TOYOTA AVENSIS 2005 Service Repair Manual

AVENSIS 2005

TOYOTA

TOYOTA

https://www.carmanualsonline.info/img/14/57441/w960_57441-0.png

TOYOTA AVENSIS 2005 Service Repair Manual

Trending: oil capacity, Oil, MOTOR, airbag off, steering wheel, height, recommended oil

Page 1021 of 5135

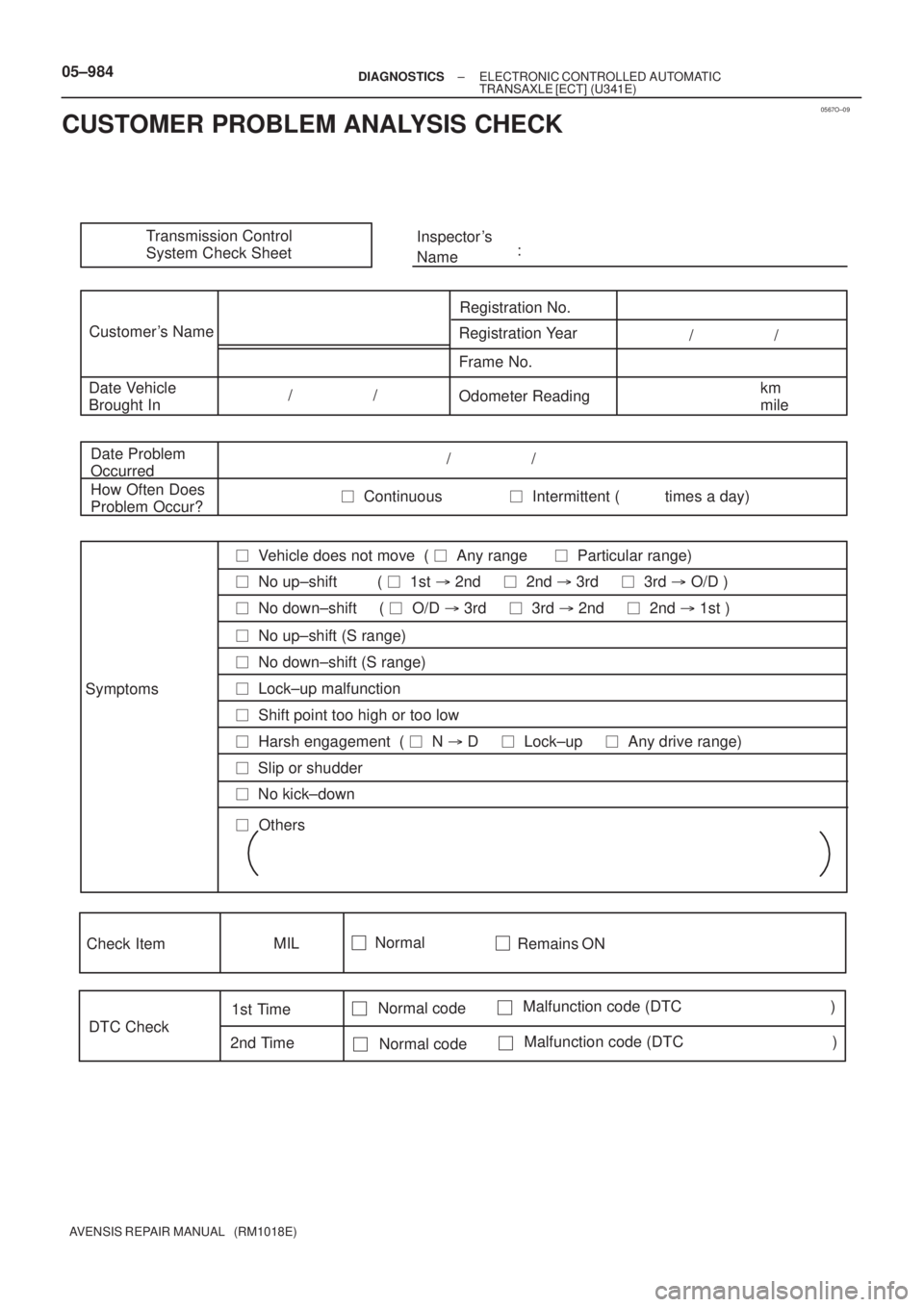

0567O±09

Transmission Control

System Check SheetInspector 's

Name:

Customer 's Name

Registration No.

Registration Year

Frame No.

Date Vehicle

Brought InOdometer Readingkm

mile / /

/ /

Date Problem

Occurred

How Often Does

Problem Occur?/ /

� Continuous � Intermittent ( times a day)

Symptoms

� Vehicle does not move ( � Any range � Particular range)

� No up±shift ( � 1st � 2nd � 2nd � 3rd � 3rd � O/D )

� No down±shift ( � O/D � 3rd � 3rd � 2nd � 2nd � 1st )

� Lock±up malfunction

� Shift point too high or too low

� Harsh engagement ( � N � D � Lock±up � Any drive range)

� Slip or shudder

� No kick±down

� Others

DTC Check1st Time

2nd Time Check Item

Normal codeMalfunction code (DTC )

Normal codeMalfunction code (DTC )

MILNormal

Remains ON

� No up±shift (S range)

� No down±shift (S range) 05±984

± DIAGNOSTICSELECTRONIC CONTROLLED AUTOMATIC

TRANSAXLE [ECT] (U341E)

AVENSIS REPAIR MANUAL (RM1018E)

CUSTOMER PROBLEM ANALYSIS CHECK

Page 1022 of 5135

05CBZ±01

± DIAGNOSTICSELECTRONIC CONTROLLED AUTOMATIC

TRANSAXLE [ECT] (U341E)05±983

AVENSIS REPAIR MANUAL (RM1018E)

PRECAUTION

CAUTION:

Perform the RESET MEMORY (AT initialization) when replacing the automatic transaxle assy, engine

assy or ECM.

HINT:

Initialization can not be completed by only removing the battery.

Page 1023 of 5135

0567N±10

05±980±

DIAGNOSTICS ELECTRONIC CONTROLLED AUTOMATIC

TRANSAXLE [ECT](U341E)

AVENSIS REPAIR MANUAL (RM1018E)

ELECTRONIC CONTROLLED AUTOMATIC TRANSAXLE

[ECT](U341E)

HOW TO PROCEED WITH TROUBLESHOOTING

HINT:

The ECM of this system is connected to the multiplex communication system. \

Therefore, before starting trou-

bleshooting, make sure to check that there is no trouble in the multiplex communicat\

ion system.

1Vehicle Brought to Workshop

2Customer Problem Analysis (See page 05±984)

3 Connect the hand±held tester to DLC3

4Check and Clear DTC and Freeze Frame Data (See page 05±985)

5 Visual Inspection

6Setting the Check Mode Diagnosis (See page 05±985)

7 Problem Symptom Confirmation

Symptom does not occur: Go to step 8

Symptom occur: Go to step 9

8Symptom Simulation (See page 01±22)

9DTC Check (See page 05±996)

DTC is not output: Go to step 10

DTC is output: Go to step 17

Page 1024 of 5135

±

DIAGNOSTICS ELECTRONIC CONTROLLED AUTOMATIC

TRANSAXLE [ECT] (U341E)05±981

AVENSIS REPAIR MANUAL (RM1018E)

10 Basic Inspection ( See page 40±2, 40±8 and 40±69 )

NG Go to step 19

OK

1 1 Mechanical System Test ( See page 05±985 )

NG Go to step 16

OK

1 2 Manual Shifting T est ( See page 05±985 )

NG Go to step 14

OK

1 3 Problem Symptoms T able Chapter 1 ( See page 05±1000 )

NG Go to step 18

OK

1 4 Problem Symptoms T able Chapter 2 ( See page 05±1000 )

NG Go to step 16

OK

1 5 Problem Symptoms T able Chapter 3 ( See page 05±1000 )

NG

16 Part Inspection

Go to step 19

17 DTC Chart ( See page 05±996 )

1 8 Circuit Inspection ( See page 05±1003)

Page 1025 of 5135

05±982± DIAGNOSTICSELECTRONIC CONTROLLED AUTOMATIC

TRANSAXLE [ECT] (U341E)

AVENSIS REPAIR MANUAL (RM1018E)

19 Identification of Problem

20 Repair

21 Confirmation Test

End

Page 1026 of 5135

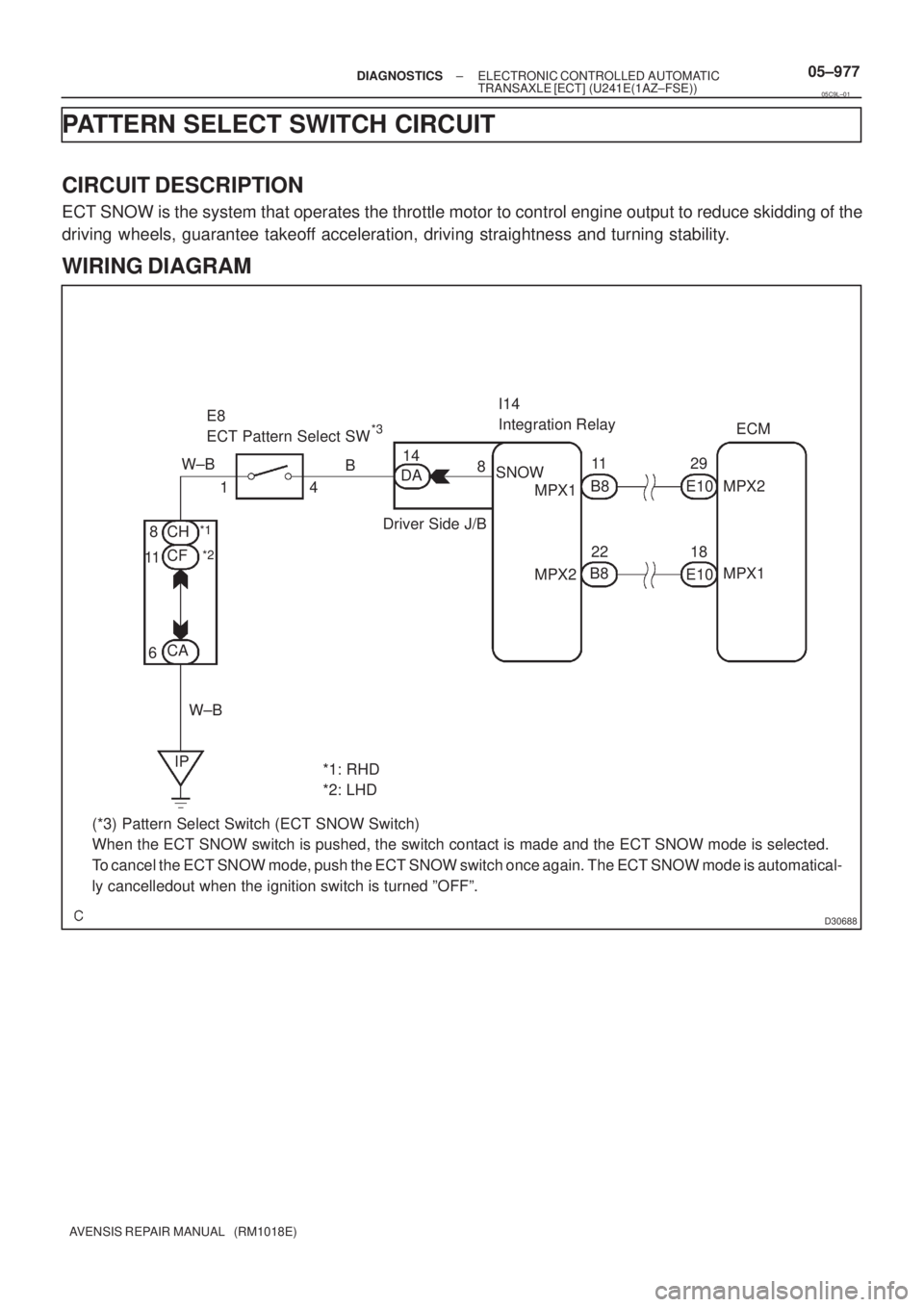

D30688

ECM

MPX2

MPX1 29

18 E10 11

B8

22 SNOWI14

Integration Relay

8

Driver Side J/B14

DA B E8

ECT Pattern Select SW

*1: RHD

*2: LHD 4 1 W±B

CH

CF

CA 8

11

6

W±B

IPE10 MPX1

MPX2

*1

*2

B8

(*3) Pattern Select Switch (ECT SNOW Switch)

When the ECT SNOW switch is pushed, the switch contact is made and the ECT SNOW mode is selected.

To cancel the ECT SNOW mode, push the ECT SNOW switch once again. The ECT SNOW mode is automatical-

ly cancelledout when the ignition switch is turned ºOFFº.

*3

± DIAGNOSTICSELECTRONIC CONTROLLED AUTOMATIC

TRANSAXLE [ECT] (U241E(1AZ±FSE))05±977

AVENSIS REPAIR MANUAL (RM1018E)

PATTERN SELECT SWITCH CIRCUIT

CIRCUIT DESCRIPTION

ECT SNOW is the system that operates the throttle motor to control engine output to reduce skidding of the

driving wheels, guarantee takeoff acceleration, driving straightness and turning stability.

WIRING DIAGRAM

05C9L±01

Page 1027 of 5135

![TOYOTA AVENSIS 2005 Service Repair Manual B59192

Wire Harness Side:

D30685

Switch Side:

05±978± DIAGNOSTICSELECTRONIC CONTROLLED AUTOMATIC

TRANSAXLE [ECT] (U241E(1AZ±FSE))

AVENSIS REPAIR MANUAL (RM1018E)

INSPECTION PROCEDURE

1 DRIVING TE TOYOTA AVENSIS 2005 Service Repair Manual B59192

Wire Harness Side:

D30685

Switch Side:

05±978± DIAGNOSTICSELECTRONIC CONTROLLED AUTOMATIC

TRANSAXLE [ECT] (U241E(1AZ±FSE))

AVENSIS REPAIR MANUAL (RM1018E)

INSPECTION PROCEDURE

1 DRIVING TE](/img/14/57441/w960_57441-1026.png)

B59192

Wire Harness Side:

D30685

Switch Side:

05±978± DIAGNOSTICSELECTRONIC CONTROLLED AUTOMATIC

TRANSAXLE [ECT] (U241E(1AZ±FSE))

AVENSIS REPAIR MANUAL (RM1018E)

INSPECTION PROCEDURE

1 DRIVING TEST

(a) Start the engine.

(b) Turn the ECT SNOW switch ºOFFº.

(c) Confirm vehicle response by driving from a parked position to fully depressing the accelerator pedal.

(d) Turn the ECT SNOW switch on and perform the same check as (c).

Confirm that there is a difference between ECT SNOW switch ºONº and ºOFFº.

HINT:

�Driving test should be done on a paved road (a nonskid road).

�Make sure not to use the TRAC system when testing a vehicle equipped with one.

Standard:

There is a difference in acceleration between ºONº and ºOFFº.

NG Go to step 2

OK

PROCEED TO NEXT CIRCUIT INSPECTION SHOWN ON PROBLEM SYMPTOMS TABLE

(See page xx±xxx)

2 CHECK HARNESS AND CONNECTOR(PATTERN SELECT SWITCH ASSY ± BODY

GROUND)

(a) Disconnect the connector of pattern select switch (ECT

SNOW switch).

(b) Measure the resistance between 4 of the wire harness

connector and body ground.

Standard:

Tester connectionSpecified condition

4 ± Body groundBelow 1 �

NG REPAIR OR REPLACE HARNESS AND

CONNECTOR

OK

3 INSPECT PATTERN SELECT SWITCH ASSY

(a) Measure the resistance between terminals 1 and 4 of pat-

tern select switch (ECT SNOW switch).

Standard:

Switch conditionTester connectionSpecified condition

Press continuously

Pattern select switch1 ± 4Continuity

Release

Pattern select switch1 ± 4No continuity

NG REPLACE PATTERN SELECT SWITCH ASSY

OK

Page 1028 of 5135

D30751

Instrument Panel J/B Assy

Vehicle Front Side:

DA

DA

SNOW

± DIAGNOSTICSELECTRONIC CONTROLLED AUTOMATIC

TRANSAXLE [ECT] (U241E(1AZ±FSE))05±979

AVENSIS REPAIR MANUAL (RM1018E)

4 CHECK HARNESS AND CONNECTOR(PATTERN SELECT SWITCH ASSY ±

INTEGRATION RELAY)

(a) Connect the connector of pattern select switch (ECT

SNOW switch).

(b) Disconnect the instrument panel J/B assy (integration

relay) connector.

(c) Measure the resistance between terminal SNOW of

instrument panel J/B assy (integration relay) and body

ground.

Standard:

Switch conditionTester connectionSpecified condition

Press continuously

Pattern select switchDA±14 (SNOW) ± Body

groundBelow 1 �

Release

Pattern select switchDA±14 (SNOW) ± Body

ground10 k� or higher

NG REPAIR OR REPLACE HARNESS AND

CONNECTOR

OK

PROCEED TO NEXT CIRCUIT INSPECTION SHOWN ON PROBLEM SYMPTOMS TABLE

(See page xx±xxx)

Page 1029 of 5135

05±972± DIAGNOSTICSELECTRONIC CONTROLLED AUTOMATIC

TRANSAXLE [ECT] (U241E(1AZ±FSE))

AVENSIS REPAIR MANUAL (RM1018E)

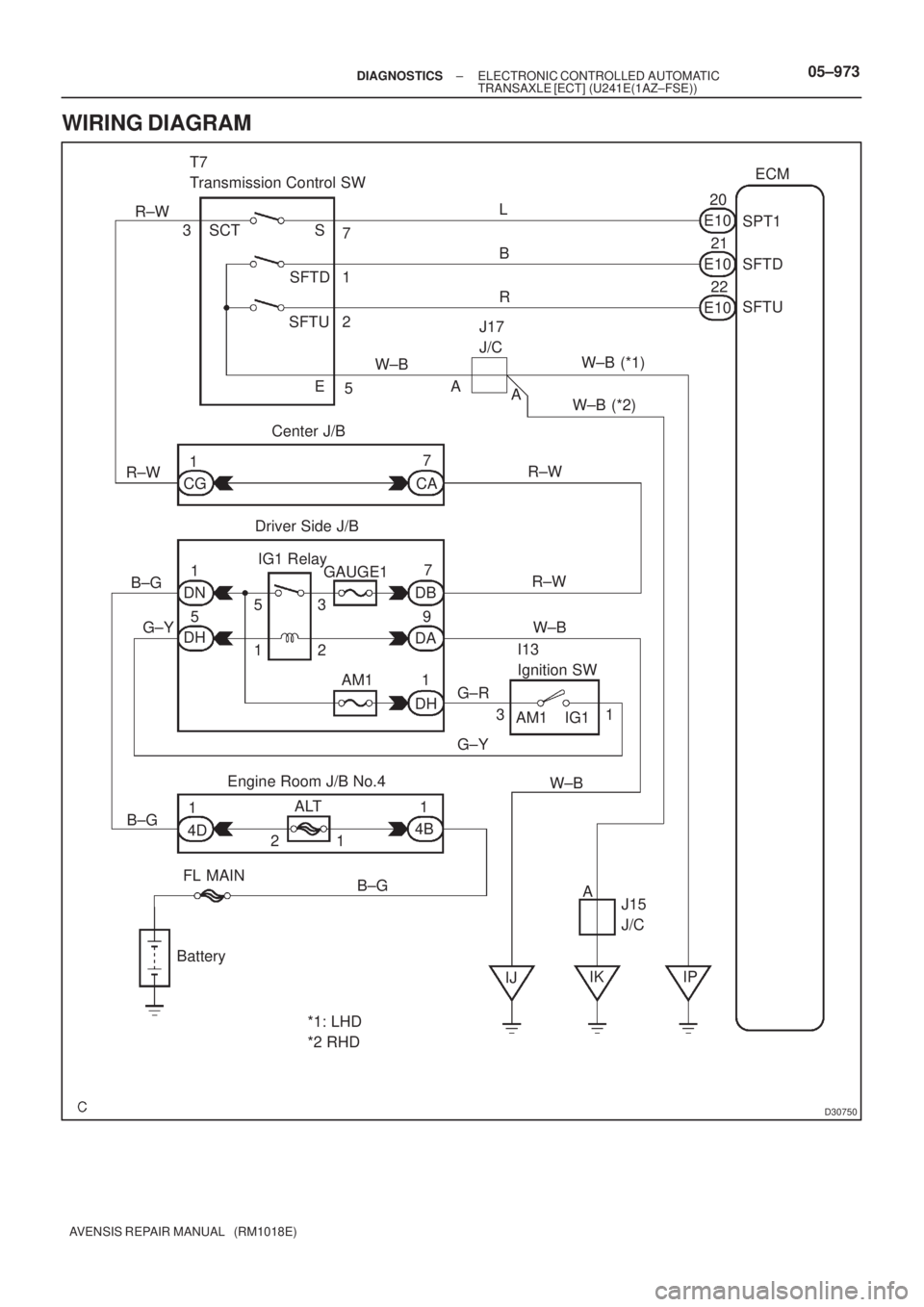

TRANSMISSION CONTROL SWITCH CIRCUIT

CIRCUIT DESCRIPTION

When shifting the shift lever into S position using the transmission control switch, it is possible to shift in 1

to 4 positions.

Shifting º+º once changes up 1 shift range position, º±º once changes down 1 shift range position respective-

ly.

05C9K±01

Page 1030 of 5135

D30750

ECM

SPT1

SFTD

SFTU L

B

R20

21

22 E10

7

1

2

5J17

J/C

W±B(*1)

(*2) A

A S

SFTD

SFTU

E SCT 3 R±WT7

Transmission Control SW

Center J/B

Driver Side J/B

I13

Ignition SW

Engine Room J/B No.4

FL MAIN

Battery

*1: LHD

*2 RHDIJIK IPJ15

J/C A AM1 IG1R±W

W±B B±G

G±Y7

1

CA

7

DB

9

DA

1

DH AM1 GAUGE1 IG1 Relay

5

13

2 DN

31

1

4D1

4B ALT

21E10

E10

W±B

W±B

CG

R±W 1

5

DH

G±R

G±Y

W±B

B±G R±W

B±G

± DIAGNOSTICSELECTRONIC CONTROLLED AUTOMATIC

TRANSAXLE [ECT] (U241E(1AZ±FSE))05±973

AVENSIS REPAIR MANUAL (RM1018E)

WIRING DIAGRAM

Trending: jump cable, remote start, service schedule, SHOCK, seats, Abs sensor, odo

![TOYOTA AVENSIS 2005 Service Repair Manual 05CBZ±01

± DIAGNOSTICSELECTRONIC CONTROLLED AUTOMATIC

TRANSAXLE [ECT] (U341E)05±983

AVENSIS REPAIR MANUAL (RM1018E)

PRECAUTION

CAUTION:

Perform the RESET MEMORY (AT initialization) when replacing TOYOTA AVENSIS 2005 Service Repair Manual 05CBZ±01

± DIAGNOSTICSELECTRONIC CONTROLLED AUTOMATIC

TRANSAXLE [ECT] (U341E)05±983

AVENSIS REPAIR MANUAL (RM1018E)

PRECAUTION

CAUTION:

Perform the RESET MEMORY (AT initialization) when replacing](/img/14/57441/w960_57441-1021.png)

AVENSIS REPAIR MANUAL (RM1018E)

ELECTRONIC CONTROLLED AUTOMATIC TRANSAXLE

[ECT](U341E)

HOW TO PROCEED WITH TROU TOYOTA AVENSIS 2005 Service Repair Manual 0567N±10

05±980±

DIAGNOSTICS ELECTRONIC CONTROLLED AUTOMATIC

TRANSAXLE [ECT](U341E)

AVENSIS REPAIR MANUAL (RM1018E)

ELECTRONIC CONTROLLED AUTOMATIC TRANSAXLE

[ECT](U341E)

HOW TO PROCEED WITH TROU](/img/14/57441/w960_57441-1022.png)

![TOYOTA AVENSIS 2005 Service Repair Manual ±

DIAGNOSTICS ELECTRONIC CONTROLLED AUTOMATIC

TRANSAXLE [ECT] (U341E)05±981

AVENSIS REPAIR MANUAL (RM1018E)

10 Basic Inspection ( See page 40±2, 40±8 and 40±69 )

NG Go to step 19

OK

1 1 Mechan TOYOTA AVENSIS 2005 Service Repair Manual ±

DIAGNOSTICS ELECTRONIC CONTROLLED AUTOMATIC

TRANSAXLE [ECT] (U341E)05±981

AVENSIS REPAIR MANUAL (RM1018E)

10 Basic Inspection ( See page 40±2, 40±8 and 40±69 )

NG Go to step 19

OK

1 1 Mechan](/img/14/57441/w960_57441-1023.png)

![TOYOTA AVENSIS 2005 Service Repair Manual 05±982± DIAGNOSTICSELECTRONIC CONTROLLED AUTOMATIC

TRANSAXLE [ECT] (U341E)

AVENSIS REPAIR MANUAL (RM1018E)

19 Identification of Problem

20 Repair

21 Confirmation Test

End TOYOTA AVENSIS 2005 Service Repair Manual 05±982± DIAGNOSTICSELECTRONIC CONTROLLED AUTOMATIC

TRANSAXLE [ECT] (U341E)

AVENSIS REPAIR MANUAL (RM1018E)

19 Identification of Problem

20 Repair

21 Confirmation Test

End](/img/14/57441/w960_57441-1024.png)

![TOYOTA AVENSIS 2005 Service Repair Manual B59192

Wire Harness Side:

D30685

Switch Side:

05±978± DIAGNOSTICSELECTRONIC CONTROLLED AUTOMATIC

TRANSAXLE [ECT] (U241E(1AZ±FSE))

AVENSIS REPAIR MANUAL (RM1018E)

INSPECTION PROCEDURE

1 DRIVING TE TOYOTA AVENSIS 2005 Service Repair Manual B59192

Wire Harness Side:

D30685

Switch Side:

05±978± DIAGNOSTICSELECTRONIC CONTROLLED AUTOMATIC

TRANSAXLE [ECT] (U241E(1AZ±FSE))

AVENSIS REPAIR MANUAL (RM1018E)

INSPECTION PROCEDURE

1 DRIVING TE](/img/14/57441/w960_57441-1026.png)

![TOYOTA AVENSIS 2005 Service Repair Manual D30751

Instrument Panel J/B Assy

Vehicle Front Side:

DA

DA

SNOW

± DIAGNOSTICSELECTRONIC CONTROLLED AUTOMATIC

TRANSAXLE [ECT] (U241E(1AZ±FSE))05±979

AVENSIS REPAIR MANUAL (RM1018E)

4 CHECK HARNESS TOYOTA AVENSIS 2005 Service Repair Manual D30751

Instrument Panel J/B Assy

Vehicle Front Side:

DA

DA

SNOW

± DIAGNOSTICSELECTRONIC CONTROLLED AUTOMATIC

TRANSAXLE [ECT] (U241E(1AZ±FSE))05±979

AVENSIS REPAIR MANUAL (RM1018E)

4 CHECK HARNESS](/img/14/57441/w960_57441-1027.png)

![TOYOTA AVENSIS 2005 Service Repair Manual 05±972± DIAGNOSTICSELECTRONIC CONTROLLED AUTOMATIC

TRANSAXLE [ECT] (U241E(1AZ±FSE))

AVENSIS REPAIR MANUAL (RM1018E)

TRANSMISSION CONTROL SWITCH CIRCUIT

CIRCUIT DESCRIPTION

When shifting the shift TOYOTA AVENSIS 2005 Service Repair Manual 05±972± DIAGNOSTICSELECTRONIC CONTROLLED AUTOMATIC

TRANSAXLE [ECT] (U241E(1AZ±FSE))

AVENSIS REPAIR MANUAL (RM1018E)

TRANSMISSION CONTROL SWITCH CIRCUIT

CIRCUIT DESCRIPTION

When shifting the shift](/img/14/57441/w960_57441-1028.png)