sensor TOYOTA CELICA 1987 Service Manual PDF

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 1987, Model line: CELICA, Model: TOYOTA CELICA 1987Pages: 346, PDF Size: 35.13 MB

Page 272 of 346

IGNITION SYSTEM - On-Vehicle Inspection (7M-GTE)

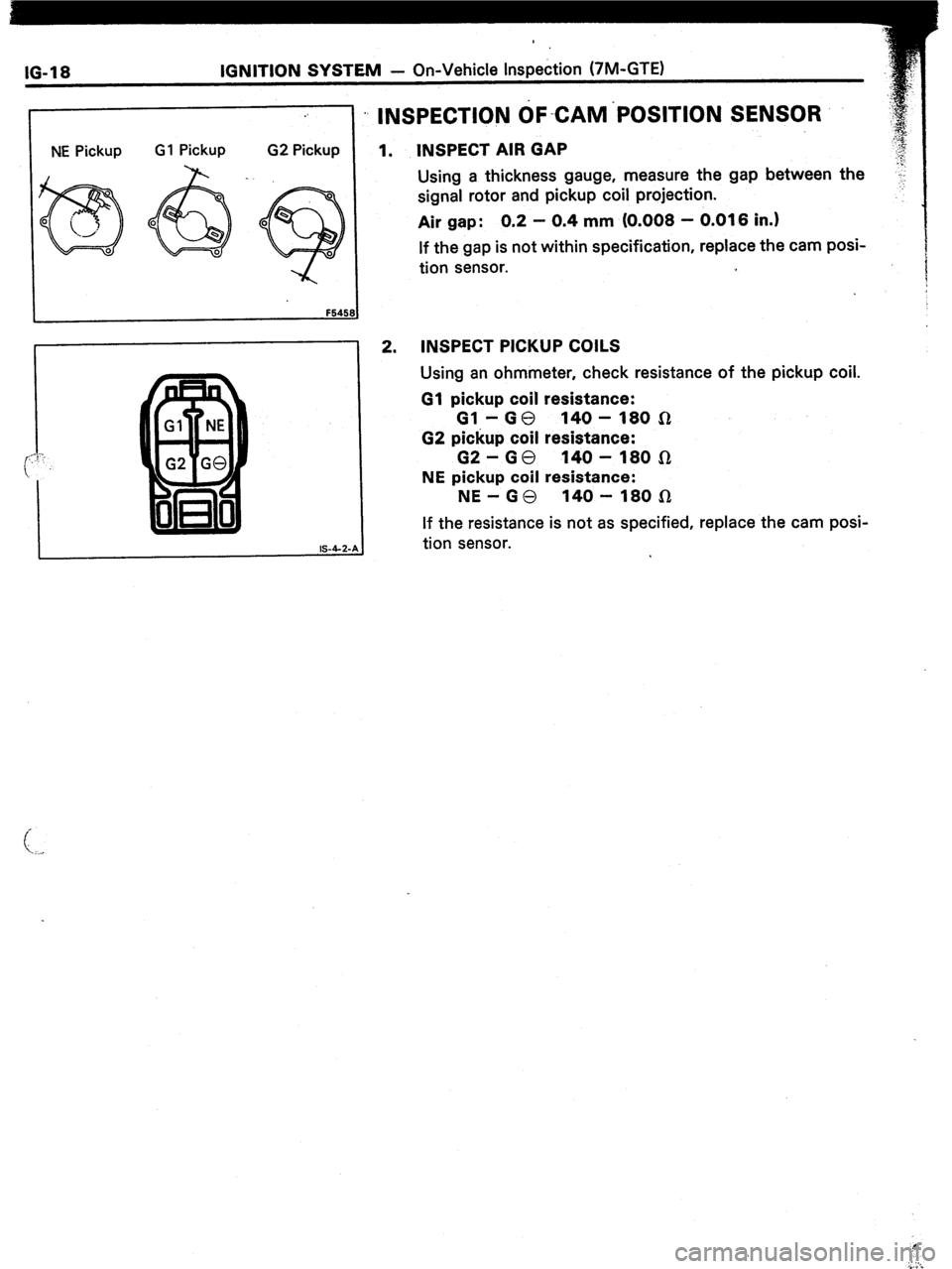

NE Pickup Gl Pickup G2 Pickup

.’ INSPECTION dF -CAM .POSITION SENSOR

1. INSPECT AIR GAP

Using a thickness gauge, measure the gap between the ?

signal rotor and pickup coil projection.

Air gap: 0.2 - 0.4 mm (0.008 - 0.016 in.)

If the gap is not within specification, replace the cam posi-

tion sensor.

2. INSPECT PICKUP COILS

Using an ohmmeter, check resistance of the pickup coil.

Gl pickup coil resistance:

Gl -GQ 140-180n

62 pickup coil resistance:

G2-GO 140-180n

NE pickup coil resistance:

NE-GO 140-180n

If the resistance is not as specified, replace the cam posi-

tion sensor.

Page 277 of 346

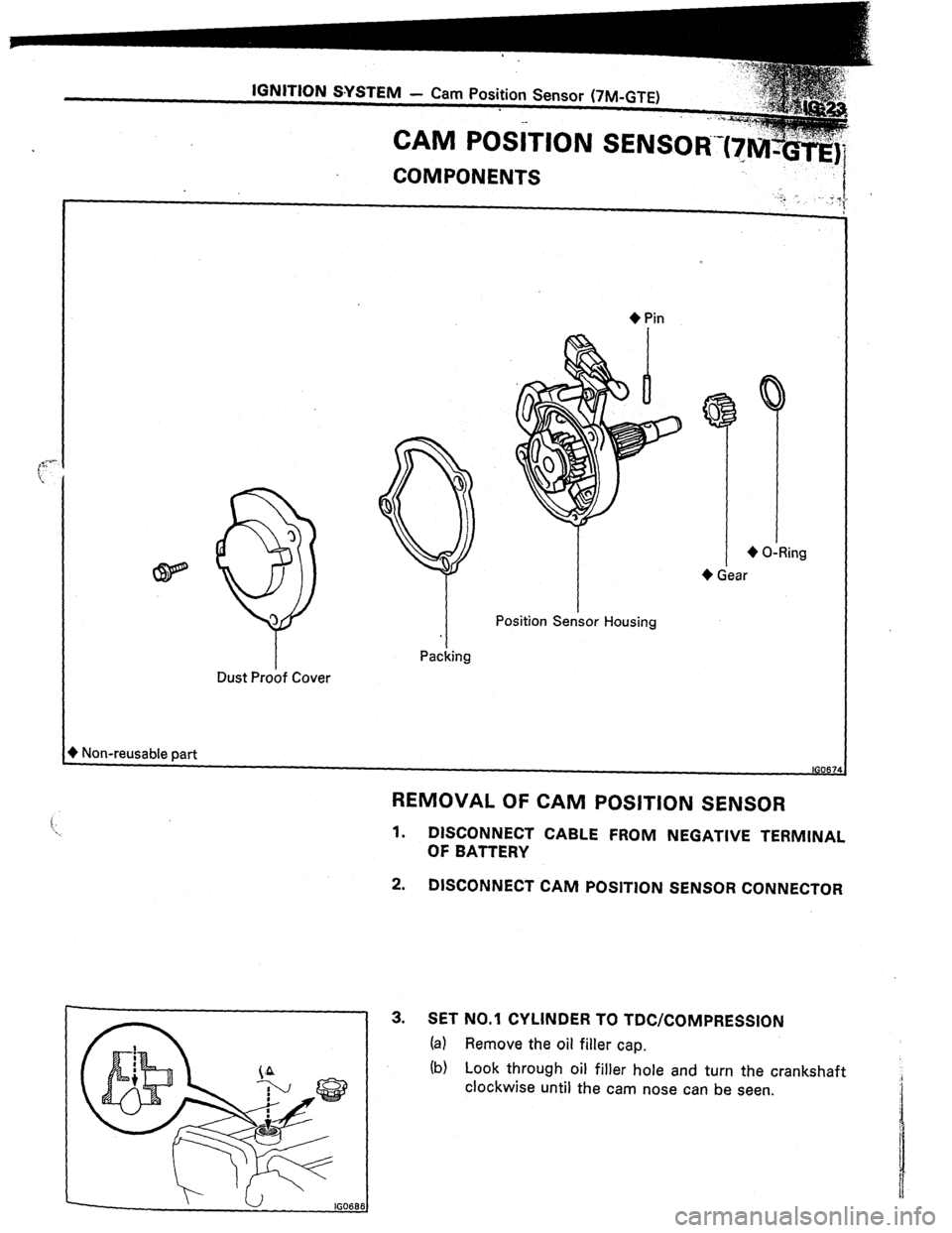

CAM POSiTION SENSOR-(7

COMPONENTS

* Non-reusable part

3

9 3

Dust Proof Cover Packing + Pin

Position Sensor Housing + Gear

-

~~-

REMOVAL OF CAM POSITION SENSOR

1. DISCONNECT CABLE FROM NEGATIVE TERMINAL

Oi- BATTERY

2.

DISCONNECT CAM POSITION SENSOR CONNECTOR

3.

SET NO.1 CYLINDER TO TDWCOMPRESSION

(a) Remove the oil filler cap.

(b) Look through oil filler hole and turn the crankshaft

clockwise until the cam nose can be seen. :I

it

Page 278 of 346

IQ-24 IGNITION SYSTEM - Cam Position Sensor (7M-GTE)

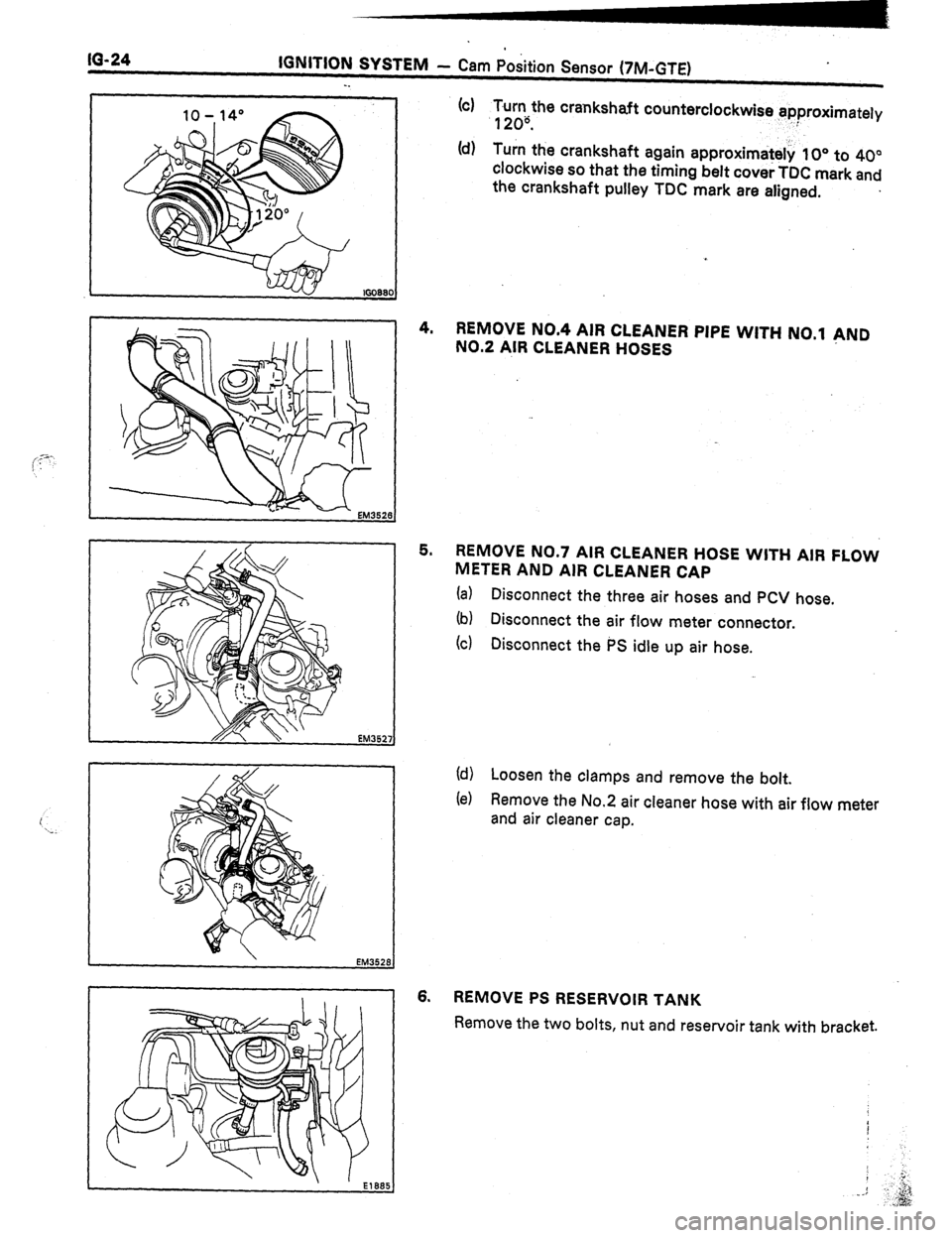

(cl y2;dthe crankshaft counterclockwise arjproximately

(d) Turn the crankshaft again approximtiteli 10” to 40”

clockwise so that the timing belt cove; TDC mark and

the crankshaft pulley TDC mark are aligned.

.

4. REMOVE NO.4 AIR CLEANER PIPE WITH NO.1 PND

NO.2 AIR CLEANER HOSES

5.

REMOVE NO.7 AIR CLEANER HOSE WITH AIR FLOW

METER AND AIR CLEANER CAP

(a) Disconnect the three air hoses and PCV hose.

(b) Disconnect the air flow meter connector.

(c) Disconnect the PS idle up air hose.

(d) Loosen the clamps and remove the bolt.

(e) Remove the No.2 air cleaner hose with air flow meter

and air cleaner cap.

6.

REMOVE PS RESERVOIR TANK

Remove the two bolts, nut and reservoir tank with bracket.

Page 279 of 346

IGNITION SYiTEM - Cam Position Sensor (‘IM-GTE)

IG-26.

-_

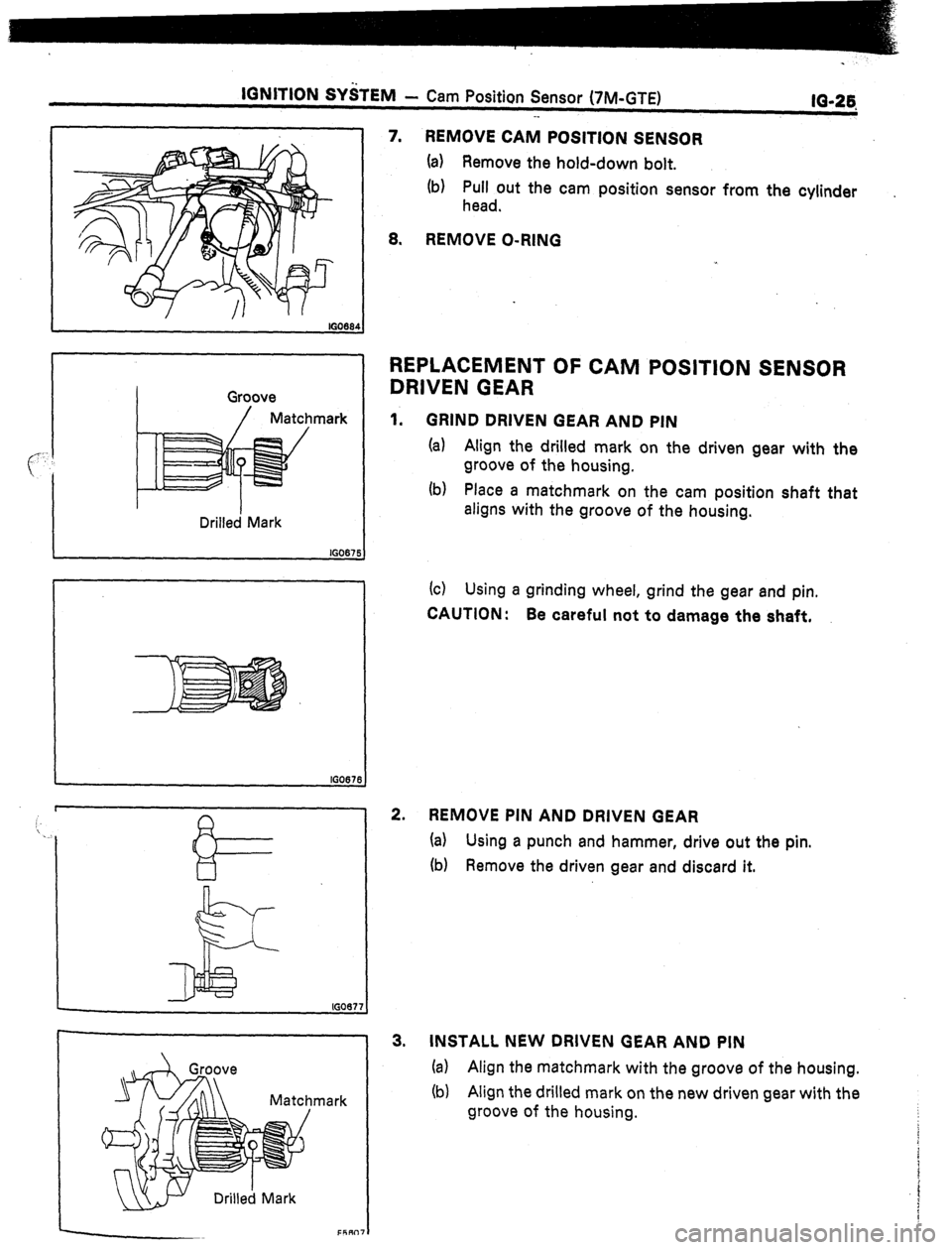

Groove

/ Matchmark

Drilled Mark

IGO

lGO67i

7. REMOVE CAM POSITION SENSOR

(a) Remove the hold-down bolt.

lb) Pull out the cam position sensor from the cylinder

head.

8. REMOVE O-RING

REPLACEMENT OF CAM POSITION SENSOR

DRIVEN GEAR

1.

GRIND DRIVEN GEAR AND PIN

(a) Align the drilled mark on

the driven gear with the

groove of the housing.

lb) Place a matchmark on the cam position shaft that

aligns with the groove of the housing.

(cl Using a grinding wheel, grind the gear and pin.

CAUTION: Be careful not to damage the shaft.

2.

REMOVE PIN AND DRIVEN GEAR

(a) Using a punch and hammer, drive out the pin.

(b) Remove the driven gear and discard it.

3. INSTALL NEW DRIVEN GEAR AND PIN

(a) Align the matchmark with the groove of the housing.

(b) Align the drilled mark on the new driven gear with the

groove of

the housing.

Page 280 of 346

IG-26 IGNITION SYbTEM - Cam Position Sensor (7M-GTE)

li ‘Jr. .

> ,I_ 1 .I..: .‘ ,,,. 2,,,“--.

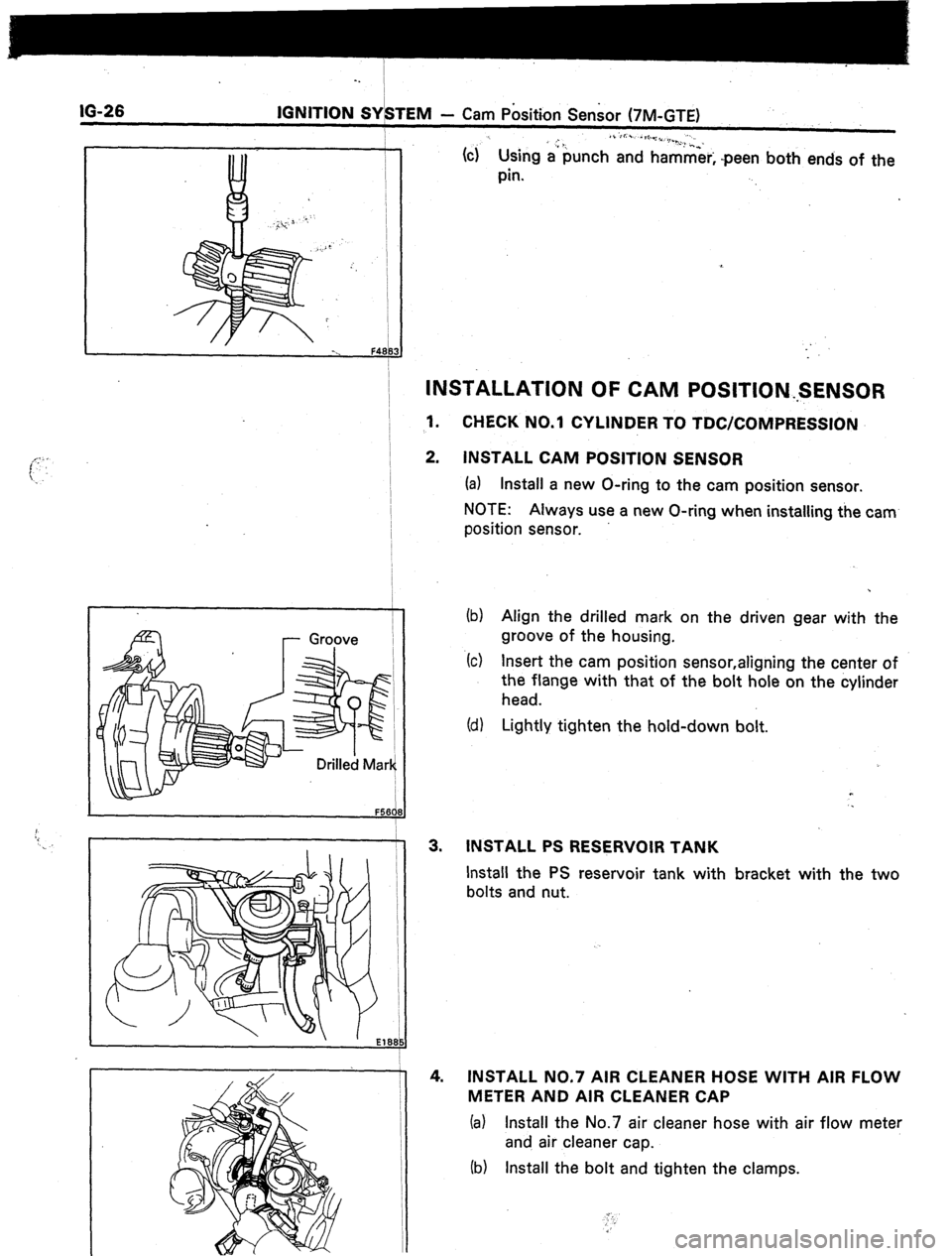

(4 Using a‘ punch and hammei, *peen both ends of the

pin.

I- Groove

INSTALLATION OF CAM POSITION.SENSOR

1. CHECK NO.1 CYLINDER TO TDCXOMPRESSION

2. INSTALL CAM POSITION SENSOR

(a) Install a new O-ring to the cam position sensor.

NOTE: Always use a new O-ring when installing the cam

position sensor.

(b) Align the drilled mark on the driven gear with the

groove of the housing.

(c) Insert the cam position sensor,aligning the center of

the flange with that of the bolt hole on the cylinder

head.

(d) Lightly tighten the hold-down bolt.

. .

3.

INSTALL PS RESERVOIR TANK

Install the PS reservoir tank with bracket with the two

bolts and nut.

4.

INSTALL NO.7 AIR CLEANER HOSE WITH AIR FLOW

METER AND AIR CLEANER CAP

(a) Install the No.7 air cleaner hose with air flow meter

and air cleaner cap.

(b) Install the bolt and tighten the clamps.

Page 281 of 346

IGNITION SY-$TEM

- Cam Position Sensor (‘/M-GTE)

IO-27

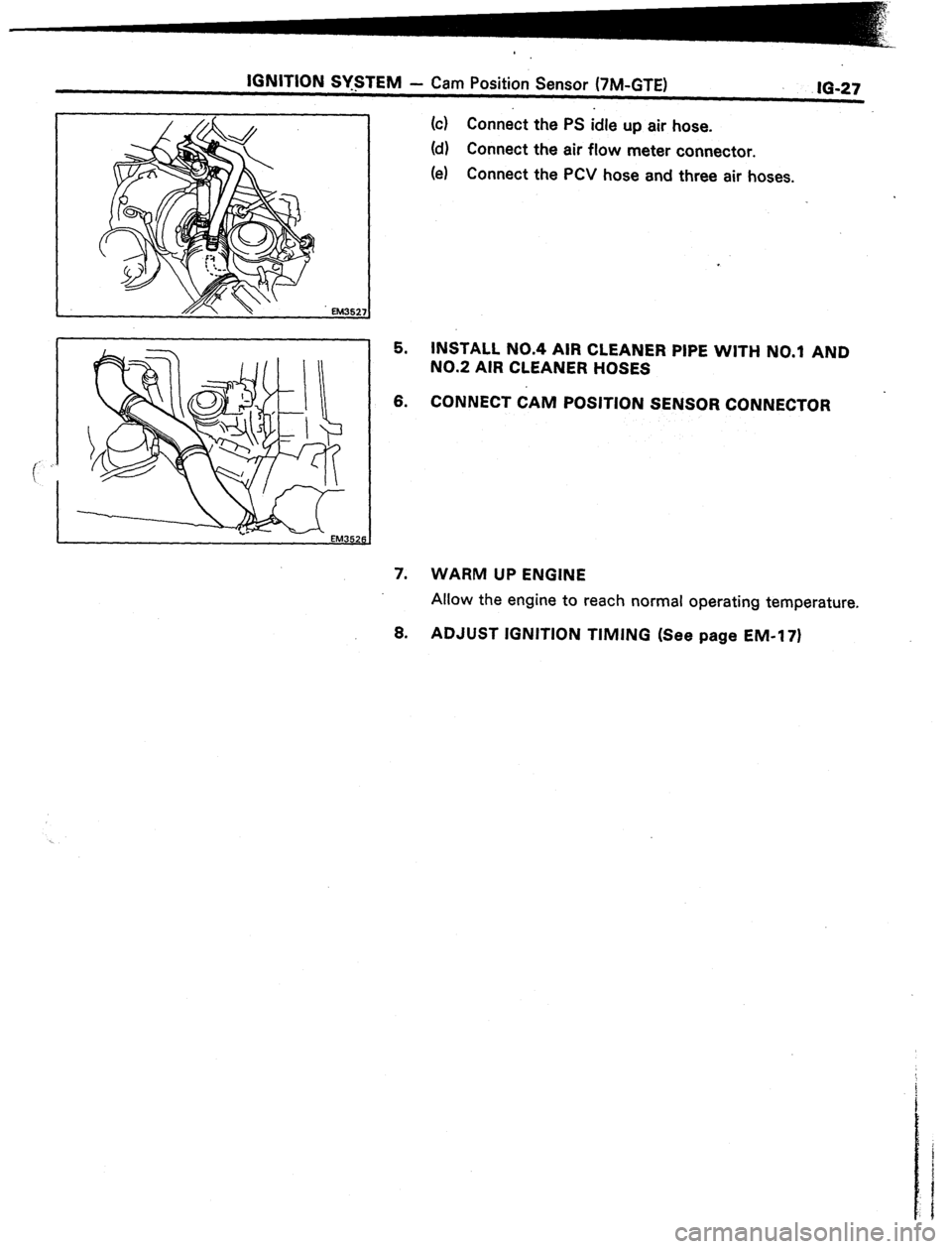

(cl Connect the PS idle up air hose.

(d) Connect the air flow meter connector.

(e) Connect the PCV hose and three air hoses.

5. INSTALL NO.4 AIR CLEANER PIPE WITH NO.1 AND

NO.2 AIR CLEANER HOSES

6. CONNECT CAM POSITION SENSOR CONNECTOR

7.

WARM UP ENGINE

Allow the engine to reach normal operating temperature.

8. ADJUST IGNITION TIMING (See page EM-171

Page 330 of 346

x-2 TURBOCHARGER SYSTEM - Description

.

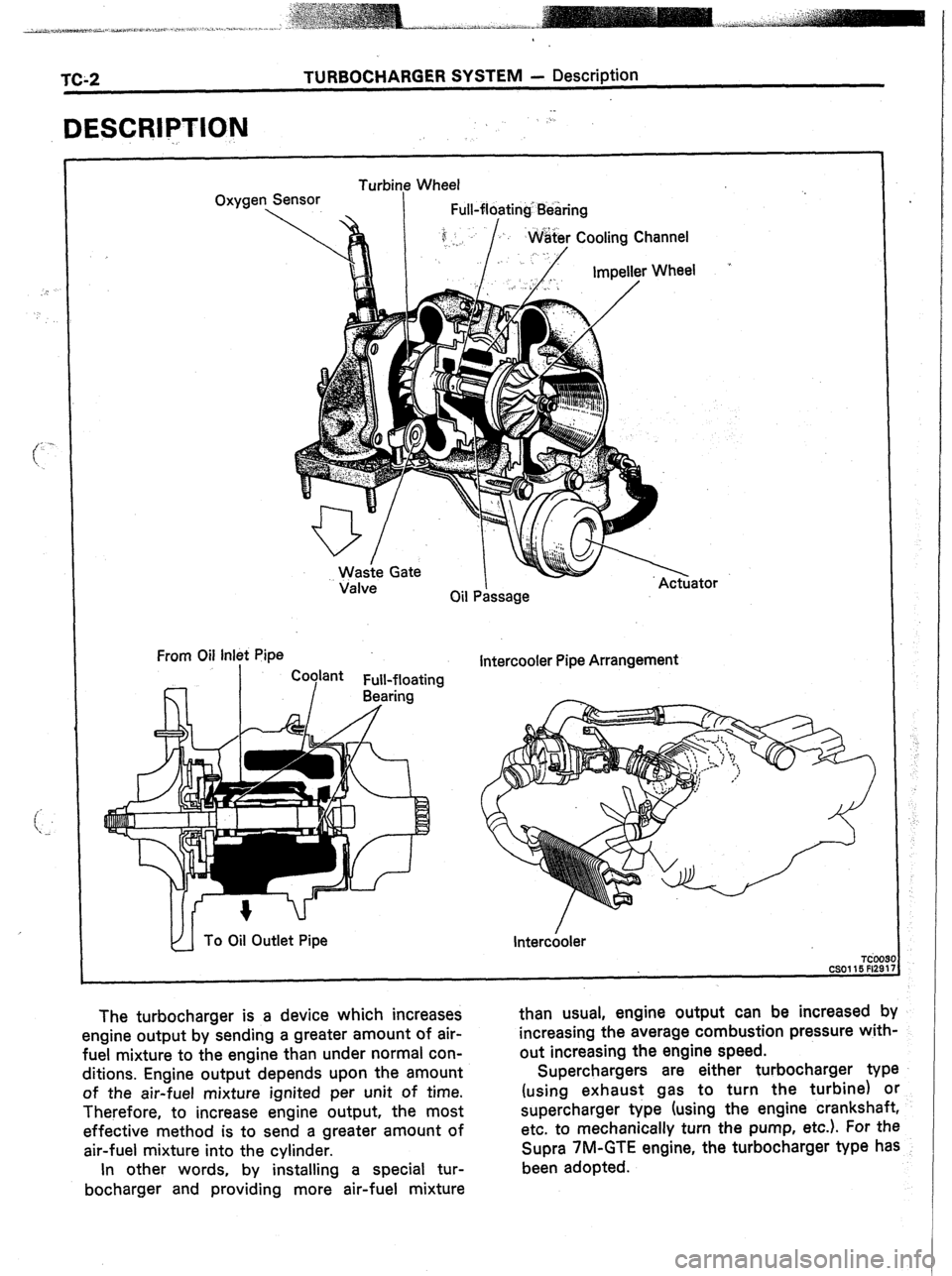

DESCRIPTION

-.

“

Oxygen

. Turbine Wheel

Sensor

.

I Full-floating Bearing

Valve

Oil P&sage

From Oil Inlet Pipe

Intercooler Pipe Arrangement

TdO

CSOll5 Fl2

The turbocharger is a device which increases

engine output by sending a greater amount of air-

fuel mixture to the engine than under normal con-

ditions. Engine output depends upon the amount

of the air-fuel mixture ignited per unit of time.

Therefore, to increase engine output, the most

effective method is to send a greater amount of

air-fuel mixture into the cylinder. than usual, engine output can be increased by

.

increasing the average combustion pressure with-

out increasing the engine speed.

Superchargers are either turbocharger type

(using exhaust gas to turn the turbine) or

supercharger type (using the engine crankshaft,

etc. to mechanically turn the pump, etc.). For the

Supra 7M-GTE engine, the turbocharger type has

been adopted.

In other words, by installing a special tur-

bocharger and providing more air-fuel mixture

Page 338 of 346

m-1 0 TURBOCHARGER SYSTEM .- Turbocharaer

. .

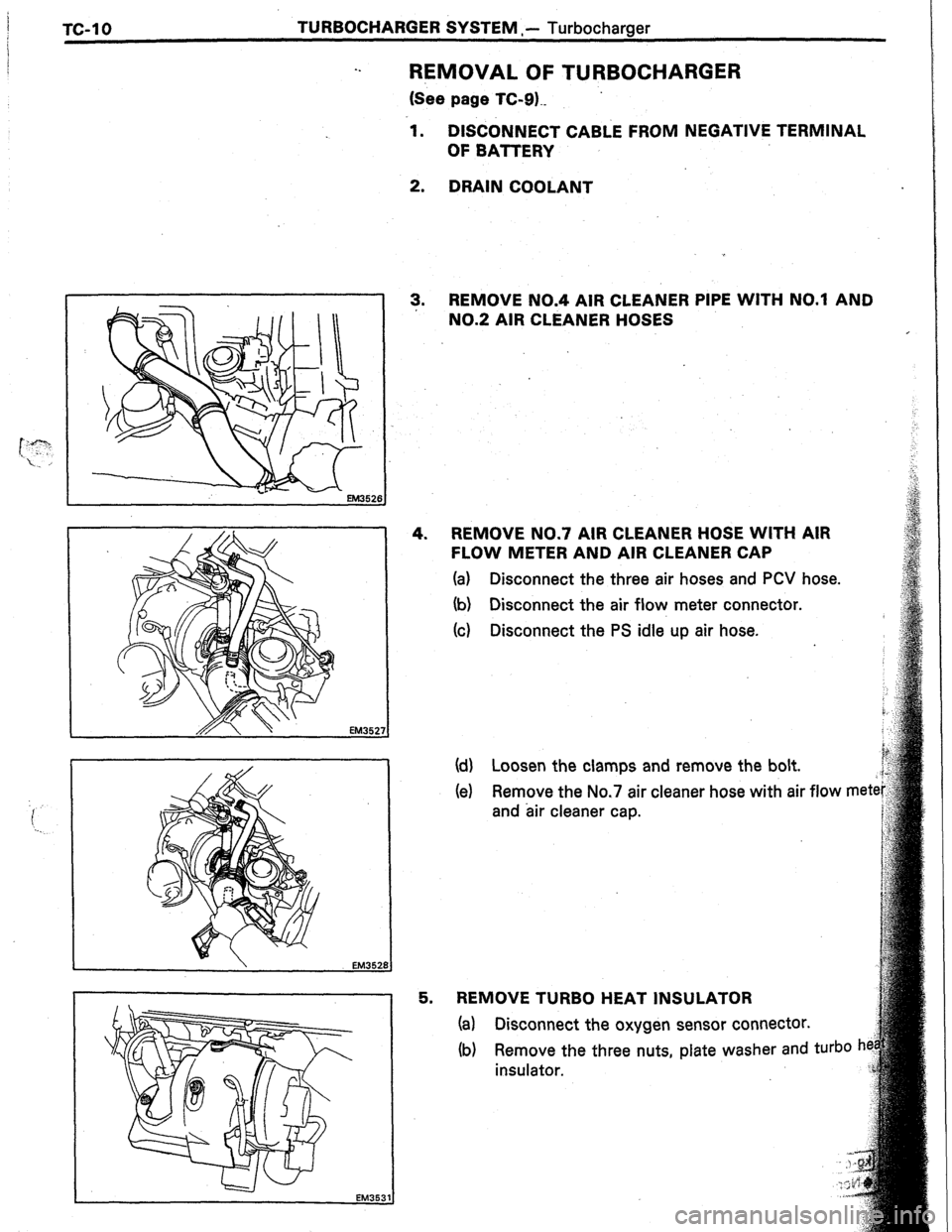

REMOVAL OF TURBOCHARGER

(See page TC-91..

1.

DISCONNECT CABLE FROM NEGATIVE TERMINAL

OF BATTERY

2. DRAIN COOLANT

1 3.

REMOVE NO.4 AIR CLEANER PIPE WITH NO.1 AND

NO.2 AIR CLEANER HOSES

4. REMOVE NO.7 AIR CLEANER HOSE WITH AIR

FLOW METER AND AIR CLEANER CAP

(a) Disconnect the three air hoses and PCV hose.

(b) Disconnect the air flow meter connector.

(cl Disconnect the PS idle up air hose.

I (d) Loosen the clamps and remove the bolt.

1 EM3528

5. (e) Remove the No.7 air cleaner hose with air flow mete#

and air cleaner cap. i.,%$

: ,::j

REMOVE TURBO HEAT INSULATOR

(a) Disconnect the oxygen sensor connector.

(b) Remove the three nuts, plate washer and turbo h’

insulator.

Page 345 of 346

8 SYS

NTEM - - Turbocharger

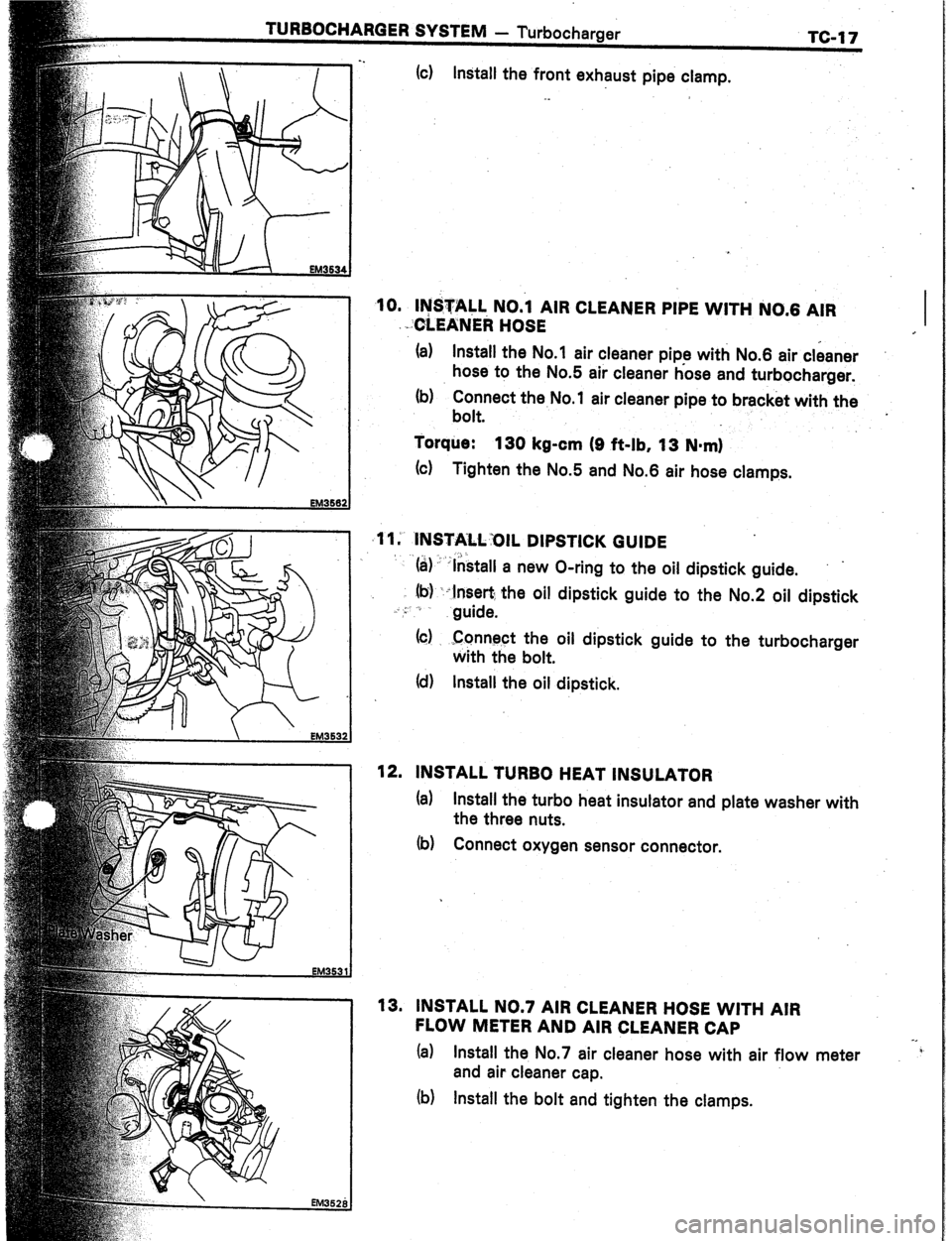

(cl Install

the front exhaust pipe

clamp. TC-17

10. Ih$TA& NO.1 AIR CLEANER PIPE WITH NO.6 AIR

.-GLEANER HOSE I

.

(a)

Install the No.1 air cleaner pipe with No.6 air cleaner

hose to the No.5 air cleaner hose and turbocharger.

(b) Connect the No.1 air cleaner pipe to bracket with the

bolt.

Torque:

130 kg-cm (9 ft-lb, 13 N-m)

(c) Tighten the No.5 and No.6 air hose clamps.

11 i INSTALL “OIL DIPSTICK GUIDE

‘(a) ‘.‘lnstall a new O-ring to the oil dipstick guide.

lb) ,-insert the oil dipstick guide to the No.2 oil dipstick

: ‘/

guide.

(c) Connect the oil dipstick guide to the turbocharger

with the bolt.

(d) Install the oil dipstick.

12. INSTALL TURBO HEAT INSULATOR

(a) Install the turbo heat insulator and plate washer with

the three nuts.

(b) Connect oxygen sensor connector.

13. INSTALL NO.7 AIR CLEANER HOSE WITH AIR

FLOW METER AND AIR CLEANER CAP

(a) Install the No.7 air cleaner hose with air flow meter

and air cleaner cap.

(b) Install the bolt and tighten the clamps.