sensor TOYOTA CELICA 1987 Service Workshop Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 1987, Model line: CELICA, Model: TOYOTA CELICA 1987Pages: 346, PDF Size: 35.13 MB

Page 166 of 346

LM-4

I ENGINE MECHANICAL -* Troubleshooting

_.

TROUBLESHOOTING

Problem Possible cause I Remedy Page

Engine overheats Cooling system faulty Troubleshoot cooling system co-4

Incorrect ignition timing Reset timing EM-1 7

Engine will not crank or Starting system faulty Troubleshoot starting system ST-2

cranks slowly : .

Engine will not start/ Vacuum leaks Repair as necessary

hard to start 0 PCV hoses ”

(cranks OK) 0 (w/ EGR)

EGR valve

0 Intake manifold

0 Air intake chamber

0 Throttle body

0 ISC valve

Pulling in air between air flow meter and Repair as necessary FI-96, 93

throttle body

Ignition problems Perform spark test IG-5, 12

0 Ignition coil

0 Igniter

0 (7M-GE)

Distributor

(7M-GTE)

Cam position sensor

High-tension cord disconnected or broken Inspect cord IG-6, 13

No fuel supply to injector Troubleshoot EFI system FI-I 2

l No fuel in tank

0 Fuel pump not working

l Fuel filter clogged

0 Fuel line clogged or leaking

EFI system problems Repair as necessary

ISC system problem Check ISC system FL- 108

Spark plugs faulty Inspect plugs IG-7

Low compression Check compression EM-26, 2

Rough idle, stalls or Vacuum leaks Repair as necessary

misses 0 PCV hoses

0 (w/ EGR)

EGR valve

0 Intake manifold

0 Air intake chamber

0 Throttle body I

0 ISC valve

Pulling in air between sir flow meter and FI-96, 9

throttle body

Incorrect idle speed Check ISC system FI- 108

Incorrect ignition timing Reset timing EM-1 7

Ignition problems Perform spark test IG-5, 12

0 Ignition coil

0 Igniter

0 (-/M-GE)

Distributor

(-/M-GTE)

Cam position sensor

High-tension cord faulty Inspect cord IG-6, 13

EFI system problems Repair as necessary

Page 170 of 346

EM-8 ENGINE MECHANICAL -I Engine Tune-up

-.

lNS.PECTlON AND. ADJUSTMEtiT OF VALVE

CLEARANCE’

NOTE: Check and adjust the valve clearance while the

engine is cold.

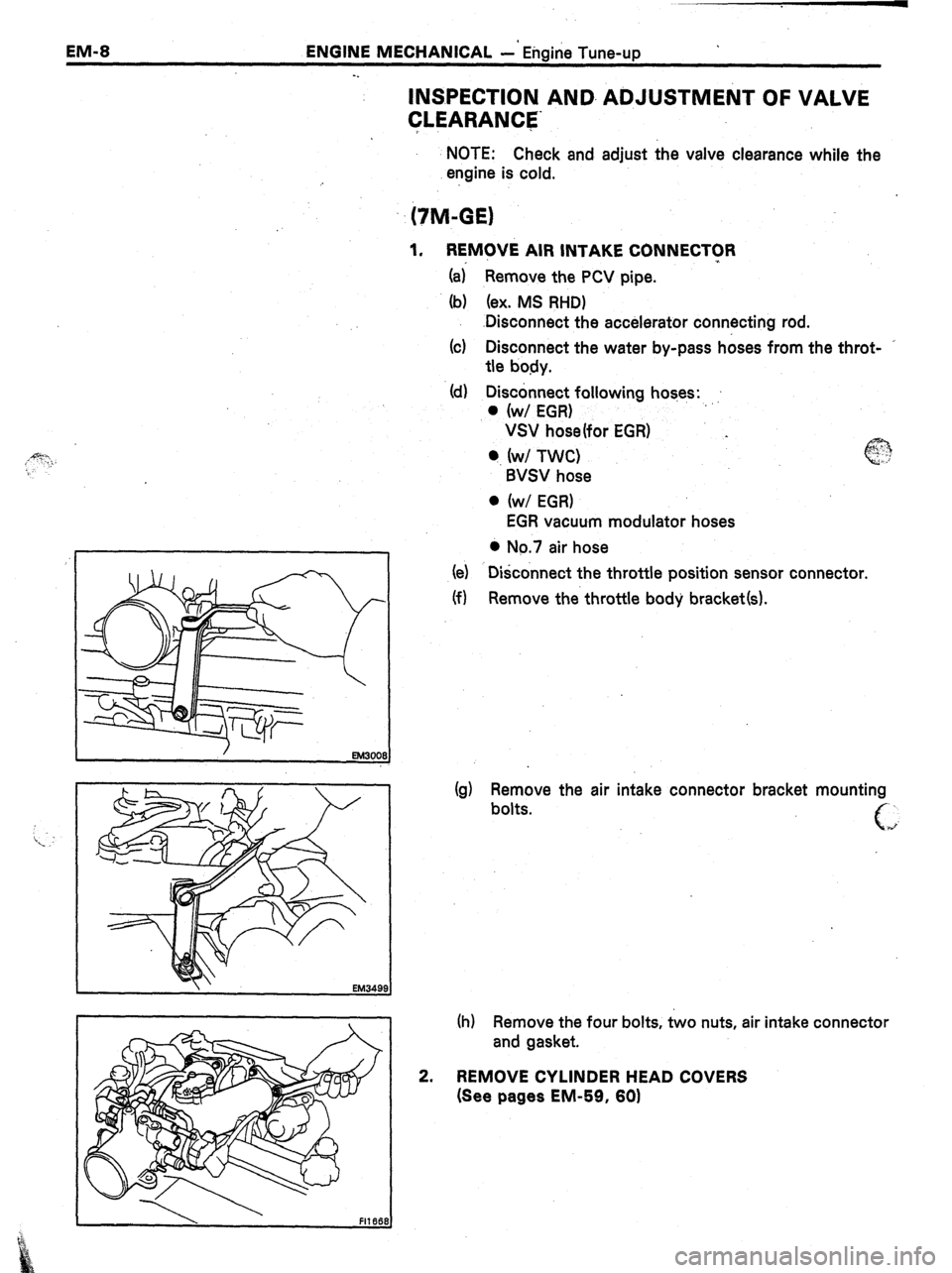

1. REM?VE AIR INTAKE CONNECTOR

j

(a) Remove the PCV pipe.

(b) (ex. MS RHD)

.Disconnect the accelerator connecting rod.

(c) Disconnect the water by-pass hoses from the throt-

tie body.

(d) Disconnect following hoses:

. (w/ EGR)

VSV hose(for EGR) .

l . (w/ TWC)

BVSV hose

. (w/ EGR)

EGR vacuum modulator hoses

0 No.7 air hose

(e) Disconnect the throttle position sensor connector.

(f) Remove the. throttle body bracket(s).

(g) Remove the air intake connector bracket mounting

bolts.

c J

I (h) Remove the four bolts, two nuts, air intake connect01

and gasket.

2. REMOVE CYLINDER HEAD COVERS

(See pages EM-59,601

Page 173 of 346

” .

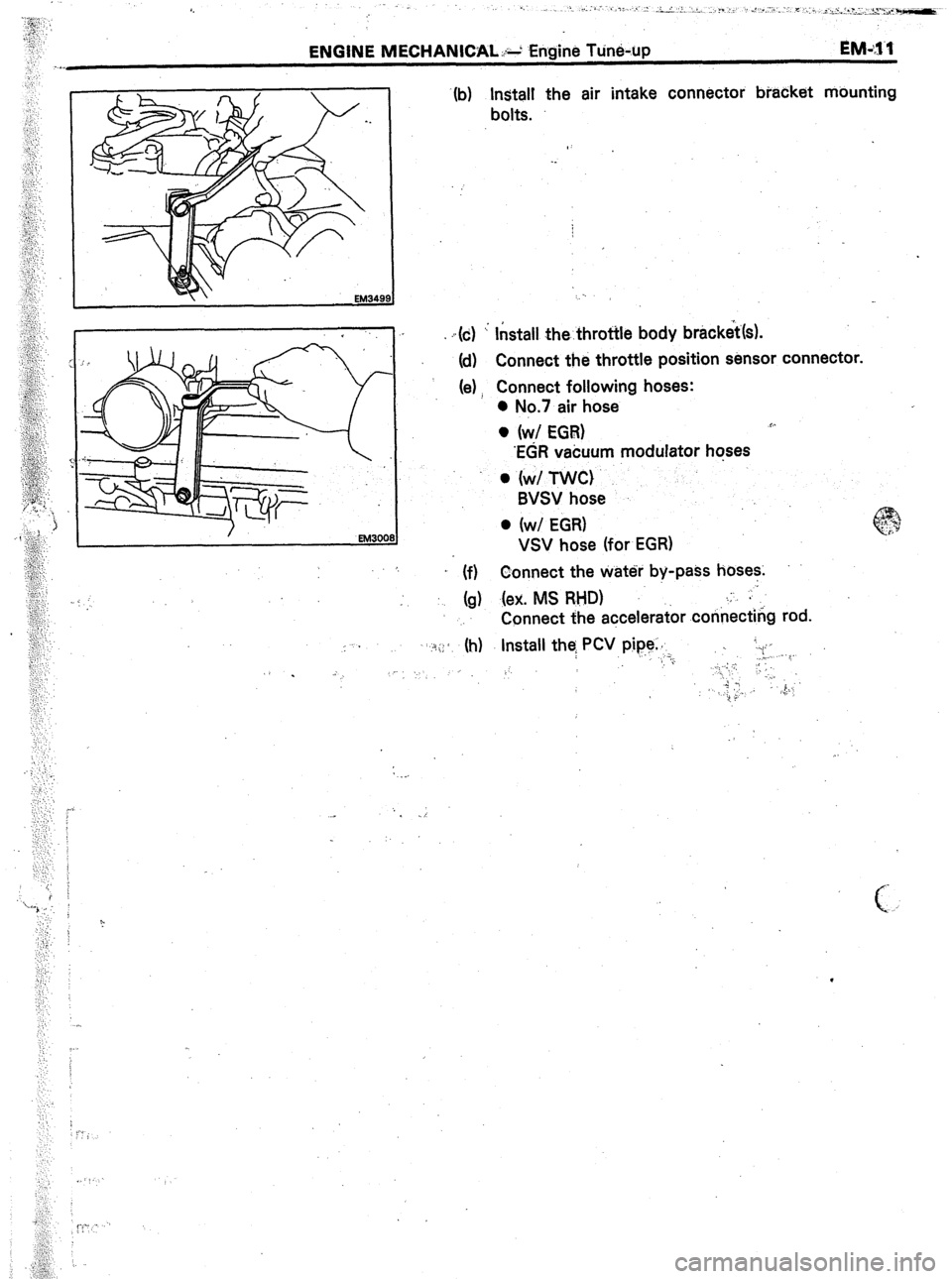

.(b) Install the air intake connector bracket mounting

bolts.

. .

. ~(6) ’ Install the.throttle body bracket’(s).

(d) Connect the throttle position sensor connector.

(e) ! Connect following hoses:

0 No.7 air hose

0 (w/ EGR) 6.

‘E6R vaixum modulator hoses

. (w/WC)’

BVSW hose

.’

l (w/ EGR)

VSV hose (for EGR)

1 (f) Connect the water by-pass hoses.

(g) (ex. MS RHD) ::‘. . ‘.

Connect the accelerator connecting rod.

.++:s (h) Install the: PCV pipe;. .:, ‘.f. -.,,

: ‘:

:, -’

‘2.. 1 :

,.:’ . j;:..

r’ r

c , .

Page 174 of 346

EM-12 ENGINE MECHANICAL - Engine Tune-up

r

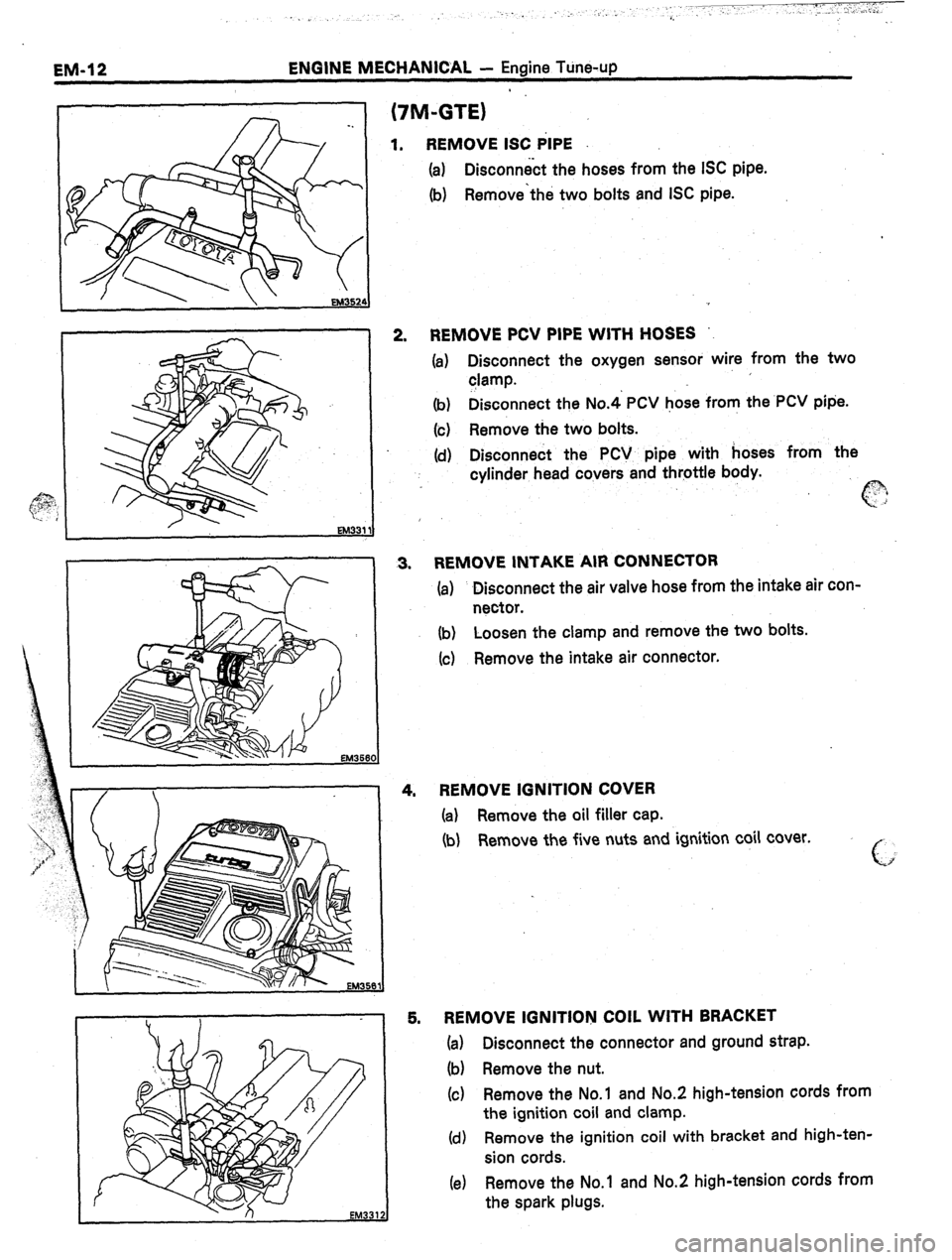

(7M-GTE)

1. REMOVE ISC PIPE

(a) Disconn&t the hoses from the ISC pipe.

(b) Remove‘the two bolts and ISC pipe.

2. REMOVE PCV PIPE WITH HOSES

(a) Disconnect the oxygen sensor wire from the two

clamp.

:

(b) Disconnect the No.4 PCV hose from the ‘PCV pitie.

(c) Remove the two bolts.

(d) Disconnect the PCV pipe with hoses from the

cylinder head covers and throttle body.

‘. ,$’

ci ;- ,

. .

3. REMOVE INTAKE AIR CONNECTOR

(a) Disconnect the air valve hose from the intake air con-

nector.

(b) Loosen the clamp and remove the two bolts.

(c) Remove the intake air connector.

4. REMOVE IGNITION COVER

(a) Remove the oil filler cap.

(b) Remove the five nuts and ignition coil cover.

c ,r

5. REMOVE IGNITION COIL WITH BRACKET

(a) Disconnect the connector and ground strap.

(b) Remove the nut.

(c) Remove the No.1 and No.2 high-tension cords from

the ignition coil and clamp.

IdI Remove the ignition coil with bracket and high-ten-

sion cords.

(e) Remove the No.1 and No.2 high-tension cords from

the spark plugs.

Page 176 of 346

EM-14 ,ENG!NE M&XlANICAL~ - Engine Tuhe-up

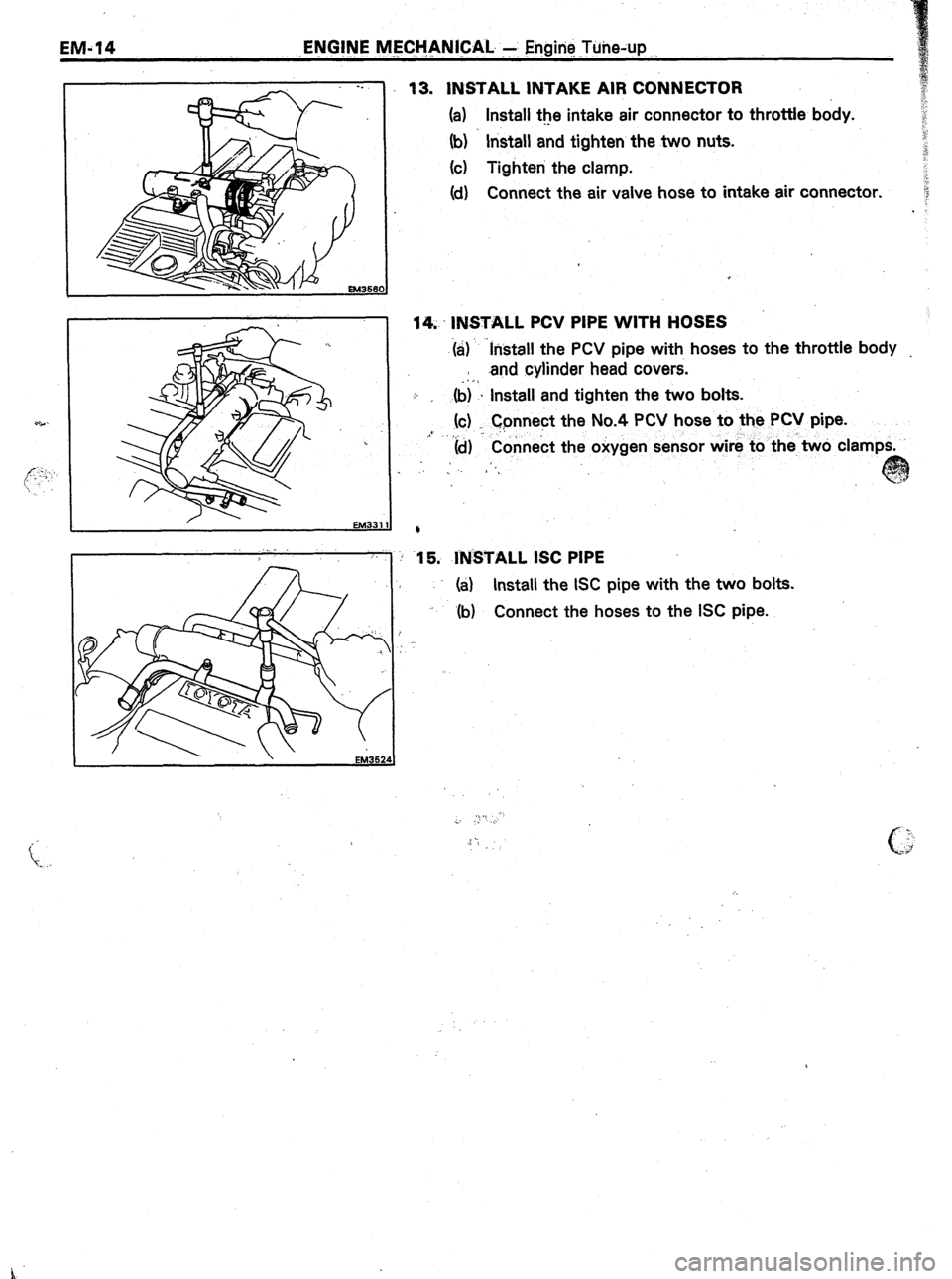

13. lNSTALL INTAKE AIR CONNECTOR

(a) Install the intake air connector to throttle body.

6) Iristall and tighten the two nuts. li

s

s

(cl Tighten the clamp.

Ed) Connect the air valve hose to intake air connector. i

, -

r

14;: INSTALL PCV PIPE WITH HOSES

(a) install the PCV pipe with hoses to the throttle body

.and cylinder head covers.

I . . /

, (b) . Install and tighten the two bolts.

,r ., F) .:, Connect the No.4 PCV hose to the PCV pipe.

(d) Connect the oxygen sensor wire to the two clam

‘,

. . . L. ,.

1: .15. INSTALL ISC PIPE

(a) Install the ISC pipe with the two bolts.

‘(b) Connect the hoses to the ISC pipe.

,,,1

. . -:

s.

.I

Page 179 of 346

ENGINE MECHANICAL. - Engine Tune-up

EM-?1 7.

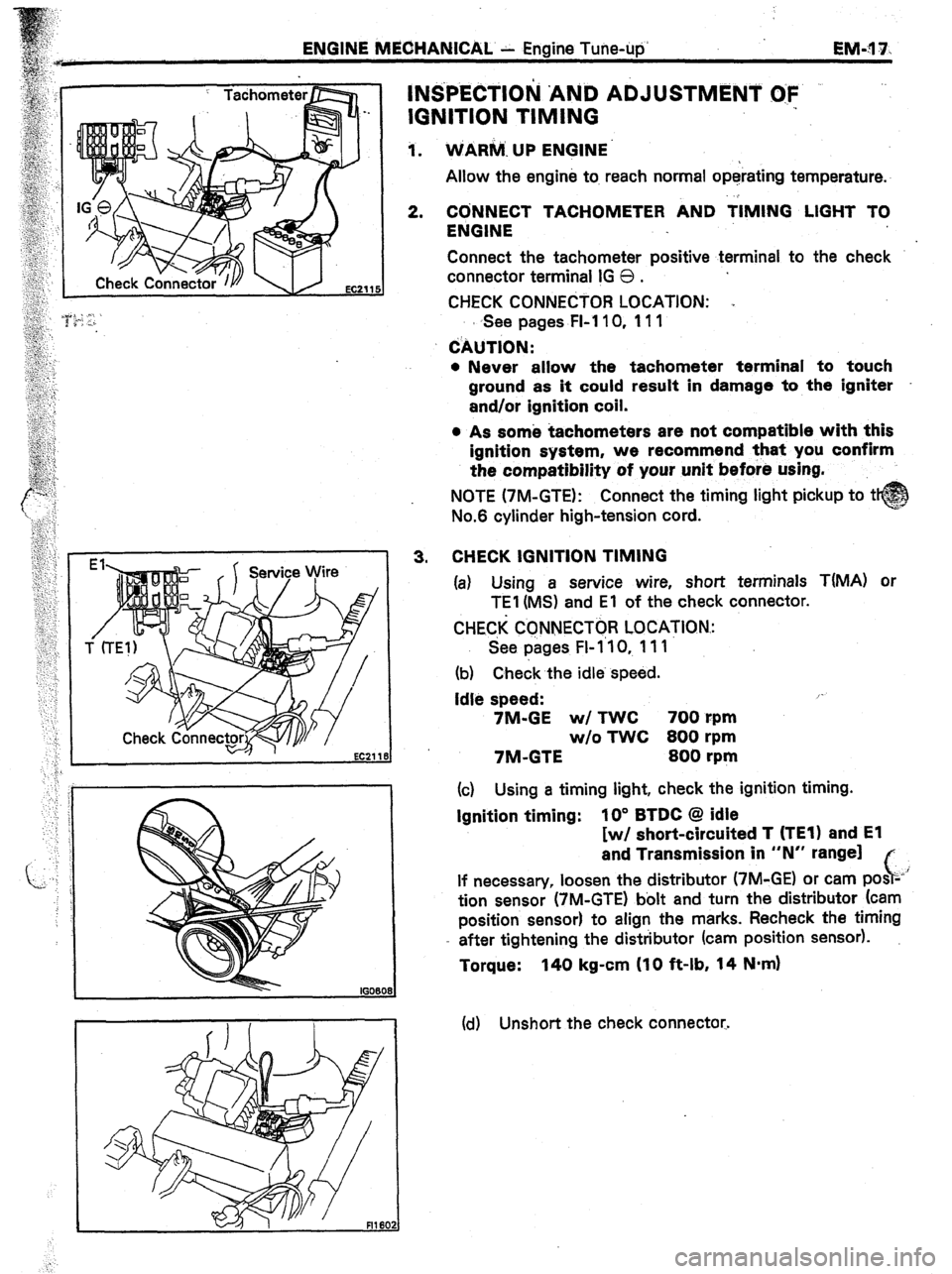

INS’PECTIOlil ‘AhiD ADJUSTMENT O:F .-

IGNITION TIMING

1. VriARiiA. UP ENGINE.

Allow the engine to. reach normal operating temperature.

2.

CbNNECT TACHOMETER AND TIMING LIGHT TO

ENGINE

Connect the tachometer positive terminal to the check

connector terminal IG 0 .

CHECK CONNECTOR LOCATION: .,

s See pages FI-110, 111

CAUTION:

l Never allow the tachometer terminal to touch

ground as it could result in damage to the igniter

and/or ignition coil.

, 4% 3.

EC21 18

s As some tachometers are not compatible with this

ignition system, we recommend that you confirm

the compatibility of your unit before using.

NOTE (7M-GTE): Connect the timing light pickup to t

No.6 cylinder high-tension cord.

CHECK IGNITION TIMING

(a) Using a service wire, short terminals T(MA) or

TEI (MS) and El of the check connector.

CHEC,K CCNNECTOR LOCATION.:

See pages FI- 1’10, 111

(b) Check the idle. speed.

Idle speed: /-

7M-GE w/ TWC 700 rpm

w/o TWC 800 rpm

7M-GTE 800 rpm

(c) Using a timing light, check the ignition timing.

Ignition timing: IO” BTDC @ idle

[w/ short-circuited T (TEl) and El

and Transmission in “N” range]

c,

If necessary, loosen the distributor (7M-GE) or cam posz-’

tion sensor (7M-GTE) bolt and turn the distributor (cam

position sensor) to align the marks. Recheck the timing

- after tightening the distributor (cam position sensor).

Torque: 140 kg-cm (10 ft-lb, 14 N-m)

(cl) Unshort the check connector.

Page 182 of 346

EM-20 ENGIN lVlECHAN!CAL - Engine Tune-up

-.

EM288

c

HC

Aigh

High

High co

Normal

Low

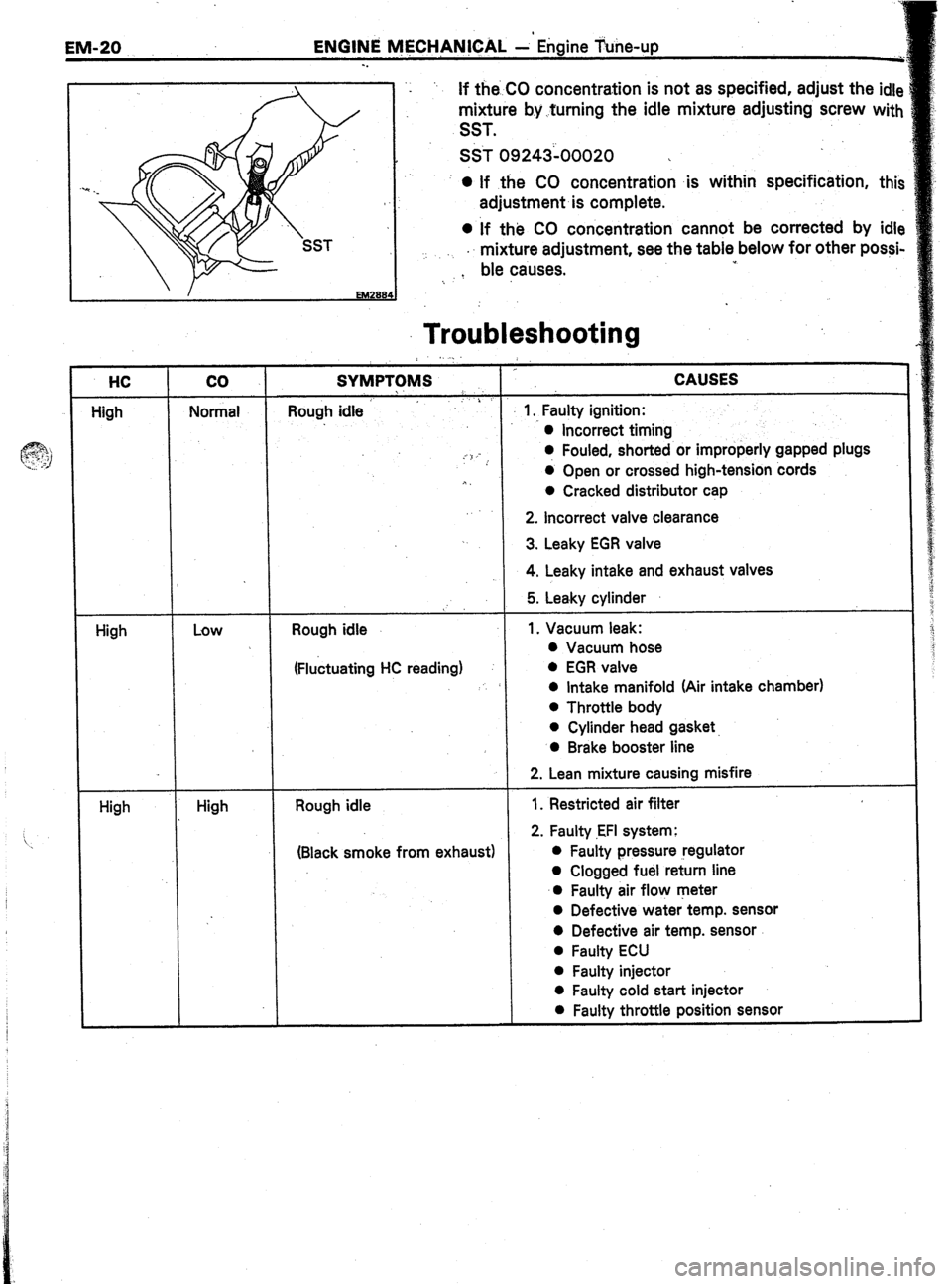

High ‘- ‘, If the CO concentration is not as specified, adjust the idle

mixture by.furning the idle mixture adjusting screw with

SST.

SST 09243-00020 >

0 If the CO concentration is within specification, this

adjustment is complete.

l if the CO concentration cannot be corrected by idle

mixture adjustment, see the table below for other possi-

t ble causes. w

Troubleshooting

SYMPTOMS

Rough idle

’ ’

.-‘:I -

Rough idle

(Fluctuating HC reading)

Rough idle

(Black smoke from exhaust CAUSES

1. Faulty ignition:

0 Incorrect timing

0 Fouled, shorted or improperly gapped plugs

6 Open or crossed high-tension cords

0 Cracked distributor cap

2. Incorrect valve clearance

3. Leaky EGR valve

4. Leaky intake and exhaust valves

5. Lea,kv cvlinder

1. Vacuum leak:

0 Vacuum hose

0 EGR valve

0 Intake manifold (Air intake chamber)

0 Throttle body

l Cylinder head gasket,

0 Brake booster line

2. Lean mixture causing misfire

1. Restricted air filter

2. Faulty ,EFI system:

0 Faulty pressure regulator

0 Clogged fuel return line

0 Faulty air flow meter

0 Defective water temp. sensor

0 Defective air temp. sensor

0 Faulty ECU

l Faulty injector

0 Faulty cold start injector

l Faulty throttle position sensor

Page 184 of 346

EM-22 ENGINE MECHANICAL - Engine Tune-up

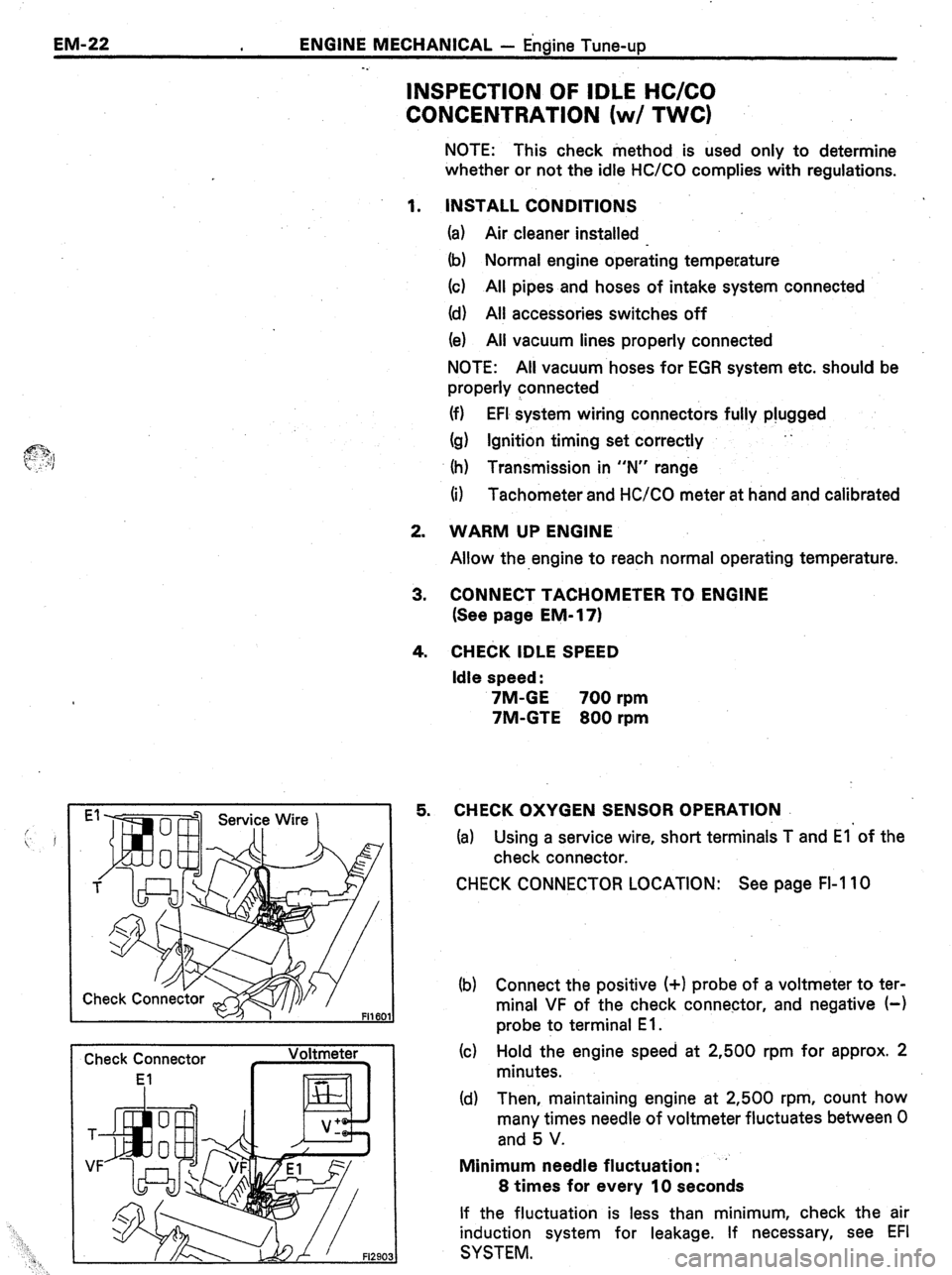

INSPECTION OF IDLE HC/CO

CONCENTRATION (w/ TWC)

NOTE: This check method is used only to determine

whether or not the idle HWCO complies with regulations.

1. INSTALL CONDITIONS

(a) Air cleaner installed

(b) Normal engine operating temperature

(c) All pipes and hoses of intake system connected

(d) All accessories switches off

(e) All vacuum lines properly connected

NOTE: All vacuum hoses for EGR system etc. should be

properly connected

(f) EFI system wiring connectors fully p!ugged

(g) Ignition timing set correctly ‘.

(h) Transmission in “N” range

6) Tachometer and HWCO meter at hand and calibrated

2. WARM UP ENGINE

Allow the engine to reach normal operating temperature.

3. CONNECT TACHOMETER TO ENGINE

(See page EM- 17)

w ‘I” FI16C

4. CHECK IDLE SPEED

Idle speed :

7M-GE 700 rpm

7M-GTE 800 rpm

5. CHECK OXYGEN SENSOR OPERATION

(a) Using a service wire, short terminals T and El’of the

check connector.

CHECK CONNECTOR LOCATION: See page FI-I 10

(b) Connect the positive (+I probe of a voltmeter to ter-

minal VF of the check connector, and negative (-1

probe to terminal E 1.

(c) Hold the engine speed at 2,500 rpm for approx. 2

minutes.

(d) Then, maintaining engine at 2,500 rpm, count how

many times needle of voltmeter fluctuates between 0

and 5 V.

Minimum needle fluctuation : ’

8 times for every 10 seconds

If the fluctuation is less than minimum, check the air

induction system for leakage, If necessary, see EFI

SYSTEM.

Page 188 of 346

EM-26 ENGINE MECHANICAL - Compression Check

d

COMPRESSION CHECK

NOTE: If there is lack of power, excessive oil consump-

tion or poor fuel mileage, measure the cylinder compres-

sion pressure.

(7M-GE)

1.

2.

3.

4.

5.

6. REMOVE SPARK PLUGS (See page IO-71

7.

EM3003

WARM UP ENGINE

DISCONNECT COLD START INJECTOR CONNECTOR

DISCONNECT SOLEtiOlD RESISTOR CONNECTOR

DISCONNECT DISTRIBUTOR CONNECTOR

REMOVE THROTTLE BODY

(a) Remove the PCV hose.

(b) Disconnect the water by-pass hoses and plug the

hose end.

(c) Disconnect following hoses:

. fwl EGR)

VSV hoses

. (wl TWC)

BVSV hoses

. (w/ EGR)

EGR vacuum modulator hoses

l No.7 air hose

id) Disconnect the throttle position sensor connector.

(e) Remove the throttle body bracket(s).

(f) Remove the four bolts, throttle body and gasket.

CHECK CYLINDER COMPRESSION PRESSURE

(a) Insert a compression gauge into the spark plug hole.

(b) While cranking the engine with the starter motor,

measure the compression pressure.

NOTE: Always use a

fully charged battery to obtain an

engine revolution of more than 250 rpm.

(c) Repeat steps Ia) through Ib) for each cylinder.

Compression pressure:

11.0 kg/cm2 (156 psi, 1,079 kPa) or more

Minimum pressure:

9.0 kg/cm2 (128 psi, 883 kPa)

Difference between each cylinder:

1 .O kg/cm2 (14 psi, 98 kPa) or less

(d) If cylinder compression in one or more cylinders is

low, pour a smali amount of engine oil into the

cylinder through the spark plug hole and repeat steps

(a) through (b) for the cylinder with low compression.

0 If adding oil helps the compression, chances are

that the piston rings and/or cylinder bore are worn

or damaged.

0 If pressure stays low, a valve may be sticking or

seating improperly, or there may be leakage past

the gasket.

Page 189 of 346

ENGINE MECHANICAL 1 Compression Ctwck

;

EMy27.

,* I,, ._ ,. .,

. . . . . Ij,_

--.

(7M-GTE)

1. WARM UP ENGINE

2. DISCONNECT SOLENOID RESISTOR CONNECTOR

3. DISCONNECT CAM POSITION SENSOR CONNECTOR

’ ’

F5129,

4. REMOVE NO.1 AIR CLEANER HOSE

5. REMOVE PCV PIPE

‘1 6. REMOVE IGNITION COIL

(See steps 4, 5 on page EM-121

7. REMOVE SPARK PLUGS (See page IO-121 .

‘_

-.

8. CHECK CYLlNDER COMPRESSION PRESSURE

(See step 7 on page EM-261

Compression pressure:

10.0 kg/cm2 (142 psi, 981 kPa) or more

Minimum pressure:

.

9.0 kg/cm2 (128 psi, 883.kPa)

Difference between each cylinder:

1 .O kg/cm2 (14 psi, 98 kPa1 or less