check engine TOYOTA CELICA 1987 Service Manual Online

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 1987, Model line: CELICA, Model: TOYOTA CELICA 1987Pages: 346, PDF Size: 35.13 MB

Page 243 of 346

., : I. ,, ;: .I” ..: ;.., -..*::a* .,,. I.

ENGINE MECHANICAL - Cylinder Block

EMd81

. .

EM29&

CD

_

iii,

\,

EM3765 EM3780

INSPECTIC)N OF CRANKSHAFT

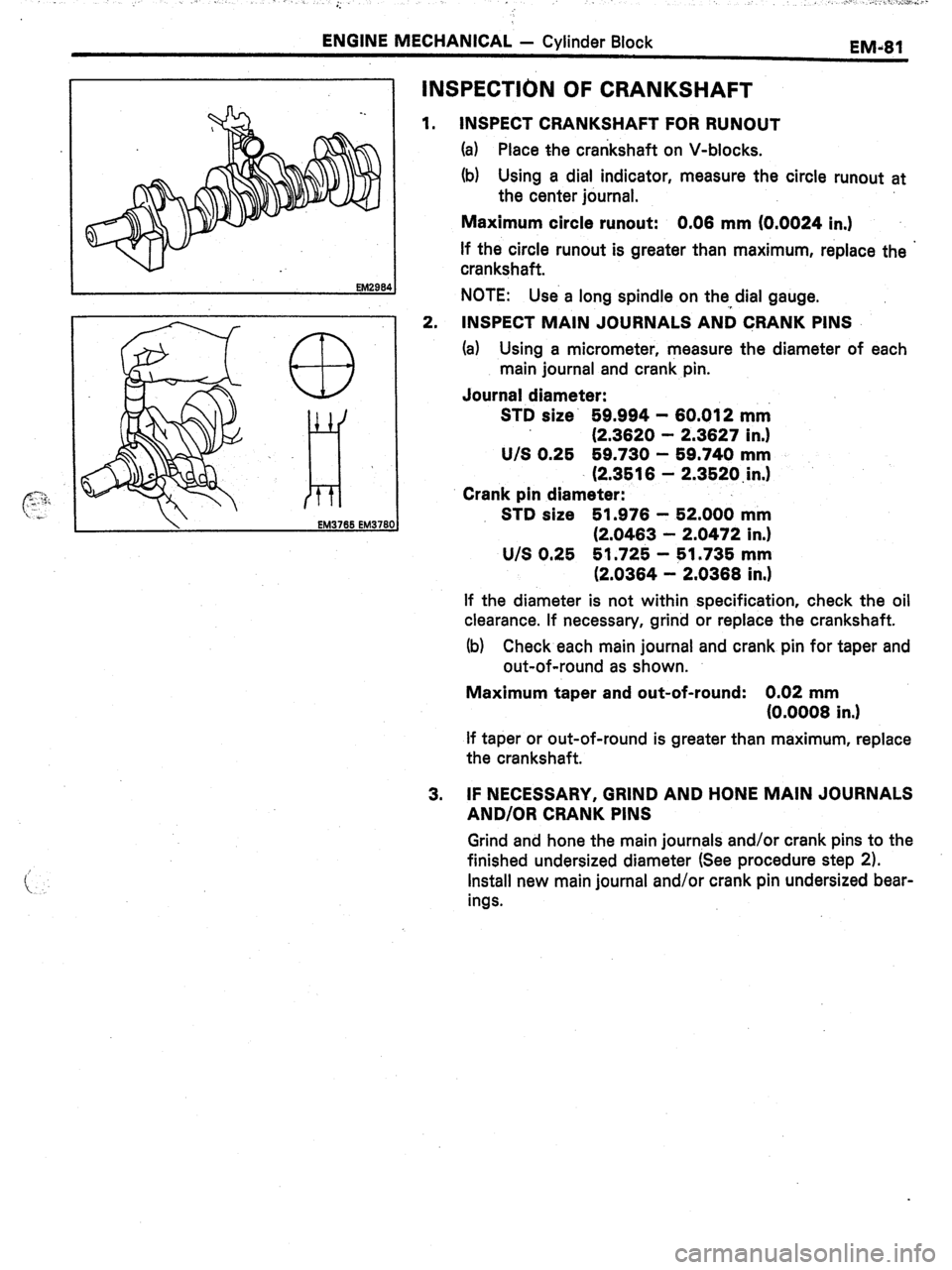

1. INSPECT CRANKSHAFT FOR RUNOUT

(a) Place the crankshaft on V-blocks.

(b) Using a dial indicator, measure the circle runout at

the center journal.

Maximum circle runout: 0.08 mm (0.0024 in.)

If the circle runout is greater than maximum, replace the ’

crankshaft.

NOTE: Use a long spindle on the,,dial gauge.

2. INSPECT MAIN JOURNALS AND CRANK PINS

(a) Using a micrometer, measure the diameter of each

main journal and crank pin.

Journal diameter:

STD size’ 59.994 - 60.012 mm

(2.3620 - 2.3627 in.1

U/S 0.25 59.730 - 59.740 mm

(2.3516 - 2.3520,in.I

Crank pin diameter:

STD size 51.976 - 52.000 mm

(2.0463 - 2.0472 in.)

U/S 0.25 51.725 - 51.735 mm

(2.0364 - 2.0368 in.)

If the diameter is not within specification, check the oil

clearance. If necessary, grind or replace the crankshaft.

(b) Check each main journal and crank pin for taper and

out-of-round as shown.

Maximum taper and out-of-round: 0.02 mm

(0.0008 in.1

If taper or out-of-round is greater than maximum, replace

the crankshaft.

3. IF NECESSARY, GRIND AND HONE MAIN JOURNALS

AND/OR CRANK PINS

Grind and hone the main journals and/or crank pins to the

finished undersized diameter (See procedure step 2).

Install new main journal and/or crank pin undersized bear-

ings.

Page 247 of 346

ENGINE :MECHANICAL.;:y Cylinder, B&k:

Elg781i.

.,. ,.,. .._. >,, \I . ,_

“. 1 . , ,_ ., “_ , ; . . .

EM2994

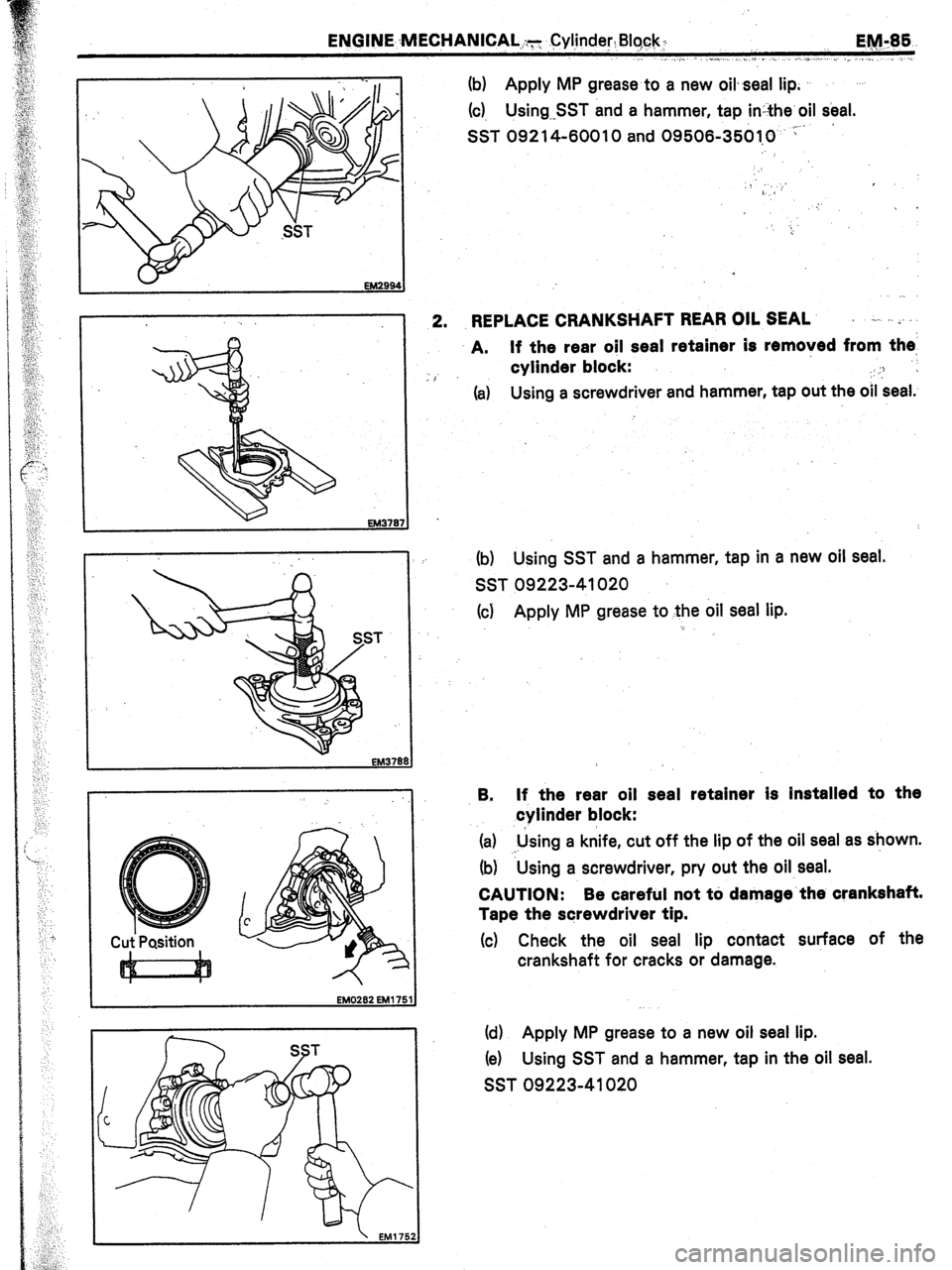

SST (b) Apply MP grease to a new oil, seal lip.

(~1, Using--SST and a hammer, tap in-the oil seal.

SST 09214-60010 and 09506-3501.0 ;”

.

2. REPLACE CRANKSHAFT REAR OIL SEAL ‘-. ‘. :

A. If the rear oil seal retainer is removed from the,

cylinder block: ‘: <

.:

(a) Using a screwdriver and hammer, tap out the oil seal.

(b) Using SST and a hammer, tap in a new oil seal.

SST 09223-41020

(cl Apply MP grease to the oil seal lip.

8. If the rear oil seal retainer is installed to the

cylinder block:

(a) :Using a knife, cut off the lip of the oil seal as shown.

(b) Using a screwdriver, pry out the oil seal.

CAUTION: Be careful not to damage the crankshaft.

Tape the screwdriver tip.

(c) Check the oil seal lip contact surface of the

crankshaft for cracks or damage.

(d)

Apply MP grease to a new oil seal lip.

(e)

Using SST and a hammer, tap in the oil seal.

SST 09223-41020

Page 248 of 346

EM-86

,, ENGINE MF@ANl,CAL - Cjrlinder Block

EM456:

?==--zpe EM0262 EM1 761

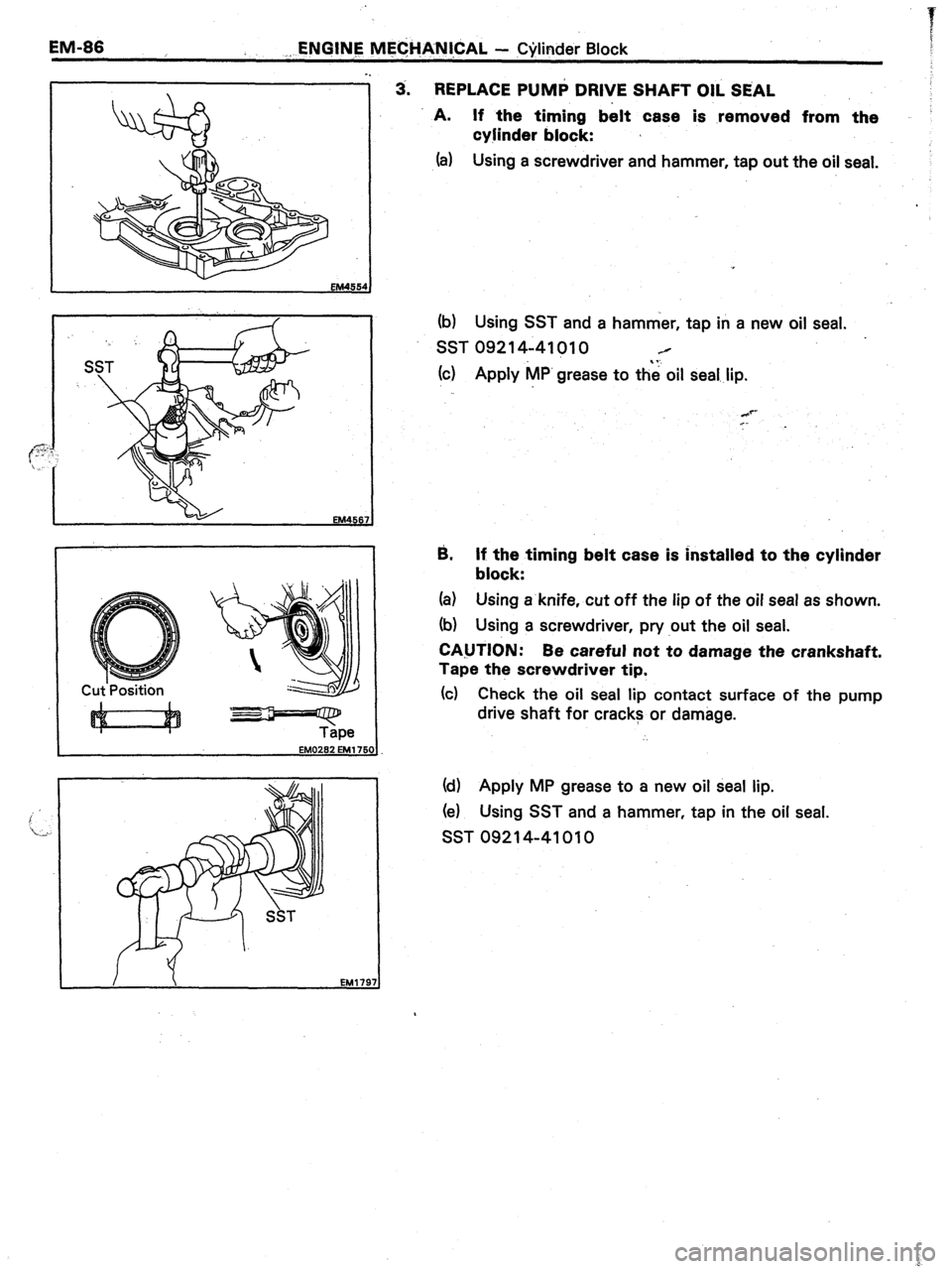

3. REPLACE PUM+ DRIVE SHAFT OIL SEAL

A. If the timing b&t case is removed from the

cyjinder block:

(a) Using a screwdriver and hammer, tap out the oil seal.

(b) Using SST and a hammer, tap in a new oil seal.

SST 09214-41ClO C

, . . .

(c) Apply MP grease to the oil seal, lip.

A--

*- .

& If the timing belt case is installed to the cylinder

block:

(a) Using a knife, cut off the lip of the oil seal as shown.

(b) Using a screwdriver, pry .out the oil seal.

CAUTION: Be careful not

to damage the crankshaft.

Tape the screwdriver tip.

(c) Check the oil seal lip contact surface of the pump

drive shaft for cracks or damage.

(d) Apply MP grease to a new oil seal lip.

(e) Using SST and a hammer, tap in the oil seal.

SST 09214-41010

Page 251 of 346

ENGINE MECHANICAL A Cylinder Block

EM-@-

3.

4.

5. (a)

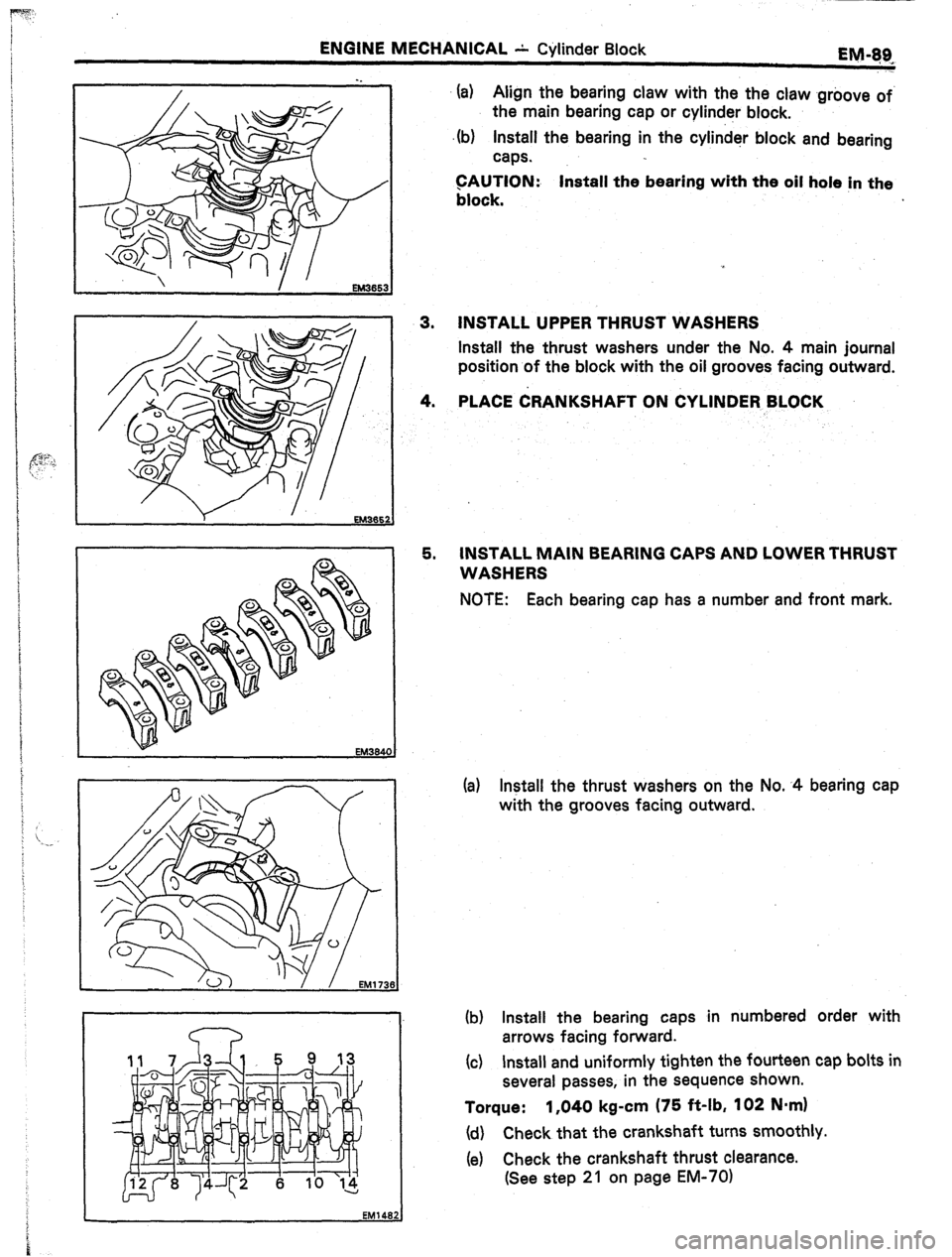

Align the bearing claw with the the claw -groove of.

the main bearing cap or cylind,er block.

(b)

Install the bearing in the cylinder block and bearing

caps.

GAUTION:

Install the bearing with the oil hole in the

block.

INSTALL UPPER THRUST WASHERS

Install the thrust washers under the No. 4 main journal

position of the block with the oil grooves facing outward.

PLACE &ANKSHAFT ON CYLINDER BLOCK

INSTALL MAIN BEARING CAPS AND LOWER THRUST

WASHERS

NOTE: Each bearing cap has a number and front mark.

(a) Install the thrust washers on the No. -4 bearing cap

with the grooves facing outward.

(b) Install the bearing caps in numbered order with

arrows facing forward.

(c) Install and uniformly tighten the fourteen cap bolts in

several passes, in the sequence shown.

Torque: 1,040 kg-cm (75 ft-lb, 102 N.mI

(d) Check that the crankshaft turns smoothly.

(e) Check the crankshaft thrust clearance.

(See step 21 on page EM-701

Page 256 of 346

16-2 IGNITION SYSTEM - precautions

-.

PRECAUTIONS

1.

2.

3.

4.

5.

6.

. *

Do not leave the ignition switch on for more than 10

minutes if the engine does not start.

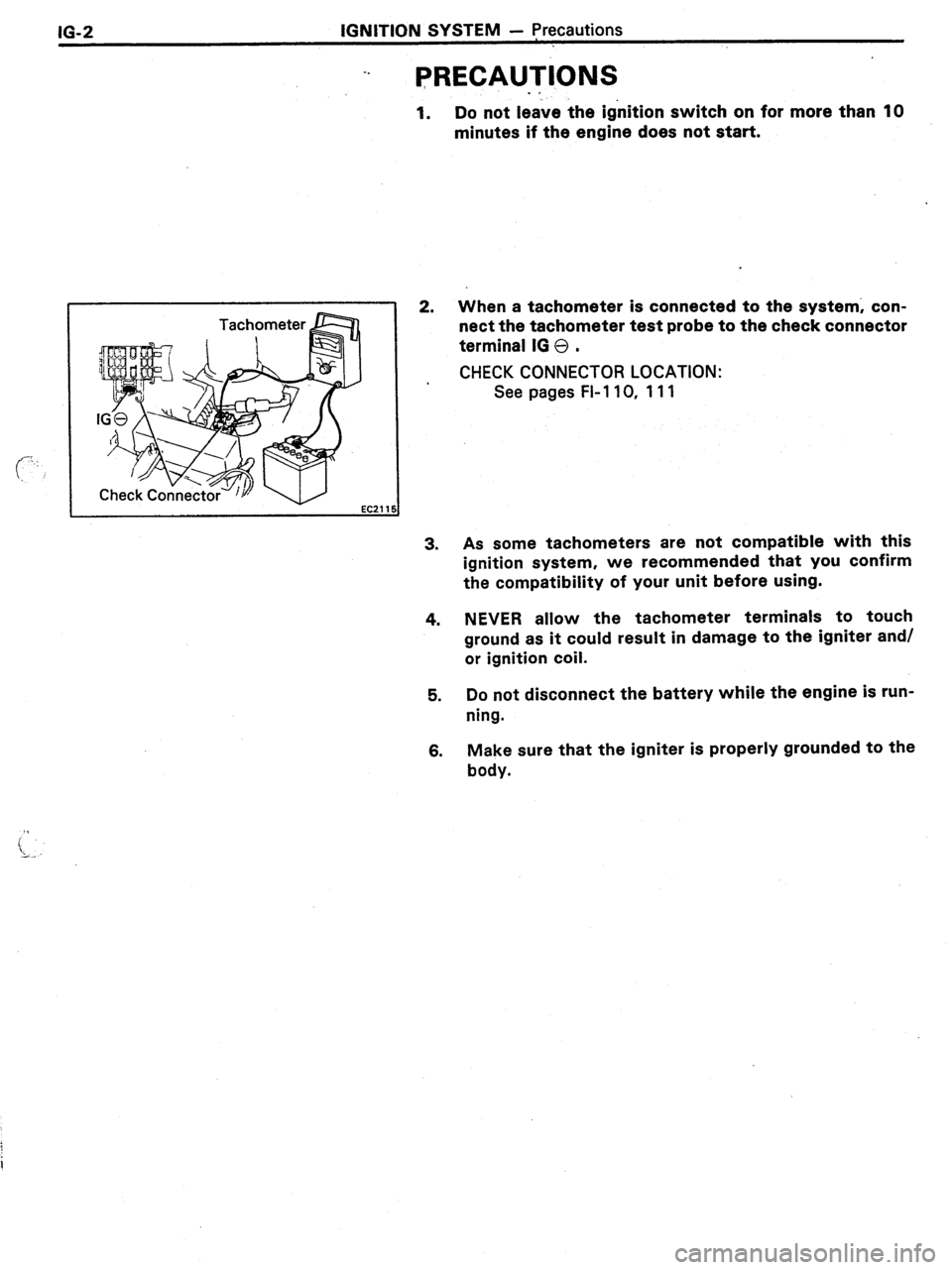

When a tachometer is connected to the system; con-

nect the tachometer test probe to the check connector

terminal IG 0 .

CHECK CONNECTOR LOCATION:

See pages FI-110, 111

As some tachometers are not compatible with this

ignition system, we recommended that you confirm

the compatibility of your unit before using.

NEVER allow the tachometer terminals to touch

ground as it could result in damage to the igniter and/

or ignition coil.

Do not disconnect the battery while the engine is run-

ning.

Make sure that the igniter is properly grounded to the

body.

Page 259 of 346

IGNITION SYSTEM - On-Vehicle Inspection (7M-GE)

IO-6 *

-. ON-VEHICLE INSPECTION (7M43E)‘;

SPARK TEST --

CHECK THAT SPARK OCCURS

(a) Disconnect high-tension cord from the distributor.

(b) Hold the end about 12.5 mm (0.49 in.) from body of

vehicle.

(G) See if spark occurs while engine is being cranked.

NOTE: To prevent gasoline from being injected from

injectors during this test, crank the engine for no more

than l-2 seconds at a time.

If the spark does not occur, perform the test as follows:

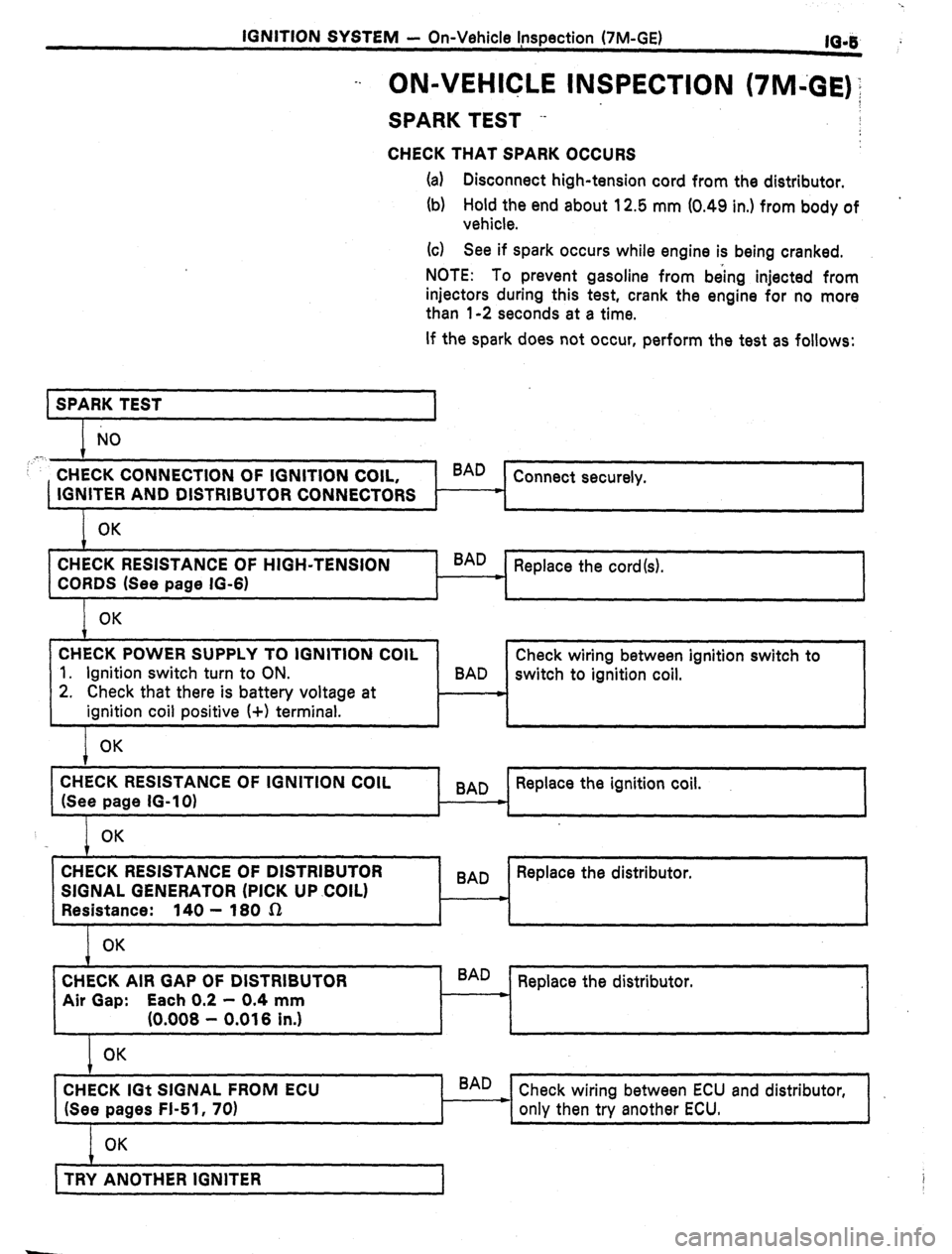

SPARK TEST

1

NO

,‘.

CHECK CONNECTION OF IGNITION COIL, BAD

Connect securely.

IGNITER AND DISTRIBUTOR CONNECTORS c

OK

CHECK RESISTANCE OF HIGH-TENSION

CORDS (See page IG-6) ’ BAD

Replace the cord(s).

OK

CHECK POWER SUPPLY TO IGNITION COIL

1. Ignition switch turn to ON.

2. Check that there is battery voltage at

ignition coil positive I+) terminal. Check wiring between ignition switch to

BAD

switch to ignition coil.

OK

CHECK RESISTANCE OF IGNITION COIL

(See page IG-10) 9

BAD Replace the ignition coil.

*

OK

1 , , 1

CHECK RESISTANCE OF DISTRIBUTOR

SIGNAL GENERATOR (PICK UP .COIL)

Resistance: 140 - 180 sz

OK BAD Replace the distributor.

m

CHECK AIR GAP OF DISTRIBUTOR

Air Gap: Each 0.2 - 0.4 mm

(0.008 - 0.016 in.) BAD

Replace the distributor.

L

OK

CHECK IGt SIGNAL FROM ECU

(See pages FI-51, 70) BAD

Check wiring between ECU and distributor,

only then try another ECU.

OK

t ,

TRY ANOTHER IGNITER

1 i

Page 267 of 346

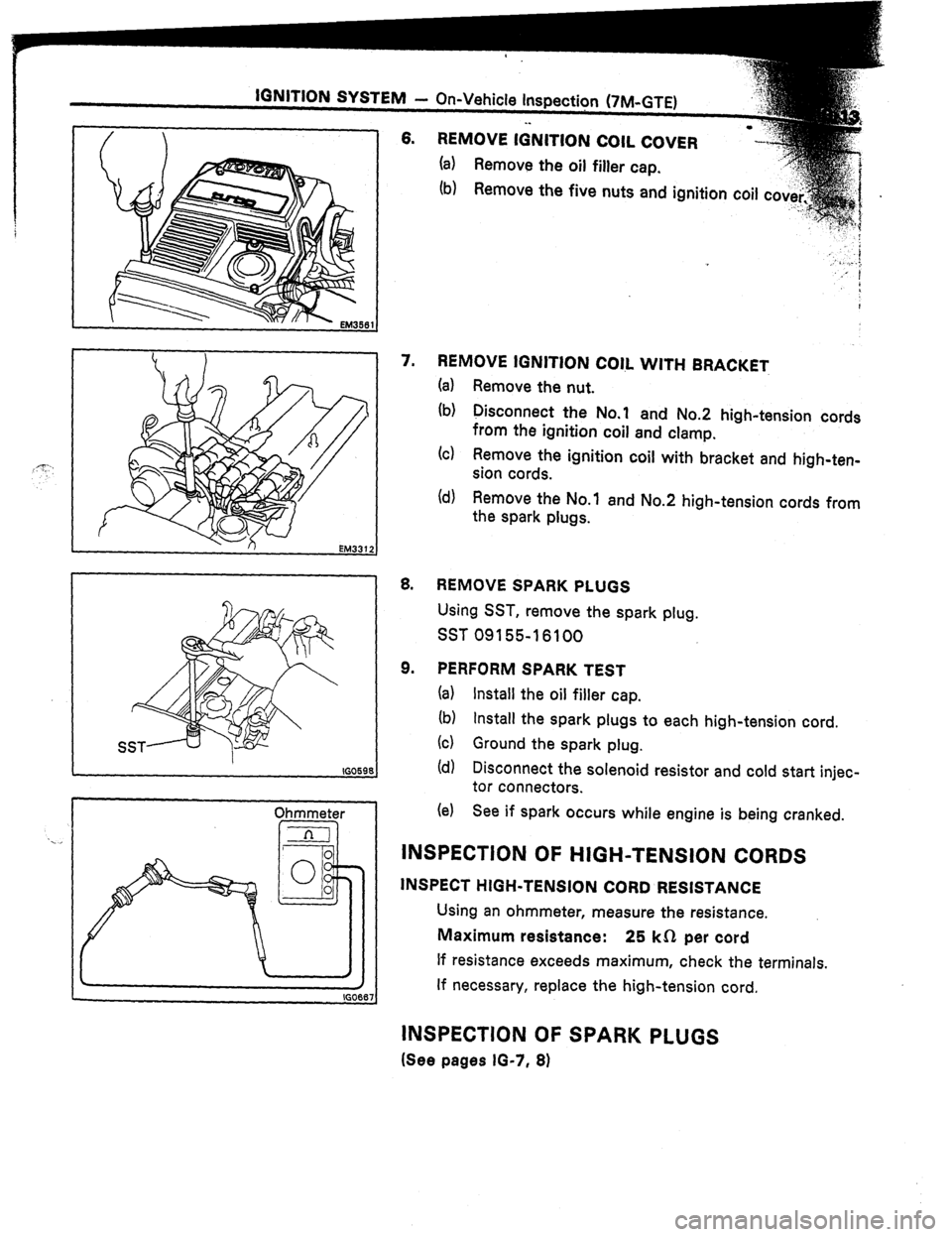

6. REMOVE IGNITION COIL COVER

(a) Remove the oil filler cap.

‘...”

I I

I(30598

Ohmmeter

/

IGO

7. REMOVE IGNITION C0l.L WITH BRACKET

(a) Remove the nut.

(b) Disconnect the No.1 and No.2 high-tension cords

from the ignition coil and clamp.

(cl Remove the ignition coil with bracket and high-ten-

sion cords.

id) Remove the No.1 and No.2 high-tension cords from

the spark plugs.

8.

9. REMOVE SPARK PLUGS

Using SST, remove the spark plug.

SST 09155-16100

PERFORM SPARK TEST

Ia) Install the oil filler cap.

(b) Install the spark plugs to each high-tension cord.

(4 Ground the spark plug.

(d) Disconnect the solenoid resistor and cold start injec-

tor connectors.

(e) See if spark occurs while engine is being cranked.

INSPECTION OF HIGH-TENSION CORDS

INSPECT HIGH-TENSION CORD RESISTANCE

Using an ohmmeter, measure the resistance.

Maximum resistance: 25 kfl per cord

If resistance exceeds maximum, check the terminals.

If necessary, replace the high-tension cord.

INSPECTION OF SPARK PLUGS

(See pages IG-7, 8)

Page 282 of 346

-.

. .

..,I -_

LUBRICATION SYSTEM: . . I-

Page

DESCRIPTION . . ..*.*.........*......*........

LU-2

TROUBLESHOOTING ..I....*........*.‘....... b-4

OIL PRESSURE CHECK . . , . . . . . .

l . . . . . . , . . . . . . . ‘LU-5

REPLACEMENT OF ENGINE OIL

AND OIL FILTER I*......**.~.....~..,,,,..,.

LU-6

OIL PUMP *I...~.......~.~.,,,...~...~‘,,...,.

LU-6

OIL COOLER AND OIL PRESSURE

REGULATOR (7M-GE) . . . . . . . . . . . . . . . . . . . . . . . LU-15

OIL COOLER AND OIL PRESSURE

REGULATOR (7M-GTE) . . . . . . . . . . . . . . a. . . . . . LU-16

Page 284 of 346

LUBRICATION SYSTEM - Description

.,LU-3

A pressure feeding lubrication system has been

adopted to supply oil to the moving parts of this

engine. The lubrication system consists of an oil

pan, oil pump, oil filter and other external parts

which supply oil to the moving parts in the engine

block. The oil circuit is shown in the illustration at

the top of the previous page. Oil from the oil pan is

pumped up by the oil pump. After it passes

through the oil filter, it is fed through the various

oil holes in the crankshaft and cylinder block. After

passing through the cylinder block and performing

its lubricating function, the oil is returned by gra-

vity to the oil pan. A dipstick on the side of the

cylinder block is provided to check the oil level.

OIL PUMP

The oil pump pumps up oil from the oil pan and

sends it under pressure to the various parts of the

engine. An oil strainer is mounted in front of the

inlet to the oil pump. The oil pump itself is a gear

pump, which uses a drive gear and driven gear

inside the pump body. When the drive gear

rotates, the driven gear rotates in the opposite

direction. When the gear teeth disengage oil is

drak n in, and when the gear teeth engage oil is

discharged.

OIL PRESSURE REGULATOR

At high engine speeds, the engine oil supplied

bY thr oil pump exceeds the capacity of the engine

10 utiiize it.

For that reason, the oil pressure regula-

tor i ,>rks to prevent an oversupply of oil. During

norm.tl oil

supply, a coil spring and valve keep the

bYPcls:s closed, but when too much oil is being fed,

the I’tt’essure becomes extremely high, overpower-

9 the force of the spring and opening the valves.

This ;:ilows the excess oil to flow through the

Yalvtj :snd return to the oil pan. Olii FILTER

The oil filter is a full flow type filter with a built-

in paper filter element. Particles of :metal ‘from

wear, a&born dirt, carbon and other impurities can ’

get in the oil during use and could cause acceler-

ated wear or siezing if allowed to circulate through

the engine. The oil filter, integrated into the oil line,

removes these impurities as the oil passes through

it. The filter is mounted outside the engine to

simplify replacement of the filter element. A relief

valve is also included ahead of the filter element to

relieve the high oil pressure in case the filter ele-

ment becomes clogged with impurities. The relief

valve opens when the oil pressure overpowers the

force of the spring. Oil passing through the relief

valve bypasses the oil filter and flows directly into

the main oil hole in the engine.

Page 286 of 346

rutmwCiA rlON SYSTEM - Oil Pressure Che,ck’:q. .’ ‘f,“,; .! . ,_ _,, __ _ ,-tiu,e

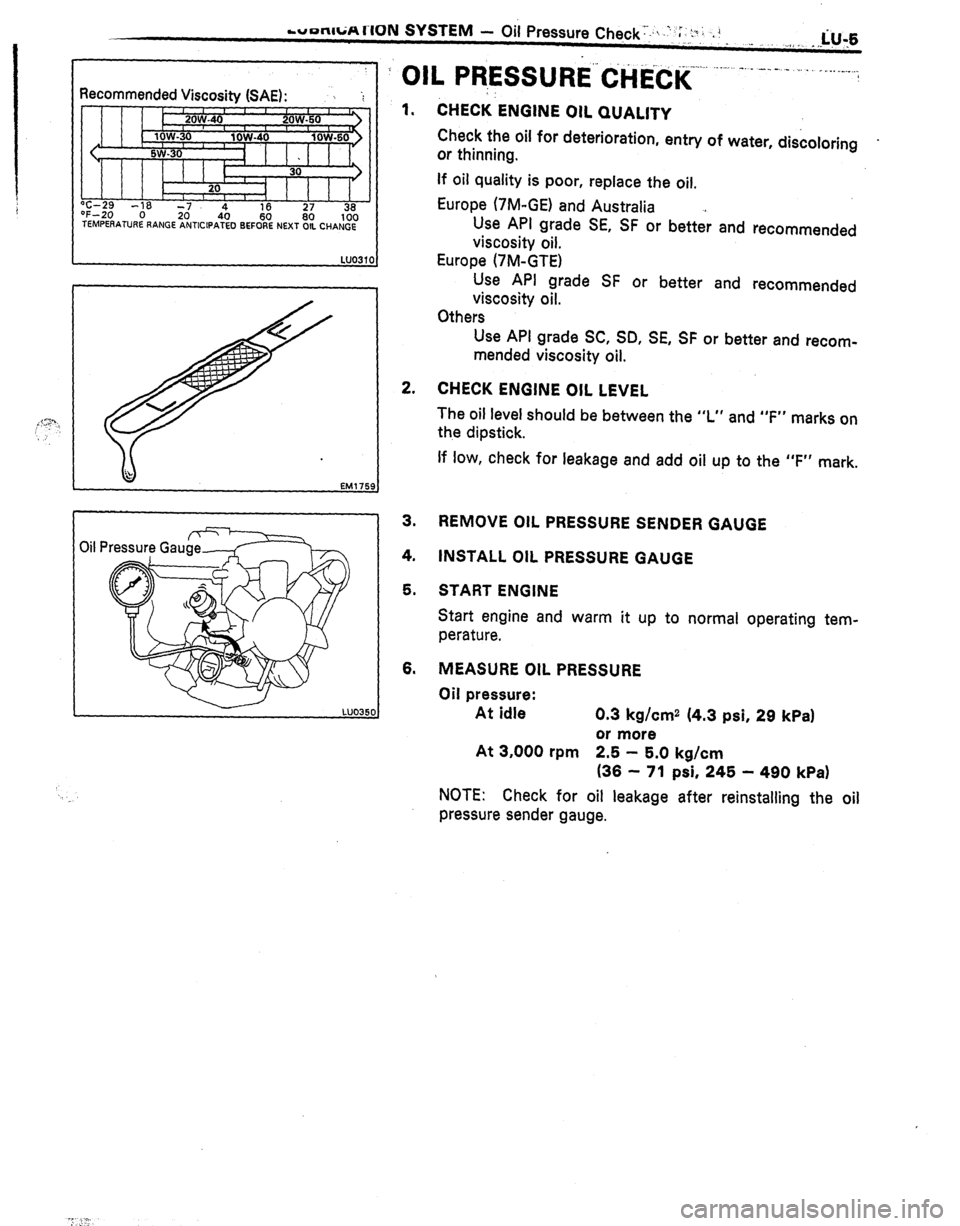

Recommended

Viscositv (SAE):

I 1 1 1 h T-29 -,a 7 “F-20 0 TEMPEAATURE LY

I I b I I I I

I

z 4 16 36

/

RANGE ANTICIPA$O B&i% NEXT OIL CHANGE 100 ._. .-- . . .

?’ OIL PR,ESSURE’($liCK . .._.

-. - -_-. _

. _ _.. _ _...

1. 1 CHECK-ENGINE OIL QUALITY

Check the oil for deterioration, entry of water, discoloring .

or thinning.

2.

3.

4.

5.

6. If oil quality is poor, replace the oil,

Europe (‘IM-GE) and Australia *

Use API grade SE, SF or better and recommended

viscosity oil.

Europe (7M-GTE)

Use API grade SF or better and recommended

viscosity oil.

Others

Use API grade SC, SD, SE, SF or better and recom-

mended viscosity oil.

CHECK ENGINE OIL LEVEL

The oil level should be between the “L” and “F” marks on

the dipstick.

If low, check for leakage and add oil up to the “F” mark.

REMOVE OIL PRESSURE SENDER GAUGE

INSTALL OIL PRESSURE GAUGE

START ENGINE

Start engine and warm it up to normal operating tem-

perature.

MEASURE OIL PRESSURE

Oil pressure:

At idle 0.3 kg/cm2 (4.3 psi, 29 kPa1

or more

At 3,000 rpm 2.5 - 5.0 kg/cm

(36 - 71 psi, 245 - 490 kPa1

NOTE: Check for oil leakage after reinstalling the oil

pressure sender gauge.