engine TATA SAFARI 2015 Service Manual

[x] Cancel search | Manufacturer: TATA, Model Year: 2015, Model line: SAFARI, Model: TATA SAFARI 2015Pages: 161, PDF Size: 2.55 MB

Page 108 of 161

108

Changing of Engine Oil and Oil Filter Changing of Engine Oil and Oil FilterChanging of Engine Oil and Oil Filter Changing of Engine Oil and Oil Filter

Changing of Engine Oil and Oil Filter

Change the oil and oil filter at specified service intervals. (Engine oil and

oil filter may be changed earlier inline with recommendation given for

additional maintenance schedule under severe driving condition)

Changing of oil and oil filter requires access from underneath the vehicle.

Vehicle should be raised on a hydraulic lift of a service station or should

be on a service pit.

1 . Run the engine until it reaches normal operating temperature. Then

shut it off.

2. Remove oil sump guard.

3. Open the bonnet and remove engine oil filler cap. Remove the drain

plug of the oil sump from the bottom of the engine. Drain the oil into

an appropriate container.

4. Remove the oil filter with the help of special wrench. The removed

oil filter should not be reused and hence should be destroyed to

avoid recycling of the same. Used filter and oil should be disposed

in compliance with the current legislation.

5. Ensure cooler is tightened to it’s position.

6. Smear a little fresh engine oil on rubber gasket of new engine oil

filter. Hand tighten the engine oil filter fully and further 3/4 turn with

special tool.

Do not over tighten engine oil filter as this may damage oil filter and

oil may leak out.

7. Before filling in fresh oil in the engine, clean the drain plug..

ENGINE OIL & OIL FIL ENGINE OIL & OIL FILENGINE OIL & OIL FIL ENGINE OIL & OIL FIL

ENGINE OIL & OIL FIL

TER TERTER TER

TER

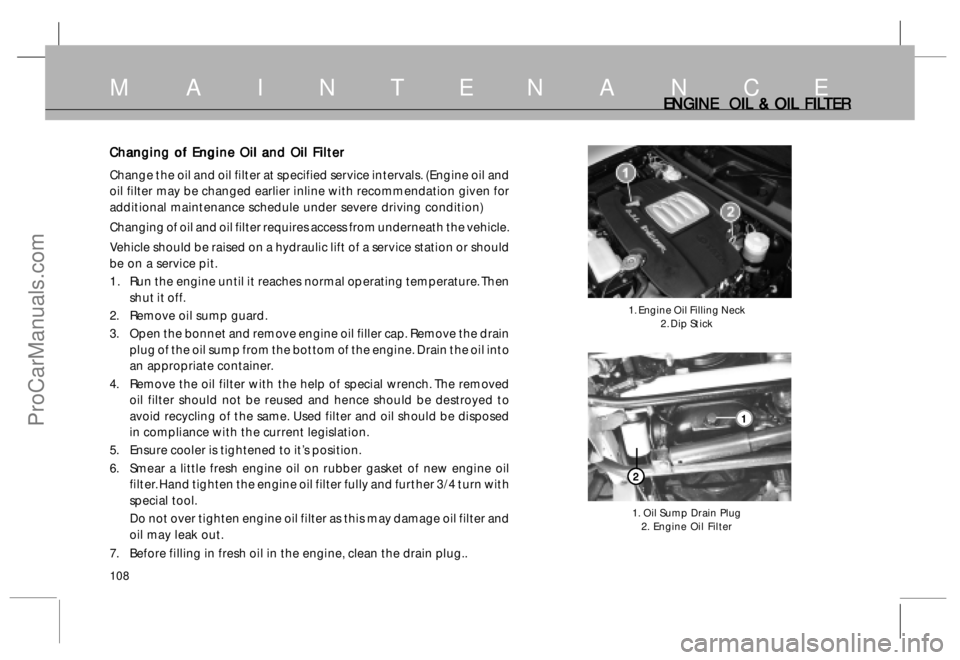

1. Engine Oil Filling Neck

2. Dip Stick

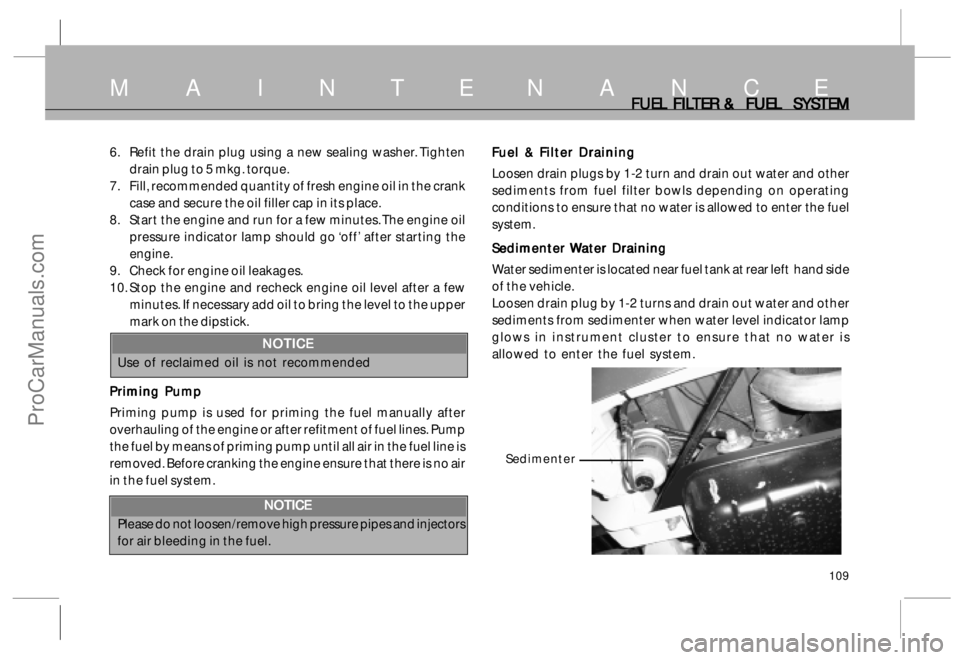

1. Oil Sump Drain Plug

2. Engine Oil Filter

M A I N T E N A N C E

2 22 2

21 11 1

1

ProCarManuals.com

Page 109 of 161

109

FUEL FIL FUEL FILFUEL FIL FUEL FIL

FUEL FIL

TER & FUEL SY TER & FUEL SYTER & FUEL SY TER & FUEL SY

TER & FUEL SY

STEM STEMSTEM STEM

STEM

6. Refit the drain plug using a new sealing washer. Tighten

drain plug to 5 mkg. torque.

7. Fill, recommended quantity of fresh engine oil in the crank

case and secure the oil filler cap in its place.

8. Start the engine and run for a few minutes. The engine oil

pressure indicator lamp should go ‘off ’ after starting the

engine.

9. Check for engine oil leakages.

10. Stop the engine and recheck engine oil level after a few

minutes. If necessary add oil to bring the level to the upper

mark on the dipstick.

NOTICE NOTICENOTICE NOTICE

NOTICE

Use of reclaimed oil is not recommended

Priming Pump Priming PumpPriming Pump Priming Pump

Priming Pump

Priming pump is used for priming the fuel manually after

overhauling of the engine or after refitment of fuel lines. Pump

the fuel by means of priming pump until all air in the fuel line is

removed. Before cranking the engine ensure that there is no air

in the fuel system.

NOTICE NOTICENOTICE NOTICE

NOTICE

Please do not loosen/remove high pressure pipes and injectors

for air bleeding in the fuel.

M A I N T E N A N C E

F FF F

F

uel & F uel & Fuel & F uel & F

uel & F

ilt iltilt ilt

ilt

er D er Der D er D

er D

r rr r

r

aining ainingaining aining

aining

Loosen drain plugs by 1-2 turn and drain out water and other

sediments from fuel filter bowls depending on operating

conditions to ensure that no water is allowed to enter the fuel

system.

S SS S

S

edimen edimenedimen edimen

edimen

t tt t

t

er er er er

er

W WW W

W

a aa a

a

t tt t

t

er D er Der D er D

er D

r rr r

r

aining ainingaining aining

aining

Water sedimenter is located near fuel tank at rear left hand side

of the vehicle.

Loosen drain plug by 1-2 turns and drain out water and other

sediments from sedimenter when water level indicator lamp

glows in instrument cluster to ensure that no water is

allowed to enter the fuel system.

Sedimenter

ProCarManuals.com

Page 110 of 161

110

Gear Box Oil Gear Box OilGear Box Oil Gear Box Oil

Gear Box Oil

C CC C

C

heck heckheck heck

heck

ing of Oil L ing of Oil Ling of Oil L ing of Oil L

ing of Oil L

e ee e

e

v vv v

v

el elel el

el

1. Clean the oil level plug and surrounding area.

2 . Remove the oil level plug and check whether oil is dripping out.

Oil level must not be below the filler plug. Add oil to bring it to

the level.

3. Tighten oil level plug to 2-3 mkg. torque.

C CC C

C

hanging Oil in G hanging Oil in Ghanging Oil in G hanging Oil in G

hanging Oil in G

ear B ear Bear B ear B

ear B

o oo o

o

x xx x

x

1. Let the engine idle for about 5 min. in neutral, so that the gear box

oil is warmed up.

2. Clean the oil level plug, drain plug and surrounding area.

3. Place a container under gear box to collect the oil.

4. Remove the drain plug and let the oil drain out.

5. Also remove the oil level plug.

6. Tighten the oil drain plug and fill new recommended oil through oil

level plug and tighten the oil drain plug oil level plug to 2-3 mkg.

torque.

GEAR BO GEAR BOGEAR BO GEAR BO

GEAR BO

X OIL X OILX OIL X OIL

X OIL

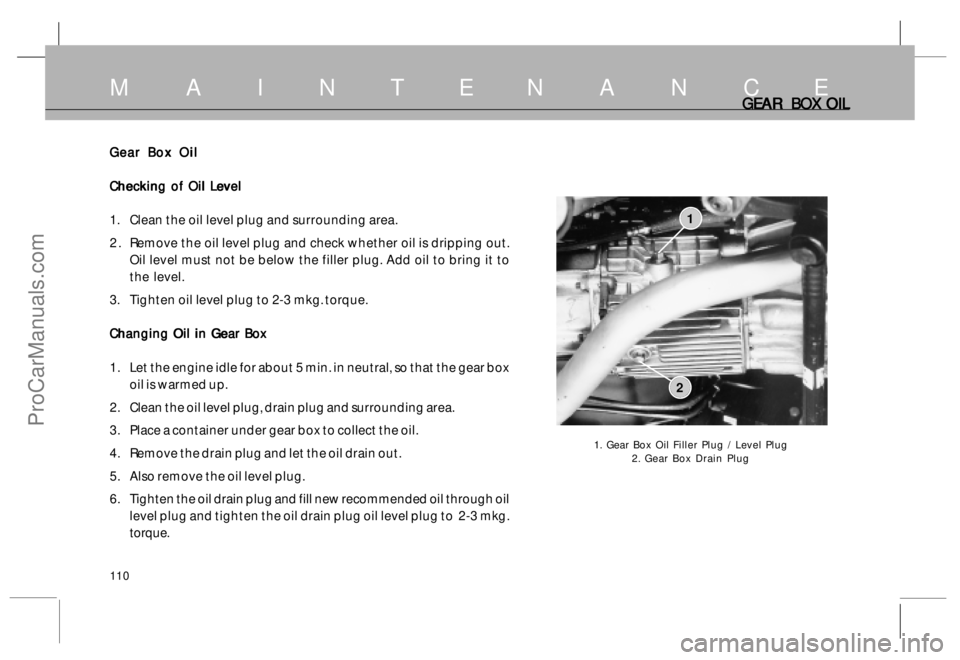

1. Gear Box Oil Filler Plug / Level Plug

2. Gear Box Drain Plug

1

2

M A I N T E N A N C E

ProCarManuals.com

Page 115 of 161

115

CL CLCL CL

CL

UT UTUT UT

UT

CH, CH,CH, CH,

CH,

BR BR BR BR

BR

AKE AKEAKE AKE

AKE

,, ,,

,

PO PO PO PO

PO

WER STEERING WER STEERINGWER STEERING WER STEERING

WER STEERING

Clutch Fluid Clutch FluidClutch Fluid Clutch Fluid

Clutch Fluid

The Tata Safari vehicle is equipped with a diaphragm type clutch Which is

hydraulically actuated.

The level of clutch fluid in clutch fluid container should be in between

Min. and Max. marks. If it is not, then add clutch fluid.

In case of spongy or hard clutch pedal, please contact the nearest

Authorised Workshop and get the defect rectified.

Brake Fluid Brake FluidBrake Fluid Brake Fluid

Brake Fluid

Check the level of Brake fluid in Brake fluid container.

It should be in between Min. and Mix. marks.

If it is not, then add brake fluid.

In case of spongy or hard pedal or low brake efficiency, please contact

the nearest Authorised Workshop and get the defect rectified.

Power Steering Fluid Power Steering FluidPower Steering Fluid Power Steering Fluid

Power Steering Fluid

Power steering is fitted for lighter steering effect and easy

manoeuverability. The system consists of steering gear box, hydraulic

pump and hydraulic tank suitably connected by piping. Pump drive is

though ‘V’ belt from engine. Power assistance is available during normal

operating conditions. In case of failure in hydraulic system, the steering

can be operated mechanically with increased steering effort for bringing

the vehicle to Authorised Workshop.

M A I N T E N A N C E

1. Brake Fluid Container

2. Clutch Fluid Container

Power Steering Fluid Container

ProCarManuals.com

Page 116 of 161

116

POWER STEERING POWER STEERINGPOWER STEERING POWER STEERING

POWER STEERING

Procedure for Oil Filling and Bleeding of Power Procedure for Oil Filling and Bleeding of PowerProcedure for Oil Filling and Bleeding of Power Procedure for Oil Filling and Bleeding of Power

Procedure for Oil Filling and Bleeding of Power

Steering SteeringSteering Steering

Steering (Ensure that Power Steering fluid reservoir is totally

clean before starting the work)

1 . Fill the reservoir nearly full. Crank the engine for 10

seconds without allowing it to start (if possible). If engine

does start, shut the engine immediately. Check & refill

the reservoir repeat atleast three times, each time

checking & refilling the reservoir.

2 . Check for leakage in the system and if noticed take

corrective action.

3 . Start the engine and steer the vehicle from full left to full

right turns 3-4 times.

4 . Add fluid if necessary to maintain the level upto filter top.

NOTICE NOTICENOTICE NOTICE

NOTICE

Do not force the wheel against lock position either

extreme left or right. The power steering pump may get

damaged. Hold it lightly.

5 . When the engine is at steady speed, check for bubble

or foaming in the oil. If present it indicates that air is

getting sucked into the systems. Check the suction

line/fittings and correct if necessary.

6 . Once the system is bled properly and free from foaming

there should not be any appreciable change in oil level

in the reservoir, when the engine is started or stopped

repeatedly.

7 . Now the system is ready for driving.

Final oil level should be at ‘H’ mark on dip stick.

NOTICE NOTICENOTICE NOTICE

NOTICE

* Do not allow fluid level to drop significantly or run out

of the reservoir during the above operation. This may

induce air to the system.

* Do not start the engine without oil in the power steering

system. This will result in serious damage to the

pump. In case of emergency disconnect the pump belt

and then start the engine.

* Always use recommended oil from closed containers.

Any dirty oil poured in the system will result in damage

to pump and gear box.

M A I N T E N A N C E

ProCarManuals.com

Page 117 of 161

117

L LL L

L

oad C oad Coad C oad C

oad C

onscious P onscious Ponscious P onscious P

onscious P

r rr r

r

essur essuressur essur

essur

e R e Re R e R

e R

educing educing educing educing

educing

V VV V

V

alv alvalv alv

alv

e (I e (Ie (I e (I

e (I

f fitt f fittf fitt f fitt

f fitt

ed) ed)ed) ed)

ed)

( Not applicable in ABS system) ( Not applicable in ABS system)( Not applicable in ABS system) ( Not applicable in ABS system)

( Not applicable in ABS system)

A load conscious pressure reducing valve eliminates the

possibility of rear wheels from locking and achieves optimum

braking in any load condition of the vehicle.

The valve, is fitted on RH long member connecting it to rear

axle through its link and control spring.

If any, alteration is done in rear suspension, the performance

of this valve will be impaired.

R RR R

R

emot emotemot emot

emot

e B e Be B e B

e B

y-pass y-pass y-pass y-pass

y-pass

V VV V

V

alv alvalv alv

alv

e (I e (Ie (I e (I

e (I

f fitt f fittf fitt f fitt

f fitt

ed) ed)ed) ed)

ed)

(Applicable in ABS system) (Applicable in ABS system)(Applicable in ABS system) (Applicable in ABS system)

(Applicable in ABS system)

The by-pass valve is provided in the rear brake circuit between

tandem master cylinder and ABS unit. The by-pass valve

bypasses the ABS unit in rear only braking (i.e. front brake

failed) condition. The feedback of front line pressure is

provided to the by-pass valve. in case of front brake failure,

the low front line presure being sensed by the by-pass valve

and the 100% brake line pressure from tandem master

cylinder is applied on to the rear brakes without reduction

in pressure.

M A I N T E N A N C EL LL L

L

CR CRCR CR

CR

V (IF FIT V (IF FITV (IF FIT V (IF FIT

V (IF FIT

TED), TED),TED), TED),

TED),

REMO REMO REMO REMO

REMO

TE BY P TE BY PTE BY P TE BY P

TE BY P

ASS ASS ASS ASS

ASS

V VV V

V

AL ALAL AL

AL

VE AND ECU VE AND ECUVE AND ECU VE AND ECU

VE AND ECU

ECU : ECU :ECU : ECU :

ECU :

DICOR engine common rail system consists of ECU, sensors

and actuators. The Electronic control unit (ECU) is a 32 bit

microprocessor which controls the injection parameters as well

as some of the vehicle related outputs. The ECU receives input

from various sensors located on the engine and the vehicle to

decide the injected quantity and injection timing best suited

for the engine to work with maximum efficiency and safety.

ECU is fitted inside the engine compartment.

C CC C

C

AUTIONS AUTIONSAUTIONS AUTIONS

AUTIONS

• •• •

•DO NOT DO NOT DO NOT DO NOT

DO NOT wash engine compartment with high

pressure water

• •• •

•DO NOT DO NOTDO NOT DO NOT

DO NOT tamper with ECU sensors and connectors

• •• •

•DO NOT DO NOTDO NOT DO NOT

DO NOT remove battery connections when the ignition

switch is in ‘ON’ position ( This may damage ECU)

• •• •

•AV AVAV AV

AV

OID OIDOID OID

OID jump start/push start, Use fully charged battery.

• •• •

•DO NO DO NODO NO DO NO

DO NO

T T T T

T run the vehicle if ‘CHECK ENGINE’ lamp on

dashboard is ‘ON.

• •• •

•If any abnormality in performance of engine occurs - like

lack of power- the vehicle to be taken to the

T TT T

T

A AA A

A

T TT T

T

A MO A MOA MO A MO

A MO

T TT T

T

ORS ORSORS ORS

ORS

authorised service outlet.

ProCarManuals.com

Page 118 of 161

118

B BB B

B

A AA A

A

T TT T

T

TER TERTER TER

TER

Y YY Y

Y

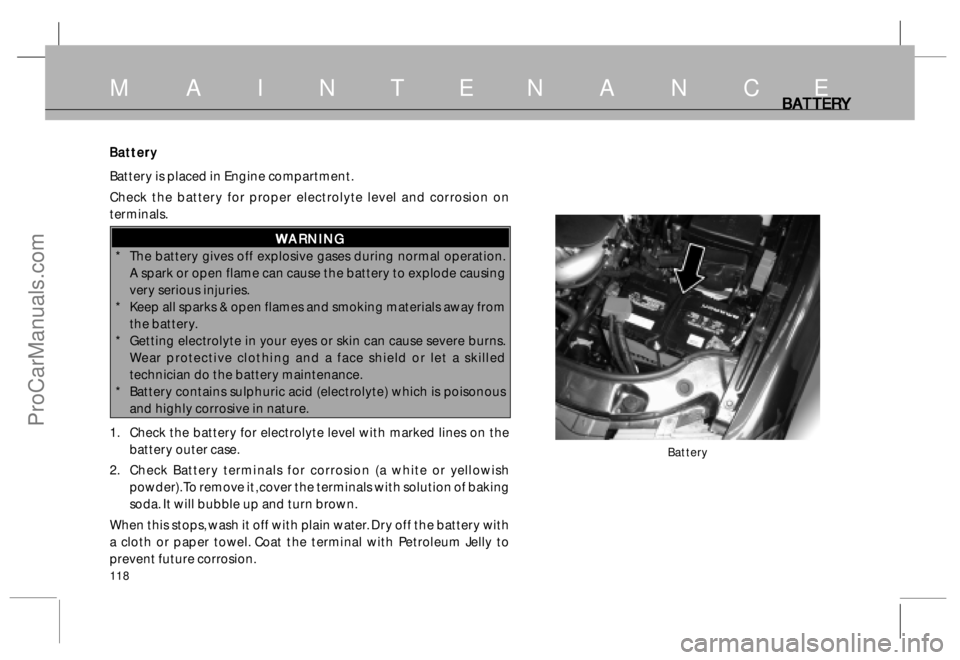

Battery BatteryBattery Battery

Battery

Battery is placed in Engine compartment.

Check the battery for proper electrolyte level and corrosion on

terminals.

W WW W

W

ARNING ARNINGARNING ARNING

ARNING

* The battery gives off explosive gases during normal operation.

A spark or open flame can cause the battery to explode causing

very serious injuries.

* Keep all sparks & open flames and smoking materials away from

the battery.

* Getting electrolyte in your eyes or skin can cause severe burns.

Wear protective clothing and a face shield or let a skilled

technician do the battery maintenance.

* Battery contains sulphuric acid (electrolyte) which is poisonous

and highly corrosive in nature.

1. Check the battery for electrolyte level with marked lines on the

battery outer case.

2. Check Battery terminals for corrosion (a white or yellowish

powder). To remove it, cover the terminals with solution of baking

soda. It will bubble up and turn brown.

When this stops, wash it off with plain water. Dry off the battery with

a cloth or paper towel. Coat the terminal with Petroleum Jelly to

prevent future corrosion.

Battery

M A I N T E N A N C E

ProCarManuals.com

Page 119 of 161

119

B BB B

B

A AA A

A

T TT T

T

TER TERTER TER

TER

Y YY Y

Y

,, ,,

,

ST ST ST ST

ST

AR ARAR AR

AR

TING TING TING TING

TING

THE ENGINE THE ENGINE THE ENGINE THE ENGINE

THE ENGINE

WITH JUMP LEADS WITH JUMP LEADSWITH JUMP LEADS WITH JUMP LEADS

WITH JUMP LEADS

The use of a wrench to loosen and remove cables from the

terminals should be made. Always disconnect the negative

(-ve) cable first and reconnect it last. Clean the battery

terminals with a terminal cleaning tool or wire brush.

Reconnect and tighten the cables, coat the terminals with

petroleum jelly. If you need to connect the battery to a

charger, disconnect both cables to prevent damage to the

vehicle’s electrical system.

NOTICE NOTICENOTICE NOTICE

NOTICE

Charging the battery with the cables connected can

seriously damage your vehicle’s electronic controls.

Detach the battery cables before connecting battery to

a charger.

* Swallowing electrolyte can cause fatal poisoning if

immediate action is not taken.

Starting the Engine with Jump Leads Starting the Engine with Jump LeadsStarting the Engine with Jump Leads Starting the Engine with Jump Leads

Starting the Engine with Jump Leads

Your Safari with a discharged battery may be started by

transferring electrical power from a battery in another vehicle.

This may be dangerous as any deviation from the following

instructions could lead to personal injury or damage

resulting from battery explosion, as well as the damage to

the electrical systems in both vehicles.• Never expose the battery to open flames or sparks.

• Do not allow battery electrolyte to come in contact with

eyes, skins, fabrics or painted surfaces. The fluid

contains sulphuric acid which can cause injuries and

damage in the event of direct contact.

• To lessen the risk of injury wear eye protection when

working near any battery.

• Make sure that battery providing the jump start has the

same voltage as the battery in your vehicle (12 V). Its

capacity must not be substantially lower than that of the

discharged battery. The voltage and capacity are given

on the batteries.

• Do not disconnect the discharged battery from the vehicle.

• Switch off all unnecessary electrical loads.

• Do not lean over the battery during jump starting.

• Do not allow the terminals of one lead to touch those of

the other lead.

• Apply hand brake. Place gear shift lever to neutral.

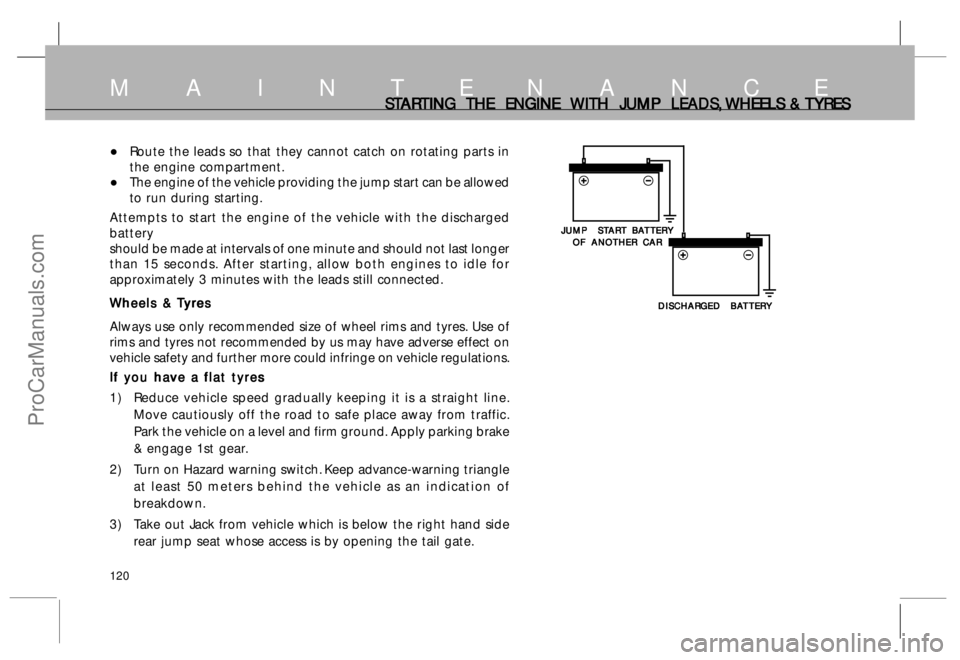

Connect Leads in the Order as shown Connect Leads in the Order as shownConnect Leads in the Order as shown Connect Leads in the Order as shown

Connect Leads in the Order as shown

on next page on next page on next page on next page

on next page

•Do not connect lead to negative terminal of discharged

battery.

•The connection point should be as far away from the

discharged battery as possible.

M A I N T E N A N C E

ProCarManuals.com

Page 120 of 161

120

ST STST ST

ST

AR ARAR AR

AR

TING TING TING TING

TING

THE ENGINE THE ENGINE THE ENGINE THE ENGINE

THE ENGINE

WITH JUMP LEADS, WITH JUMP LEADS,WITH JUMP LEADS, WITH JUMP LEADS,

WITH JUMP LEADS,

WHEELS & WHEELS & WHEELS & WHEELS &

WHEELS &

T TT T

T

YRES YRESYRES YRES

YRES

•Route the leads so that they cannot catch on rotating parts in

the engine compartment.

•The engine of the vehicle providing the jump start can be allowed

to run during starting.

Attempts to start the engine of the vehicle with the discharged

battery

should be made at intervals of one minute and should not last longer

than 15 seconds. After starting, allow both engines to idle for

approximately 3 minutes with the leads still connected.

W WW W

W

heels & heels & heels & heels &

heels &

T TT T

T

yr yryr yr

yr

es eses es

es

Always use only recommended size of wheel rims and tyres. Use of

rims and tyres not recommended by us may have adverse effect on

vehicle safety and further more could infringe on vehicle regulations.

If you have a flat tyres If you have a flat tyresIf you have a flat tyres If you have a flat tyres

If you have a flat tyres

1) Reduce vehicle speed gradually keeping it is a straight line.

Move cautiously off the road to safe place away from traffic.

Park the vehicle on a level and firm ground. Apply parking brake

& engage 1st gear.

2) Turn on Hazard warning switch. Keep advance-warning triangle

at least 50 meters behind the vehicle as an indication of

breakdown.

3) Take out Jack from vehicle which is below the right hand side

rear jump seat whose access is by opening the tail gate.

M A I N T E N A N C E

JUMP ST JUMP STJUMP ST JUMP ST

JUMP ST

AR ARAR AR

AR

T B T BT B T B

T B

A AA A

A

T TT T

T

TER TERTER TER

TER

Y YY Y

Y

OF ANOTHER CAR OF ANOTHER CAROF ANOTHER CAR OF ANOTHER CAR

OF ANOTHER CAR

DISCHAR DISCHARDISCHAR DISCHAR

DISCHAR

GED B GED BGED B GED B

GED B

A AA A

A

T TT T

T

TER TERTER TER

TER

Y YY Y

Y

ProCarManuals.com

Page 127 of 161

127

Maintaining the car when not in extended use : Maintaining the car when not in extended use :Maintaining the car when not in extended use : Maintaining the car when not in extended use :

Maintaining the car when not in extended use :

Park the car in covered, dry and if possible well-ventilated

premises.

Engage a gear.

Remove the cables from the battery terminals (first remove

the cable from the negative terminal).

Make sure the handbrake is not engaged.

Clean and protect the painted parts using protective wax.

Clean and protect the shiny metal parts using commercially

available special compounds.

Sprinkle talcum powder on the rubber windscreen wiper and

rear window wiper blades and lift them off the glass.

Slightly open the windows.

Cover the car with a cloth or perforated plastic sheet. Do

not use sheets of imperforated plastic as they do not allow

moisture on the car body to evaporate.

Inflate the tyres to 0.5 bar above the normal specified

pressure and check it at regular intervals.

Check the battery charge every six weeks.

Do not drain the engine cooling system.

VEHICLE C VEHICLE CVEHICLE C VEHICLE C

VEHICLE C

ARE AREARE ARE

ARE

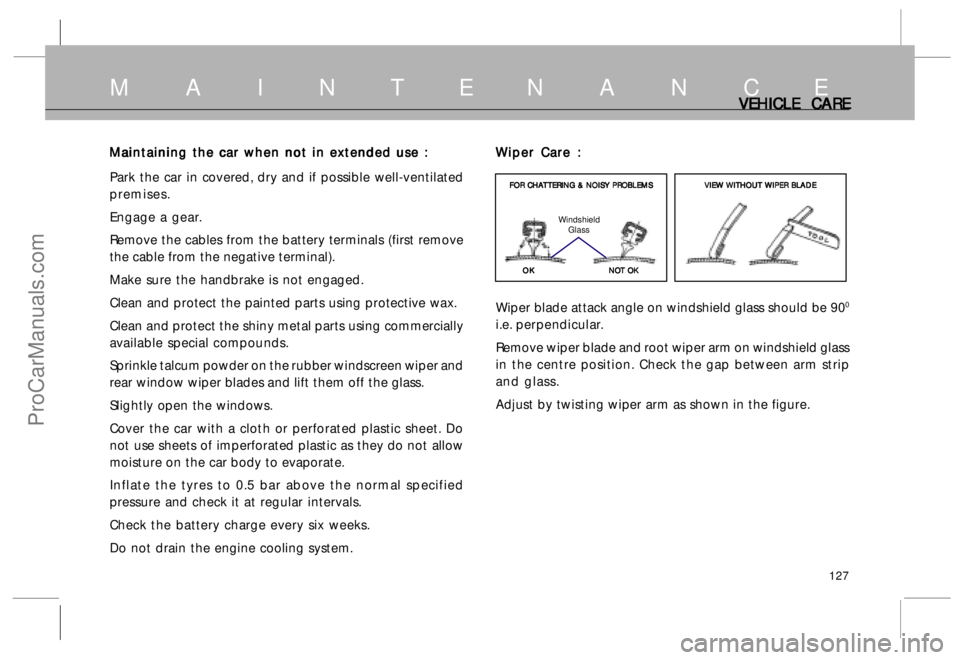

Wiper Care : Wiper Care :Wiper Care : Wiper Care :

Wiper Care :

Wiper blade attack angle on windshield glass should be 90

0

i.e. perpendicular.

Remove wiper blade and root wiper arm on windshield glass

in the centre position. Check the gap between arm strip

and glass.

Adjust by twisting wiper arm as shown in the figure.

OK OKOK OK

OK FOR CHA FOR CHAFOR CHA FOR CHA

FOR CHA

T TT T

T

TERING & NOISY PR TERING & NOISY PRTERING & NOISY PR TERING & NOISY PR

TERING & NOISY PR

OBLEMS OBLEMSOBLEMS OBLEMS

OBLEMS

NO NONO NO

NO

T OK T OKT OK T OK

T OK Windshield

GlassVIE VIEVIE VIE

VIE

W W W W

W

WITHOUT WITHOUT WITHOUT WITHOUT

WITHOUT

WIPER BL WIPER BLWIPER BL WIPER BL

WIPER BL

ADE ADEADE ADE

ADE

M A I N T E N A N C E

ProCarManuals.com