try to turn the ignition to LOCK in each

shift lever position.

The ignition should turn to LOCK only

when the shift lever is in PARK (P).

The ignition key should come out only in

LOCK.

Contact your dealer if service is required.

Parking Brake and Automatic Transaxle

Park (P) Mechanism Check

Park on a fairly steep hill, with the vehicle

facing downhill. Keeping your foot on the

regular brake, set the parking brake.

To check the parking brake’s holding

ability: With the engine running and tran-

saxle in NEUTRAL (N), slowly remove

foot pressure from the regular brake

pedal. Do this until the vehicle is held by

the parking brake only. To check the PARK (P) mechanism’s

holding ability: With the engine running,

shift to PARK (P). Then release the

parking brake followed by the regular

brake.

Contact your dealer if service is required.

Underbody Flushing Service

At least every spring, use plain water to

flush any corrosive materials such as win-

ter road salt from the underbody. Take

care to clean thoroughly any areas where

mud and other debris can collect.

WARNING

When you are doing this inspection,

the vehicle could move suddenly. If

the vehicle moves, you or others

could be injured.

WARNING

When you are doing this check, your

vehicle could begin to move. You or

others could be injured and property

could be damaged. Make sure there

is room in front of your vehicle in

case it begins to roll. Be ready to

apply the regular brake at once

should the vehicle begin to move.

Page 258 of 274

6-16 MAINTENANCE SCHEDULE

78J00-03E

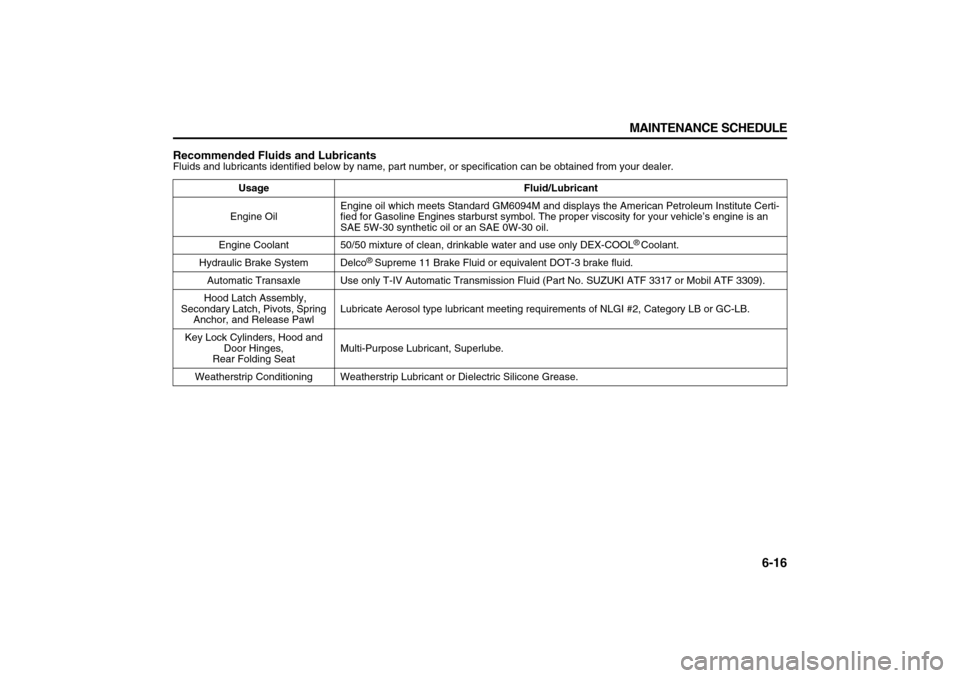

Recommended Fluids and LubricantsFluids and lubricants identified below by name, part number, or specification can be obtained from your dealer.

Usage Fluid/Lubricant

Engine OilEngine oil which meets Standard GM6094M and displays the American Petroleum Institute Certi-

fied for Gasoline Engines starburst symbol. The proper viscosity for your vehicle’s engine is an

SAE 5W-30 synthetic oil or an SAE 0W-30 oil.

Engine Coolant 50/50 mixture of clean, drinkable water and use only DEX-COOL

® Coolant.

Hydraulic Brake System Delco

® Supreme 11 Brake Fluid or equivalent DOT-3 brake fluid.

Automatic Transaxle Use only T-IV Automatic Transmission Fluid (Part No. SUZUKI ATF 3317 or Mobil ATF 3309).

Hood Latch Assembly,

Secondary Latch, Pivots, Spring

Anchor, and Release PawlLubricate Aerosol type lubricant meeting requirements of NLGI #2, Category LB or GC-LB.

Key Lock Cylinders, Hood and

Door Hinges,

Rear Folding SeatMulti-Purpose Lubricant, Superlube.

Weatherstrip Conditioning Weatherstrip Lubricant or Dielectric Silicone Grease.