TOYOTA CAMRY 1999 Service Repair Manual

Manufacturer: TOYOTA, Model Year: 1999, Model line: CAMRY, Model: TOYOTA CAMRY 1999Pages: 4592, PDF Size: 55.16 MB

Page 3821 of 4592

Toyota Supports ASE CertificationPage 1 of 1

EG009±99

Title:

M.I.L. ON" DTC P1133

Models:

'97±'99 Camry and '99 Solara: 5S±FE CA Spec.

Technical Service

BULLETIN

October 1, 1999

Under certain driving conditions, some 5S±FE equipped 1997±1999 Camry and 1999

Solara California emission specification vehicles may exhibit a M.I.L. ªONº DTC P1133.

An improved Air Fuel Ratio Sensor has been developed to correct this condition.

�1997 ± 1999 Camry & 1999 Solara (5S±FE) with California emission

specification.

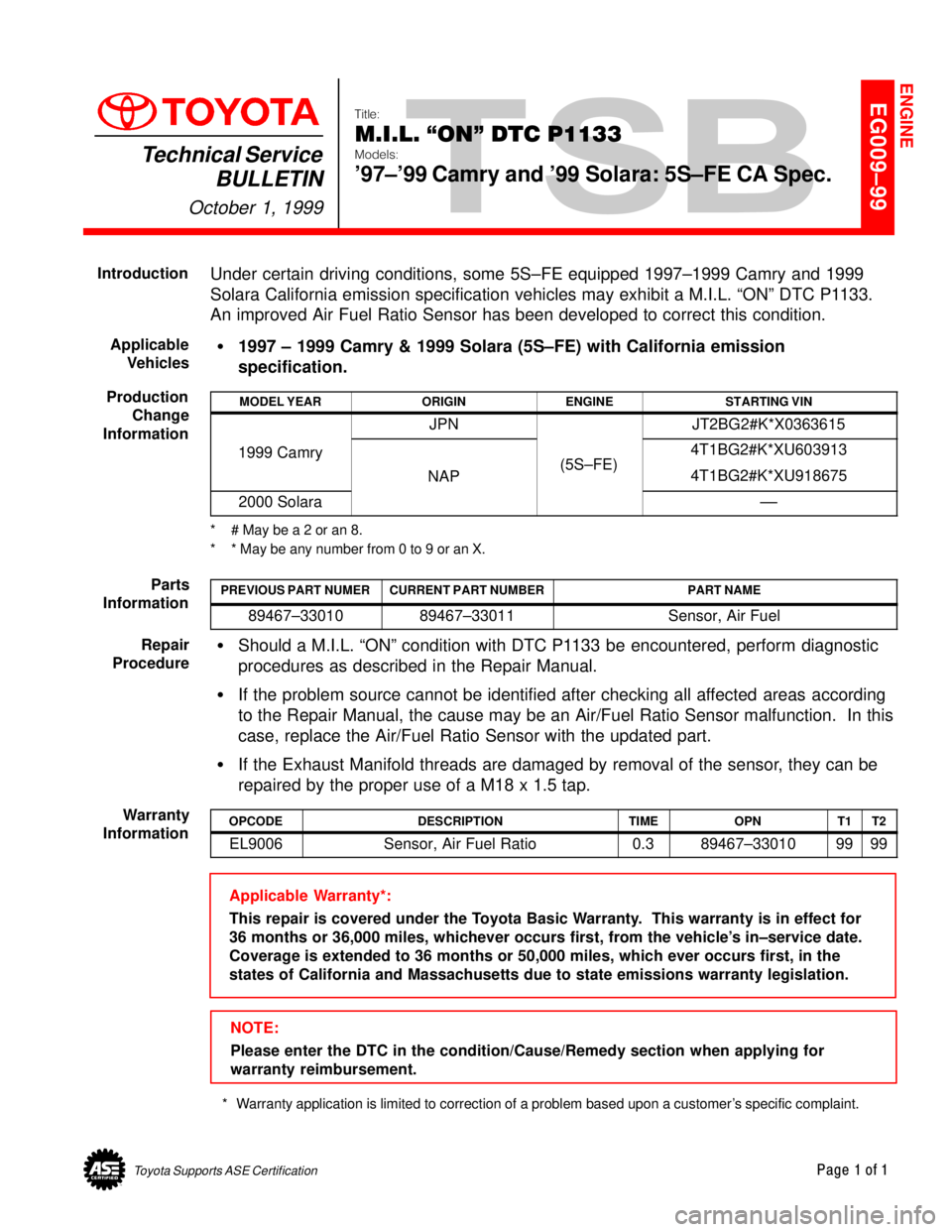

MODEL YEARORIGINENGINESTARTING VIN

JPNJT2BG2#K*X0363615

1999 Camry

NAP(5S±FE)4T1BG2#K*XU603913

4T1BG2#K*XU918675

2000 Solara±±

* # May be a 2 or an 8.

* * May be any number from 0 to 9 or an X.

PREVIOUS PART NUMERCURRENT PART NUMBERPART NAME

89467±3301089467±33011Sensor, Air Fuel

�Should a M.I.L. ªONº condition with DTC P1133 be encountered, perform diagnostic

procedures as described in the Repair Manual.

�If the problem source cannot be identified after checking all affected areas according

to the Repair Manual, the cause may be an Air/Fuel Ratio Sensor malfunction. In this

case, replace the Air/Fuel Ratio Sensor with the updated part.

�If the Exhaust Manifold threads are damaged by removal of the sensor, they can be

repaired by the proper use of a M18 x 1.5 tap.

OPCODEDESCRIPTIONTIMEOPNT1T2

EL9006Sensor, Air Fuel Ratio0.389467±330109999

Applicable Warranty*:

This repair is covered under the Toyota Basic Warranty. This warranty is in effect for

36 months or 36,000 miles, whichever occurs first, from the vehicle's in±service date.

Coverage is extended to 36 months or 50,000 miles, which ever occurs first, in the

states of California and Massachusetts due to state emissions warranty legislation.

NOTE:

Please enter the DTC in the condition/Cause/Remedy section when applying for

warranty reimbursement.

* Warranty application is limited to correction of a problem based upon a customer's specific complaint.

ENGINE

Introduction

Applicable

Vehicles

Production

Change

Information

Parts

Information

Repair

Procedure

Warranty

Information

Page 3822 of 4592

Toyota Supports ASE CertificationPage 1 of 2

EL002±98Title:

CIGARETTE LIGHTER SERVICE

Models:

All Models

Technical Service

BULLETIN

Apirl 10, 1998

When receiving customer complaints to repair the lighter or lighter socket, please

carefully investigate the cause of the failure to prevent further occurrences. If the

customer uses the wrong size lighter element or power accessory plug, damage may

occur to the lighter socket. When applicable, instruct the customer to replace the lighter

element with original equipment components or to use an appropriate sized accessory

plug. Dimensional information included within this document will instruct you on

component specifications.

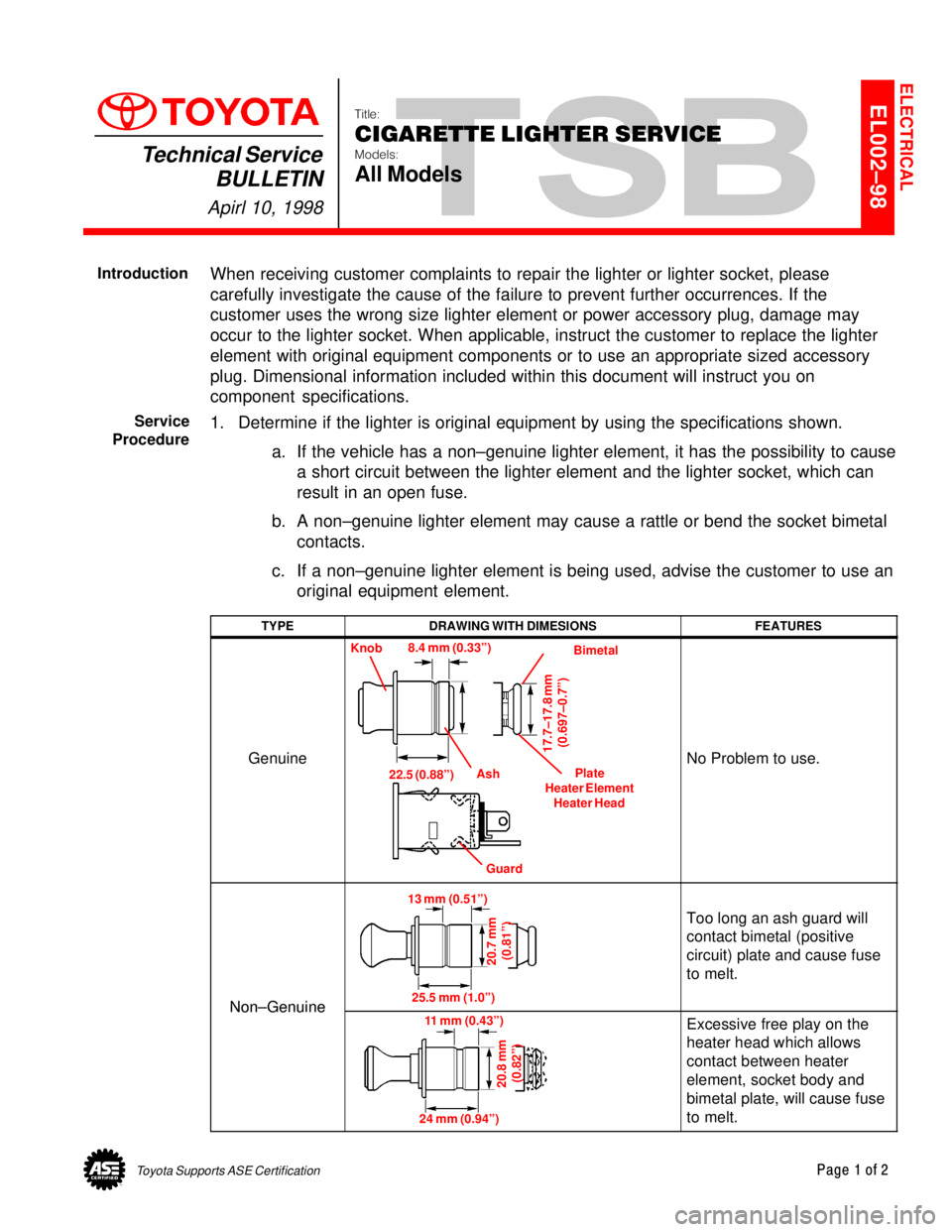

1. Determine if the lighter is original equipment by using the specifications shown.

a. If the vehicle has a non±genuine lighter element, it has the possibility to cause

a short circuit between the lighter element and the lighter socket, which can

result in an open fuse.

b. A non±genuine lighter element may cause a rattle or bend the socket bimetal

contacts.

c. If a non±genuine lighter element is being used, advise the customer to use an

original equipment element.

TYPEDRAWING WITH DIMESIONSFEATURES

Genuine

Knob

Bimetal

Plate

Heater Element

Heater Head

Guard Ash 8.4 mm (0.33º)

17.7±17.8 mm

(0.697±0.7º)

22.5 (0.88º)No Problem to use.

Non±Genuine

13 mm (0.51º)

20.7 mm

(0.81º)

25.5 mm (1.0º)

Too long an ash guard will

contact bimetal (positive

circuit) plate and cause fuse

to melt.

Non±Genuine11 mm (0.43º)

20.8 mm

(0.82º)

24 mm (0.94º)

Excessive free play on the

heater head which allows

contact between heater

element, socket body and

bimetal plate, will cause fuse

to melt.

ELECTRICAL

Introduction

Service

Procedure

Page 3823 of 4592

CIGARETTE LIGHTER SERVICE ± EL002-98 April 10, 1998

Page 2 of 2

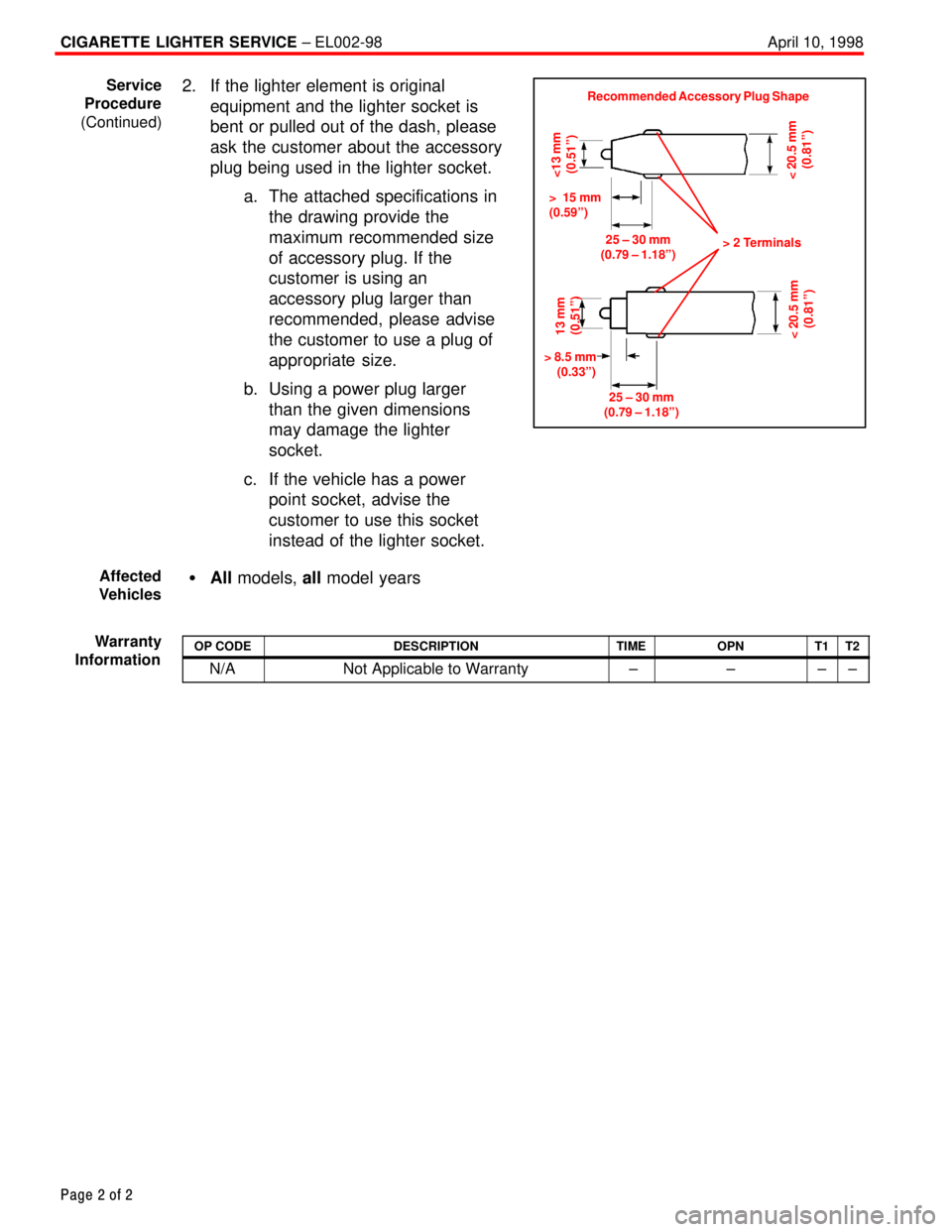

2. If the lighter element is original

equipment and the lighter socket is

bent or pulled out of the dash, please

ask the customer about the accessory

plug being used in the lighter socket.

a. The attached specifications in

the drawing provide the

maximum recommended size

of accessory plug. If the

customer is using an

accessory plug larger than

recommended, please advise

the customer to use a plug of

appropriate size.

b. Using a power plug larger

than the given dimensions

may damage the lighter

socket.

c. If the vehicle has a power

point socket, advise the

customer to use this socket

instead of the lighter socket.

�All models, all model years

OP CODEDESCRIPTIONTIMEOPNT1T2

N/ANot Applicable to Warranty ±±±±

> 2 Terminals

< 20.5 mm

(0.81º)

25 ± 30 mm

(0.79 ± 1.18º)

<13 mm

(0.51º) 13 mm

(0.51º)

25 ± 30 mm

(0.79 ± 1.18º)

< 20.5 mm

(0.81º)

> 8.5 mm

(0.33º)> 15 mm

(0.59º)

Recommended Accessory Plug ShapeService

Procedure

(Continued)

Affected

Vehicles

Warranty

Information

Page 3824 of 4592

Toyota Supports ASE CertificationPage 1 of 2

EL003±00Title:

SPEEDOMETER/TACHOMETER

NEEDLE MOVEMENT

Models:

'99 ± '00 Camry, Corolla, Sienna, & Solara

& '00 Avalon

Technical Service

BULLETIN

February 11, 2000

December 13, 2002

TSB REVISION NOTICE:

The information contained in this TSB was revised on December 13, 2002.

The previous TSB should be discarded.

Some vehicles may experience a slight, intermittent resistance to movement of the

speedometer or tachometer needle near zero during the first few miles of travel. The

condition can be corrected by following the repair method outlined below.

NOTE:

This repair does not apply to speedometers or tachometers which are permanently

inoperative.

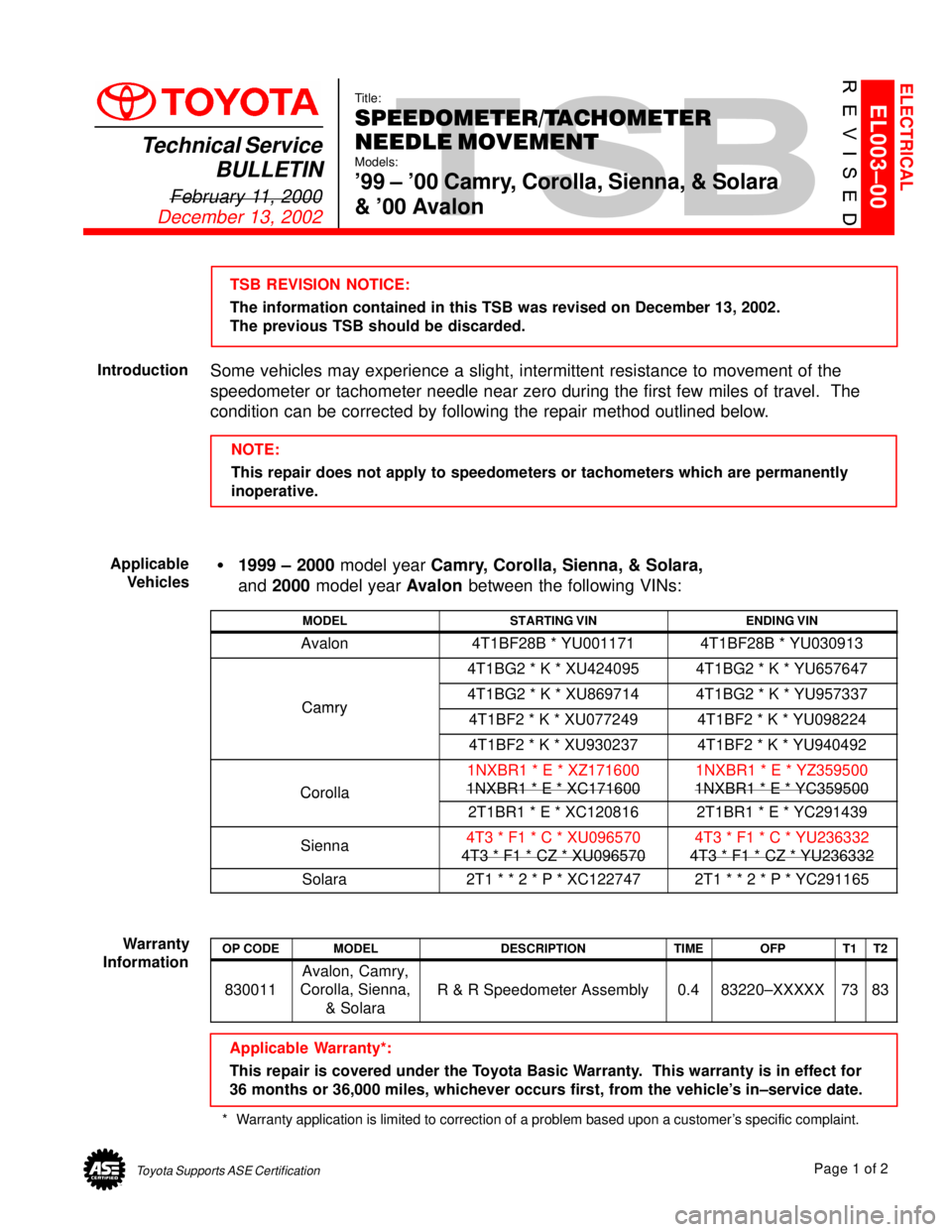

�1999 ± 2000 model year Camry, Corolla, Sienna, & Solara,

and 2000 model year Avalon between the following VINs:

MODELSTARTING VINENDING VIN

Avalon4T1BF28B * YU0011714T1BF28B * YU030913

4T1BG2 * K * XU4240954T1BG2 * K * YU657647

Camry4T1BG2 * K * XU8697144T1BG2 * K * YU957337Camry4T1BF2 * K * XU0772494T1BF2 * K * YU098224

4T1BF2 * K * XU9302374T1BF2 * K * YU940492

Corolla

1NXBR1 * E * XZ171600

1NXBR1 * E * XC1716001NXBR1 * E * YZ359500

1NXBR1 * E * YC359500

Corolla

2T1BR1 * E * XC1208162T1BR1 * E * YC291439

Sienna4T3 * F1 * C * XU096570

4T3 * F1 * CZ * XU0965704T3 * F1 * C * YU236332

4T3 * F1 * CZ * YU236332

Solara2T1 * * 2 * P * XC1227472T1 * * 2 * P * YC291165

OP CODEMODELDESCRIPTIONTIMEOFPT1T2

830011

Avalon, Camry,

Corolla, Sienna,

& Solara

R & R Speedometer Assembly0.483220±XXXXX7383

Applicable Warranty*:

This repair is covered under the Toyota Basic Warranty. This warranty is in effect for

36 months or 36,000 miles, whichever occurs first, from the vehicle's in±service date.

* Warranty application is limited to correction of a problem based upon a customer's specific complaint.

ELECTRICAL

Introduction

Applicable

Vehicles

Warranty

Information

Page 3825 of 4592

SPEEDOMETER/TACHOMETER NEEDLE MOVEMENT ± EL003-02Revised: December 13, 2002 February 11, 2000

Page 2 of 2

PREVIOUS PART NUMBERCURRENT PART NUMBERPART NAME

83220 XXXXXSameSpeedometer83220-XXXXXSameTachometer

TOOLS & MATERIALSQUANTITY

Double Sided Cotton Swab1

Distilled Water1 oz.

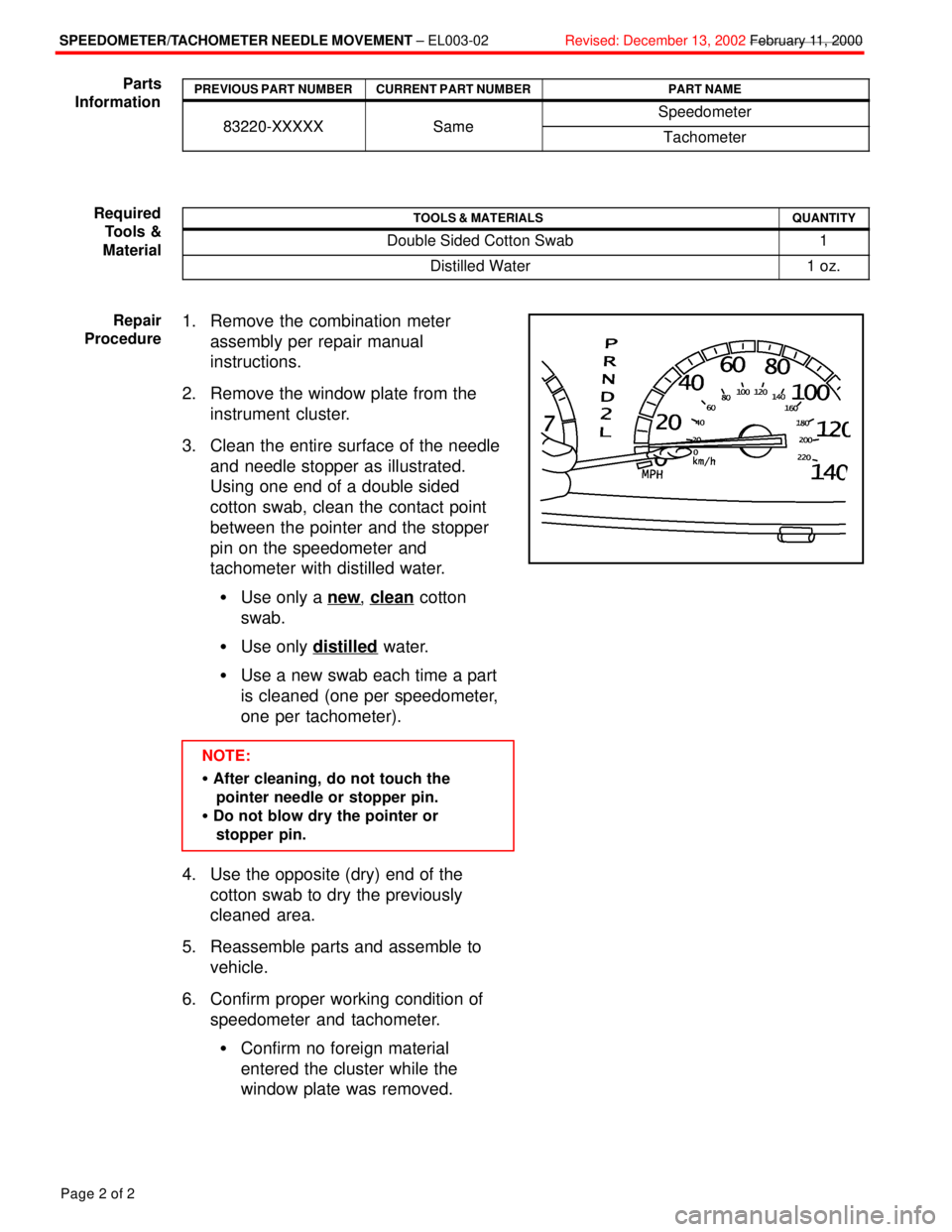

1. Remove the combination meter

assembly per repair manual

instructions.

2. Remove the window plate from the

instrument cluster.

3. Clean the entire surface of the needle

and needle stopper as illustrated.

Using one end of a double sided

cotton swab, clean the contact point

between the pointer and the stopper

pin on the speedometer and

tachometer with distilled water.

�Use only a new

, clean cotton

swab.

�Use only distilled

water.

�Use a new swab each time a part

is cleaned (one per speedometer,

one per tachometer).

NOTE:

� After cleaning, do not touch the

pointer needle or stopper pin.

� Do not blow dry the pointer or

stopper pin.

4. Use the opposite (dry) end of the

cotton swab to dry the previously

cleaned area.

5. Reassemble parts and assemble to

vehicle.

6. Confirm proper working condition of

speedometer and tachometer.

�Confirm no foreign material

entered the cluster while the

window plate was removed.

Parts

Information

Required

Tools &

Material

Repair

Procedure

Page 3826 of 4592

Toyota Supports ASE CertificationPage 1 of 1

EL006±99Title:

ENGINE IMMOBILIZER SYSTEM

PRECAUTIONS

Models:

All Models

Technical Service

BULLETIN

October 8, 1999

REVISION NOTICE:

The information contained in this TSB updates EL001±98 dated January 23, 1998.

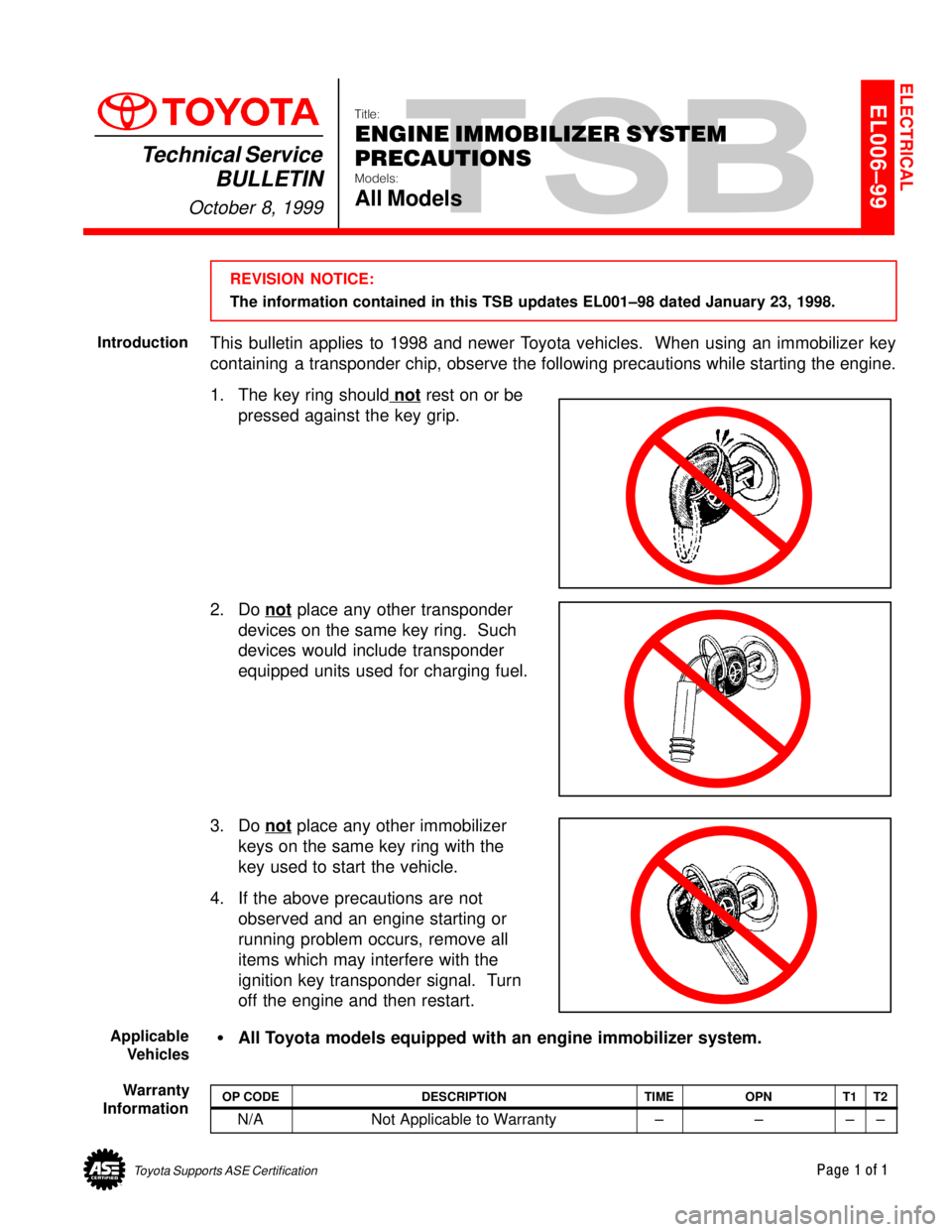

This bulletin applies to 1998 and newer Toyota vehicles. When using an immobilizer key

containing a transponder chip, observe the following precautions while starting the engine.

1. The key ring should not

rest on or be

pressed against the key grip.

2. Do not

place any other transponder

devices on the same key ring. Such

devices would include transponder

equipped units used for charging fuel.

3. Do not

place any other immobilizer

keys on the same key ring with the

key used to start the vehicle.

4. If the above precautions are not

observed and an engine starting or

running problem occurs, remove all

items which may interfere with the

ignition key transponder signal. Turn

off the engine and then restart.

�All Toyota models equipped with an engine immobilizer system.

OP CODEDESCRIPTIONTIMEOPNT1T2

N/ANot Applicable to Warranty±±±±

ELECTRICAL

Introduction

Applicable

Vehicles

Warranty

Information

Page 3827 of 4592

Toyota Supports ASE CertificationPage 1 of 4

EL007±00Title:

HEATER CONTROL ASSEMBLY

INSTRUCTIONS

Models:

'97 ± '99 Camry

Technical Service

BULLETIN

April 14, 2000

The attached instructions have been developed to supplement the Repair Manual to

assure corrrect cable routing of the heater control assembly during a service repair.

PUBLICATIONNUMBER

1997 Camry Repair Manual, Vol. 2RM503U2

1998 Camry Repair Manual, Vol. 2RM589U2

1999 Camry Repair Manual, Vol. 2RM654U2

NOTE:

For maximum heater performance the coolant ratio should be 50 to 60 percent.

�1997 ± 1999 model year Camry

OP CODEDESCRIPTIONTIMEOPNT1T2

N/ANot Applicable to Warranty ±±±±

ELECTRICAL

Introduction

Applicable

Vehicles

Warranty

Information

Page 3828 of 4592

POOR HEATER PERFORMANCE ± EL007±00 April 14, 2000

Page 2 of 4

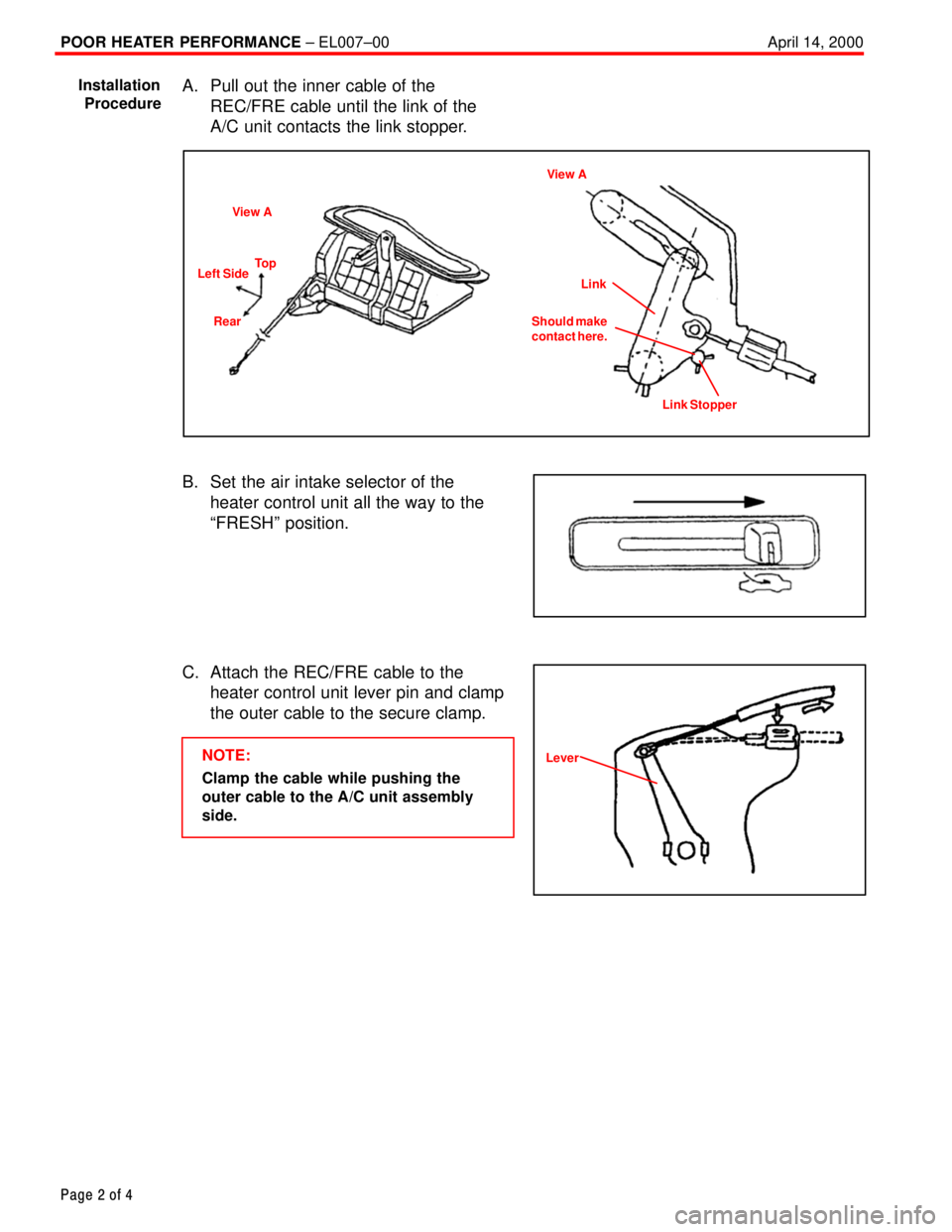

A. Pull out the inner cable of the

REC/FRE cable until the link of the

A/C unit contacts the link stopper.

View A

To p

Left Side

RearView A

Link

Should make

contact here.

Link Stopper

B. Set the air intake selector of the

heater control unit all the way to the

ªFRESHº position.

C. Attach the REC/FRE cable to the

heater control unit lever pin and clamp

the outer cable to the secure clamp.

NOTE:

Clamp the cable while pushing the

outer cable to the A/C unit assembly

side. Installation

ProcedureLever

Page 3829 of 4592

POOR HEATER PERFORMANCE ± EL007±00 April 14, 2000

Page 3 of 4

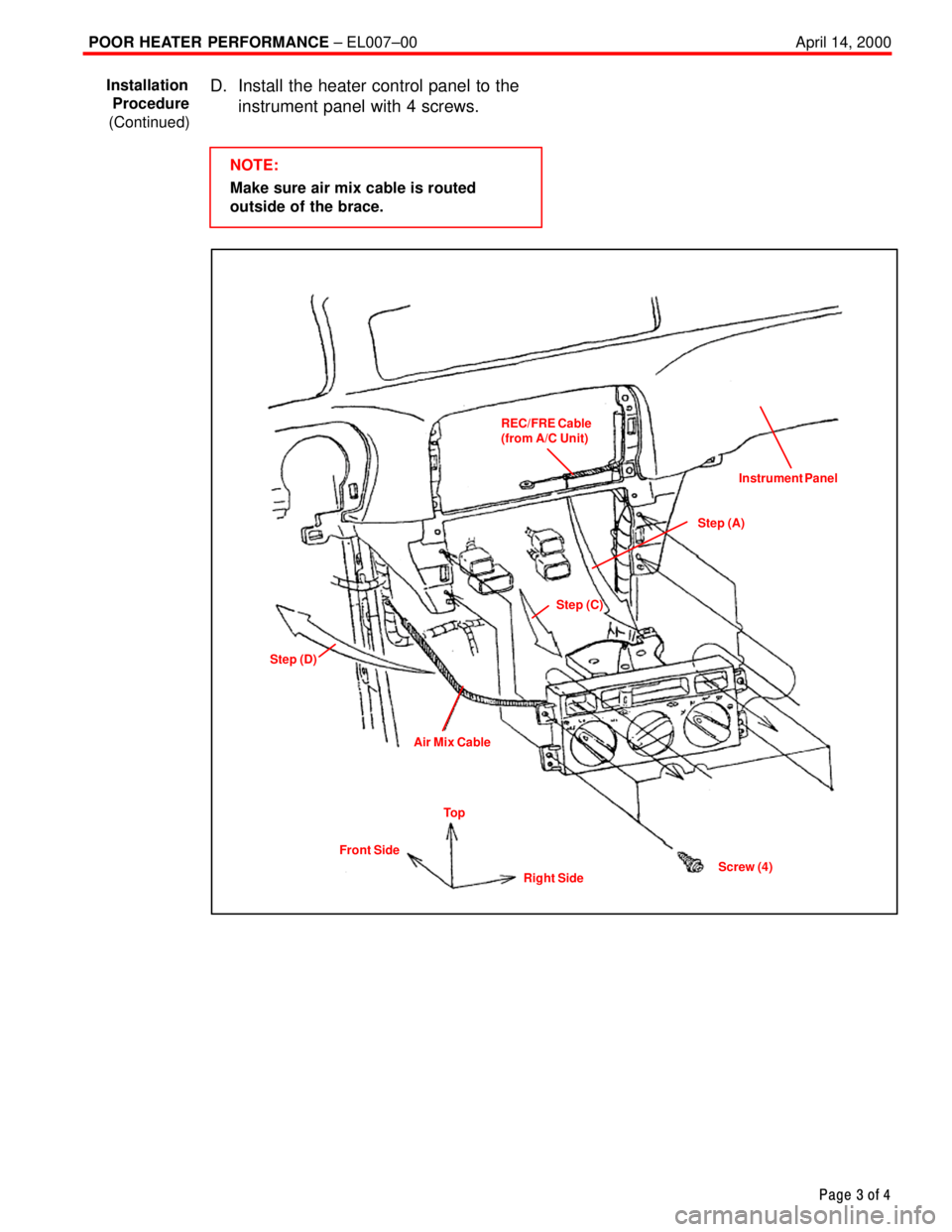

D. Install the heater control panel to the

instrument panel with 4 screws.

NOTE:

Make sure air mix cable is routed

outside of the brace.

REC/FRE Cable

(from A/C Unit)

Step (C)Instrument Panel

Step (A)

Step (D)

Air Mix Cable

Screw (4)

Right Side Front SideTo p

Installation

Procedure

(Continued)

Page 3830 of 4592

POOR HEATER PERFORMANCE ± EL007±00 April 14, 2000

Page 4 of 4

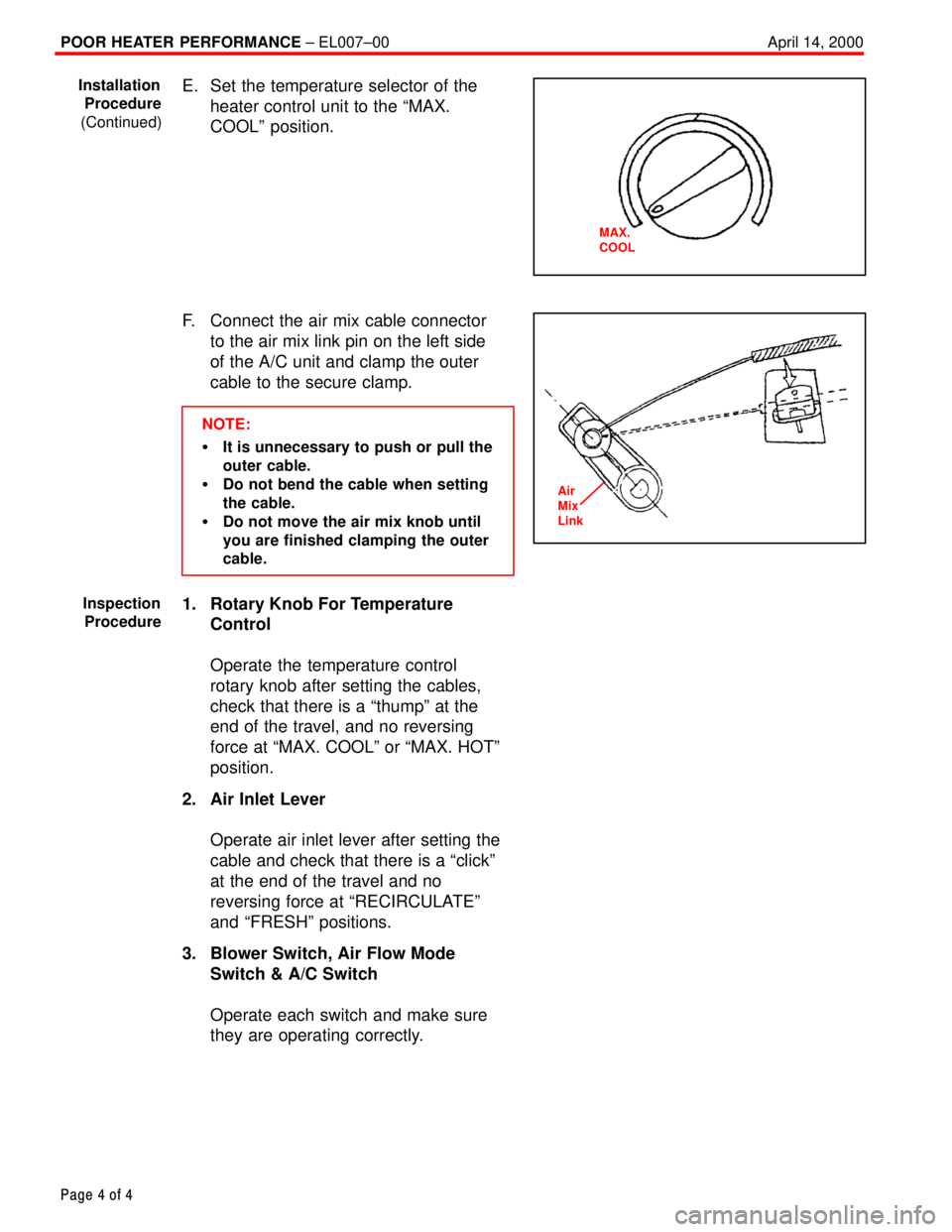

E. Set the temperature selector of the

heater control unit to the ªMAX.

COOLº position.

F. Connect the air mix cable connector

to the air mix link pin on the left side

of the A/C unit and clamp the outer

cable to the secure clamp.

NOTE:

�It is unnecessary to push or pull the

outer cable.

�Do not bend the cable when setting

the cable.

�Do not move the air mix knob until

you are finished clamping the outer

cable.

1. Rotary Knob For Temperature

Control

Operate the temperature control

rotary knob after setting the cables,

check that there is a ªthumpº at the

end of the travel, and no reversing

force at ªMAX. COOLº or ªMAX. HOTº

position.

2. Air Inlet Lever

Operate air inlet lever after setting the

cable and check that there is a ªclickº

at the end of the travel and no

reversing force at ªRECIRCULATEº

and ªFRESHº positions.

3. Blower Switch, Air Flow Mode

Switch & A/C Switch

Operate each switch and make sure

they are operating correctly.

Installation

Procedure

(Continued)

MAX.

COOL

Air

Mix

Link

Inspection

Procedure