TOYOTA AVENSIS 2005 Service Repair Manual

Manufacturer: TOYOTA, Model Year: 2005, Model line: AVENSIS, Model: TOYOTA AVENSIS 2005Pages: 5135, PDF Size: 95.28 MB

Page 4331 of 5135

−

DIAGNOSTICS ECD SYSTEM (1CD −FTV)(From September, 2003)

05 −267

AVENSIS Supplement (RM 1045E)

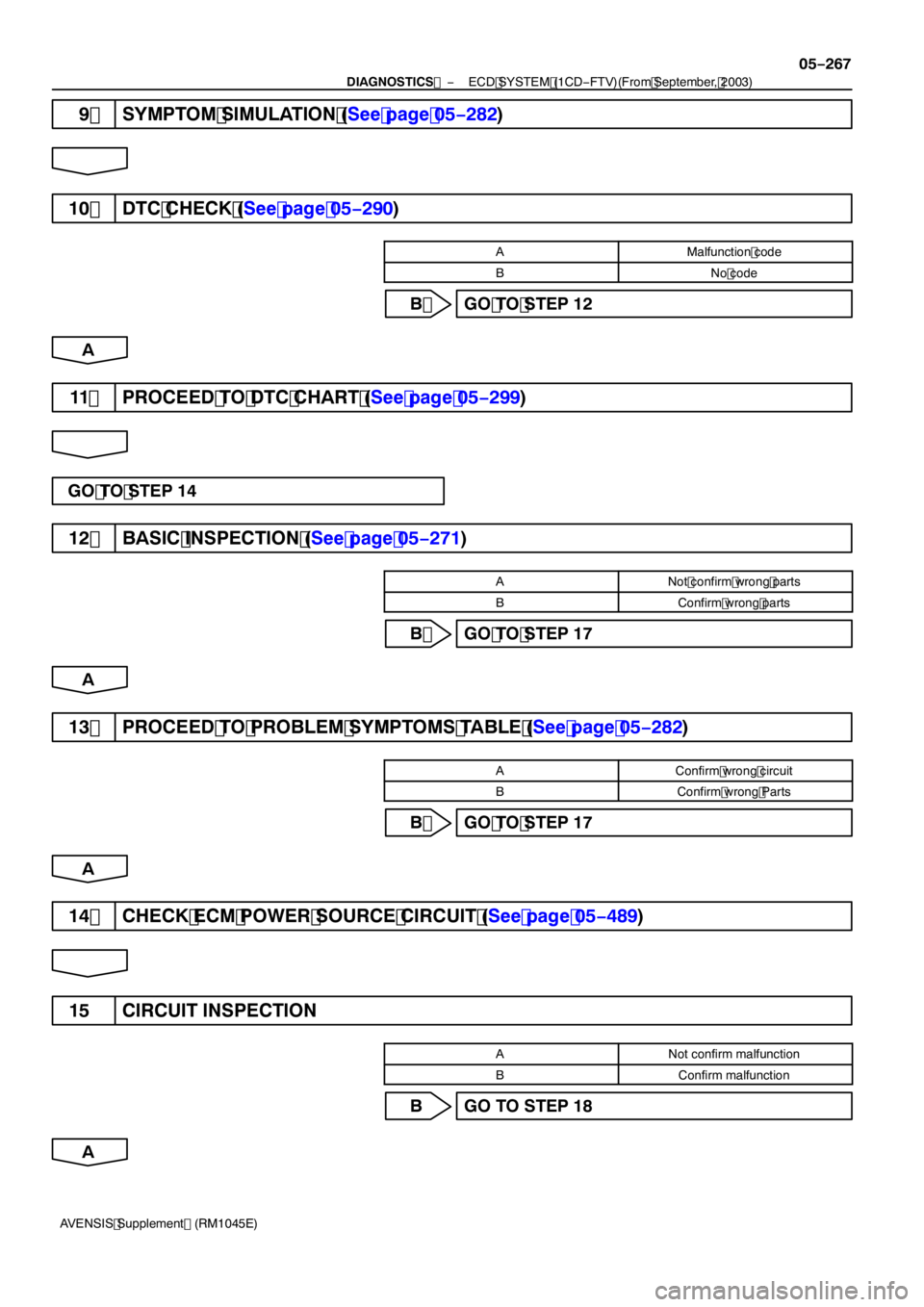

9 SYMPTOM SIMULATION (See page 05 −282)

1 0 DTC CHECK (See page 05 −290)

AMalfunction code

BNo code

B GO TO STEP 12

A

11 PROCEED TO DTC CHART (See page 05 −299)

GO TO STEP 14

12 BASIC INSPECTION (See page 05 −27 1)

ANot confirm wrong parts

BConfirm wrong parts

B GO TO STEP 17

A

1 3 PROCEED TO PROBLEM SYMPTOMS TABLE (See page 05 −282)

AConfirm wrong circuit

BConfirm wrong Parts

B GO TO STEP 17

A

1 4 CHECK ECM POWER SOURCE CIRCUIT (See page 05 −489)

1 5 CIRCUIT INSPECTION

ANot confirm malfunction

BConfirm malfunction

B GO TO STEP 18

A

Page 4332 of 5135

05−268

−

DIAGNOSTICS ECD SYSTEM (1CD −FTV)(From September, 2003)

AVENSIS Supplement (RM 1045E)

16 CHECK FOR INTERMITTENT PROBLEMS (See page 05 −270)

GO TO STEP 18

17 PARTS INSPECTION

1 8 PROBLEM IDENTIFICATION

1 9 ADJUSTMENT AND/OR REPAIR

20 CONFIRMATION TEST

END

Page 4333 of 5135

05I7Z−01

A91210

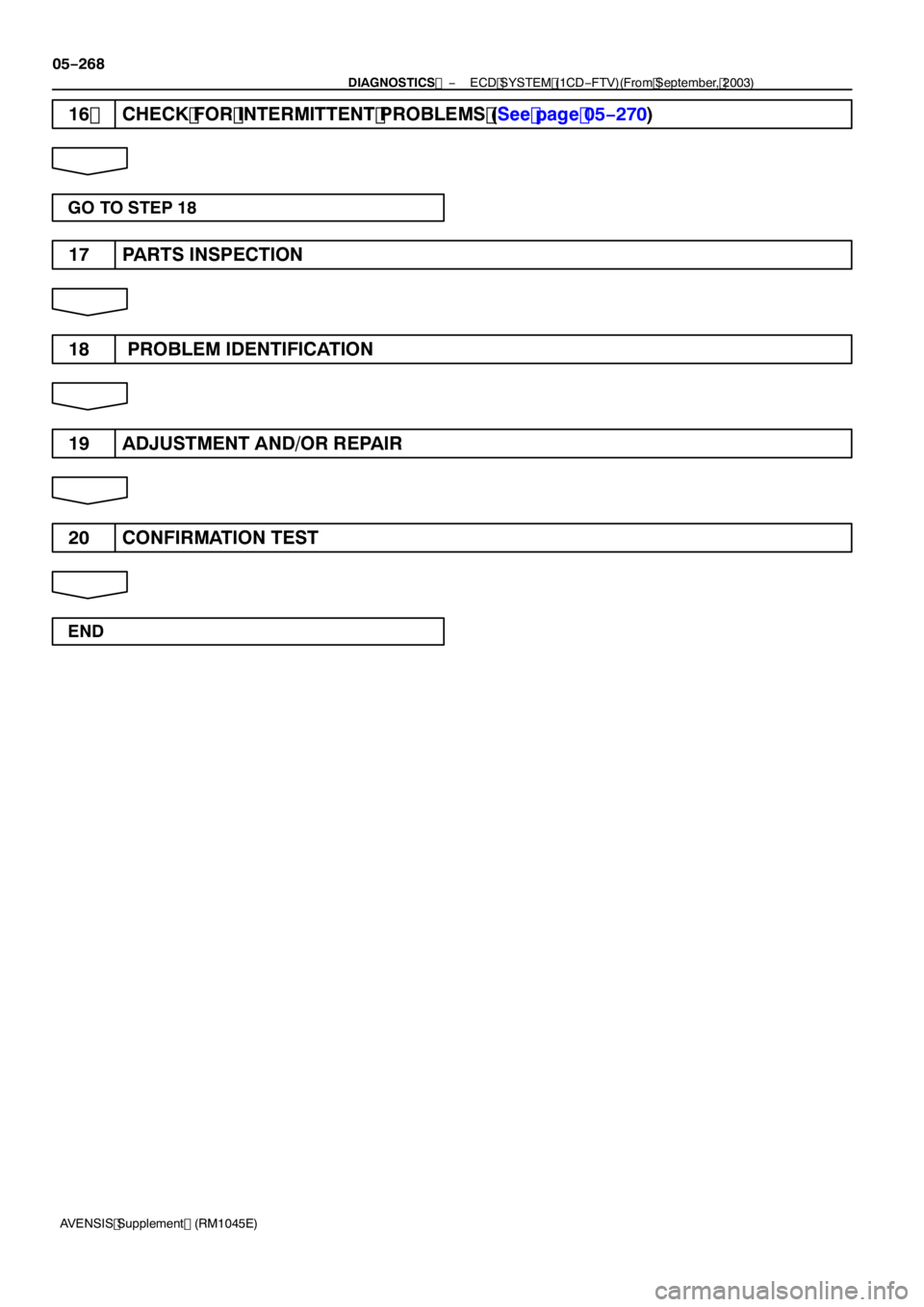

Engine Control System Diagram:

Accelerator Pedal

Position Sensor

Ignition Switch Signal

Starter Signal

Vehicle Speed Signal

DLC3Supply Pump

Pressure Discharge Valve Fuel Pressure Sensor

EDU Relay

EDU

Atmospheric

Temperature

Sensor

Glow

Plug Relay

Crankshaft Position SensorCamshaft

Position

SensorCommon Rail Suction Control Valve

Alternator Duty SignalDCAT Switch

ECM

Atmospheric

Pressure

Sensor

A/F Sensor Heater

Mass Air Flow Meter

Differential

Pressure Sensor

A/F Sensor Actuator

E−VRV

Exhaust Gas Temperature Sensor

(Up Stream)

Exhaust Gas Temperature Sensor

(Down Stream)Glow Plug EGR Valve

Injector

Turbo Pressure

Sensor

Engine Coolant

Temperature Sensor

Intake Air

Temperature

Sensor

Fuel Temperature Sensor

EGR Cooler Inter Cooler

Exhaust Fuel

Addition

Injector

DPNR Catalytic Converter

Turbocharger

(INJT and PRD Signal)

(INJF Signal)

Intake Shutter

(Throttle Valve)

Oxidation Catalytic

Converter

− DIAGNOSTICSECD SYSTEM (1CD−FTV)(From September, 2003)

05−255

AVENSIS Supplement (RM1045E)

SYSTEM DESCRIPTION

1. ENGINE CONTROL SYSTEM

Page 4334 of 5135

A85344

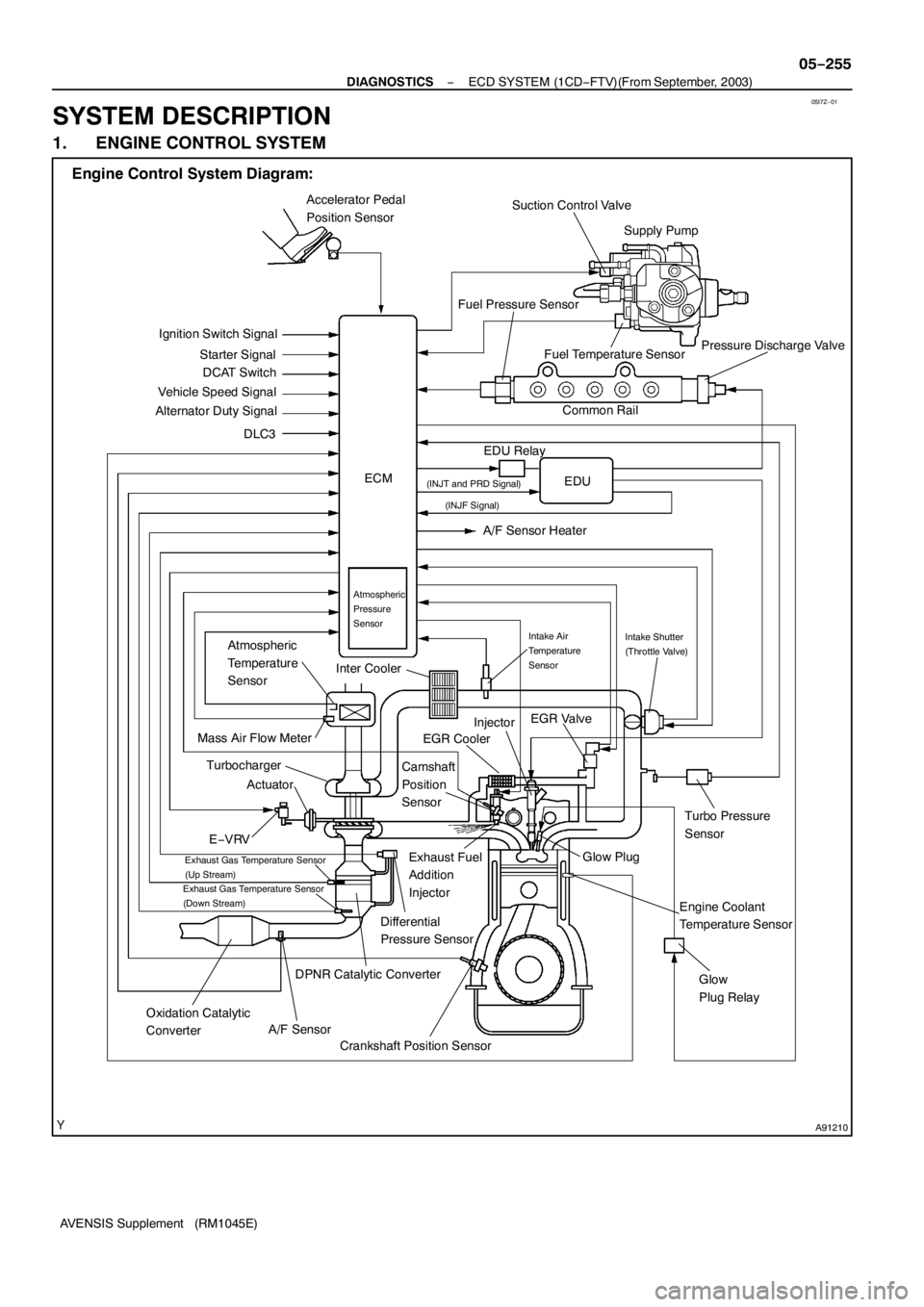

TOYOTA D−CAT Diagram:

DCAT

Switch

EDU

ECM

Common RailInjector

Fuel Tank EGR Valve

FReduces NOx (Linear Solenoid Type)EGR Cooler

FCools Down EGR GasExhaust Fuel Addition

Injector

FReduces NOxEGR Cooler Catalyst

FMaintains proper operation of EGR cooler

Differential Pressure

Sensor

Exhaust Gas

Temperature Sensor

FMonitors catalyst

A/F Sensor

Oxidation Catalytic Converter

FReduces HC and CO Manifold Converter Sub−assy

(DPNR Catalytic Converter)

FReduces NOx, PM, HC, and CO Intake Shutter (Throttle Valve)

Supply Pump

FSupplies fuel to exhaust fuel addition injector

temperature FDPNR catalyst regeneration

FSupplies high pressure fuel to main injector via common rail

Pressure Discharge Valve

Fuel Pressure sensor

05−256

− DIAGNOSTICSECD SYSTEM (1CD−FTV)(From September, 2003)

AVENSIS Supplement (RM1045E)

2. TOYOTA D−CAT DESCRIPTION

(a)TOYOTA D−CAT:

Diesel Clean Advanced Technology (TOYOTA D−CAT) comprehensively regulates engine control (consists

of a catalytic system and a fuel injection system) that purifies both particulate matter (PM) and nitrogen ox-

ides (NOx) discharged by diesel engines.

The catalytic system purifies hydrocarbons (HC) and carbon monoxides (CO), and reduces PM and NOx

with a catalytic converter with the Diesel Particulate−NOx Reduction system (DPNR). The fuel injection sys-

tem adds fuel into the exhaust port using the exhaust fuel addition injector to produce RICH state for NOx

reduction and maintain a proper catalyst temperature for DPNR catalyst regeneration.

Page 4335 of 5135

− DIAGNOSTICSECD SYSTEM (1CD−FTV)(From September, 2003)

05−257

AVENSIS Supplement (RM1045E)

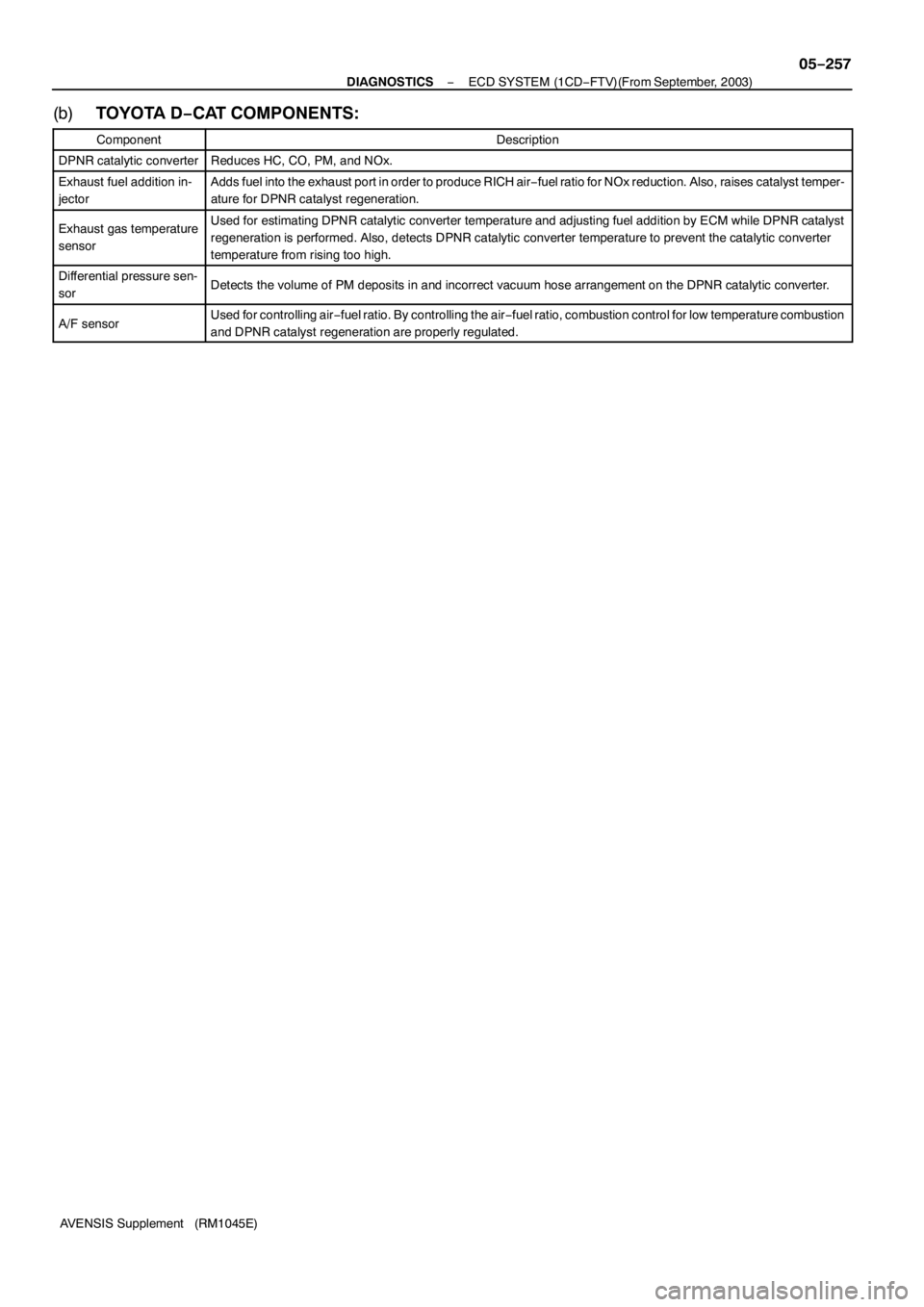

(b)TOYOTA D−CAT COMPONENTS:

ComponentDescription

DPNR catalytic converterReduces HC, CO, PM, and NOx.

Exhaust fuel addition in-

jectorAdds fuel into the exhaust port in order to produce RICH air−fuel ratio for NOx reduction. Also, raises catalyst temper-

ature for DPNR catalyst regeneration.

Exhaust gas temperature

sensorUsed for estimating DPNR catalytic converter temperature and adjusting fuel addition by ECM while DPNR catalyst

regeneration is performed. Also, detects DPNR catalytic converter temperature to prevent the catalytic converter

temperature from rising too high.

Differential pressure sen-

sorDetects the volume of PM deposits in and incorrect vacuum hose arrangement on the DPNR catalytic converter.

A/F sensorUsed for controlling air−fuel ratio. By controlling the air−fuel ratio, combustion control for low temperature combustion

and DPNR catalyst regeneration are properly regulated.

Page 4336 of 5135

DTC No.

( ): Potential DTCs

( F )

ABCDE F G HI JKL MNOPQ RS T

P003 1 (See page 05 −305)

P0544 (See page 05 −415)

P0545 (See page 05 −415)

P0546 (See page 05 −415)

P 1386 (See page 05 −444)

P 1425 (See page 05 −457)

P 1426 (See page 05 −462)

P 1427 (See page 05 −457)

P 1428 (See page 05 −457)

P2002 (See page 05 −466)

P203 1 (See page 05 −415)

P2032 (See page 05 −415)

P2033 (See page 05 −415)

P2047 (See page 05 −470)

P2238 (See page 05 −484)

P2239 (See page 05 −484)

F

F

F F

F

F FF

FF F F FFF

FF

F

F

F

F FF

F

F

F

F F F

F

F

F

FFF

F (

F )(F)

( F )

(F )(F )(F ) (

F )(F )

( F )

F

F

F F

F

F

(F )(

F )

( F )

( F )(

F )

F F F

F

( F )

( F )(F)( F)

05

−258

−

DIAGNOSTICS ECD SYSTEM (1CD −FTV)(From September, 2003)

AVENSIS Supplement (RM 1045E)

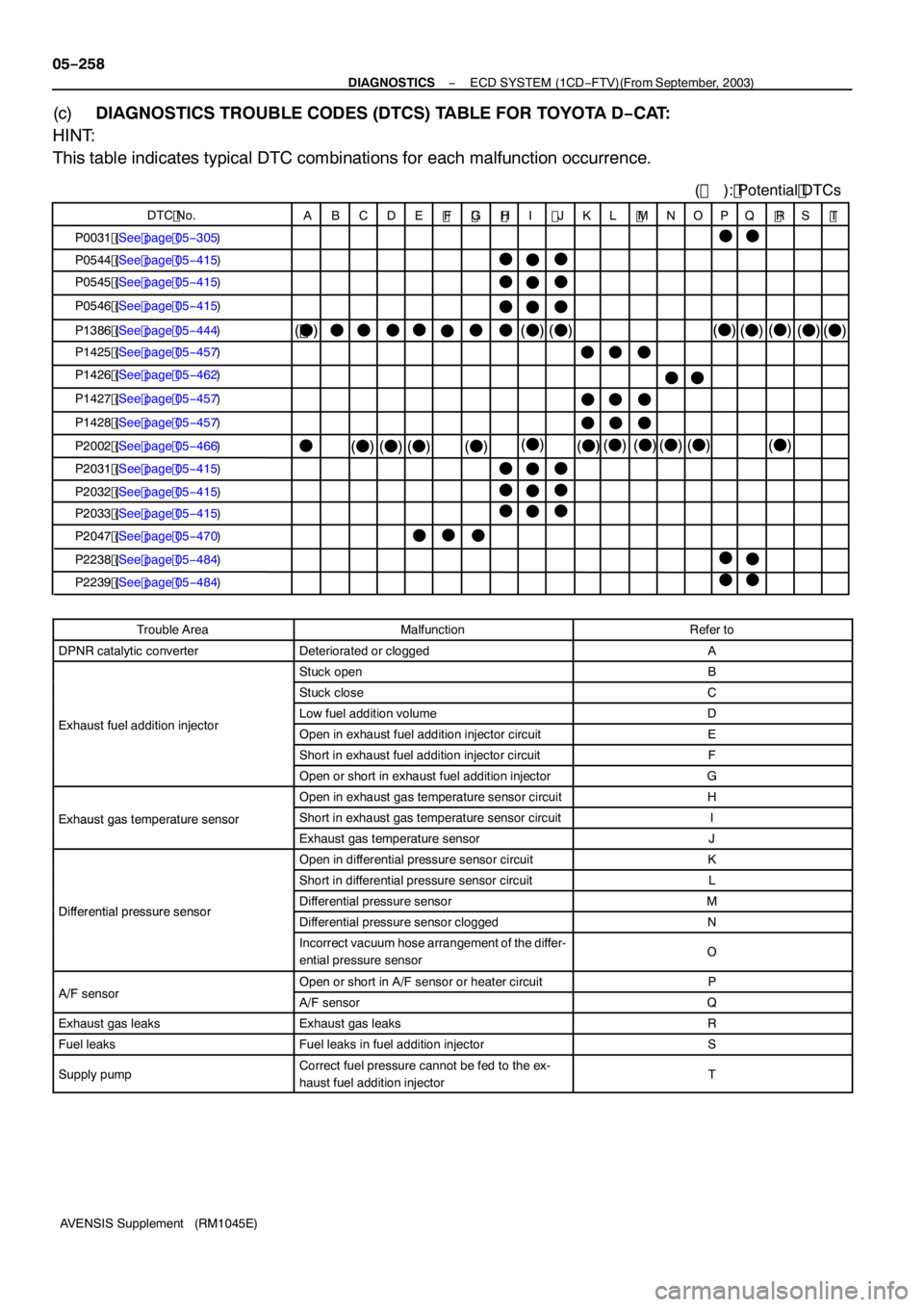

(c) DIAGNOSTICS TROUBLE CODES (DTCS) TABLE FOR TOYOTA D −CAT:

HINT:

This table indicates typical DTC combinations for each malfunction occurrence.

Trouble AreaMalfunctionRefer to

DPNR catalytic converterDeteriorated or cloggedA

Stuck openB

Stuck closeC

Eha stfeladditioi jectoLow fuel addition volumeDExhaust fuel addition injectorOpen in exhaust fuel addition injector circuitE

Short in exhaust fuel addition injector circuitF

Open or short in exhaust fuel addition injectorG

Open in exhaust gas temperature sensor circuitH

Exhaust gas temperature sensorShort in exhaust gas temperature sensor circuitIExhaustgastemperaturesensor

Exhaust gas temperature sensorJ

Open in differential pressure sensor circuitK

Short in differential pressure sensor circuitL

DifferentialpressuresensorDifferential pressure sensorMDifferential pressure sensorDifferential pressure sensor cloggedN

Incorrect vacuum hose arrangement of the differ-

ential pressure sensorO

A/Fse soOpen or short in A/F sensor or heater circuitPA/F sensorA/F sensorQ

Exhaust gas leaksExhaust gas leaksR

Fuel leaksFuel leaks in fuel addition injectorS

Supply pumpCorrect fuel pressure cannot be fed to the ex-

haust fuel addition injectorT

Page 4337 of 5135

− DIAGNOSTICSECD SYSTEM (1CD−FTV)(From September, 2003)

05−259

AVENSIS Supplement (RM1045E)

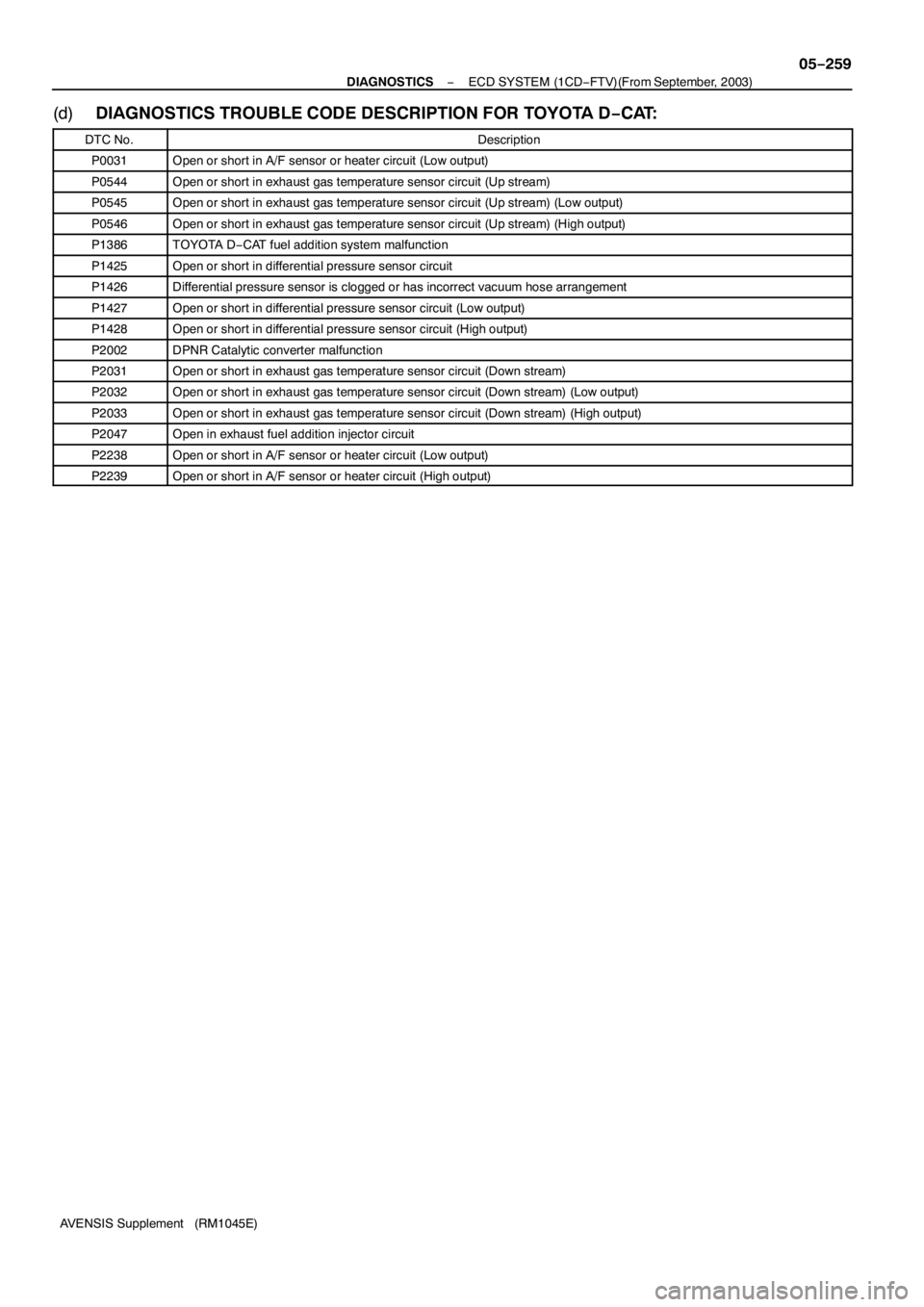

(d)DIAGNOSTICS TROUBLE CODE DESCRIPTION FOR TOYOTA D−CAT:

DTC No.Description

P0031Open or short in A/F sensor or heater circuit (Low output)

P0544Open or short in exhaust gas temperature sensor circuit (Up stream)

P0545Open or short in exhaust gas temperature sensor circuit (Up stream) (Low output)

P0546Open or short in exhaust gas temperature sensor circuit (Up stream) (High output)

P1386TOYOTA D−CAT fuel addition system malfunction

P1425Open or short in differential pressure sensor circuit

P1426Differential pressure sensor is clogged or has incorrect vacuum hose arrangement

P1427Open or short in differential pressure sensor circuit (Low output)

P1428Open or short in differential pressure sensor circuit (High output)

P2002DPNR Catalytic converter malfunction

P2031Open or short in exhaust gas temperature sensor circuit (Down stream)

P2032Open or short in exhaust gas temperature sensor circuit (Down stream) (Low output)

P2033Open or short in exhaust gas temperature sensor circuit (Down stream) (High output)

P2047Open in exhaust fuel addition injector circuit

P2238Open or short in A/F sensor or heater circuit (Low output)

P2239Open or short in A/F sensor or heater circuit (High output)

Page 4338 of 5135

A91221

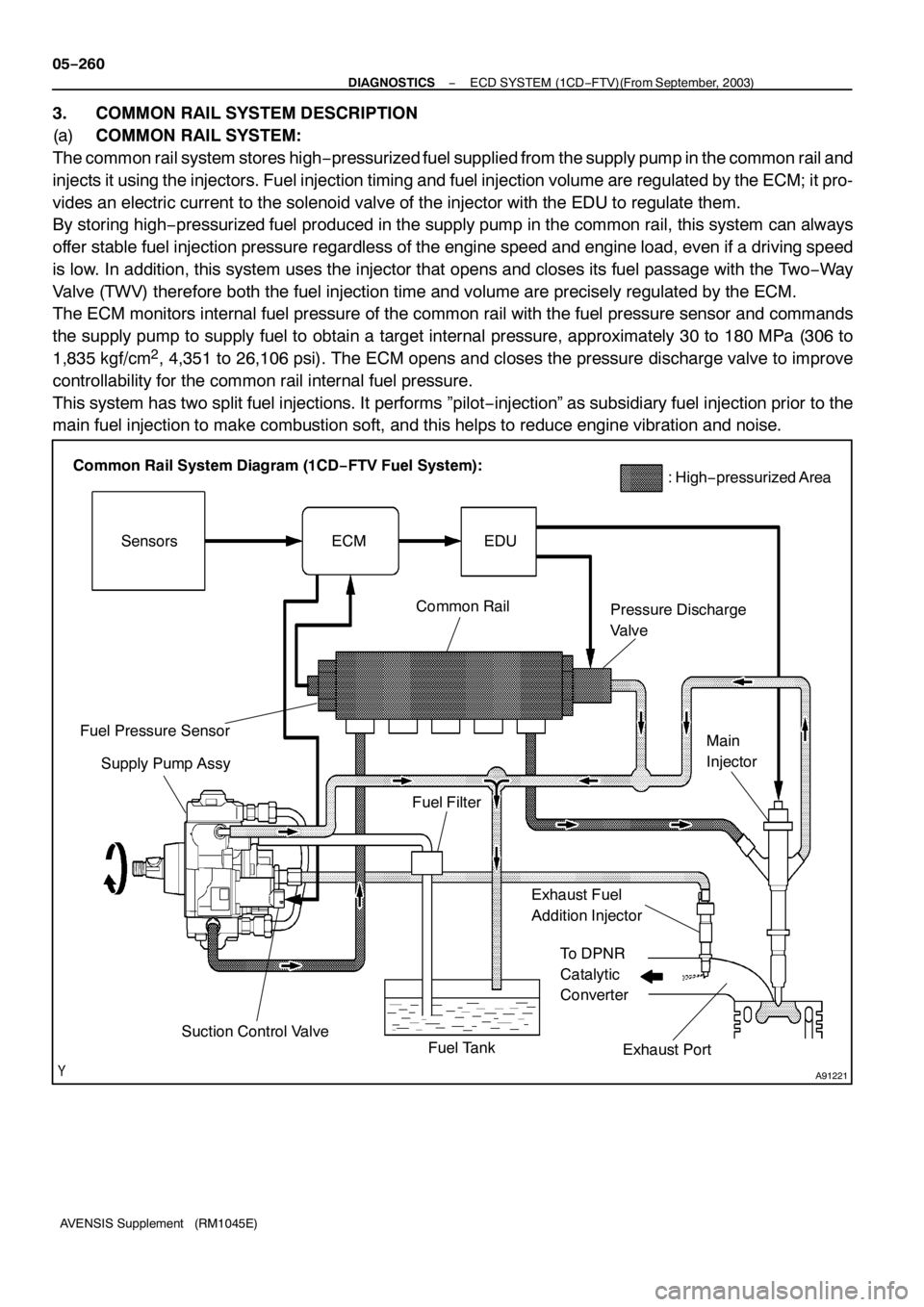

Common Rail System Diagram (1CD−FTV Fuel System):

Sensors ECM EDU

Common Rail

Fuel Pressure SensorPressure Discharge

Valve

Supply Pump Assy

Suction Control Valve

Fuel TankMain

Injector

Fuel Filter

: High−pressurized Area

Exhaust Fuel

Addition Injector

Exhaust Port

To DPNR

Catalytic

Converter 05−260

− DIAGNOSTICSECD SYSTEM (1CD−FTV)(From September, 2003)

AVENSIS Supplement (RM1045E)

3. COMMON RAIL SYSTEM DESCRIPTION

(a)COMMON RAIL SYSTEM:

The common rail system stores high−pressurized fuel supplied from the supply pump in the common rail and

injects it using the injectors. Fuel injection timing and fuel injection volume are regulated by the ECM; it pro-

vides an electric current to the solenoid valve of the injector with the EDU to regulate them.

By storing high−pressurized fuel produced in the supply pump in the common rail, this system can always

offer stable fuel injection pressure regardless of the engine speed and engine load, even if a driving speed

is low. In addition, this system uses the injector that opens and closes its fuel passage with the Two−Wa y

Valve (TWV) therefore both the fuel injection time and volume are precisely regulated by the ECM.

The ECM monitors internal fuel pressure of the common rail with the fuel pressure sensor and commands

the supply pump to supply fuel to obtain a target internal pressure, approximately 30 to180 MPa (306 to

1,835 kgf/cm

2, 4,351to 26,106 psi). The ECM opens and closes the pressure discharge valve to improve

controllability for the common rail internal fuel pressure.

This system has two split fuel injections. It performs ”pilot−injection” as subsidiary fuel injection prior to the

main fuel injection to make combustion soft, and this helps to reduce engine vibration and noise.

Page 4339 of 5135

P0087 (See page 05−314)

P0088 (See page 05 −32 1)

P0093 (See page 05 −328)

P0 190 (See page 05 −314)

P0 192 (See page 05 −314)

P0 193 (See page 05 −314)

P0200 (See page 05 −368)

P0627 (See page 05 −429)

P 1229 (See page 05 −32 1)

P 127 1 (See page 05 −435)

P 1272 (See page 05 −435)

P

1238 (See page 05 −43 1)

DTC No. A

BC DEF

GH IJKL

(

F )

F

( F )

F F

FF F

F

F

F

F F

(

F )

( F ) F

(

F )( F)( F)

F F

F F (

F )

( F )

( F )

(

F ) F

P0

191 (See page 05 −367)

F ( ): Potential DTCs

(F )

−

DIAGNOSTICS ECD SYSTEM (1CD −FTV)(From September, 2003)

05 −26 1

AVENSIS Supplement (RM 1045E)

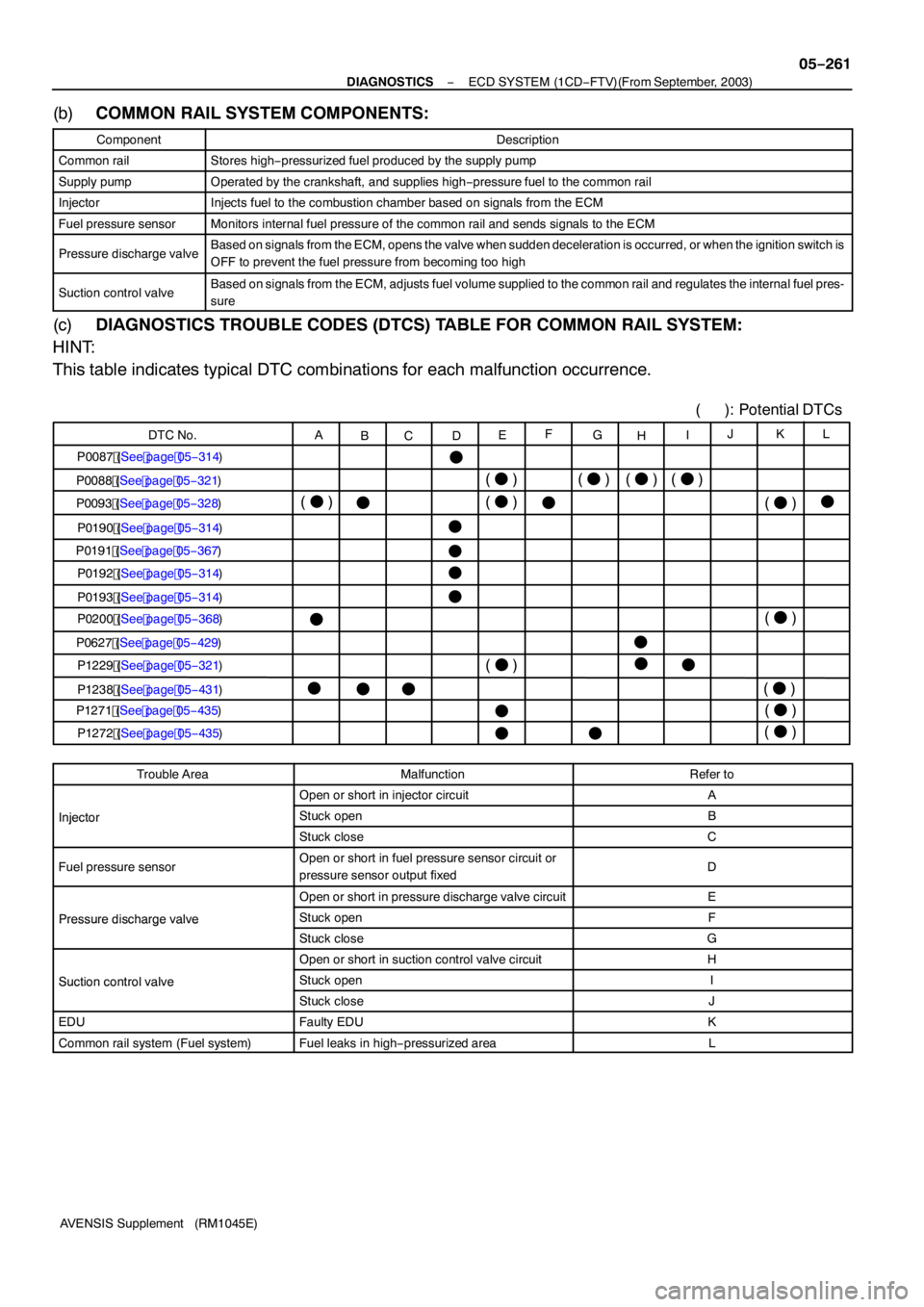

(b) COMMON RAIL SYSTEM COMPONENTS:

ComponentDescription

Common railStores high −pressurized fuel produced by the supply pump

Supply pumpOperated by the crankshaft, and supplies high −pressure fuel to the common rail

InjectorInjects fuel to the combustion chamber based on signals from the ECM

Fuel pressure sensorMonitors internal fuel pressure of the common rail and sends signals to the ECM

Pressure discharge valveBased on signals from the ECM, opens the valve when sudden deceleration is occurred, or when the ignition switch is

OFF to prevent the fuel pressure from becoming too high

Suction control valveBased on signals from the ECM, adjusts fuel volume supplied to the common rail and regulates the internal fuel pres-

sure

(c) DIAGNOSTICS TROUBLE CODES (DTCS) TABLE FOR COMMON RAIL SYSTEM:

HINT:

This table indicates typical DTC combinations for each malfunction occurrence.

Trouble AreaMalfunctionRefer to

Open or short in injector circuitA

InjectorStuck openBInjector

Stuck closeC

Fuel pressure sensorOpen or short in fuel pressure sensor circuit or

pressure sensor output fixedD

Open or short in pressure discharge valve circuitE

Pressure discharge valveStuck openFPressuredischargevalve

Stuck closeG

Open or short in suction control valve circuitH

Suction control valveStuck openISuctioncontrolvalve

Stuck closeJ

EDUFaulty EDUK

Common rail system (Fuel system)Fuel leaks in high −pressurized areaL

Page 4340 of 5135

05−262

− DIAGNOSTICSECD SYSTEM (1CD−FTV)(From September, 2003)

AVENSIS Supplement (RM1045E)

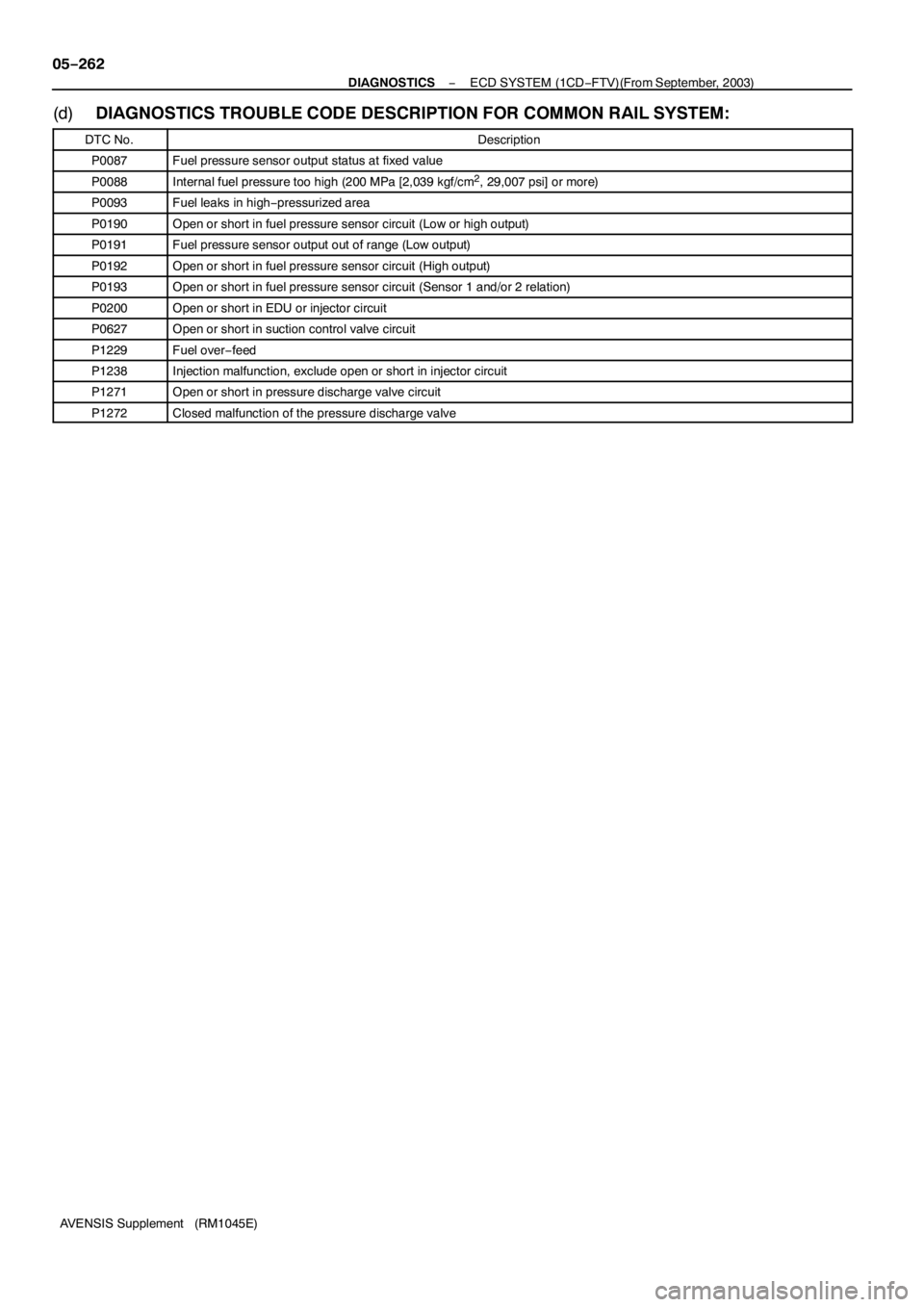

(d)DIAGNOSTICS TROUBLE CODE DESCRIPTION FOR COMMON RAIL SYSTEM:

DTC No.Description

P0087Fuel pressure sensor output status at fixed value

P0088Internal fuel pressure too high (200 MPa [2,039 kgf/cm2, 29,007 psi] or more)

P0093Fuel leaks in high−pressurized area

P0190Open or short in fuel pressure sensor circuit (Low or high output)

P0191Fuel pressure sensor output out of range (Low output)

P0192Open or short in fuel pressure sensor circuit (High output)

P0193Open or short in fuel pressure sensor circuit (Sensor1and/or 2 relation)

P0200Open or short in EDU or injector circuit

P0627Open or short in suction control valve circuit

P1229Fuel over−feed

P1238Injection malfunction, exclude open or short in injector circuit

P1271Open or short in pressure discharge valve circuit

P1272Closed malfunction of the pressure discharge valve