TOYOTA AVENSIS 2005 Service Repair Manual

Manufacturer: TOYOTA, Model Year: 2005, Model line: AVENSIS, Model: TOYOTA AVENSIS 2005Pages: 5135, PDF Size: 95.28 MB

Page 4831 of 5135

D03860

C56360

Underdrive

Clutch

Return

Spring

Underdrive

Clutch Drum

C56359

Clutch

Balancer

Underdrive

Clutch Drum

D03703

SST

− AUTOMATIC TRANSMISSION / TRANSUNDERDRIVE CLUTCH ASSY (U151E/U151F)

40−97

U151E, U151F A/T REPAIR MANUAL (RM1021U)

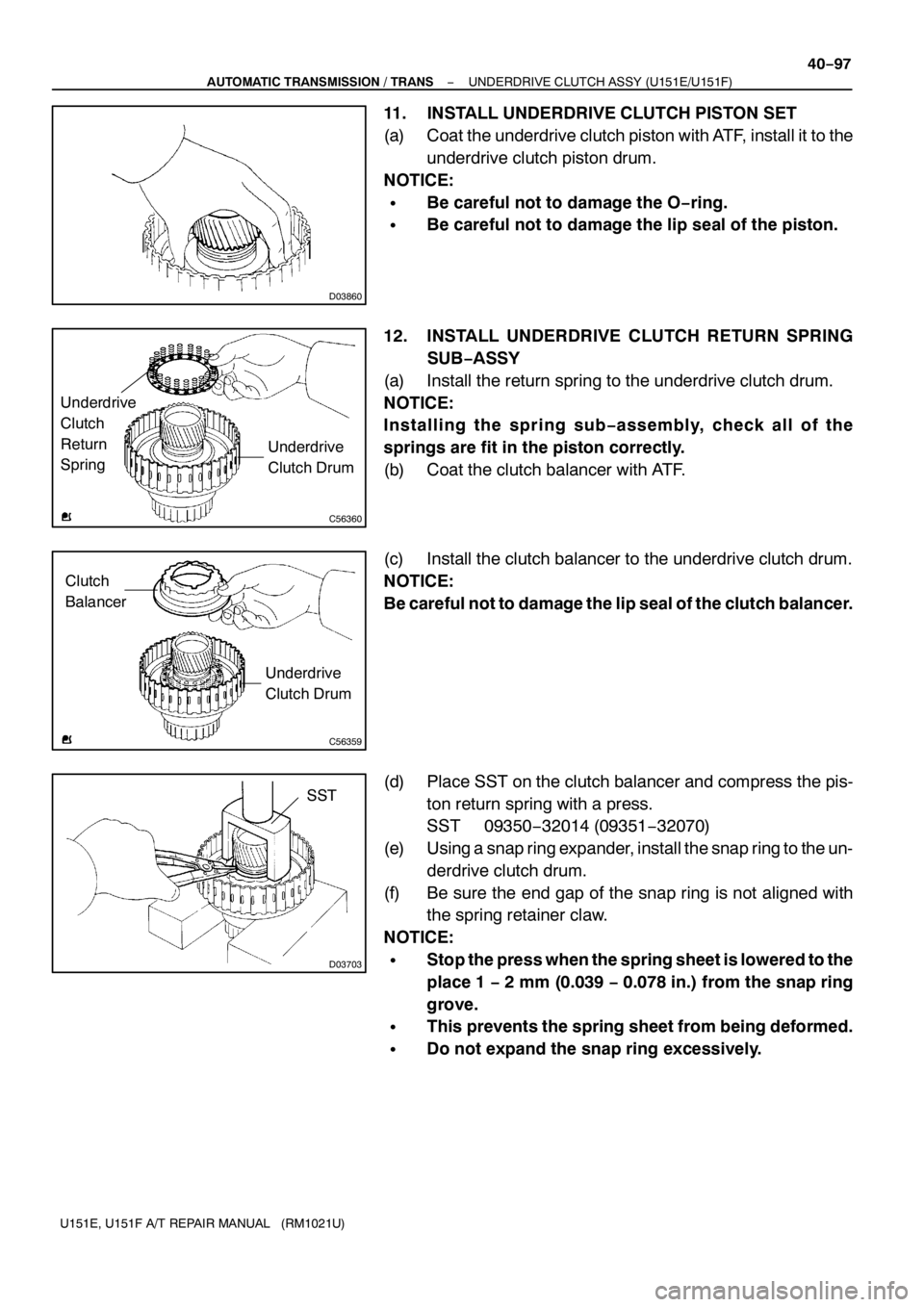

11. INSTALL UNDERDRIVE CLUTCH PISTON SET

(a) Coat the underdrive clutch piston with ATF, install it to the

underdrive clutch piston drum.

NOTICE:

SBe careful not to damage the O−ring.

SBe careful not to damage the lip seal of the piston.

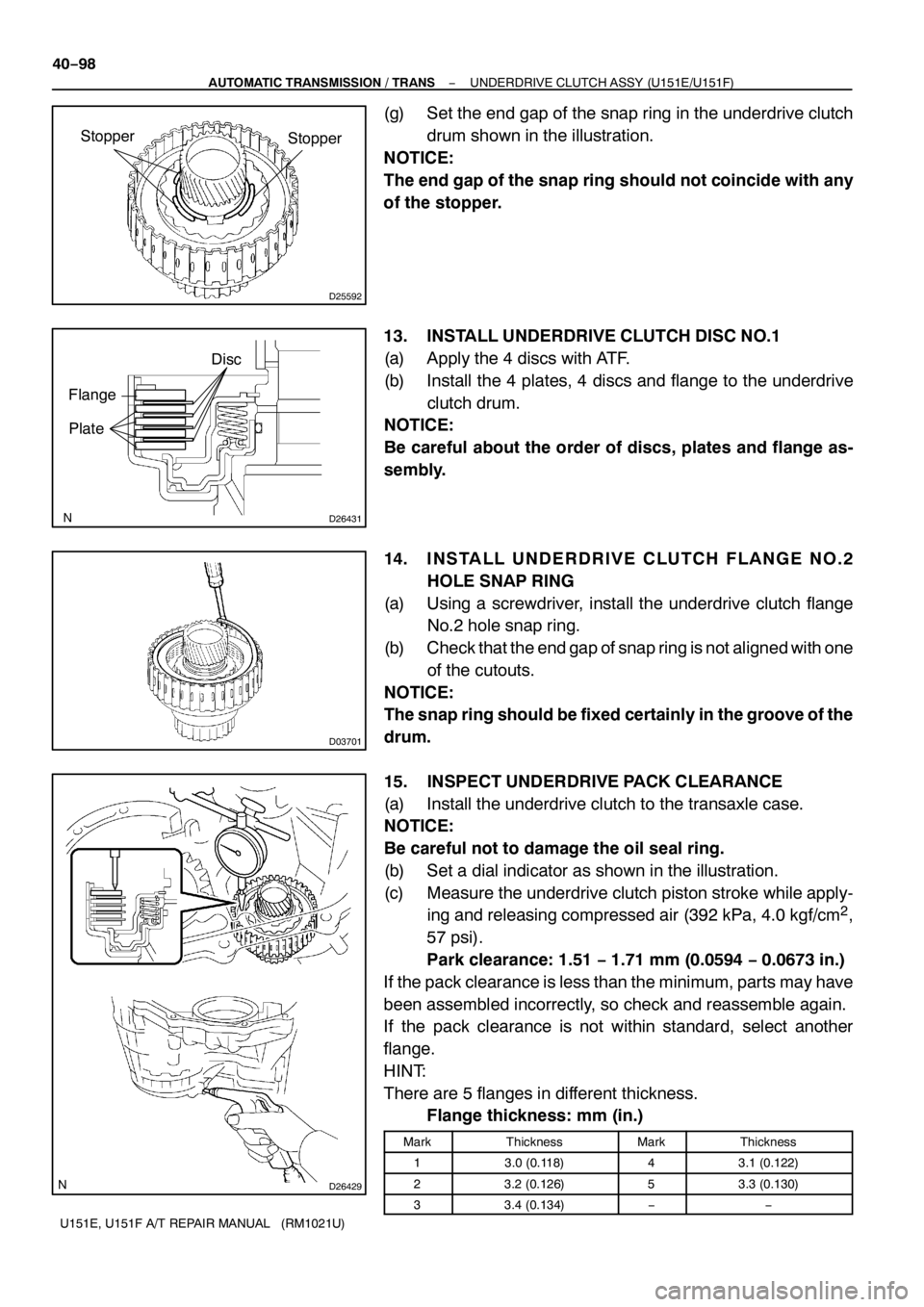

12. INSTALL UNDERDRIVE CLUTCH RETURN SPRING

SUB−ASSY

(a) Install the return spring to the underdrive clutch drum.

NOTICE:

Installing the spring sub−assembly, check all of the

springs are fit in the piston correctly.

(b) Coat the clutch balancer with ATF.

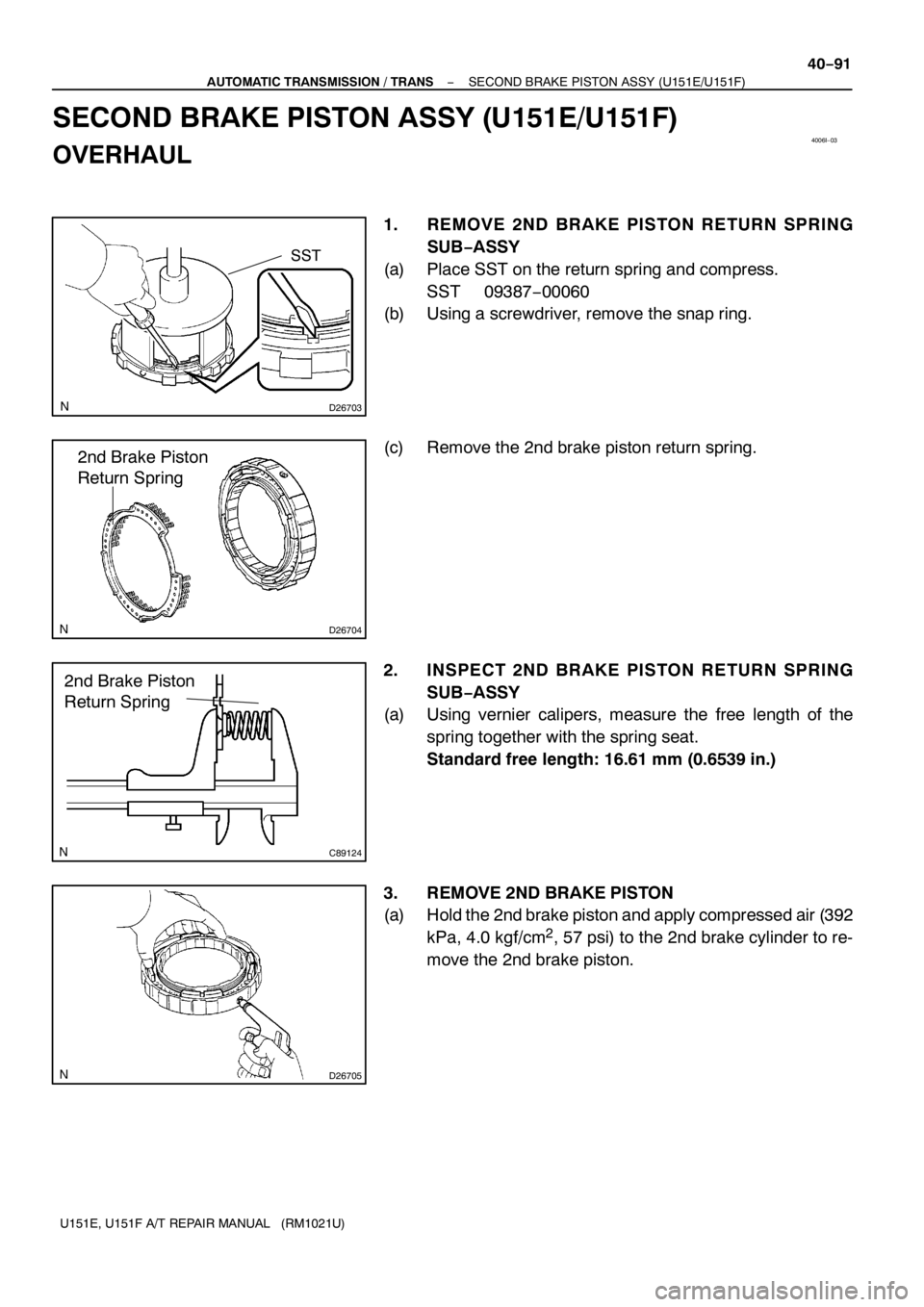

(c) Install the clutch balancer to the underdrive clutch drum.

NOTICE:

Be careful not to damage the lip seal of the clutch balancer.

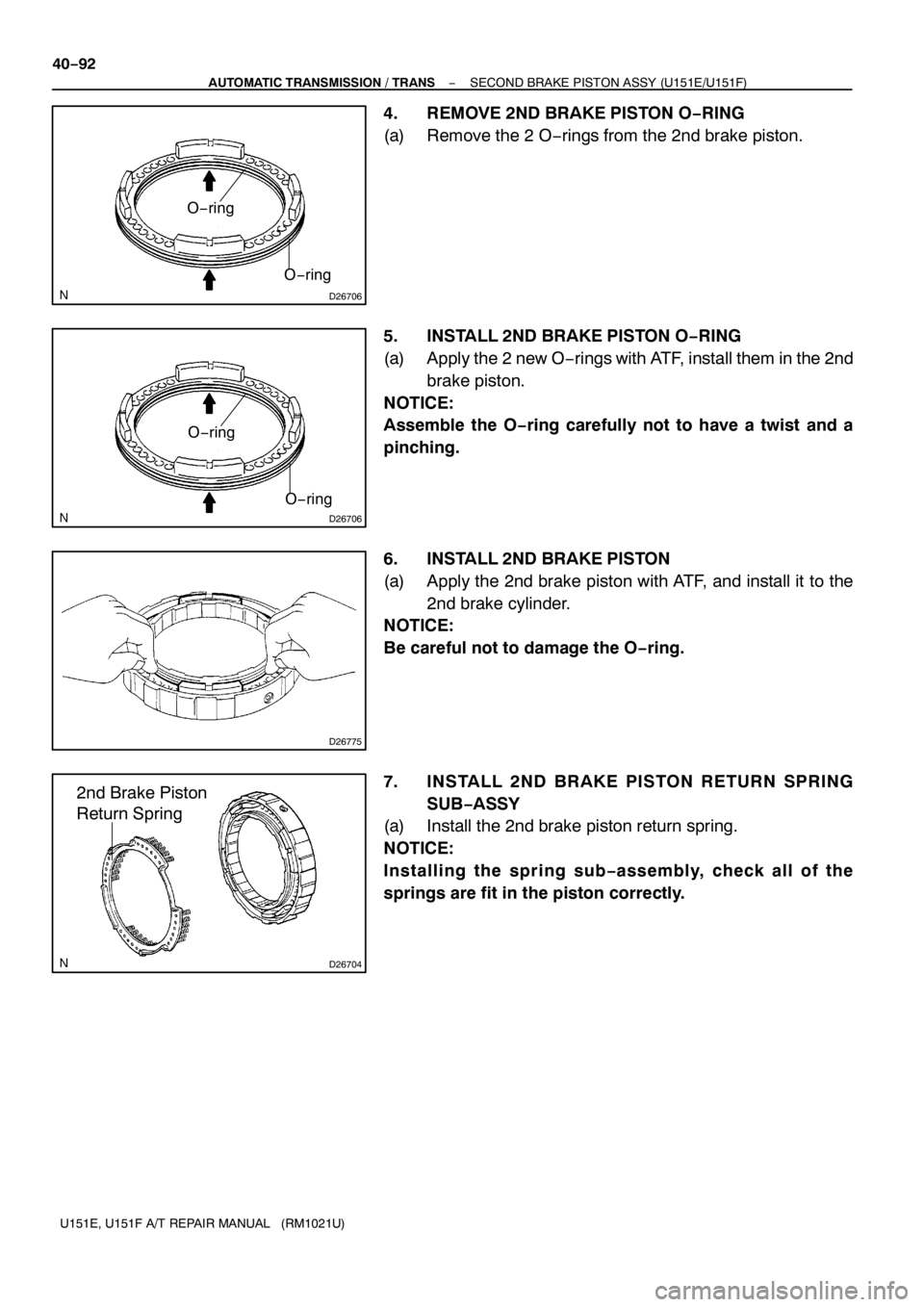

(d) Place SST on the clutch balancer and compress the pis-

ton return spring with a press.

SST 09350−32014 (09351−32070)

(e) Using a snap ring expander, install the snap ring to the un-

derdrive clutch drum.

(f) Be sure the end gap of the snap ring is not aligned with

the spring retainer claw.

NOTICE:

SStop the press when the spring sheet is lowered to the

place1−2 mm (0.039−0.078 in.) from the snap ring

grove.

SThis prevents the spring sheet from being deformed.

SDo not expand the snap ring excessively.

Page 4832 of 5135

D25592

StopperStopper

D26431

Disc

Flange

Plate

D03701

D26429

40−98

− AUTOMATIC TRANSMISSION / TRANSUNDERDRIVE CLUTCH ASSY (U151E/U151F)

U151E, U151F A/T REPAIR MANUAL (RM1021U)

(g) Set the end gap of the snap ring in the underdrive clutch

drum shown in the illustration.

NOTICE:

The end gap of the snap ring should not coincide with any

of the stopper.

13. INSTALL UNDERDRIVE CLUTCH DISC NO.1

(a) Apply the 4 discs with ATF.

(b) Install the 4 plates, 4 discs and flange to the underdrive

clutch drum.

NOTICE:

Be careful about the order of discs, plates and flange as-

sembly.

14. INSTALL UNDERDRIVE CLUTCH FLANGE NO.2

HOLE SNAP RING

(a) Using a screwdriver, install the underdrive clutch flange

No.2 hole snap ring.

(b) Check that the end gap of snap ring is not aligned with one

of the cutouts.

NOTICE:

The snap ring should be fixed certainly in the groove of the

drum.

15. INSPECT UNDERDRIVE PACK CLEARANCE

(a) Install the underdrive clutch to the transaxle case.

NOTICE:

Be careful not to damage the oil seal ring.

(b) Set a dial indicator as shown in the illustration.

(c) Measure the underdrive clutch piston stroke while apply-

ing and releasing compressed air (392 kPa, 4.0 kgf/cm

2,

57 psi).

Park clearance:1.51−1.71mm (0.0594−0.0673 in.)

If the pack clearance is less than the minimum, parts may have

been assembled incorrectly, so check and reassemble again.

If the pack clearance is not within standard, select another

flange.

HINT:

There are 5 flanges in different thickness.

Flange thickness: mm (in.)

MarkThicknessMarkThickness

13.0 (0.118)43.1(0.122)

23.2 (0.126)53.3 (0.130)

33.4 (0.134)−−

Page 4833 of 5135

4006I−03

D26703

SST

D26704

2nd Brake Piston

Return Spring

C89124

2nd Brake Piston

Return Spring

D26705

− AUTOMATIC TRANSMISSION / TRANSSECOND BRAKE PISTON ASSY (U151E/U151F)

40−91

U151E, U151F A/T REPAIR MANUAL (RM1021U)

SECOND BRAKE PISTON ASSY (U151E/U151F)

OVERHAUL

1. REMOVE 2ND BRAKE PISTON RETURN SPRING

SUB−ASSY

(a) Place SST on the return spring and compress.

SST 09387−00060

(b) Using a screwdriver, remove the snap ring.

(c) Remove the 2nd brake piston return spring.

2. INSPECT 2ND BRAKE PISTON RETURN SPRING

SUB−ASSY

(a) Using vernier calipers, measure the free length of the

spring together with the spring seat.

Standard free length:16.61mm (0.6539 in.)

3. REMOVE 2ND BRAKE PISTON

(a) Hold the 2nd brake piston and apply compressed air (392

kPa, 4.0 kgf/cm

2, 57 psi) to the 2nd brake cylinder to re-

move the 2nd brake piston.

Page 4834 of 5135

D26706

O−ring

O−ring

D26706

O−ring

O−ring

D26775

D26704

2nd Brake Piston

Return Spring

40−92

− AUTOMATIC TRANSMISSION / TRANSSECOND BRAKE PISTON ASSY (U151E/U151F)

U151E, U151F A/T REPAIR MANUAL (RM1021U)

4. REMOVE 2ND BRAKE PISTON O−RING

(a) Remove the 2 O−rings from the 2nd brake piston.

5. INSTALL 2ND BRAKE PISTON O−RING

(a) Apply the 2 new O−rings with ATF, install them in the 2nd

brake piston.

NOTICE:

Assemble the O−ring carefully not to have a twist and a

pinching.

6. INSTALL 2ND BRAKE PISTON

(a) Apply the 2nd brake piston with ATF, and install it to the

2nd brake cylinder.

NOTICE:

Be careful not to damage the O−ring.

7. INSTALL 2ND BRAKE PISTON RETURN SPRING

SUB−ASSY

(a) Install the 2nd brake piston return spring.

NOTICE:

Installing the spring sub−assembly, check all of the

springs are fit in the piston correctly.

Page 4835 of 5135

D26703

SST

− AUTOMATIC TRANSMISSION / TRANSSECOND BRAKE PISTON ASSY (U151E/U151F)

40−93

U151E, U151F A/T REPAIR MANUAL (RM1021U)

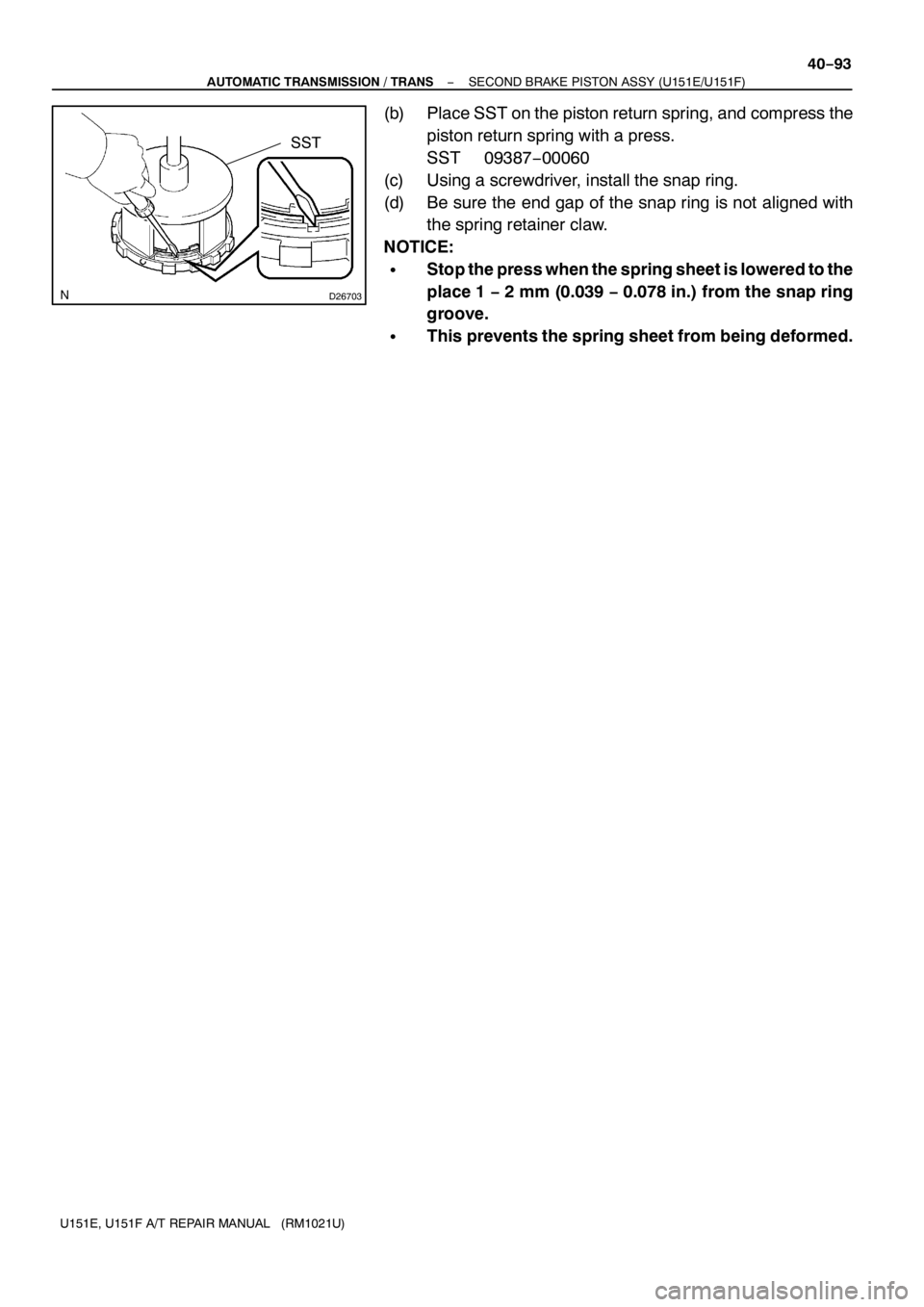

(b) Place SST on the piston return spring, and compress the

piston return spring with a press.

SST 09387−00060

(c) Using a screwdriver, install the snap ring.

(d) Be sure the end gap of the snap ring is not aligned with

the spring retainer claw.

NOTICE:

SStop the press when the spring sheet is lowered to the

place1−2 mm (0.039−0.078 in.) from the snap ring

groove.

SThis prevents the spring sheet from being deformed.

Page 4836 of 5135

400H2−02

D26426

D26427

40−84

− AUTOMATIC TRANSMISSION / TRANSDIRECT CLUTCH ASSY (U151E/U151F)

U151E, U151F A/T REPAIR MANUAL (RM1021U)

DIRECT CLUTCH ASSY (U151E/U151F)

OVERHAUL

1. INSPECT PACK CLEARANCE OF REVERSE CLUTCH

(a) Install the intermediate shaft and needle roller bearing on

the transaxle rear cover .

(b) Using a dial indicator, measure the reverse clutch pack

clearance while applying and releasing compressed air

(392 kPa, 4.0 kgf/cm

2, 57 psi).

Pack clearance:0.60−0.82 mm (0.02362−0.03228 in.)

If the pack clearance is not within standard, inspect the discs,

plates and flange.

2. INSPECT PACK CLEARANCE OF DIRECT CLUTCH &

OVERDRIVE CLUTCH

(a) Using a dial indicator, measure the direct clutch & over-

drive clutch pack clearance while applying and releasing

compressed air (392 kPa, 4.0 kgf/cm

2, 57 psi).

Pack clearance:0.61−0.83 mm (0.02401−0.03268 in.)

If the pack clearance is not within standard, inspect the discs,

plates and flange.

Page 4837 of 5135

D26419

Snap Ring

D26420

D26718

D26422

D26719

− AUTOMATIC TRANSMISSION / TRANSDIRECT CLUTCH ASSY (U151E/U151F)

40−85

U151E, U151F A/T REPAIR MANUAL (RM1021U)

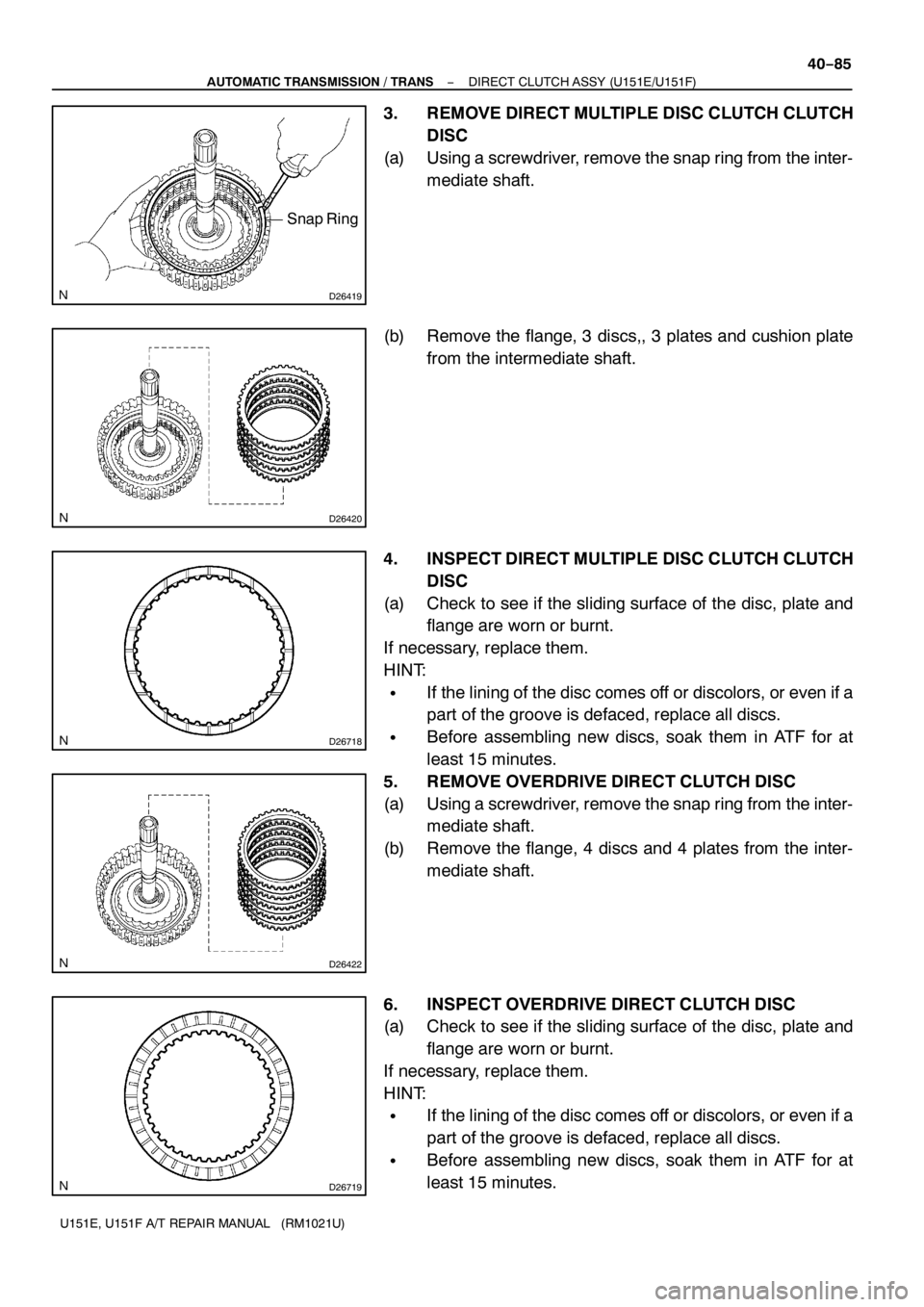

3. REMOVE DIRECT MULTIPLE DISC CLUTCH CLUTCH

DISC

(a) Using a screwdriver, remove the snap ring from the inter-

mediate shaft.

(b) Remove the flange, 3 discs,, 3 plates and cushion plate

from the intermediate shaft.

4. INSPECT DIRECT MULTIPLE DISC CLUTCH CLUTCH

DISC

(a) Check to see if the sliding surface of the disc, plate and

flange are worn or burnt.

If necessary, replace them.

HINT:

SIf the lining of the disc comes off or discolors, or even if a

part of the groove is defaced, replace all discs.

SBefore assembling new discs, soak them in ATF for at

least15 minutes.

5. REMOVE OVERDRIVE DIRECT CLUTCH DISC

(a) Using a screwdriver, remove the snap ring from the inter-

mediate shaft.

(b) Remove the flange, 4 discs and 4 plates from the inter-

mediate shaft.

6. INSPECT OVERDRIVE DIRECT CLUTCH DISC

(a) Check to see if the sliding surface of the disc, plate and

flange are worn or burnt.

If necessary, replace them.

HINT:

SIf the lining of the disc comes off or discolors, or even if a

part of the groove is defaced, replace all discs.

SBefore assembling new discs, soak them in ATF for at

least15 minutes.

Page 4838 of 5135

D03677

SST

D26424

Clutch

Balancer

Direct Clutch

Drum

D26423

Direct Clutch

Drum

Overdrive

Clutch Return

Spring

D09211

Overdrive Clutch

Return Spring

40−86

− AUTOMATIC TRANSMISSION / TRANSDIRECT CLUTCH ASSY (U151E/U151F)

U151E, U151F A/T REPAIR MANUAL (RM1021U)

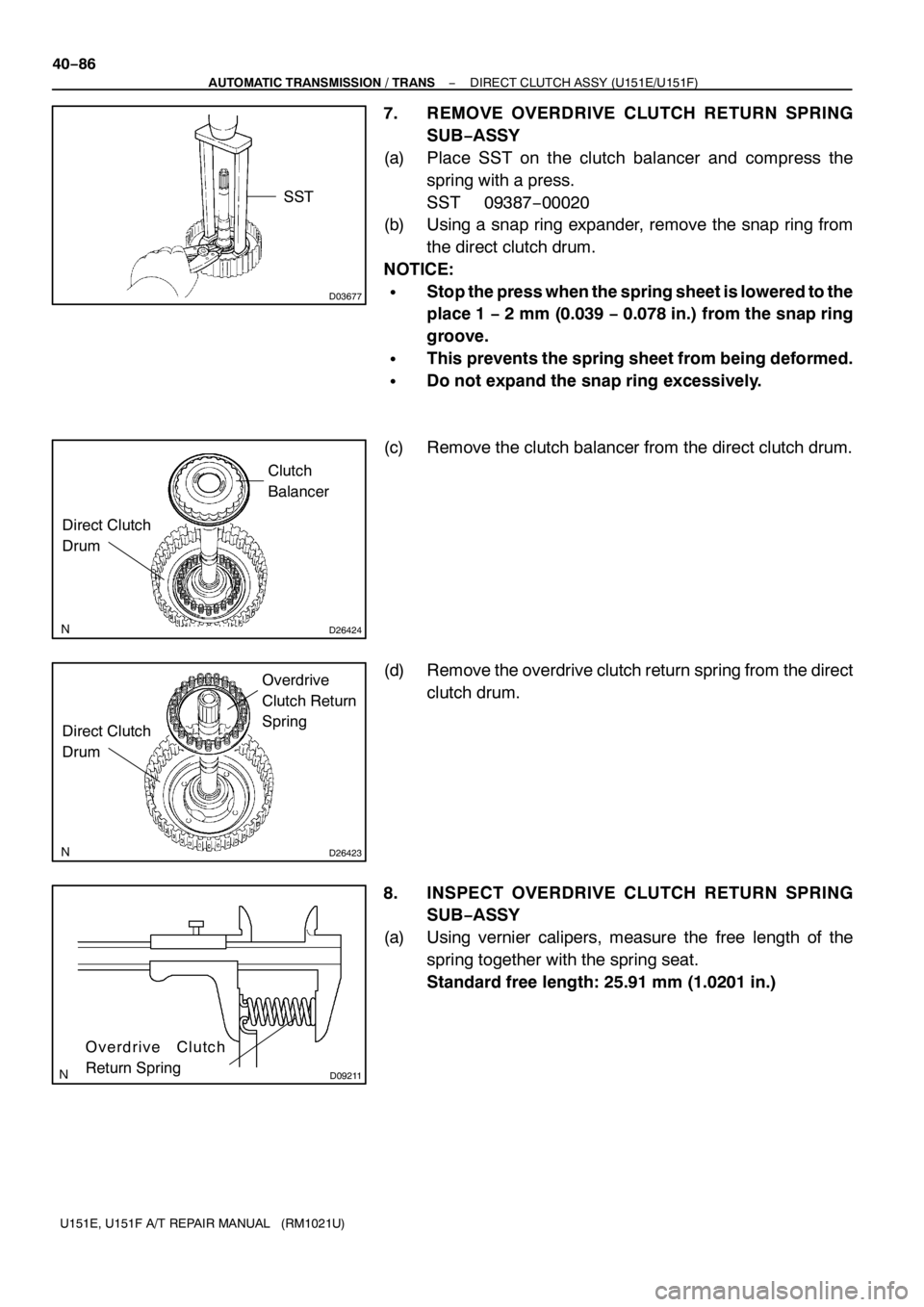

7. REMOVE OVERDRIVE CLUTCH RETURN SPRING

SUB−ASSY

(a) Place SST on the clutch balancer and compress the

spring with a press.

SST 09387−00020

(b) Using a snap ring expander, remove the snap ring from

the direct clutch drum.

NOTICE:

SStop the press when the spring sheet is lowered to the

place1−2 mm (0.039−0.078 in.) from the snap ring

groove.

SThis prevents the spring sheet from being deformed.

SDo not expand the snap ring excessively.

(c) Remove the clutch balancer from the direct clutch drum.

(d) Remove the overdrive clutch return spring from the direct

clutch drum.

8. INSPECT OVERDRIVE CLUTCH RETURN SPRING

SUB−ASSY

(a) Using vernier calipers, measure the free length of the

spring together with the spring seat.

Standard free length: 25.91mm (1.0201in.)

Page 4839 of 5135

D26463

D26425

D26464

O−ring

D26464

O−ring

D26462

Intermediate

ShaftDirect Clutch

Drum

− AUTOMATIC TRANSMISSION / TRANSDIRECT CLUTCH ASSY (U151E/U151F)

40−87

U151E, U151F A/T REPAIR MANUAL (RM1021U)

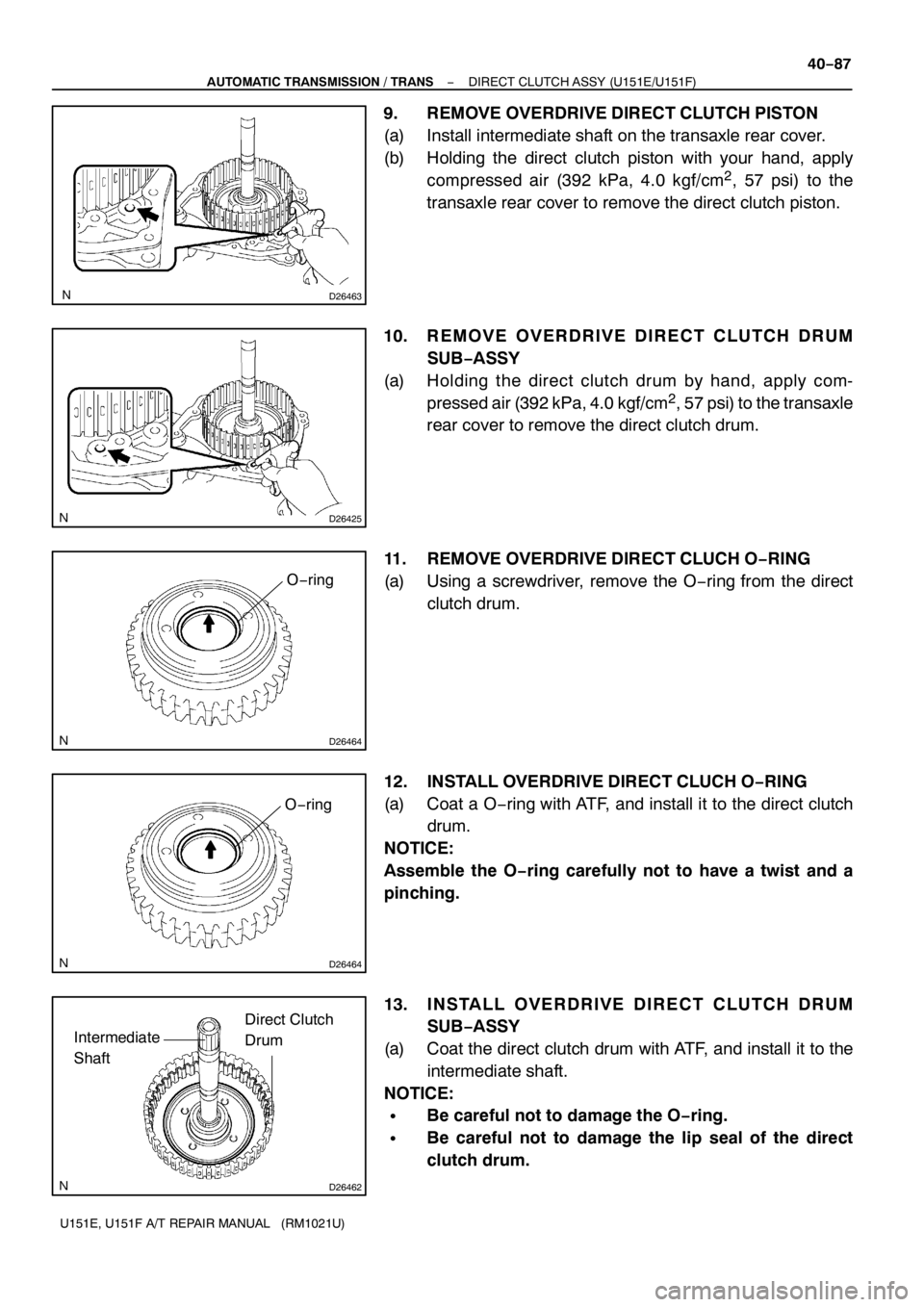

9. REMOVE OVERDRIVE DIRECT CLUTCH PISTON

(a) Install intermediate shaft on the transaxle rear cover.

(b) Holding the direct clutch piston with your hand, apply

compressed air (392 kPa, 4.0 kgf/cm

2,57psi)tothe

transaxle rear cover to remove the direct clutch piston.

10. REMOVE OVERDRIVE DIRECT CLUTCH DRUM

SUB−ASSY

(a) Holding the direct clutch drum by hand, apply com-

pressed air (392 kPa, 4.0 kgf/cm

2, 57 psi) to the transaxle

rear cover to remove the direct clutch drum.

11. REMOVE OVERDRIVE DIRECT CLUCH O−RING

(a) Using a screwdriver, remove the O−ring from the direct

clutch drum.

12. INSTALL OVERDRIVE DIRECT CLUCH O−RING

(a) Coat a O−ring with ATF, and install it to the direct clutch

drum.

NOTICE:

Assemble the O−ring carefully not to have a twist and a

pinching.

13. INSTALL OVERDRIVE DIRECT CLUTCH DRUM

SUB−ASSY

(a) Coat the direct clutch drum with ATF, and install it to the

intermediate shaft.

NOTICE:

SBe careful not to damage the O−ring.

SBe careful not to damage the lip seal of the direct

clutch drum.

Page 4840 of 5135

D26461

Overdrive Direct

Clutch Piston

D26423

Overdrive

Clutch Return

Spring

D26424

Clutch

BalancerDirect Clutch

Drum

D03677

SST

40−88

− AUTOMATIC TRANSMISSION / TRANSDIRECT CLUTCH ASSY (U151E/U151F)

U151E, U151F A/T REPAIR MANUAL (RM1021U)

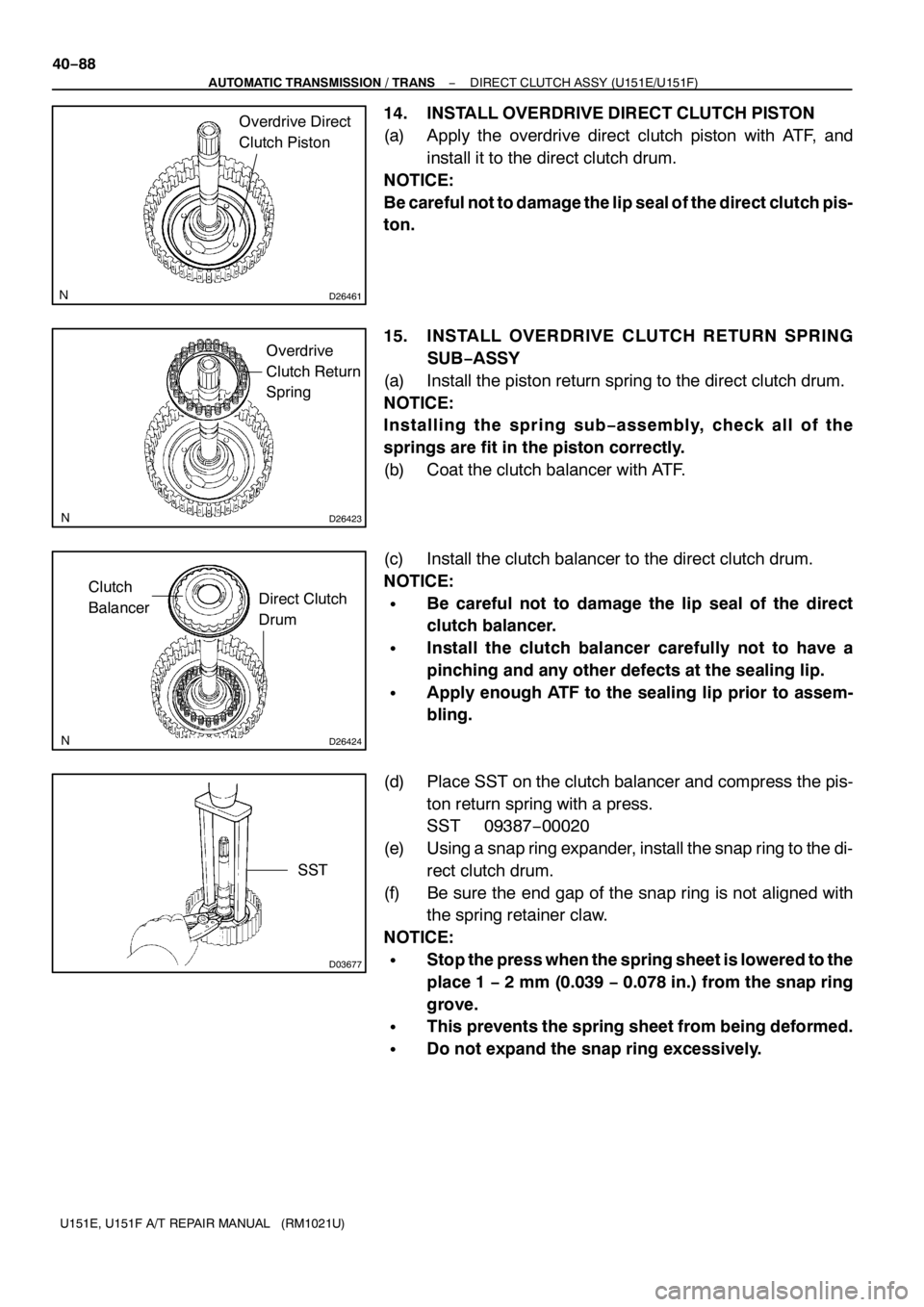

14. INSTALL OVERDRIVE DIRECT CLUTCH PISTON

(a) Apply the overdrive direct clutch piston with ATF, and

install it to the direct clutch drum.

NOTICE:

Be careful not to damage the lip seal of the direct clutch pis-

ton.

15. INSTALL OVERDRIVE CLUTCH RETURN SPRING

SUB−ASSY

(a) Install the piston return spring to the direct clutch drum.

NOTICE:

Installing the spring sub−assembly, check all of the

springs are fit in the piston correctly.

(b) Coat the clutch balancer with ATF.

(c) Install the clutch balancer to the direct clutch drum.

NOTICE:

SBe careful not to damage the lip seal of the direct

clutch balancer.

SInstall the clutch balancer carefully not to have a

pinching and any other defects at the sealing lip.

SApply enough ATF to the sealing lip prior to assem-

bling.

(d) Place SST on the clutch balancer and compress the pis-

ton return spring with a press.

SST 09387−00020

(e) Using a snap ring expander, install the snap ring to the di-

rect clutch drum.

(f) Be sure the end gap of the snap ring is not aligned with

the spring retainer claw.

NOTICE:

SStop the press when the spring sheet is lowered to the

place1−2 mm (0.039−0.078 in.) from the snap ring

grove.

SThis prevents the spring sheet from being deformed.

SDo not expand the snap ring excessively.