sensor TOYOTA CELICA 1987 Service Owner's Guide

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 1987, Model line: CELICA, Model: TOYOTA CELICA 1987Pages: 346, PDF Size: 35.13 MB

Page 90 of 346

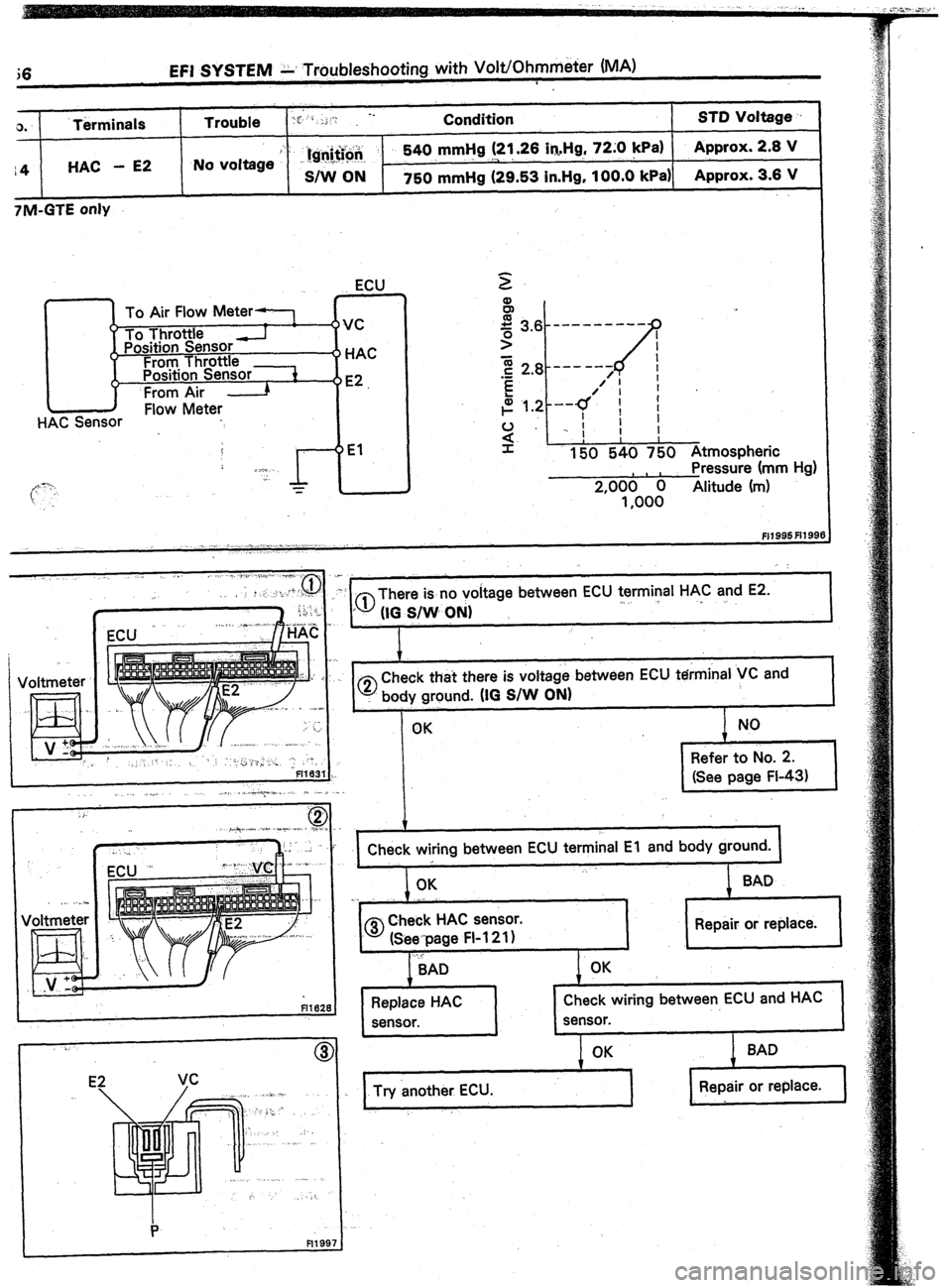

;6 EFI SYSTEM .L Troubleshooting with VoWOhmmeier (MA)

0. Terminals

r4 HAC - E2

7M-GTE only Trouble ‘Z’ ‘f .: ‘I *-

Condition STD Voltage

;> :

1 ‘Ig+i@ 540 mmHg (2l,.26 h.Hg, 72:O !Pa) Approx. 2.8 V

No voltage

S/W ON

750 mmHg (29.53 in.Hg, 100.0 kPa) Approx. 3.8 V

To Air Flow Meter-

Her Flow Meter ECU

1 HAC

bE2.

2,000 0 Alitude (m)

1,000

FI1995Fil99

.,~ .._ .,_

I... ~ _ . . ., , .

,.;_

itage between ECU terminal HAC and E2.

.,, ”

Check that there is voltage between ECU tdrminal VC and

body ground. (IG S/W ON)

,..

.._

Refer to No. 2.

(See page FI-43)

,. . . .

Voltmeter

EL . 1,

.v ‘_

E2 VC

b

FI199

Check wiring between ECU terminal El and body ground.

BAD

.

0 Check HAC sensor.

(See page FI-121) Repair or replace.

4

. ...<,

BAD OK

Replace HAC Check wiring between ECU and HAC

sensor. sensor.

OK BAD

Try another ECU.

I Repair or replace.

Page 92 of 346

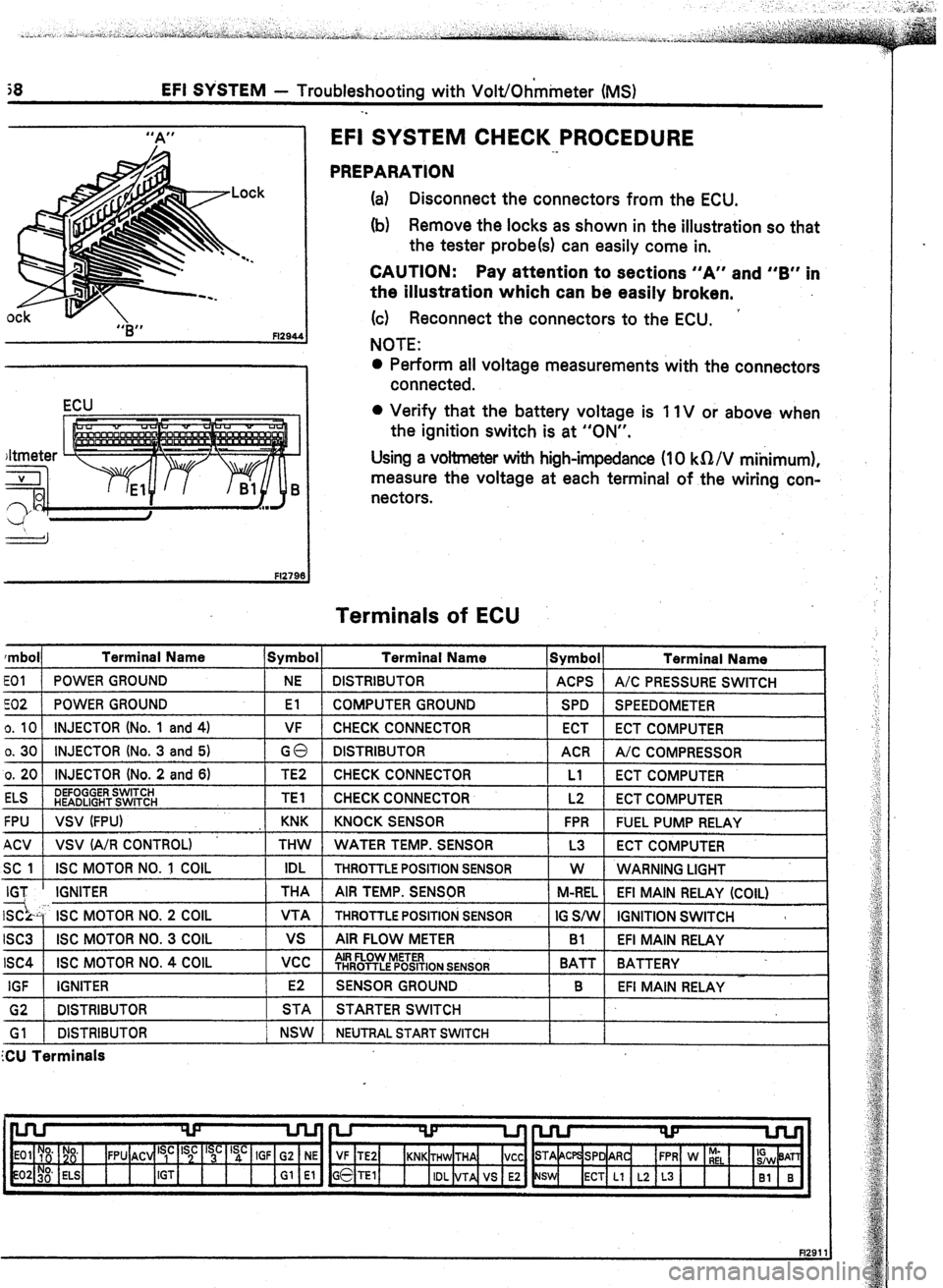

jS EFI SYSTEM - Troubleshooting with Volt/Ohmmeter (MS)

-.

0

“B”

Fl294.

ECU

EFI SYSTEM CHECK PROCEDURE

._

PREPARATION

(a) Disconnect the connectors from the ECU.

(b) Remove the locks as shown in the illustration so that

the tester probe(s) can easily come in.

CAUTION: Pay attention to sections “A” and “B” in

the illustration which can be easily broken,

(c) Reconnect the connectors to the ECU.

’

NOTE:

0 Perform ail voltage measurements with the connectors

connected.

0 Verify that the battery voltage is 1 IV or above when

the ignition switch is at “ON”.

Using a voltmeter with high-impedance (10 kQ/V mihimum),

measure the voltage at each terminal of the wiring con-

nectors.

Terminals of ECU

rmbol Terminal Name Symbol Terminal Name

Symbol Terminal Name

EOI POWER GROUND NE DISTRIBUTOR ACPS A/C PRESSURE SWITCH

co2 POWER GROUND El COMPUTER GROUND SPD SPEEDOMETER

o. 10 INJECTOR (No. 1 and 4) VF CHECK CONNECTOR ECT ECT COMPUTER

o. 30 INJECTOR (No. 3 and 5)

GO DISTRIBUTOR ACR A/C COMPRESSOR

o. 20 INJECTOR (No. 2 and 6) TE2 CHECK CONNECTOR Ll

ECT COMPUTER

ELS DEFOGGER SWITCH

HEADLIGHT SWITCH TEl CHECK CONNECTOR L2

ECT COMPUTER

FPU VSV (FPU) KNK KNOCK SENSOR FPR FUEL PUMP RELAY

ACV VSV (A/R CONTROL) THW WATER TEMP. SENSOR L3 ECT COMPUTER

SC 1 ISC MOTOR NO. 1 COIL IDL

THROTTLE POSITION SENSOR W

WARNING LIGHT

IGT IGNITER THA AIR TEMP. SENSQR

M-REL EFI MAIN RELAY (COIL)

SC- ISC MOTOR NO. 2 COIL VTA THROlTLE POSITION SENSOR IG SiW IGNITION SWITCH 3

ISC3 ISC MOTOR NO. 3 COIL vs AIR FLOW METER Bl EFI MAIN RELAY

ISC4 ISC MOTOR NO. 4 COIL vcc AIR FLOW METER

THROTTLE POSITION SENSOR BATT BATTERY

IGF IGNITER E2

SENSOR GROUND B

EFI MAIN RELAY

G2 1 DISTRIBUTOR 1 STA 1 STARTER SWITCH

Gl 1 DISTRIBUTOR 1 NSW 1 NEUTRALSTARTSWITCH

ZU Terminals

Page 97 of 346

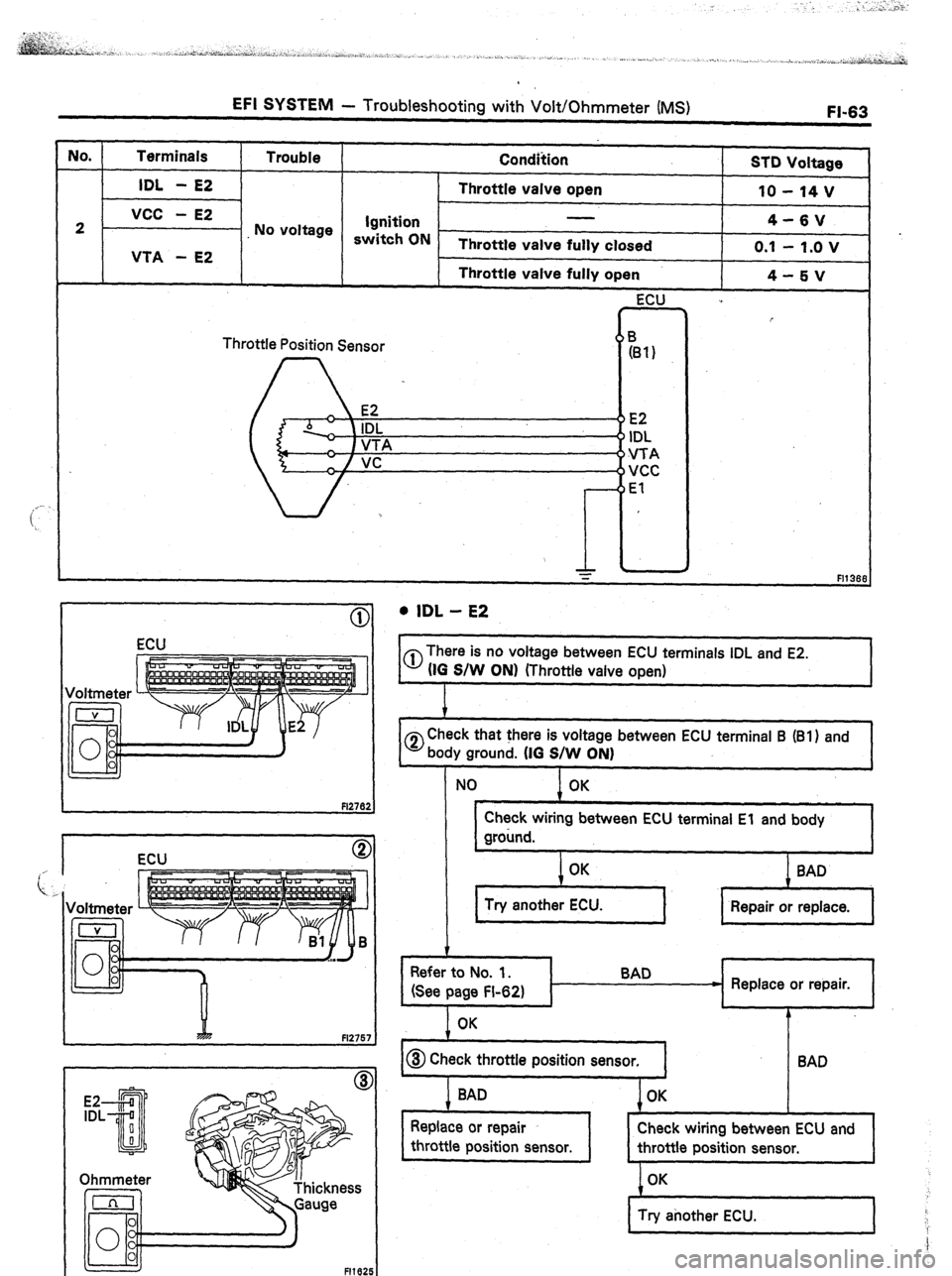

EFI SYSTEM - Troubleshooting with Volt/Ohmmeter (MS)

FI-63

No. 1 Terminals 1 Trouble 1

Condition S-m Vnlttlnq --- ‘-‘-P-~

IDL

- E2 Throttle valve open

10 - 14 v

vcc - E2

2

No voltage Ignition 4-6V

switch ON

VTA - E2 Throttle valve fully closed 0.1 - l.OV

Throttle valve fully open

4-!iv

ECU .s

r

Fl136

I . IDL - E2

ECU

I ECU

I Y ,

F12767

0 There is no voltage between ECU terminals IDL and E2.

(IO S/W ON) (Throttle valve open)

I

1

0 Check that there is voltage between ECU terminal B (Bl) and

body ground.

(IO S/W ON)

NO

OK

, 1

I I Check wiring between ECU terminal El and body

I

1 ground.

OK

Try another ECU. 1

BAD

I Repair or replace.

I i

t

Refer to No. 1. BAD

(See page FI-62) p Replace or repair.

t

OK

, t

I@ Check throttle position sensor, ]

BAD

BAD

OK

*

Replace or repair Check wiring between ECU and

throttle position sensor. throttle position sensor.

1

OK

Try another ECU.

‘!

t

Page 98 of 346

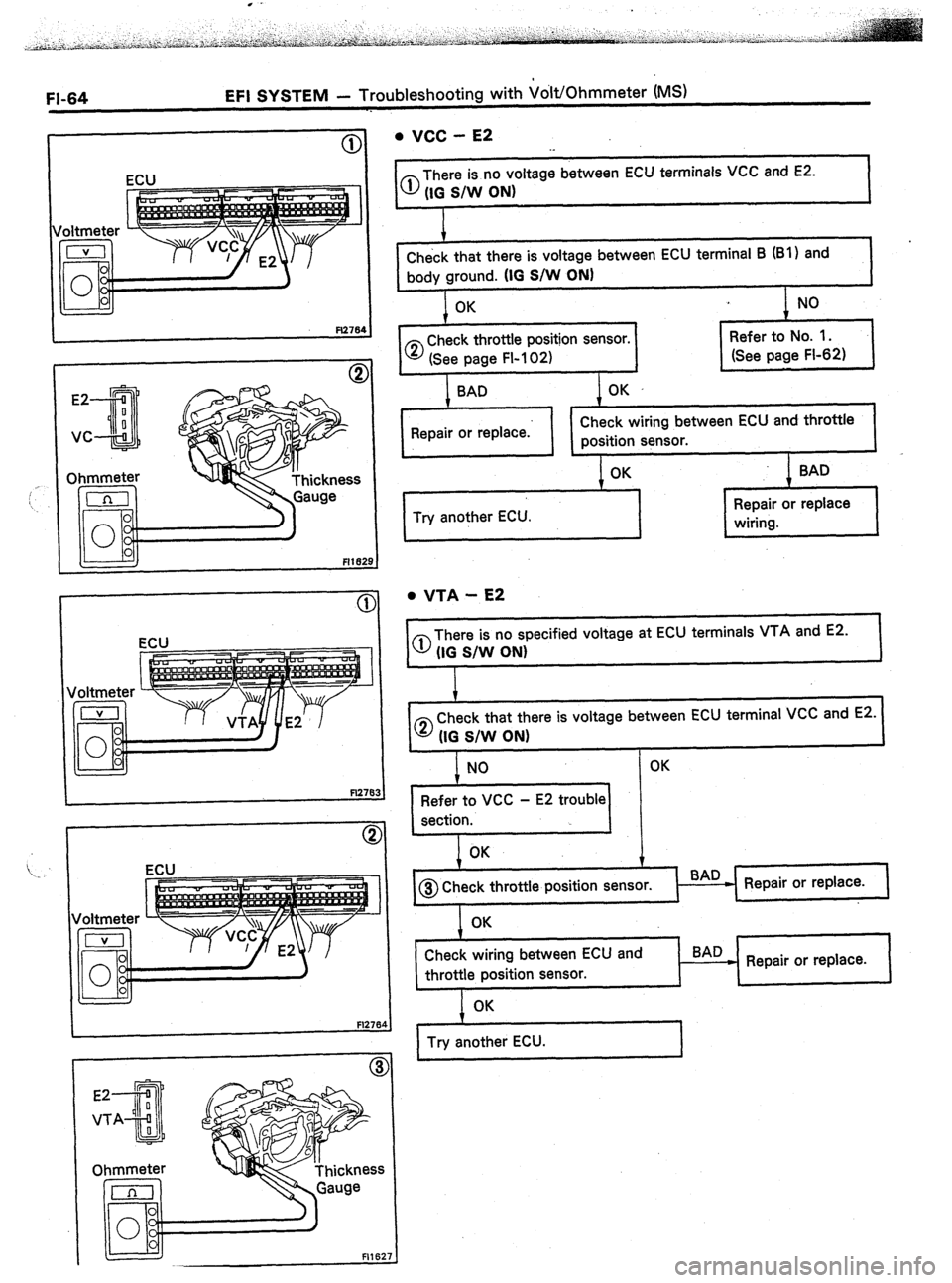

FI-64 EFI SYSTEM - Troubleshooting with Volt/Ohmmeter (MS)

Fl162

. VCC - E2 .

0

There is no voltage between ECU terminals VCC and E2.

(IO S/W ON)

1

I

Check that there is voltage between ECU terminal B (Bl) and

body ground. II0 S/W ON1

OK

7

0 Check throttle position sensor. Refer to No. 1.

(See page FL102)

(See page FL62)

k

I OK

,

1 Repair or replace.‘ / Check wiring between ECU and throttle position sensor.

OK

t I , 1 BAD ,

1 Rwe;ix3;.or replace ]

Try another ECU.

l VTA - E2

I- I

0 There is no specified voltage at ECU terminals VTA and E2.

(IG S/W ON)

I

0 Check that there is voltage between ECU terminal VCC and E2.

(IO S/W ON)

I 1

I OK

I

[@ Check thrc1 BAD 4 Repair or replace. 1

I

1 OK I ‘1 4 Check wiring between ECU and

throttle position sensor.

I

1 OK BAD

- Repair or replace.

1 Try another ECU.

1

I

Page 101 of 346

No. Terminals Trouble Condition STD Voltage

I I I I I

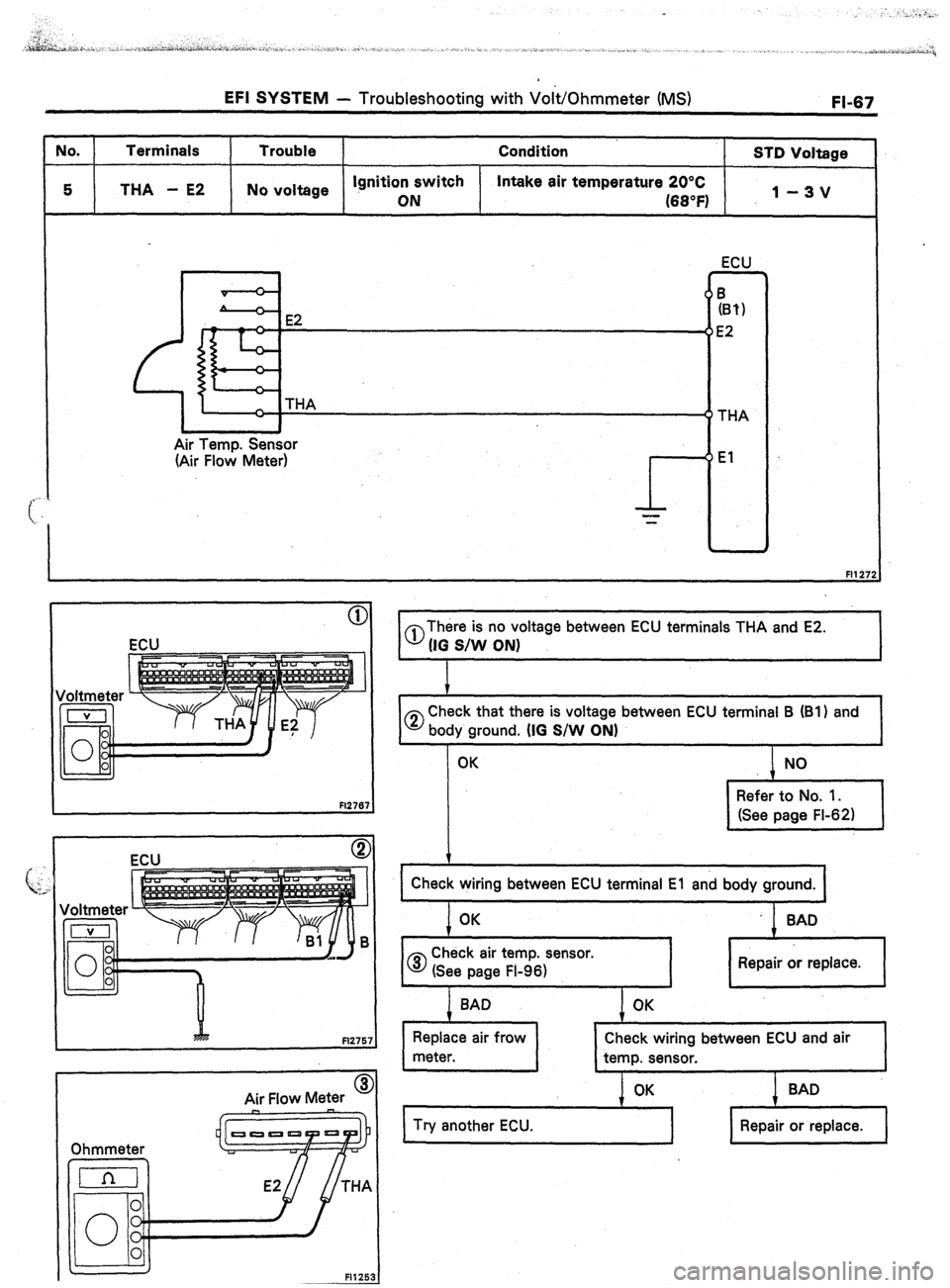

5 THA - E2

I No voltage ON

I Ignition switch Intake air temperature 20°C

(66°F) 1 -3v

0 ”

0 6

L -

,’ E2 (B?)

(5E2

( THA

Air Temp. Sensor

(Air Flow Meter) o El

ECU

fl275'

Air Flow Meter ’

0 There is no voltage between ECU terminals THA and E2.

(IG S/W ON)

I

0 Check that there is voltage between ECU terminal B (Bl 1 and

body ground. (IG S/W ON)

OK NO

Refer to No. 1.

(See page FI-62)

1

Check wiring between ECU terminal El and body ground.

OK

0 Check air temp. sensor.

(See page FI-96) Repair or replace.

c

BAD

OK

Replace air frow Check wiring between ECU and air

meter. temp. sensor.

OK BAD

Try another ECU.

I 1 Repair or replace. 1

Page 102 of 346

EFI SYSTEM

- Troubleshooting with Voltkhmmeter (MS)

-.

No. 1

Terminals

I Trouble

I Condition ._

I STD Voltage

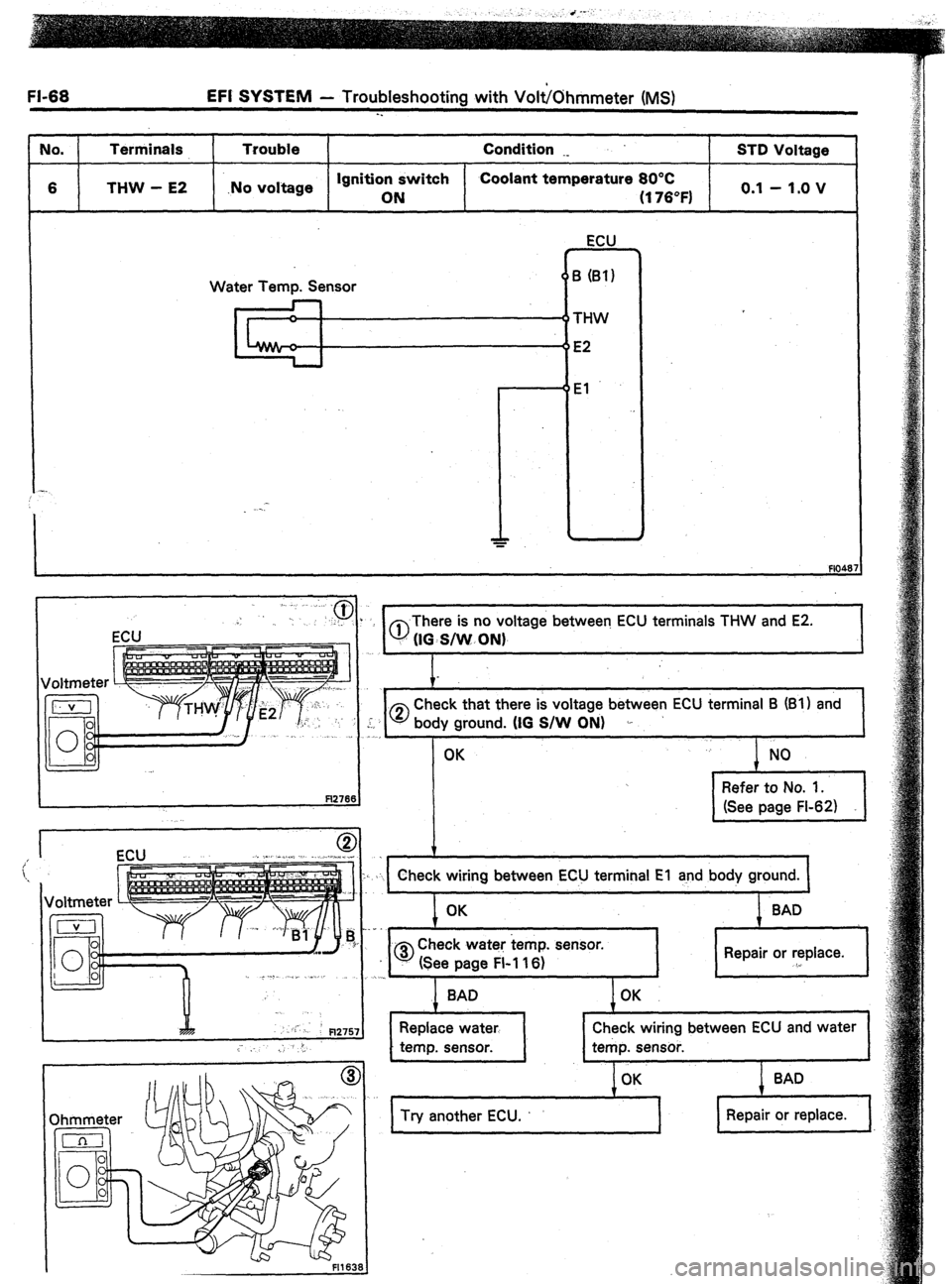

6 THW - E2 .No voltage Ignition switch Coolant temperature 80°C

ON (, 760F) 0.1 - 1.0 v

Water Temp. Sensor

. ECU

5 031)

THW

E2

:1

ECU I terminals THW and E2.

I

0 There is no voltage between ECU

(IG S/W ON)

I-

:.

0 Check that there is voltage between ECU terminal B (61) and

body ground. (IG S/W ON) -

1

OK NO

I

I 8 1

I

Refer to No. 1.

(See page FL62)

I

I I . -

I

Check wiring between ECU terminal El and body ground.

I BAD

Check water temp. sensor.

Repair or replace.

BAD

Replace water

temp. sensor. OK

Check wiring between ECU and water

I temp. sensor.

OK BAD

Try another ECU. 1 Repair or replace. 1

Page 121 of 346

EFI SYSTEM - Fuel System

-.

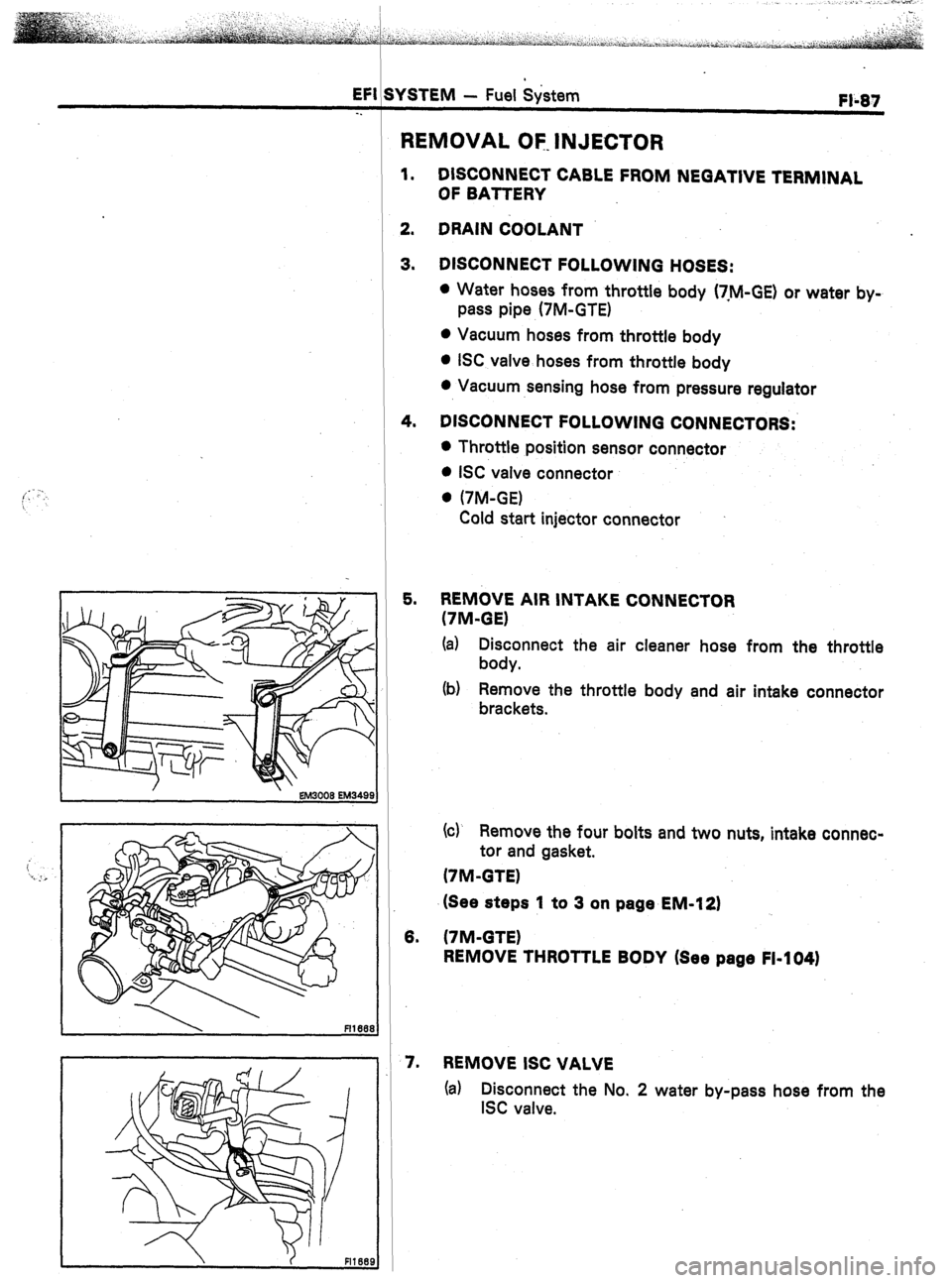

REMOVAL OF. INJECTOR

FI-87

1.

2.

3.

I A k DISCONNECT FOLLOWING CONNECTORS:

5.

8.

7. DISCONNECT CABLE FROM NEGATIVE TERMINAL

OF BATTERY

DRAIN COOLANT

DISCONNECT FOLLOWING HOSES:

l Water hoses from throttle body (7-M-GE) or water by-

pass pipe (‘IM-GTE)

0 Vacuum hoses from throttle body

0 ISC valve hoses from throttle body

0 Vacuum sensing hose from pressure regulator

0 Throttle position sensor connector

0 ISC valve connector

0 (‘IM-GE)

Cold start injector connector

REMOVE AIR INTAKE CONNECTOR

(7M-GE)

(a) Disconnect the air cleaner hose from the throttle

body.

(b) Remove the throttle body and air intake connector

brackets.

(c) Remove the four bolts and two nuts, intake connec-

tor and gasket.

(7M-GTE)

(See steps 1 to 3 on page EM-121

(‘IM-GTE)

REMOVE THROTTLE BODY (See page Fi-104)

REMOVE ISC VALVE

(a) Disconnect the No. 2 water by-pass hose from the

ISC valve.

Page 136 of 346

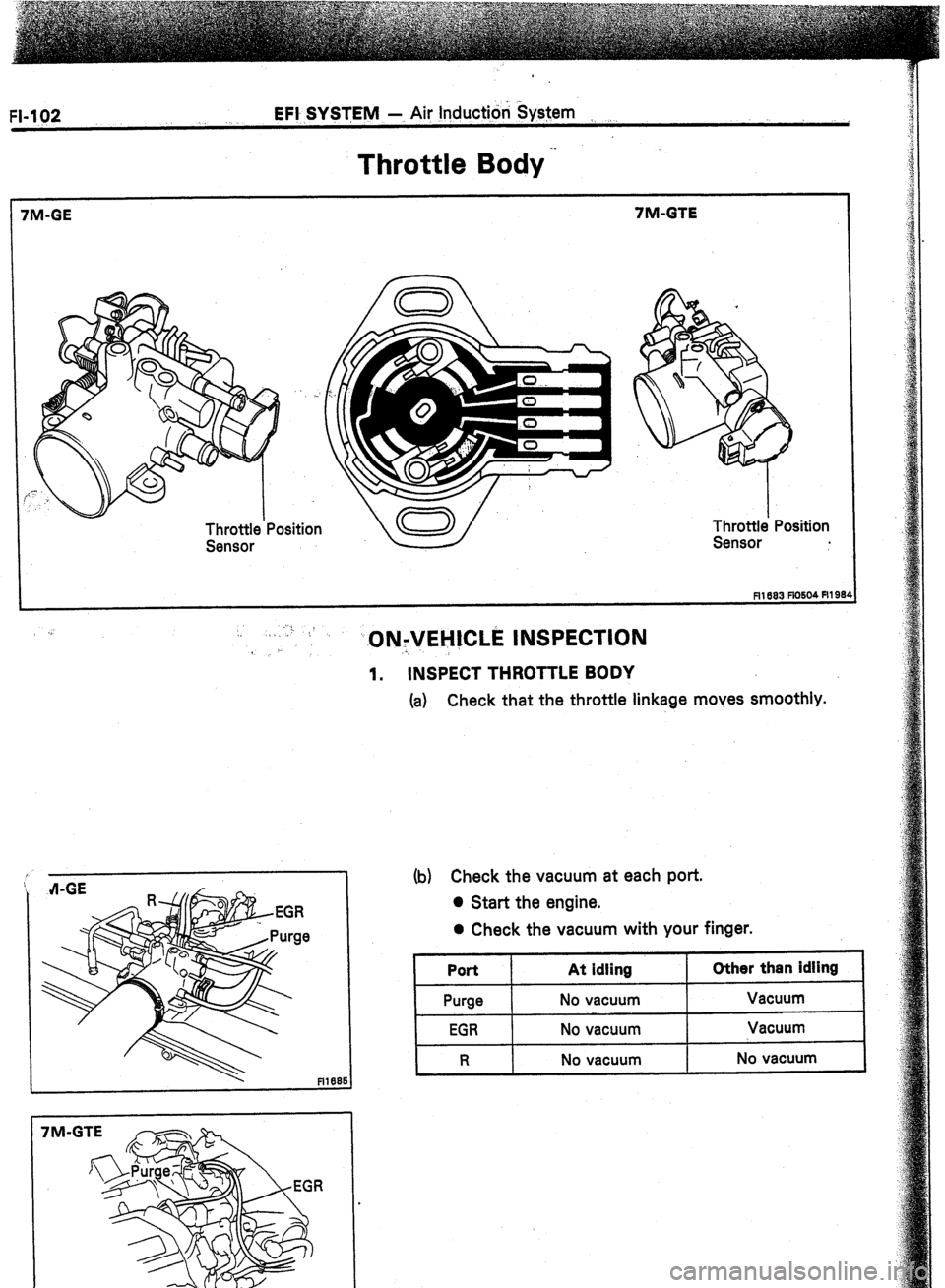

EFI ,SY$TEM - Air Inducti& System

Throttle Body --

‘M-GE 7M-GTE

Throttle’Position

Sensor Throttle’ Position

fl1693 Flo504nl9f

.,.

,. ,F .,’

1 .ON:VEHtCLE INSPECTION

1. INSPECT THROTTLE BODY

(a) Check that the throttle linkage moves smoothly.

(b) Check the vacuum at each port.

0 Start the engine.

0 Check the vacuum with your finger.

Port

Purge

EGR

R

At idling

No vacuum

No vacuum

No vacuum

Other than idling

Vacuum

Vacuum

No vacuum

Page 137 of 346

EFI SYSTEM - Air Inductioi System

PI-1 03

-

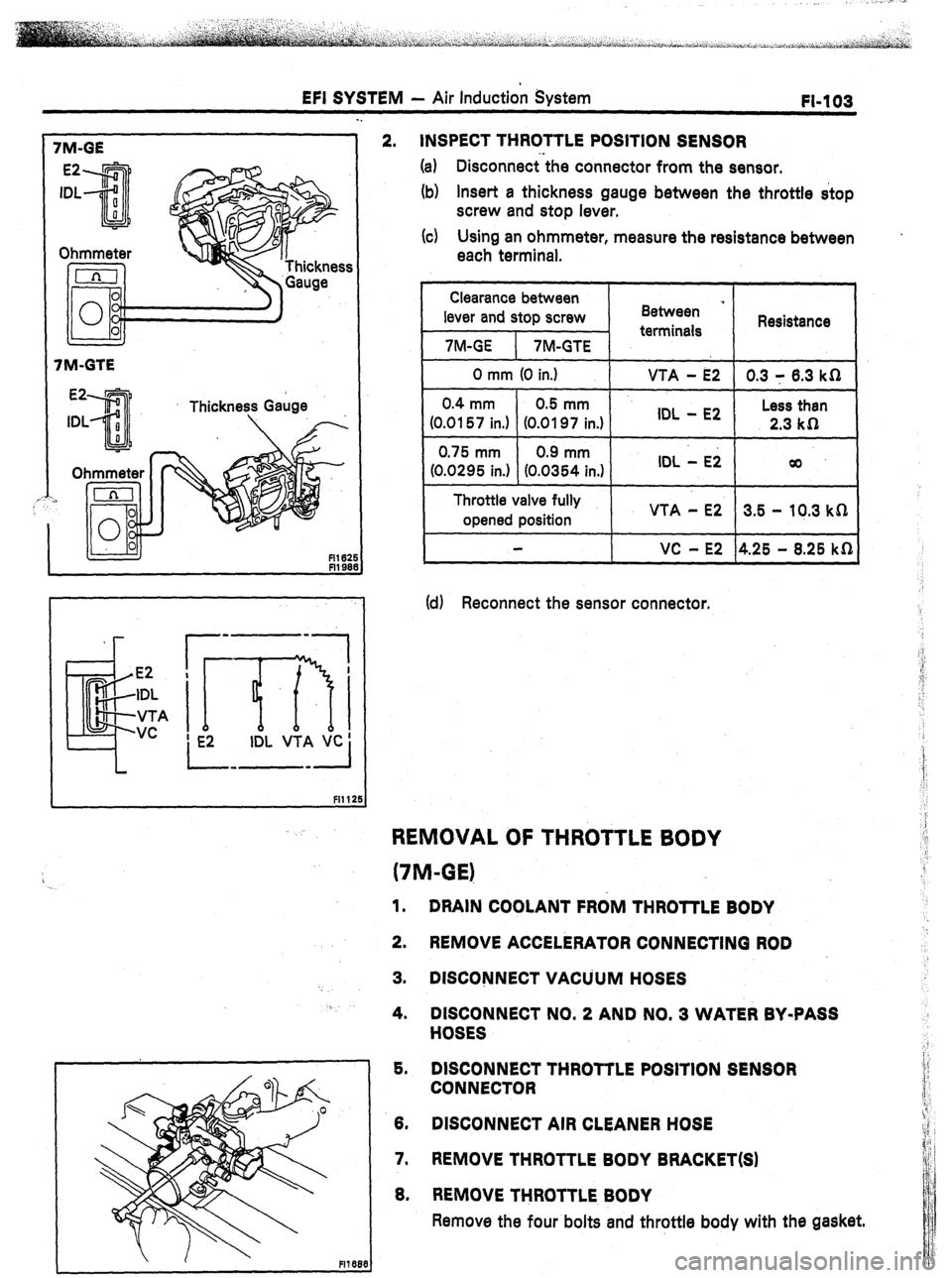

1 7M-GE

I 7M-GTE

d

c q-rEA

vc

1

I I

in-7.h

IDL VTA VC ’

s --I

2. INSPECT THROTTLE POSITION SENSOR

(a) Disconnectthe connector from the sensor.

(b) Insert a thickness gauge between the throttle stop

screw and stop lever.

(c) Using an ohmmeter, measure the resistance between

each terminal.

(d) Reconnect the sensor connector.

./ !’

REMOVAL OF THROTTLE BODY ‘.

/ (7M-GE)

1. DRAIN COOLANT FRdM THROTTLE BODY

2. REMOVE ACCELERATOR CONNECTING ROD

3. DISCONNECT VACUUM HOSES

4.

DISCONNECT NO. 2 AND NO. 3 WATER BY-PASS

HOSES

. 1 5. DISCONNECT THROTTLE POSITION SEI

7.

REMOVE THROTTLE BODY BRACKET(S)

6. REMOVE THROTTLE BODY

Remove the four bolts and throttle body with the gasket,

Page 138 of 346

Fl-104 EFI SYSTEM - Air Induction Svstem

;i7M-GTE)

1.

2.

3. thAIhi COOLANT -kROM THROTTLE BODY

DISCONNECT ACCELERATOR CONNECTING ROD

REMOVE AIR INTAKE CONNECTOR

(See steps 1 to 3 on page EM-121

4.

5.

/A-.( /w /

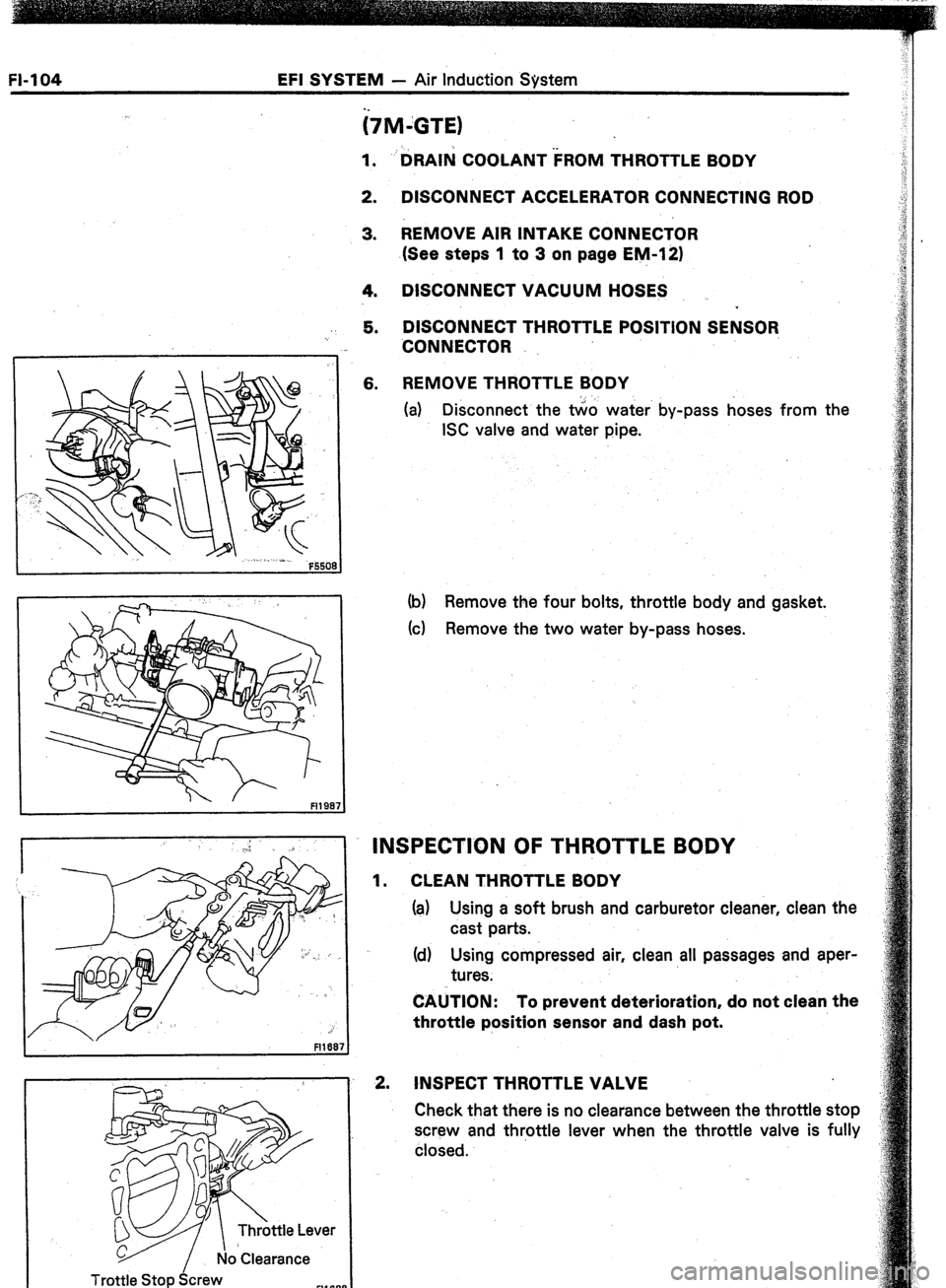

Trottle Stop Screw

DISCONNECT VACUUM HOSES

*

DISCONNECT THROTTLE POSITION SENSOR

CONNECTOR

REMOVE THROTTLE BODY

(a) Disconnect the tko water by-pass hoses from the

ISC valve and water pipe.

(b) Remove the four bolts, throttle body and gasket.

(cl Remove the two water by-pass hoses.

INSPECTION OF THROTTLE BODY

1. CLEAN THROTTLE BODY

(a) Using a soft brush and carburetor cleaner, clean the

cast parts.

(d) Using compressed air, clean all passages and aper-

tures.

CAUTION: To prevent deterioration, do not clean the

throttle position sensor and dash pot.

2. INSPECT THROTTLE VALVE

Check that there is no clearance between the throttle stop

screw and throttle lever when the throttle valve is fully

closed.