engine TATA SAFARI 2015 Workshop Manual

[x] Cancel search | Manufacturer: TATA, Model Year: 2015, Model line: SAFARI, Model: TATA SAFARI 2015Pages: 161, PDF Size: 2.55 MB

Page 130 of 161

130

M A I N T E N A N C EFUSES FUSESFUSES FUSES

FUSES

Fuse Box - Cabin

Fuse Box - Engine Compartment

Fuses FusesFuses Fuses

Fuses

All the electrical circuits in your vehicle have fuses to protect them

from a short circuit or overload. These fuses are located in 2 fuse boxes.

The interior fuse box is below the dash board on driver’s side. Remove

the fuse box lid by grabbing and pulling down the slot.

The under bonnet fuse box is located in engine compartment on LHS.

Checking and Replacing Fuses Checking and Replacing FusesChecking and Replacing Fuses Checking and Replacing Fuses

Checking and Replacing Fuses

If any electrical unit in your vehicle has stopped functioning, the fuses

should be checked first.

1. Turn the ignition key to lock position.

2. Remove the cover of the fuse box.

3. Check each fuse and look for burnt wire inside the fuse. If it is burnt,

replace it with one of the spare fuses of same rating or lower.

4. If the replacement fuse of same rating burns out in short time, there

is probably a serious electrical problem. Get the vehicle attended at

nearest Authorised Workshop.

NOTICE NOTICENOTICE NOTICE

NOTICE

Ensure that the replaced fuses have the same rating as indicated on

the sticker.

ProCarManuals.com

Page 131 of 161

131

M A I N T E N A N C E

R RR R

R

ela elaela ela

ela

y yy y

y

s and s and s and s and

s and

T TT T

T

r rr r

r

ansf ansfansf ansf

ansf

er C er Cer C er C

er C

ase ECU ase ECUase ECU ase ECU

ase ECU

Relays are fitted to protect the voltage drawing units from low

voltage.

Relays are fitted in 2 locations :

1 . In the fuse box situated inside engine compartment.

2 . Behind glove box.

ECU for transfer case is fitted under RH seat.

FUSES & REL FUSES & RELFUSES & REL FUSES & REL

FUSES & REL

A AA A

A

Y YY Y

Y

S AND INTER S AND INTERS AND INTER S AND INTER

S AND INTER

C CC C

C

OOLER OOLEROOLER OOLER

OOLER

Transfercase ECU under driver’s seat

ProCarManuals.com

Page 132 of 161

132

M A I N T E N A N C EEGR SYSTEM EGR SYSTEMEGR SYSTEM EGR SYSTEM

EGR SYSTEM

T TT T

T

AKING C AKING CAKING C AKING C

AKING C

ARE OF ENVIR ARE OF ENVIRARE OF ENVIR ARE OF ENVIR

ARE OF ENVIR

ONMENT : ONMENT :ONMENT : ONMENT :

ONMENT :

Your vehicle is equipped with the EGR ( Exhaust Gas

Recirculation) System to reduce exhaust pollution.

EGR SYSTEM : EGR SYSTEM :EGR SYSTEM : EGR SYSTEM :

EGR SYSTEM :

The engine is fitted with EGR valve, EGR pipe, vacuum

modulator and associated electrical circuitry. With this,

controlled amount of exhaust gas is mixed with intake air of

the engine, in part load and speed conditions. This helps in

reducing harmful pollutants.

Close Couple Catalytic Converter : Close Couple Catalytic Converter :Close Couple Catalytic Converter : Close Couple Catalytic Converter :

Close Couple Catalytic Converter :

Tata Safari is fitted with Diesel Oxidation Catalytic Converter

to reduce exhaust pollution. The two way Catalytic

Converter has coating of precious metals which enables

conversion of pollutants.

Care of the Catalytic Converter Care of the Catalytic ConverterCare of the Catalytic Converter Care of the Catalytic Converter

Care of the Catalytic Converter

The Catalytic Converter does not require any special

maintenance however, following precautions should be

taken for the effective functioning of the converter and to

avoid damage to the converter.

1 It is mandatory to use Diesel fuel with low sulphur

content (Refer recommended fuels). Use of any other

diesel fuel can increase the pollutants.

2 Avoid parking the vehicle over inflammable materials,such as dry leaves, grass, etc., as the exhaust system

is hot enough to initiate “FIRE”.

Maintenance of Catalytic Converter Maintenance of Catalytic ConverterMaintenance of Catalytic Converter Maintenance of Catalytic Converter

Maintenance of Catalytic Converter

Catalytic Converter should be flushed by giving full throttle

(4 to 5 times) in standing condition of vehicle on daily basis.

In addition to this it is recommended to run the vehicle at

high speeds (80 to 100 kmph) for few km as this will help to

flush the carbon soot deposits from exhaust system and

catalytic converter. High speed running of the vehicle may

be done periodically to avoid chocking of catalytic converter.

Alternatively flushing operation for cleaning the catalytic

converter can be done by dry compressed air draft (3 to 4

bar) directed on the honeycomb structure of catalytic

converter (after removing from vehicle)

Closed Catalytic Converter

ProCarManuals.com

Page 133 of 161

133

TURBO CHARGER (IF FITTED) TURBO CHARGER (IF FITTED)TURBO CHARGER (IF FITTED) TURBO CHARGER (IF FITTED)

TURBO CHARGER (IF FITTED)

V VV V

V

ar arar ar

ar

iable iable iable iable

iable

T TT T

T

urbine urbine urbine urbine

urbine

T TT T

T

echnolo echnoloechnolo echnolo

echnolo

g gg g

g

y- y- y- y-

y-

VT VTVT VT

VT

T T T T

T

T TT T

T

urb urburb urb

urb

o oo o

o

char charchar char

char

ger : ger :ger : ger :

ger :

Your vehicle is fitted with a turbocharger having variable

turbine technology ( VTT ). Turbocharger is an efficient

supercharging device used in our engine. It makes optimal

use of thermal energy of engine exhaust gases to run a

turbine which in turn drives a compressor to force air under

pressure into the inlet manifold. This turbocharger is

optimized for higher power output flat torque across large

engine speed range and better fuel consumption.

L LL L

L

ubr ubrubr ubr

ubr

ic icic

ic

ic

a aa a

a

tion of tion of tion of tion of

tion of

T TT T

T

urb urburb urb

urb

o oo o

o

char charchar char

char

ger : ger :ger : ger :

ger :

The turbocharger rotor assembly is supported by two fully

floating bearing bushes in the bearing housing. These

bearing bushes are lubricated with finely filtered engine

oil from the lubrication system of the engine.

Idle the engine for a while (30 seconds) after starting the

engine and before stopping the engine to ensure adequate

lubricating oil supply to the turbocharger.

T TT T

T

urb urburb urb

urb

o oo o

o

char charchar char

char

ger C ger Cger C ger C

ger C

onnec onneconnec onnec

onnec

tions : tions :tions : tions :

tions :

All turbocharger connections must be leak-proof. Check air

inlet, air outlet, exhaust gas inlet and exhaust outlet

connections as well as oil inlet and outlet connections to

the turbocharger and tighten the connections where

required.Proper maintenance of air filter, oil filter as well as use of

correct grade of oil and adherence to oil change intervals is

essential for proper functioning of the turbocharger.

If you suspect any malfunctioning of the turbocharger, take

the vehicle to the nearest dealer. Do not remove the

turbocharger yourself.

M A I N T E N A N C E

Turbocharger ( VTT )

ProCarManuals.com

Page 134 of 161

134

AIR CONDITIONING AIR CONDITIONING AIR CONDITIONING AIR CONDITIONING

AIR CONDITIONING

Air Conditioning Air ConditioningAir Conditioning Air Conditioning

Air Conditioning

The Air Conditioning is a sealed system. Any major maintenance

should be done by Authorised Workshop.

There are couple of things which can be done by you to ensure proper

working of Air conditioning / Heating.

Periodically check the engine’s radiator and air conditioning

condensers for leaves, insects and dirt stuck in front surface.

These block the air flow and reduce the cooling efficiency. Use a light

water spray from a hose or a soft brush to remove them.

NO NONO NO

NO

TICE TICETICE TICE

TICE

Use only low pressure spray or soft bristle brush to clean condenser

and radiator fins.

Run the air conditioning at least once a week during winter season.

Run it at least for ten minutes with vehicle at steady speed and engine

at normal operating condition. This circulates lubrication oil in the

compressor.

For any complaint on A.C. and Heating get it attended at Authorised

Workshop.

NO NONO NO

NO

TICE TICETICE TICE

TICE

The system is charged with R 134 (a) - ‘Non C.F.C.’ refrigerant. Do

not top up with any other refrigerant.

M A I N T E N A N C E

ProCarManuals.com

Page 135 of 161

135

BEL BELBEL BEL

BEL

T T T T

T

TENSION TENSIONTENSION TENSION

TENSIONM A I N T E N A N C E

B BB B

B

elt elt elt elt

elt

T TT T

T

ension : ension :ension : ension :

ension :

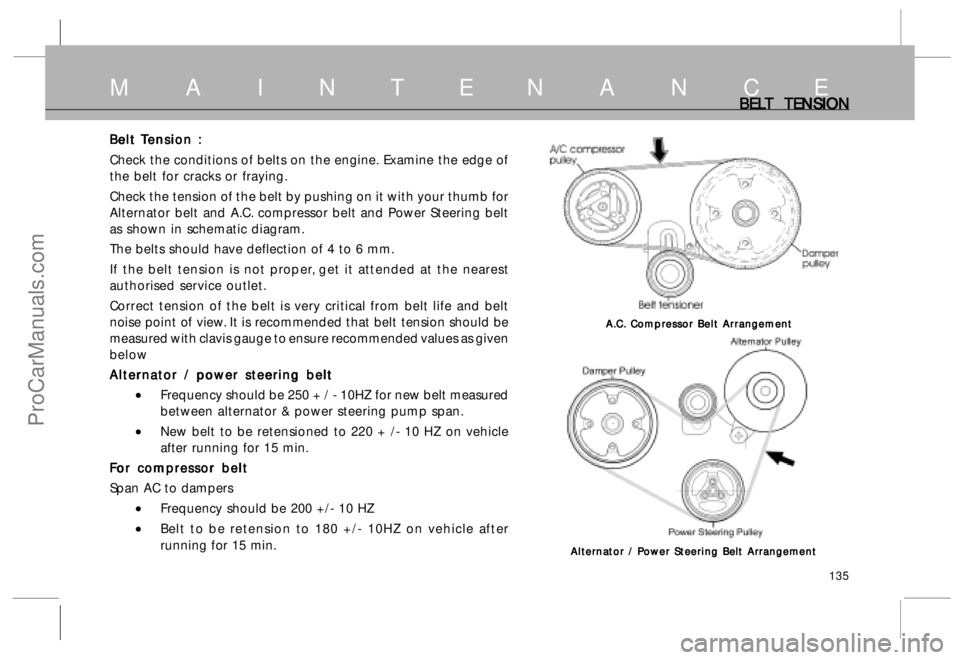

Check the conditions of belts on the engine. Examine the edge of

the belt for cracks or fraying.

Check the tension of the belt by pushing on it with your thumb for

Alternator belt and A.C. compressor belt and Power Steering belt

as shown in schematic diagram.

The belts should have deflection of 4 to 6 mm.

If the belt tension is not proper, get it attended at the nearest

authorised service outlet.

Correct tension of the belt is very critical from belt life and belt

noise point of view. It is recommended that belt tension should be

measured with clavis gauge to ensure recommended values as given

below

Alternator / power steering belt Alternator / power steering beltAlternator / power steering belt Alternator / power steering belt

Alternator / power steering belt

•Frequency should be 250 + / - 10HZ for new belt measured

between alternator & power steering pump span.

•New belt to be retensioned to 220 + /- 10 HZ on vehicle

after running for 15 min.

F FF F

F

or c or cor c or c

or c

ompr omprompr ompr

ompr

essor b essor bessor b essor b

essor b

elt eltelt elt

elt

Span AC to dampers

•Frequency should be 200 +/- 10 HZ

•Belt to be retension to 180 +/- 10HZ on vehicle after

running for 15 min.

Alternator / Power Steering Belt Arrangement Alternator / Power Steering Belt ArrangementAlternator / Power Steering Belt Arrangement Alternator / Power Steering Belt Arrangement

Alternator / Power Steering Belt Arrangement

A.C. Compressor Belt Arrangement A.C. Compressor Belt ArrangementA.C. Compressor Belt Arrangement A.C. Compressor Belt Arrangement

A.C. Compressor Belt Arrangement

ProCarManuals.com

Page 136 of 161

136

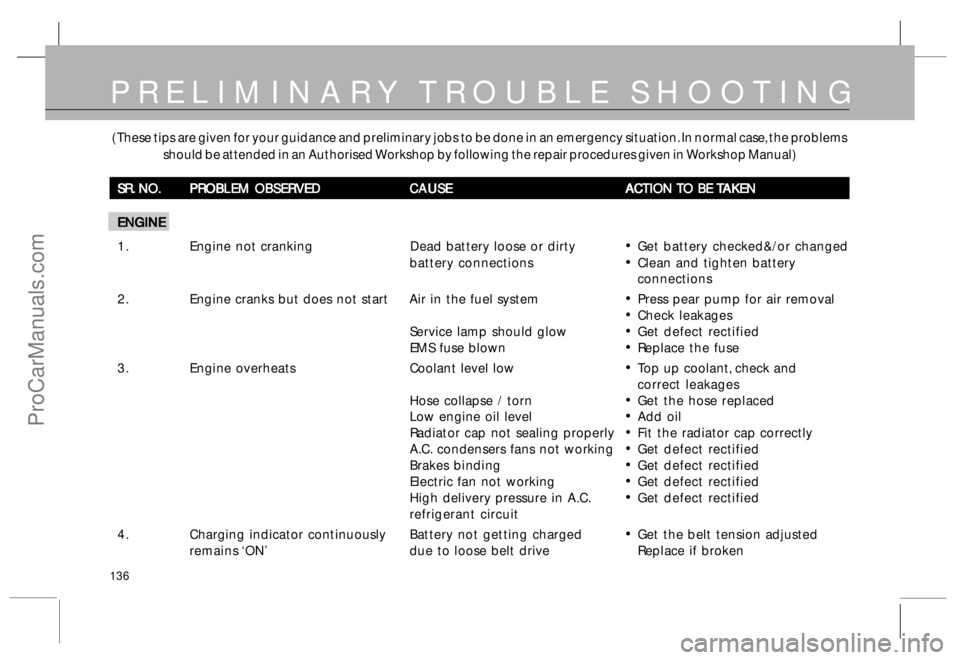

( These tips are given for your guidance and preliminary jobs to be done in an emergency situation. In normal case, the problems

should be attended in an Authorised Workshop by following the repair procedures given in Workshop Manual)

SR. NO. SR. NO.SR. NO. SR. NO.

SR. NO.

PROBLEM OBSERVED PROBLEM OBSERVEDPROBLEM OBSERVED PROBLEM OBSERVED

PROBLEM OBSERVED

CAUSE CAUSECAUSE CAUSE

CAUSE

A AA A

A

CTION CTION CTION CTION

CTION

T TT T

T

O BE O BE O BE O BE

O BE

T TT T

T

AKEN AKENAKEN AKEN

AKEN

ENGINE ENGINEENGINE ENGINE

ENGINE

1 . Engine not cranking Dead battery loose or dirty

•Get battery checked&/or changed

battery connections

•Clean and tighten battery

connections

2 . Engine cranks but does not start Air in the fuel system

•Press pear pump for air removal

•Check leakages

Service lamp should glow

•Get defect rectified

EMS fuse blown

•Replace the fuse

3. Engine overheatsCoolant level low

•Top up coolant, check and

correct leakages

Hose collapse / torn

•Get the hose replaced

Low engine oil level

•Add oil

Radiator cap not sealing properly

•Fit the radiator cap correctly

A.C. condensers fans not working

•Get defect rectified

Brakes binding

•Get defect rectified

Electric fan not working

•Get defect rectified

High delivery pressure in A.C.

•Get defect rectified

refrigerant circuit

4 . Charging indicator continuouslyBattery not getting charged

•Get the belt tension adjusted

remains ‘ON’due to loose belt drive Replace if broken

PRELIMINARY TROUBLE SHOOTING

ProCarManuals.com

Page 146 of 161

146

S E R V I C E S C H E D U L ESERVICE SCHEDULE SERVICE SCHEDULESERVICE SCHEDULE SERVICE SCHEDULE

SERVICE SCHEDULE

SR SRSR SR

SR

x 1000 km x 1000 kmx 1000 km x 1000 km

x 1000 km

NO NONO NO

NO

OPER OPEROPER OPER

OPER

A AA A

A

TIONS TIONSTIONS TIONS

TIONS

FREQUENCY FREQUENCYFREQUENCY FREQUENCY

FREQUENCY

1-1.5 1-1.51-1.5 1-1.5

1-1.5

15 1515 15

15

30 3030 30

30

45 4545 45

45

60 6060 60

60

75 7575 75

75

90 9090 90

90

105 105105 105

105

GENERAL GENERALGENERAL GENERAL

GENERAL

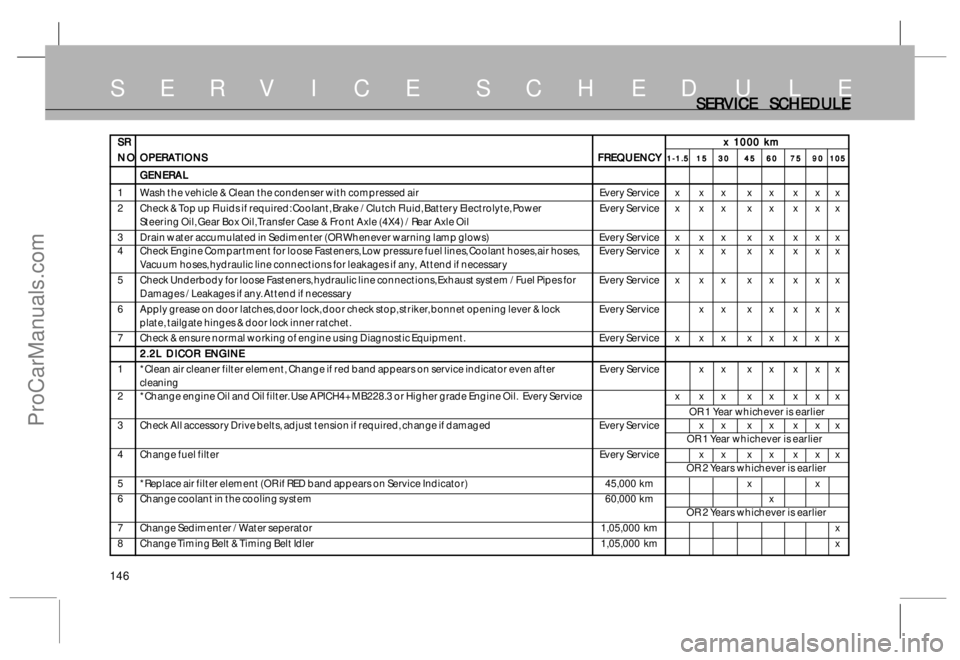

1 Wash the vehicle & Clean the condenser with compressed air Every Service x x x x x x x x

2 Check & Top up Fluids if required: Coolant, Brake / Clutch Fluid, Battery Electrolyte, Power Every Service x x x x x x x x

Steering Oil, Gear Box Oil, Transfer Case & Front Axle (4X4) / Rear Axle Oil

3 Drain water accumulated in Sedimenter (OR Whenever warning lamp glows) Every Service x x x x x x x x

4 Check Engine Compartment for loose Fasteners, Low pressure fuel lines, Coolant hoses, air hoses, Every Service x x x x x x x x

Vacuum hoses, hydraulic line connections for leakages if any, Attend if necessary

5 Check Underbody for loose Fasteners, hydraulic line connections, Exhaust system / Fuel Pipes for Every Service x x x x x x x x

Damages / Leakages if any. Attend if necessary

6 Apply grease on door latches, door lock, door check stop, striker, bonnet opening lever & lock Every Service x x x x x x x

plate, tailgate hinges & door lock inner ratchet.

7 Check & ensure normal working of engine using Diagnostic Equipment. Every Service x x x x x x x x

2.2L DICOR ENGINE 2.2L DICOR ENGINE2.2L DICOR ENGINE 2.2L DICOR ENGINE

2.2L DICOR ENGINE

1 *Clean air cleaner filter element, Change if red band appears on service indicator even after Every Service x x x x x x x

cleaning

2 *Change engine Oil and Oil filter. Use APICH4+MB228.3 or Higher grade Engine Oil.Every Service x x x x x x x x

OR 1 Year whichever is earlier

3 Check All accessory Drive belts, adjust tension if required, change if damaged Every Service x x x x x x x

OR 1 Year whichever is earlier

4 Change fuel filterEvery Service x x x x x x x

OR 2 Years whichever is earlier

5 *Replace air filter element (OR if RED band appears on Service Indicator) 45,000 km x x

6 Change coolant in the cooling system 60,000 km x

OR 2 Years whichever is earlier

7 Change Sedimenter / Water seperator1,05,000 km x

8 Change Timing Belt & Timing Belt Idler1,05,000 km x

ProCarManuals.com

Page 148 of 161

148

S E R V I C E S C H E D U L ESER SERSER SER

SER

VICE SCHEDULE VICE SCHEDULEVICE SCHEDULE VICE SCHEDULE

VICE SCHEDULE

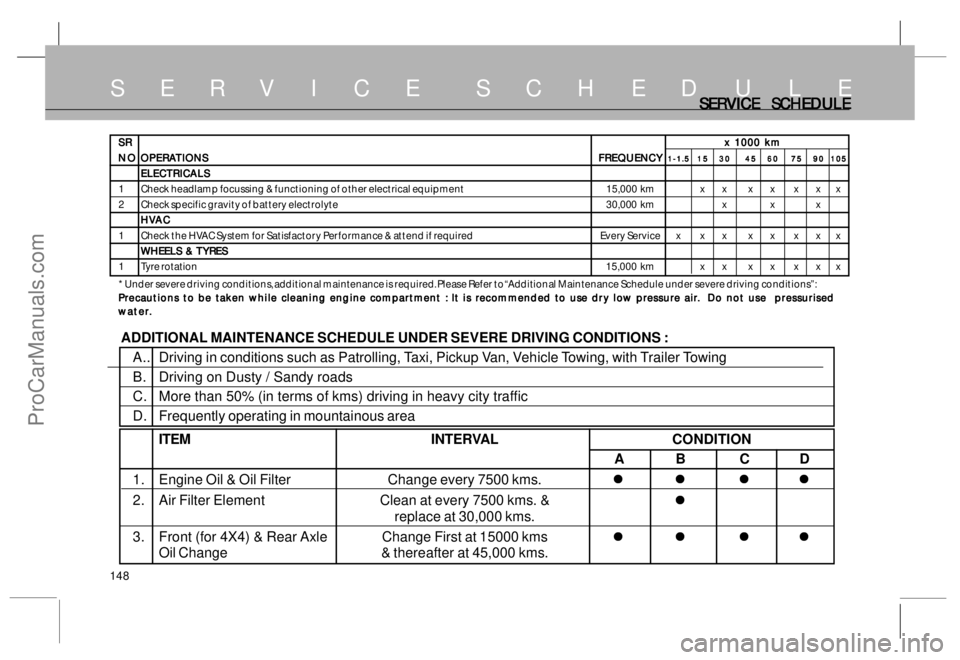

ADDITIONAL MAINTENANCE SCHEDULE UNDER SEVERE DRIVING CONDITIONS :

A.. Driving in conditions such as Patrolling, Taxi, Pickup Van, Vehicle Towing, with Trailer Towing

B. Driving on Dusty / Sandy roads

C. More than 50% (in terms of kms) driving in heavy city traffic

D. Frequently operating in mountainous area

ITEMINTERVAL CONDITION

AB CD

1. Engine Oil & Oil Filter Change every 7500 kms.

�z �z�z �z

�z

�z �z�z �z

�z

�z �z�z �z

�z

�z �z�z �z

�z

2. Air Filter Element Clean at every 7500 kms. &

�z �z�z �z

�z

replace at 30,000 kms.

3. Front (for 4X4) & Rear Axle Change First at 15000 kms

�z �z�z �z

�z

�z �z�z �z

�z

�z �z�z �z

�z

�z �z�z �z

�z

Oil Change & thereafter at 45,000 kms.

SR SRSR SR

SR

x 1000 km x 1000 kmx 1000 km x 1000 km

x 1000 km

NO NONO NO

NO

OPER OPEROPER OPER

OPER

A AA A

A

TIONS TIONSTIONS TIONS

TIONS

FREQUENCY FREQUENCYFREQUENCY FREQUENCY

FREQUENCY

1-1.5 1-1.51-1.5 1-1.5

1-1.5

15 1515 15

15

30 3030 30

30

45 4545 45

45

60 6060 60

60

75 7575 75

75

90 9090 90

90

105 105105 105

105

ELECTRICALS ELECTRICALSELECTRICALS ELECTRICALS

ELECTRICALS

1 Check headlamp focussing & functioning of other electrical equipment 15,000 km x x x x x x x

2 Check specific gravity of battery electrolyte 30,000 km x x x

HV HVHV HV

HV

A AA A

A

C CC C

C

1 Check the HVAC System for Satisfactory Performance & attend if required Every Service x x x x x x x x

WHEELS & WHEELS & WHEELS & WHEELS &

WHEELS &

T TT T

T

YRES YRESYRES YRES

YRES

1 Tyre rotation15,000 km x x x x x x x

* Under severe driving conditions, additional maintenance is required. Please Refer to “Additional Maintenance Schedule under severe driving conditions”:

P PP P

P

r rr r

r

ec ecec ec

ec

autions t autions tautions t autions t

autions t

o b o bo b o b

o b

e tak e take tak e tak

e tak

en while cleaning engine c en while cleaning engine cen while cleaning engine c en while cleaning engine c

en while cleaning engine c

ompar omparompar ompar

ompar

tmen tmentmen tmen

tmen

t : t :t : t :

t :

I I I I

I

t is r t is rt is r t is r

t is r

ec ecec ec

ec

ommended t ommended tommended t ommended t

ommended t

o use dr o use dro use dr o use dr

o use dr

y lo y loy lo y lo

y lo

w pr w prw pr w pr

w pr

essur essuressur essur

essur

e air e aire air e air

e air

.. ..

.

D D D D

D

o not use pr o not use pro not use pr o not use pr

o not use pr

essur essuressur essur

essur

ised isedised ised

ised

w ww w

w

a aa a

a

t tt t

t

er erer er

er

.. ..

.

ProCarManuals.com

Page 155 of 161

155

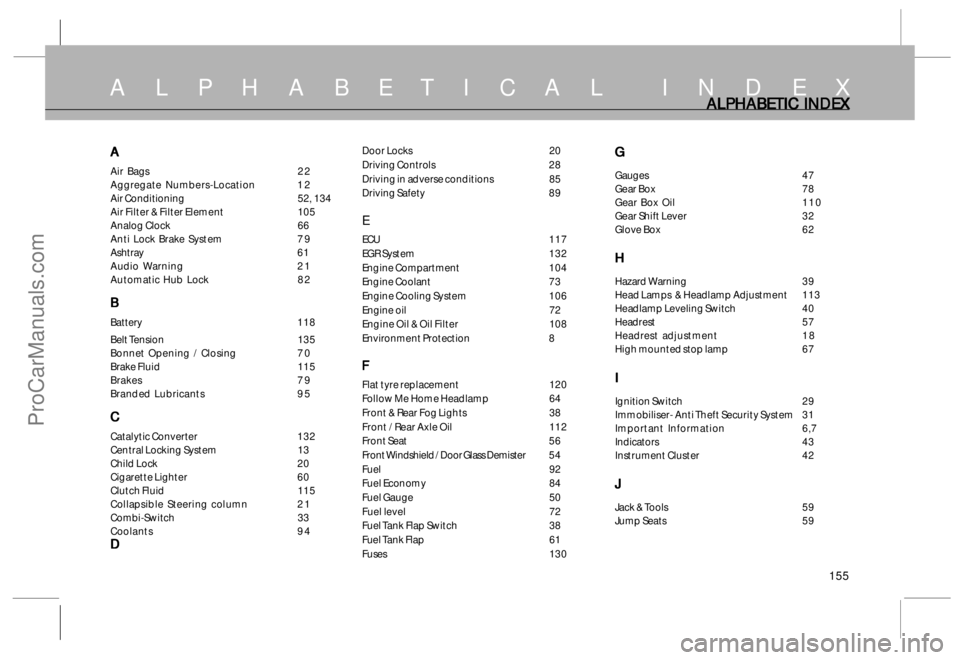

A L P H A B E T I C A L I N D E X ALPHABETIC INDEX ALPHABETIC INDEX ALPHABETIC INDEX ALPHABETIC INDEX

ALPHABETIC INDEX

A AA A

A

Air Bags 2 2

Aggregate Numbers-Location 1 2

Air Conditioning52, 134

Air Filter & Filter Element 105

Analog Clock 66

Anti Lock Brake System 7 9

Ashtray 6 1

Audio Warning 2 1

Automatic Hub Lock 8 2

B BB B

B

Battery 118

Belt Tension 135

Bonnet Opening / Closing 7 0

Brake Fluid 115

Brakes 7 9

Branded Lubricants 9 5

C CC C

C

Catalytic Converter 132

Central Locking System 13

Child Lock 20

Cigarette Lighter 60

Clutch Fluid 115

Collapsible Steering column 2 1

Combi-Switch 33

Coolants 9 4

D DD D

D

Door Locks 20

Driving Controls 28

Driving in adverse conditions 85

Driving Safety 89

E

ECU 1 1 7

EGR System 132

Engine Compartment 104

Engine Coolant 73

Engine Cooling System 106

Engine oil 72

Engine Oil & Oil Filter 108

Environment Protection 8

F FF F

F

Flat tyre replacement 120

Follow Me Home Headlamp 64

Front & Rear Fog Lights 38

Front / Rear Axle Oil 112

Front Seat 56

Front Windshield / Door Glass Demister 5 4

Fuel 92

Fuel Economy 84

Fuel Gauge 50

Fuel level 72

Fuel Tank Flap Switch 38

Fuel Tank Flap 61

Fuses 130

G GG G

G

Gauges 4 7

Gear Box 78

Gear Box Oil 1 1 0

Gear Shift Lever 32

Glove Box 62

H HH H

H

Hazard Warning 39

Head Lamps & Headlamp Adjustment 113

Headlamp Leveling Switch 40

Headrest 57

Headrest adjustment 1 8

High mounted stop lamp 67

I II I

I

Ignition Switch 29

Immobiliser- Anti Theft Security System 31

Important Information 6,7

Indicators 43

Instrument Cluster 42

J JJ J

J

Jack & Tools 59

Jump Seats 59

ProCarManuals.com