TOYOTA AVENSIS 2005 Service Repair Manual

Manufacturer: TOYOTA, Model Year: 2005, Model line: AVENSIS, Model: TOYOTA AVENSIS 2005Pages: 5135, PDF Size: 95.28 MB

Page 4411 of 5135

− DIAGNOSTICSECD SYSTEM (1CD−FTV)(From September, 2003)

05−453

AVENSIS Supplement (RM1045E)

11READ VALUE OF HAND−HELD TESTER(COMPENSATION OF INJECTION

VOLUME FOR EACH CYLINDER)

(a) Connect the hand−held tester to the DLC3.

(b) Turn the ignition switch to ON and turn the hand−held tester ON.

(c) Start the engine.

(d) Select the item ”DIAGNOSIS / OBD/MOBD / DATA LIST / ALL / INJ VOLUME FB” and read its value

displayed on the hand−held tester.

Result:

ResultProceed to

Compensatory Injection Volume is more than 3.0 mm3A

Compensatory Injection Volume is 3.0 mm3or lessB

HINT:

Usually compensation injection volume is 3.0 mm

3or less.

B Go to step13

A

12 CHECK ENGINE COMPONENTS PARTS

(a) Check that there is no abnormality in the main injector, cylinder compression pressure, valve timing

and valve clearance.

(b) Check that there is no leakage or blockage in the air intake, exhaust and EGR systems.

NG REPAIR OR REPLACE

OK

Page 4412 of 5135

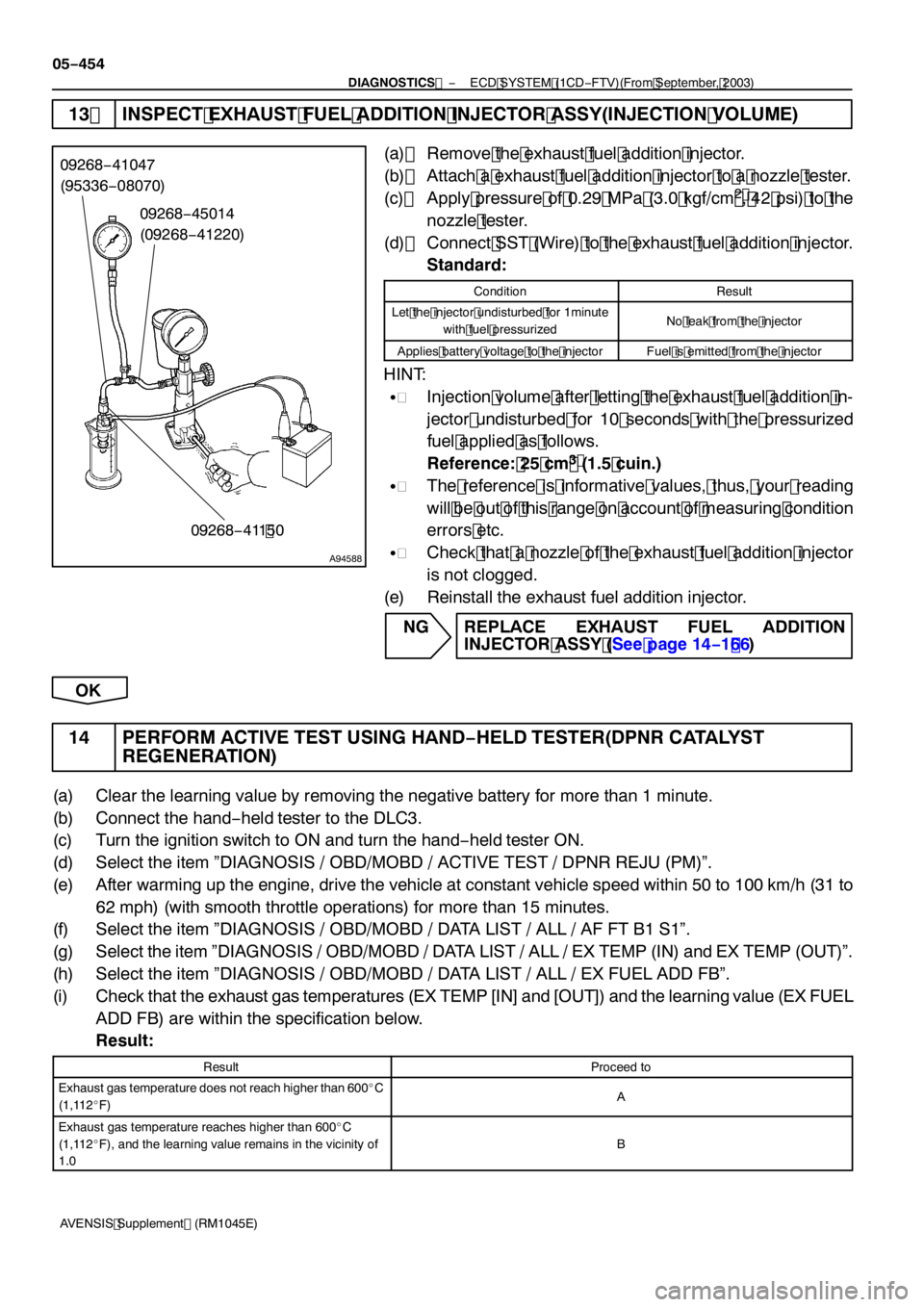

A94588

09268−41047

(95336 −08070)

09268 −450 14

(09268 −41220)

09268 −411 50

05 −454

−

DIAGNOSTICS ECD SYSTEM (1CD −FTV)(From September, 2003)

AVENSIS Supplement (RM 1045E)

13 INSPECT EXHAUST FUEL ADDITION INJECTOR ASSY(INJECTION VOLUME)

(a) Remove the exhaust fuel addition injector.

(b) Attach a exhaust fuel addition injector to a nozzle tester.

(c) Apply pressure of 0.29 MPa (3.0 kgf/cm

2 , 42 psi) to the

nozzle tester.

(d) Connect SST (Wire) to the exhaust fuel addition injector. Standard:

ConditionResult

Let the injector undisturbed for 1minute

with fuel pressurizedNo leak from the injector

Applies battery voltage to the injectorFuel is emitted from the injector

HINT:

S Injection volume after letting the exhaust fuel addition in-

jector undisturbed for 10 seconds with the pressurized

fuel applied as follows.

Reference: 25 cm

3 ( 1 .5 cuin.)

S The reference is informative values, thus, your reading

will be out of this range on account of measuring condition

errors etc.

S Check that a nozzle of the exhaust fuel addition injector

is not clogged.

(e) Reinstall the exhaust fuel addition injector.

NG REPLACE EXHAUST FUEL ADDITION INJECTOR ASSY (See page 14−1 66)

OK

1 4 PERFORM ACTIVE TEST USING HAND −HELD TESTER(DPNR CATALYST

REGENERATION)

(a) Clear the learning value by removing the negative battery for more than 1minute.

(b) Connect the hand −held tester to the DLC3.

(c) Turn the ignition switch to ON and turn the hand −held tester ON.

(d) Select the item ”DIAGNOSIS / OBD/MOBD / ACTIVE TEST / DPNR REJU (PM)”.

(e) After warming up the engine, drive the vehicle at constant vehicle speed within 50 to 100 km/h (3 1to

62 mph) (with smooth throttle operations) for more than 15 minutes.

(f) Select the item ”DIAGNOSIS / OBD/MOBD / DATA LIST / ALL / AF FT B 1S1”.

(g) Select the item ”DIAGNOSIS / OBD/MOBD / DATA LIST / ALL / EX TEMP (IN) and EX TEMP (OUT)”.

(h) Select the item ”DIAGNOSIS / OBD/MOBD / DATA LIST / ALL / EX FUEL ADD FB”.

(i) Check that the exhaust gas temperatures (EX TEMP [IN] and [OUT]) and the learning value (EX FUEL ADD FB) are within the specification below.

Result:

ResultProceed to

Exhaust gas temperature does not reach higher than 600 _C

( 1 ,11 2_F)A

Exhaust gas temperature reaches higher than 600 _C

( 1 ,11 2_F), and the learning value remains in the vicinity of

1 .0

B

Page 4413 of 5135

−

DIAGNOSTICS ECD SYSTEM (1CD −FTV)(From September, 2003)

05 −455

AVENSIS Supplement (RM 1045E)

B CHECK FOR INTERMITTENT PROBLEMS

(See page 05 −270)

A

1 5 REPLACE EXHAUST FUEL ADDITION INJECTOR ASSY (See page 14−1 66)

GO

16 PERFORM ACTIVE TEST USING HAND −HELD TESTER(DPNR CATALYST

REGENERATION)

(a) Clear the learning value by removing the negative battery cable for more than 1 minute.

(b) Connect the hand −held tester to the DLC3.

(c) Turn the ignition switch to ON and turn the hand −held tester ON.

(d) Select the item ”DIAGNOSIS / OBD/MOBD / ACTIVE TEST / DPNR REJU (PM)”.

(e) After warming up the engine, drive the vehicle at constant vehicle speed within 50 to 100 km/h (3 1 to

62 mph) (with smooth throttle operations) for more than 15 minutes.

(f) Select the item ”DIAGNOSIS / OBD/MOBD / DATA LIST / ALL / AF FT B 1 S1”.

(g) Select the item ”DIAGNOSIS / OBD/MOBD / DATA LIST / ALL / EX TEMP (IN) and EX TEMP (OUT)”.

(h) Select the item ”DIAGNOSIS / OBD/MOBD / DATA LIST / ALL / EX FUEL ADD FB”.

(i) Check that the exhaust gas temperatures (EX TEMP [IN] and [OUT]) and the learning value (EX FUEL ADD FB) are within the specification below.

Result:

ResultProceed to

Exhaust gas temperature does not reach higher than 600 _ C

( 1 ,11 2_ F)A

Exhaust gas temperature reaches higher than 600 _ C

( 1 ,11 2_F), and the learning value remains in the vicinity of

1 .0

B

B SYSTEM OK

A

REPLACE MANIFOLD CONVERTER SUB −ASSY (DPNR CATALYTIC CONVERTER)

(See page 14−1 08)

Page 4414 of 5135

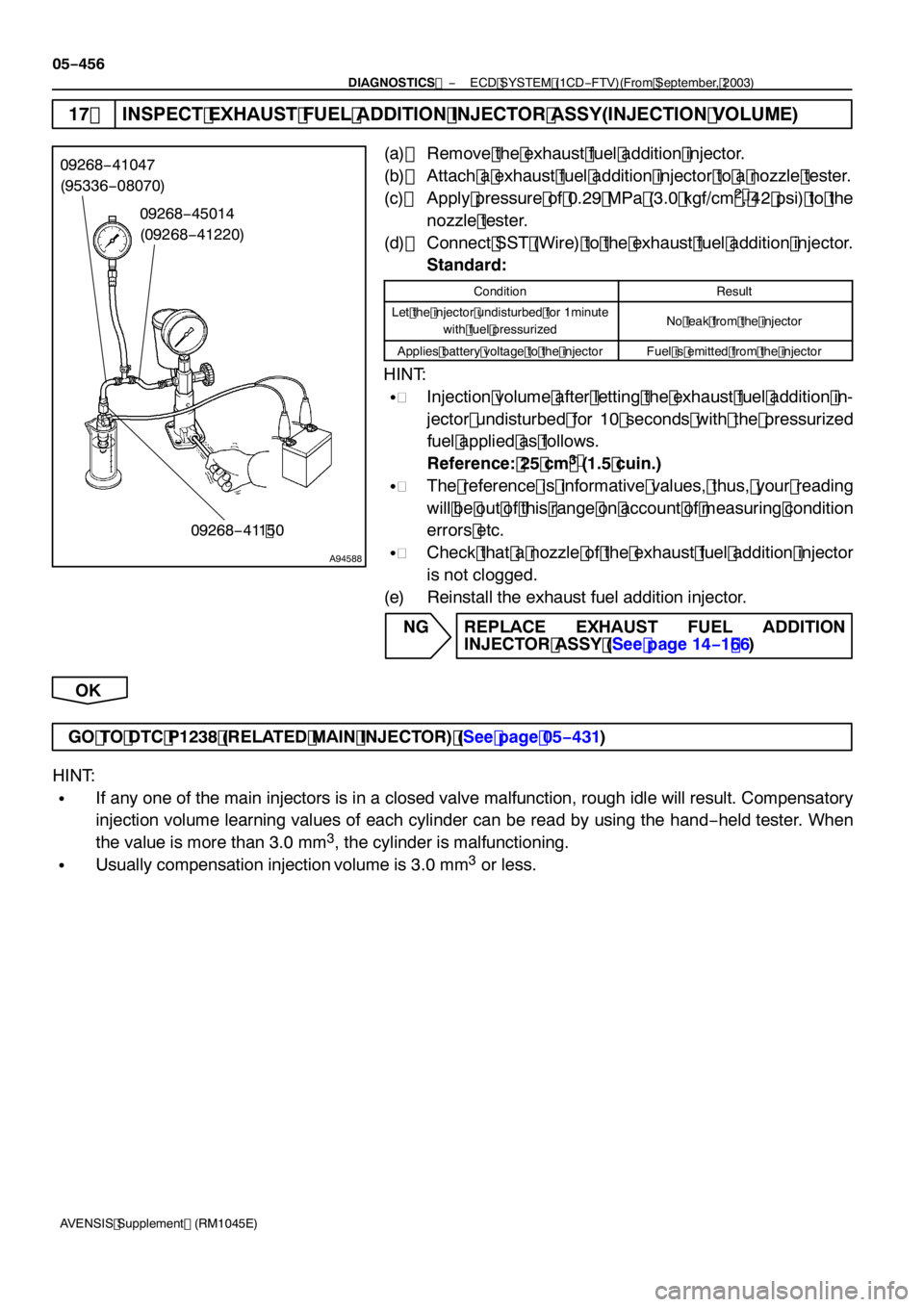

A94588

09268−41047

(95336 −08070)

09268 −450 14

(09268 −41220)

09268 −411 50

05 −456

−

DIAGNOSTICS ECD SYSTEM (1CD −FTV)(From September, 2003)

AVENSIS Supplement (RM 1045E)

17 INSPECT EXHAUST FUEL ADDITION INJECTOR ASSY(INJECTION VOLUME)

(a) Remove the exhaust fuel addition injector.

(b) Attach a exhaust fuel addition injector to a nozzle tester.

(c) Apply pressure of 0.29 MPa (3.0 kgf/cm

2 , 42 psi) to the

nozzle tester.

(d) Connect SST (Wire) to the exhaust fuel addition injector. Standard:

ConditionResult

Let the injector undisturbed for 1minute

with fuel pressurizedNo leak from the injector

Applies battery voltage to the injectorFuel is emitted from the injector

HINT:

S Injection volume after letting the exhaust fuel addition in-

jector undisturbed for 10 seconds with the pressurized

fuel applied as follows.

Reference: 25 cm

3 ( 1 .5 cuin.)

S The reference is informative values, thus, your reading

will be out of this range on account of measuring condition

errors etc.

S Check that a nozzle of the exhaust fuel addition injector

is not clogged.

(e) Reinstall the exhaust fuel addition injector.

NG REPLACE EXHAUST FUEL ADDITION INJECTOR ASSY (See page 14−1 66)

OK

GO TO DTC P 1238 (RELATED MAIN INJECTOR) (See page 05 −43 1)

HINT:

SIf any one of the main injectors is in a closed valve malfunction, rough idle will result. Compensatory

injection volume learning values of each cylinder can be read by using the hand −held tester. When

the value is more than 3.0 mm

3, the cylinder is malfunctioning.

SUsually compensation injection volume is 3.0 mm3or less.

Page 4415 of 5135

A81485

Fuel Pressure

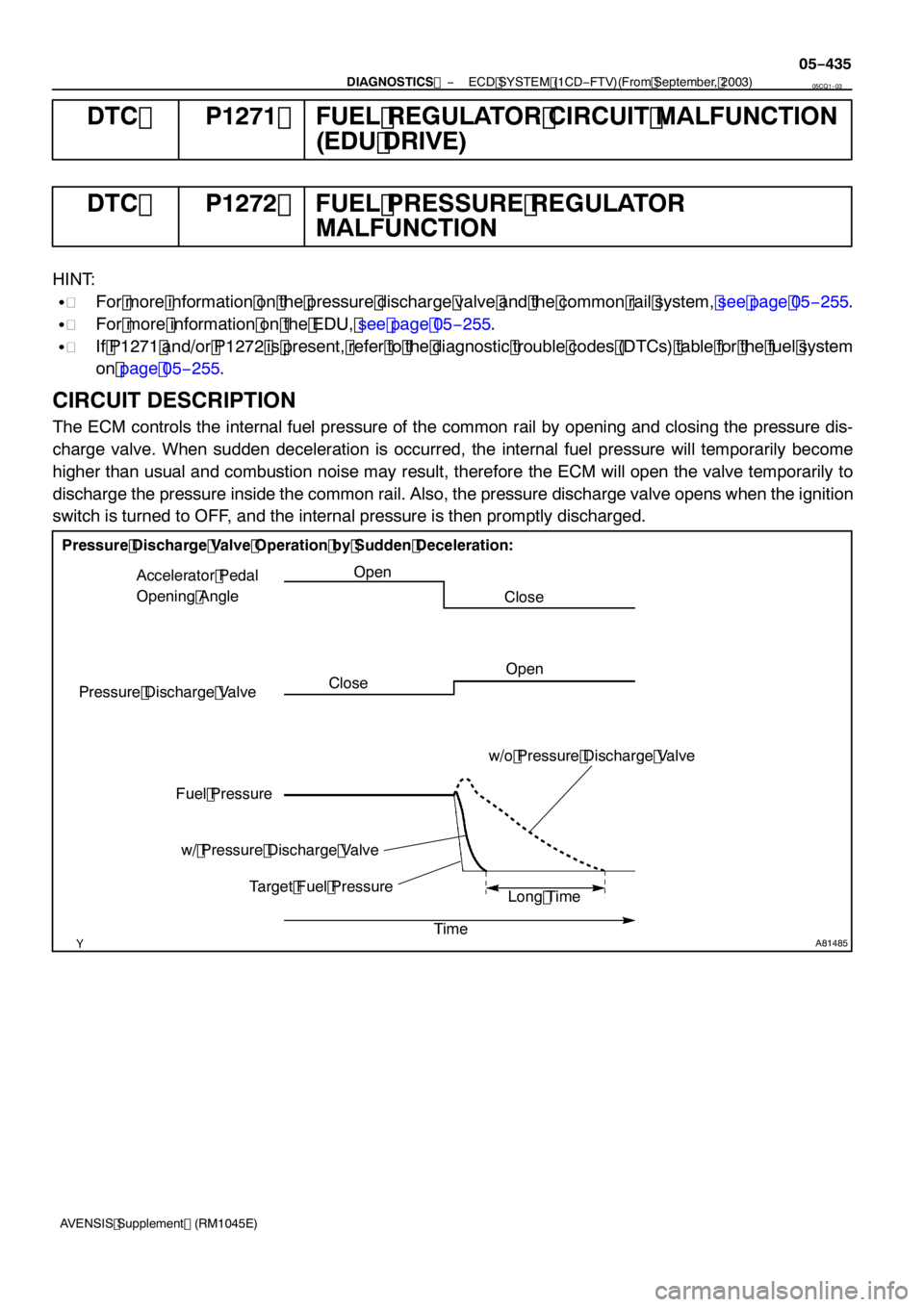

Pressure Discharge Valve Operation by Sudden Deceleration:

Pressure Discharge Valve w/o Pressure Discharge Valve

Close

Accelerator Pedal

Opening Angle

Open

Close

Open

w/ Pressure Discharge Valve

Target Fuel Pressure TimeLong Time

−

DIAGNOSTICS ECD SYSTEM (1CD−FTV)(From September, 2003)

05 −435

AVENSIS Supplement (RM1045E)

DTC P 127 1 FUEL REGULATOR CIRCUIT MALFUNCTION

(EDU DRIVE)

DTC P 1272 FUEL PRESSURE REGULATOR

MALFUNCTION

HINT:

S For more information on the pressure discharge valve and the common rail system, see page 05 −255.

S For more information on the EDU, see page 05 −255.

S If P1271 and/or P1272 is present, refer to the diagnostic trouble codes (DTCs) table for the fuel system

on page 05 −255.

CIRCUIT DESCRIPTION

The ECM controls the internal fuel pressure of the common rail by opening and closing the pressure dis-

charge valve. When sudden deceleration is occurred, the internal fuel pressure will temporarily become

higher than usual and combustion noise may result, therefore the ECM will open the valve temporarily to

discharge the pressure inside the common rail. Also, the pressure discharge valve opens when the ignition

switch is turned to OFF, and the internal pressure is then promptly discharged.

05CQ1 −03

Page 4416 of 5135

A81505

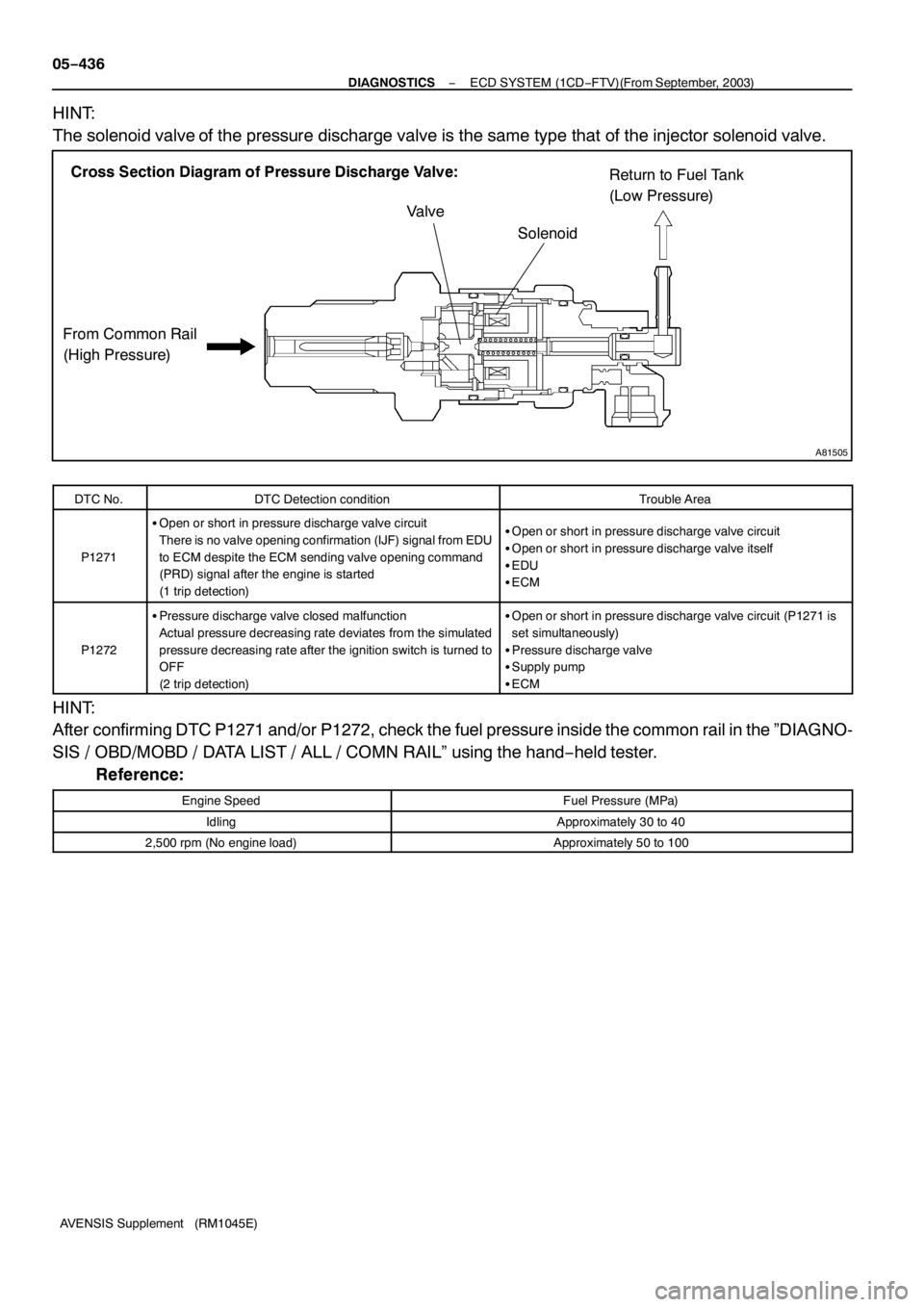

Cross Section Diagram of Pressure Discharge Valve:

From Common Rail

(High Pressure)Return to Fuel Tank

(Low Pressure)

Valve

Solenoid

05−436

− DIAGNOSTICSECD SYSTEM (1CD−FTV)(From September, 2003)

AVENSIS Supplement (RM1045E)

HINT:

The solenoid valve of the pressure discharge valve is the same type that of the injector solenoid valve.

DTC No.DTC Detection conditionTrouble Area

P1271

SOpen or short in pressure discharge valve circuit

There is no valve opening confirmation (IJF) signal from EDU

to ECM despite the ECM sending valve opening command

(PRD) signal after the engine is started

(1 trip detection)SOpen or short in pressure discharge valve circuit

SOpen or short in pressure discharge valve itself

SEDU

SECM

P1272

SPressure discharge valve closed malfunction

Actual pressure decreasing rate deviates from the simulated

pressure decreasing rate after the ignition switch is turned to

OFF

(2 trip detection)SOpen or short in pressure discharge valve circuit (P1271 is

set simultaneously)

SPressure discharge valve

SSupply pump

SECM

HINT:

After confirming DTC P1271 and/or P1272, check the fuel pressure inside the common rail in the ”DIAGNO-

SIS / OBD/MOBD / DATA LIST / ALL / COMN RAIL” using the hand−held tester.

Reference:

Engine SpeedFuel Pressure (MPa)

IdlingApproximately 30 to 40

2,500 rpm (No engine load)Approximately 50 to 100

Page 4417 of 5135

A81500

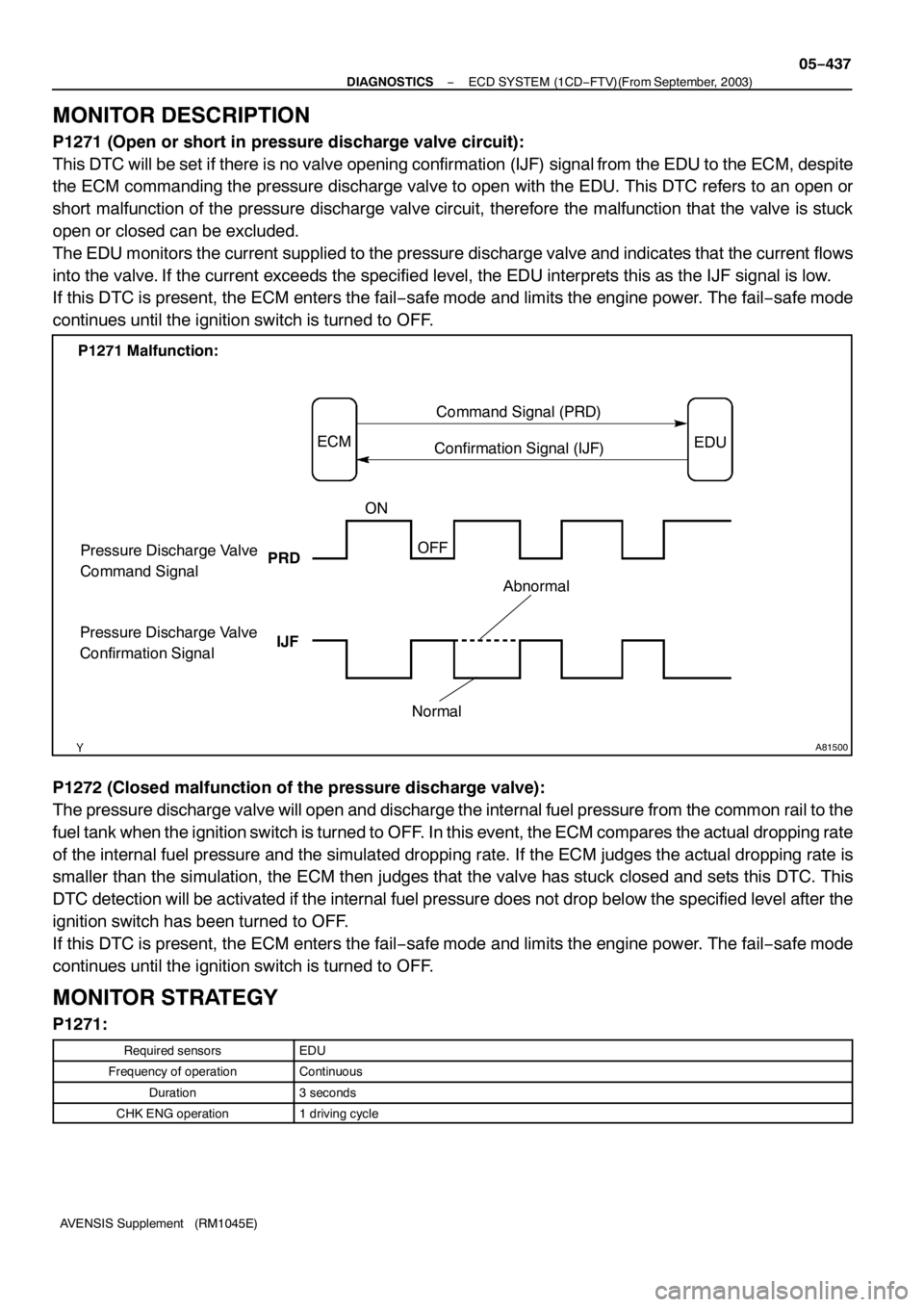

P1271Malfunction:

ECMCommand Signal (PRD)

EDU

Confirmation Signal (IJF)

Pressure Discharge Valve

Command Signal

Pressure Discharge Valve

Confirmation SignalPRD

IJFON

OFF

Normal

Abnormal

− DIAGNOSTICSECD SYSTEM (1CD−FTV)(From September, 2003)

05−437

AVENSIS Supplement (RM1045E)

MONITOR DESCRIPTION

P1271(Open or short in pressure discharge valve circuit):

This DTC will be set if there is no valve opening confirmation (IJF) signal from the EDU to the ECM, despite

the ECM commanding the pressure discharge valve to open with the EDU. This DTC refers to an open or

short malfunction of the pressure discharge valve circuit, therefore the malfunction that the valve is stuck

open or closed can be excluded.

The EDU monitors the current supplied to the pressure discharge valve and indicates that the current flows

into the valve. If the current exceeds the specified level, the EDU interprets this as the IJF signal is low.

If this DTC is present, the ECM enters the fail−safe mode and limits the engine power. The fail−safe mode

continues until the ignition switch is turned to OFF.

P1272 (Closed malfunction of the pressure discharge valve):

The pressure discharge valve will open and discharge the internal fuel pressure from the common rail to the

fuel tank when the ignition switch is turned to OFF. In this event, the ECM compares the actual dropping rate

of the internal fuel pressure and the simulated dropping rate. If the ECM judges the actual dropping rate is

smaller than the simulation, the ECM then judges that the valve has stuck closed and sets this DTC. This

DTC detection will be activated if the internal fuel pressure does not drop below the specified level after the

ignition switch has been turned to OFF.

If this DTC is present, the ECM enters the fail−safe mode and limits the engine power. The fail−safe mode

continues until the ignition switch is turned to OFF.

MONITOR STRATEGY

P1271:

Required sensorsEDU

Frequency of operationContinuous

Duration3 seconds

CHK ENG operation1 driving cycle

Page 4418 of 5135

05−438

− DIAGNOSTICSECD SYSTEM (1CD−FTV)(From September, 2003)

AVENSIS Supplement (RM1045E)

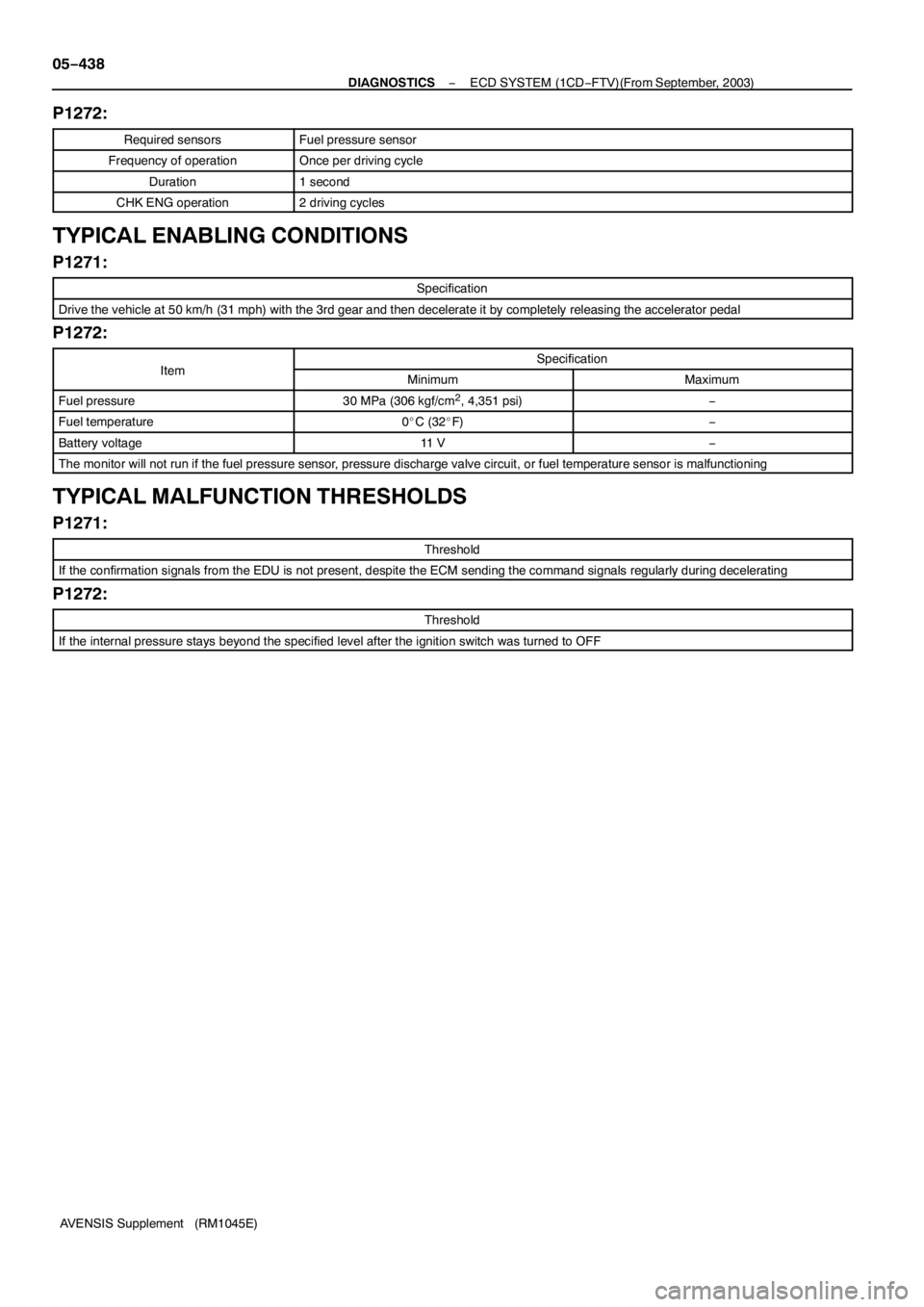

P1272:

Required sensorsFuel pressure sensor

Frequency of operationOnce per driving cycle

Duration1 second

CHK ENG operation2 driving cycles

TYPICAL ENABLING CONDITIONS

P1271:

Specification

Drive the vehicle at 50 km/h (31 mph) with the 3rd gear and then decelerate it by completely releasing the accelerator pedal

P1272:

ItemSpecificationItemMinimumMaximum

Fuel pressure30 MPa (306 kgf/cm2, 4,351 psi)−

Fuel temperature0_C (32_F)−

Battery voltage11 V−

The monitor will not run if the fuel pressure sensor, pressure discharge valve circuit, or fuel temperature sensor is malfunctioning

TYPICAL MALFUNCTION THRESHOLDS

P1271:

Threshold

If the confirmation signals from the EDU is not present, despite the ECM sending the command signals regularly during decelerating

P1272:

Threshold

If the internal pressure stays beyond the specified level after the ignition switch was turned to OFF

Page 4419 of 5135

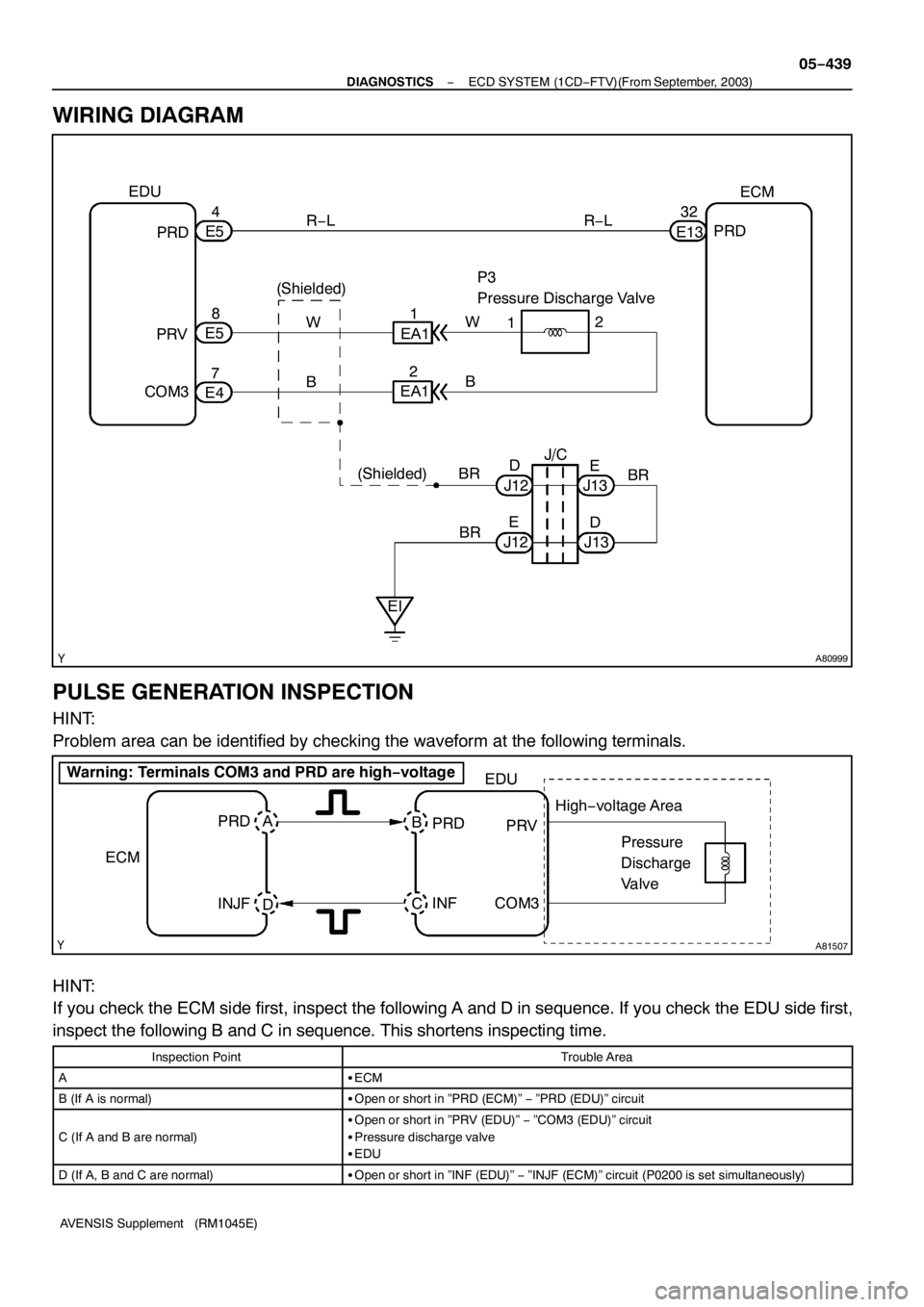

A80999

EDU

1 R−L

PRDECM

E1332

1

EA1 PRDR−L

E54

W

PRVE58

B

COM3

E472 P3

Pressure Discharge Valve

W

B 2

EA1

(Shielded) (Shielded)

BR

BR

BR

EIJ12D

J12E

J13D J13E J/C

A81507

ECMEDU

PRD

Pressure

Discharge

Valve

INJFCOM3 A

PRD

INFPRV B

C

D

Warning: Terminals COM3 and PRD are high−voltage

High−voltage Area

− DIAGNOSTICSECD SYSTEM (1CD−FTV)(From September, 2003)

05−439

AVENSIS Supplement (RM1045E)

WIRING DIAGRAM

PULSE GENERATION INSPECTION

HINT:

Problem area can be identified by checking the waveform at the following terminals.

HINT:

If you check the ECM side first, inspect the following A and D in sequence. If you check the EDU side first,

inspect the following B and C in sequence. This shortens inspecting time.

Inspection PointTrouble Area

ASECM

B (If A is normal)SOpen or short in ”PRD (ECM)”−”PRD (EDU)” circuit

C (If A and B are normal)

SOpen or short in ”PRV (EDU)”−”COM3 (EDU)” circuit

SPressure discharge valve

SEDU

D (If A, B and C are normal)SOpen or short in ”INF (EDU)”−”INJF (ECM)” circuit (P0200 is set simultaneously)

Page 4420 of 5135

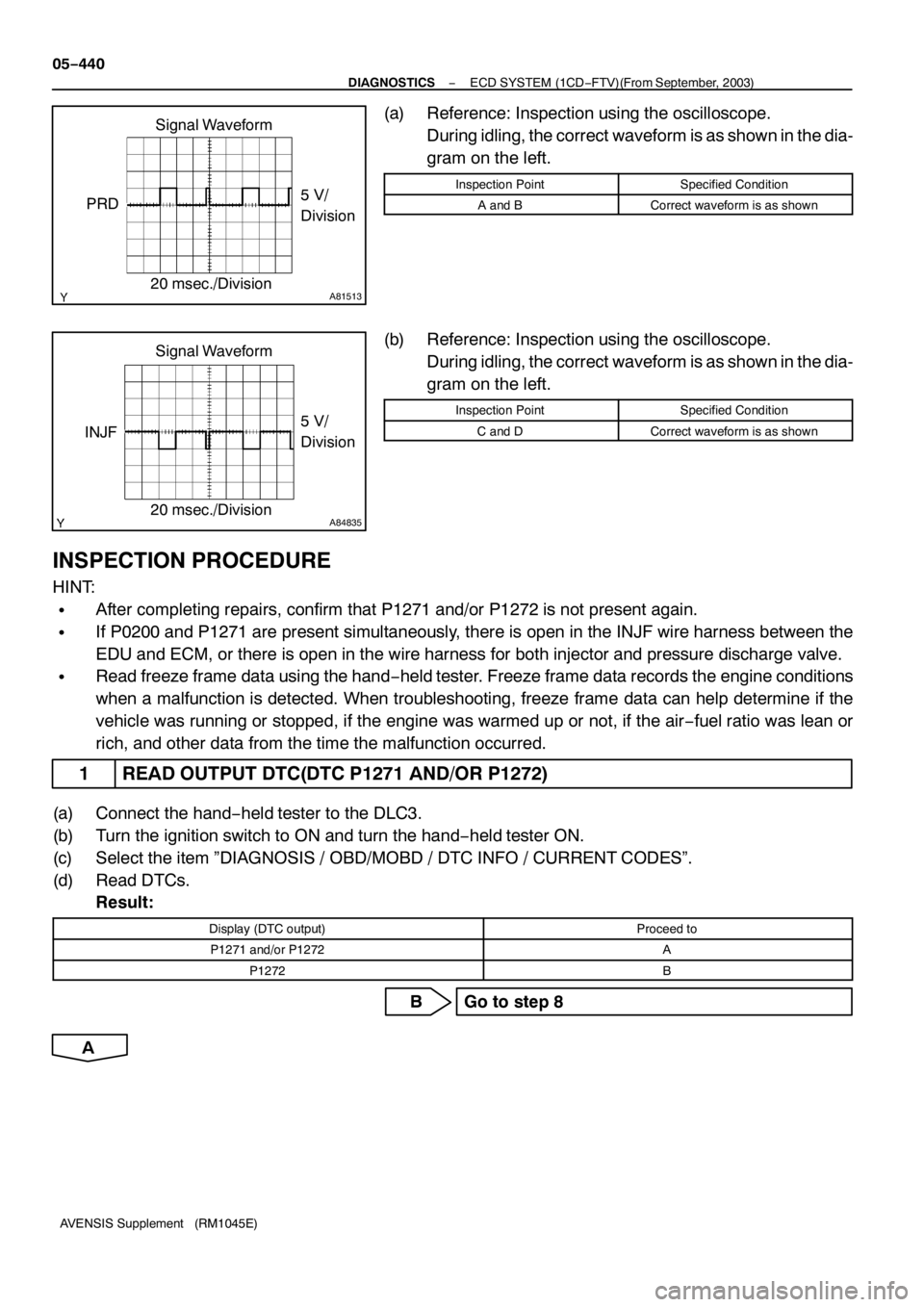

A81513

5V/

Division

20 msec./Division PRDSignal Waveform

A84835

5V/

Division

20 msec./Division INJFSignal Waveform

05−440

− DIAGNOSTICSECD SYSTEM (1CD−FTV)(From September, 2003)

AVENSIS Supplement (RM1045E)

(a) Reference: Inspection using the oscilloscope.

During idling, the correct waveform is as shown in the dia-

gram on the left.

Inspection PointSpecified Condition

A and BCorrect waveform is as shown

(b) Reference: Inspection using the oscilloscope.

During idling, the correct waveform is as shown in the dia-

gram on the left.

Inspection PointSpecified Condition

C and DCorrect waveform is as shown

INSPECTION PROCEDURE

HINT:

SAfter completing repairs, confirm that P1271 and/or P1272 is not present again.

SIf P0200 and P1271 are present simultaneously, there is open in the INJF wire harness between the

EDU and ECM, or there is open in the wire harness for both injector and pressure discharge valve.

SRead freeze frame data using the hand−held tester. Freeze frame data records the engine conditions

when a malfunction is detected. When troubleshooting, freeze frame data can help determine if the

vehicle was running or stopped, if the engine was warmed up or not, if the air−fuel ratio was lean or

rich, and other data from the time the malfunction occurred.

1READ OUTPUT DTC(DTC P1271AND/OR P1272)

(a) Connect the hand−held tester to the DLC3.

(b) Turn the ignition switch to ON and turn the hand−held tester ON.

(c) Select the item ”DIAGNOSIS / OBD/MOBD / DTC INFO / CURRENT CODES”.

(d) Read DTCs.

Result:

Display (DTC output)Proceed to

P1271 and/or P1272A

P1272B

B Go to step 8

A