sensor TOYOTA CELICA 1987 Service Manual PDF

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 1987, Model line: CELICA, Model: TOYOTA CELICA 1987Pages: 346, PDF Size: 35.13 MB

Page 201 of 346

ENGINE MECHANICAL - Cylinder Head

EM-&j

REMOVAL OF CYLINDER HEAD

1. (See pages EM-37, 38)

REMOVE AiiERNATOR

(a) Disconnect the No.3 PCV hose.

(b) Remove the drive belt.

(c) Remove the alternator and adjusting bar.

2.

3.

4. (7M-GTE)

REMOVE PS RESERVOIR TANK

Remove the two bolts, nut and, reservoir tank with bracket.

(‘IM-GTE),

REMOVE CAM POSITION SENSOR

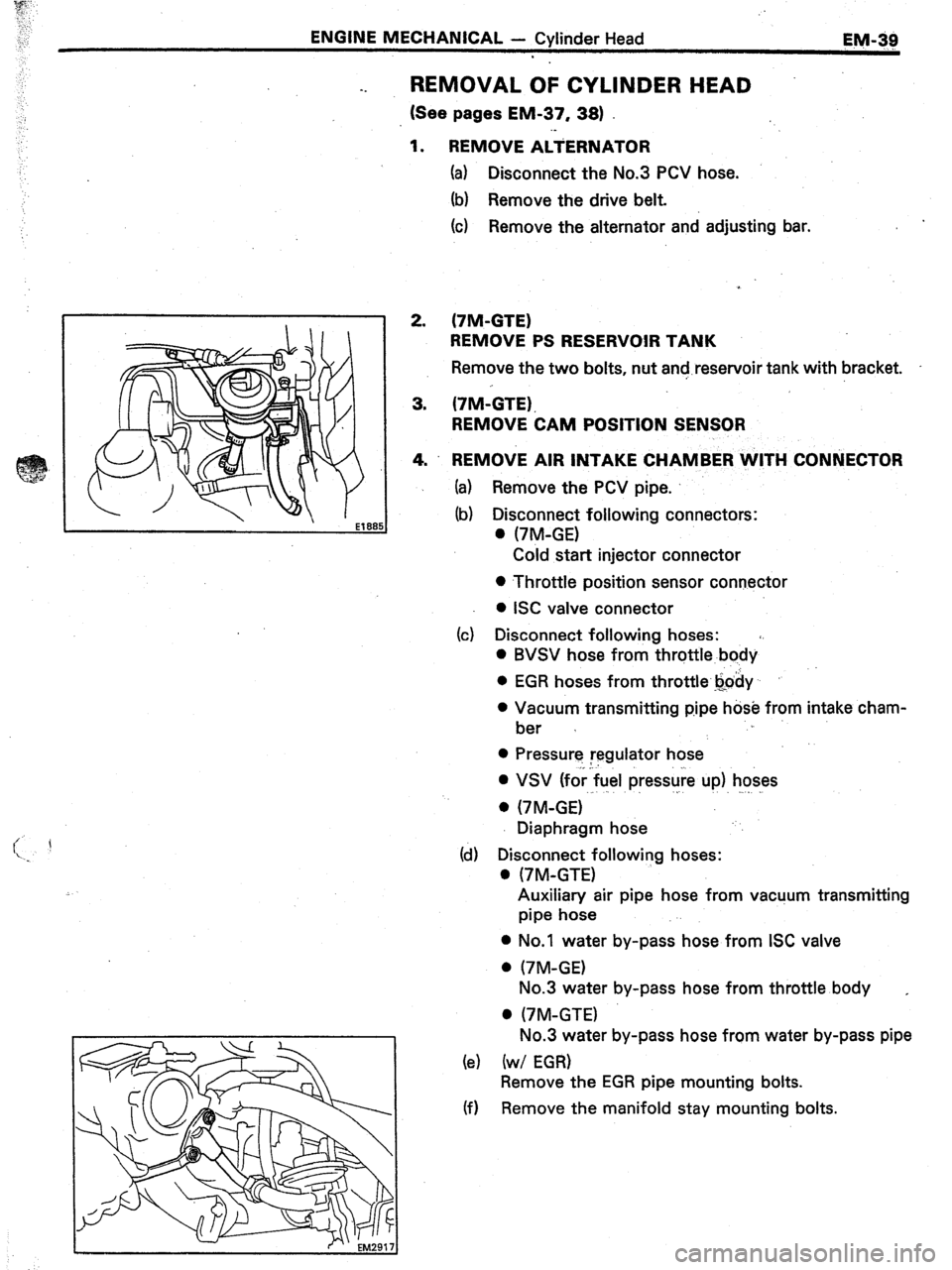

REMOVE AIR INTAKE CHAMBER WITH CONNECTOR

(a) Remove the PCV pipe.

(b) Disconnect following connectors:

. (7M-GE)

Cold start injector connector

l Throttle position sensor connector

l ISC valve connector

(c) Disconnect following hoses: aI

l BVSV hose from throttle body

l EGR hoses from throttle.boby

l Vacuum transmitting p.ipe hose from intake cham-

ber

0 Pressure regulator hose

;, I

l VSV (for fuel pressure up) &es

. (7 M-GE)

Diaphragm hose

(d) Disconnect following hoses:

-

0 (7M-GTE)

Auxiliary air pipe hose from vacuum transmitting

pipe hose

l No.1 water by-pass hose from ISC valve

. (7M-GE)

No.3 water by-pass hose from throttle body ,

0 (-/M-GTE)

No.3 water by-pass hose from water by-pass pipe

(e) (w/ EGR)

Remove the EGR pipe mounting bolts.

(f) Remove the manifold stay mounting bolts.

Page 203 of 346

.

ENGINE MECHANICAL - Cylinder Head

-. 6. REMOVE ENGINE WIRE

(a) Disconnect following wires:

. fw/ TWC)

Oxygen sensor connector

l Oil pressure sender gauge connector

l Water temp. sensor connector

l Water temp. sender gauge connector

_-

l Cold start injector time switch connector

l Distributor connector

.,

l Injector connectors

l Three VSV connectors

l Knock sensor connectors

l Ground strap from intake manifold

(b) Remove the engine wire from the each clamps.

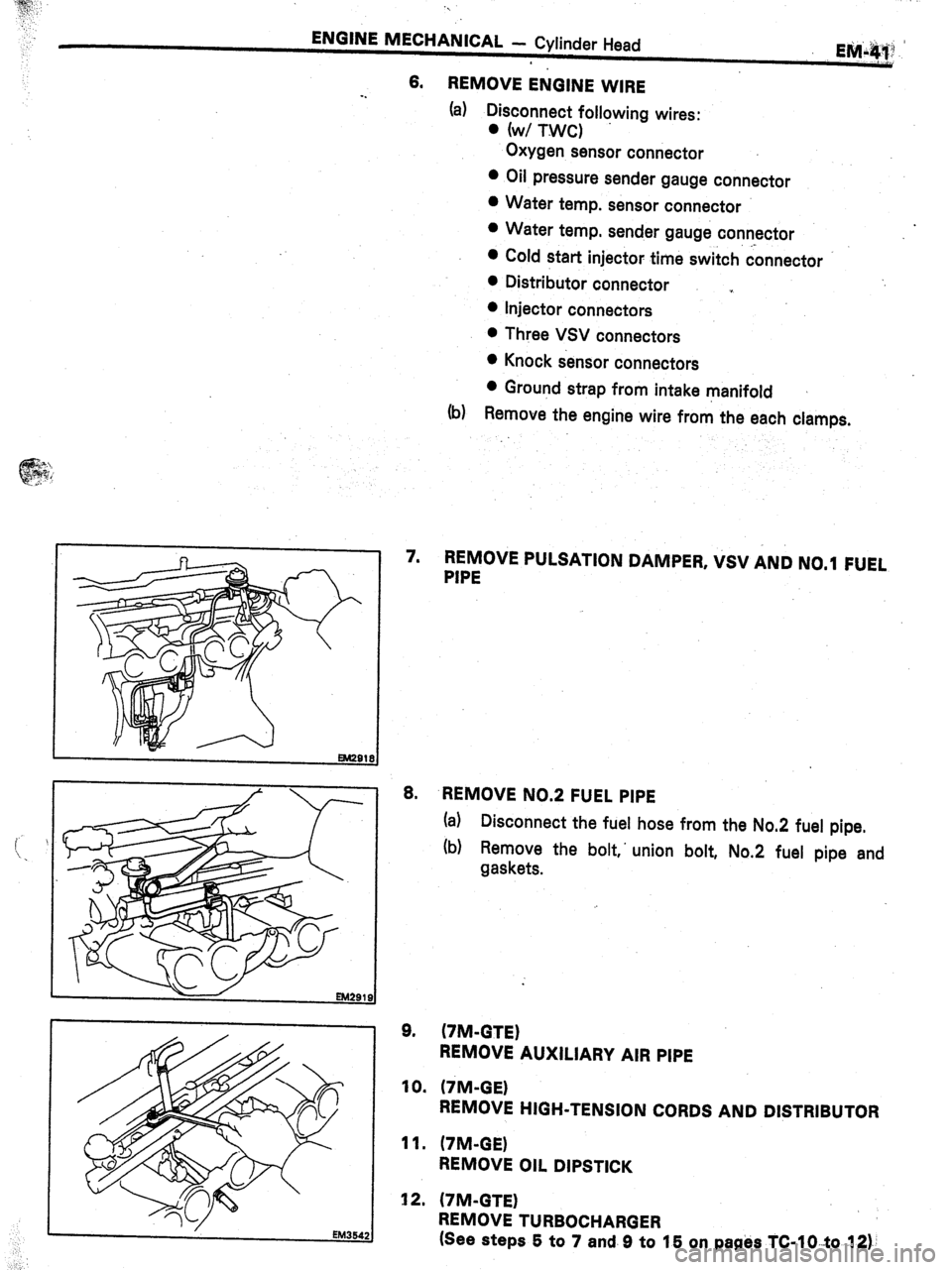

7.

REMOVE PULSATION DAMPER, VSV AND NO.1 FUEL

PIPE

6.

REMOVE NO.2 FUEL PIPE

(a) Disconnect the fuel hose from the No.2 fuel pipe.

(b) Remove the bolt,’ union bolt, No.2 fuel pipe and

gaskets.

9. (7M-GTE)

REMOVE AUXILIARY AIR PIPE

10. (7M-GE)

REMOVE HIGH-TENSION CORDS AND DISTRIBUTOR

11. (7M-GE)

REMOVE OIL DIPSTICK

12. (7M-GTE)

REMOVE TURBOCHARGER

(See steps 5 to 7 and 9 to 15 on pages TC-IO-to 12):

Page 218 of 346

EM-56

ENGINE MECHANICAL - Cylinder f-lead

I-

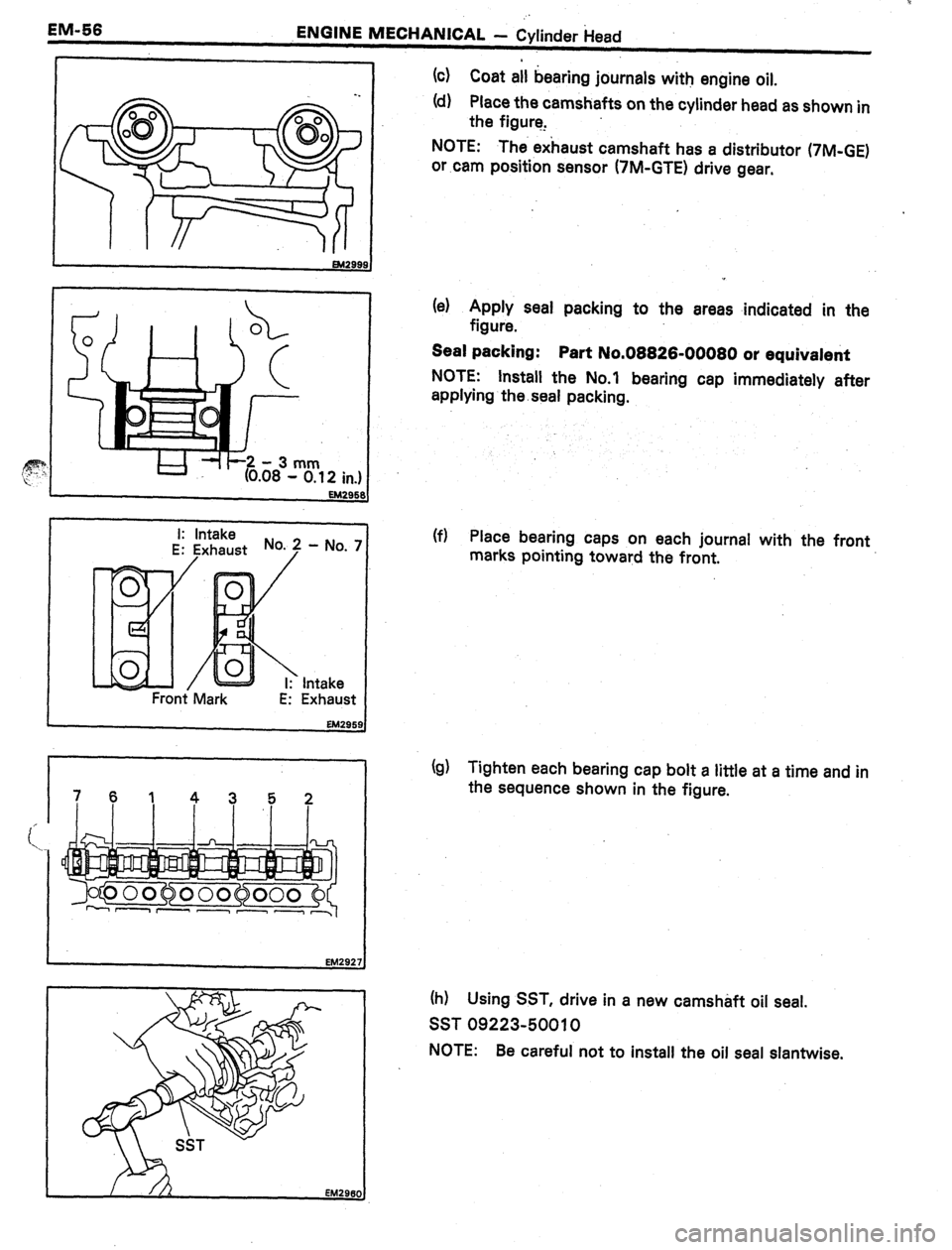

I: Intake

E: ljxhaust No.? - No. 7

Front Mark Intake

Exhaust (4 Coat all bearing journals with engine oil.

(d) Place the camshafts on the cylinder head as shown in

the figure,

NOTE: The eihaust camshaft has a distributor (‘IM-GE)

or cam position sensor (7M-GTE) drive gear.

(e) Apply seal packing to the areas indicated in the

figure.

Seal packing:

Part No.06826-00080 or equivalent

NOTE: Install the No.1 bearing cap immediately after

applying the. seal packing.

(f) Place bearing caps on each journal with the front

marks pointing toward the front.

(g) Tighten each bearing cap bolt a little at a time and in

the sequence shown in the figure.

(h) Using SST, drive in a new camshaft oil seal.

SST 09223-50010

NOTE: Be careful not to install the oil seal slantwise.

Page 224 of 346

EM-62

ENGINE MECHANICAL + Cylinder Head

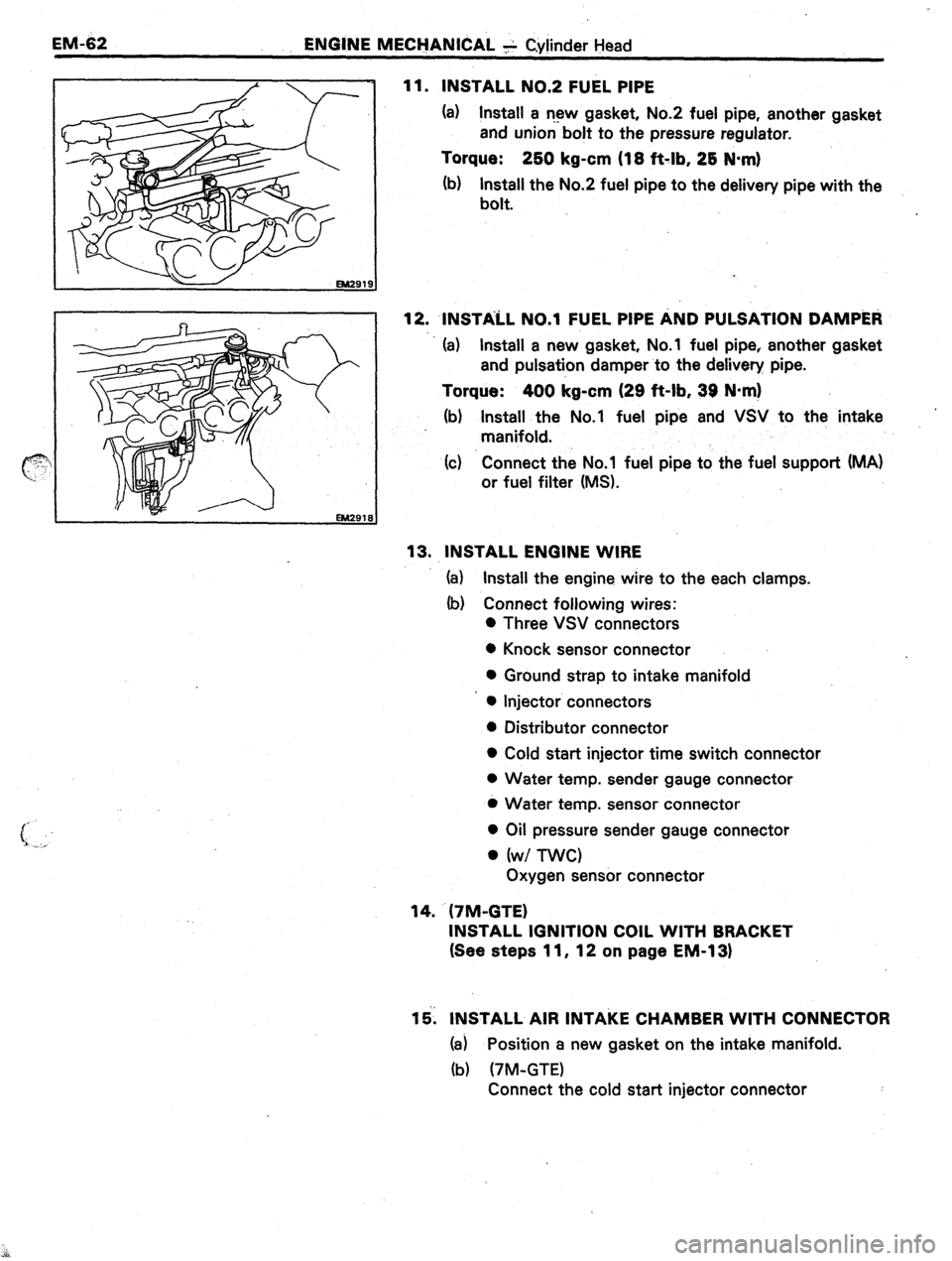

11. INSTALL NO.2 FUEL PIPE

(a) Install a r-13~ gasket, No.2 fuel pipe, another gasket

and union bolt to the pressure regulator.

Torque: 2bO kg-cm (18 ft-lb, 28 N-m)

(b) Install the No.2 fuel pipe to the delivery pipe with the

bolt.

12. INSTALL ~0.1 FUEL PIPE AND PULSATION DAMP&~

(a) Install a new gasket, No.1 fuel pipe, another gasket

and pulsation damper to the delivery pipe.

Torque: 400 kg-cm (29 ft-lb, 39 N*m)

(b) Install the No.1 fuel pipe and VSV to the intake

manifold.

(c) Connect the No.1 fuel pipe to the fuel support (MA)

or fuel filter (MS).

13. INSTALL ENGINE WIRE

(a) Install the engine wire to the each clamps.

(b) Connect following wires:

0 Three VSV connectors

0 Knock sensor connector

0 Ground strap to intake manifold

l Injector connectors

l Distributor connector

l Cold start injector time switch connector

0 Water temp. sender gauge connector

l Water temp. sensor connector

l Oil pressure sender gauge connector

l (w/ nvc)

Oxygen sensor connector

14. (7M-GTE)

INSTALL IGNITION COIL WITH BRACKET

(See steps 11, 12 on page EM-1 31

15. INSTALL AIR INTAKE CHAMBER WITH CONNECTOR

(a) Position a new gasket on the intake manifold.

(b) (7M-GTE)

Connect the cold start injector connector

Page 226 of 346

-.

,y. ,. P > .: (i) install the EGR

pipe mounting bolts.

:i

(k) Install the manifold ‘stay mounting bolt.

(I) Connect following hoses:

. 47M-GE)

No.3 water by-pass hose to throttle body

(‘IM-GTE)

0 Auxiliary air pipe hose to vacuum transmitting pipe ’

l No.1 water by-pass hose to ISC valve .

(m) Connect following hoses: .,

. (7M-GE)

Diaphragm hose

0 VSWfor fuel. pressure up)hoses

l Pressure regulator hose

0 EGR hoses to throttle body and vacuum transmit-

ting pipe.

0 Vacuum transmitting pipe hose to intake chamber

-I

0 BVSV hose to throttle body

(r-r) Connect following wires:

0 ISC valve connector

0 Throttle position sensor connector

0 (‘/M-GE)

Cold start injector connector.

(01 Install the PCV pipe.

16. (‘IM-GTE)

INSTALL CAM POSITION SENSOR

(See steps 1, 2 on page 10-26)

17. (7M-GTE)

INSTALL PS RESERVOIR TANK

Install the PS reservoir tank with bracket.

18. INSTALL ALTERNATOR AND ADJUSTING BAR

(a) Install the alternator and adjusting bar.

(b) Install the drive belt.

(See page EM-361

(c) Connect the No.3 PCV pipe.

Page 255 of 346

. .

-.

.’ .,

-.. . . t .’

. . . ,..

1.1 .I.. -I ““... _.. ____ ,,_

_ ..I,. ..-. It

_-

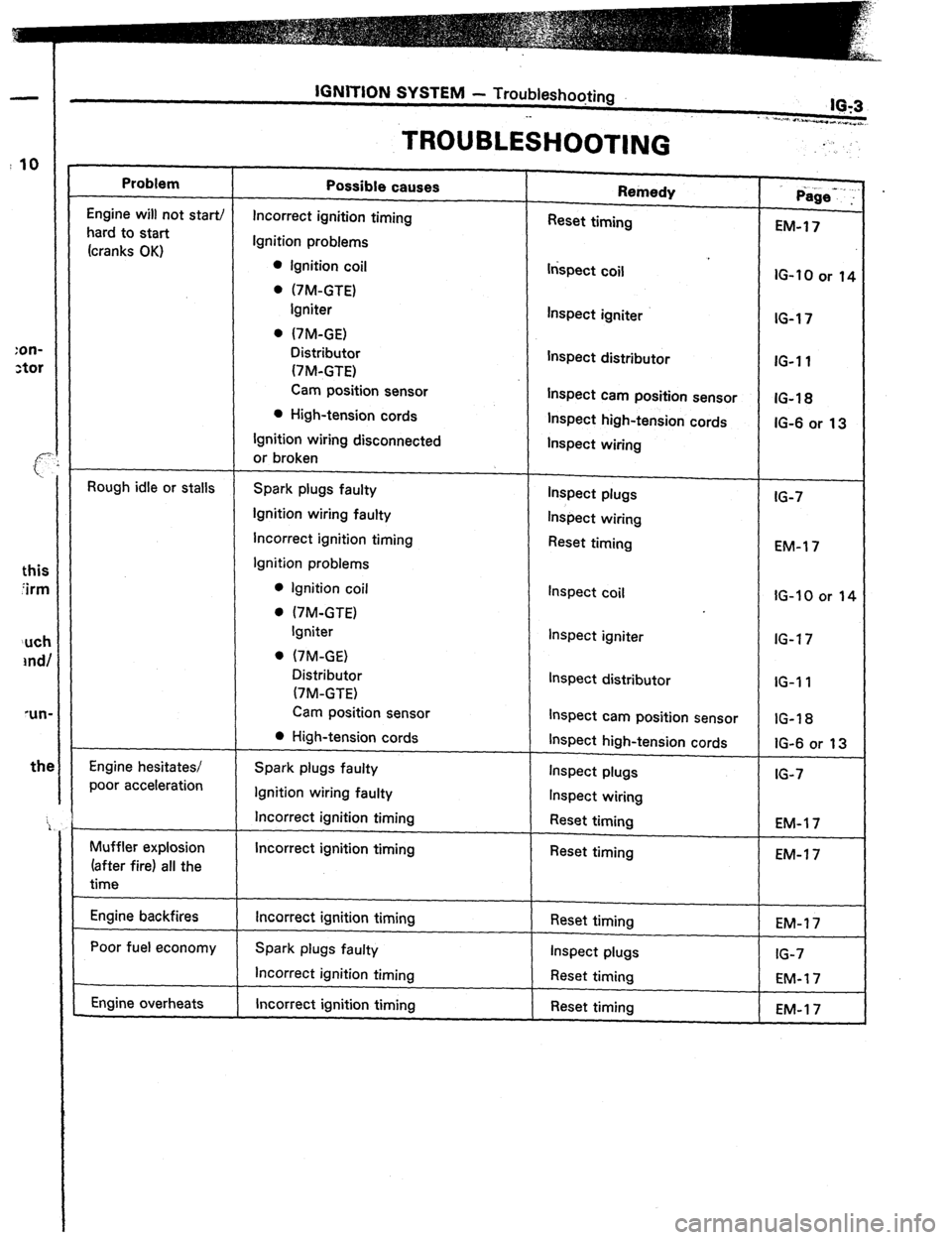

IGNiiid’N SYSTEM

PRECAUTIONS Page

................................

16-2

TROUBLESHOOTING

............................

IG-3

IGNITION SYSTEM CIRCUIT

....................

ON-VEHICLE INSPkTlON (7M-GE) IO-4

............. IO-5

ON-VEHICLE INSPECTION (7M-GTE)

............ IO-1 2

DISTRIBUTOR (7M-GE)

.........................

IO-19

CAM POSITION SENSOR (7M-GTE)

............. 16-23

Page 257 of 346

:on-

ztor

thi

‘irr

‘UC

mc

WI

tf

Problem

Engine will not star-t/

hard to start

(cranks OK)

Rough idle or stalls

Engine hesitates/

poor acceleration

Muffler explosion

(after fire) all the

time

Engine backfires

Poor fuel economy

Engine overheats

TROUBLESHOOTING

Possible causes

Incorrect ignition timing

Ignition problems

0 Ignition coil

. (7M-GTE)

Igniter

. (7M-GE)

Distributor

(7M-GTE)

Cam position sensor

l High-tension cords

Ignition wiring disconnected

or broken

Spark plugs faulty

Ignition wiring faulty

Incorrect ignition timing

Ignition problems

0 Ignition coil

. I7M-GTE)

Igniter

. (7M-GE)

Distributor

(7M-GTE)

Cam position sensor

0 High-tension cords

Spark plugs faulty

Ignition wiring faulty

Incorrect ignition timing

Incorrect ignition timing

Incorrect ignition timing

Spark plugs faulty

Incorrect ignition timing

Incorrect ignition timing Remedy

Reset timing

lrkpect coil

Inspect igniter

Inspect distributor

Inspect cam position sensor

Inspect high-tension cords

Inspect wiring

Inspect plugs

Inspect wiring

Reset timing

Inspect coil

Inspect igniter

Inspect distributor

Inspect cam position sensor

Inspect high-tension cords

Inspect plugs

Inspect wiring

Reset timing

Reset timing

Reset timing

Inspect plugs

Reset timing

Reset timing =

Page-.. :

-

EM-17

IG-10 or 14

IG-17

IG-11

IG-1%

IG-6 or 13

IG-7

EM-l 7

IG-10 or 11

IG-17

IG-I 1

IG-18

IG-6 or 13

IG-7

EM-l 7

EM-1 7

Page 258 of 346

IQ-4

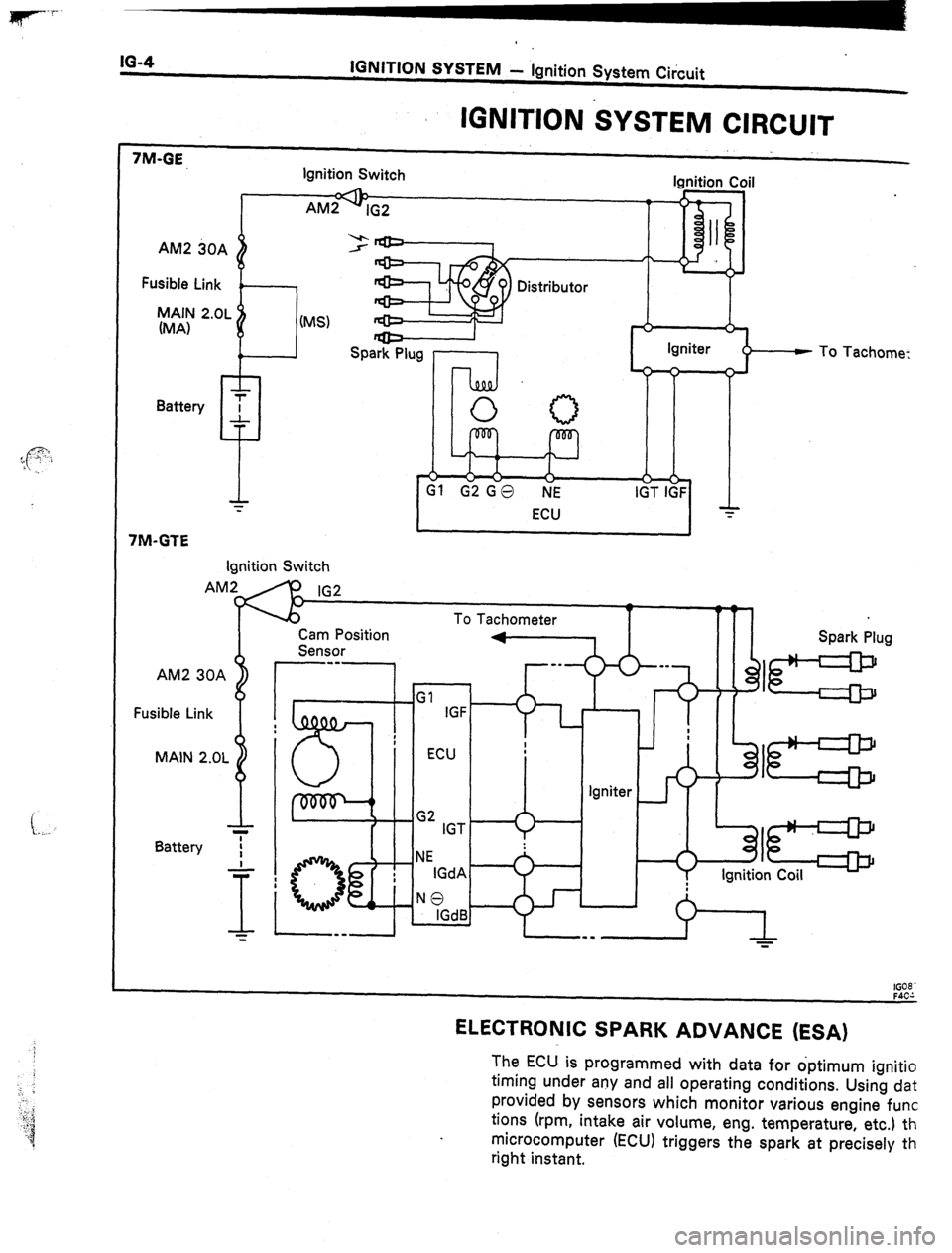

IGNITION SYSTEM - Ignition System Circuit

IGNlTlON SYSTEM CIRCUIT

7M-GE, Ignition Switch lanitian Cnil

AM2 30A

Fusible Link

MAIN 2.OL

(MA)

~“. _._. _ _..

AM29~2

I “i!l A II

I

(MS)

I

Spark Plug l-1 II

R Igniter

1

7M-GTE

I

Ignition Switch

AM2 30A

Fusible Link

MAIN 2.OL

Battery IG2

To Tachometer

1 f

Cam Position

Sensor

r--1

G2 IGT

NE

IGdA

NO

IGdB f

To Tachome:

n Spark Plug

Igniter

: I=

B

I=

Ignition Coil

It08

ELECTRONIC SPARK ADVANCE (ESA)

The ECU is programmed with data for optimum ignitio

timing under any and all operating conditions. Using dat

provided by sensors which monitor various engine func

tions (rpm,

intake air volume, eng. temperature, etc.) th

microcomputer (ECU) triggers the spark at precisely th

right instant.

Page 266 of 346

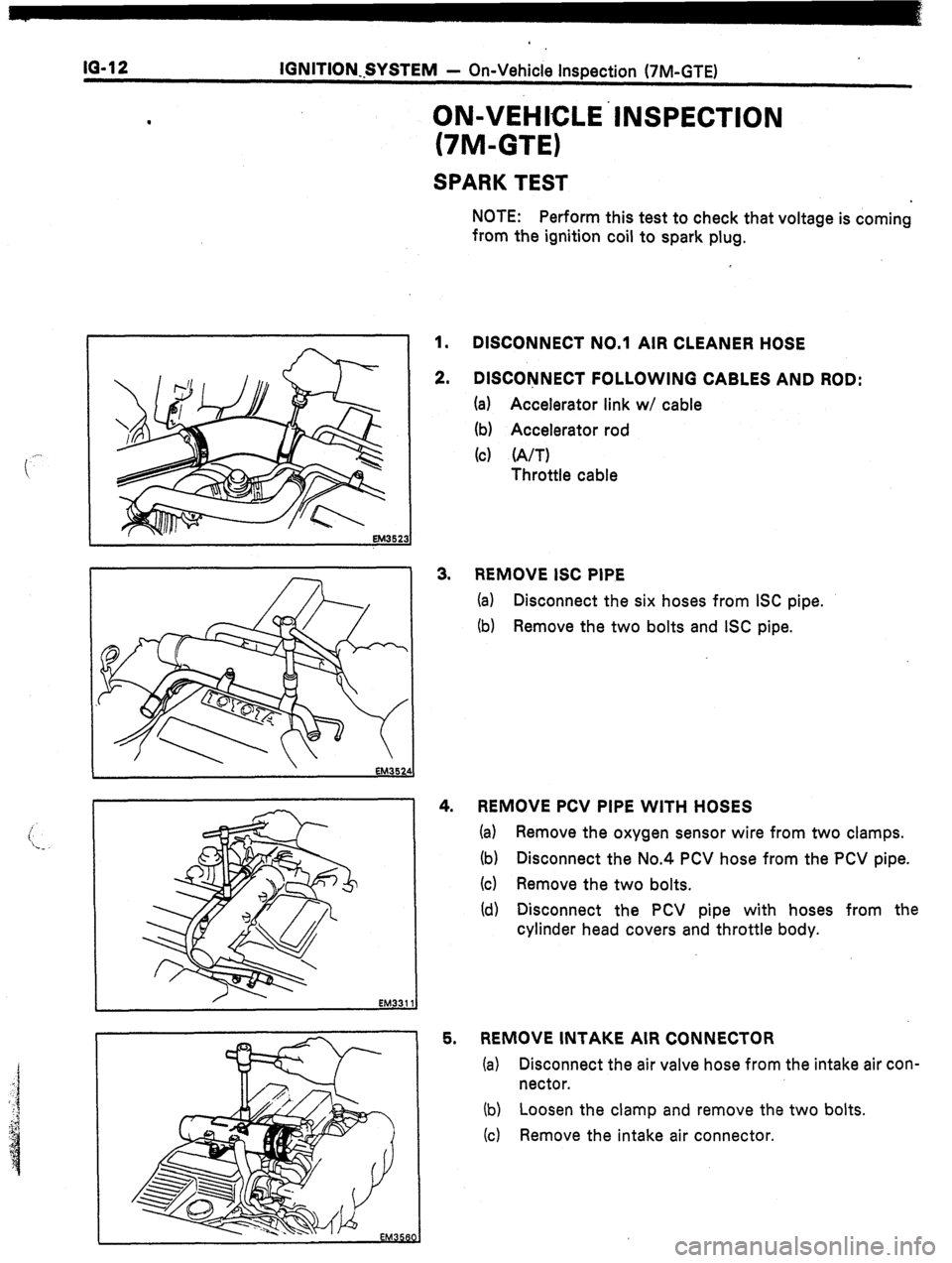

IQ-12 IGNITION~.SYSTEM - On-Vehicle Inspection (‘IM-GTE)

. ON-VEHICLE’INSPECTION

(7M-GTE)

SPARK TEST

EM35

3. NOTE: Perform this test to check that voltage is coming

from the ignition coil to spark plug.

DISCONNECT NO.1 AIR CLEANER HOSE

DISCONNECT FOLLOWING CABLES AND ROD:

(a) Accelerator link w/ cable

(b) Accelerator rod

(cl (A/T)

Throttle cable

REMOVE ISC PIPE

(a) Disconnect the six hoses from ISC pipe.

(b) Remove the two bolts and ISC pipe.

REMOVE PCV PIPE WITH HOSES

(a) Remove the oxygen sensor wire from two clamps.

(b) Disconnect the No.4 PCV hose from the PCV pipe.

(c) Remove the two bolts.

(d) Disconnect the PCV pipe with hoses from the

cylinder head covers and throttle body.

:

5. REMOVE INTAKE AIR CONNECTOR

(a) Disconnect the air valve hose from the intake air con-

nector.

(b) Loosen the clamp and remove the two bolts.

ic) Remove the intake air connector.

Page 270 of 346

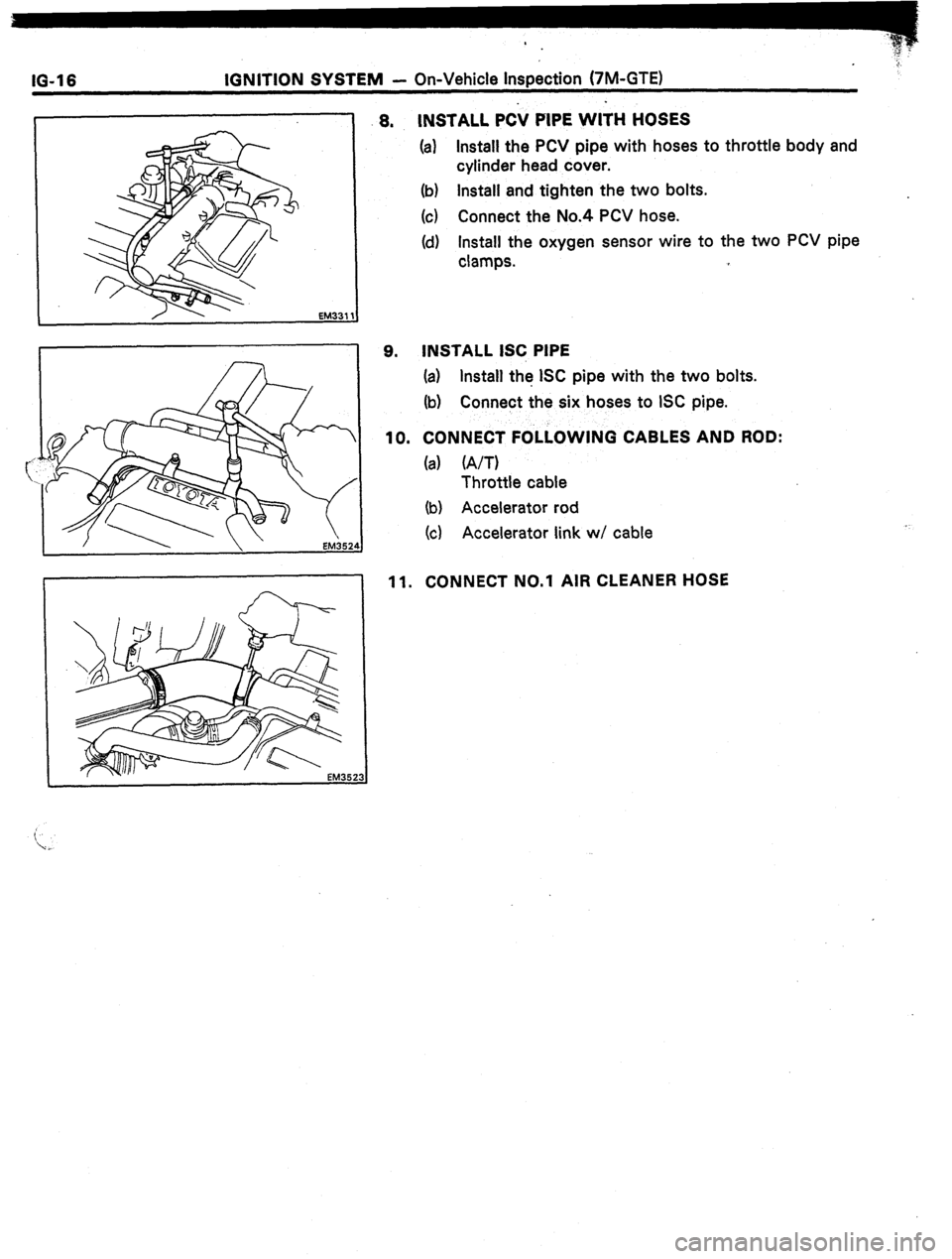

IO-16 IGNITION SYSTEM - On-Vehicle Inspection (7M-GTE)

.8. INSTALL PCi/ PIPE WITH HOSES

(a) Install the PCV pipe with hoses to throttle body and

cylinder head cover.

(b) Install and tighten the two bolts.

(c) Connect the No.4 PCV hose.

(d) Install the oxygen sensor wire to the two PCV pipe

clamps.

9. INSTALL ISC PIPE

(a) Install the ISC pipe with the two bolts.

(b) Connect the six hoses to ISC pipe.

10. CONNECT FOLLOWING CABLES AND ROD:

(a) (A/T)

Throttle cable

(b) Accelerator rod

(cl Accelerator link w/ cable

11. CONNECT NO.1 AIR CLEANER HOSE

I