TOYOTA CAMRY V20 1986 Service Information

Manufacturer: TOYOTA, Model Year: 1986, Model line: CAMRY V20, Model: TOYOTA CAMRY V20 1986Pages: 2389, PDF Size: 84.44 MB

Page 1891 of 2389

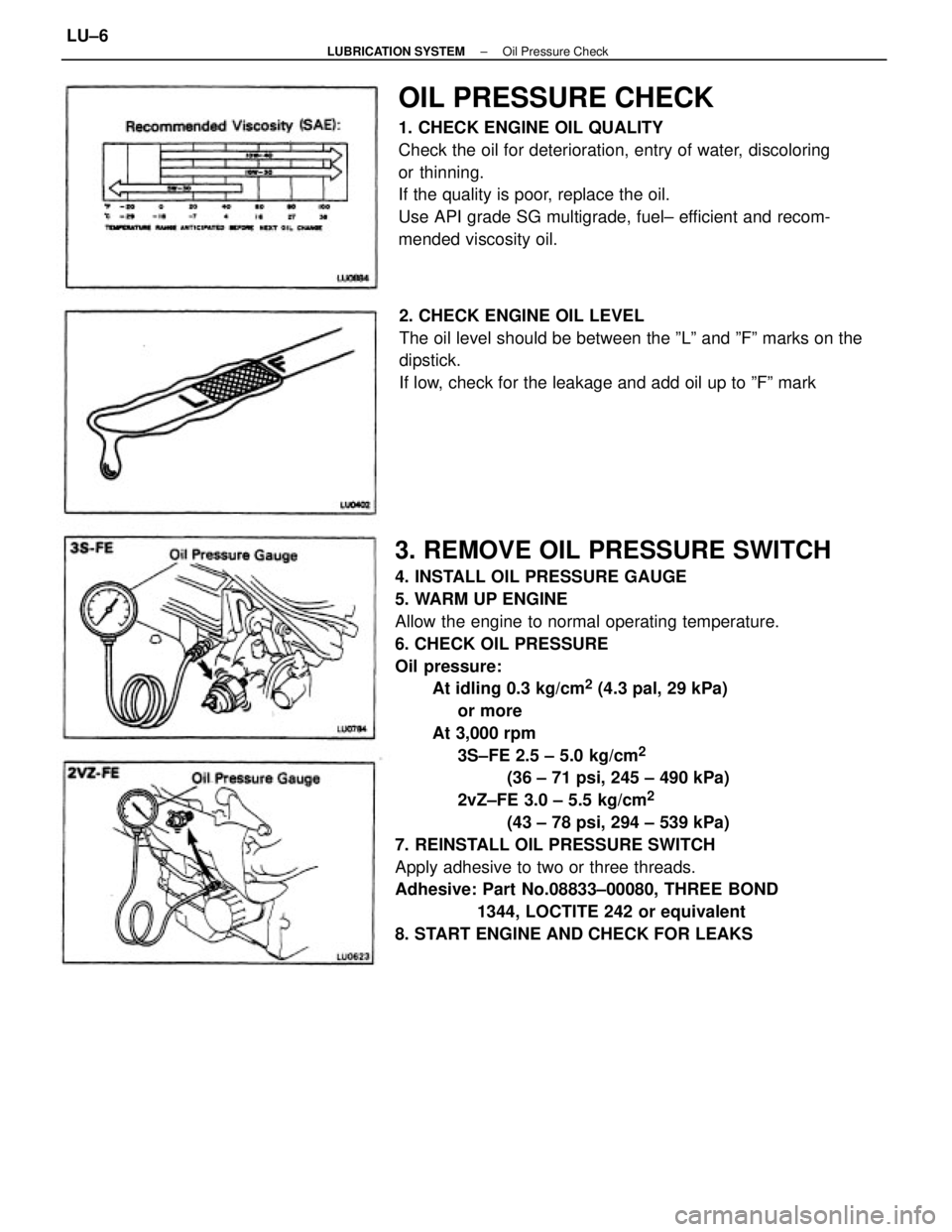

3. REMOVE OIL PRESSURE SWITCH

4. INSTALL OIL PRESSURE GAUGE

5. WARM UP ENGINE

Allow the engine to normal operating temperature.

6. CHECK OIL PRESSURE

Oil pressure:

At idling 0.3 kg/cm

2 (4.3 pal, 29 kPa)

or more

At 3,000 rpm

3S±FE 2.5 ± 5.0 kg/cm

2

(36 ± 71 psi, 245 ± 490 kPa)

2vZ±FE 3.0 ± 5.5 kg/cm

2

(43 ± 78 psi, 294 ± 539 kPa)

7. REINSTALL OIL PRESSURE SWITCH

Apply adhesive to two or three threads.

Adhesive: Part No.08833±00080, THREE BOND

1344, LOCTITE 242 or equivalent

8. START ENGINE AND CHECK FOR LEAKS

OIL PRESSURE CHECK

1. CHECK ENGINE OIL QUALITY

Check the oil for deterioration, entry of water, discoloring

or thinning.

If the quality is poor, replace the oil.

Use API grade SG multigrade, fuel± efficient and recom-

mended viscosity oil.

2. CHECK ENGINE OIL LEVEL

The oil level should be between the ºLº and ºFº marks on the

dipstick.

If low, check for the leakage and add oil up to ºFº mark

± LUBRICATION SYSTEMOil Pressure CheckLU±6

Page 1892 of 2389

REPLACEMENT OF ENGINE OIL

AND OIL FILTER

NOTICE:

wProlonged and repeated contact with mineral oil will re-

sult in the removal of natural¿¿ts from the skin, leading

to dryness, irritation and dermatitis. In addition, used en-

gine oil contains potentially harmful contaminants

which may cause skin cancer.

wCare should be taken, therefore, when changing engine

oil, to minimize the frequency and length of time your

skin is exposed to used engine oil. Protective clothing

and gloves, that cannot be penetrated by oil, should be

worn. The skin should be thoroughly washed with soap

and water, or use waterless hand cleaner, to remove any

used engine oil. Do not use gasoline, thinners, or sol-

vents.

wIn order to preserve the environment, used oil must be

disposed of only at designated disposal sites.

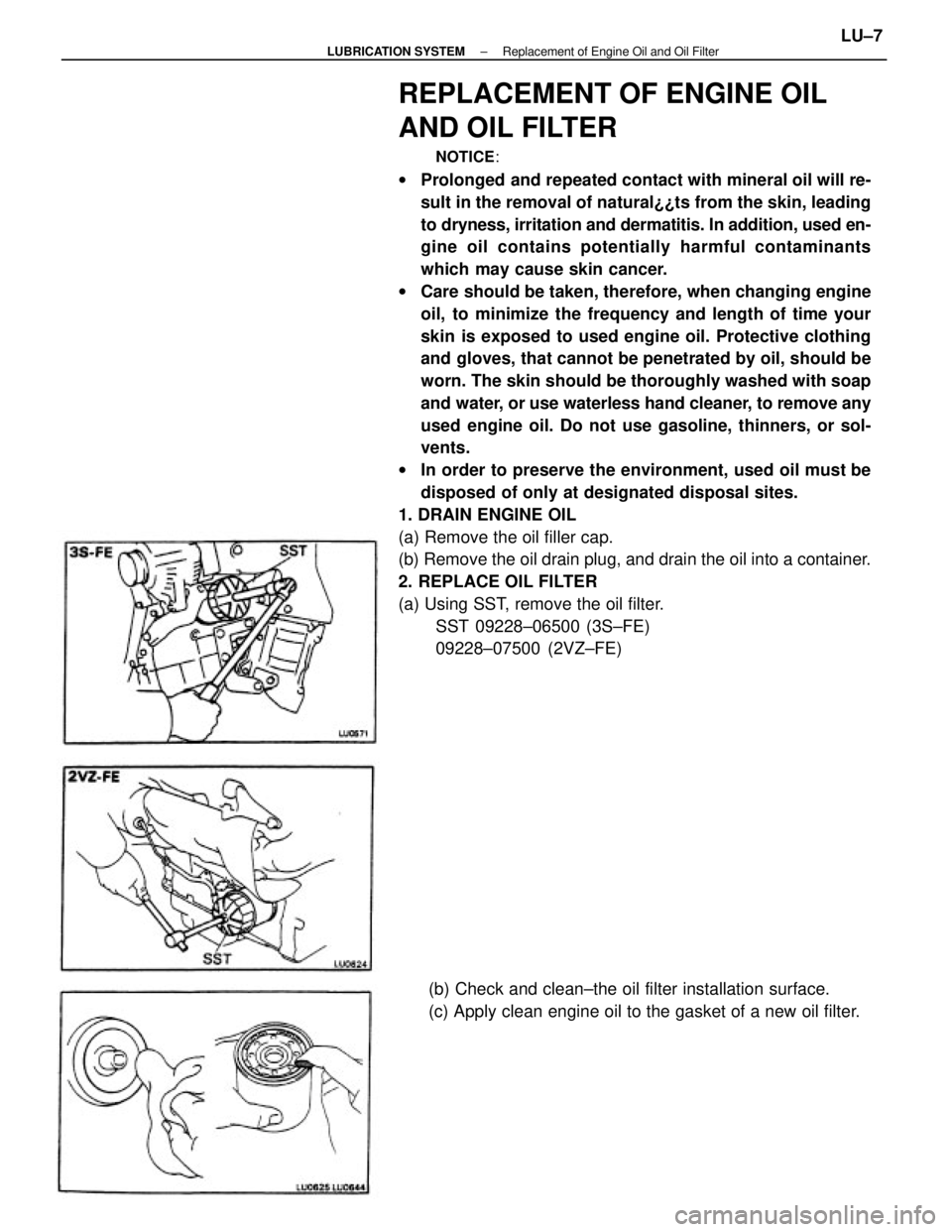

1. DRAIN ENGINE OIL

(a) Remove the oil filler cap.

(b) Remove the oil drain plug, and drain the oil into a container.

2. REPLACE OIL FILTER

(a) Using SST, remove the oil filter.

SST 09228±06500 (3S±FE)

09228±07500 (2VZ±FE)

(b) Check and clean±the oil filter installation surface.

(c) Apply clean engine oil to the gasket of a new oil filter.

± LUBRICATION SYSTEMReplacement of Engine Oil and Oil FilterLU±7

Page 1893 of 2389

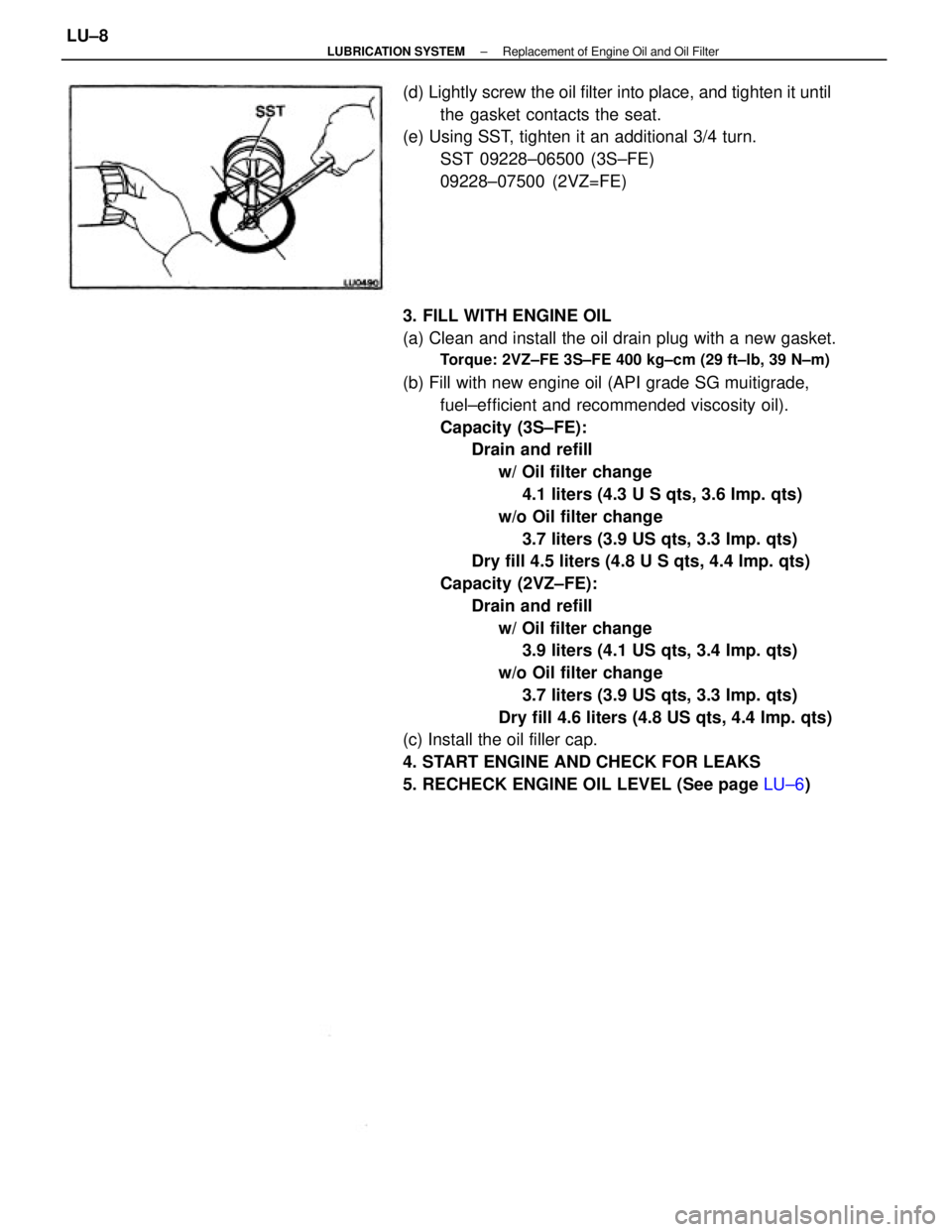

3. FILL WITH ENGINE OIL

(a) Clean and install the oil drain plug with a new gasket.

Torque: 2VZ±FE 3S±FE 400 kg±cm (29 ft±lb, 39 N±m)

(b) Fill with new engine oil (API grade SG muitigrade,

fuel±efficient and recommended viscosity oil).

Capacity (3S±FE):

Drain and refill

w/ Oil filter change

4.1 liters (4.3 U S qts, 3.6 Imp. qts)

w/o Oil filter change

3.7 liters (3.9 US qts, 3.3 Imp. qts)

Dry fill 4.5 liters (4.8 U S qts, 4.4 Imp. qts)

Capacity (2VZ±FE):

Drain and refill

w/ Oil filter change

3.9 liters (4.1 US qts, 3.4 Imp. qts)

w/o Oil filter change

3.7 liters (3.9 US qts, 3.3 Imp. qts)

Dry fill 4.6 liters (4.8 US qts, 4.4 Imp. qts)

(c) Install the oil filler cap.

4. START ENGINE AND CHECK FOR LEAKS

5. RECHECK ENGINE OIL LEVEL (See page LU±6) (d) Lightly screw the oil filter into place, and tighten it until

the gasket contacts the seat.

(e) Using SST, tighten it an additional 3/4 turn.

SST 09228±06500 (3S±FE)

09228±07500 (2VZ=FE)

± LUBRICATION SYSTEMReplacement of Engine Oil and Oil FilterLU±8

Page 1894 of 2389

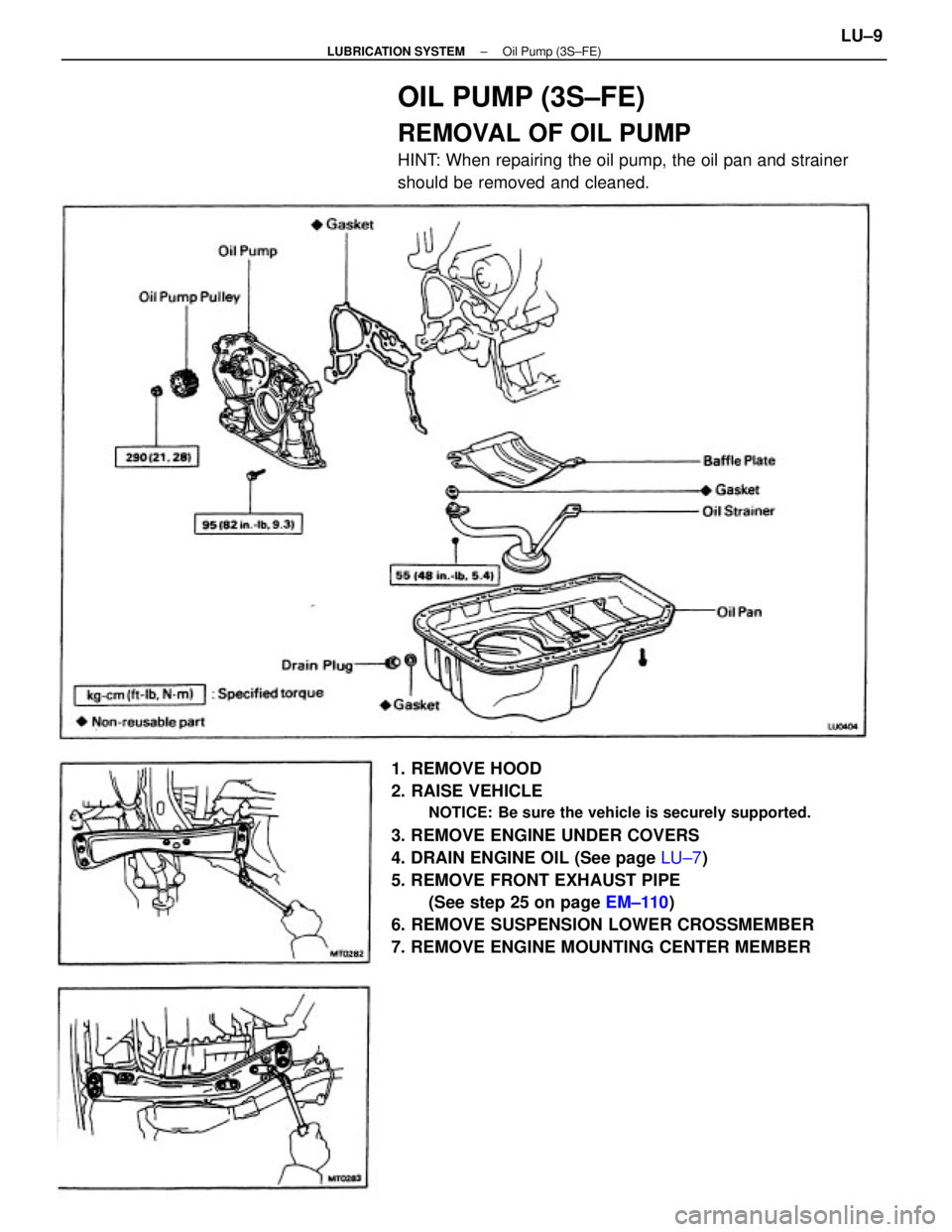

1. REMOVE HOOD

2. RAISE VEHICLE

NOTICE: Be sure the vehicle is securely supported.

3. REMOVE ENGINE UNDER COVERS

4. DRAIN ENGINE OIL (See page LU±7)

5. REMOVE FRONT EXHAUST PIPE

(See step 25 on page EM±110)

6. REMOVE SUSPENSION LOWER CROSSMEMBER

7. REMOVE ENGINE MOUNTING CENTER MEMBER

OIL PUMP (3S±FE)

REMOVAL OF OIL PUMP

HINT: When repairing the oil pump, the oil pan and strainer

should be removed and cleaned.

± LUBRICATION SYSTEMOil Pump (3S±FE)LU±9

Page 1895 of 2389

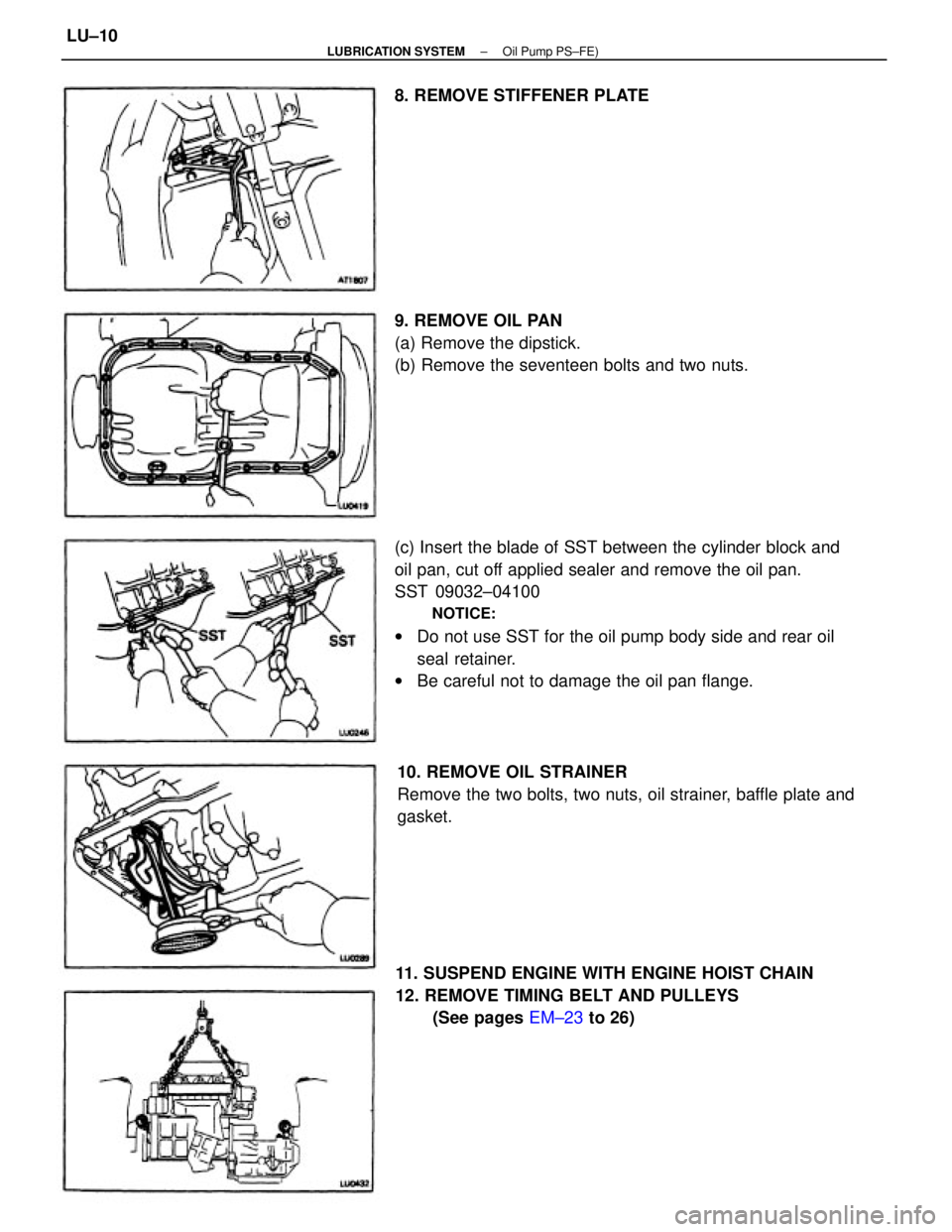

(c) Insert the blade of SST between the cylinder block and

oil pan, cut off applied sealer and remove the oil pan.

SST 09032±04100

NOTICE:

wDo not use SST for the oil pump body side and rear oil

seal retainer.

wBe careful not to damage the oil pan flange.

11. SUSPEND ENGINE WITH ENGINE HOIST CHAIN

12. REMOVE TIMING BELT AND PULLEYS

(See pages EM±23 to 26) 10. REMOVE OIL STRAINER

Remove the two bolts, two nuts, oil strainer, baffle plate and

gasket. 9. REMOVE OIL PAN

(a) Remove the dipstick.

(b) Remove the seventeen bolts and two nuts. 8. REMOVE STIFFENER PLATE

± LUBRICATION SYSTEMOil Pump PS±FE)LU±10

Page 1896 of 2389

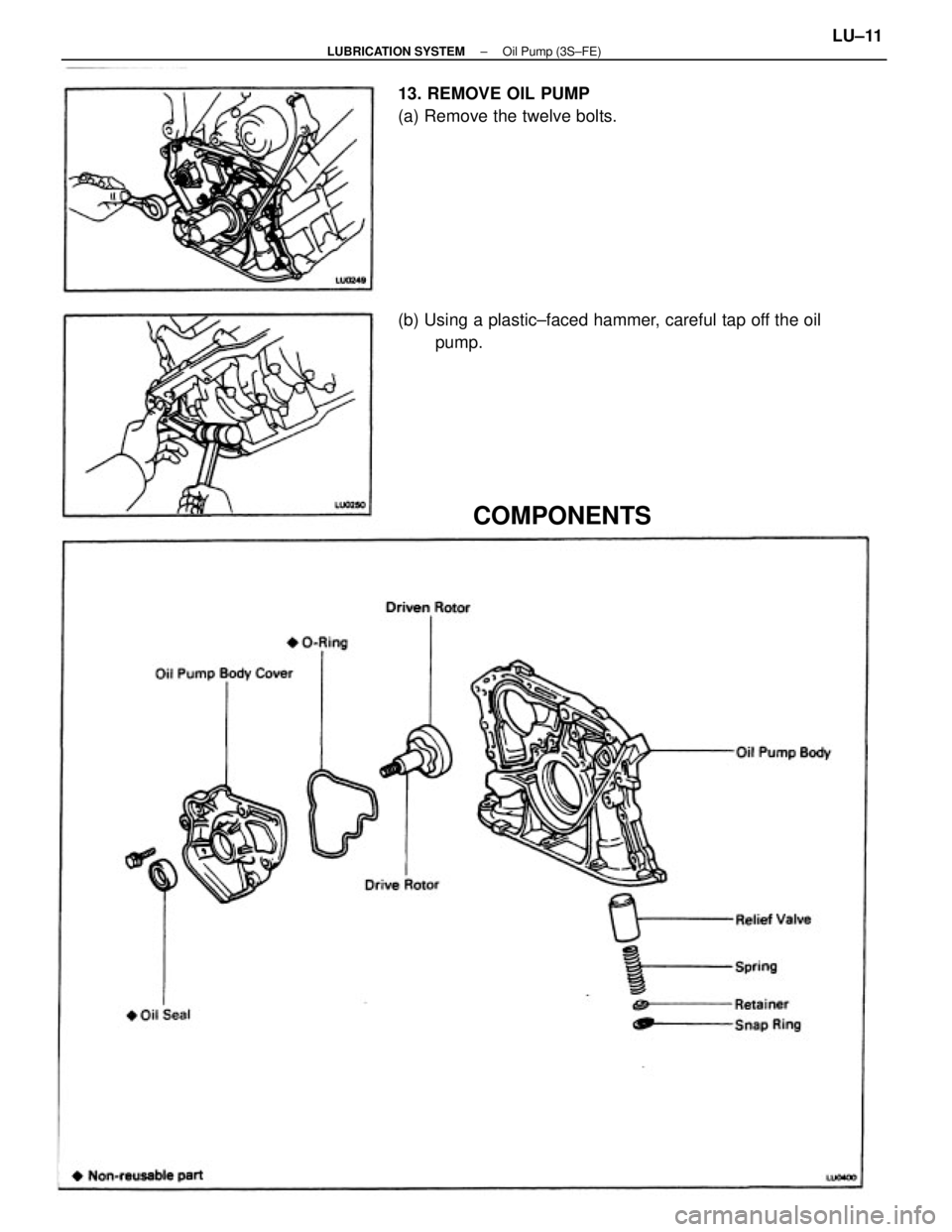

(b) Using a plastic±faced hammer, careful tap off the oil

pump. 13. REMOVE OIL PUMP

(a) Remove the twelve bolts.

COMPONENTS

± LUBRICATION SYSTEMOil Pump (3S±FE)LU±11

Page 1897 of 2389

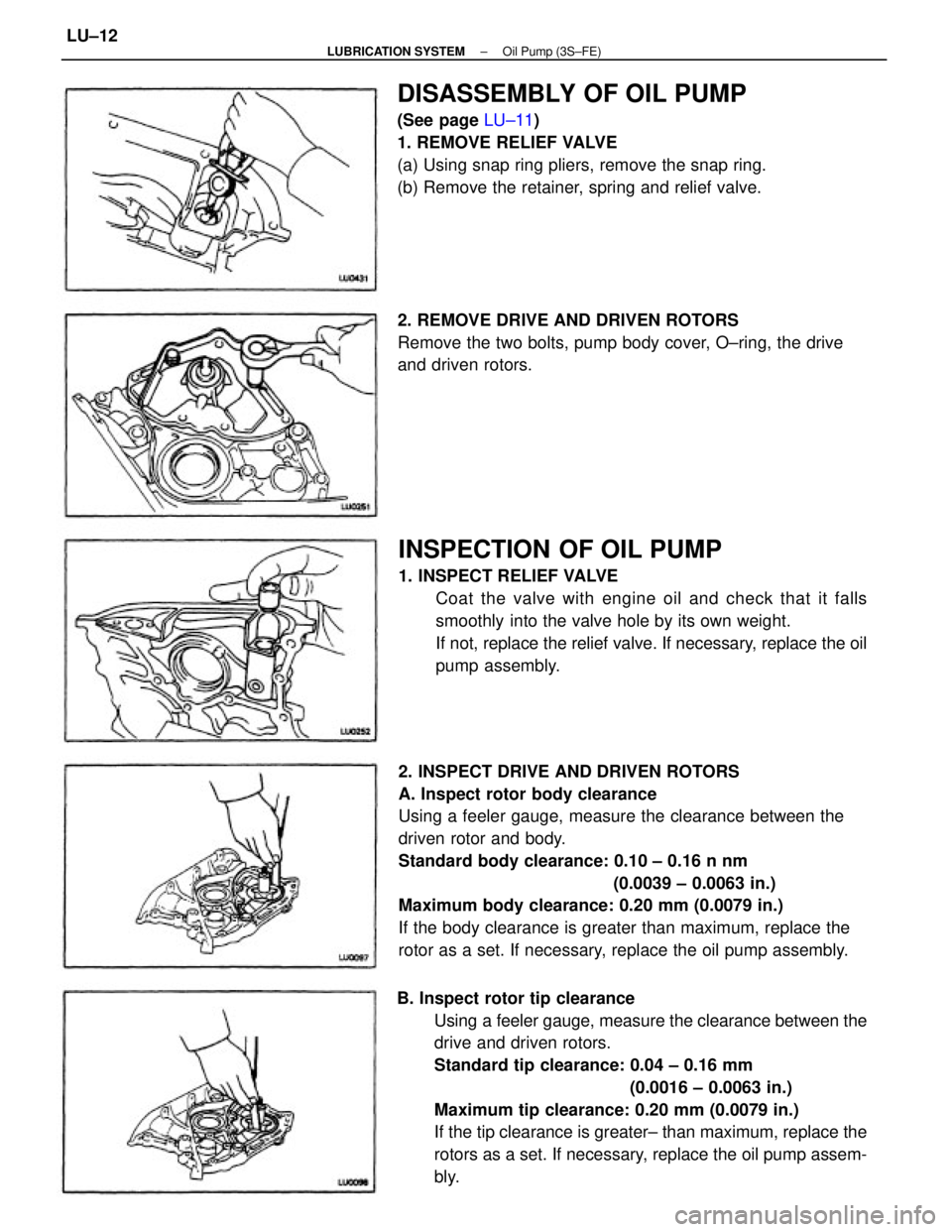

2. INSPECT DRIVE AND DRIVEN ROTORS

A. Inspect rotor body clearance

Using a feeler gauge, measure the clearance between the

driven rotor and body.

Standard body clearance: 0.10 ± 0.16 n nm

(0.0039 ± 0.0063 in.)

Maximum body clearance: 0.20 mm (0.0079 in.)

If the body clearance is greater than maximum, replace the

rotor as a set. If necessary, replace the oil pump assembly.

B. Inspect rotor tip clearance

Using a feeler gauge, measure the clearance between the

drive and driven rotors.

Standard tip clearance: 0.04 ± 0.16 mm

(0.0016 ± 0.0063 in.)

Maximum tip clearance: 0.20 mm (0.0079 in.)

If the tip clearance is greater± than maximum, replace the

rotors as a set. If necessary, replace the oil pump assem-

bly.

INSPECTION OF OIL PUMP

1. INSPECT RELIEF VALVE

Coat the valve with engine oil and check that it falls

smoothly into the valve hole by its own weight.

If not, replace the relief valve. If necessary, replace the oil

pump assembly.

DISASSEMBLY OF OIL PUMP

(See page LU±11)

1. REMOVE RELIEF VALVE

(a) Using snap ring pliers, remove the snap ring.

(b) Remove the retainer, spring and relief valve.

2. REMOVE DRIVE AND DRIVEN ROTORS

Remove the two bolts, pump body cover, O±ring, the drive

and driven rotors.

± LUBRICATION SYSTEMOil Pump (3S±FE)LU±12

Page 1898 of 2389

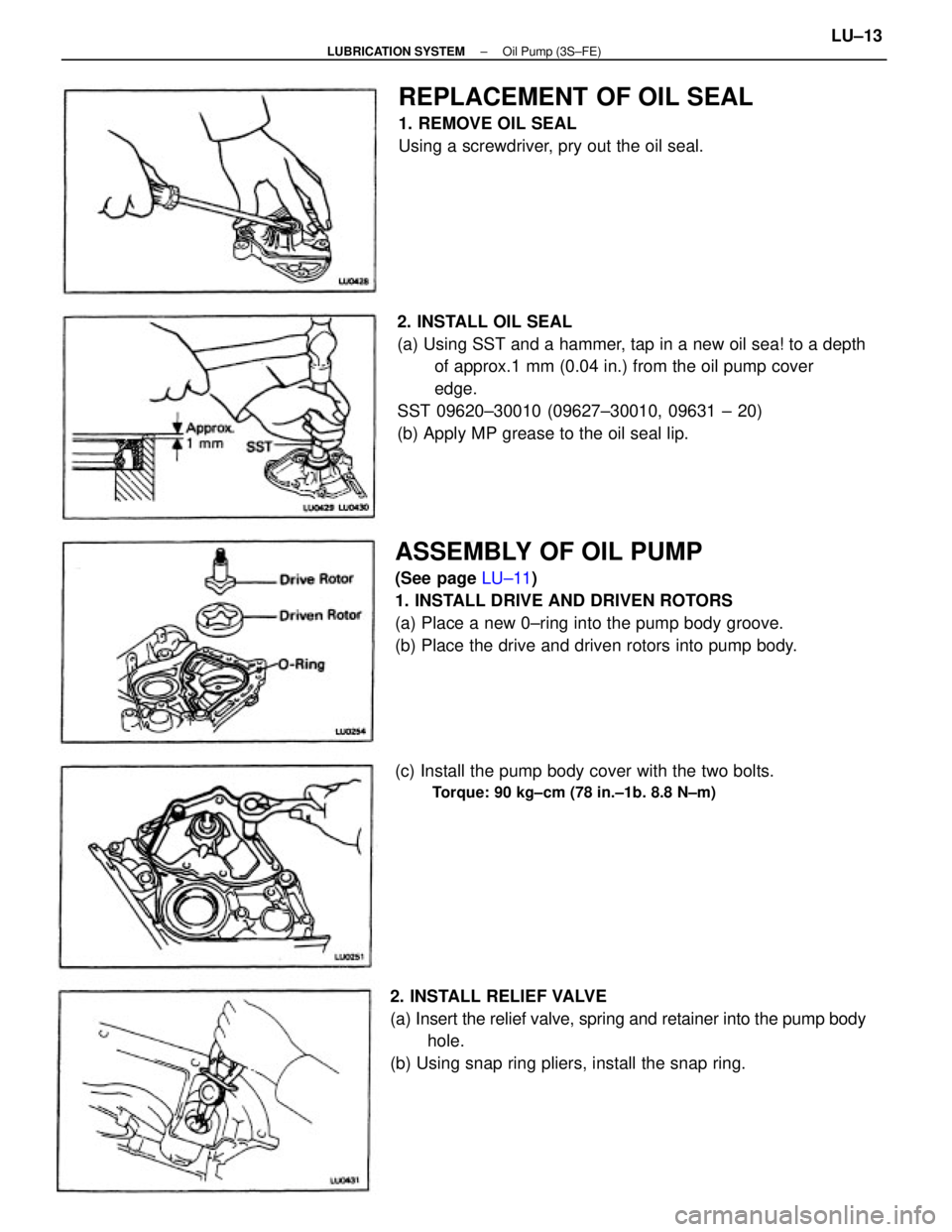

2. INSTALL OIL SEAL

(a) Using SST and a hammer, tap in a new oil sea! to a depth

of approx.1 mm (0.04 in.) from the oil pump cover

edge.

SST 09620±30010 (09627±30010, 09631 ± 20)

(b) Apply MP grease to the oil seal lip.

ASSEMBLY OF OIL PUMP

(See page LU±11)

1. INSTALL DRIVE AND DRIVEN ROTORS

(a) Place a new 0±ring into the pump body groove.

(b) Place the drive and driven rotors into pump body.

2. INSTALL RELIEF VALVE

(a) Insert the relief valve, spring and retainer into the pump body

hole.

(b) Using snap ring pliers, install the snap ring.

REPLACEMENT OF OIL SEAL

1. REMOVE OIL SEAL

Using a screwdriver, pry out the oil seal.

(c) Install the pump body cover with the two bolts.

Torque: 90 kg±cm (78 in.±1b. 8.8 N±m)

± LUBRICATION SYSTEMOil Pump (3S±FE)LU±13

Page 1899 of 2389

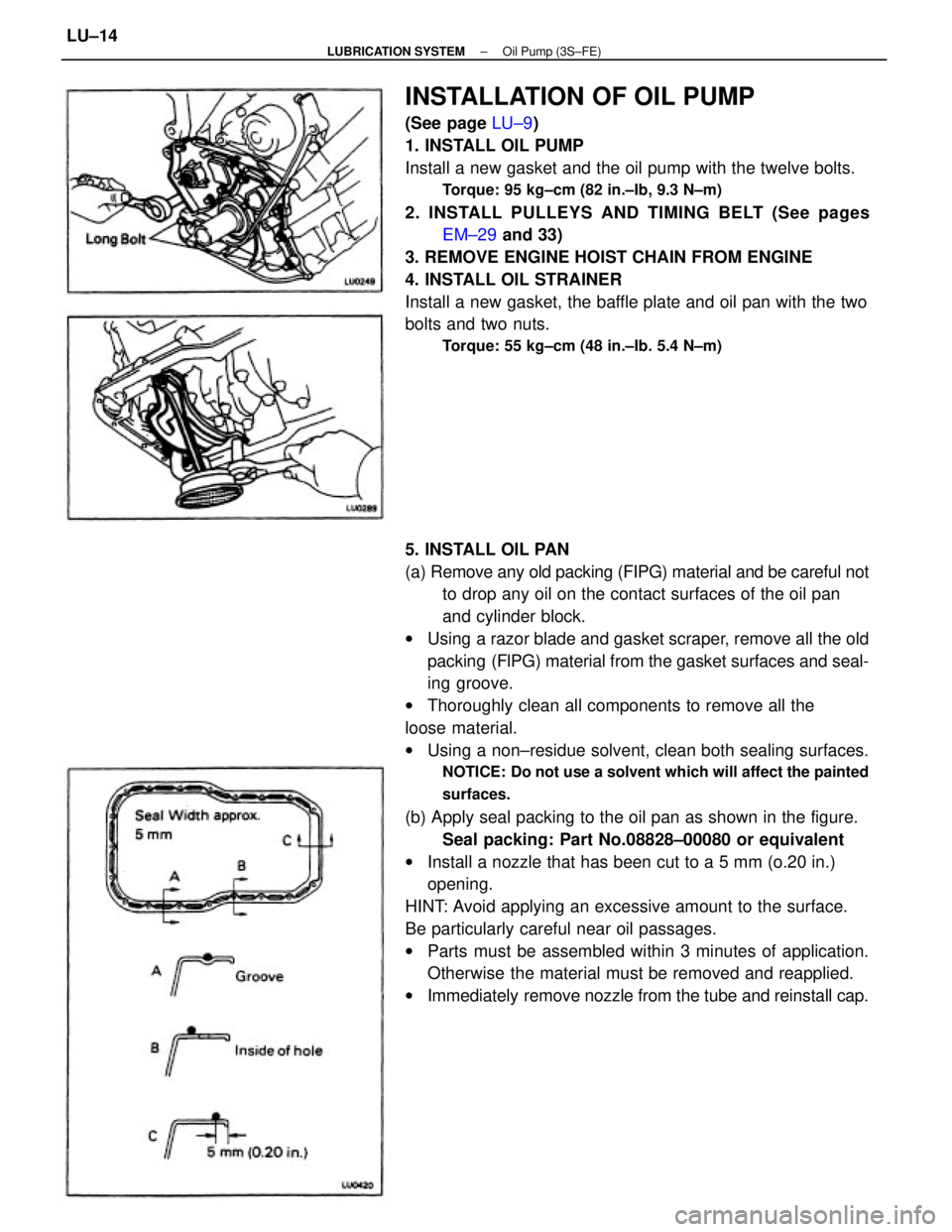

5. INSTALL OIL PAN

(a) Remove any old packing (FIPG) material and be careful not

to drop any oil on the contact surfaces of the oil pan

and cylinder block.

wUsing a razor blade and gasket scraper, remove all the old

packing (FlPG) material from the gasket surfaces and seal-

ing groove.

wThoroughly clean all components to remove all the

loose material.

wUsing a non±residue solvent, clean both sealing surfaces.

NOTICE: Do not use a solvent which will affect the painted

surfaces.

(b) Apply seal packing to the oil pan as shown in the figure.

Seal packing: Part No.08828±00080 or equivalent

wInstall a nozzle that has been cut to a 5 mm (o.20 in.)

opening.

HINT: Avoid applying an excessive amount to the surface.

Be particularly careful near oil passages.

wParts must be assembled within 3 minutes of application.

Otherwise the material must be removed and reapplied.

wImmediately remove nozzle from the tube and reinstall cap.

INSTALLATION OF OIL PUMP

(See page LU±9)

1. INSTALL OIL PUMP

Install a new gasket and the oil pump with the twelve bolts.

Torque: 95 kg±cm (82 in.±Ib, 9.3 N±m)

2. INSTALL PULLEYS AND TIMING BELT (See pages

EM±29 and 33)

3. REMOVE ENGINE HOIST CHAIN FROM ENGINE

4. INSTALL OIL STRAINER

Install a new gasket, the baffle plate and oil pan with the two

bolts and two nuts.

Torque: 55 kg±cm (48 in.±Ib. 5.4 N±m)

± LUBRICATION SYSTEMOil Pump (3S±FE)LU±14

Page 1900 of 2389

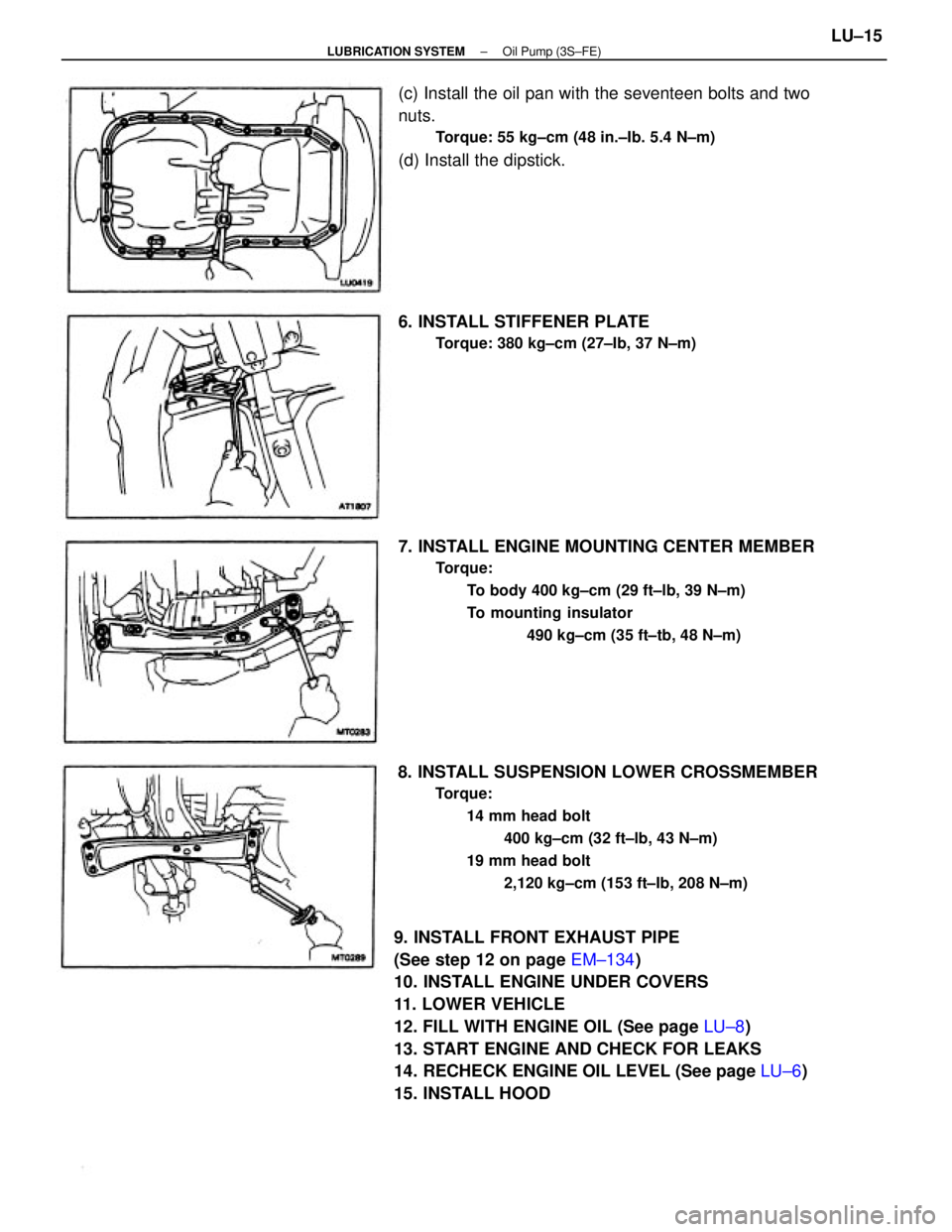

9. INSTALL FRONT EXHAUST PIPE

(See step 12 on page EM±134)

10. INSTALL ENGINE UNDER COVERS

11. LOWER VEHICLE

12. FILL WITH ENGINE OIL (See page LU±8)

13. START ENGINE AND CHECK FOR LEAKS

14. RECHECK ENGINE OIL LEVEL (See page LU±6)

15. INSTALL HOOD8. INSTALL SUSPENSION LOWER CROSSMEMBER

Torque:

14 mm head bolt

400 kg±cm (32 ft±lb, 43 N±m)

19 mm head bolt

2,120 kg±cm (153 ft±Ib, 208 N±m)

7. INSTALL ENGINE MOUNTING CENTER MEMBER

Torque:

To body 400 kg±cm (29 ft±lb, 39 N±m)

To mounting insulator

490 kg±cm (35 ft±tb, 48 N±m)

(c) Install the oil pan with the seventeen bolts and two

nuts.

Torque: 55 kg±cm (48 in.±Ib. 5.4 N±m)

(d) Install the dipstick.

6. INSTALL STIFFENER PLATE

Torque: 380 kg±cm (27±Ib, 37 N±m)

± LUBRICATION SYSTEMOil Pump (3S±FE)LU±15