ABS TOYOTA CAMRY V20 1986 Service Information

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 1986, Model line: CAMRY V20, Model: TOYOTA CAMRY V20 1986Pages: 2389, PDF Size: 84.44 MB

Page 1860 of 2389

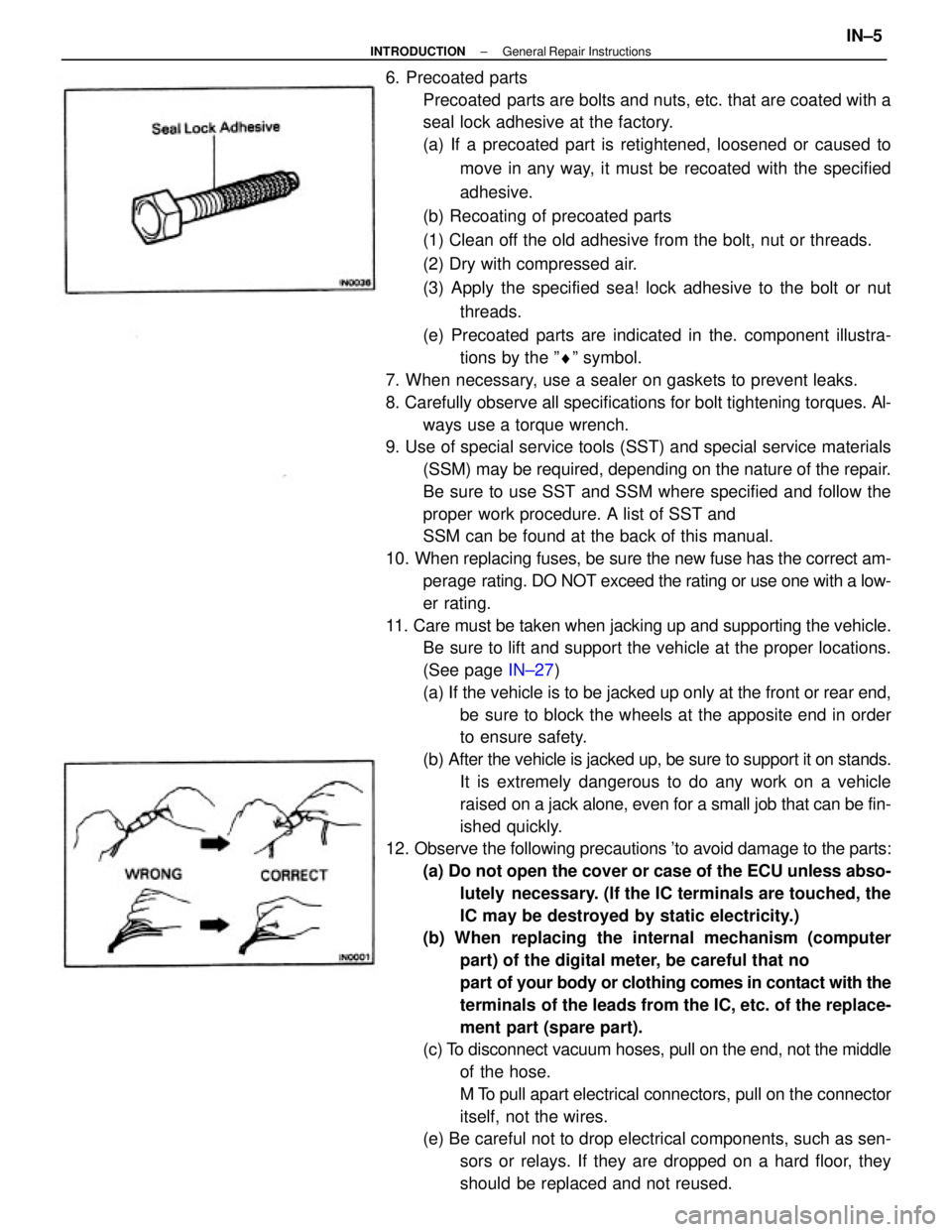

6. Precoated parts

Precoated parts are bolts and nuts, etc. that are coated with a

seal lock adhesive at the factory.

(a) If a precoated part is retightened, loosened or caused to

move in any way, it must be recoated with the specified

adhesive.

(b) Recoating of precoated parts

(1) Clean off the old adhesive from the bolt, nut or threads.

(2) Dry with compressed air.

(3) Apply the specified sea! lock adhesive to the bolt or nut

threads.

(e) Precoated parts are indicated in the. component illustra-

tions by the ºrº symbol.

7. When necessary, use a sealer on gaskets to prevent leaks.

8. Carefully observe all specifications for bolt tightening torques. Al-

ways use a torque wrench.

9. Use of special service tools (SST) and special service materials

(SSM) may be required, depending on the nature of the repair.

Be sure to use SST and SSM where specified and follow the

proper work procedure. A list of SST and

SSM can be found at the back of this manual.

10. When replacing fuses, be sure the new fuse has the correct am-

perage rating. DO NOT exceed the rating or use one with a low-

er rating.

11. Care must be taken when jacking up and supporting the vehicle.

Be sure to lift and support the vehicle at the proper locations.

(See page IN±27)

(a) If the vehicle is to be jacked up only at the front or rear end,

be sure to block the wheels at the apposite end in order

to ensure safety.

(b) After the vehicle is jacked up, be sure to support it on stands.

It is extremely dangerous to do any work on a vehicle

raised on a jack alone, even for a small job that can be fin-

ished quickly.

12. Observe the following precautions 'to avoid damage to the parts:

(a) Do not open the cover or case of the ECU unless abso-

lutely necessary. (If the IC terminals are touched, the

IC may be destroyed by static electricity.)

(b) When replacing the internal mechanism (computer

part) of the digital meter, be careful that no

part of your body or clothing comes in contact with the

terminals of the leads from the IC, etc. of the replace-

ment part (spare part).

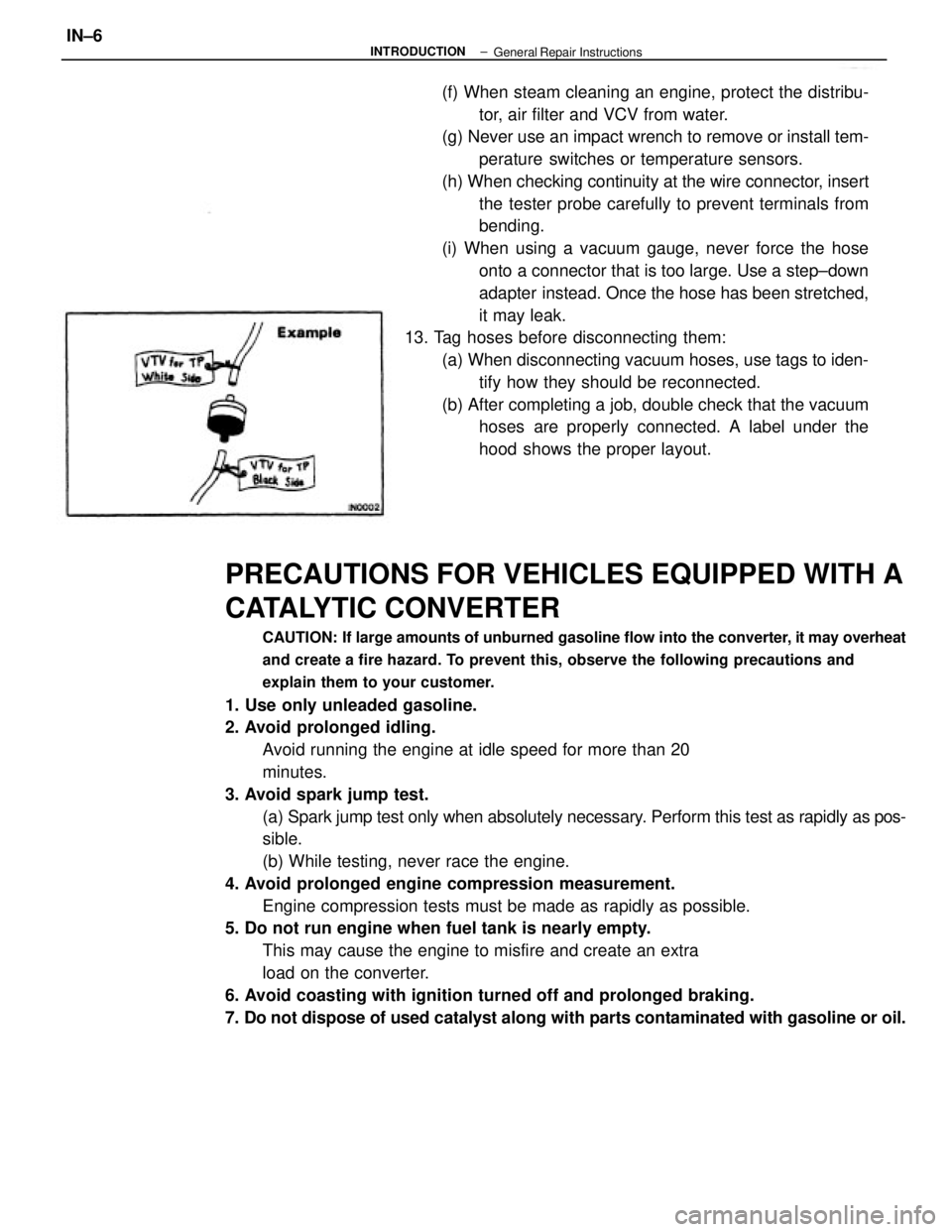

(c) To disconnect vacuum hoses, pull on the end, not the middle

of the hose.

M To pull apart electrical connectors, pull on the connector

itself, not the wires.

(e) Be careful not to drop electrical components, such as sen-

sors or relays. If they are dropped on a hard floor, they

should be replaced and not reused.

± INTRODUCTIONGeneral Repair InstructionsIN±5

Page 1861 of 2389

PRECAUTIONS FOR VEHICLES EQUIPPED WITH A

CATALYTIC CONVERTER

CAUTION: If large amounts of unburned gasoline flow into the converter, it may overheat

and create a fire hazard. To prevent this, observe the following precautions and

explain them to your customer.

1. Use only unleaded gasoline.

2. Avoid prolonged idling.

Avoid running the engine at idle speed for more than 20

minutes.

3. Avoid spark jump test.

(a) Spark jump test only when absolutely necessary. Perform this test as rapidly as pos-

sible.

(b) While testing, never race the engine.

4. Avoid prolonged engine compression measurement.

Engine compression tests must be made as rapidly as possible.

5. Do not run engine when fuel tank is nearly empty.

This may cause the engine to misfire and create an extra

load on the converter.

6. Avoid coasting with ignition turned off and prolonged braking.

7. Do not dispose of used catalyst along with parts contaminated with gasoline or oil.(f) When steam cleaning an engine, protect the distribu-

tor, air filter and VCV from water.

(g) Never use an impact wrench to remove or install tem-

perature switches or temperature sensors.

(h) When checking continuity at the wire connector, insert

the tester probe carefully to prevent terminals from

bending.

(i) When using a vacuum gauge, never force the hose

onto a connector that is too large. Use a step±down

adapter instead. Once the hose has been stretched,

it may leak.

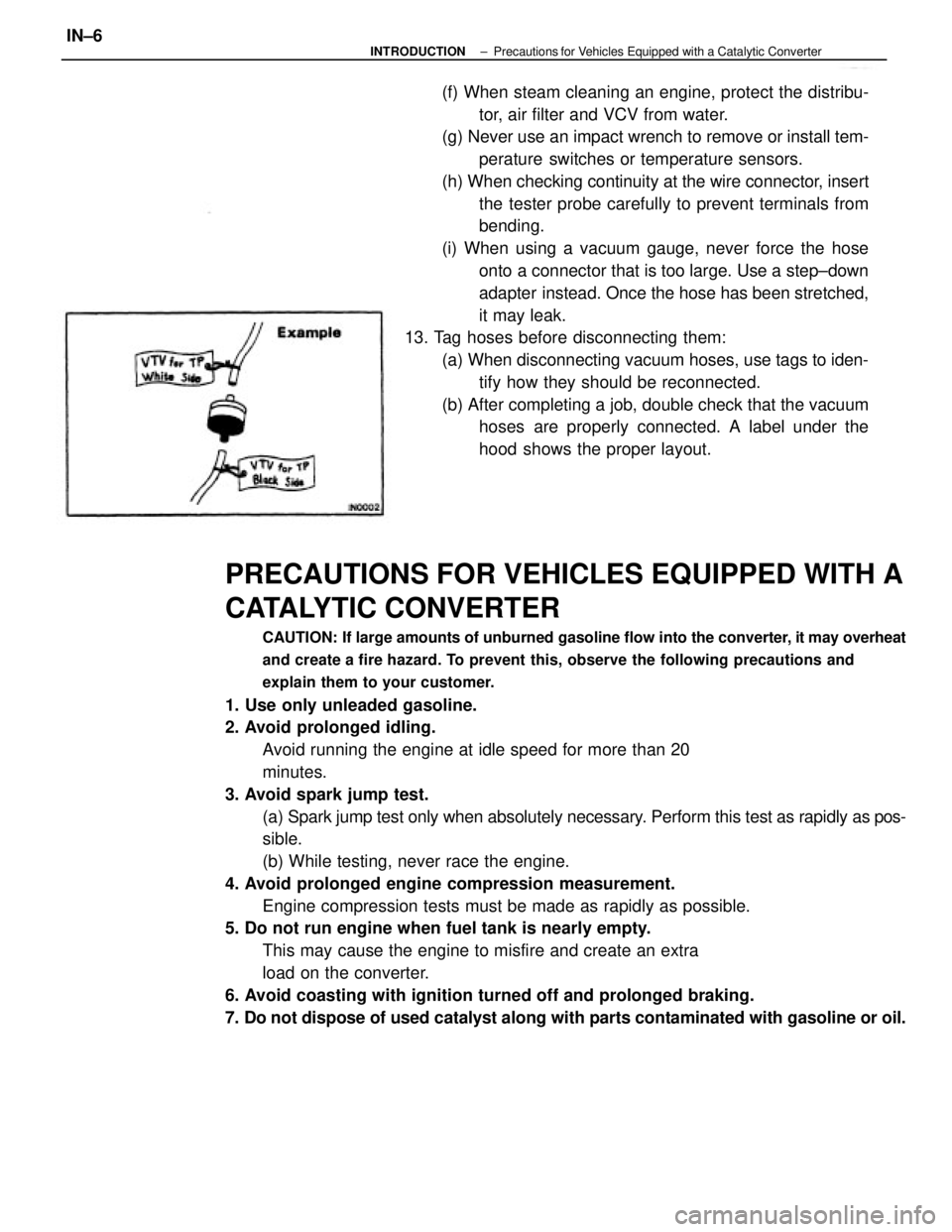

13. Tag hoses before disconnecting them:

(a) When disconnecting vacuum hoses, use tags to iden-

tify how they should be reconnected.

(b) After completing a job, double check that the vacuum

hoses are properly connected. A label under the

hood shows the proper layout.

± INTRODUCTIONIN±6General Repair Instructions

Page 1862 of 2389

PRECAUTIONS FOR VEHICLES EQUIPPED WITH A

CATALYTIC CONVERTER

CAUTION: If large amounts of unburned gasoline flow into the converter, it may overheat

and create a fire hazard. To prevent this, observe the following precautions and

explain them to your customer.

1. Use only unleaded gasoline.

2. Avoid prolonged idling.

Avoid running the engine at idle speed for more than 20

minutes.

3. Avoid spark jump test.

(a) Spark jump test only when absolutely necessary. Perform this test as rapidly as pos-

sible.

(b) While testing, never race the engine.

4. Avoid prolonged engine compression measurement.

Engine compression tests must be made as rapidly as possible.

5. Do not run engine when fuel tank is nearly empty.

This may cause the engine to misfire and create an extra

load on the converter.

6. Avoid coasting with ignition turned off and prolonged braking.

7. Do not dispose of used catalyst along with parts contaminated with gasoline or oil.(f) When steam cleaning an engine, protect the distribu-

tor, air filter and VCV from water.

(g) Never use an impact wrench to remove or install tem-

perature switches or temperature sensors.

(h) When checking continuity at the wire connector, insert

the tester probe carefully to prevent terminals from

bending.

(i) When using a vacuum gauge, never force the hose

onto a connector that is too large. Use a step±down

adapter instead. Once the hose has been stretched,

it may leak.

13. Tag hoses before disconnecting them:

(a) When disconnecting vacuum hoses, use tags to iden-

tify how they should be reconnected.

(b) After completing a job, double check that the vacuum

hoses are properly connected. A label under the

hood shows the proper layout.

± INTRODUCTIONPrecautions for Vehicles Equipped with a Catalytic ConverterIN±6

Page 2148 of 2389

Replace tires or inflate to

proper pressure

Check alignment

Replace hub bearing

Tighten or replace suspension

parts

Inflate tires to proper pressure

Replace shock absorbers

Check camber and toe±in

Replace suspension parts Alignment incorrect

Hub bearing worn

Rear suspension parts loose or broken

Tire improperly inflated

Shock absorber worn out

Alignment incorrect

Suspension parts worn Tires improperly inflated

Stabilizer bar bent or broken

Shock absorber worn outInflate tires to proper pressure

Inspect stabilizer bar

Replace shock absorber

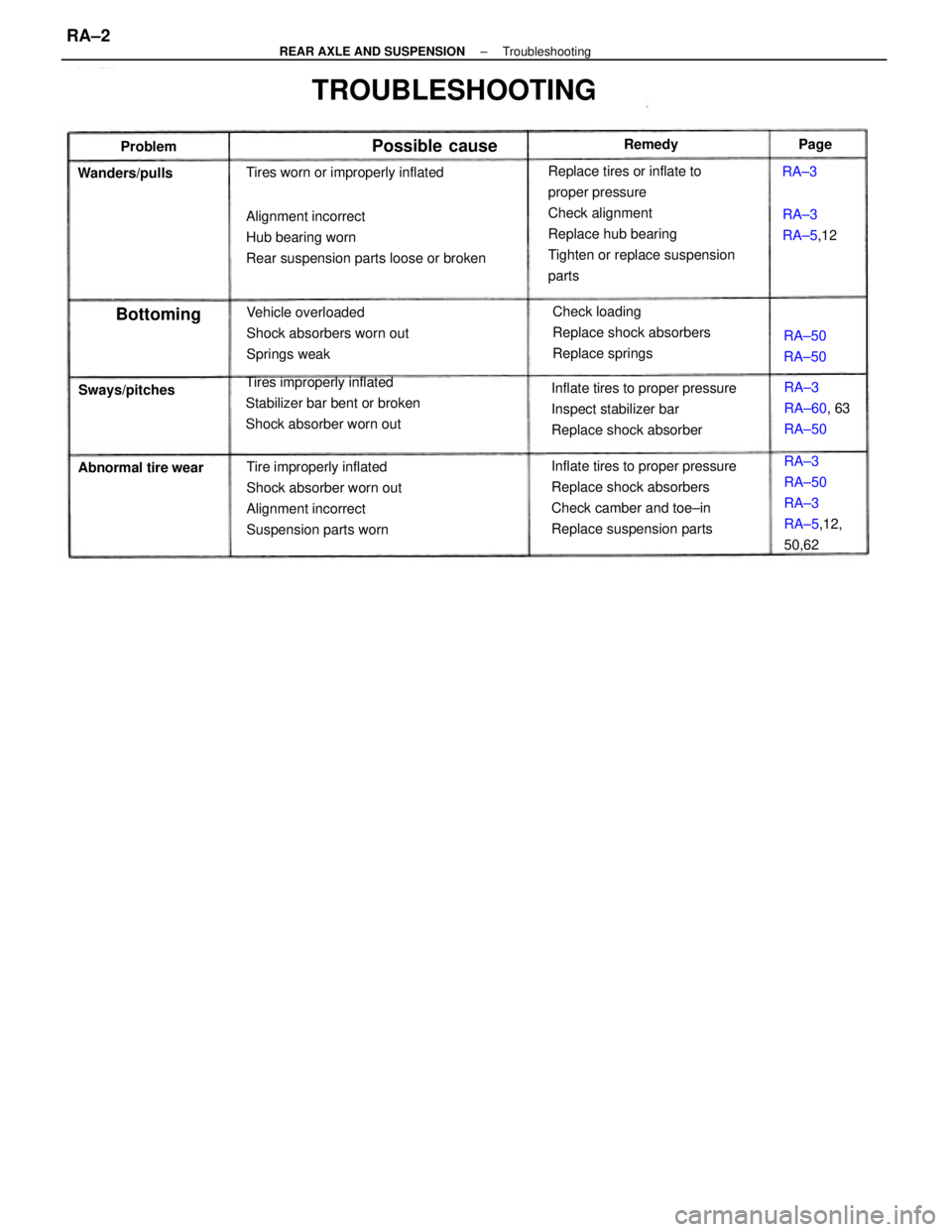

TROUBLESHOOTING

Vehicle overloaded

Shock absorbers worn out

Springs weakCheck loading

Replace shock absorbers

Replace springs

RA±3

RA±50

RA±3

RA±5,12,

50,62 Tires worn or improperly inflated

RA±3

RA±60, 63

RA±50

Abnormal tire wearRA±3

RA±5,12 Wanders/pulls

Sways/pitches

Possible cause

RA±50

RA±50

Bottoming

Remedy

ProblemPage

RA±3

± REAR AXLE AND SUSPENSIONTroubleshootingRA±2

Page 2149 of 2389

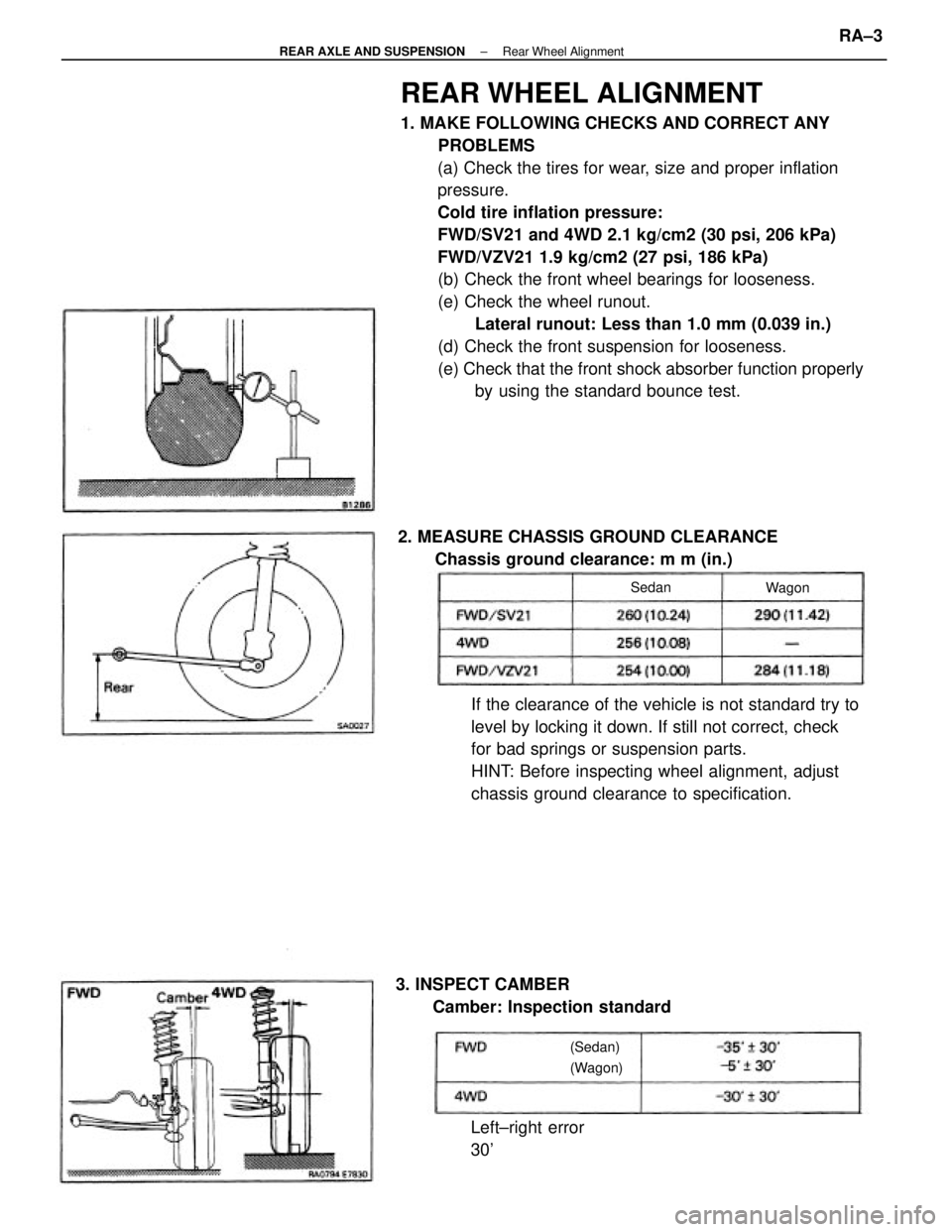

REAR WHEEL ALIGNMENT

1. MAKE FOLLOWING CHECKS AND CORRECT ANY

PROBLEMS

(a) Check the tires for wear, size and proper inflation

pressure.

Cold tire inflation pressure:

FWD/SV21 and 4WD 2.1 kg/cm2 (30 psi, 206 kPa)

FWD/VZV21 1.9 kg/cm2 (27 psi, 186 kPa)

(b) Check the front wheel bearings for looseness.

(e) Check the wheel runout.

Lateral runout: Less than 1.0 mm (0.039 in.)

(d) Check the front suspension for looseness.

(e) Check that the front shock absorber function properly

by using the standard bounce test.

If the clearance of the vehicle is not standard try to

level by locking it down. If still not correct, check

for bad springs or suspension parts.

HINT: Before inspecting wheel alignment, adjust

chassis ground clearance to specification. 2. MEASURE CHASSIS GROUND CLEARANCE

Chassis ground clearance: m m (in.)

3. INSPECT CAMBER

Camber: Inspection standard

Left±right error

30'

(Sedan)

(Wagon)Wagon Sedan

± REAR AXLE AND SUSPENSIONRear Wheel AlignmentRA±3

Page 2155 of 2389

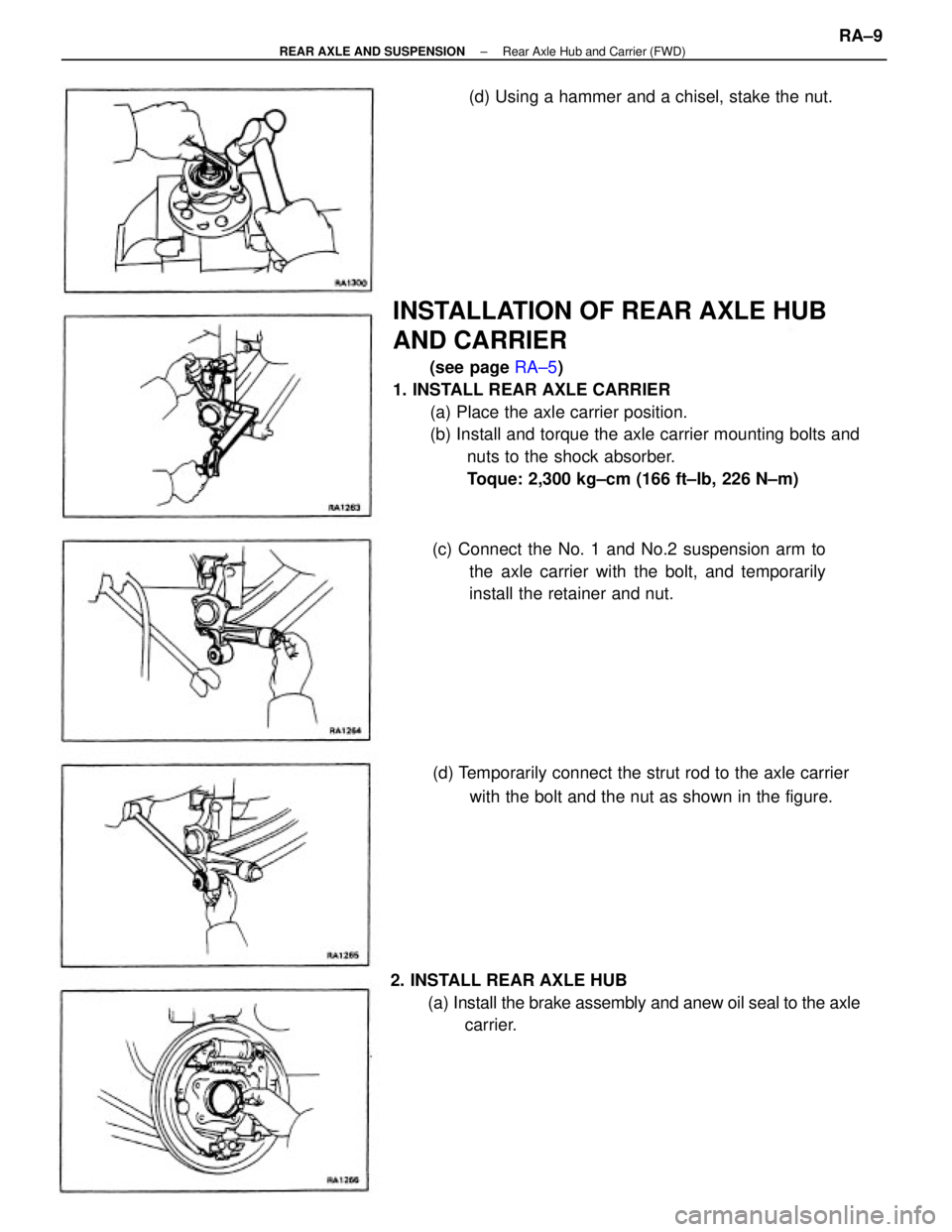

INSTALLATION OF REAR AXLE HUB

AND CARRIER

(see page RA±5)

1. INSTALL REAR AXLE CARRIER

(a) Place the axle carrier position.

(b) Install and torque the axle carrier mounting bolts and

nuts to the shock absorber.

Toque: 2,300 kg±cm (166 ft±Ib, 226 N±m)

2. INSTALL REAR AXLE HUB

(a) Install the brake assembly and anew oil seal to the axle

carrier. (c) Connect the No. 1 and No.2 suspension arm to

the axle carrier with the bolt, and temporarily

install the retainer and nut.

(d) Temporarily connect the strut rod to the axle carrier

with the bolt and the nut as shown in the figure. (d) Using a hammer and a chisel, stake the nut.

± REAR AXLE AND SUSPENSIONRear Axle Hub and Carrier (FWD)RA±9

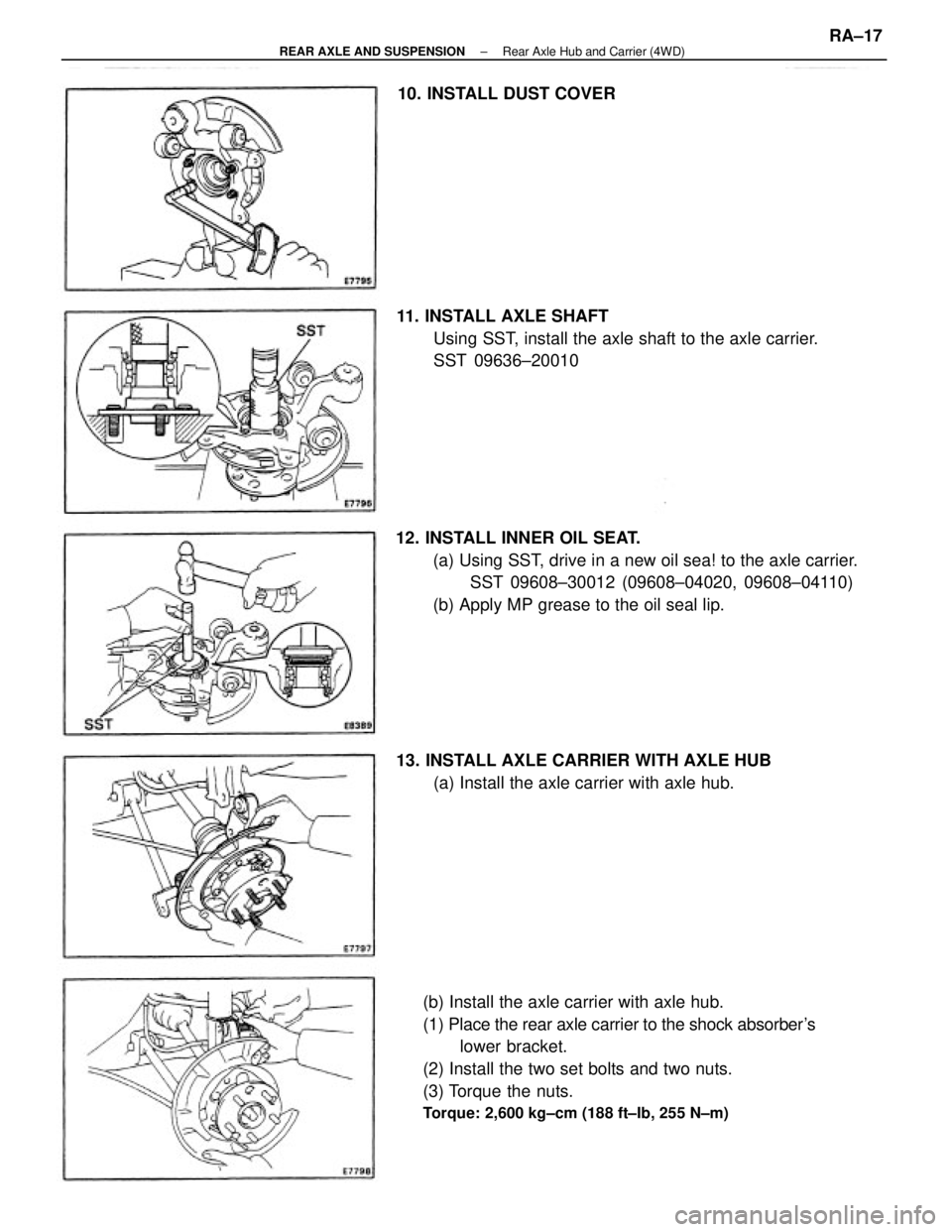

Page 2163 of 2389

(b) Install the axle carrier with axle hub.

(1) Place the rear axle carrier to the shock absorber's

lower bracket.

(2) Install the two set bolts and two nuts.

(3) Torque the nuts.

Torque: 2,600 kg±cm (188 ft±Ib, 255 N±m)

12. INSTALL INNER OIL SEAT.

(a) Using SST, drive in a new oil sea! to the axle carrier.

SST 09608±30012 (09608±04020, 09608±04110)

(b) Apply MP grease to the oil seal lip. 11. INSTALL AXLE SHAFT

Using SST, install the axle shaft to the axle carrier.

SST 09636±20010

13. INSTALL AXLE CARRIER WITH AXLE HUB

(a) Install the axle carrier with axle hub. 10. INSTALL DUST COVER

± REAR AXLE AND SUSPENSIONRear Axle Hub and Carrier (4WD)RA±17

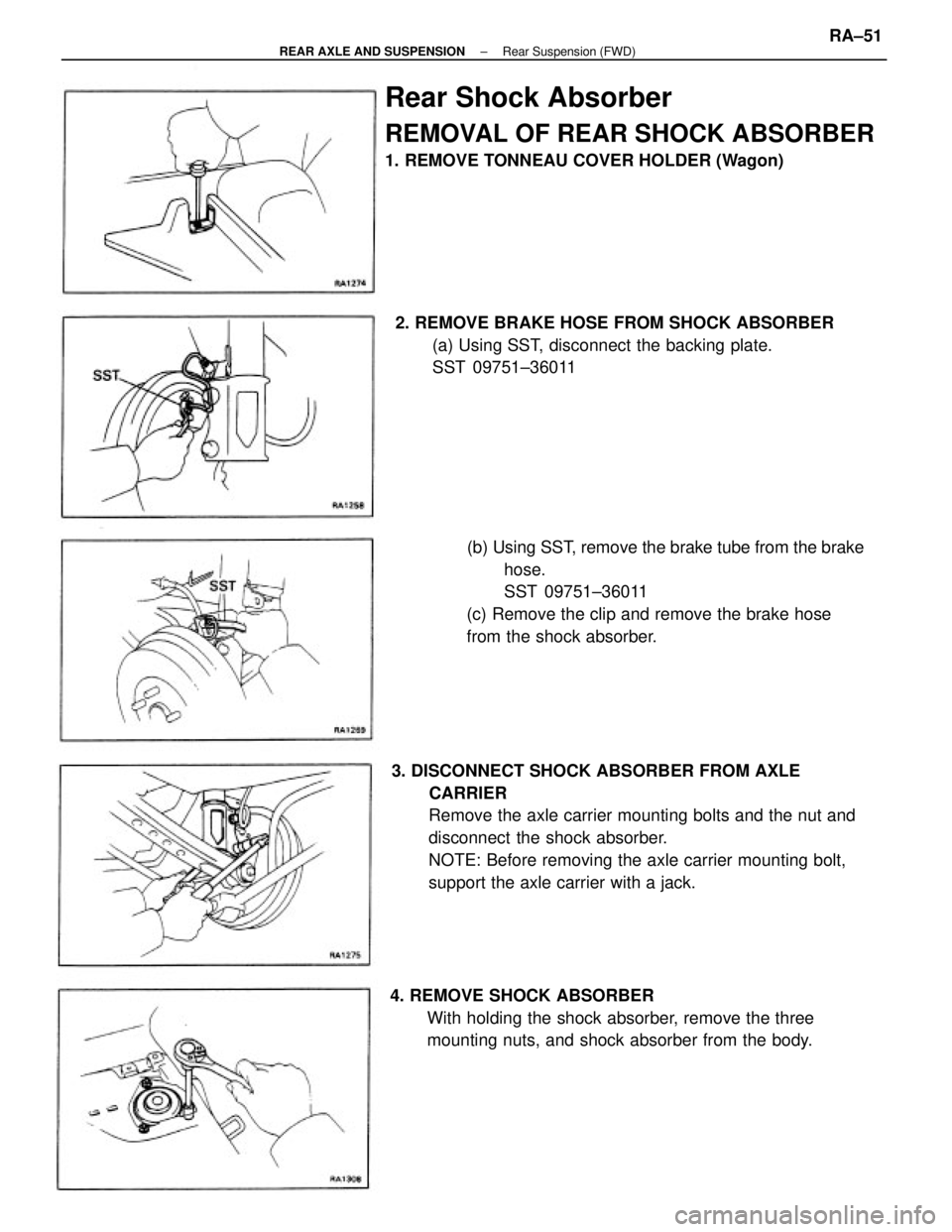

Page 2197 of 2389

3. DISCONNECT SHOCK ABSORBER FROM AXLE

CARRIER

Remove the axle carrier mounting bolts and the nut and

disconnect the shock absorber.

NOTE: Before removing the axle carrier mounting bolt,

support the axle carrier with a jack.(b) Using SST, remove the brake tube from the brake

hose.

SST 09751±36011

(c) Remove the clip and remove the brake hose

from the shock absorber.

Rear Shock Absorber

REMOVAL OF REAR SHOCK ABSORBER

1. REMOVE TONNEAU COVER HOLDER (Wagon)

2. REMOVE BRAKE HOSE FROM SHOCK ABSORBER

(a) Using SST, disconnect the backing plate.

SST 09751±36011

4. REMOVE SHOCK ABSORBER

With holding the shock absorber, remove the three

mounting nuts, and shock absorber from the body.

± REAR AXLE AND SUSPENSIONRear Suspension (FWD)RA±51

Page 2198 of 2389

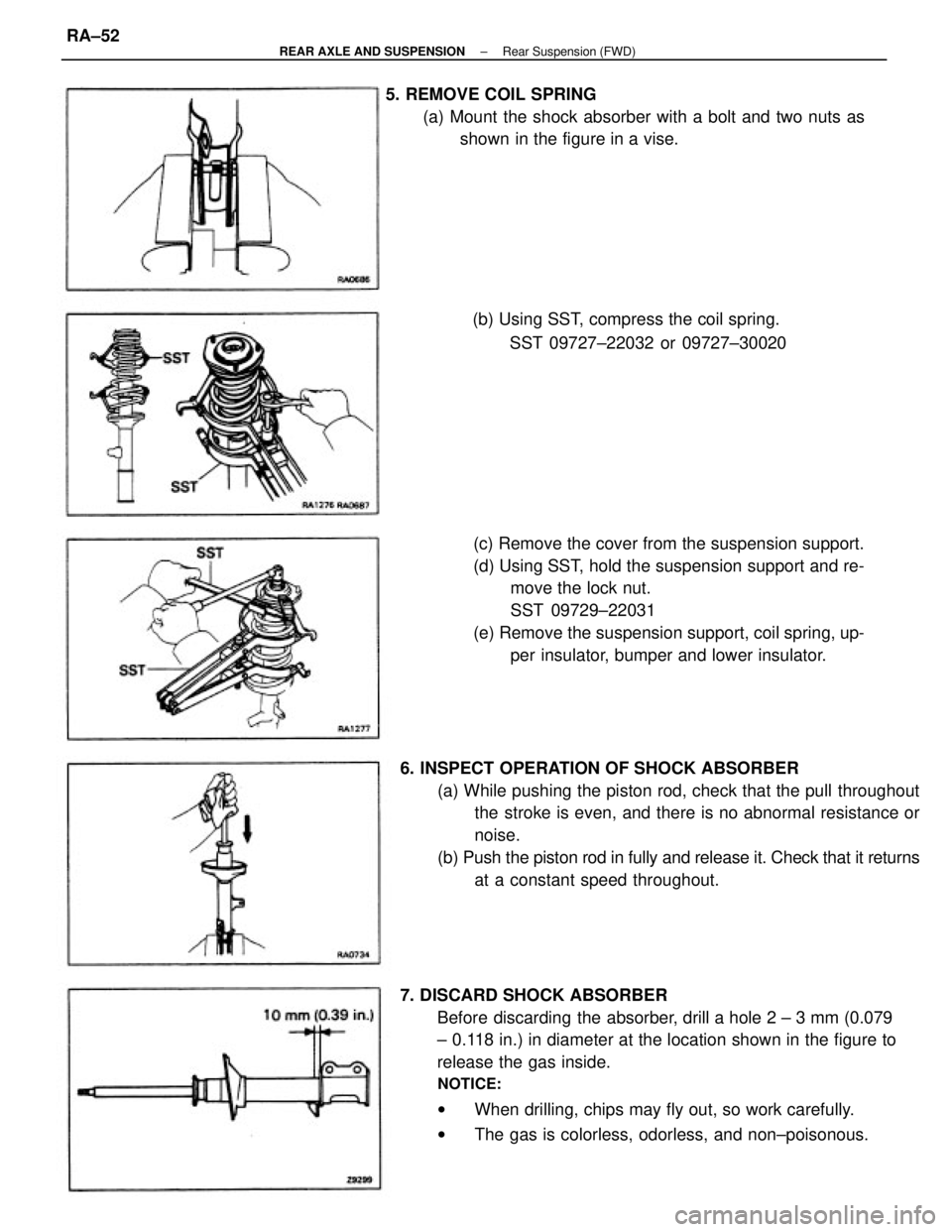

7. DISCARD SHOCK ABSORBER

Before discarding the absorber, drill a hole 2 ± 3 mm (0.079

± 0.118 in.) in diameter at the location shown in the figure to

release the gas inside.

NOTICE:

wWhen drilling, chips may fly out, so work carefully.

wThe gas is colorless, odorless, and non±poisonous. 6. INSPECT OPERATION OF SHOCK ABSORBER

(a) While pushing the piston rod, check that the pull throughout

the stroke is even, and there is no abnormal resistance or

noise.

(b) Push the piston rod in fully and release it. Check that it returns

at a constant speed throughout. (c) Remove the cover from the suspension support.

(d) Using SST, hold the suspension support and re-

move the lock nut.

SST 09729±22031

(e) Remove the suspension support, coil spring, up-

per insulator, bumper and lower insulator. 5. REMOVE COIL SPRING

(a) Mount the shock absorber with a bolt and two nuts as

shown in the figure in a vise.

(b) Using SST, compress the coil spring.

SST 09727±22032 or 09727±30020

± REAR AXLE AND SUSPENSIONRear Suspension (FWD)RA±52

Page 2199 of 2389

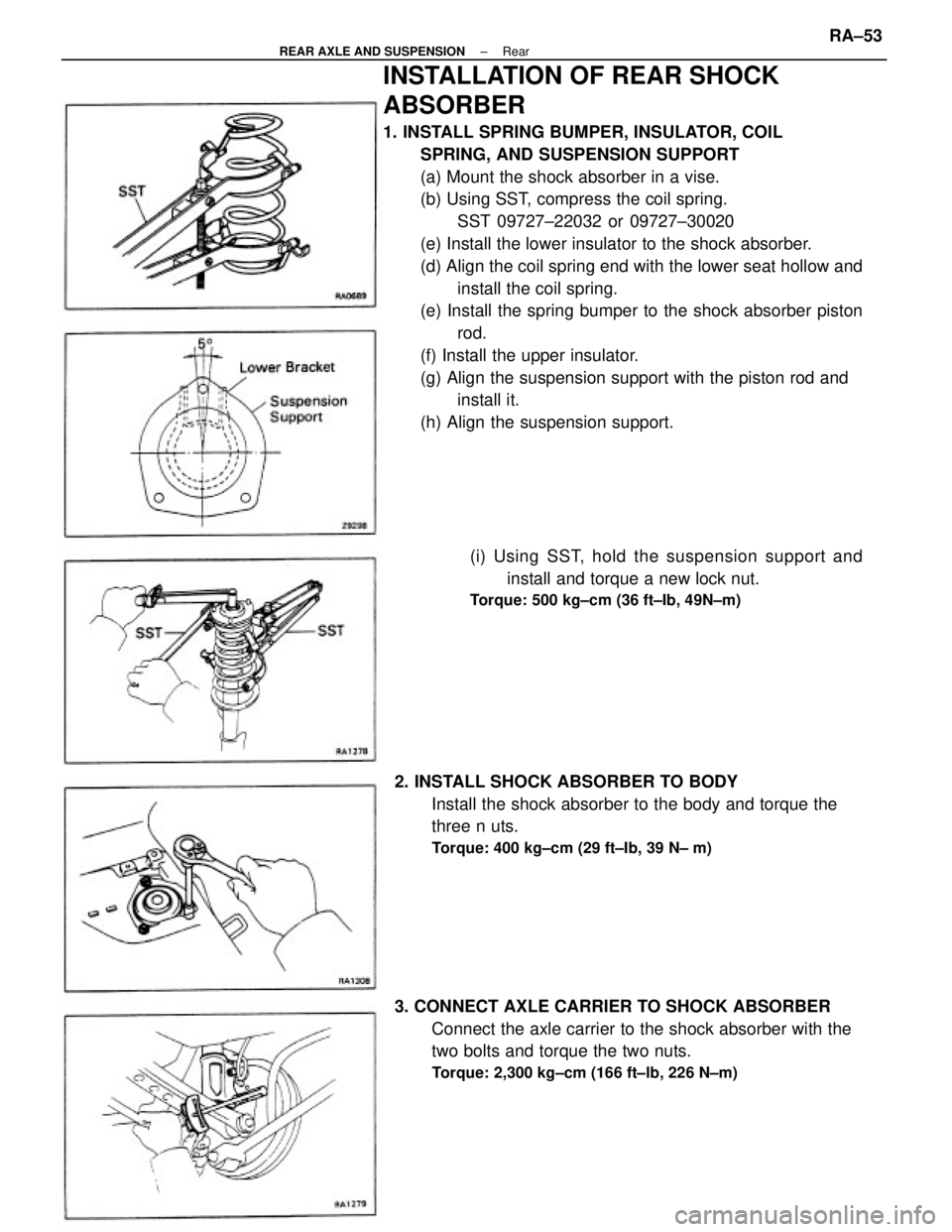

INSTALLATION OF REAR SHOCK

ABSORBER

1. INSTALL SPRING BUMPER, INSULATOR, COIL

SPRING, AND SUSPENSION SUPPORT

(a) Mount the shock absorber in a vise.

(b) Using SST, compress the coil spring.

SST 09727±22032 or 09727±30020

(e) Install the lower insulator to the shock absorber.

(d) Align the coil spring end with the lower seat hollow and

install the coil spring.

(e) Install the spring bumper to the shock absorber piston

rod.

(f) Install the upper insulator.

(g) Align the suspension support with the piston rod and

install it.

(h) Align the suspension support.

3. CONNECT AXLE CARRIER TO SHOCK ABSORBER

Connect the axle carrier to the shock absorber with the

two bolts and torque the two nuts.

Torque: 2,300 kg±cm (166 ft±lb, 226 N±m)

2. INSTALL SHOCK ABSORBER TO BODY

Install the shock absorber to the body and torque the

three n uts.

Torque: 400 kg±cm (29 ft±Ib, 39 N± m)

(i) Using SST, hold the suspension support and

install and torque a new lock nut.

Torque: 500 kg±cm (36 ft±Ib, 49N±m)

± REAR AXLE AND SUSPENSIONRearRA±53