TOYOTA AVENSIS 2005 Service Repair Manual

Manufacturer: TOYOTA, Model Year: 2005, Model line: AVENSIS, Model: TOYOTA AVENSIS 2005Pages: 5135, PDF Size: 95.28 MB

Page 4321 of 5135

A66074

− DIAGNOSTICSECD SYSTEM (1CD−FTV)(From September, 2003)

05−281

AVENSIS Supplement (RM1045E)

(q) Press the ”NO” button to complete the registration.

HINT:

SIf you want to register other compensation codes for the

other cylinders, press the ”YES” button instead of ”NO”.

SBy pressing the ”NO” button, the hand−held tester returns

to the ”DIAGNOSTIC MENU ECD” screen.

(r) Turn the ignition switch to OFF and wait for 30 seconds

or more.

Page 4322 of 5135

05DVV−02

−

DIAGNOSTICS ECD SYSTEM (1CD −FTV)(From September, 2003)

05 −273

AVENSIS Supplement (RM 1045E)

READING REGISTERED DATA

NOTICE:

S The injector compensation code will be required to register with the ECM when replacing injec-

tors or the ECM.

S If an incorrect injector compensation code was registered with the ECM, it may rattle the engine

assembly or the engine idling may become rough. In addition, it may become a cause of engine

failure or shorten the life of the engine.

1 . If you replace the ECM with a new one, register all the injector compensation codes with the

new ECM as follows:

(a) Prior to replacing the ECM, read all the injector compensation codes stored in the existing ECM using the hand −held tester, and then write them down (see page 05 −273).

(b) After replacing the ECM, enter the written injector compensation codes into the ECM using the hand −

held tester (see page 05 −277).

(c) Turn the ignition switch to OFF and turn the hand −held tester OFF, then wait for 30 seconds or more.

(d) Turn the ignition switch to ON and turn the hand −held tester ON, then clear DTC P 160 1 using the

hand −held tester (see page 05 −290).

2. If you replace the injector with a new one, register its compensation code of the new injector as follows:

(a) Replace an injector.

(b) Read a new injector ’s compensation code which is imprinted on the head portion of the injector.

(c) Enter the compensation code into the ECM using the hand −held tester (see page 05 −277).

(d) Turn the ignition switch to OFF and turn the hand −held tester OFF, then wait for 30 seconds or more.

(e) Turn the ignition switch to ON and turn the hand −held tester ON, then clear DTC P 160 1 using the

hand −held tester (see page 05 −290).

HINT:

SIn order to optimize the injector’s fuel injection characteristic, the ECM compensates the injection dura-

tion by each cylinder. The ECM stores and uses compensating data in the form of a 30 −digit −alphanu-

meric value that is imprinted on the head portion of each injector as the injector compensation code.

SIf you installed a new injector, its own injector compensation code is needed to register with the ECM.

Also, if you replaced the ECM, the compensation codes of all the injectors are needed to register be-

cause the new ECM dose not have the codes until they are registered.

SOnce the ECM is replaced, DTC P 160 1will be present when turning the ignition switch to ON. This

is to inform you that the injector compensation codes are required to register with the ECM. In order

to clear the DTC, register the compensation codes first, then turn the ignition switch to OFF and wait

for 30 seconds or more.

Page 4323 of 5135

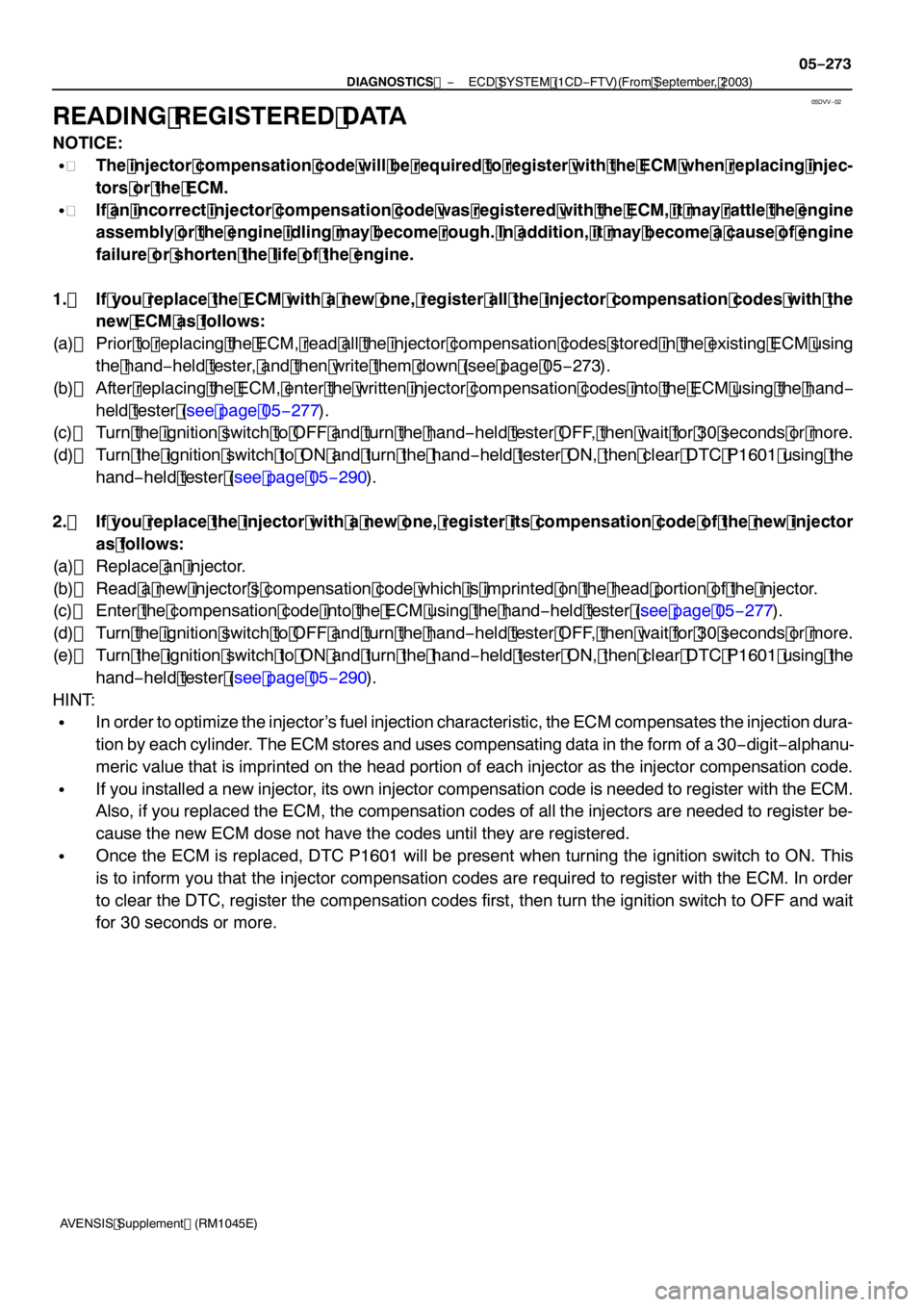

Read the injector compensation code from the ECM

END

(Reading injector compensation code is end)Do you want to read the injector

compensation code of the another

cylinder ?

A91211

Process of reading injector compensation code(s):

A85701

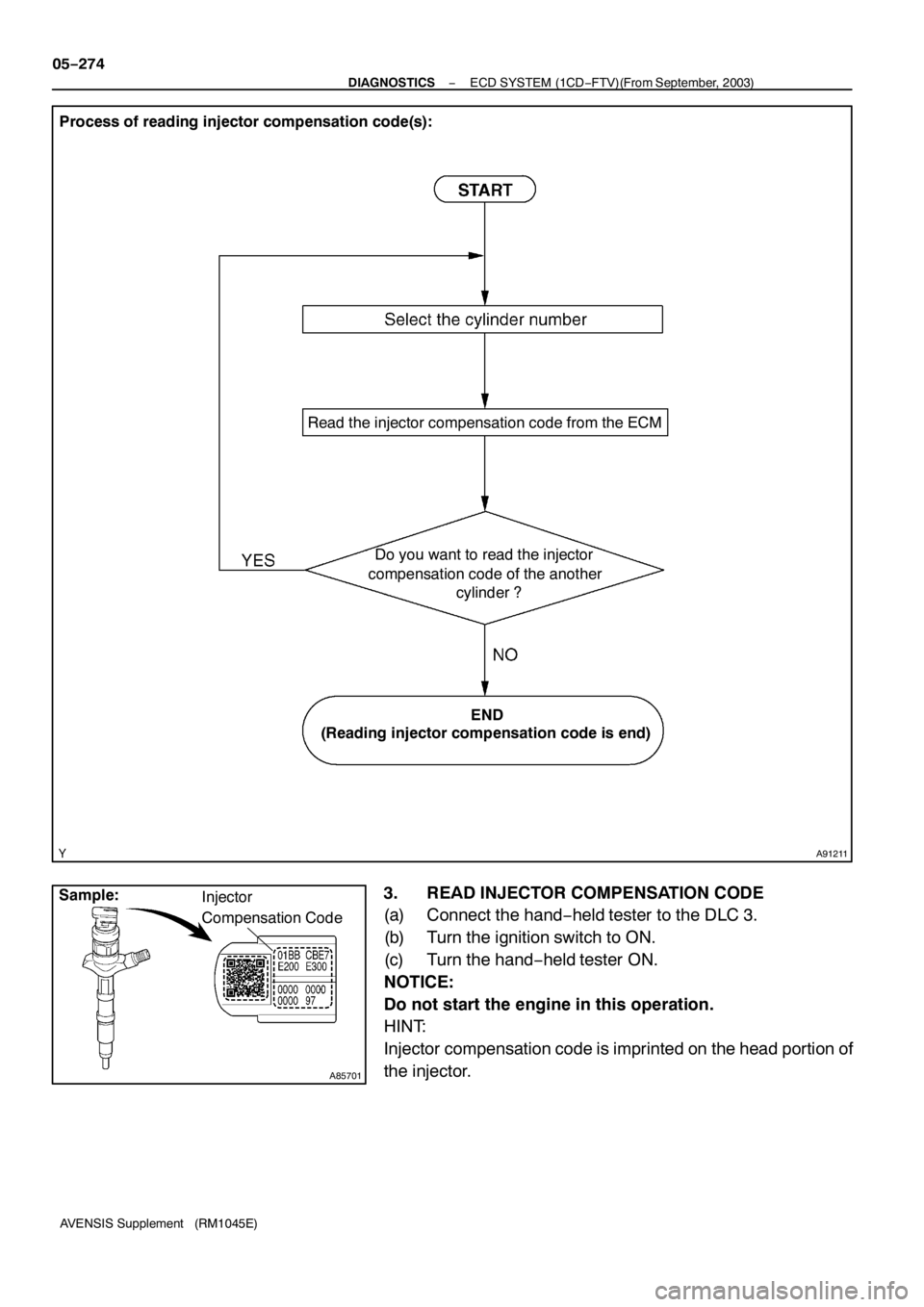

Sample:

Injector

Compensation Code

05−274

− DIAGNOSTICSECD SYSTEM (1CD−FTV)(From September, 2003)

AVENSIS Supplement (RM1045E)

3. READ INJECTOR COMPENSATION CODE

(a) Connect the hand−held tester to the DLC 3.

(b) Turn the ignition switch to ON.

(c) Turn the hand−held tester ON.

NOTICE:

Do not start the engine in this operation.

HINT:

Injector compensation code is imprinted on the head portion of

the injector.

Page 4324 of 5135

A80985

A66061

A66063

A66064

A66065

− DIAGNOSTICSECD SYSTEM (1CD−FTV)(From September, 2003)

05−275

AVENSIS Supplement (RM1045E)

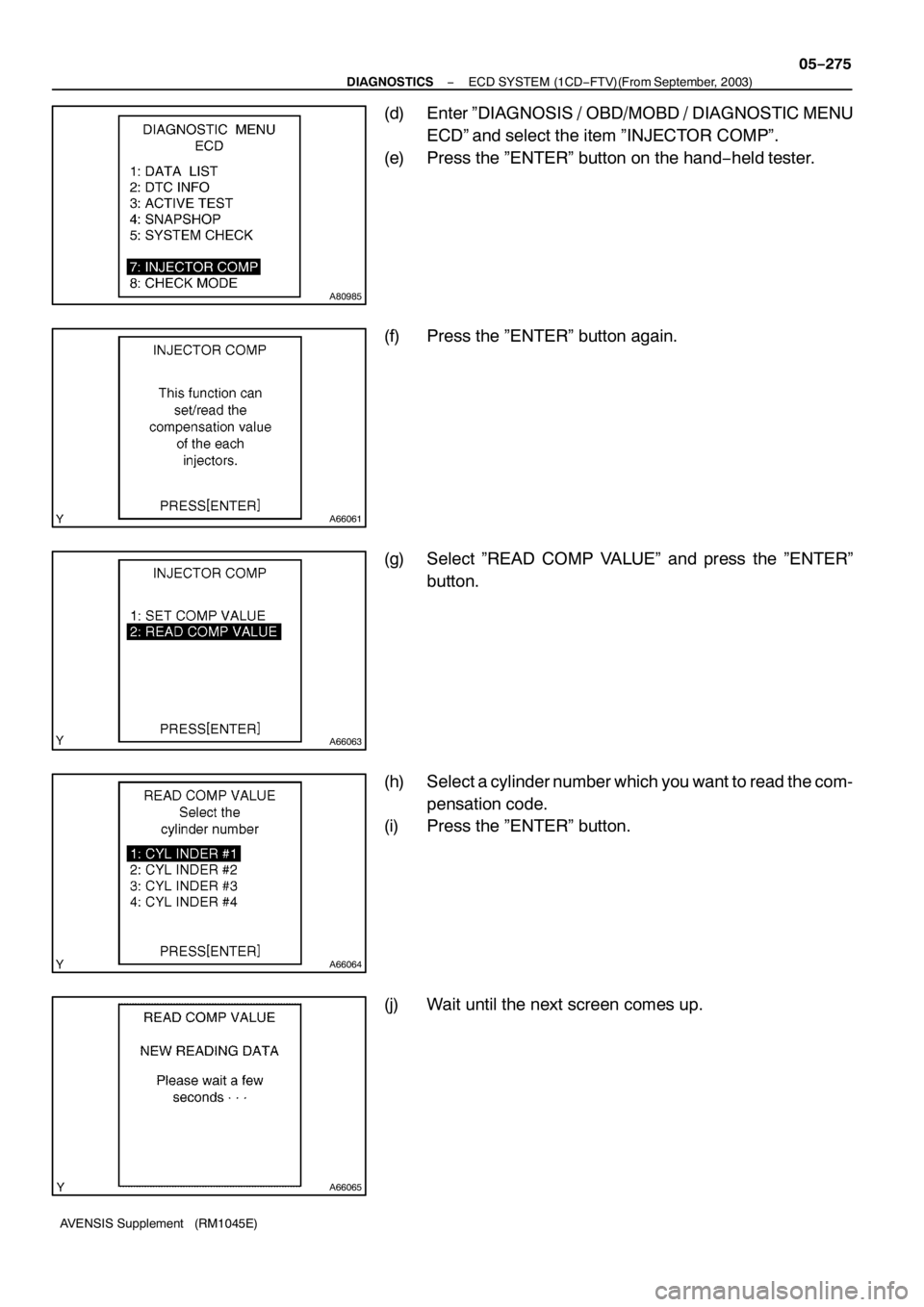

(d) Enter ”DIAGNOSIS / OBD/MOBD / DIAGNOSTIC MENU

ECD” and select the item ”INJECTOR COMP”.

(e) Press the ”ENTER” button on the hand−held tester.

(f) Press the ”ENTER” button again.

(g) Select ”READ COMP VALUE” and press the ”ENTER”

button.

(h) Select a cylinder number which you want to read the com-

pensation code.

(i) Press the ”ENTER” button.

(j) Wait until the next screen comes up.

Page 4325 of 5135

A66066

A66067

05−276

− DIAGNOSTICSECD SYSTEM (1CD−FTV)(From September, 2003)

AVENSIS Supplement (RM1045E)

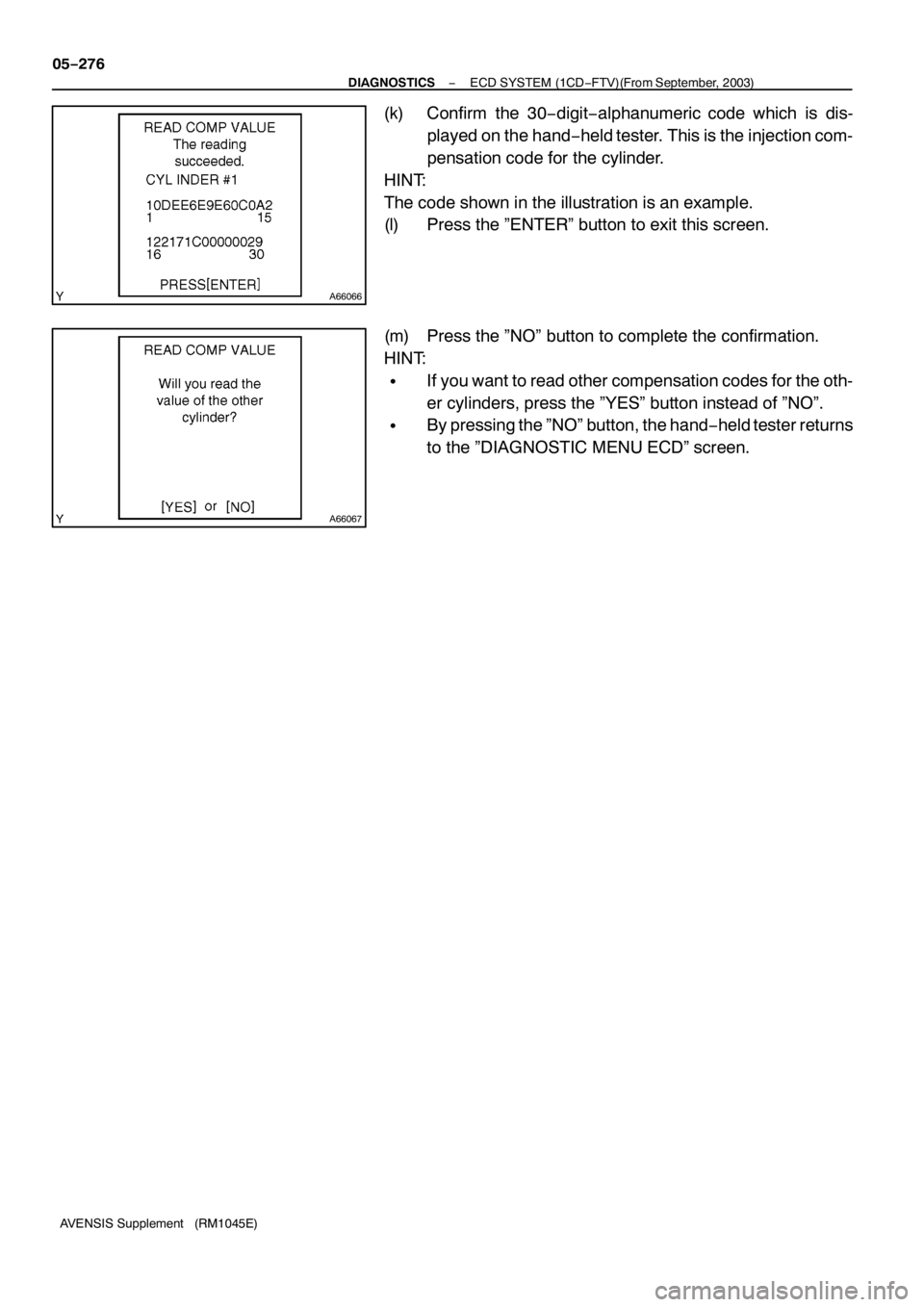

(k) Confirm the 30−digit−alphanumeric code which is dis-

played on the hand−held tester. This is the injection com-

pensation code for the cylinder.

HINT:

The code shown in the illustration is an example.

(l) Press the ”ENTER” button to exit this screen.

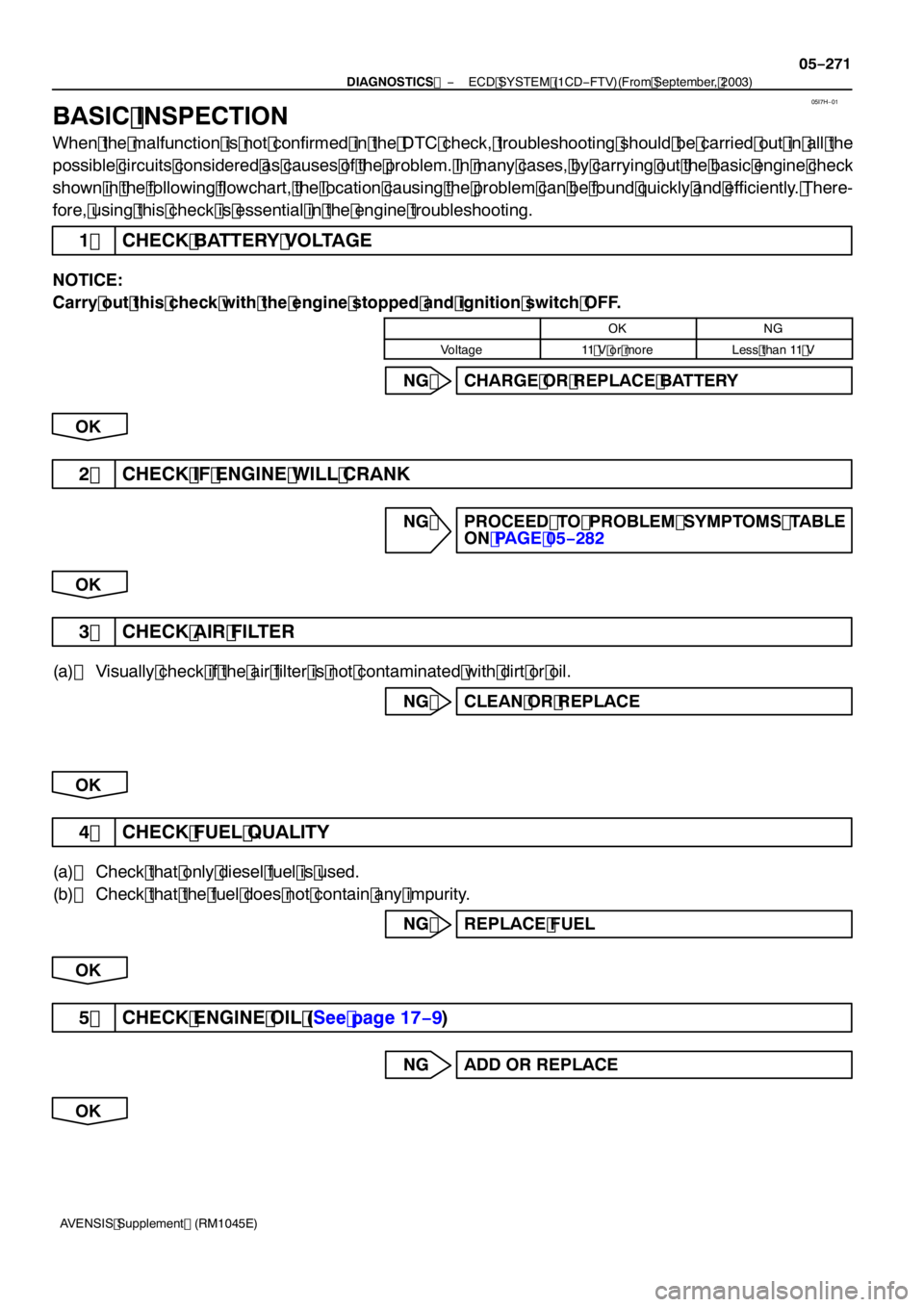

(m) Press the ”NO” button to complete the confirmation.

HINT:

SIf you want to read other compensation codes for the oth-

er cylinders, press the ”YES” button instead of ”NO”.

SBy pressing the ”NO” button, the hand−held tester returns

to the ”DIAGNOSTIC MENU ECD” screen.

Page 4326 of 5135

05I7H−01

−

DIAGNOSTICS ECD SYSTEM (1CD −FTV)(From September, 2003)

05 −27 1

AVENSIS Supplement (RM 1045E)

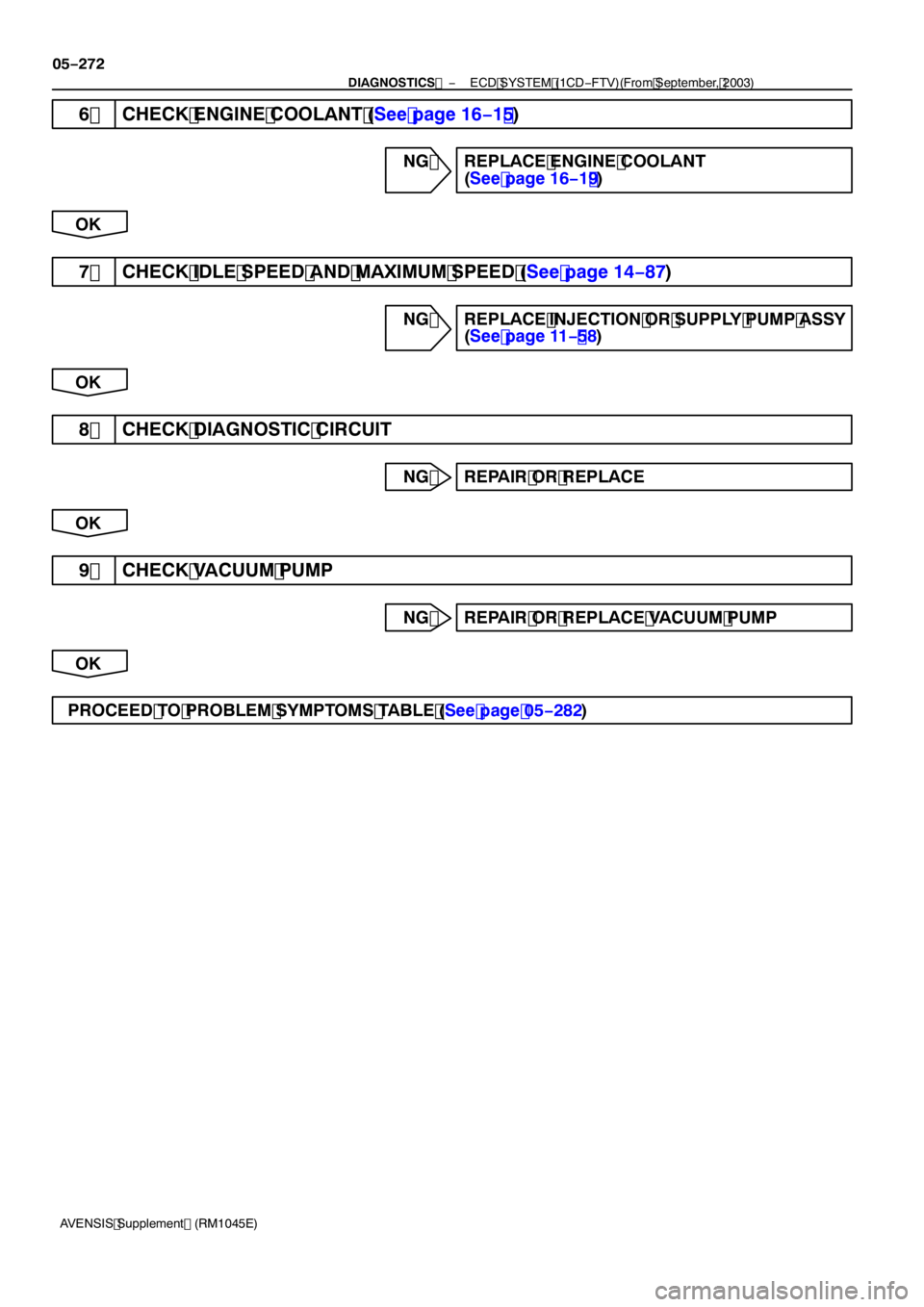

BASIC INSPECTION

When the malfunction is not confirmed in the DTC check, troubleshooting should be carried out in all the

possible circuits considered as causes of the problem. In many cases, by carrying out the basic engine check

shown in the following flowchart, the location causing the problem can be found quickly and efficiently. There-

fore, using this check is essential in the engine troubleshooting.

1 CHECK BATTERY VOLTAGE

NOTICE:

Carry out this check with the engine stopped and ignition switch OFF.

OKNG

Voltage11 V or moreLess than 11 V

NG CHARGE OR REPLACE BATTERY

OK

2 CHECK IF ENGINE WILL CRANK

NG PROCEED TO PROBLEM SYMPTOMS TABLE ON PAGE 05 −282

OK

3 CHECK AIR FILTER

(a) Visually check if the air filter is not contaminated with dirt or oil. NG CLEAN OR REPLACE

OK

4 CHECK FUEL QUALITY

(a) Check that only diesel fuel is used.

(b) Check that the fuel does not contain any impurity. NG REPLACE FUEL

OK

5 CHECK ENGINE OIL (See page 17− 9)

NG ADD OR REPLACE

OK

Page 4327 of 5135

05−272

−

DIAGNOSTICS ECD SYSTEM (1CD −FTV)(From September, 2003)

AVENSIS Supplement (RM 1045E)

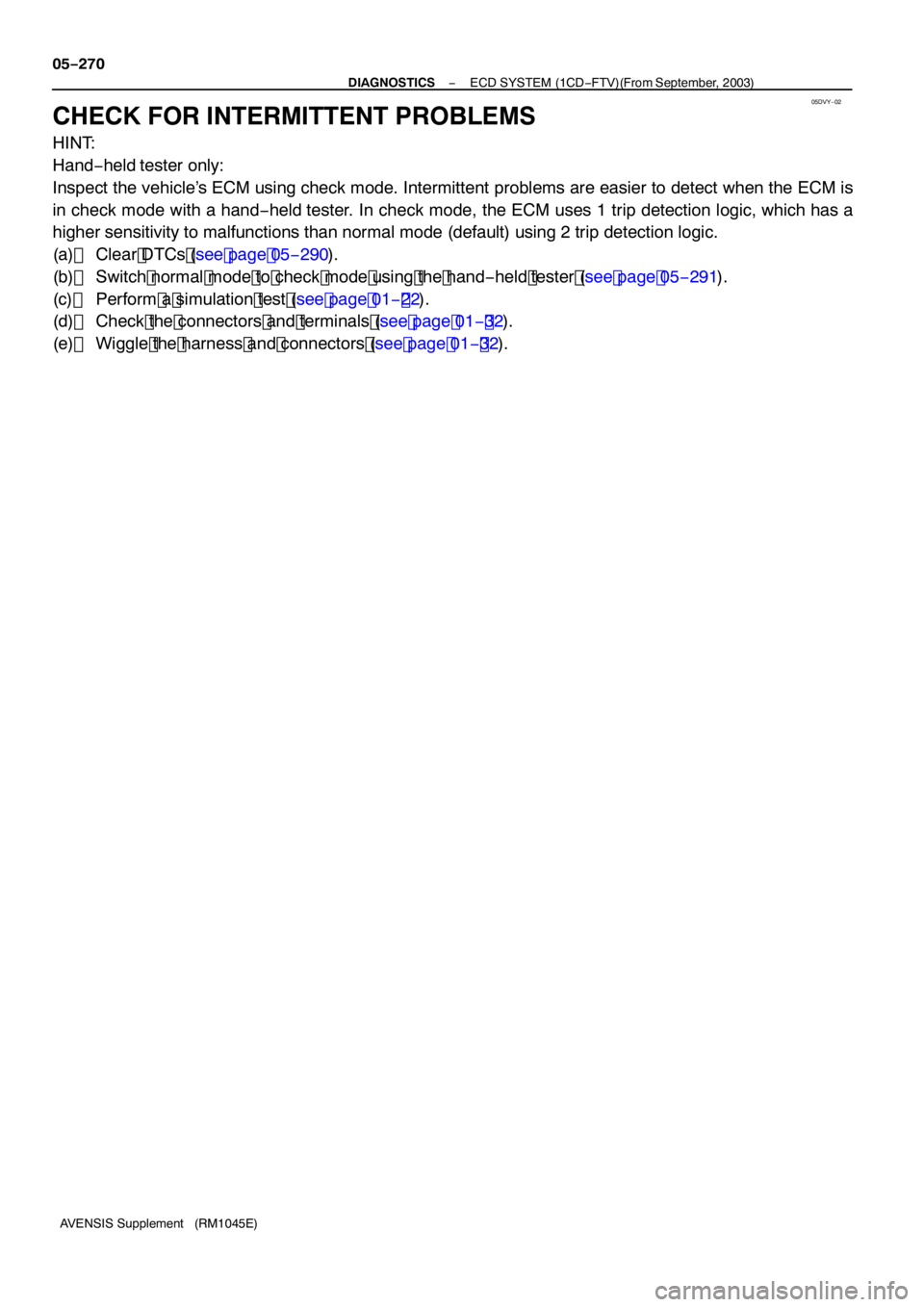

6 CHECK ENGINE COOLANT (See page 16−1 5)

NG REPLACE ENGINE COOLANT

(See page 16−1 9)

OK

7 CHECK IDLE SPEED AND MAXIMUM SPEED (See page 14− 87)

NG REPLACE INJECTION OR SUPPLY PUMP ASSY

(See page 11− 58)

OK

8 CHECK DIAGNOSTIC CIRCUIT

NG REPAIR OR REPLACE

OK

9 CHECK VACUUM PUMP

NG REPAIR OR REPLACE VACUUM PUMP

OK

PROCEED TO PROBLEM SYMPTOMS TABLE (See page 05 −282)

Page 4328 of 5135

05DVY−02

05 −270

−

DIAGNOSTICS ECD SYSTEM (1CD −FTV)(From September, 2003)

AVENSIS Supplement (RM 1045E)

CHECK FOR INTERMITTENT PROBLEMS

HINT:

Hand −held tester only:

Inspect the vehicle’s ECM using check mode. Intermittent problems are easier to detect when the ECM is

in check mode with a hand −held tester. In check mode, the ECM uses 1trip detection logic, which has a

higher sensitivity to malfunctions than normal mode (default) using 2 trip detection logic.

(a) Clear DTCs (see page 05 −290).

(b) Switch normal mode to check mode using the hand −held tester (see page 05 −29 1).

(c) Perform a simulation test (see page 0 1− 22).

(d) Check the connectors and terminals (see page 0 1− 32).

(e) Wiggle the harness and connectors (see page 0 1− 32).

Page 4329 of 5135

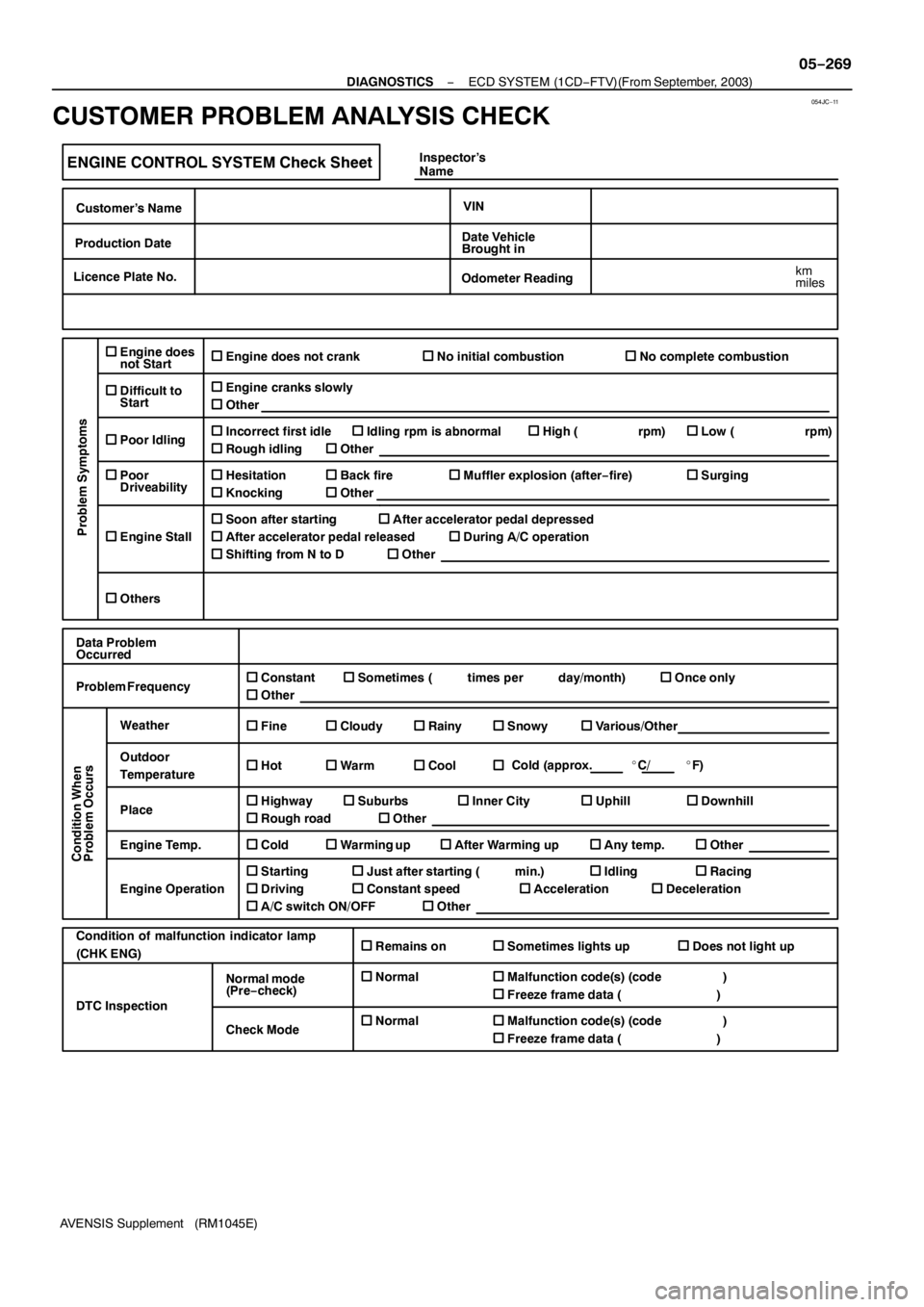

054JC−11

ENGINE CONTROL SYSTEM Check Sheet

Customer’s Name

Date Vehicle

Brought in

VIN

Production Date

Licence Plate No.

Odometer Reading

km

miles

Problem Symptoms

Engine does

not Start

Difficult to

Start

Poor Idling

Poor

Driveability

Engine Stall

Others

Engine does not crankNo initial combustionNo complete combustion

Engine cranks slowly

Other

Incorrect first idleIdling rpm is abnormalHigh ( rpm)Low ( rpm)

Rough idling

Other

HesitationBack fireMuffler explosion (after−fire)Surging

Knocking

Other

Soon after startingAfter accelerator pedal depressed

After accelerator pedal released

During A/C operation

Shifting from N to D

Other

Data Problem

Occurred

Problem Frequency

Condition When

Problem Occurs

Weather

Engine Operation

Engine Temp. Place Outdoor

TemperatureConstant

Sometimes ( times per day/month)Once only

Other

Fine

CloudyRainySnowyVarious/Other

Hot

Warm Cool

HighwaySuburbsInner CityUphillDownhill

Rough road

Other

Cold

Warming upAfter Warming upAny temp.Other

Starting

Just after starting ( min.)IdlingRacing

Driving

Constant speedAccelerationDeceleration

A/C switch ON/OFF

Other

Condition of malfunction indicator lamp

(CHK ENG)Remains on Sometimes lights up Does not light up

Normal Malfunction code(s) (code )

Freeze frame data ( )

Normal Malfunction code(s) (code )

Freeze frame data ( )

Normal mode

(Pre−check)

Check Mode DTC InspectionInspector’s

Name

Cold (approx._C/_F)

− DIAGNOSTICSECD SYSTEM (1CD−FTV)(From September, 2003)

05−269

AVENSIS Supplement (RM1045E)

CUSTOMER PROBLEM ANALYSIS CHECK

Page 4330 of 5135

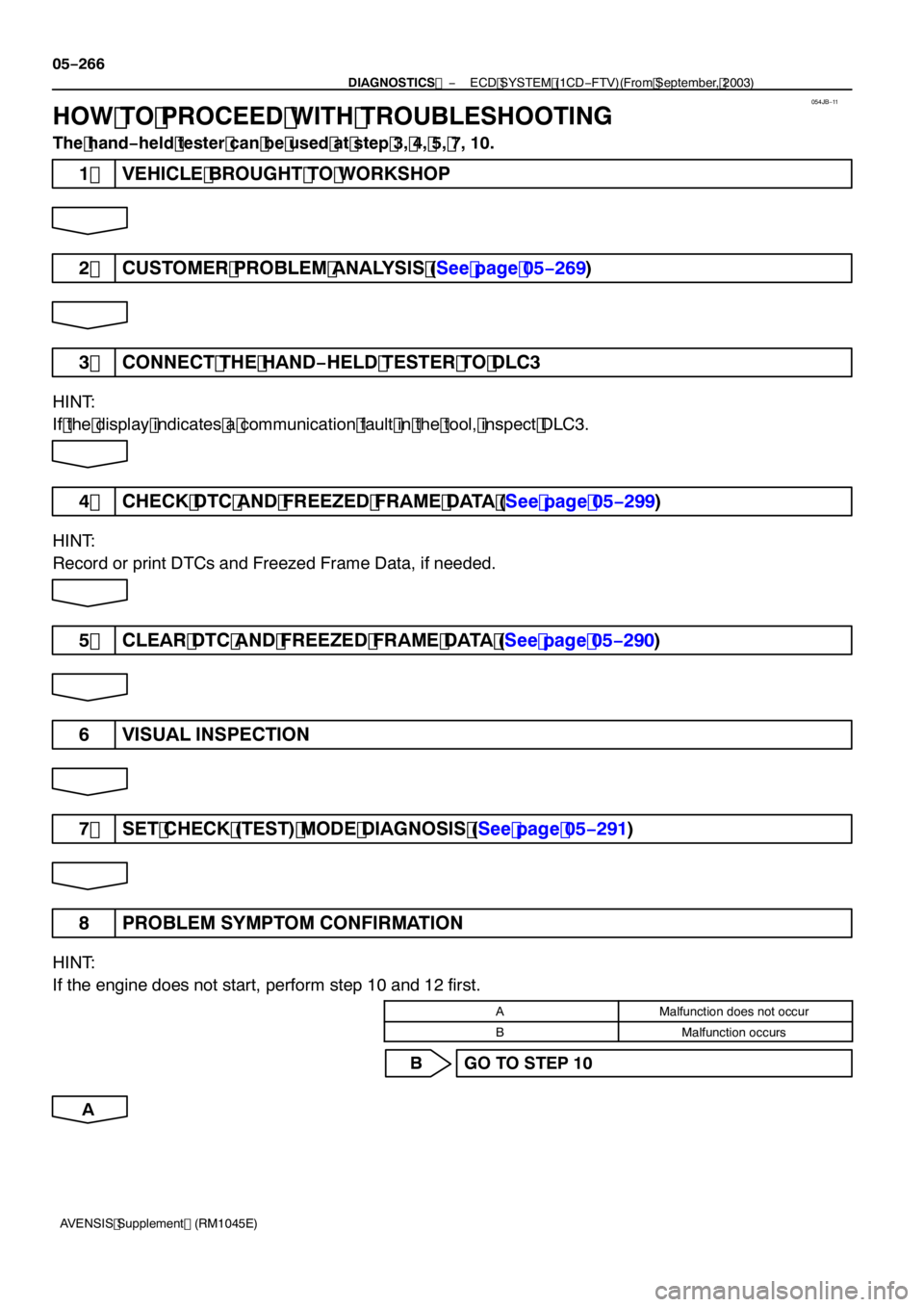

054JB−11

05−266

−

DIAGNOSTICS ECD SYSTEM (1CD −FTV)(From September, 2003)

AVENSIS Supplement (RM 1045E)

HOW TO PROCEED WITH TROUBLESHOOTING

The hand −held tester can be used at step 3, 4, 5, 7, 10.

1 VEHICLE BROUGHT TO WORKSHOP

2 CUSTOMER PROBLEM ANALYSIS (See page 05 −269)

3 CONNECT THE HAND −HELD TESTER TO DLC3

HINT:

If the display indicates a communication fault in the tool, inspect DLC3.

4 CHECK DTC AND FREEZED FRAME DATA (See page 05 −299)

HINT:

Record or print DTCs and Freezed Frame Data, if needed.

5 CLEAR DTC AND FREEZED FRAME DATA (See page 05 −290)

6 VISUAL INSPECTION

7 SET CHECK (TEST) MODE DIAGNOSIS (See page 05 −29 1)

8 PROBLEM SYMPTOM CONFIRMATION

HINT:

If the engine does not start, perform step 10 and 12 first.

AMalfunction does not occur

BMalfunction occurs

B GO TO STEP 10

A