check engine TOYOTA CELICA 1987 Service Service Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 1987, Model line: CELICA, Model: TOYOTA CELICA 1987Pages: 346, PDF Size: 35.13 MB

Page 157 of 346

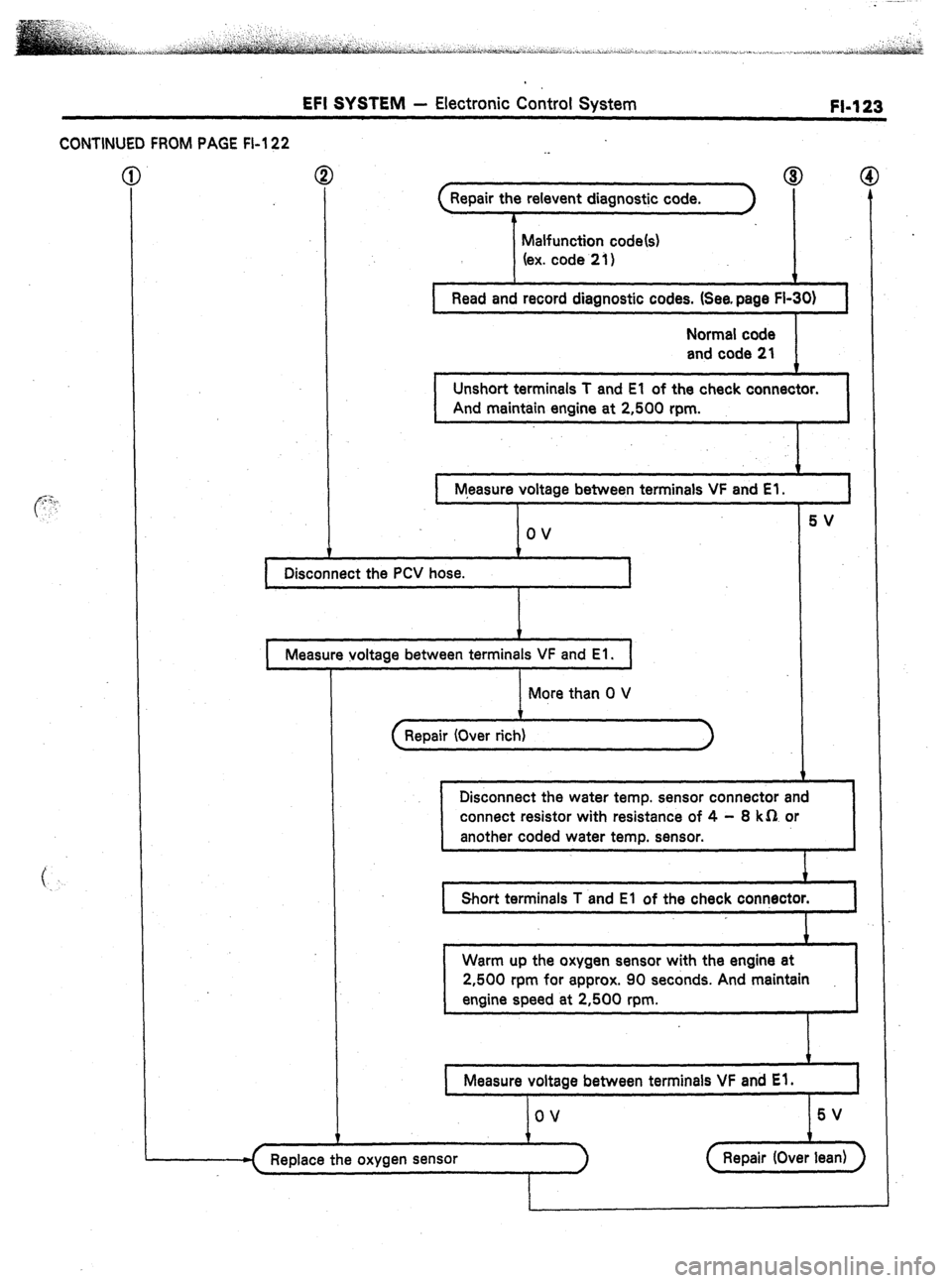

EFI SYSTEM - Electronic Control System FI-123

CONTINUED FROM PAGE FI-122

. .

t

8 (

epair the relevent diagnostic code.

Malfunction code(s)

(ex. code 21)

Read and record diagnostic codes. (See.page FL30)

Normal code

and code 21

t

Unshort terminals T and El of the check connector.

And maintain engine at 2,500 rpm.

I

I

M,easure voltage between terminals VF and El.

ov

t

1

Disconnect the PCV hose.

.

1 Measure voltage between terminals VF and El. 1

t

Replace the oxygen sensor Repair (Over lean) 5V

Disconnect the water temp. sensor connector and

connect resistor with resistance of 4 - 8 kS1 or

another coded water temp. sensor.

1

Short terminals T and El of the check connector.

I

I

Warm up the oxygen sensor with the engine at

I

1 2,500 rpm for approx. 90 seconds. And maintain 1

engine speed at 2,500 rpm.

Measure voltage between terminals VF and El.

I

I 5V

Page 160 of 346

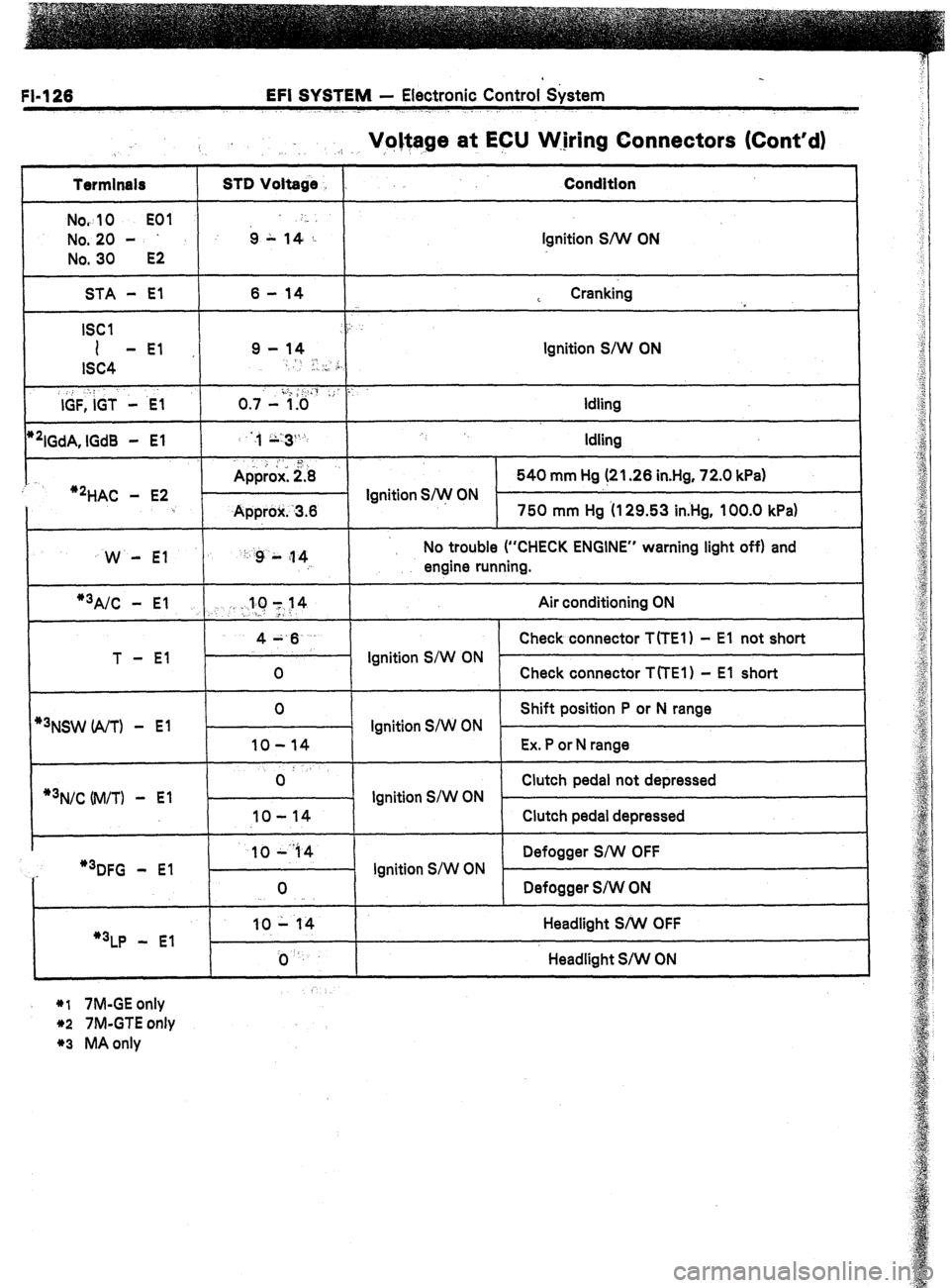

FI-126 EFI SYSTEM - Electronic Control &stem

Voltage at ECU W.jring Connectors (Cont’d)

.:. .I, ,,

Termlnals

Nov

10 EOI

No. 20 -

No. 30

E2

STD Voltage

6 L ,4-,: Condition

Ignition S/W ON

STA - El

ISCI

I -El

ISC4

,, : :

IGF, IGT - .E-1

*‘IGdA, lGd8 - El

:

‘2HAC - E2 6 - 14

9 - 14

-

I, .., ,i,

o .,.- i.;&& ,; ::

:,, ;;:3%

. . 1

Approx: 2.8

- Ignition S/w ON

Approlr. -3.6 L Cranking

,

Ignition S/W ON

Idling

Idling

540 mm Hg (21.26 in.Hg, 72.0 kPa)

750 mm Hg (I 29.53 in.Hg, 100.0 kPa)

W - El ‘: :g L ;I 4

: No trouble (“CHECK ENGINE” warning light off) and

engine running.

1

*3A/C - El .,. . :.llC 1~14 Air conditioning ON

>-

T - El 4A.6

Check connector T(TE1) - El not short

Ignition S/W ON

0 Check connector TfTEl) - El short

*3NSW (A/T) - El

*3N/C Uvl/TI -

El 0

Shift position P or N range

Ignition S/W ON

IO-14 Ex. P or N range

0: Clutch pedal not depressed

- Ignition S/W ON .

IO-14 Clutch pedal depressed

..-

I 1044 1 1 Defogger S/W OFF

I

“3DFG - El

“3LP - El 0

10 - 14

j) ‘. Ignition S/W ON

Defogger S/W ON

Headlight S/W OFF

Headlight S/W ON

*I 7M-GE only

*2 7M-GTE only

*3 MA only

Page 162 of 346

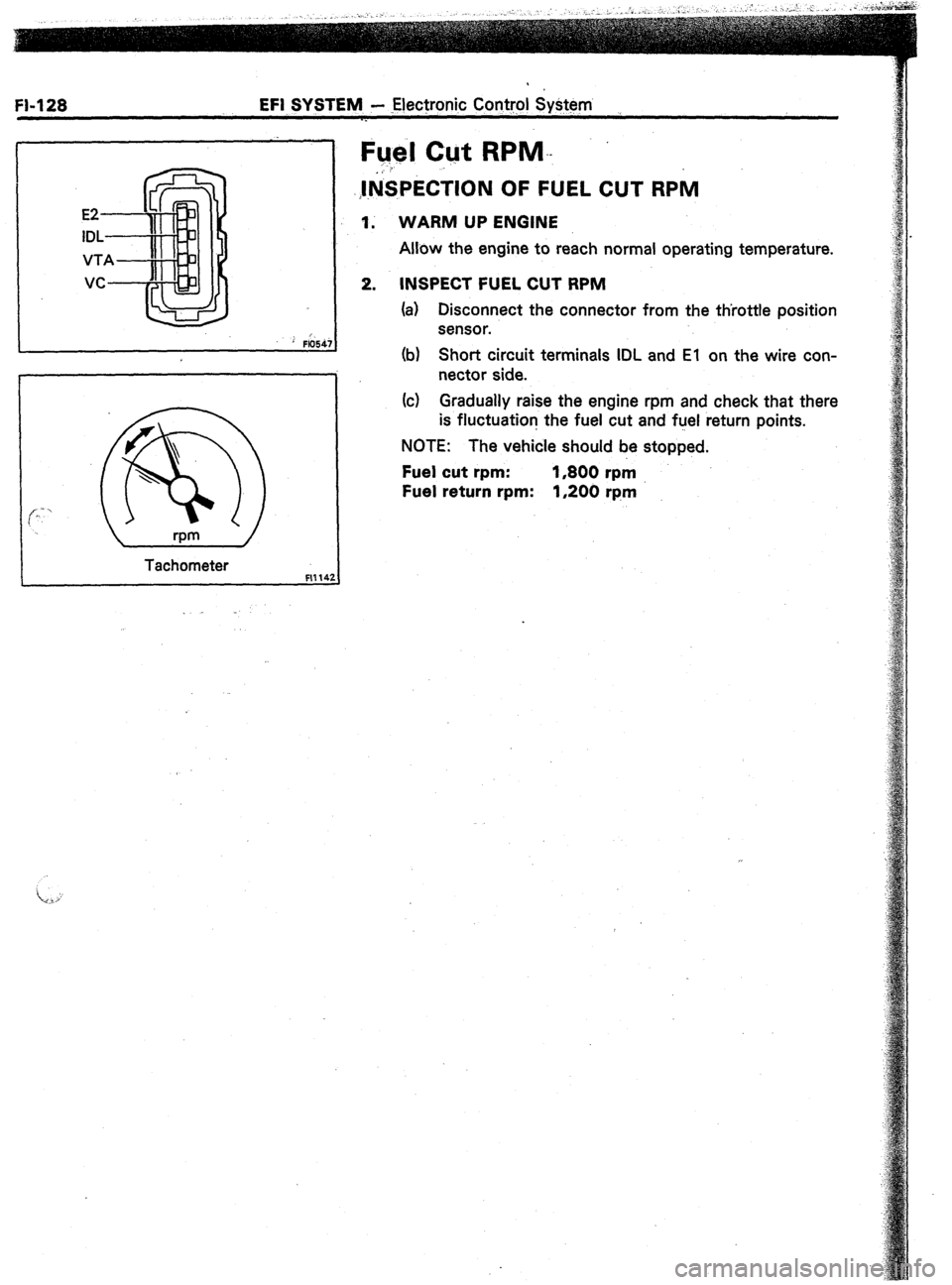

Fl-128 EFI SYSTEM - Electronic Contpl SyStem

c

’ FlO54

Tachometer Fl114:

Fuel Cut RPM--

;INSPECTION OF FUEL CUT RPM

I.

2. WARM UP ENGINE

Allow the engine to reach normal operating temperature.

INSPECT FUEL CUT RPM

(a) Disconnect the connector from the throttle position

sensor.

(b) Short circuit terminals IDL and El on the wire con-

nector side.

(c) Gradually raise the engine rpm and check that there

is fluctuation the fuel cut and fuel return points.

NOTE: The vehicle should be stopped.

Fuel cut rpm:

1,800 rpm

Fuel return rpm: 1,200 rpm

Page 163 of 346

-.

EM-1

I

ENGINE MECHANICAL .’ ../_ :.

F&e.

DESCRIPTION

. . . ..1........111.......~....~.~ E+ -;.’

TROUBLESHOOTING

. . . . . . . . . . . . . . . . n . ma m I. I.

EM-4’ ”

ENGINE TUNE-UP

. . . . . . . . . . . . ..~......~.......

COMPRESSION CHECK

s e . . . . . . . . . . . . . , . . . . . . .

TIMING BELT

,,,..,....................*.*...

EM-28

CYLINDER HEAD

. . . . . . . . . . . . . . ..*............

EM-37

CYLINDER BLOCK

1”1......1...............,..

EM-66

Page 166 of 346

LM-4

I ENGINE MECHANICAL -* Troubleshooting

_.

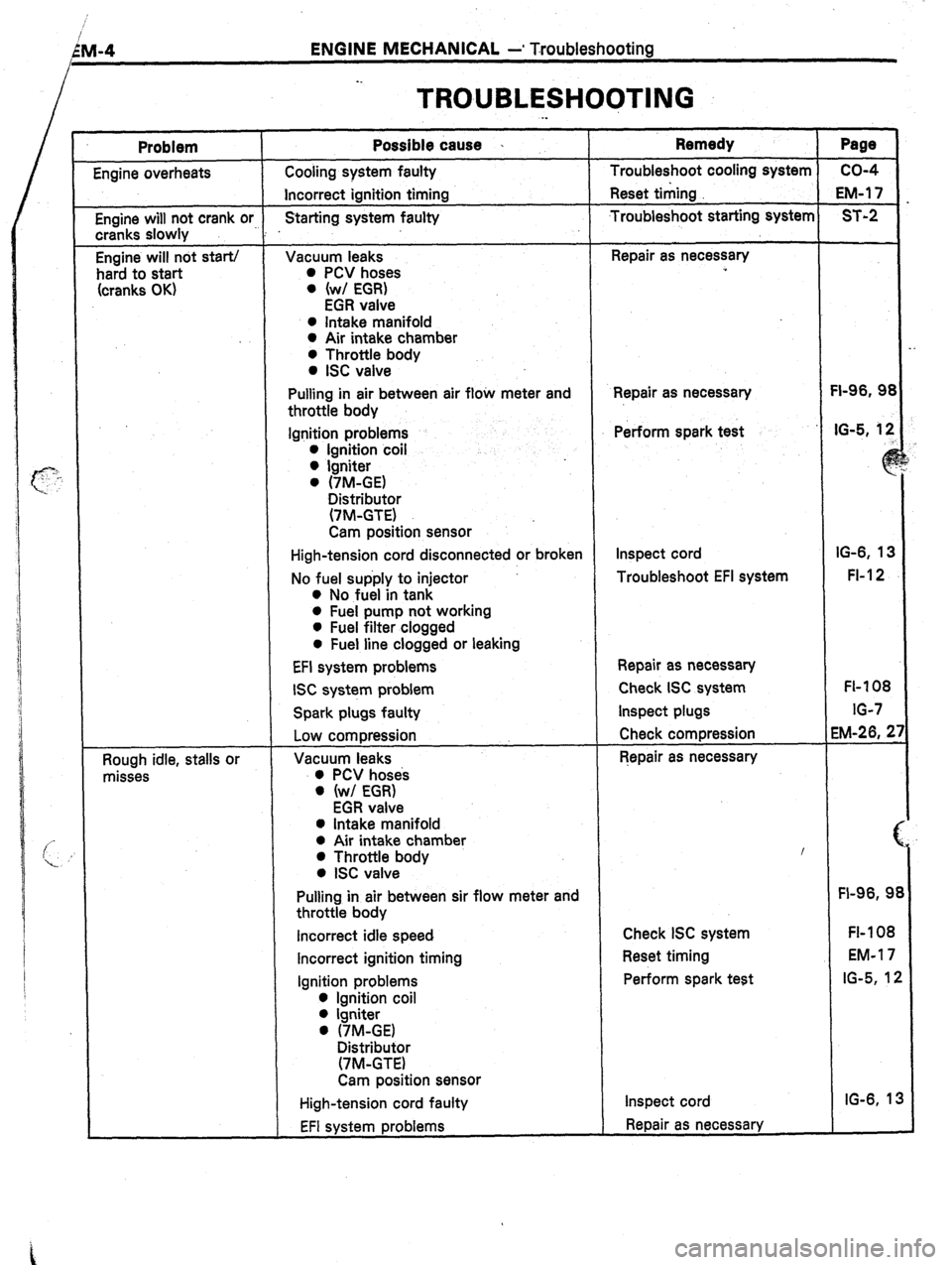

TROUBLESHOOTING

Problem Possible cause I Remedy Page

Engine overheats Cooling system faulty Troubleshoot cooling system co-4

Incorrect ignition timing Reset timing EM-1 7

Engine will not crank or Starting system faulty Troubleshoot starting system ST-2

cranks slowly : .

Engine will not start/ Vacuum leaks Repair as necessary

hard to start 0 PCV hoses ”

(cranks OK) 0 (w/ EGR)

EGR valve

0 Intake manifold

0 Air intake chamber

0 Throttle body

0 ISC valve

Pulling in air between air flow meter and Repair as necessary FI-96, 93

throttle body

Ignition problems Perform spark test IG-5, 12

0 Ignition coil

0 Igniter

0 (7M-GE)

Distributor

(7M-GTE)

Cam position sensor

High-tension cord disconnected or broken Inspect cord IG-6, 13

No fuel supply to injector Troubleshoot EFI system FI-I 2

l No fuel in tank

0 Fuel pump not working

l Fuel filter clogged

0 Fuel line clogged or leaking

EFI system problems Repair as necessary

ISC system problem Check ISC system FL- 108

Spark plugs faulty Inspect plugs IG-7

Low compression Check compression EM-26, 2

Rough idle, stalls or Vacuum leaks Repair as necessary

misses 0 PCV hoses

0 (w/ EGR)

EGR valve

0 Intake manifold

0 Air intake chamber

0 Throttle body I

0 ISC valve

Pulling in air between sir flow meter and FI-96, 9

throttle body

Incorrect idle speed Check ISC system FI- 108

Incorrect ignition timing Reset timing EM-1 7

Ignition problems Perform spark test IG-5, 12

0 Ignition coil

0 Igniter

0 (-/M-GE)

Distributor

(-/M-GTE)

Cam position sensor

High-tension cord faulty Inspect cord IG-6, 13

EFI system problems Repair as necessary

Page 167 of 346

ENGtNE MECHANKAL - Troubleshootinn EM-S

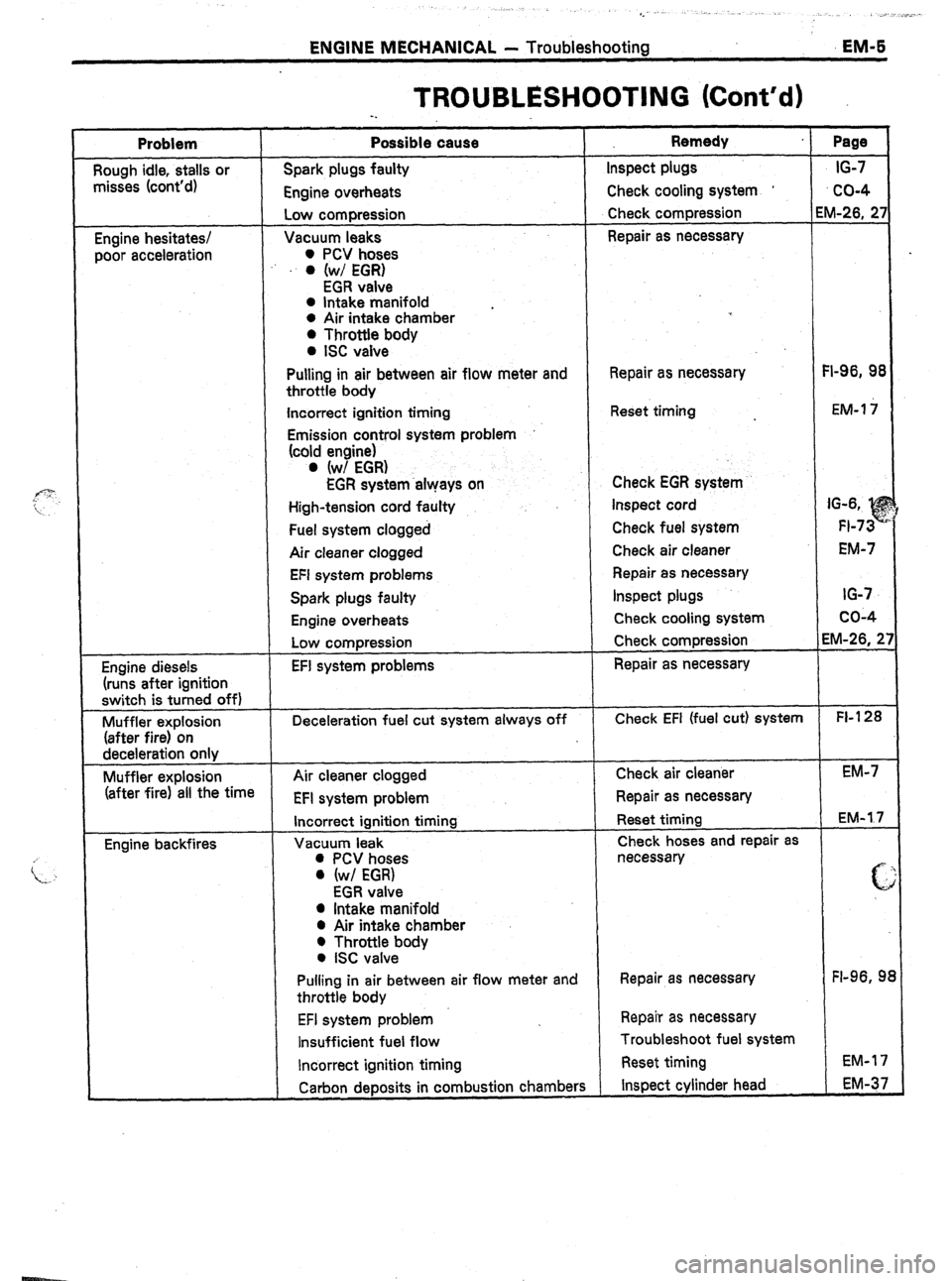

TROUBLESHOOTING (Cont’d)

-.

Problem Possible cause Remedy Page

sough idle, stalls or Spark plugs faulty Inspect plugs IG-7

misses (cont’d)

Engine overheats Check cooling system ’ co-4

Low compression Check compression EM-26, 2;

Engine hesitates/ Vacuum leaks Repair as necessary

poor acceleration 0 PCV hoses

. (w/ EGR)

EGR valve

0 Intake manifold

’ 0 Air intake chamber .c

0 Throttle body

0 ISC valve

Pulling in air between air flow meter and Repair as necessary FI-96, 96

throttle body

Incorrect ignition timing Reset timing _ EM-1 7

Emission control system problem

(cold engine)

0 (w/ EGR)

EGR system always on Check EGR system

High-tension cord faulty Inspect cord 1G-6,

Fuel system clogged Check fuel system FI-7

Air cleaner clogged Check air cleaner EM-7

EFI system problems Repair as necessary

Spark plugs faulty Inspect plugs IG-7

Engine overheats Check cooling system co-4

Low compression Check compression EM-26, 2

Engine diesels EFI system problems Repair as necessary

(runs after ignition

switch is turned off)

Muffler explosion Deceleration fuel cut system always off Check EFI (fuel cut) system FI-128

(after fire) on

deceleration only

Muffler explosion Air cleaner clogged Check air cleaner EM-7

(after fire) all the time

EFI system problem Repair as necessary

incorrect ignition timing Reset timing EM-l.7

Engine backfires Vacuum leak Check hoses and repair as

l PCV hoses necessary

. (w/ EGR)

EGR valve c

0 Intake manifold

0 Air intake chamber

l Throttle body

0 ISC valve

Pulling in air between air flow meter and Repair as necessary Fl-96, 91

throttle body

EFI system problem Repair as necessary

Insufficient fuel flow Troubleshoot fuel system

Incorrect ignition timing Reset timing EM-l 7

Carbon deposits in combustion chambers Inspect cylinder head EM-97

Page 168 of 346

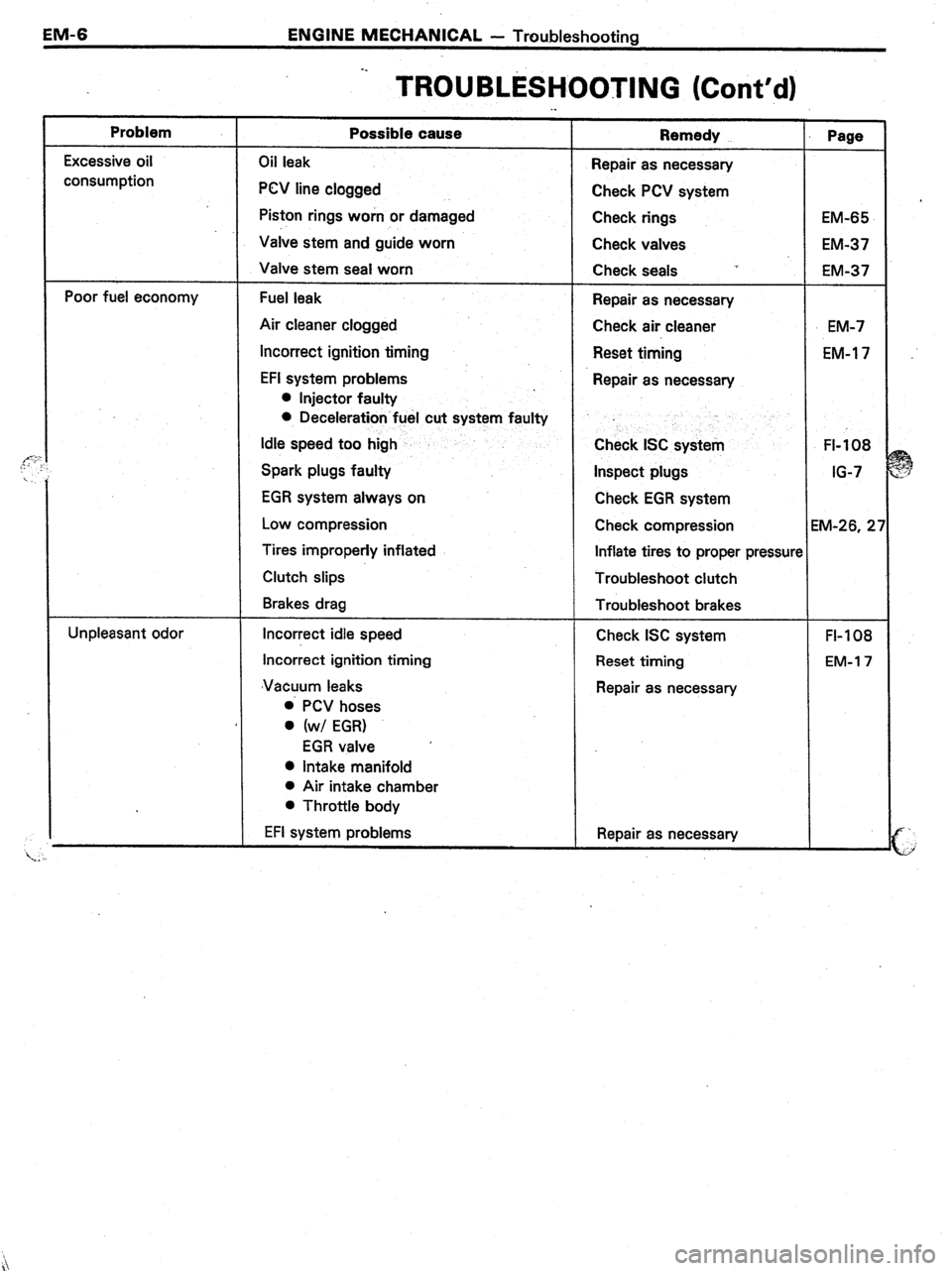

EM-6 ENGINE MECHANICAL - Troubleshooting

Problem

:- Excessive oil

consumption

Poor fuel economy

Unpleasant odor -.

TROUBLESHOOTING (Cont’d) ._

Possible cause

Oil leak

PCV line clogged

Piston rings worn or damaged

Valve stem and guide worn

Valve stem seal worn

Fuel leak

Air cleaner clogged

Incorrect ignition timing

EFI system problems

l Injector faulty

0 Deceleration fuel cut system faulty

Idle speed too high

Spark plugs faulty

EGR system always on

Low compression

Tires improperly inflated

Clutch slips

Brakes drag

Incorrect idle speed

Incorrect ignition timing

‘Vacuum leaks

0 PCV hoses

0 (w/ EGR)

EGR valve ’

0 Intake manifold

l Air intake chamber

l Throttle body

EFI system problems Remedy

Repair as necessary

Check PCV system

Check rings

Check valves

Check seals ~’

Repair as necessary

Check air cleaner

Reset timing

Repair as necessary

Check ISC system

Inspect plugs

Check EGR system

Check compression

Inflate tires to proper pressun

Troubleshoot clutch

Troubleshoot brakes

Check ISC system

Reset timing

Repair as necessary

Repair as necessary Page

EM-65

EM-37

EM-37

EM-7

EM-l 7

FI-108

IG-7

M-26, 2’

FI-108

EM-l 7

Page 169 of 346

ENGINE MECHANICAL 2 Engine Tune-up

. . EM-7

ENGINE TUNE-UP

INSPECTlOi OF ENGINE COOLANT

(See page CO-51

INSPECTION OF ENGINE OIL

(See page LU-5)

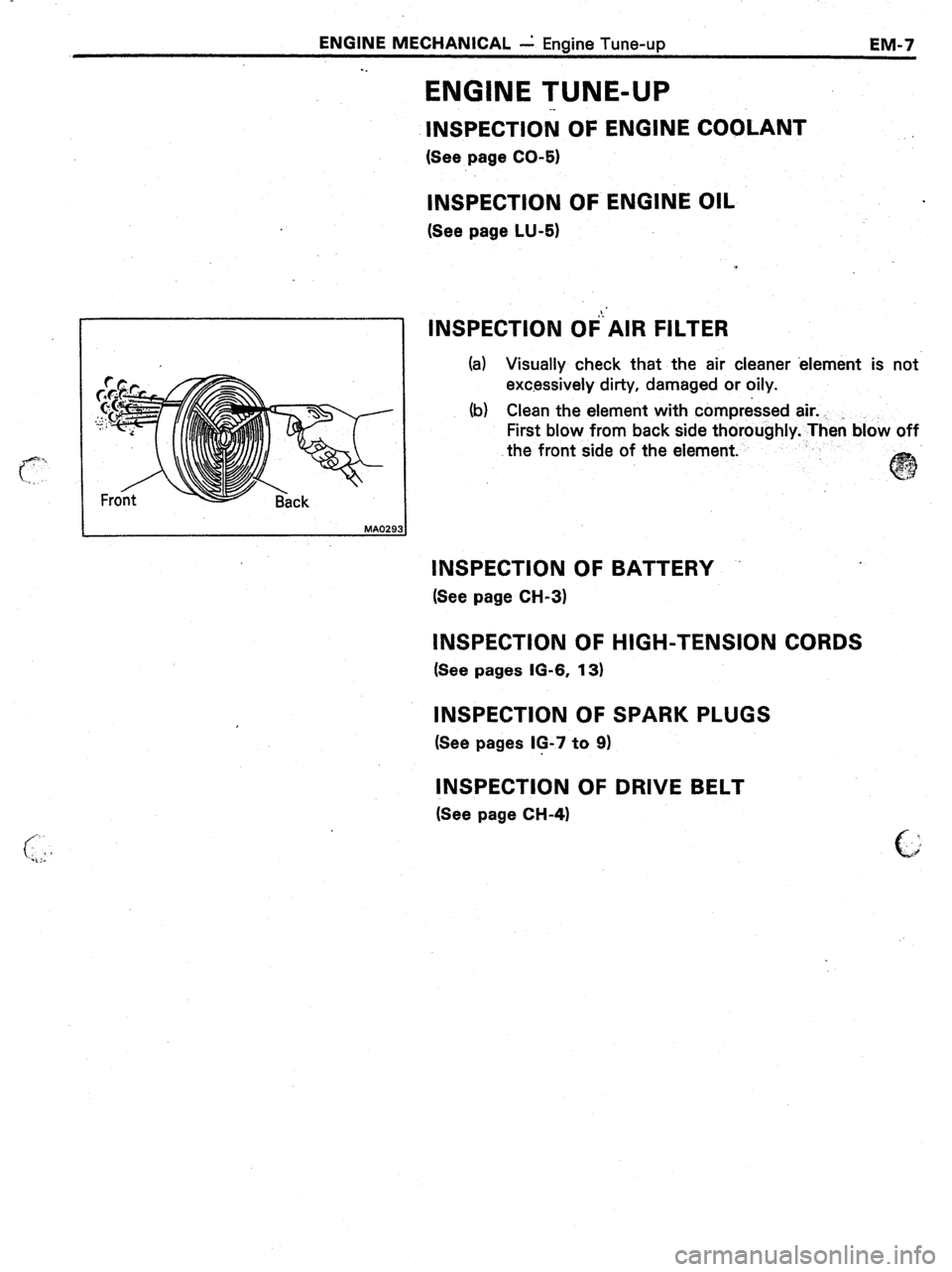

t MA02931

INSPECTION Oi’AIR FILTER

(a) Visually check that the air cleaner element is not

excessively dirty, damaged or oily.

(b) Clean the element with compr&sed air.

First blow from back side thoroughly. Then blow off

the front side of the element.

INSPECTION OF BATTERY

(See page CH-3)

INSPECTION OF HIGH-TENSION CORDS

(See pages IG-6, 13)

INSPECTION OF SPARK PLUGS

(See pages 19-7 to 9)

INSPECTION OF DRIVE BELT

(See page CH-41

Page 170 of 346

EM-8 ENGINE MECHANICAL -I Engine Tune-up

-.

lNS.PECTlON AND. ADJUSTMEtiT OF VALVE

CLEARANCE’

NOTE: Check and adjust the valve clearance while the

engine is cold.

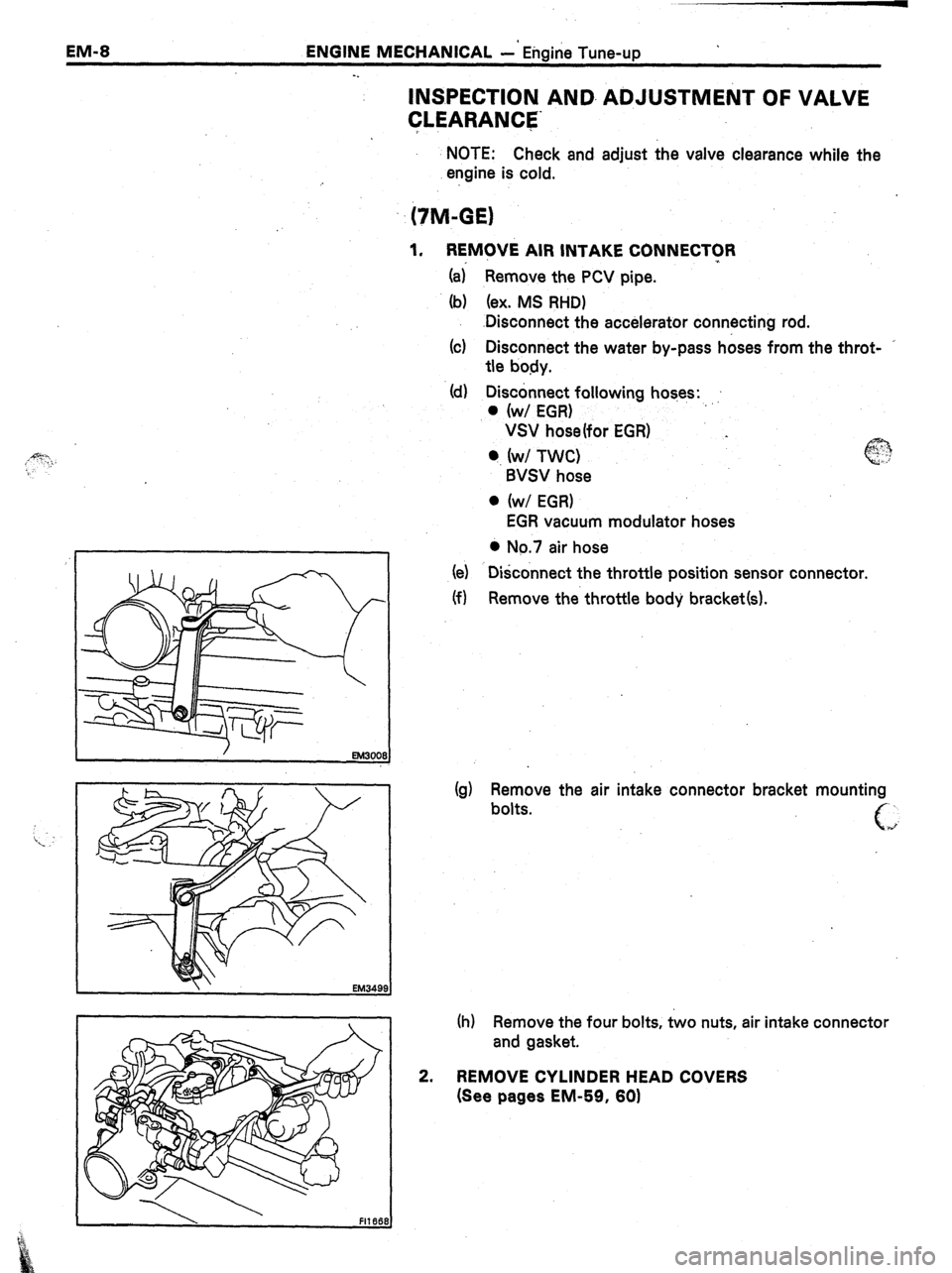

1. REM?VE AIR INTAKE CONNECTOR

j

(a) Remove the PCV pipe.

(b) (ex. MS RHD)

.Disconnect the accelerator connecting rod.

(c) Disconnect the water by-pass hoses from the throt-

tie body.

(d) Disconnect following hoses:

. (w/ EGR)

VSV hose(for EGR) .

l . (w/ TWC)

BVSV hose

. (w/ EGR)

EGR vacuum modulator hoses

0 No.7 air hose

(e) Disconnect the throttle position sensor connector.

(f) Remove the. throttle body bracket(s).

(g) Remove the air intake connector bracket mounting

bolts.

c J

I (h) Remove the four bolts, two nuts, air intake connect01

and gasket.

2. REMOVE CYLINDER HEAD COVERS

(See pages EM-59,601

Page 171 of 346

ENGINE MECHANICAL - Engine Tune-up

3.

* MEA&E VALVE CLEARANCE I

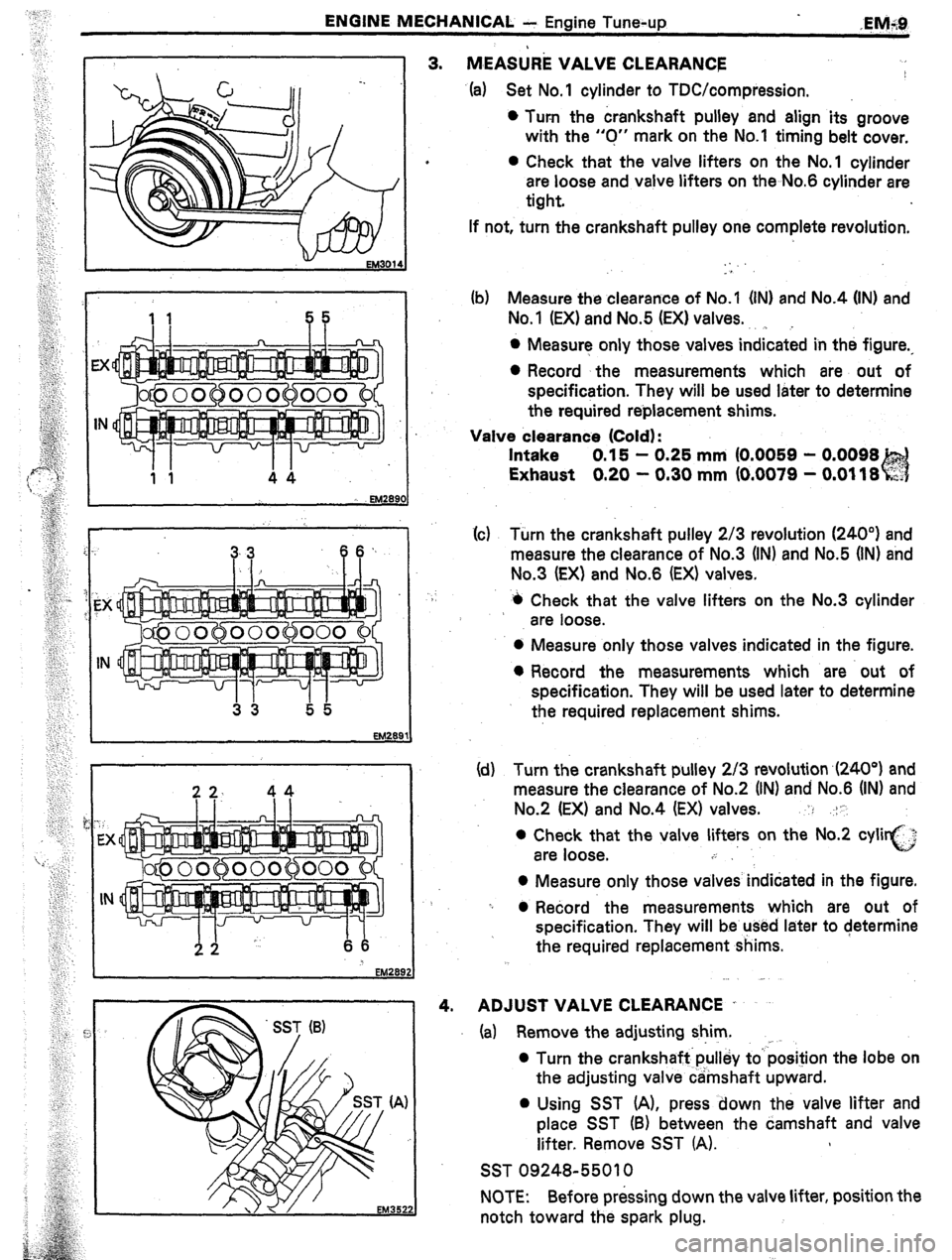

4. (a) Set No.1 cylinder to TDC/compression.

l Turn the crankshaft pulley and align its groove

with the “0” mark on the No.1 timing belt cover,

l Check that the valve lifters on the No.1 cylinder

are loose and valve lifters on the No.6 cylinder are

tight.

If not, turn the crankshaft pulley one complete revolution.

. .

. .

(b) Measure the clearance of No.1 (INI and No.4 (IN) and

No.1 (EX) and No.5 (EX) valves.

. . . .

l Measure only those valves indicated in the figure.,

0 Record the measurements which are. out of

specification. They will be used later to determine

the required reblacement shims.

Valve clearance (Cold) :

Intake 0.15 - 0.25 mm (0.0059 - 0.0098

Exhaust 0.20 - 0.30 mm (0.0079 - 0.0118

(c(c) Turn the crankshaft pulley 2/3 revolution (240”) and

measure the clearance of No.3 (IN) and No.5 (IN) and

No.3 (EX) and No.6 (EX) valves.

4 Check that the valve lifters on the No.3 cylinder

are loose.

0 Measure only those valves indicated in the figure.

l Record the measurements which are out of

specification. They will be used later to determine

the required replacement shims.

(d) Turn the crankshaft pulley 2/3 revolution ,(240°) and

measure the clearance of No.2 (IN) and No.6 (IN) and

No.2 (EX) and No.4 (EX) valves. : .-:1’.

0 Check that the valve lifters on the No.2 cyli i,:..?

are loose. c

.i

0 Measure only those valves indidated in the figure.

-I 0 Record the measurements which are out of

specification. They will be used later to determine

the required replacement shims.

ADJUST VALVE CLEARANCE .

(a) Remove the adjusting shim. ,

0 Turn the crankshaft.pulley to’ position the lobe on

the adjusting valve camshaft upward.

0 Using SST (A), press down the valve lifter and

place SST (B) between the camshaft and valve

lifter. Remove SST (A).

SST 09248-55010

NOTE: Before pressing down the valve lifter, position the

notch toward the spark plug.