TOYOTA CAMRY 2000 Service Repair Manual

Manufacturer: TOYOTA, Model Year: 2000, Model line: CAMRY, Model: TOYOTA CAMRY 2000Pages: 4770, PDF Size: 86.41 MB

Page 1741 of 4770

AUTOMATIC TRANSAXLECOMPONENT PARTS INSTALLATION ±

AX±108

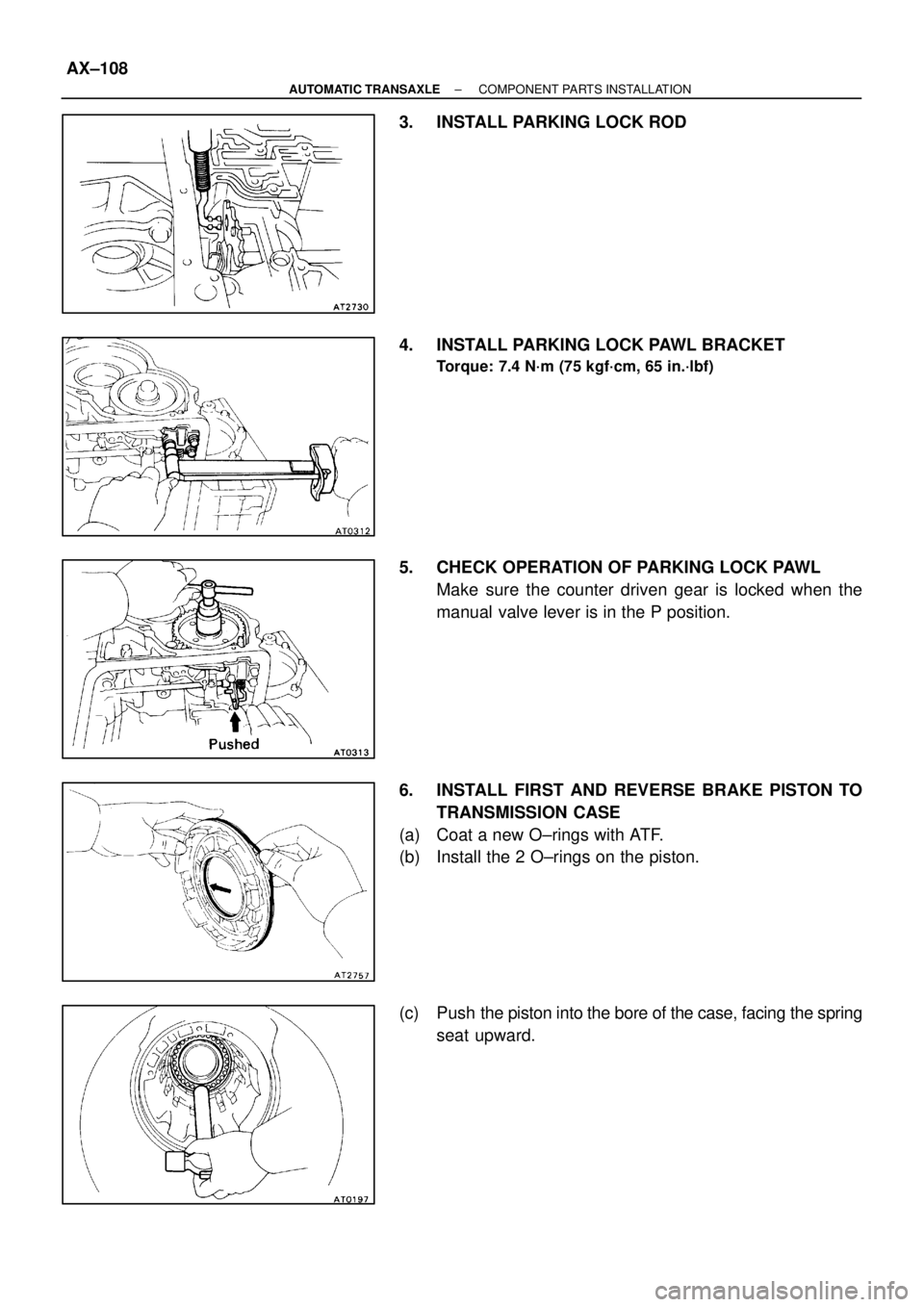

3. INSTALL PARKING LOCK ROD

4. INSTALL PARKING LOCK PAWL BRACKET

Torque: 7.4 N´m (75 kgf´cm, 65 in.´lbf)

5. CHECK OPERATION OF PARKING LOCK PAWL

Make sure the counter driven gear is locked when the

manual valve lever is in the P position.

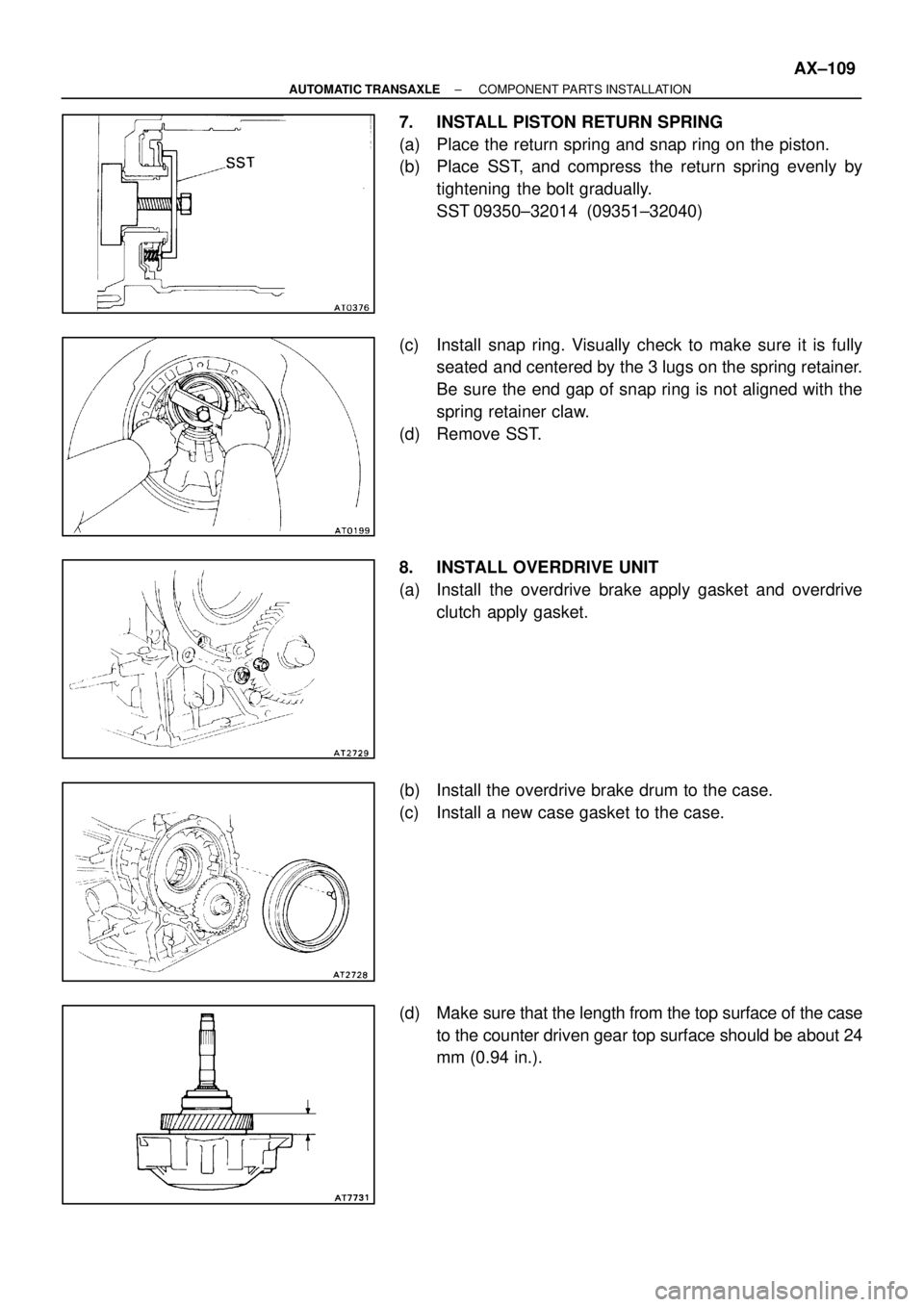

6. INSTALL FIRST AND REVERSE BRAKE PISTON TO

TRANSMISSION CASE

(a) Coat a new O±rings with ATF.

(b) Install the 2 O±rings on the piston.

(c) Push the piston into the bore of the case, facing the spring

seat upward.

Page 1742 of 4770

AUTOMATIC TRANSAXLECOMPONENT PARTS INSTALLATION ±

AX±109

7. INSTALL PISTON RETURN SPRING

(a) Place the return spring and snap ring on the piston.

(b) Place SST, and compress the return spring evenly by

tightening the bolt gradually.

SST 09350±32014 (09351±32040)

(c) Install snap ring. Visually check to make sure it is fully

seated and centered by the 3 lugs on the spring retainer.

Be sure the end gap of snap ring is not aligned with the

spring retainer claw.

(d) Remove SST.

8. INSTALL OVERDRIVE UNIT

(a) Install the overdrive brake apply gasket and overdrive

clutch apply gasket.

(b) Install the overdrive brake drum to the case.

(c) Install a new case gasket to the case.

(d) Make sure that the length from the top surface of the case

to the counter driven gear top surface should be about 24

mm (0.94 in.).

Page 1743 of 4770

AUTOMATIC TRANSAXLECOMPONENT PARTS INSTALLATION ±

AX±110

(e) Install the overdrive unit with overdrive case to the trans-

axle case.

(f) Install and tighten the bolts.

Torque: 25 N´m (250 kgf´cm, 18 ft´lbf)

9. CHECK INTERMEDIATE SHAFT END PLAY

(a) Make sure that the intermediate shaft has thrust play.

Thrust play:

0.49 ± 1.51 mm (0.0193 ± 0.0594 in.)

If the thrust play is not within specification, check the

installation of intermediate shaft.

(b) Make sure that the intermediate shaft turns smoothly.

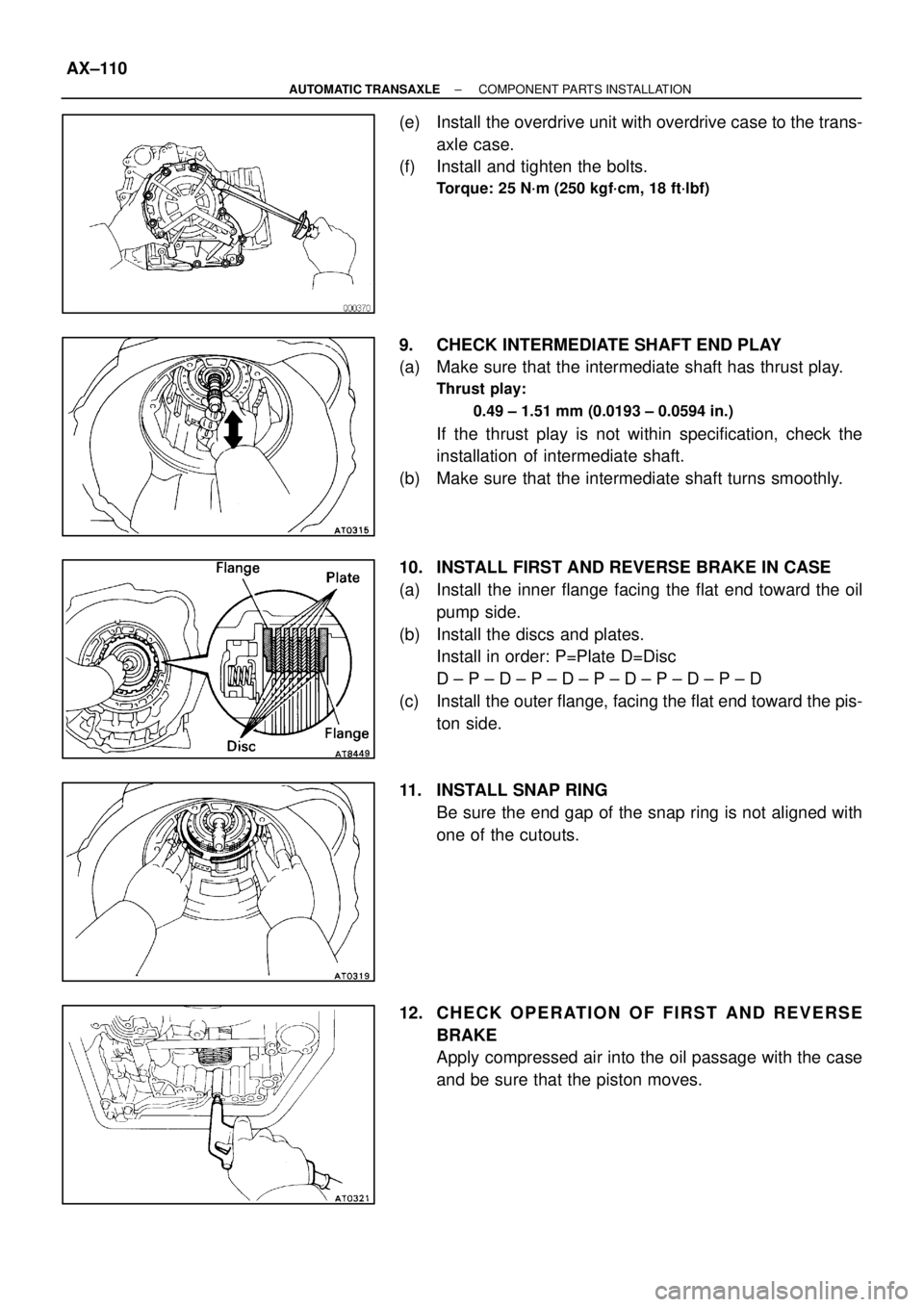

10. INSTALL FIRST AND REVERSE BRAKE IN CASE

(a) Install the inner flange facing the flat end toward the oil

pump side.

(b) Install the discs and plates.

Install in order: P=Plate D=Disc

D ± P ± D ± P ± D ± P ± D ± P ± D ± P ± D

(c) Install the outer flange, facing the flat end toward the pis-

ton side.

11. INSTALL SNAP RING

Be sure the end gap of the snap ring is not aligned with

one of the cutouts.

12. CHECK OPERATION OF FIRST AND REVERSE

BRAKE

Apply compressed air into the oil passage with the case

and be sure that the piston moves.

Page 1744 of 4770

AUTOMATIC TRANSAXLECOMPONENT PARTS INSTALLATION ±

AX±111

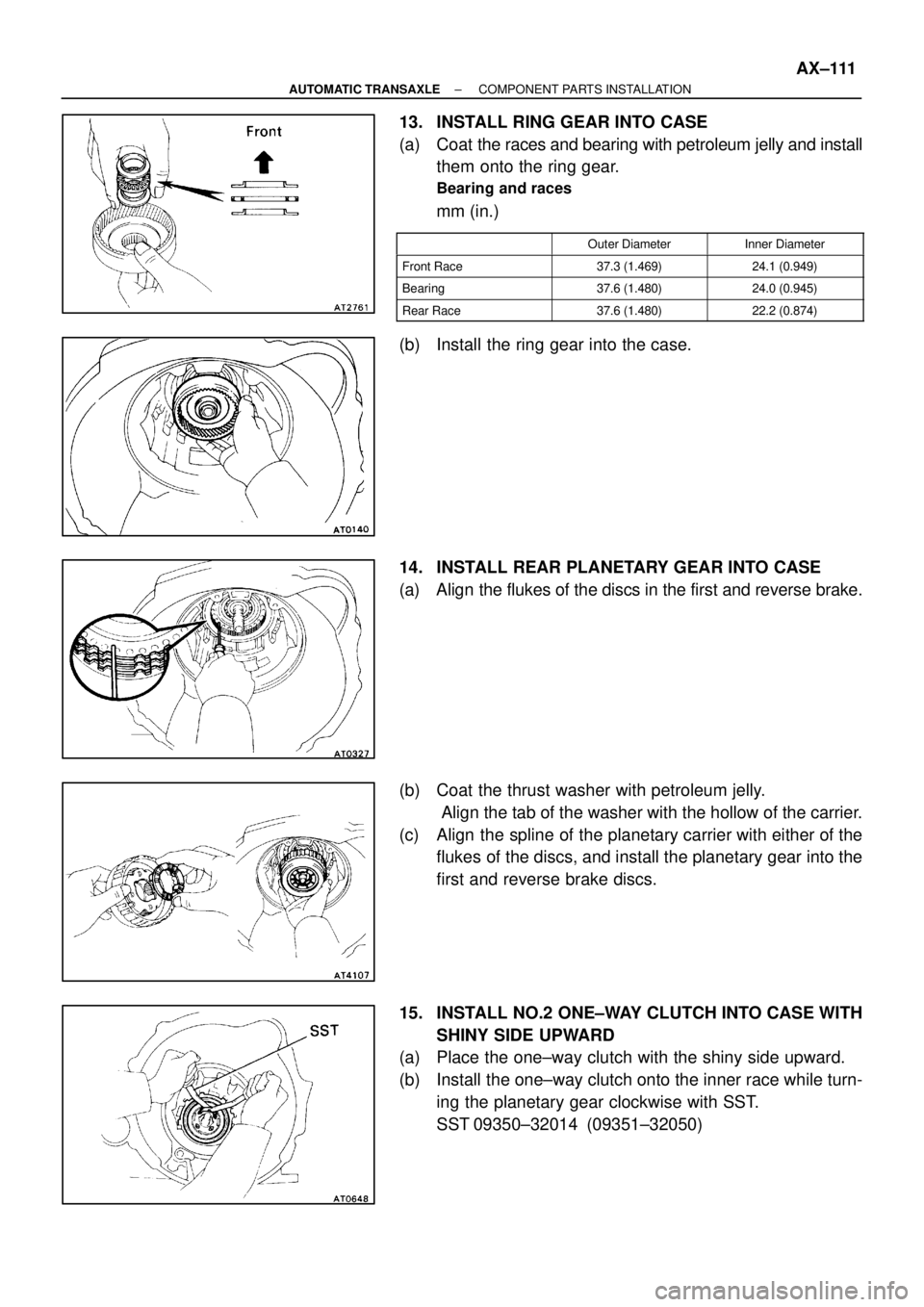

13. INSTALL RING GEAR INTO CASE

(a) Coat the races and bearing with petroleum jelly and install

them onto the ring gear.

Bearing and races

mm (in.)

Outer DiameterInner Diameter

Front Race37.3 (1.469)24.1 (0.949)

Bearing37.6 (1.480)24.0 (0.945)

Rear Race37.6 (1.480)22.2 (0.874)

(b) Install the ring gear into the case.

14. INSTALL REAR PLANETARY GEAR INTO CASE

(a) Align the flukes of the discs in the first and reverse brake.

(b) Coat the thrust washer with petroleum jelly.

Align the tab of the washer with the hollow of the carrier.

(c) Align the spline of the planetary carrier with either of the

flukes of the discs, and install the planetary gear into the

first and reverse brake discs.

15. INSTALL NO.2 ONE±WAY CLUTCH INTO CASE WITH

SHINY SIDE UPWARD

(a) Place the one±way clutch with the shiny side upward.

(b) Install the one±way clutch onto the inner race while turn-

ing the planetary gear clockwise with SST.

SST 09350±32014 (09351±32050)

Page 1745 of 4770

AUTOMATIC TRANSAXLECOMPONENT PARTS INSTALLATION ±

AX±112

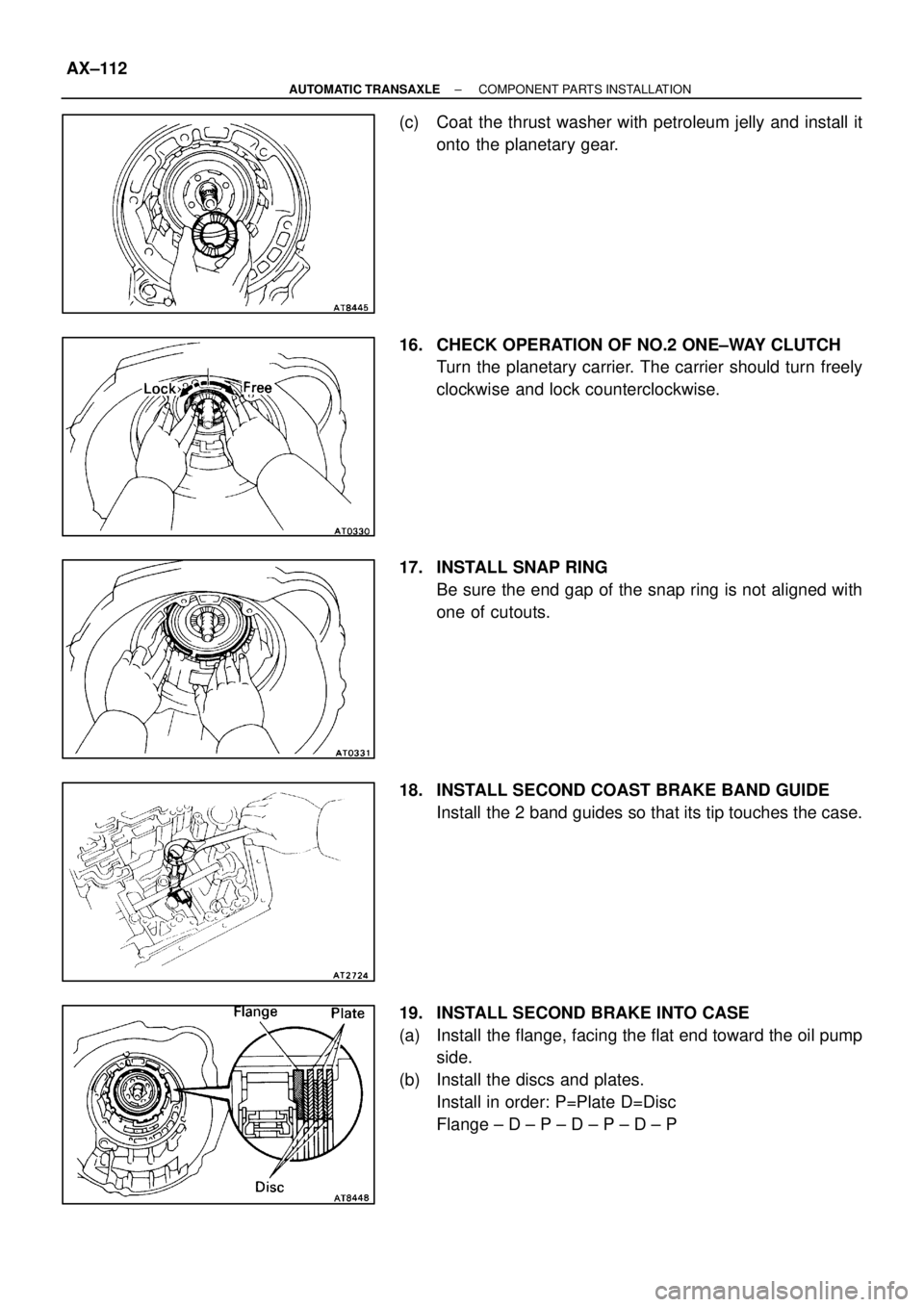

(c) Coat the thrust washer with petroleum jelly and install it

onto the planetary gear.

16. CHECK OPERATION OF NO.2 ONE±WAY CLUTCH

Turn the planetary carrier. The carrier should turn freely

clockwise and lock counterclockwise.

17. INSTALL SNAP RING

Be sure the end gap of the snap ring is not aligned with

one of cutouts.

18. INSTALL SECOND COAST BRAKE BAND GUIDE

Install the 2 band guides so that its tip touches the case.

19. INSTALL SECOND BRAKE INTO CASE

(a) Install the flange, facing the flat end toward the oil pump

side.

(b) Install the discs and plates.

Install in order: P=Plate D=Disc

Flange ± D ± P ± D ± P ± D ± P

Page 1746 of 4770

AUTOMATIC TRANSAXLECOMPONENT PARTS INSTALLATION ±

AX±113

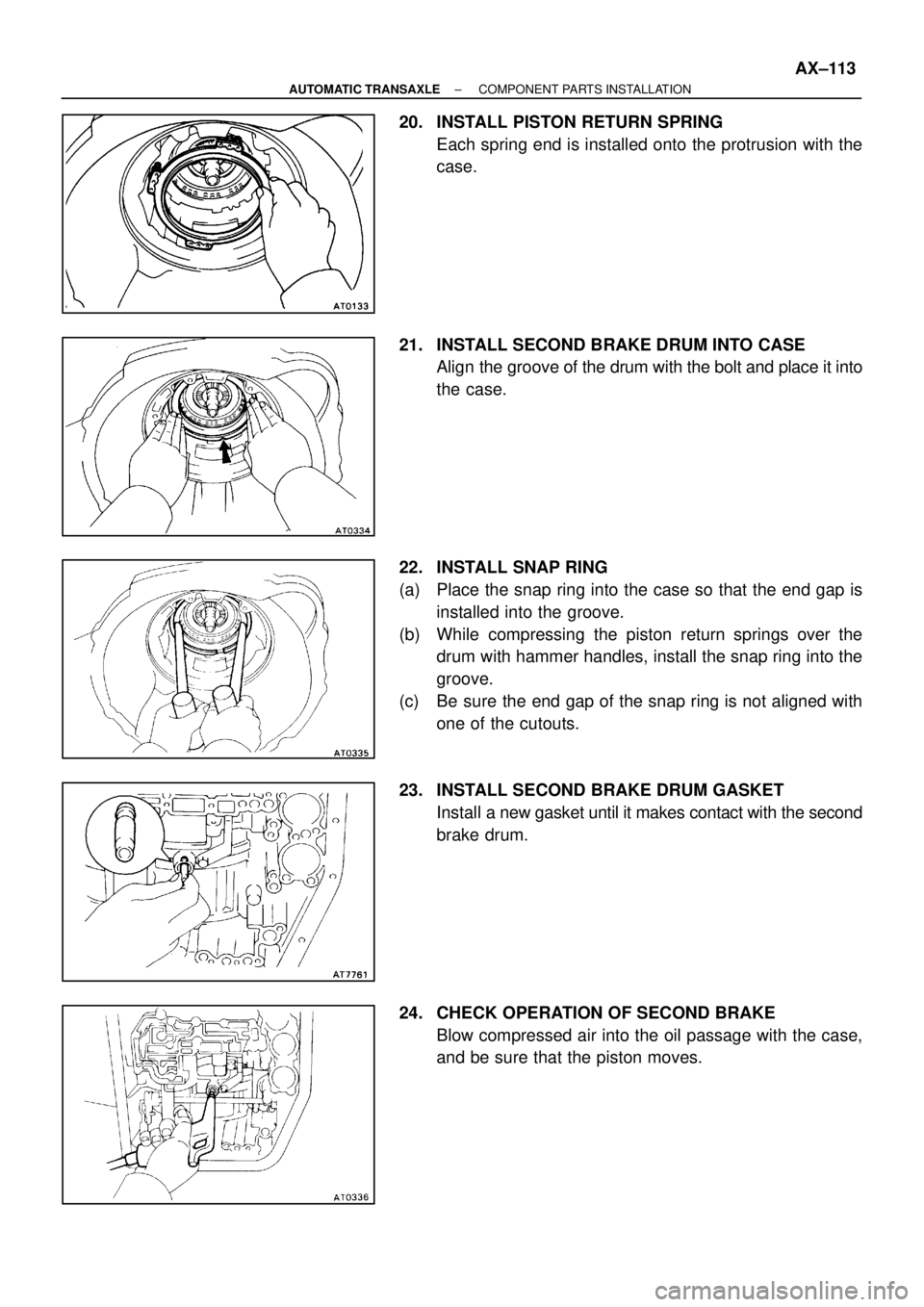

20. INSTALL PISTON RETURN SPRING

Each spring end is installed onto the protrusion with the

case.

21. INSTALL SECOND BRAKE DRUM INTO CASE

Align the groove of the drum with the bolt and place it into

the case.

22. INSTALL SNAP RING

(a) Place the snap ring into the case so that the end gap is

installed into the groove.

(b) While compressing the piston return springs over the

drum with hammer handles, install the snap ring into the

groove.

(c) Be sure the end gap of the snap ring is not aligned with

one of the cutouts.

23. INSTALL SECOND BRAKE DRUM GASKET

Install a new gasket until it makes contact with the second

brake drum.

24. CHECK OPERATION OF SECOND BRAKE

Blow compressed air into the oil passage with the case,

and be sure that the piston moves.

Page 1747 of 4770

AUTOMATIC TRANSAXLECOMPONENT PARTS INSTALLATION ±

AX±114

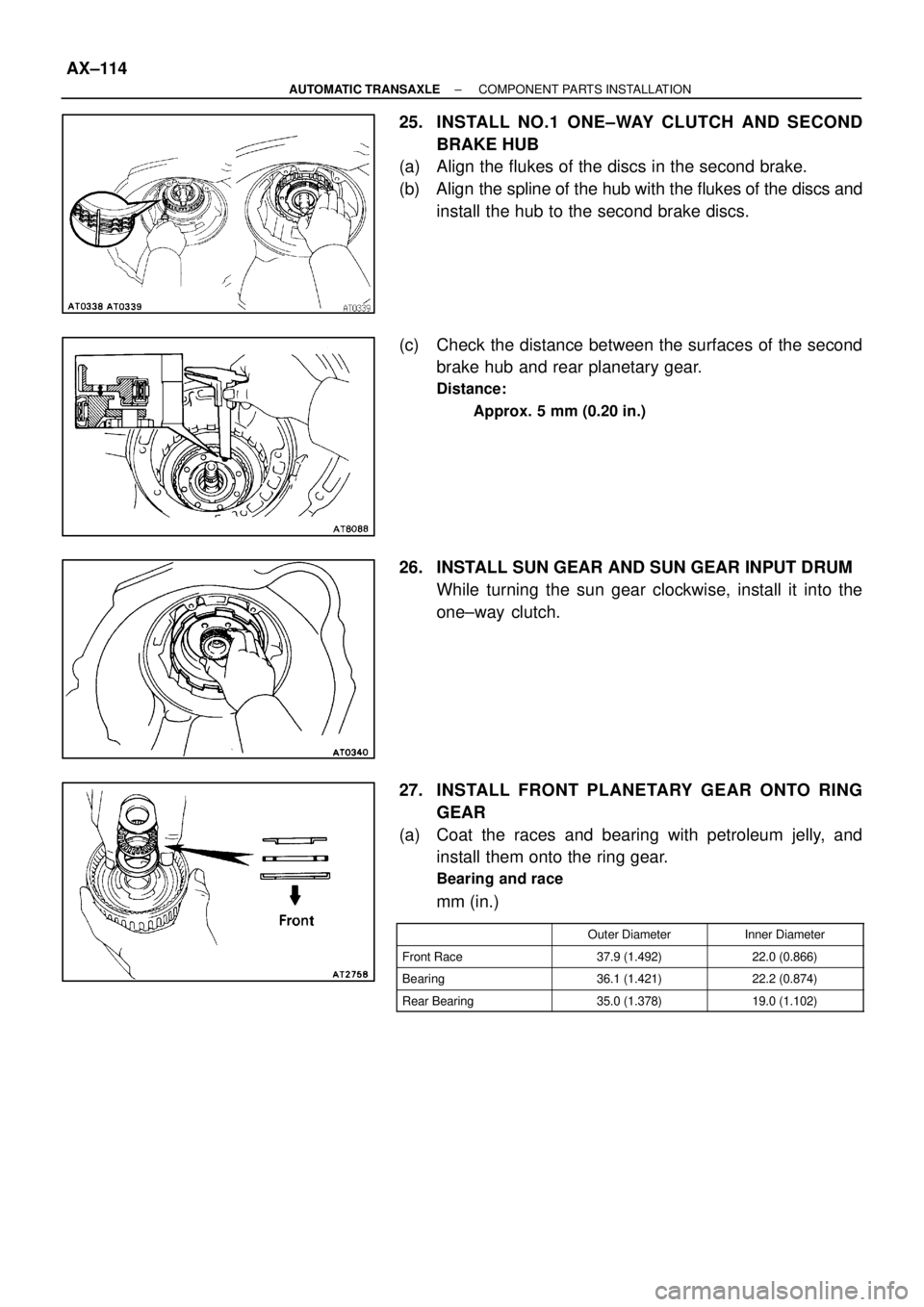

25. INSTALL NO.1 ONE±WAY CLUTCH AND SECOND

BRAKE HUB

(a) Align the flukes of the discs in the second brake.

(b) Align the spline of the hub with the flukes of the discs and

install the hub to the second brake discs.

(c) Check the distance between the surfaces of the second

brake hub and rear planetary gear.

Distance:

Approx. 5 mm (0.20 in.)

26. INSTALL SUN GEAR AND SUN GEAR INPUT DRUM

While turning the sun gear clockwise, install it into the

one±way clutch.

27. INSTALL FRONT PLANETARY GEAR ONTO RING

GEAR

(a) Coat the races and bearing with petroleum jelly, and

install them onto the ring gear.

Bearing and race

mm (in.)

Outer DiameterInner Diameter

Front Race37.9 (1.492)22.0 (0.866)

Bearing36.1 (1.421)22.2 (0.874)

Rear Bearing35.0 (1.378)19.0 (1.102)

Page 1748 of 4770

AUTOMATIC TRANSAXLECOMPONENT PARTS INSTALLATION ±

AX±115

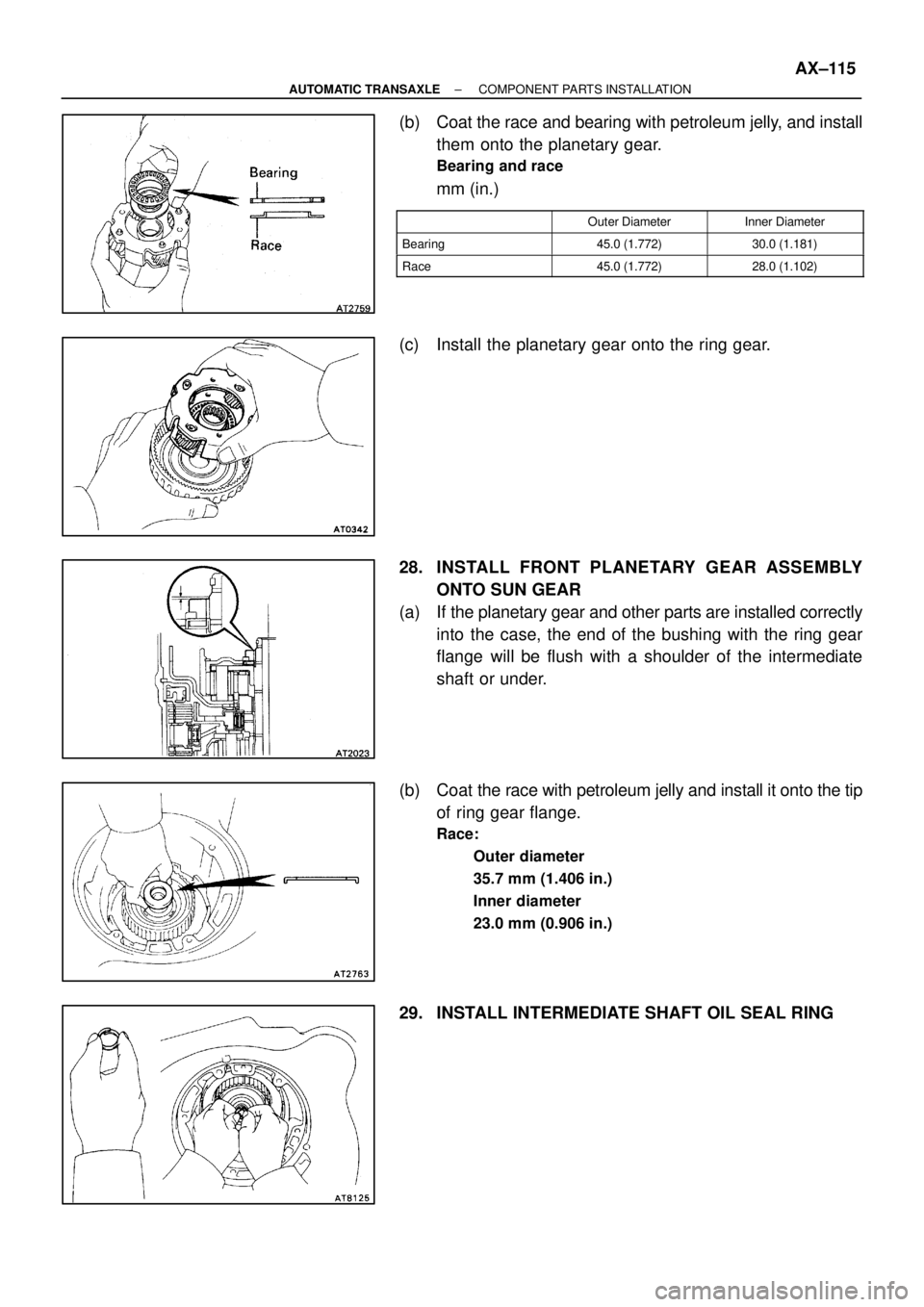

(b) Coat the race and bearing with petroleum jelly, and install

them onto the planetary gear.

Bearing and race

mm (in.)

Outer DiameterInner Diameter

Bearing45.0 (1.772)30.0 (1.181)

Race45.0 (1.772)28.0 (1.102)

(c) Install the planetary gear onto the ring gear.

28. INSTALL FRONT PLANETARY GEAR ASSEMBLY

ONTO SUN GEAR

(a) If the planetary gear and other parts are installed correctly

into the case, the end of the bushing with the ring gear

flange will be flush with a shoulder of the intermediate

shaft or under.

(b) Coat the race with petroleum jelly and install it onto the tip

of ring gear flange.

Race:

Outer diameter

35.7 mm (1.406 in.)

Inner diameter

23.0 mm (0.906 in.)

29. INSTALL INTERMEDIATE SHAFT OIL SEAL RING

Page 1749 of 4770

AUTOMATIC TRANSAXLECOMPONENT PARTS INSTALLATION ±

AX±116

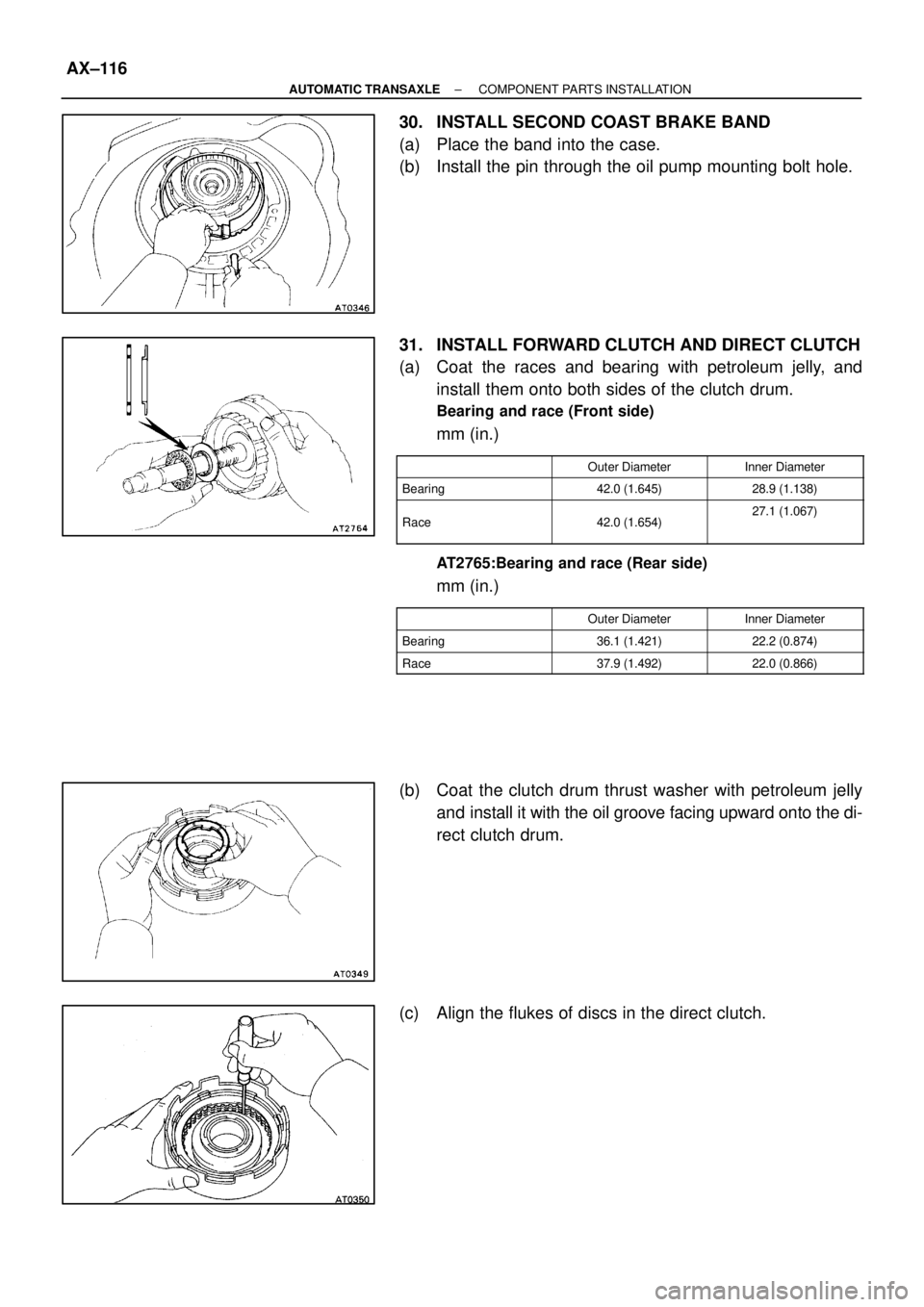

30. INSTALL SECOND COAST BRAKE BAND

(a) Place the band into the case.

(b) Install the pin through the oil pump mounting bolt hole.

31. INSTALL FORWARD CLUTCH AND DIRECT CLUTCH

(a) Coat the races and bearing with petroleum jelly, and

install them onto both sides of the clutch drum.

Bearing and race (Front side)

mm (in.)

Outer DiameterInner Diameter

Bearing42.0 (1.645)28.9 (1.138)

Race42.0 (1.654)27.1 (1.067)

AT2765:Bearing and race (Rear side)

mm (in.)

Outer DiameterInner Diameter

Bearing36.1 (1.421)22.2 (0.874)

Race37.9 (1.492)22.0 (0.866)

(b) Coat the clutch drum thrust washer with petroleum jelly

and install it with the oil groove facing upward onto the di-

rect clutch drum.

(c) Align the flukes of discs in the direct clutch.

Page 1750 of 4770

AUTOMATIC TRANSAXLECOMPONENT PARTS INSTALLATION ±

AX±117

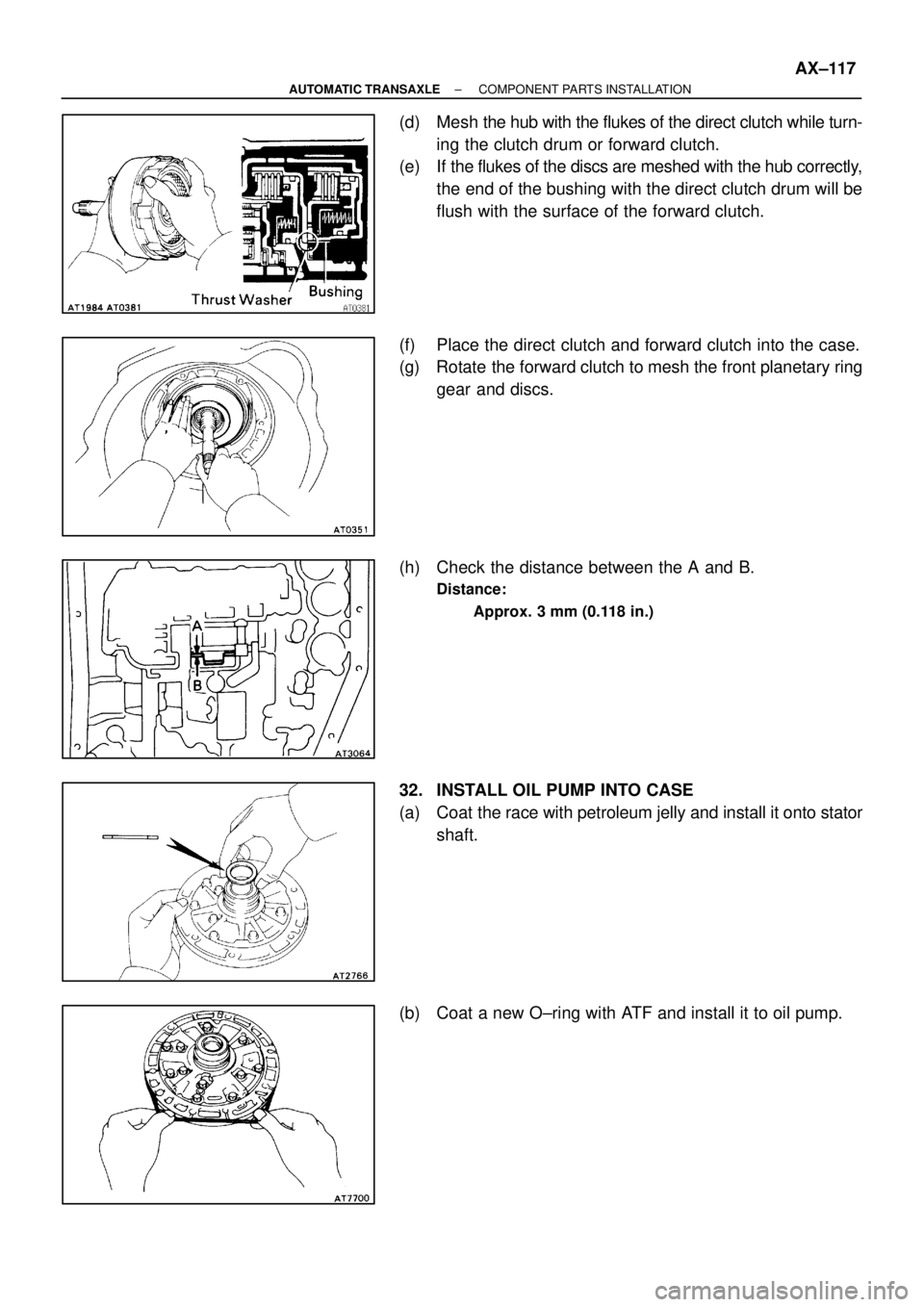

(d) Mesh the hub with the flukes of the direct clutch while turn-

ing the clutch drum or forward clutch.

(e) If the flukes of the discs are meshed with the hub correctly,

the end of the bushing with the direct clutch drum will be

flush with the surface of the forward clutch.

(f) Place the direct clutch and forward clutch into the case.

(g) Rotate the forward clutch to mesh the front planetary ring

gear and discs.

(h) Check the distance between the A and B.

Distance:

Approx. 3 mm (0.118 in.)

32. INSTALL OIL PUMP INTO CASE

(a) Coat the race with petroleum jelly and install it onto stator

shaft.

(b) Coat a new O±ring with ATF and install it to oil pump.