TOYOTA AVENSIS 2005 Service Repair Manual

Manufacturer: TOYOTA, Model Year: 2005, Model line: AVENSIS, Model: TOYOTA AVENSIS 2005Pages: 5135, PDF Size: 95.28 MB

Page 4781 of 5135

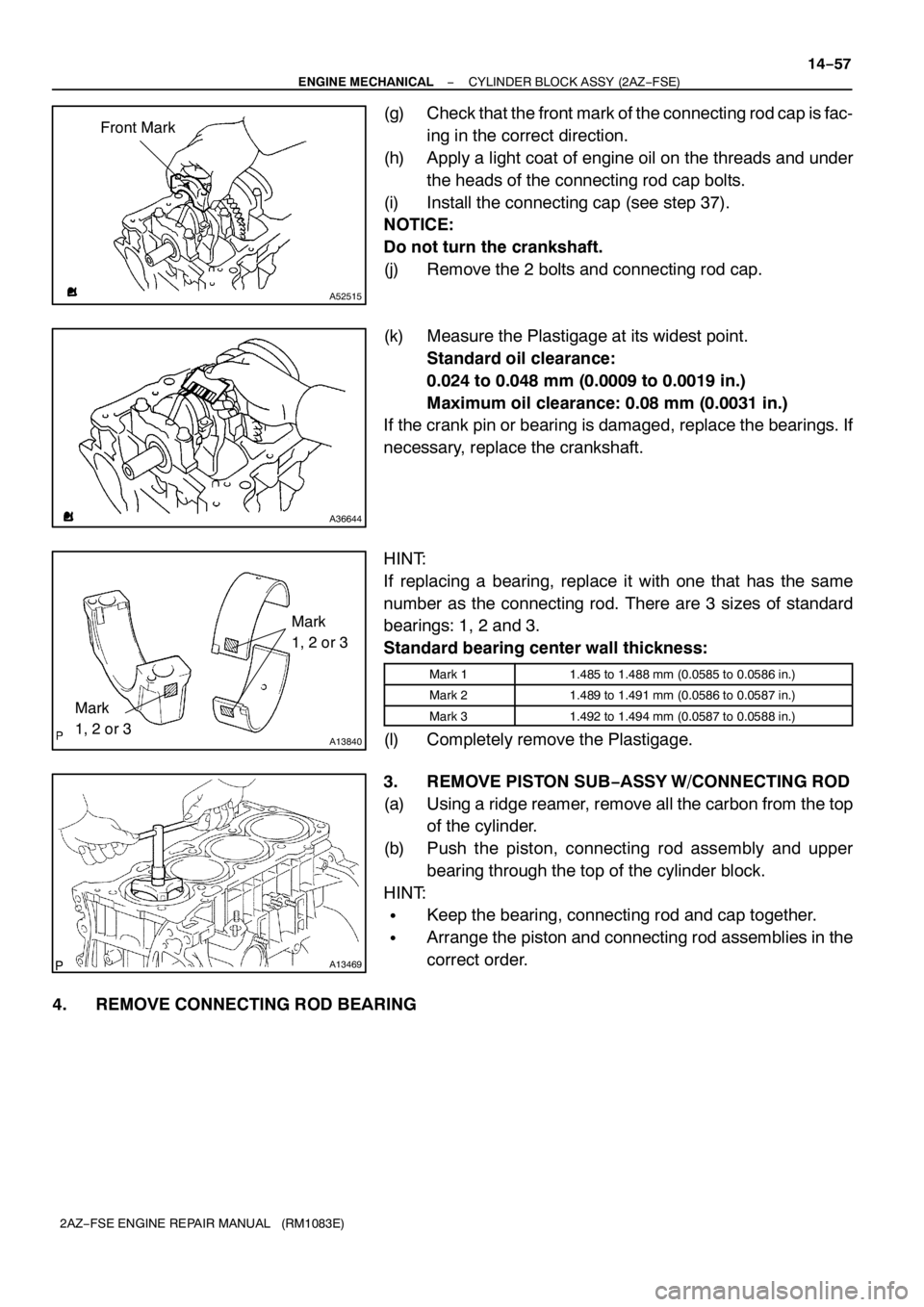

Front Mark

A52515

A36644

Mark

1, 2 or 3Mark

1, 2 or 3

A13840

A13469

− ENGINE MECHANICALCYLINDER BLOCK ASSY (2AZ−FSE)

14−57

2AZ−FSE ENGINE REPAIR MANUAL (RM1083E)

(g) Check that the front mark of the connecting rod cap is fac-

ing in the correct direction.

(h) Apply a light coat of engine oil on the threads and under

the heads of the connecting rod cap bolts.

(i) Install the connecting cap (see step 37).

NOTICE:

Do not turn the crankshaft.

(j) Remove the 2 bolts and connecting rod cap.

(k) Measure the Plastigage at its widest point.

Standard oil clearance:

0.024 to 0.048 mm (0.0009 to 0.0019 in.)

Maximum oil clearance: 0.08 mm (0.0031 in.)

If the crank pin or bearing is damaged, replace the bearings. If

necessary, replace the crankshaft.

HINT:

If replacing a bearing, replace it with one that has the same

number as the connecting rod. There are 3 sizes of standard

bearings: 1, 2 and 3.

Standard bearing center wall thickness:

Mark 11.485 to 1.488 mm (0.0585 to 0.0586 in.)

Mark 21.489 to 1.491 mm (0.0586 to 0.0587 in.)

Mark 31.492 to 1.494 mm (0.0587 to 0.0588 in.)

(l) Completely remove the Plastigage.

3. REMOVE PISTON SUB−ASSY W/CONNECTING ROD

(a) Using a ridge reamer, remove all the carbon from the top

of the cylinder.

(b) Push the piston, connecting rod assembly and upper

bearing through the top of the cylinder block.

HINT:

SKeep the bearing, connecting rod and cap together.

SArrange the piston and connecting rod assemblies in the

correct order.

4. REMOVE CONNECTING ROD BEARING

Page 4782 of 5135

A36647

A13478

A01178

80 to 90_C

A01179

A36645

14−58

− ENGINE MECHANICALCYLINDER BLOCK ASSY (2AZ−FSE)

2AZ−FSE ENGINE REPAIR MANUAL (RM1083E)

5. REMOVE PISTON RING SET

(a) Using a piston ring expander, remove the 2 compression

rings.

(b) Remove the 2 side rails and oil ring by hand.

6. REMOVE PISTON PIN HOLE SNAP RING

(a) Using a small screwdriver, pry out the 2 snap rings.

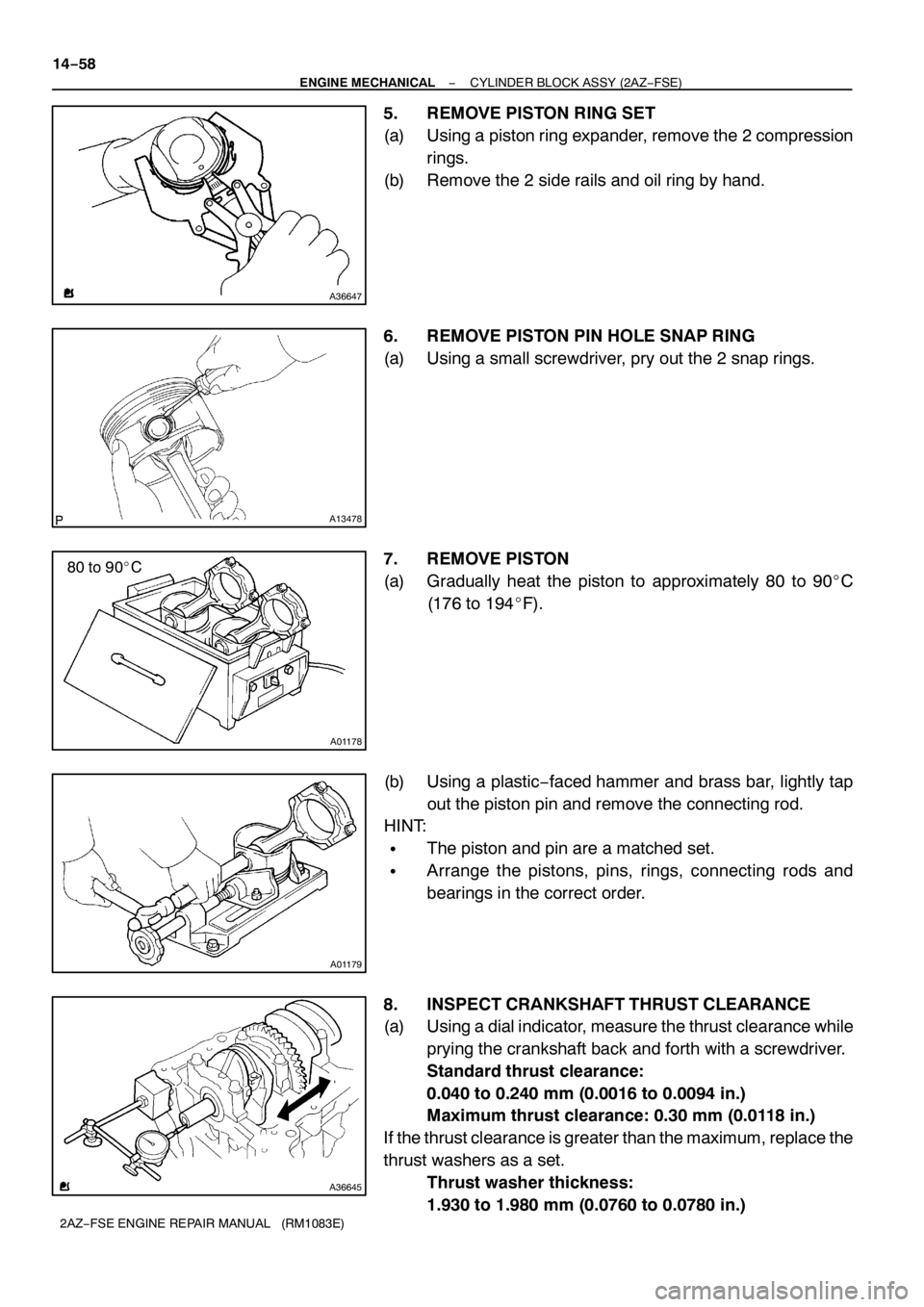

7. REMOVE PISTON

(a) Gradually heat the piston to approximately 80 to 90_C

(176 to 194_F).

(b) Using a plastic−faced hammer and brass bar, lightly tap

out the piston pin and remove the connecting rod.

HINT:

SThe piston and pin are a matched set.

SArrange the pistons, pins, rings, connecting rods and

bearings in the correct order.

8. INSPECT CRANKSHAFT THRUST CLEARANCE

(a) Using a dial indicator, measure the thrust clearance while

prying the crankshaft back and forth with a screwdriver.

Standard thrust clearance:

0.040 to 0.240 mm (0.0016 to 0.0094 in.)

Maximum thrust clearance: 0.30 mm (0.0118 in.)

If the thrust clearance is greater than the maximum, replace the

thrust washers as a set.

Thrust washer thickness:

1.930 to 1.980 mm (0.0760 to 0.0780 in.)

Page 4783 of 5135

A87780

1

2

3

4

5

68

79

10

A87781

A87782

Plastigage

A87783

− ENGINE MECHANICALCYLINDER BLOCK ASSY (2AZ−FSE)

14−59

2AZ−FSE ENGINE REPAIR MANUAL (RM1083E)

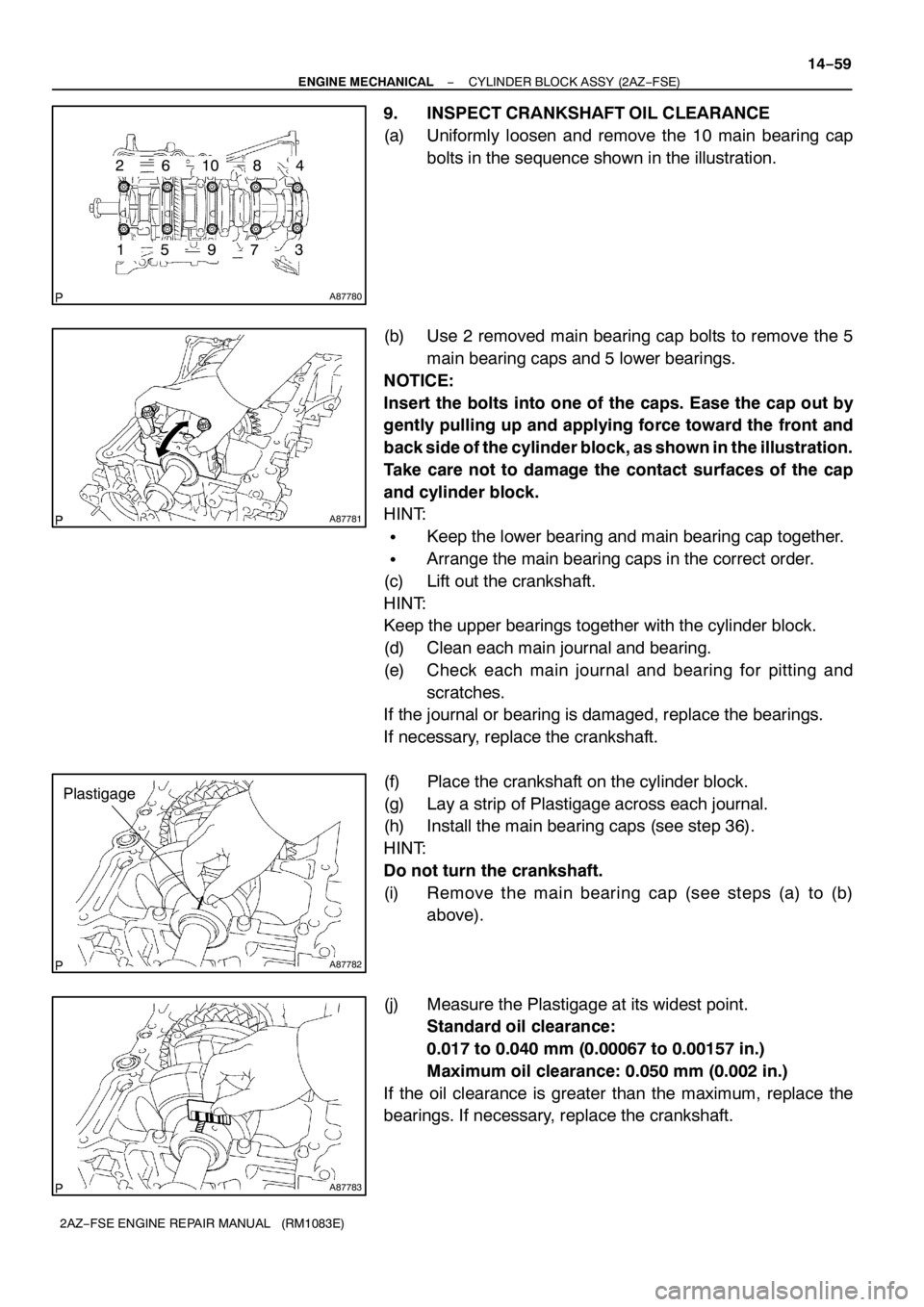

9. INSPECT CRANKSHAFT OIL CLEARANCE

(a) Uniformly loosen and remove the 10 main bearing cap

bolts in the sequence shown in the illustration.

(b) Use 2 removed main bearing cap bolts to remove the 5

main bearing caps and 5 lower bearings.

NOTICE:

Insert the bolts into one of the caps. Ease the cap out by

gently pulling up and applying force toward the front and

back side of the cylinder block, as shown in the illustration.

Take care not to damage the contact surfaces of the cap

and cylinder block.

HINT:

SKeep the lower bearing and main bearing cap together.

SArrange the main bearing caps in the correct order.

(c) Lift out the crankshaft.

HINT:

Keep the upper bearings together with the cylinder block.

(d) Clean each main journal and bearing.

(e) Check each main journal and bearing for pitting and

scratches.

If the journal or bearing is damaged, replace the bearings.

If necessary, replace the crankshaft.

(f) Place the crankshaft on the cylinder block.

(g) Lay a strip of Plastigage across each journal.

(h) Install the main bearing caps (see step 36).

HINT:

Do not turn the crankshaft.

(i) Remove the main bearing cap (see steps (a) to (b)

above).

(j) Measure the Plastigage at its widest point.

Standard oil clearance:

0.017 to 0.040 mm (0.00067 to 0.00157 in.)

Maximum oil clearance: 0.050 mm (0.002 in.)

If the oil clearance is greater than the maximum, replace the

bearings. If necessary, replace the crankshaft.

Page 4784 of 5135

A87784

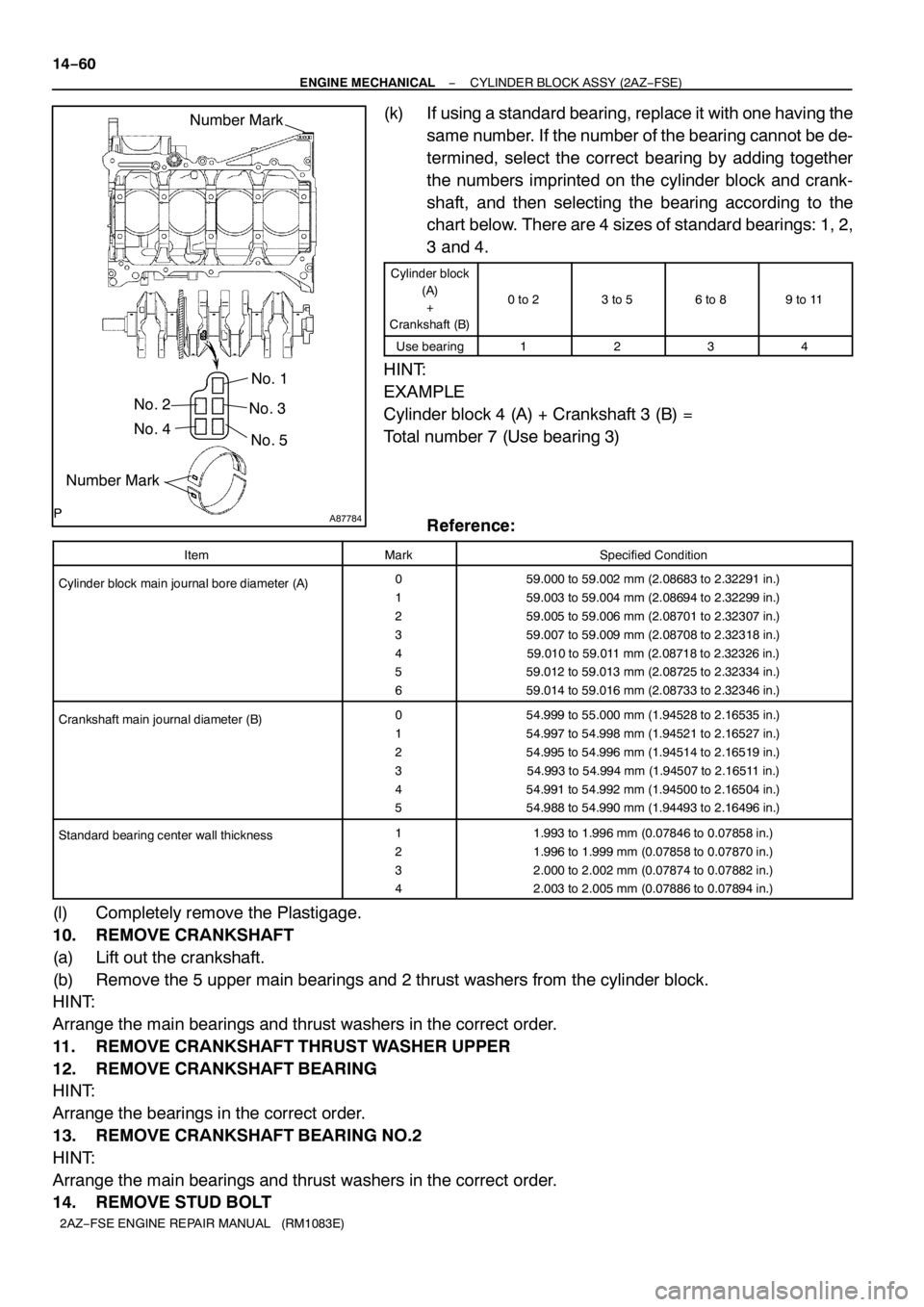

Number Mark

Number Mark

No. 1

No. 2

No. 3

No. 4

No. 5

14−60

− ENGINE MECHANICALCYLINDER BLOCK ASSY (2AZ−FSE)

2AZ−FSE ENGINE REPAIR MANUAL (RM1083E)

(k) If using a standard bearing, replace it with one having the

same number. If the number of the bearing cannot be de-

termined, select the correct bearing by adding together

the numbers imprinted on the cylinder block and crank-

shaft, and then selecting the bearing according to the

chart below. There are 4 sizes of standard bearings: 1, 2,

3 and 4.

Cylinder block

(A)

+

Crankshaft (B)

0to23to56to89to11

Use bearing1234

HINT:

EXAMPLE

Cylinder block 4 (A) + Crankshaft 3 (B) =

Total number 7 (Use bearing 3)

Reference:

ItemMarkSpecified Condition

Cylinder block main journal bore diameter (A)0

1

2

3

4

5

659.000 to 59.002 mm (2.08683 to 2.32291 in.)

59.003 to 59.004 mm (2.08694 to 2.32299 in.)

59.005 to 59.006 mm (2.08701 to 2.32307 in.)

59.007 to 59.009 mm (2.08708 to 2.32318 in.)

59.010 to 59.011 mm (2.08718 to 2.32326 in.)

59.012 to 59.013 mm (2.08725 to 2.32334 in.)

59.014 to 59.016 mm (2.08733 to 2.32346 in.)

Crankshaft main journal diameter (B)0

1

2

3

4

554.999 to 55.000 mm (1.94528 to 2.16535 in.)

54.997 to 54.998 mm (1.94521 to 2.16527 in.)

54.995 to 54.996 mm (1.94514 to 2.16519 in.)

54.993 to 54.994 mm (1.94507 to 2.16511 in.)

54.991 to 54.992 mm (1.94500 to 2.16504 in.)

54.988 to 54.990 mm (1.94493 to 2.16496 in.)

Standard bearing center wall thickness1

2

3

41.993 to 1.996 mm (0.07846 to 0.07858 in.)

1.996 to 1.999 mm (0.07858 to 0.07870 in.)

2.000 to 2.002 mm (0.07874 to 0.07882 in.)

2.003 to 2.005 mm (0.07886 to 0.07894 in.)

(l) Completely remove the Plastigage.

10. REMOVE CRANKSHAFT

(a) Lift out the crankshaft.

(b) Remove the 5 upper main bearings and 2 thrust washers from the cylinder block.

HINT:

Arrange the main bearings and thrust washers in the correct order.

11. REMOVE CRANKSHAFT THRUST WASHER UPPER

12. REMOVE CRANKSHAFT BEARING

HINT:

Arrange the bearings in the correct order.

13. REMOVE CRANKSHAFT BEARING NO.2

HINT:

Arrange the main bearings and thrust washers in the correct order.

14. REMOVE STUD BOLT

Page 4785 of 5135

A36648

Thrust Direction

Axial Direction

Front

A88899

10 mm A

B

− ENGINE MECHANICALCYLINDER BLOCK ASSY (2AZ−FSE)

14−61

2AZ−FSE ENGINE REPAIR MANUAL (RM1083E)

15. CLEAN CYLINDER BLOCK

NOTICE:

If the cylinder is washed at high temperatures, the cylinder liner sticks out beyond the cylinder block.

Always wash the cylinder block at a temperature of 45_C(113_F) or less.

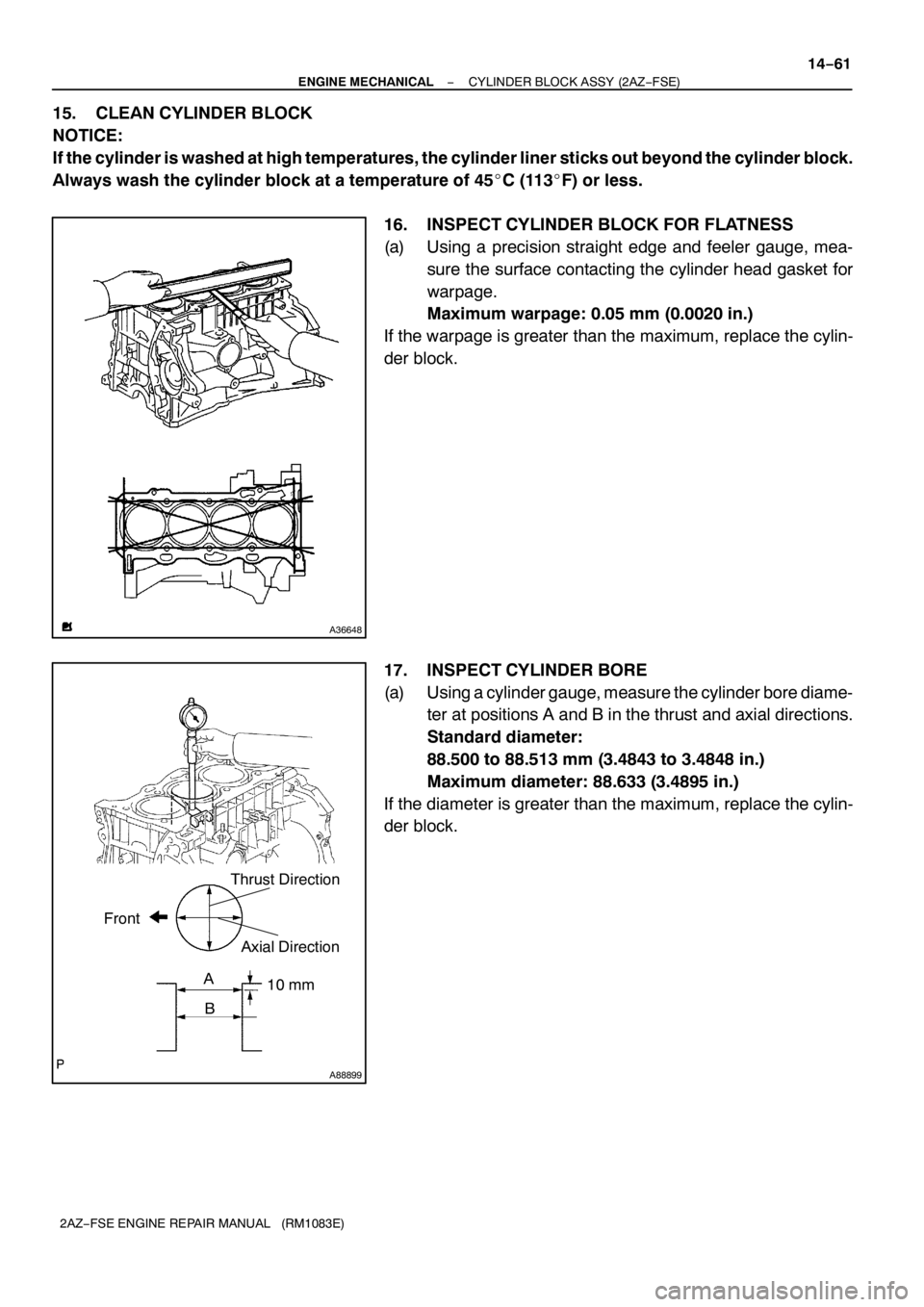

16. INSPECT CYLINDER BLOCK FOR FLATNESS

(a) Using a precision straight edge and feeler gauge, mea-

sure the surface contacting the cylinder head gasket for

warpage.

Maximum warpage: 0.05 mm (0.0020 in.)

If the warpage is greater than the maximum, replace the cylin-

der block.

17. INSPECT CYLINDER BORE

(a) Using a cylinder gauge, measure the cylinder bore diame-

ter at positions A and B in the thrust and axial directions.

Standard diameter:

88.500 to 88.513 mm (3.4843 to 3.4848 in.)

Maximum diameter: 88.633 (3.4895 in.)

If the diameter is greater than the maximum, replace the cylin-

der block.

Page 4786 of 5135

A92496

30.3 mm

A36650

Piston Ring11 0 m mA53017

EM2552

14−62

− ENGINE MECHANICALCYLINDER BLOCK ASSY (2AZ−FSE)

2AZ−FSE ENGINE REPAIR MANUAL (RM1083E)

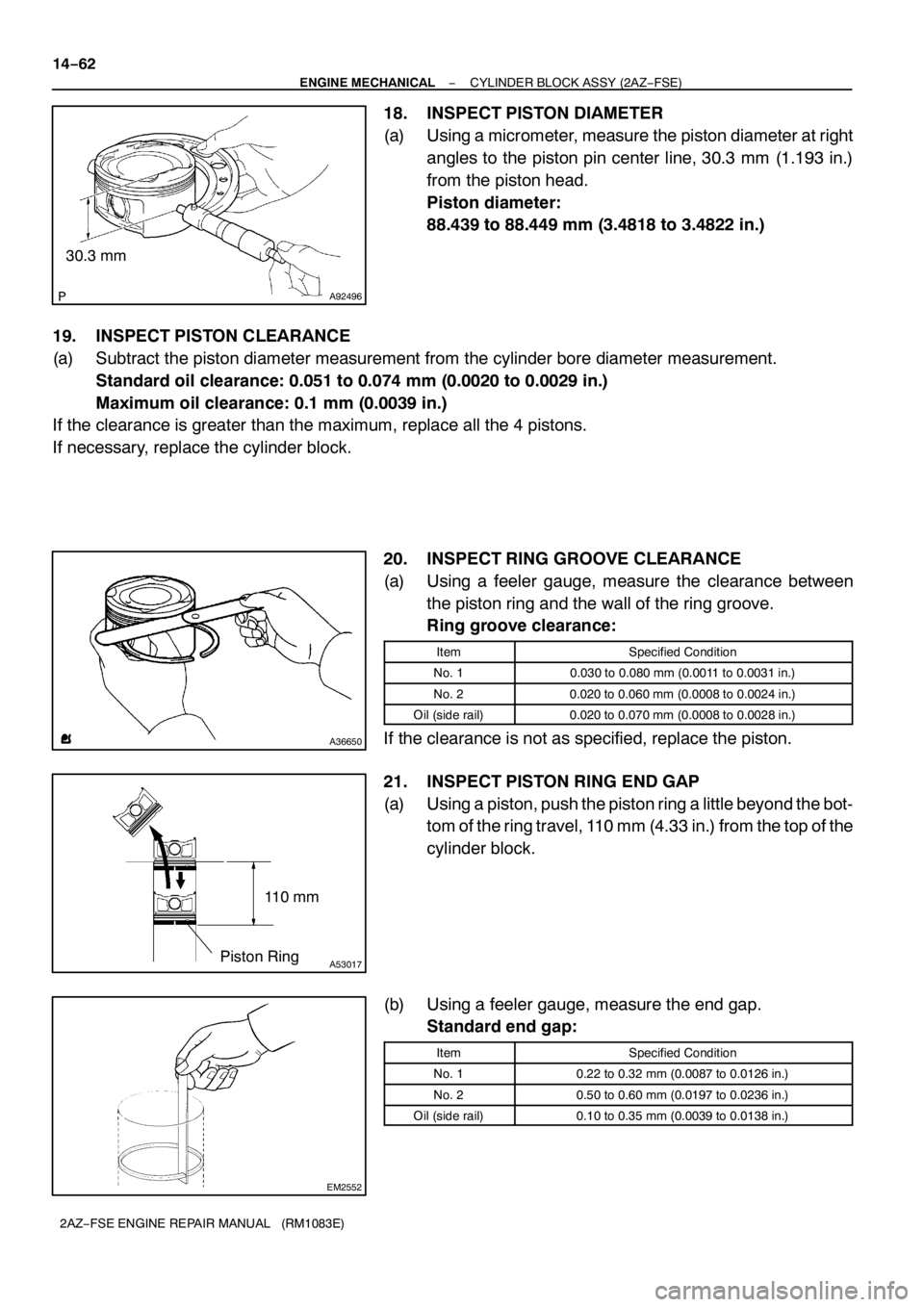

18. INSPECT PISTON DIAMETER

(a) Using a micrometer, measure the piston diameter at right

angles to the piston pin center line, 30.3 mm (1.193 in.)

from the piston head.

Piston diameter:

88.439 to 88.449 mm (3.4818 to 3.4822 in.)

19. INSPECT PISTON CLEARANCE

(a) Subtract the piston diameter measurement from the cylinder bore diameter measurement.

Standard oil clearance: 0.051 to 0.074 mm (0.0020 to 0.0029 in.)

Maximum oil clearance: 0.1 mm (0.0039 in.)

If the clearance is greater than the maximum, replace all the 4 pistons.

If necessary, replace the cylinder block.

20. INSPECT RING GROOVE CLEARANCE

(a) Using a feeler gauge, measure the clearance between

the piston ring and the wall of the ring groove.

Ring groove clearance:

ItemSpecified Condition

No. 10.030 to 0.080 mm (0.0011 to 0.0031 in.)

No. 20.020 to 0.060 mm (0.0008 to 0.0024 in.)

Oil (side rail)0.020 to 0.070 mm (0.0008 to 0.0028 in.)

If the clearance is not as specified, replace the piston.

21. INSPECT PISTON RING END GAP

(a) Using a piston, push the piston ring a little beyond the bot-

tom of the ring travel, 110 mm (4.33 in.) from the top of the

cylinder block.

(b) Using a feeler gauge, measure the end gap.

Standard end gap:

ItemSpecified Condition

No. 10.22 to 0.32 mm (0.0087 to 0.0126 in.)

No. 20.50 to 0.60 mm (0.0197 to 0.0236 in.)

Oil (side rail)0.10 to 0.35 mm (0.0039 to 0.0138 in.)

Page 4787 of 5135

A13490

EM0227

A01185

− ENGINE MECHANICALCYLINDER BLOCK ASSY (2AZ−FSE)

14−63

2AZ−FSE ENGINE REPAIR MANUAL (RM1083E)

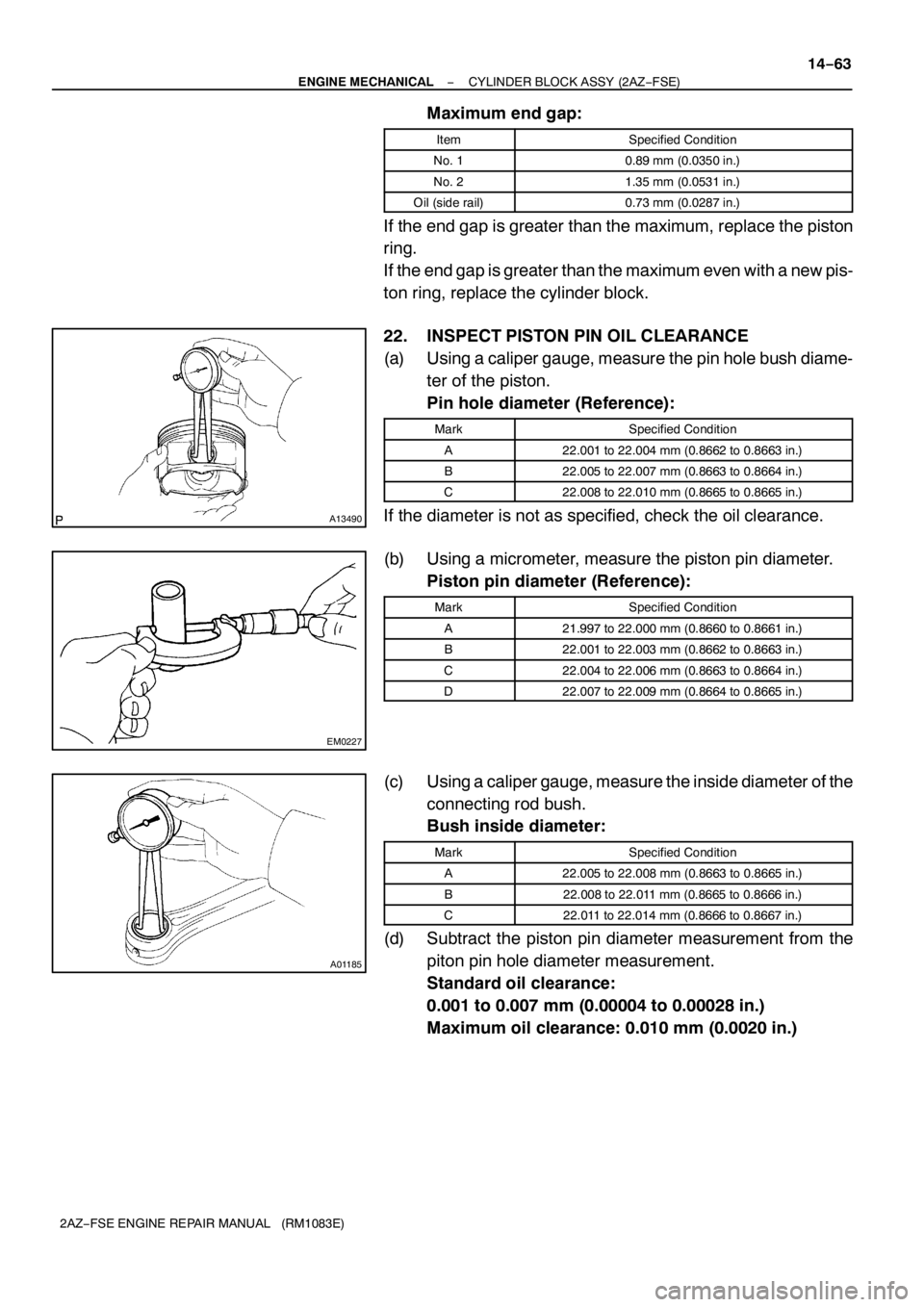

Maximum end gap:

ItemSpecified Condition

No. 10.89 mm (0.0350 in.)

No. 21.35 mm (0.0531 in.)

Oil (side rail)0.73 mm (0.0287 in.)

If the end gap is greater than the maximum, replace the piston

ring.

If the end gap is greater than the maximum even with a new pis-

ton ring, replace the cylinder block.

22. INSPECT PISTON PIN OIL CLEARANCE

(a) Using a caliper gauge, measure the pin hole bush diame-

ter of the piston.

Pin hole diameter (Reference):

MarkSpecified Condition

A22.001 to 22.004 mm (0.8662 to 0.8663 in.)

B22.005 to 22.007 mm (0.8663 to 0.8664 in.)

C22.008 to 22.010 mm (0.8665 to 0.8665 in.)

If the diameter is not as specified, check the oil clearance.

(b) Using a micrometer, measure the piston pin diameter.

Piston pin diameter (Reference):

MarkSpecified Condition

A21.997 to 22.000 mm (0.8660 to 0.8661 in.)

B22.001 to 22.003 mm (0.8662 to 0.8663 in.)

C22.004 to 22.006 mm (0.8663 to 0.8664 in.)

D22.007 to 22.009 mm (0.8664 to 0.8665 in.)

(c) Using a caliper gauge, measure the inside diameter of the

connecting rod bush.

Bush inside diameter:

MarkSpecified Condition

A22.005 to 22.008 mm (0.8663 to 0.8665 in.)

B22.008 to 22.011 mm (0.8665 to 0.8666 in.)

C22.011 to 22.014 mm (0.8666 to 0.8667 in.)

(d) Subtract the piston pin diameter measurement from the

piton pin hole diameter measurement.

Standard oil clearance:

0.001 to 0.007 mm (0.00004 to 0.00028 in.)

Maximum oil clearance: 0.010 mm (0.0020 in.)

Page 4788 of 5135

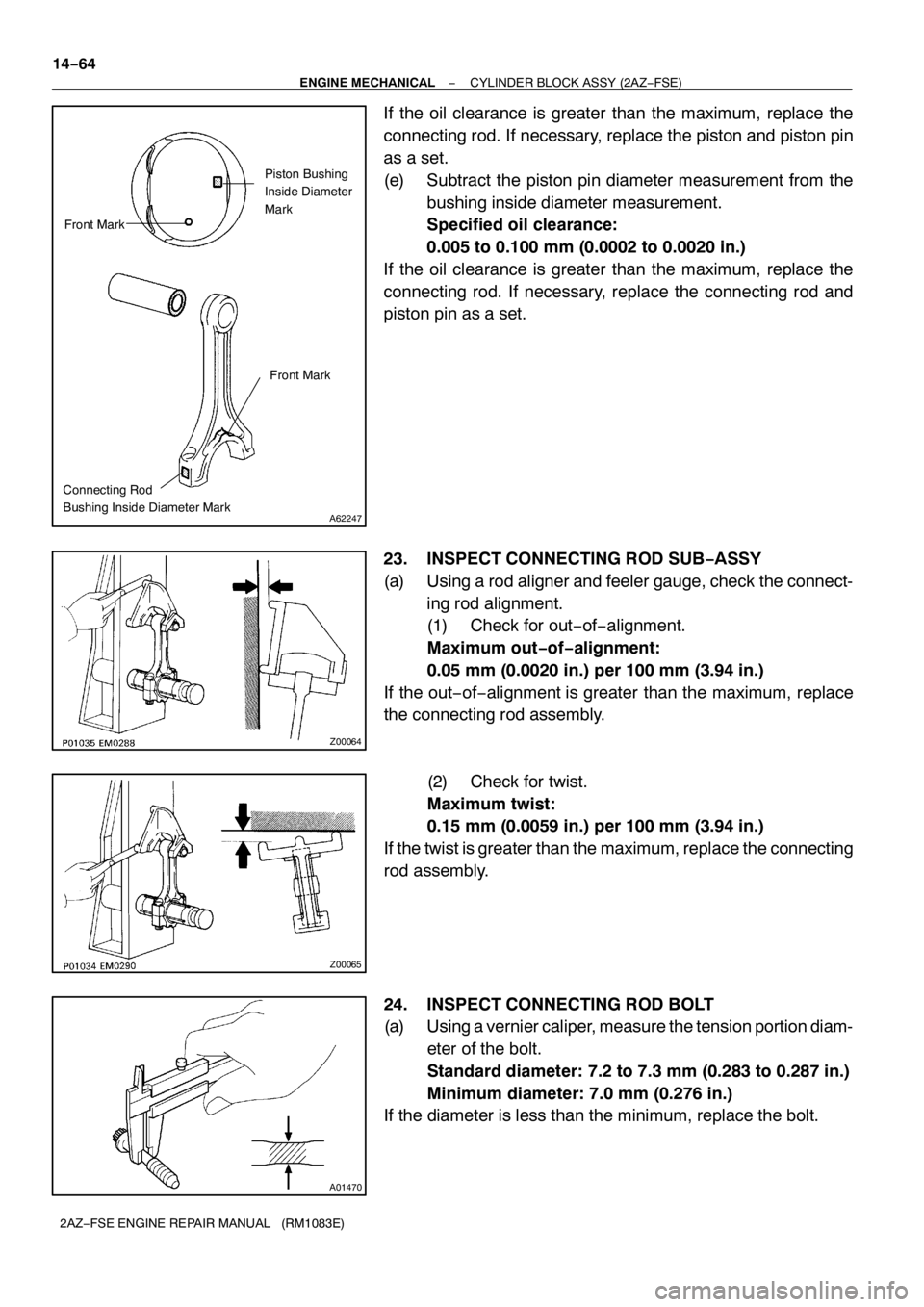

Piston Bushing

Inside Diameter

Mark

Connecting Rod

Bushing Inside Diameter MarkFront Mark

Front Mark

A62247

Z00064

Z00065

A01470

14−64

− ENGINE MECHANICALCYLINDER BLOCK ASSY (2AZ−FSE)

2AZ−FSE ENGINE REPAIR MANUAL (RM1083E)

If the oil clearance is greater than the maximum, replace the

connecting rod. If necessary, replace the piston and piston pin

as a set.

(e) Subtract the piston pin diameter measurement from the

bushing inside diameter measurement.

Specified oil clearance:

0.005 to 0.100 mm (0.0002 to 0.0020 in.)

If the oil clearance is greater than the maximum, replace the

connecting rod. If necessary, replace the connecting rod and

piston pin as a set.

23. INSPECT CONNECTING ROD SUB−ASSY

(a) Using a rod aligner and feeler gauge, check the connect-

ing rod alignment.

(1) Check for out−of−alignment.

Maximum out−of−alignment:

0.05 mm (0.0020 in.) per 100 mm (3.94 in.)

If the out−of−alignment is greater than the maximum, replace

the connecting rod assembly.

(2) Check for twist.

Maximum twist:

0.15 mm (0.0059 in.) per 100 mm (3.94 in.)

If the twist is greater than the maximum, replace the connecting

rod assembly.

24. INSPECT CONNECTING ROD BOLT

(a) Using a vernier caliper, measure the tension portion diam-

eter of the bolt.

Standard diameter: 7.2 to 7.3 mm (0.283 to 0.287 in.)

Minimum diameter: 7.0 mm (0.276 in.)

If the diameter is less than the minimum, replace the bolt.

Page 4789 of 5135

A13491

A92497

No. 1

No. 5 No. 4No. 3 No. 2

ZF6928

− ENGINE MECHANICALCYLINDER BLOCK ASSY (2AZ−FSE)

14−65

2AZ−FSE ENGINE REPAIR MANUAL (RM1083E)

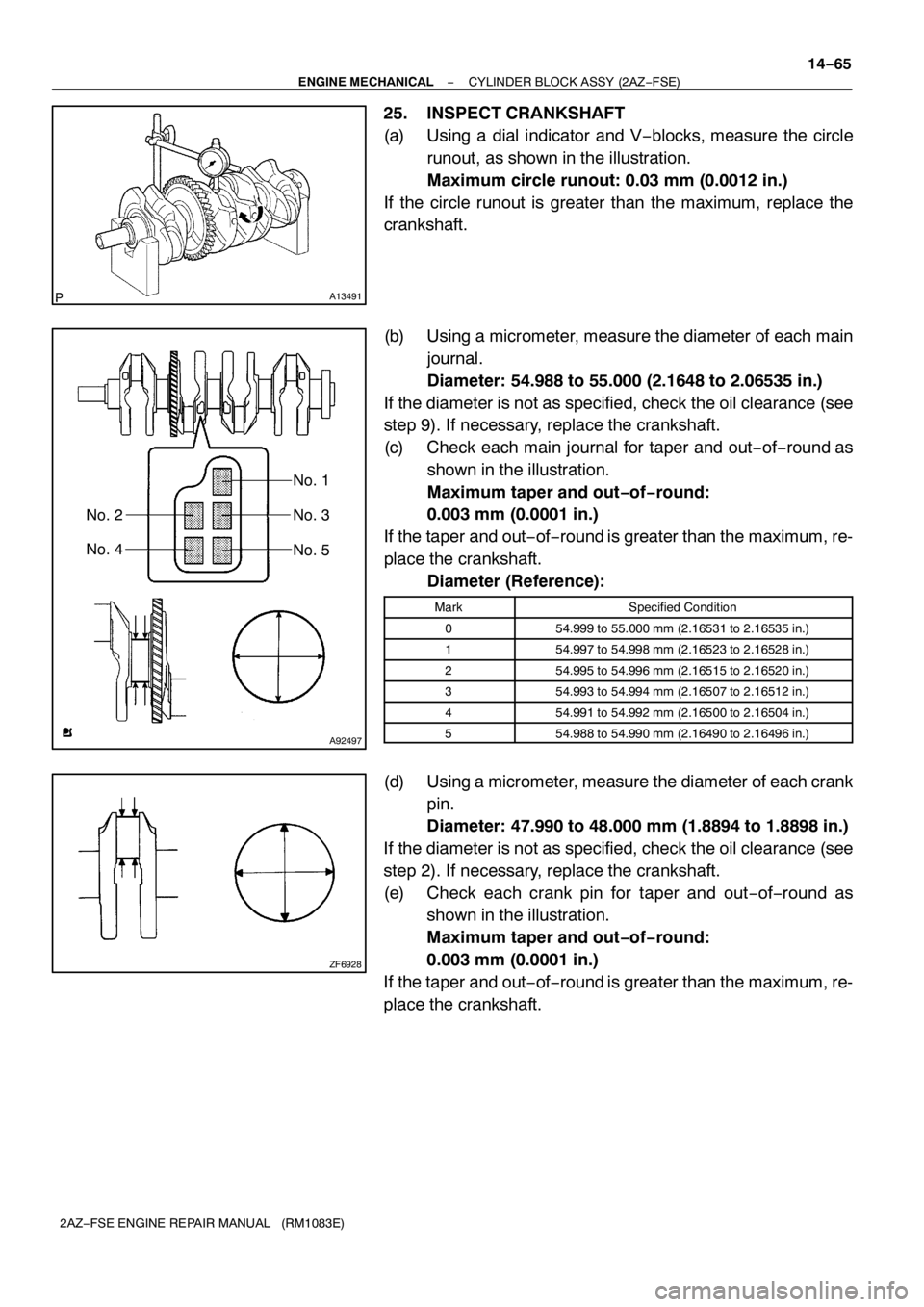

25. INSPECT CRANKSHAFT

(a) Using a dial indicator and V−blocks, measure the circle

runout, as shown in the illustration.

Maximum circle runout: 0.03 mm (0.0012 in.)

If the circle runout is greater than the maximum, replace the

crankshaft.

(b) Using a micrometer, measure the diameter of each main

journal.

Diameter: 54.988 to 55.000 (2.1648 to 2.06535 in.)

If the diameter is not as specified, check the oil clearance (see

step 9). If necessary, replace the crankshaft.

(c) Check each main journal for taper and out−of−round as

shown in the illustration.

Maximum taper and out−of−round:

0.003 mm (0.0001 in.)

If the taper and out−of−round is greater than the maximum, re-

place the crankshaft.

Diameter (Reference):

MarkSpecified Condition

054.999 to 55.000 mm (2.16531 to 2.16535 in.)

154.997 to 54.998 mm (2.16523 to 2.16528 in.)

254.995 to 54.996 mm (2.16515 to 2.16520 in.)

354.993 to 54.994 mm (2.16507 to 2.16512 in.)

454.991 to 54.992 mm (2.16500 to 2.16504 in.)

554.988 to 54.990 mm (2.16490 to 2.16496 in.)

(d) Using a micrometer, measure the diameter of each crank

pin.

Diameter: 47.990 to 48.000 mm (1.8894 to 1.8898 in.)

If the diameter is not as specified, check the oil clearance (see

step 2). If necessary, replace the crankshaft.

(e) Check each crank pin for taper and out−of−round as

shown in the illustration.

Maximum taper and out−of−round:

0.003 mm (0.0001 in.)

If the taper and out−of−round is greater than the maximum, re-

place the crankshaft.

Page 4790 of 5135

EM6347A15065

A92498

14 mm

(0.551 in.)

6 mm (0.236 in.)

for Ring Pin A

5 mm (0.197 in.)

for Ring Pin B

12 mm

(0.472 in.)12 mm

(0.472 in.) 13 mm

(0.512 in.)A

AB

B

Upper SideBottom Side 14−66

− ENGINE MECHANICALCYLINDER BLOCK ASSY (2AZ−FSE)

2AZ−FSE ENGINE REPAIR MANUAL (RM1083E)

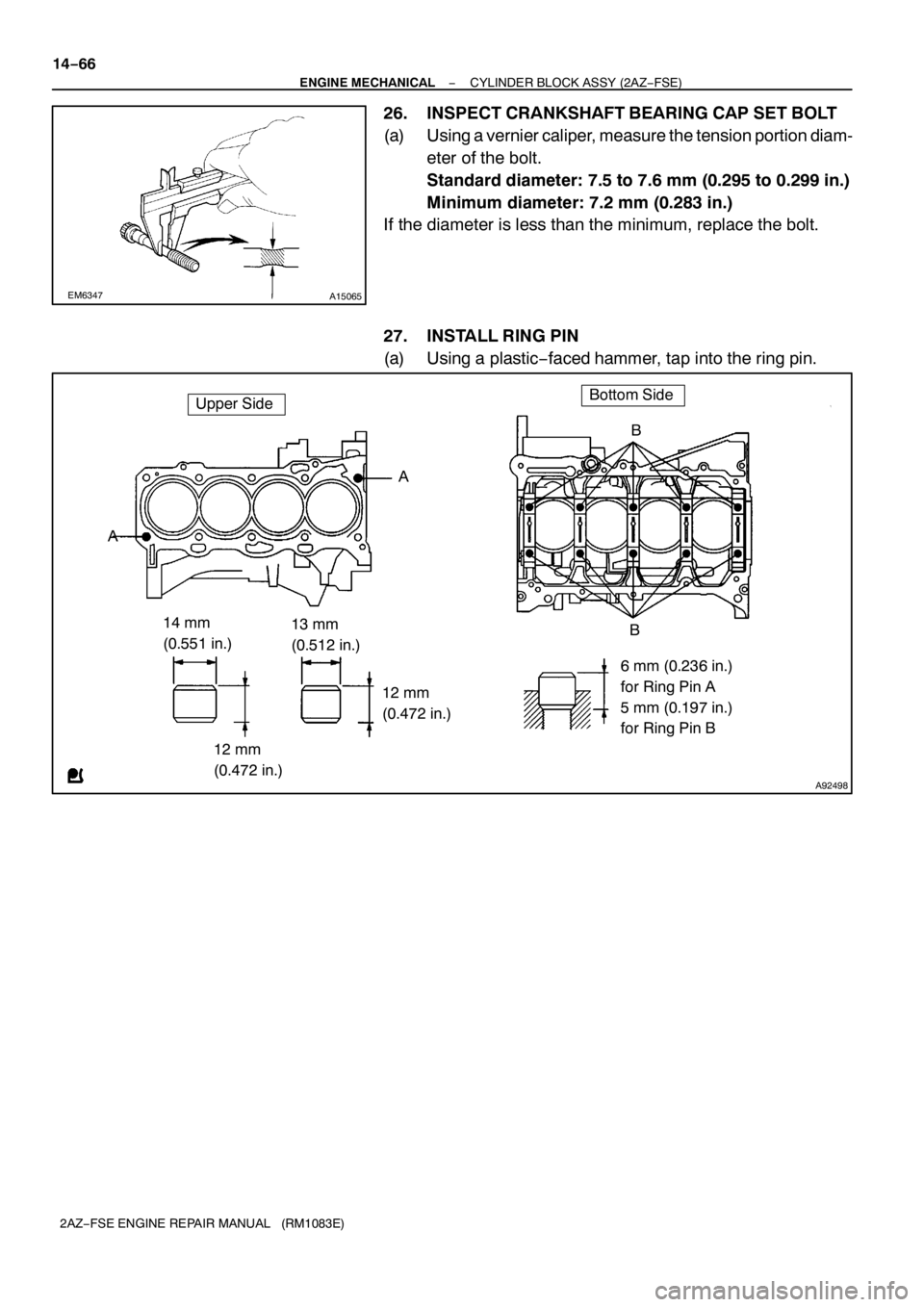

26. INSPECT CRANKSHAFT BEARING CAP SET BOLT

(a) Using a vernier caliper, measure the tension portion diam-

eter of the bolt.

Standard diameter: 7.5 to 7.6 mm (0.295 to 0.299 in.)

Minimum diameter: 7.2 mm (0.283 in.)

If the diameter is less than the minimum, replace the bolt.

27. INSTALL RING PIN

(a) Using a plastic−faced hammer, tap into the ring pin.