check engine TOYOTA CELICA 1987 Service Manual PDF

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 1987, Model line: CELICA, Model: TOYOTA CELICA 1987Pages: 346, PDF Size: 35.13 MB

Page 191 of 346

ENGINE MECHANICAL, k Timi’ng Belt-

~@Jli&%J

,_... - ,. _, ’

I 6. REMOVE NO.3 TIMING BELT COVER - ~ .-,.,.,.... ./. -~

/

Remove the five bolts, nut and No.3 timing belt’cover with:

the gasket. .,..,I

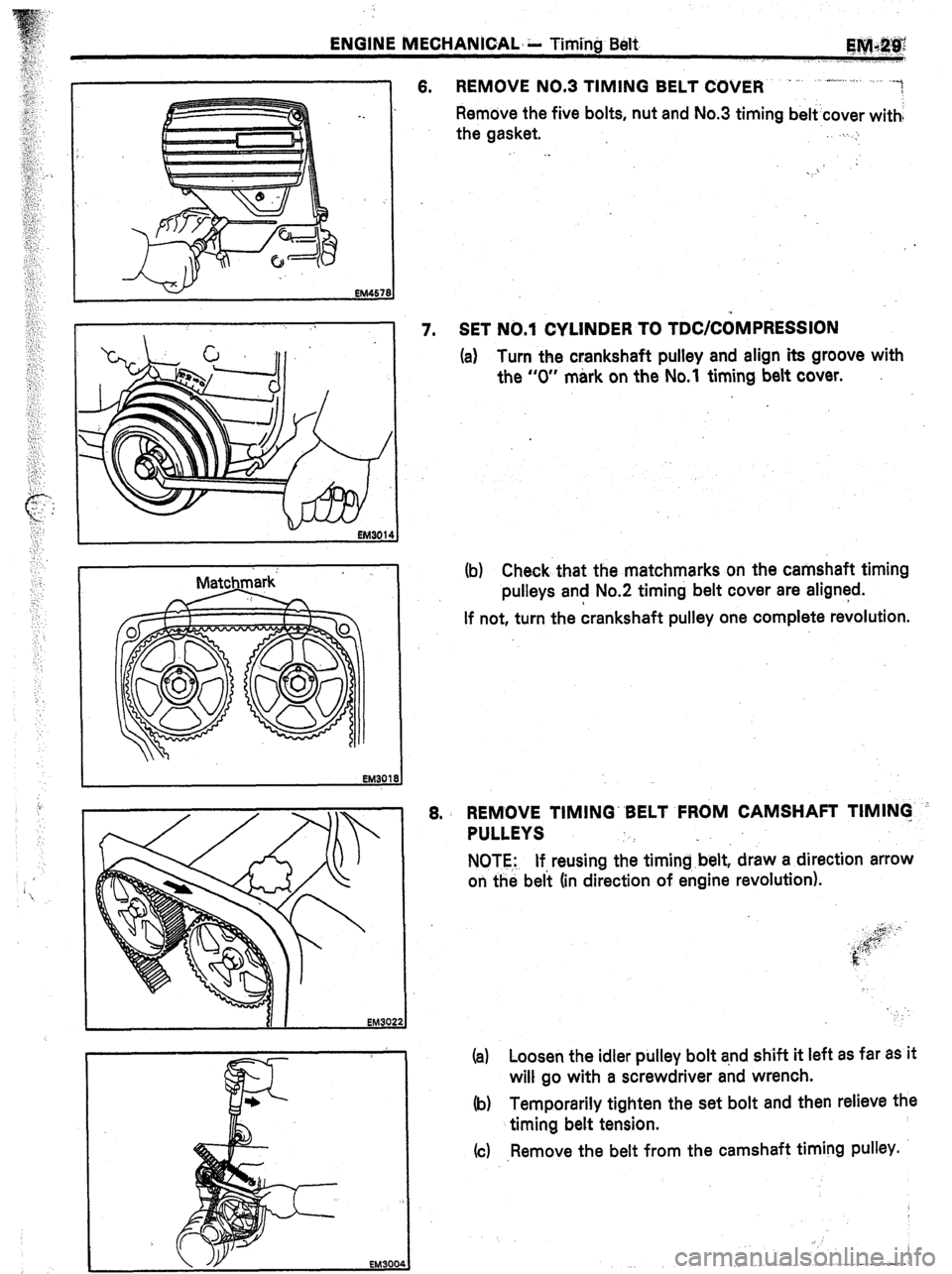

’ 7. SET NO.1 CYLINDER TO TDCICOMPRESSION

(a) Turn the crankshaft pulley and align its groove with

the “0” mark on the No.1 timing belt cover.

EM300d

(b) Check that the matchmarks on the camshaft timing

pulleys and No.2 timing belt cover are aligned.

If not, turn the crankshaft pulley one complete revolution.

8. REMOVE TIMING“BELT FROM CAMSHAFT TIMING -’

PULLEYS

NOTE.: If reusing the timingbelt, draw a direction arrow

on the bel’t (in direction of engine revolution).

(a) Loosen the idler pulley bolt and shift it left as far as it

will go with a screwdriver and wrench.

(b) Temporarily tighten the set bolt and then relieve the

timing belt tension.

(c) ,Remove the belt from the camshaft timing pulley.

. .

Page 193 of 346

ENGINE MECHANICAL - Timing Belt

Socket Wrench

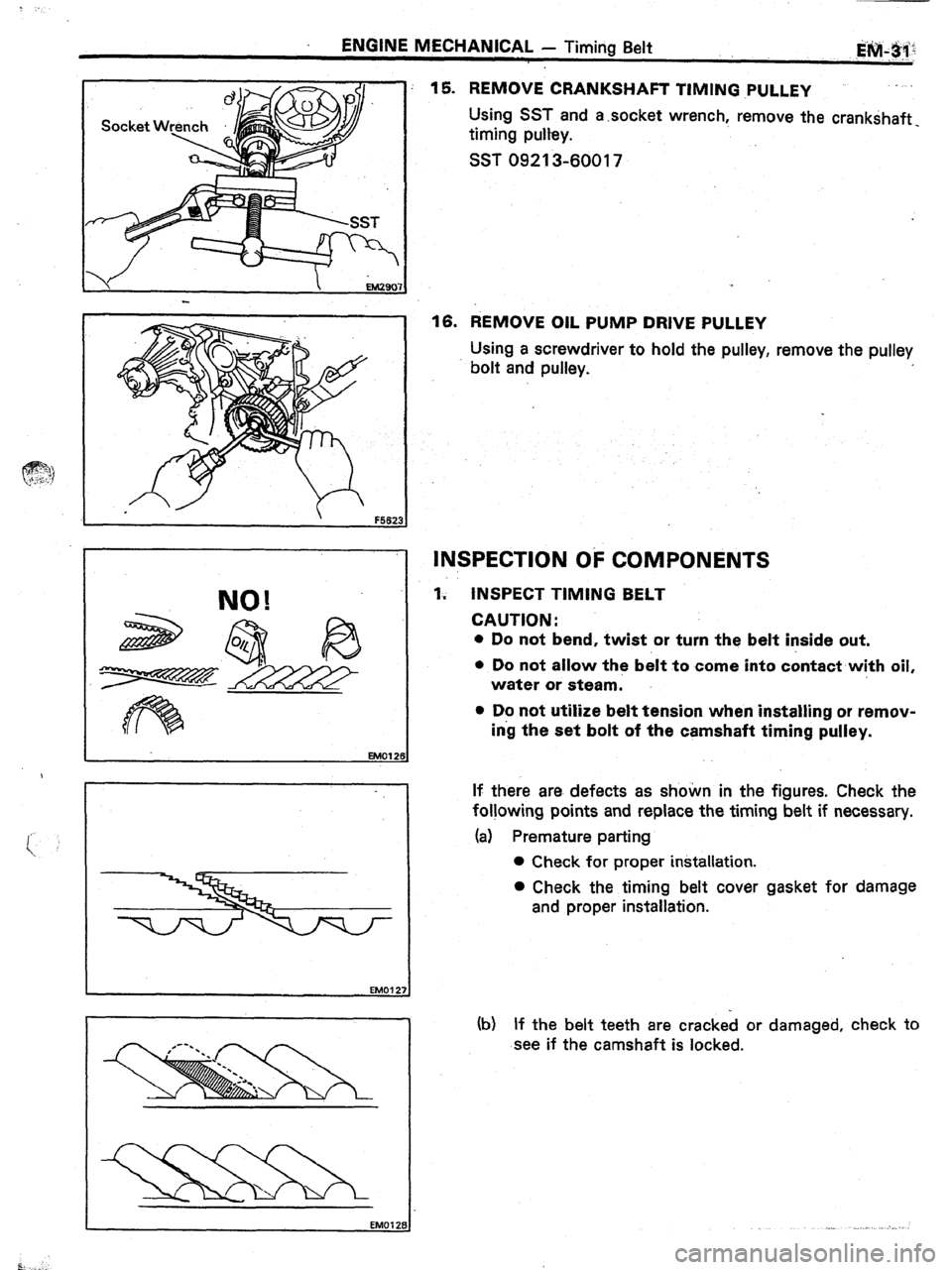

NO!

1

15. REMOVE CRANKSHAFT TIMING .PULLEY

Using SST and a .socket wrench, remove the crankshaft-

timing pultey.

SST 09213-60017

16. REMOVE OIL PUMP DRtVE PULLEY

Using a screwdriver to hold the pulley, remove the pulley

bolt and pulley.

INSPECTION Oi COMPONENTS

1.

tNSPECT TlMlNG BELT

CAUTION :

l Do not bend, twist or turn the belt inside out.

l Do not allow the belt to come into contact with oil,

water or steam.

l Do not utilize belt tension when installing or remov-

ing the set bolt of the camshaft timing pulley.

If there are defects as shotin in the figures. Check the

foljowing points and replace the timing belt if necessary.

(a) Premature parting

l Check for proper installation.

l Check the timing belt cover gasket for damage

and proper installation.

(b) If the belt teeth are crackeb or damaged, check to

see if the camshaft is locked.

Page 194 of 346

EM-32

ENGINE MECHANICAL - Timing Belt

c

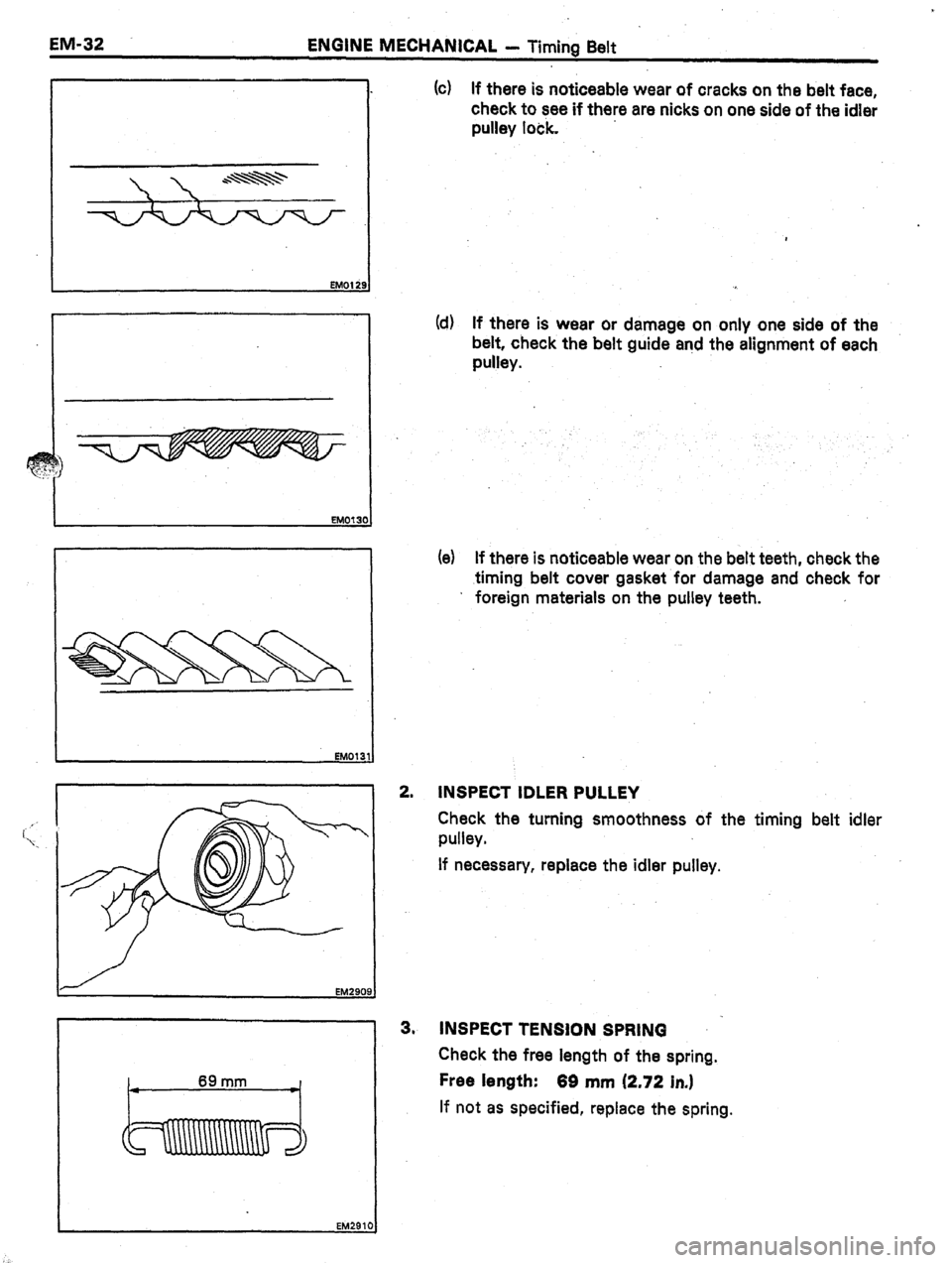

(c) If there is noticeable wear of cracks on the belt face,

check to see if there are nicks on one side of the idler

pulley lock.

Id) If there is wear or damage on only one side of the

belt, check the

belt guide and the alignment of each

pulley.

(e) If there is noticeable wear on the belt teeth, check the

.timing

belt cover gasket for damage and check for

’ foreign materials on the pulley teeth.

2,

INSPECT IDLER PULLEY

Check the turning smoothness of the timing belt idler

pulley.

If necessary, repiace the idler pulley.

EM2909.

3” INSPECT TENSION SPRING

Check the free length of the spring.

Free length:

66 mm (2.72 in.)

If not as specified, replace the spring.

Page 196 of 346

4

EM-34 ENGINE MECHANICAL - Timing Belt

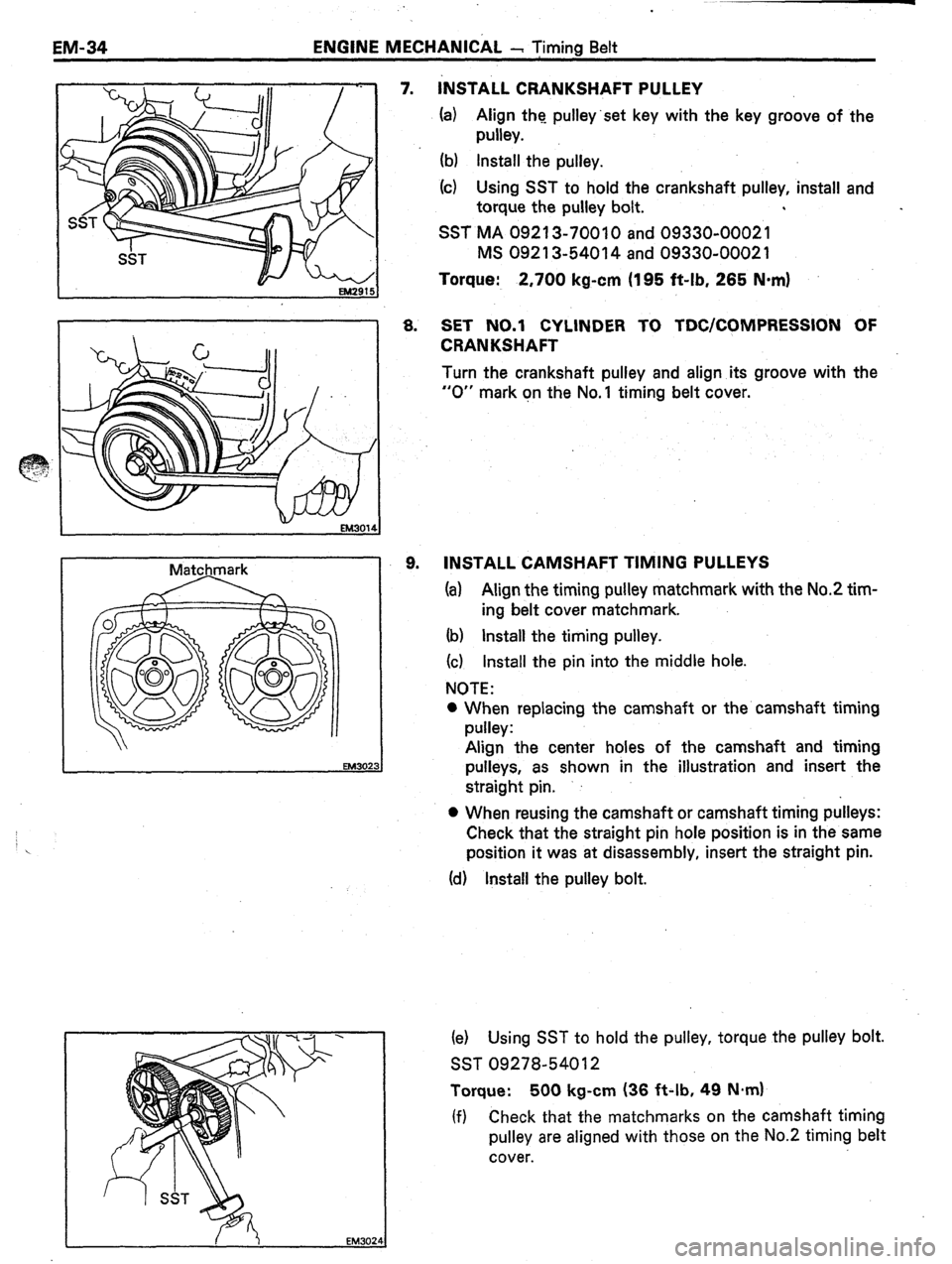

Matchmark

7. INSTALL CRANKSHAFT PULLEY

(a) Align the pulley’set key with the key groove of the

pulley.

(b) Install the pulley.

(c) Using SST to hold the crankshaft pulley, install and

torque the pulley bolt. .

SST MA 09213-70010 and 09330-00021

MS 092 13-54014 and 09330-00021

Torque: 2,700 kg-cm (195 ft-lb, 265 N-m) 8.

SET NO.1 CYLINDER TO TDC/COMPRESSION OF

CRANKSHAFT

Turn the crankshaft pulley and align its groove with the

“0” mark on the No.1 timing belt cover.

9. INSTALL CAMSHAFT TIMING PULLEYS

(a) Align the timing pulley matchmark with the No.2 tim-

ing belt cover matchmark.

(b) Install the timing pulley.

(c) Install the pin into the middle hole.

NOTE:

l When replacing the camshaft or the camshaft timing

pulley:

Align the center holes of the camshaft and timing

pulleys, as shown in the illustration and insert the

straight pin.

l When reusing the camshaft or camshaft timing pulleys:

Check that the straight pin hole position is in the same

position it was at disassembly, insert the straight pin.

(d) Install the pulley bolt.

(e) Using SST to hold the pulley, torque the pulley bolt.

SST 09278-54012

Torque: 500 kg-cm (36 ft-lb, 49 N-m)

(f) Check that the matchmarks on the camshaft timing

pulley are aligned with those on the No.2 timing belt

cover.

Page 197 of 346

.

ENGINE MECHANICAL - Timing Belt

EM-35

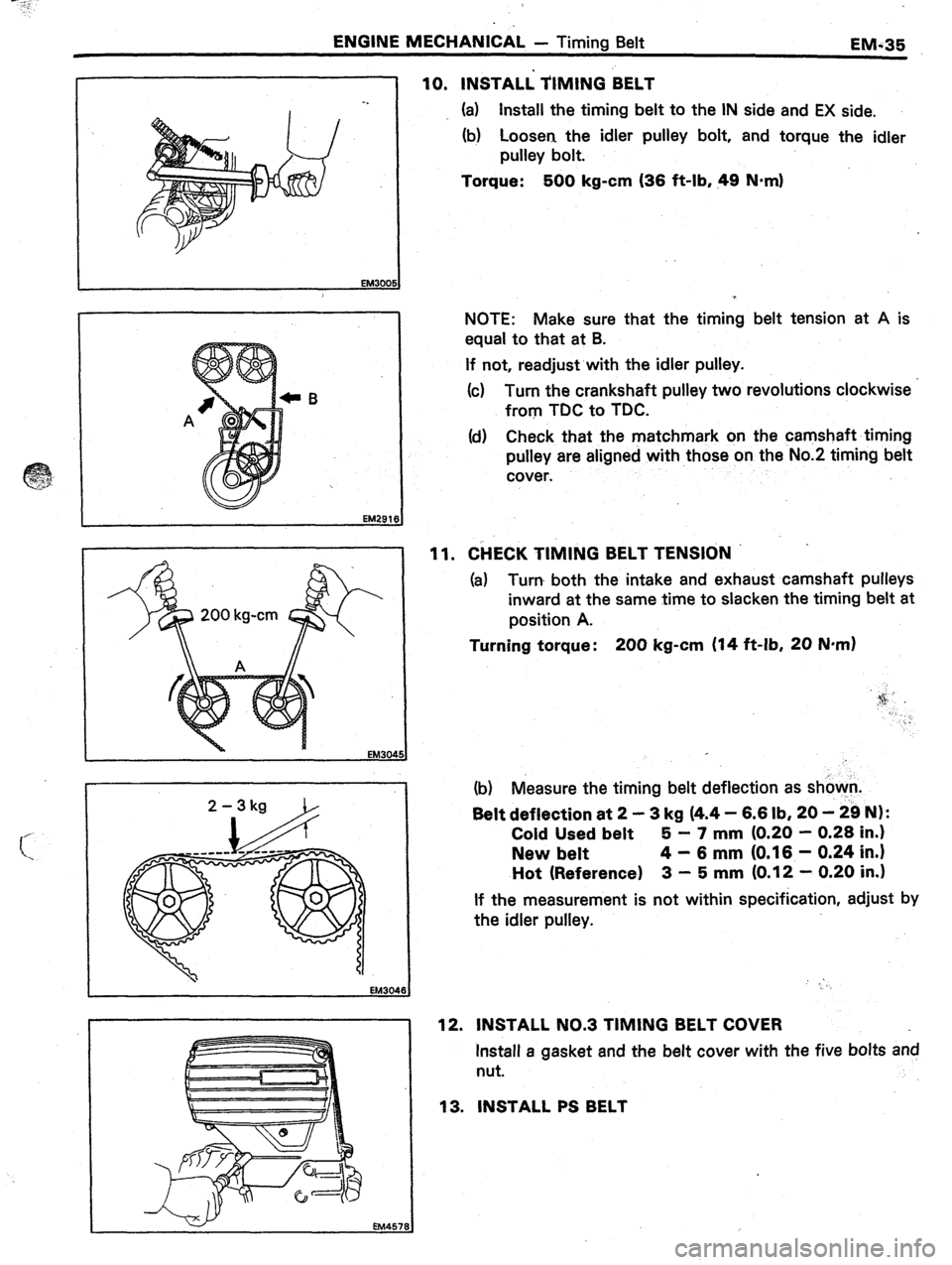

10. INSTALi TIMING BELT

B

EM304

EM457

(a) Install the timing belt to the IN side and EX side.

(b) Loosen the idler pulley bolt, and torque the idler

pulley bolt.

Torque: 500 kg-cm (36 ft-lb, 49 N.m)

7

NOTE: Make sure that the timing belt tension at A is

equal to that at B.

If not, readjust with the idler pulley.

(c) Turn the crankshaft pulley two revolutions clockwise

from TDC to TDC.

(d) Check that the matchmark on the camshaft timing

pulley are aligned with those on the No.2 timing belt

cover.

11. CHECK TIMING BELT TENSION

(a) Turn both the intake and exhaust camshaft pulleys

inward at the same time to slacken the timing belt at

position A.

Turning torque : 200 kg-cm (14 ft-lb, 20 N*m)

(b) Measure the timing belt deflection as shown.

Belt deflection at 2 - 3 kg (4.4 - 6.6 lb, 20 - 29 N):

Cold Used belt 5 - 7 mm (0.20 - 0.28 in.)

New belt 4 - 6 mm (0.16 - 0.24 in.1

Hot (Reference) 3 - 5 mm (0.12 - 0.20 in.)

If the measurement is not within specification, adjust by

the idler pulley.

12. INSTALL NO.3 TIMING BELT COVER

Install a gasket and the belt cover with the five bolts and

nut.

13. INSTALL PS BELT

Page 198 of 346

EM-36 ENGINE MECHANICAL - Timinn Belt

EM302

EM301

,

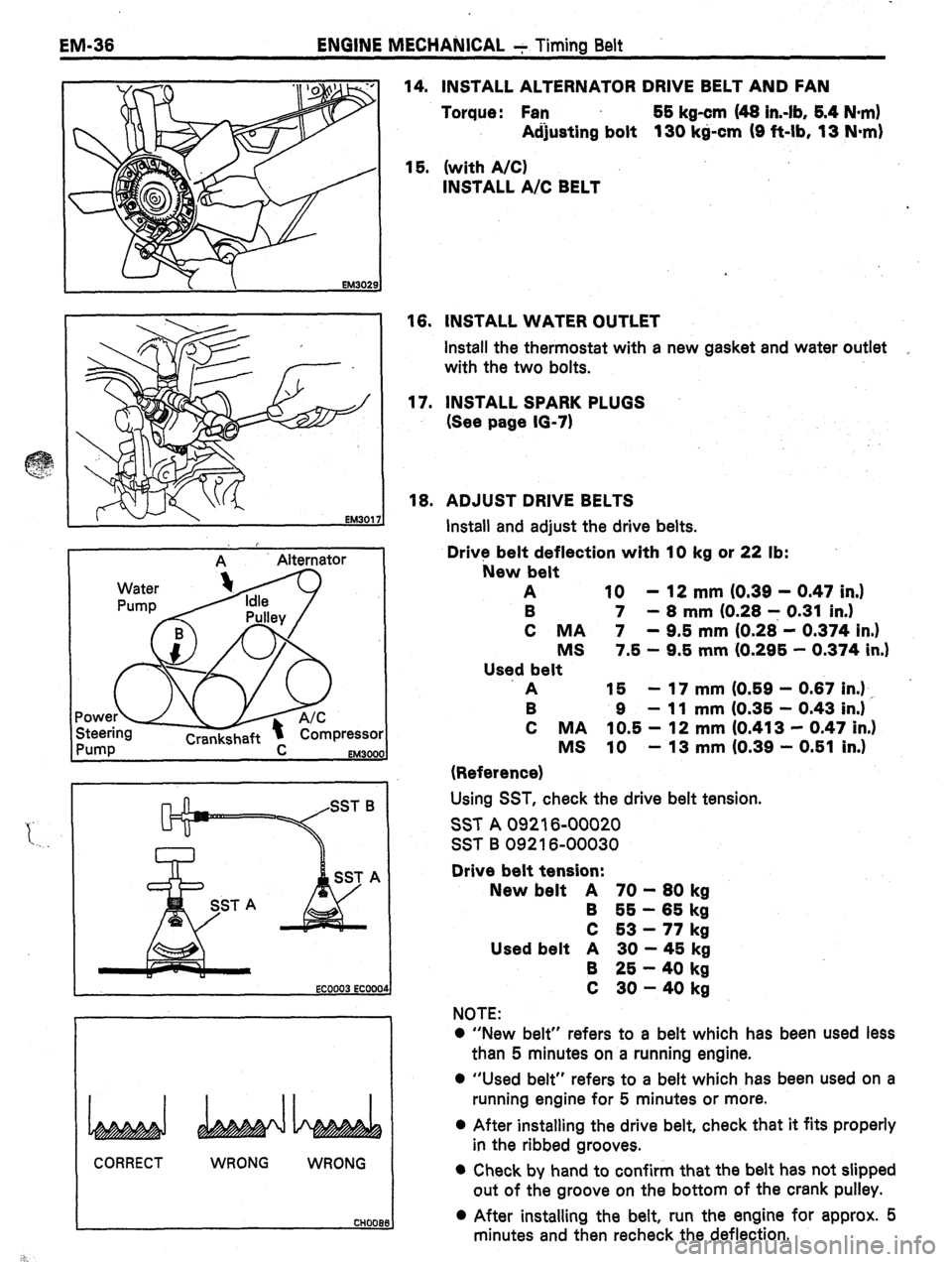

A

Alternator

1

EM3000

CORRECT WRONG

WRONG 14. INSTALL ALTERNATOR DRIVE BELT AND FAN

Torque: Fan 55 kg-cm (48 in.-lb, 6.4 N-m)

Adjusting bolt 130 kg-cm (9 ft-lb, 13 N*m)

15. (with A/C)

INSTALL A/C BELT

16. INSTALL WATER OUTLET

install the thermostat with a new gasket and water outlet

with the two bolts.

17. INSTALL SPARK PLUGS

(See page 10-7)

16. ADJUST DRIVE BELTS

Install and adjust the drive belts.

Drive belt deflection with 10 kg or 22 lb:

New belt

A 10 - 12 mm IO.39 - 0.47 in.)

B 7 - 8 mm (0.28 7 0.31 in.)

C MA 7 - 9.5 mm (0.28 - 0.374 in.)

MS 7.5 - 9.5 mm (0.296 - 0.374 in.1

Used belt

A 15 - 17 mm (0.59 - 0.67 in.1 ,

B 9 - 11 mm (0.35 - 0.43 in.)

C MA 10.5 - 12 mm (0.413 - 0.47 in.)

MS 10 - 13 mm (0.39 - 0.51 in.)

(Reference)

Using SST, check the drive belt tension.

SST A 09216-00020

SST B 09216-00030

Drive belt tension:

New belt A 70 - 80 kg

B 65 - 65 kg

C 53 - 77 kg

Used belt A 30 - 45 kg

B 25 - 40 kg

C 30 - 40 kg

NOTE:

0 “New belt” refers to a belt which has been used less

than 5 minutes on a running engine.

0 “Used belt” refers to a belt which has been used on a

running engine for 5 minutes or more.

0 After installing the drive belt, check that it fits properly

in the ribbed grooves. l Check by hand to confirm that the belt has not slipped

out of the groove on the bottom of the crank pulley.

l After installing the belt, run the engine for approx. 5

minutes and then recheck the deflection.

Page 209 of 346

i ’

‘

ENGINE MECHANICAL - Cylinder Head

EM-47

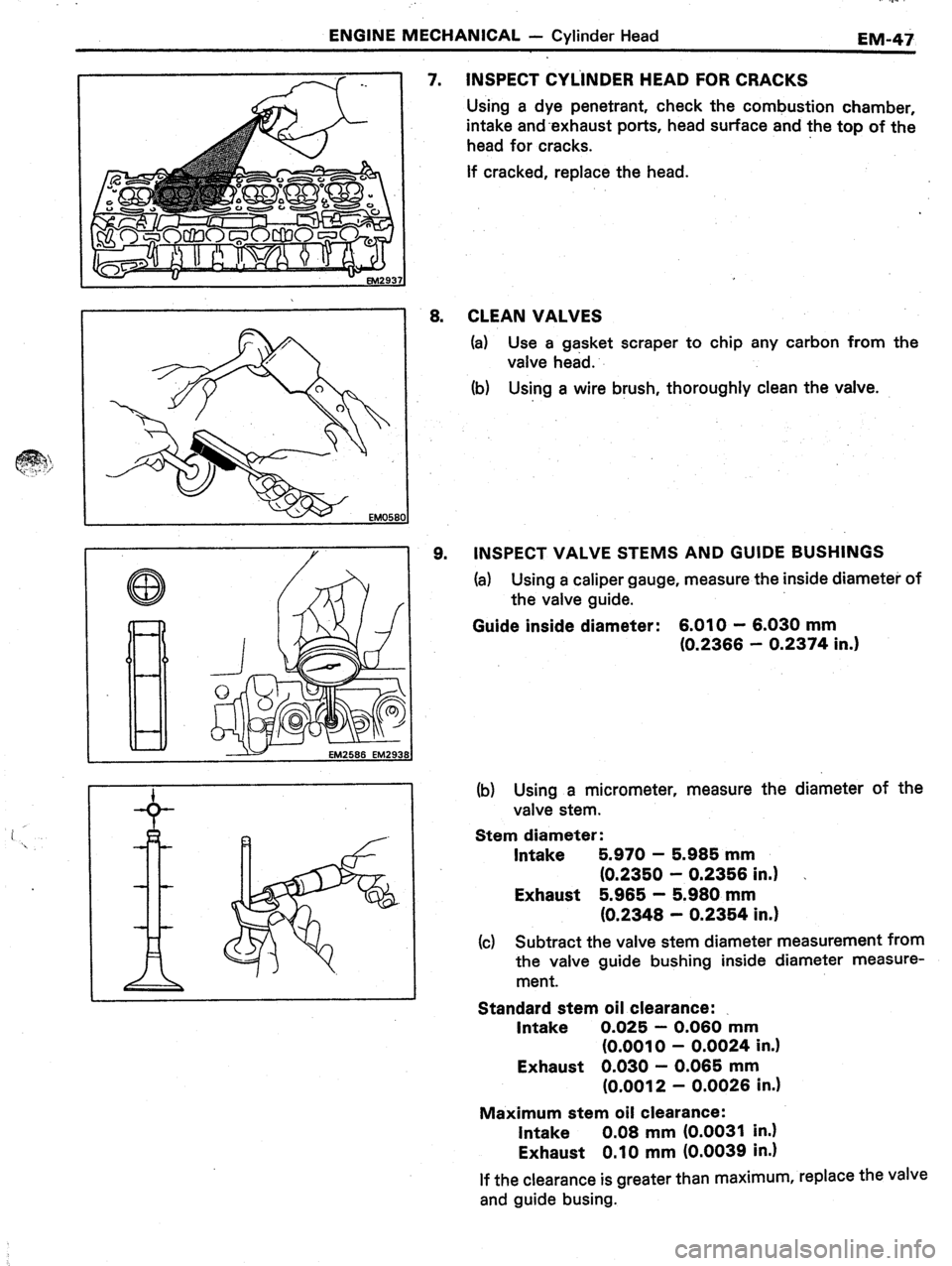

INSPECT CYLINDER HEAD FOR CRACKS

Using a dye penetrant, check the combustion chamber,

intake and-exhaust ports, head surface and the top of the

head for cracks.

if cracked, replace the head. 8.

9. CLEAN VALVES

(a) Use a gasket scraper to chip any carbon from the

valve head.

(b) Using a wire brush, thoroughly clean the valve.

INSPECT VALVE STEMS AND GUIDE BUSHINGS

(a) Using a caliper gauge, measure the inside diameter of

the valve guide.

Guide inside diameter:

6.010 - 6.030 mm

(0.2366 - 0.2374 in.)

EM2586 EM2931

(b) Using a micrometer, measure the diameter of the

valve stem.

Stem diameter:

Intake 5.970 - 5.985 mm

(0.2350 - 0.2356 in.) _

Exhaust 5.965 - 5.980 mm

(0.2348 - 0.2354 in.)

(c) Subtract the valve stem diameter measurement from

the valve guide bushing inside diameter measure-

ment.

Standard stem oil clearance:

Intake 0.025 - 0.060 mm

(0.0010 - 0.0024 in.)

Exhaust 0.030 - 0.065 mm

(0.0012 - 0.0026 in.)

Maximum stem oil clearance:

Intake 0.08 mm (0.0031 in.)

Exhaust 0.10 mm (0.0039 in.)

If the clearance is greater than maximum, replace the valve

and guide busing.

Page 211 of 346

ENGINE MECHANICAL - Cylinder Head

SST

Snap Ring

EM063

82

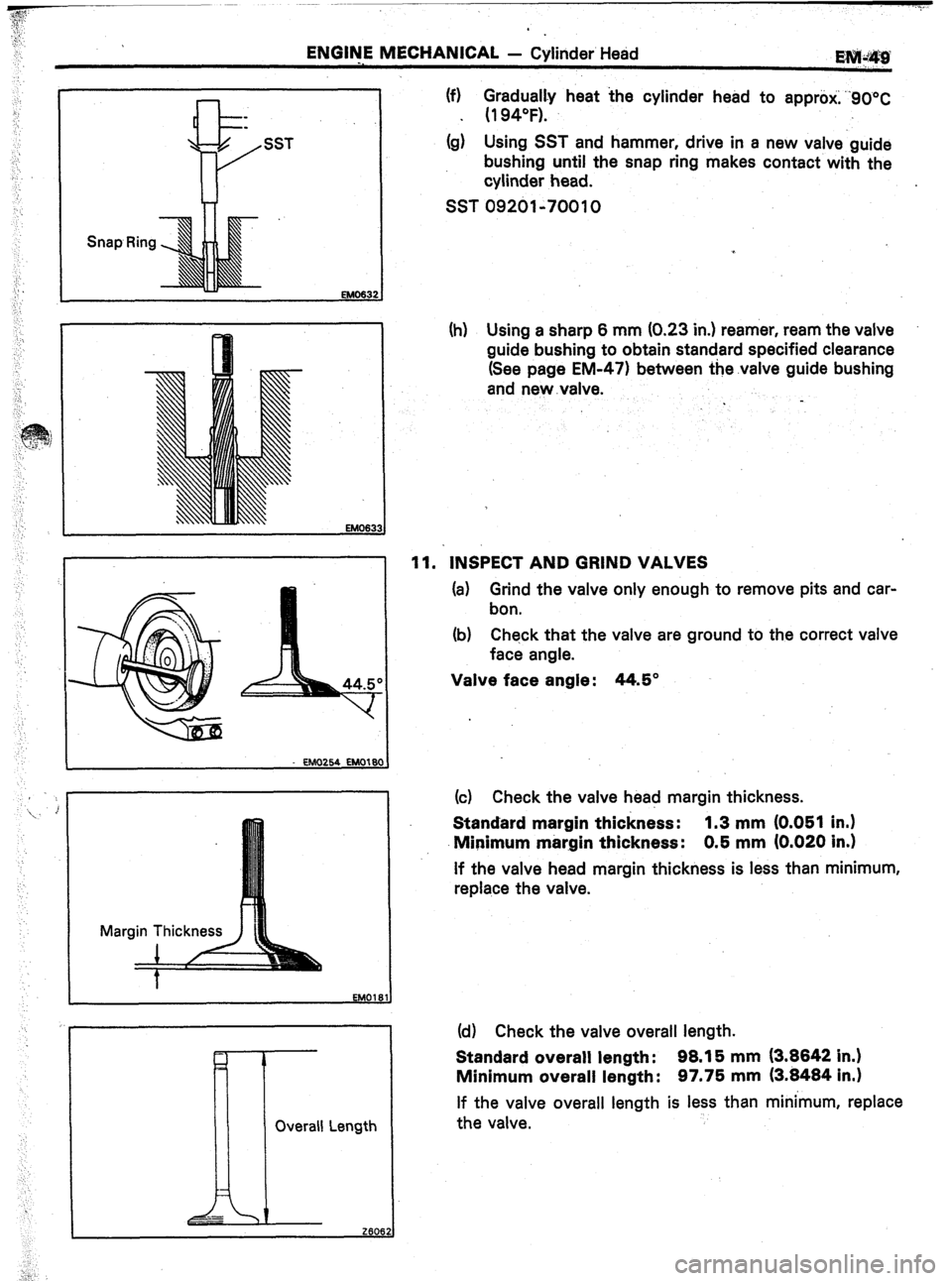

(f) $u;ily heat the cylinder head to approti; “90°C

0

*

(g) Using SST and hammer, drive in a new valve guide

bushing until the snap ring makes contact with the

cylinder head.

SST 09201-70010

Overall Length

II

[r

_-

2606.

-- ,

:,”

(h) Using a sharp 6 mm (0.23 in.) reamer, ream the valve

guide bushing to obtain standard specified clearance

(See page EM-471 between the.valve guide bushing

and new .valve.

11. INSPECT AND GRIND VALVES

(a) Grind the valve only enough to remove pits and car-

bon.

(b) Check that the valve are ground to the correct valve

face angle.

Valve face angle: 44.5”

(c) Check the valve head margin thickness.

Standard margin thickness: 1.3 mm (0.051 in.)

Minimum margin thickness: 0.5 mm (0.020 in.)

If the valve head margin thickness is less than minimum,

replace the valve.

(d) Check the valve overall length.

Standard overall length: 98.15 mm (3.8842 in.)

Minimum overall length: 97.75 mm (3.8484 in.1

If the valve overall length is less than minimum, replace

the valve.

Page 212 of 346

3

EM-50 ENGINE MECHANICAL - Cylinder Head

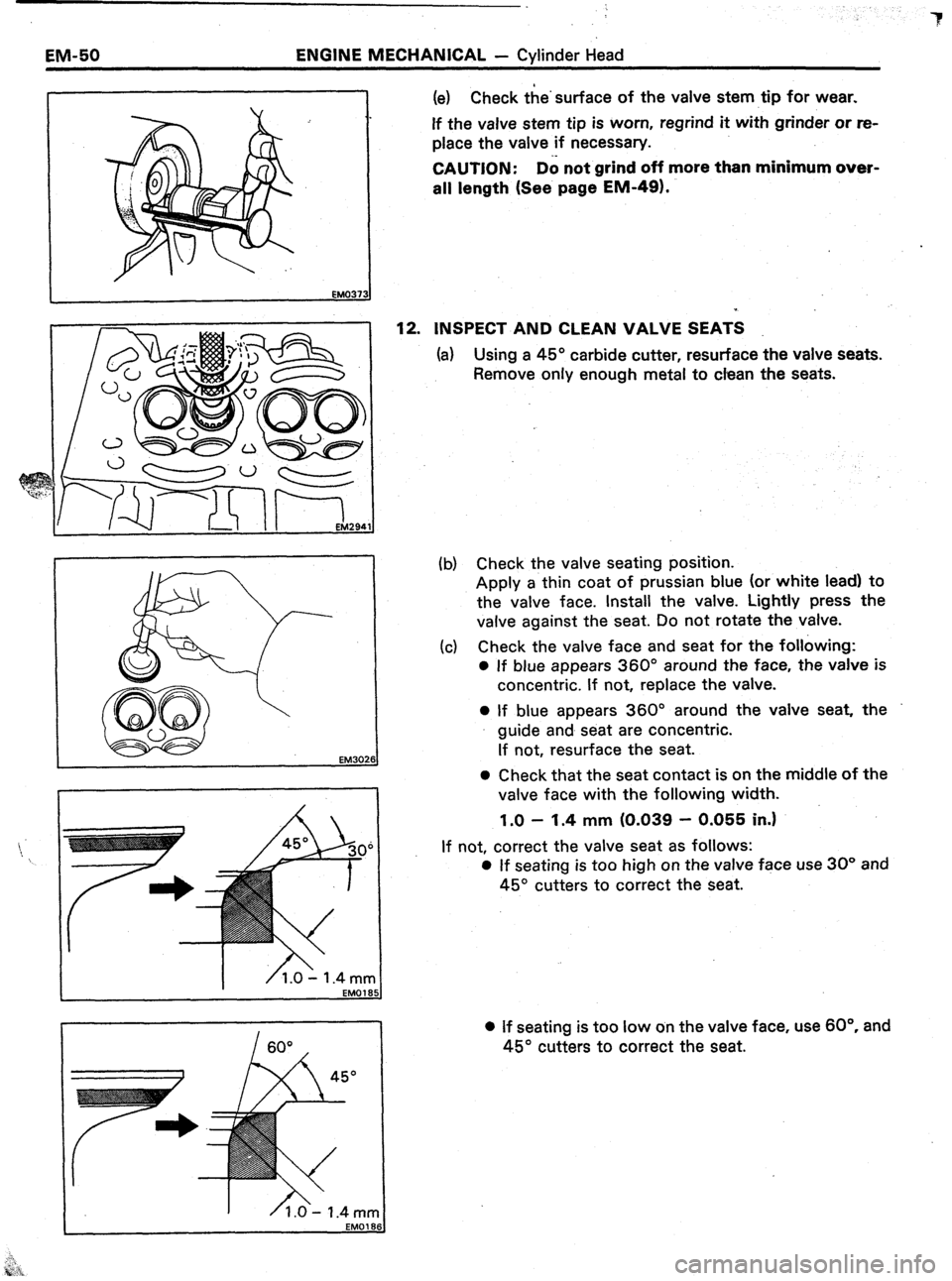

1 (e) Check the’surface of the valve stem tip for wear.

If the valve stem tip is worn, regrind it with grinder or re-

place the valve if necessary.

CAUTION: D6 not grind off more than minimum over-

all length (See page EM-49).

12.

INSPECT AND CLEAN VALVE SEATS

(a) Using a 45” carbide cutter, resurface the valve seats.

Remove only enough metal to clean the seats.

EM3026

(b) Check the valve seating position.

Apply a thin coat of prussian blue (or white lead) to

the valve face. Install the valve. Lightly press the

valve against the seat. Do not rotate the valve.

(c) Check the valve face and seat for the following:

0 If blue appears 360” around the face, the valve is

concentric. If not, replace the valve.

0 If blue appears 360” around the valve seat, the

guide and seat are concentric.

If not, resurface the seat.

0 Check that the seat contact is on the middle of the

valve face with the following width.

1.0 - 1.4 mm (0.039 - 0.055 in.1

If not, correct the valve seat as follows:

0 If seating is too high on the valve face use 30” and

45” cutters to correct the seat.

l If seating is too low on the valve face, use 60°. and

45” cutters to correct the seat.

Page 215 of 346

ENGINE MECHANICAL - Cylinder Head

L Et.4294

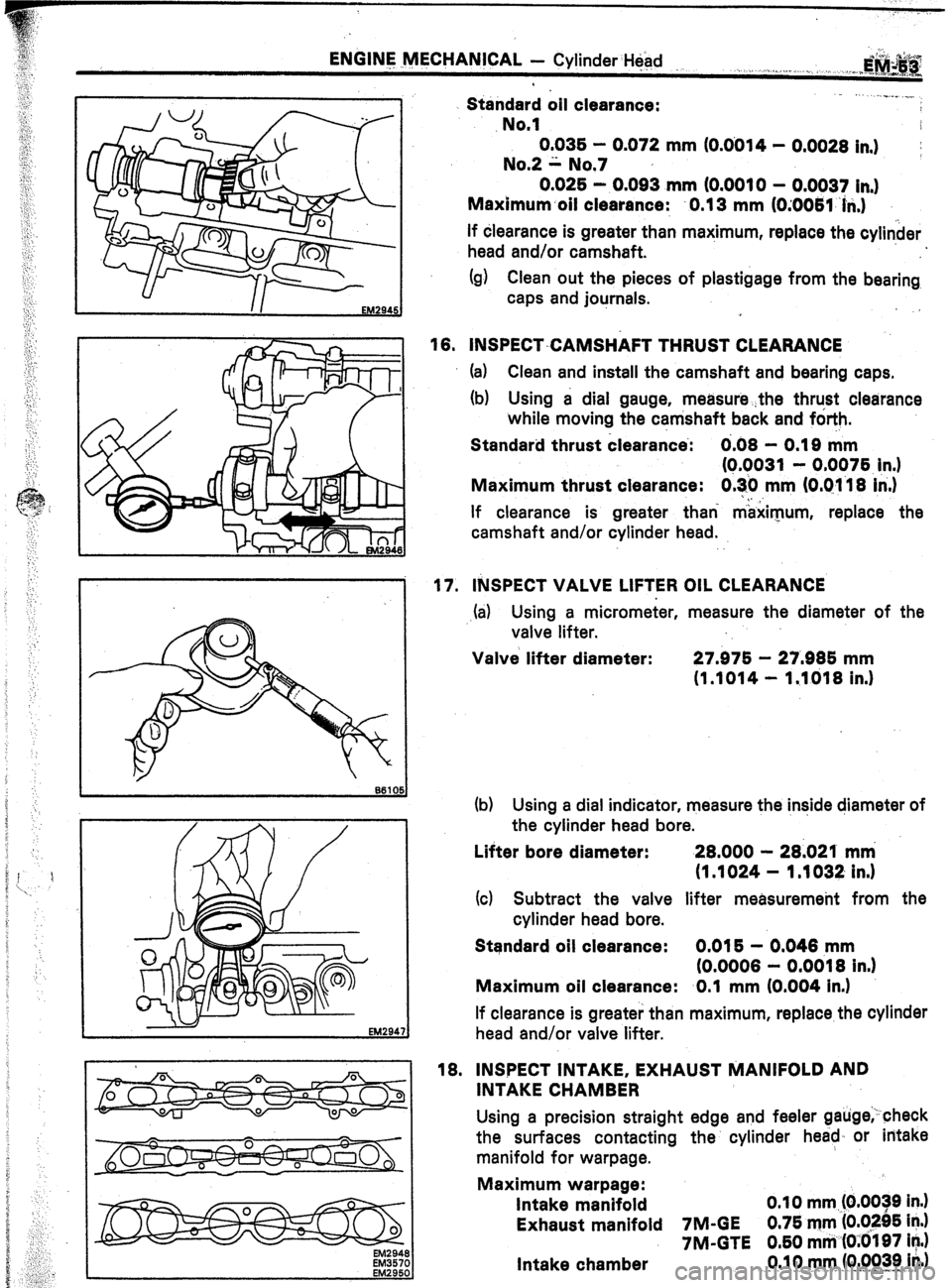

Standard oil clearance:

No.1 ... ..“..” .._.

0.036 - 0.072 mm (0.0014 - 0.0028 in,)

;

No.2 ii. No.7

0.025 - 0.093 mm (0.0010 - 0.0037 in.)

Maximum.oil clearance: 0.13 mm (0;0061 ‘hi.)

If dlearance is greater than maximum, replace the cylinder

head and/or camshaft.

(g) Clean out the pieces of plastigage from the bearing

caps and journals.

18. INSPECT-CAMSHAFT THRUST CLEARANCE

(a) Clean and install the camshaft and bearing caps.

(b) Using a dial gauge, measure

Standard thrust clearance’: 0.08 - 0.18 mm

(Q.9031 - 0.0976 in.)

Maximum thrust clearance: 0.30 mm IO.01 18 in.)

If clearance is greater than maximum, replace the

camshaft and/or cylinder head.

17. INSPECT VALVE LIFTER OIL CLEARANCE

.(a) Using a micrometer, measure the diameter of the

valve lifter.

Valve lifter diameter: 27.975 - 27.885 mm

(1.1014 - 1.1018 in.)

(b) Using a dial indicator, measure the inside diameter of

the cylinder head bore.

Lifter bore diameter: 28.000 - 28.021 mm

(1 .1024 - 1 .1032 in.)

(4 Subtract the valve lifter measuremeht from the

cylinder head bore.

Standard oil clearance: 0.015 - 0.048 mm

(0.0008 - 0.0018 in.)

Maximum oil clearance: 0.1 mm (0.004 in.)

If clearance is greater than maximum, replace the cylinder

head and/or valve lifter.

EM2948

EM3570

18. INSPECT INTAKE, EXHAUST MANIFOLD AND

INTAKE CHAMBER

Using a precision straight edge and feeler gauge;-check

the surfaces contacting the cylinder head, or intake

manifold for warpage.

Maximum warpage:

Intake manifold 0.10 mm (0.0039 in.)

Exhaust manifold IM-GE 0.75 mm (0.0295 in.)

7M-GTE 0.60 mm (OiOlQ7 in.)

Intake chamber 0.10 mm (0.0039 in.)

- .,, ,. 1. & ._i ^..s^..r*.., “,A