sensor TOYOTA CELICA 1987 Service Service Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 1987, Model line: CELICA, Model: TOYOTA CELICA 1987Pages: 346, PDF Size: 35.13 MB

Page 139 of 346

,_ ,.A< ,..,.

EFI SYSTEM - Air Induction System

FI-105

FI188

Ft162!

FHE

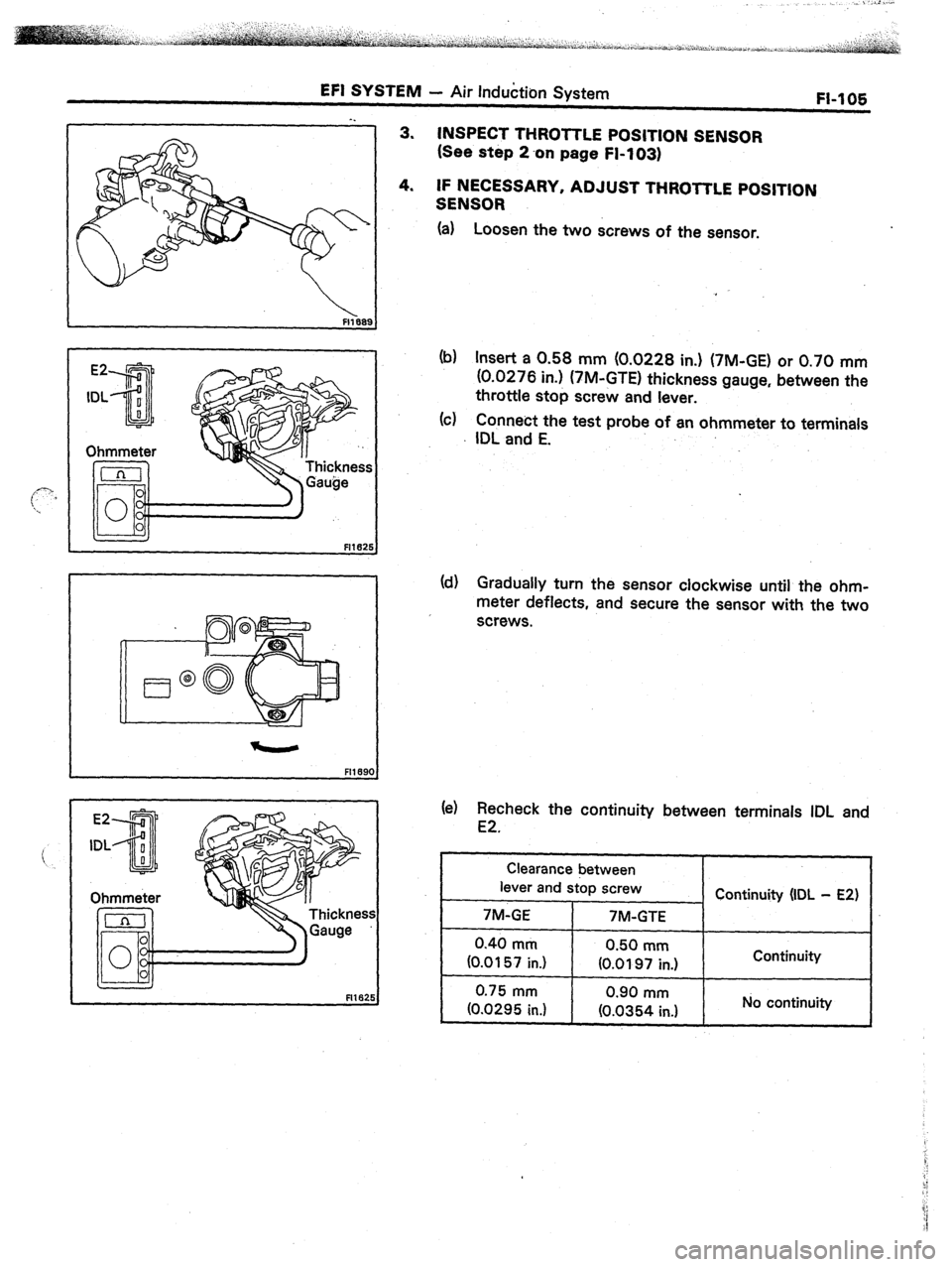

3. INSPECT THROTTLE POSITION SENSOR

(See step 2 -on page Fl-103)

4. IF NECESSARY, ADJUST THROTTLE POSITION

SENSOR

(a) Loosen the two screws of the sensor.

fll6i

(b) Insert a 0.58 mm (0.0228 in.) (7M-GE) or 0.70 mm

(0.0276 in.) (XVI-GTE) thickness gauge, between the

throttle stop screw and lever.

(c) Connect the test probe of an ohmmeter to terminals

IDL and E.

(dd) Gradually turn the sensor clockwise until the ohm-

meter deflects, and secure the sensor with the two

screws.

(e) Recheck the continuity between terminals IDL and

E2.

I Clearance between

I

I lever and stop screw

I Continuity (IDL - E2)

I 7M-GE

! 7M-GTE

I

0.40 mm

I 0.50 mm

(0.0157 in.) (0.0197 in.) Continuity

0.75 mm 0.90 mm

(0.0295 in.1 lo.0354 in.) No continuity

Page 140 of 346

FI-106 EFI SYSTEM - Air Induction S&m

-.

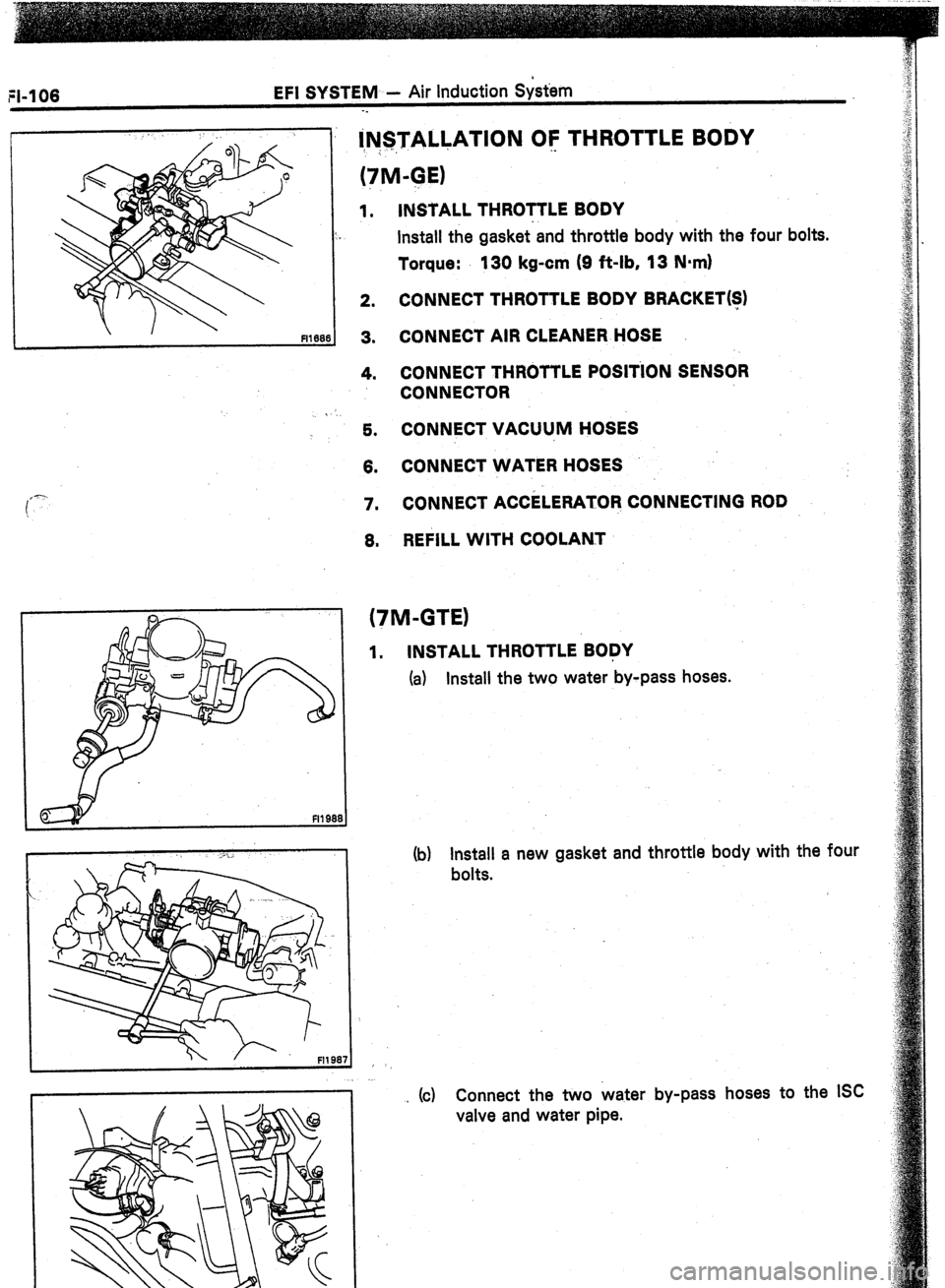

@ls,TAL&ATION OF THROTTLE BODY

(?M-QE)

I FIlW

I-

/

1.

2.

3.

4.

6.

6.

7.

6. INSTALL THROTTLE BODY

Install the gasket-and throttle body with the four bolts.

Torque: 130 kg-cm (9 ft-lb, 13 Narn)

CONNECT THROTTLE BODY BRACKET@

CONNECT AIR CLEANER HOSE

CONNECT THROTTLE POSITiON SENSOR

CONNECTOR

CONNECT VACUUM HOSES

CONNECT WATER HOSES

CONNECT ACCELERATOR CONNECTING ROD

REFILL WITH COOLANT

(‘/M-GTE)

1. INSTALL THROTTLE BOPY

(a) Install the two water by-pass hoses.

(b) Install a new gasket and throttle body with the four

bolts.

(c) Connect the two water by-pass hoses to the ISC

valve and water pipe.

Page 141 of 346

EFI SYSTEM - Air Induction System

FI-107

. .

2. CONNECT THROTTLE POSITION SENSOR

CONNiXTOR .-

3. CONNECT VACUUM HOSES

4. INSTALL AiR INTAKE CONNECTOR

:

(See steps 13 to 15 on page EM-141

5. INSTALL ACCELERATOR CONNECTING ROD

6. REFILL WITH COOLANT

Page 150 of 346

FL1 16 EFI SYSTEM - Electronic Con’trol System

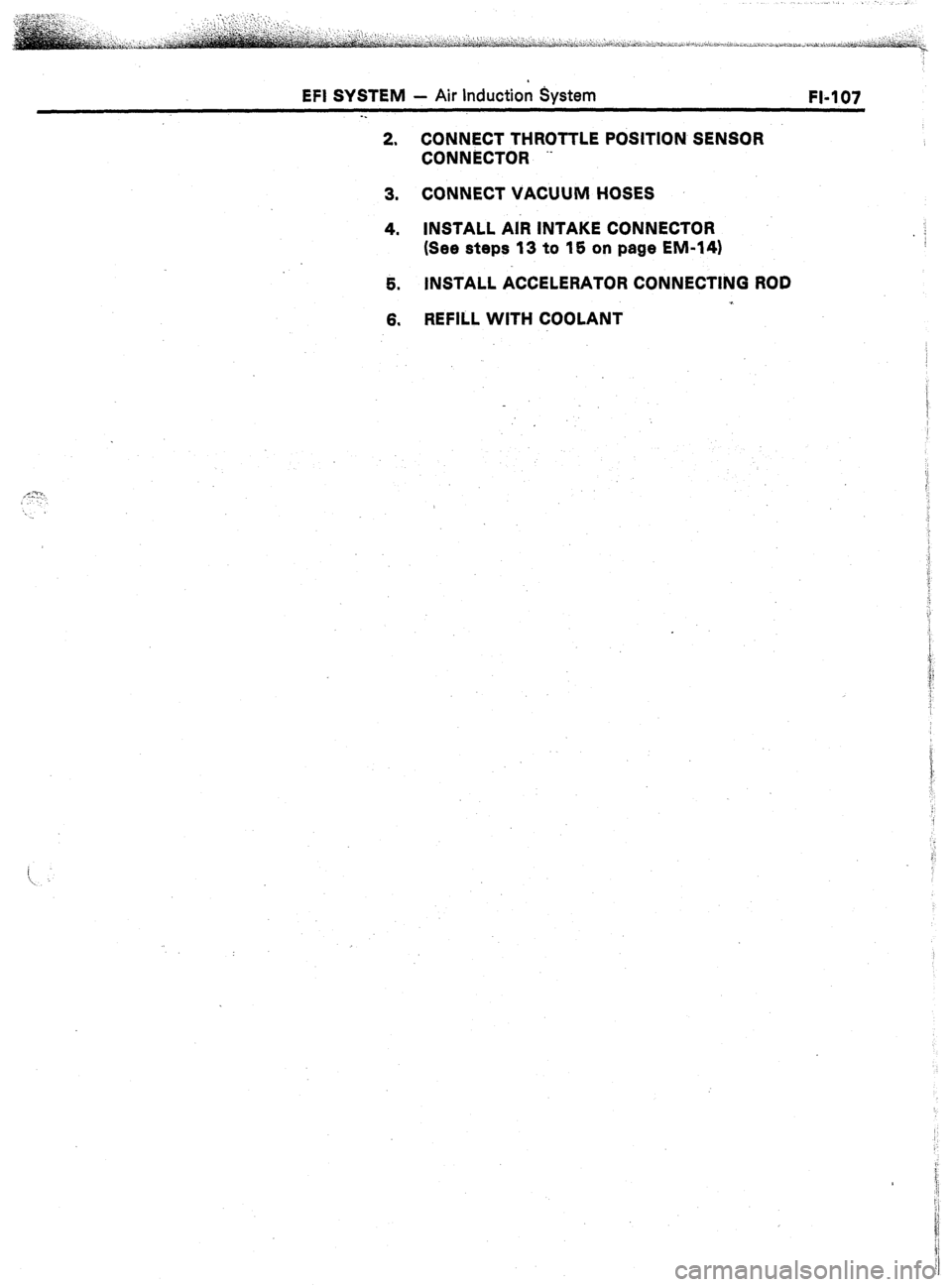

Water Temperature Sensor

._

WATER TEMP. SENSOR

I Thermistor

, I I I I

I -20 0 20 40 60 80 100 120

(-4) (32) (68)(104)(140)1176)(212) (248)

TEMPERATURE “C IoF)

Fl0516FiO7C

INSPECTION OF WATER TEMPERATURE

SENSOR

INSPECT RESISTANCE OF WATER TEMPERATURE

SENSOR

Using an ohmmeter, measure the resistance between both

terminals.

Resistance: Refer to chart.

If the.resistance is not as specified, replace the water tem-

perature sensor.

Page 153 of 346

EFI SYSTEM - Electronic Control System

Fi-119

-.

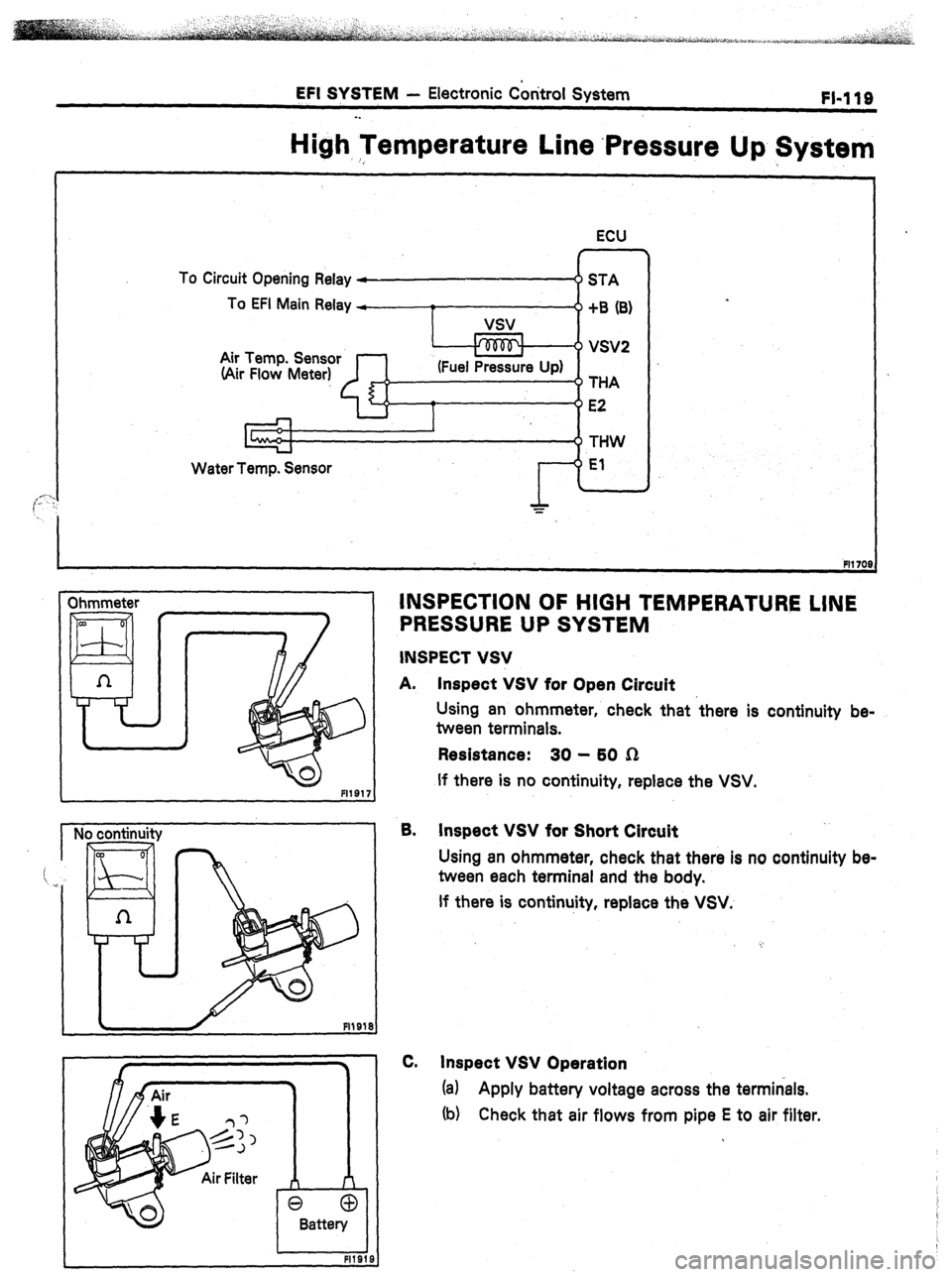

High Temperature Line .Pressure Up System

To Circuit Opening Relay

4-r STA I

Air Temp. Sensor (Air Flow Meter)

VSVP

-f-HA

E2

THW

Water Temp. Sensor

Ohmmeter INSPECTION OF HIGH TEMPERATURE LINE

PRESSURE UP SYSTEM

I Fl1917

INSPECT VSV

A. Inspect VSV for Open Circuit

Using an ohmmeter, check that there is continuity be-

tween terminals.

Resistance: 30 - 60 n

If there is no continuity, replace the VSV.

1 B. Inspect VSV for Short Circuit

Using an ohmmeter, check that there is no continuity be-

tween each terminal and the body.

If there is continuity, replace the VSV.

-

I J FllSll

C. Inspect VSV Operation

(a) Apply battery voltage across the terminals.

(b) Check that air flows from pipe E to air filter.

Page 155 of 346

EFI SYSTEM - Electronic Control System

FI-121

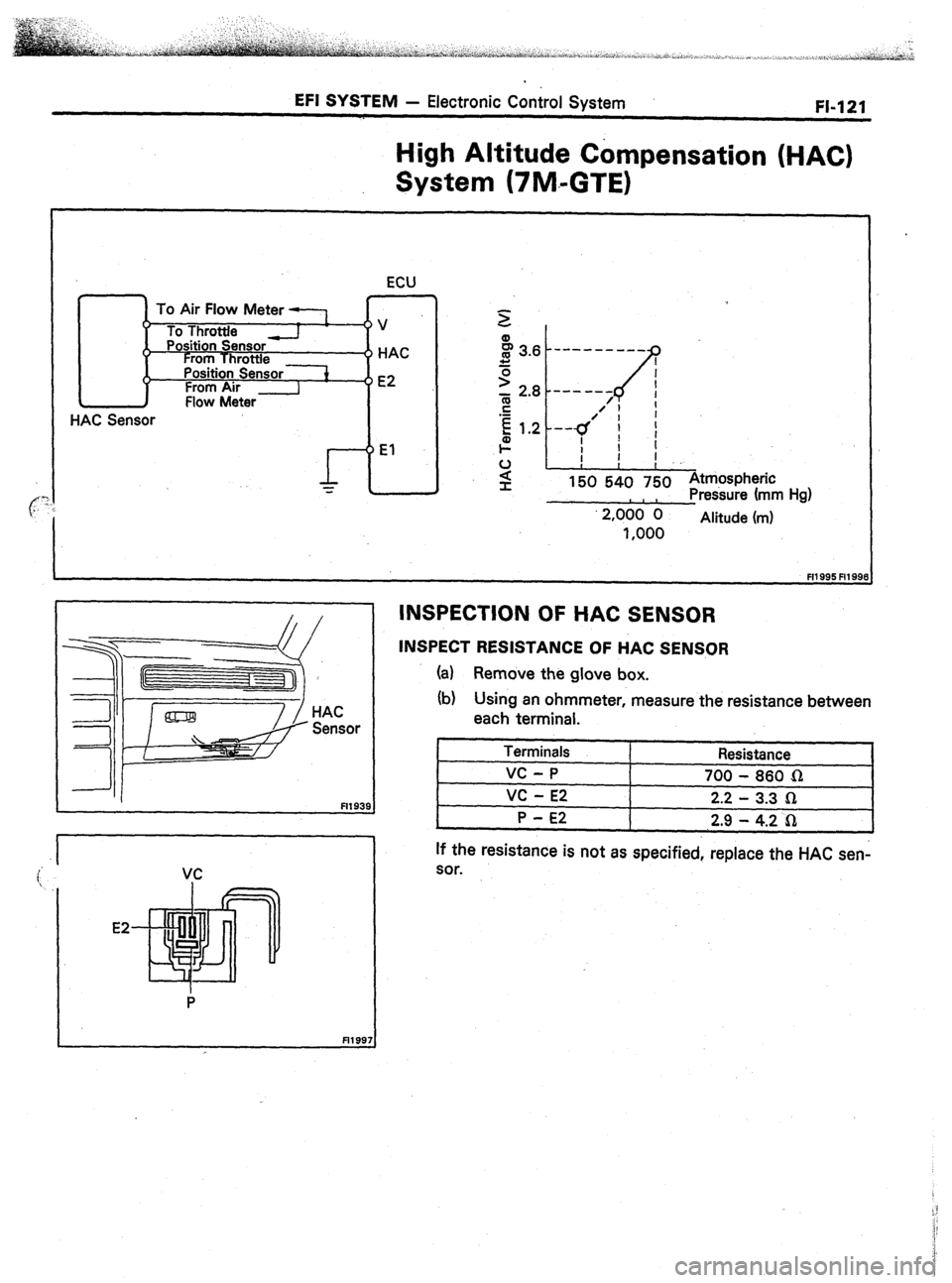

High Altitude Compensation (HAC)

System (7M.mGTE)

HAC Sensor ECU

Air Flow Meter 7

ov

I -._.. ,,nsor

From Throttle o HAC

on Sensor

t

Ai+ I o E2

) El

z

al

mnn I

T J.o -- ---- --_

Y r If

I /, / 1 INSPECTION OF HAC SENSOR

P

n199 zl

INSPECT RESISTANCE OF HAC SENSOR

(a) Remove the glove box.

(b) Using an ohmmeter, measure the resistance between

each terminal.

Terminals

vc - P

VC - E2

P - E2 Resistance

700 - 860 42

2.2 - 3.3 n

2.9 - 4.2 Q

, I

1

If the resistance is not as specified, replace the HAC sen-

sor.

Page 156 of 346

22 EFI &STEM - Electronic Control S&m

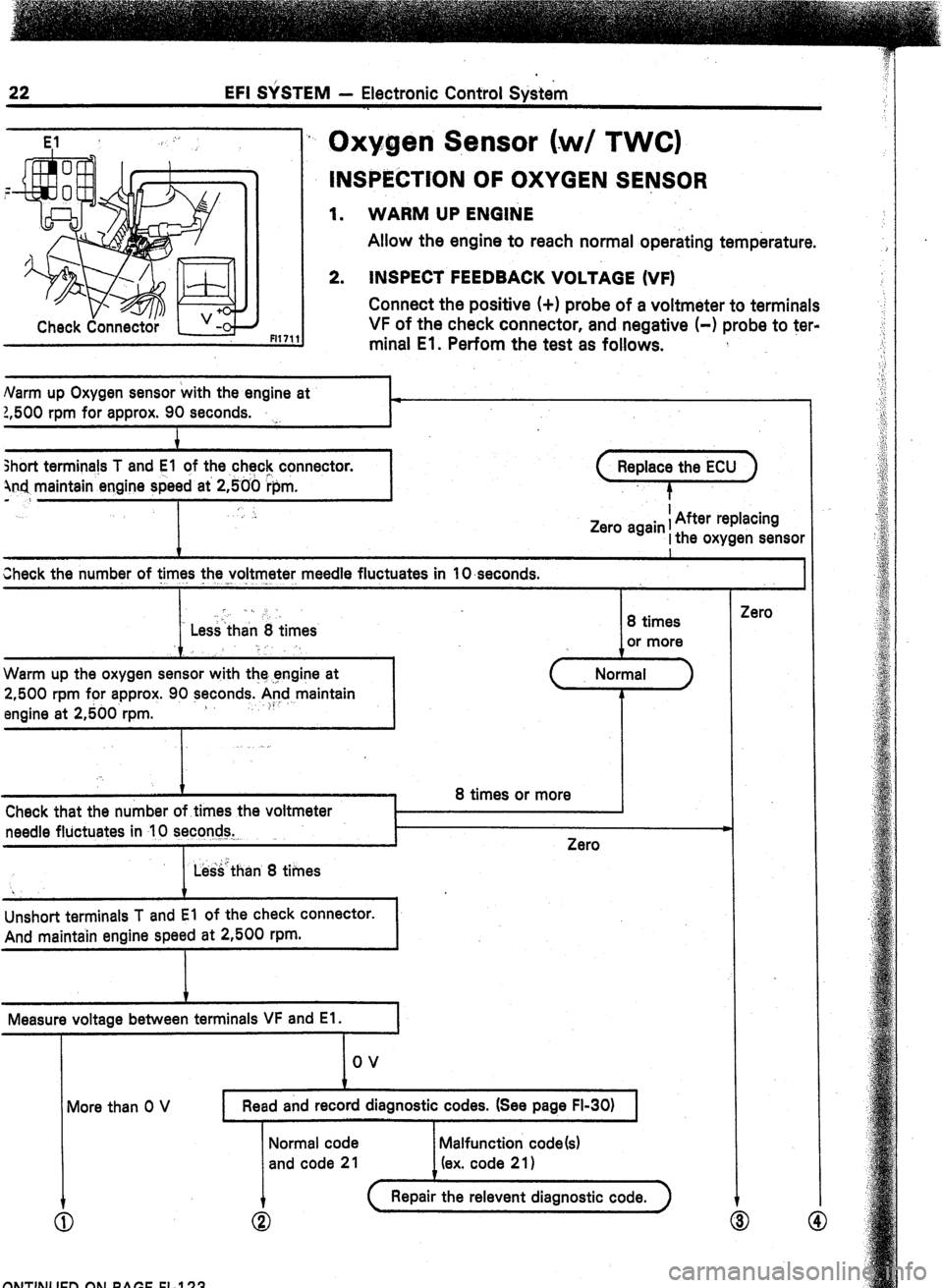

El 7 Oxygen S,ensor (-WI TWC)

INSPECTrON OF OXYGEN SENSOR

1. WARM UP ENGINE

Allow the engine to reach normal operating temperature.

2. INSPECT FEEDBACK VOLTiGE (VFI

Connect the positive (+I probe of a voltmeter to terminals

n1711 VF of the check connector, and negative (-1 probe to ter-

minal El. Perfom the test as follows.

Narm up Oxygen sensor ‘with the engine at

!,500 rpm for approx. 90 seconds.

I

1

short termina!s T and El of the check connector.

4nd maintain engine speed at 2,560 ‘i-pm.

- / (,,,;,,.,,,,

i .

Check the number of times the voltmeter meedle fluctuates in 1 Oseconds. Zero again 1 After replacing

I the oxygen sensor

i ,. ., ;

: . .

Less than 8 times

t. ., .,

Warm up the oxygen sensor with the engine at

,,I

2,500 rpm for approx. 90 seconds. And maintain

engine at 2,500 rpm.

’

I

c

Check that the number of times the voltmeter

needle fluctuates in 10 seconds,

;- 8 times or more

Zero

Leis’~than 8 times

c

Unshort terminals T and El of the check connector.

And maintain engine speed at 2,500 rpm.

Measure voltaae between terminals VF and El.

I

More than 0 V t

Read and record diagnostic codes. (See page FI-30)

I I

Normal code

and code 21 Malfunction code(s)

(ex. code 21)

Repair the relevent diagnostic code.

ONTINUED ON PAGE FI-123 !ero

Page 157 of 346

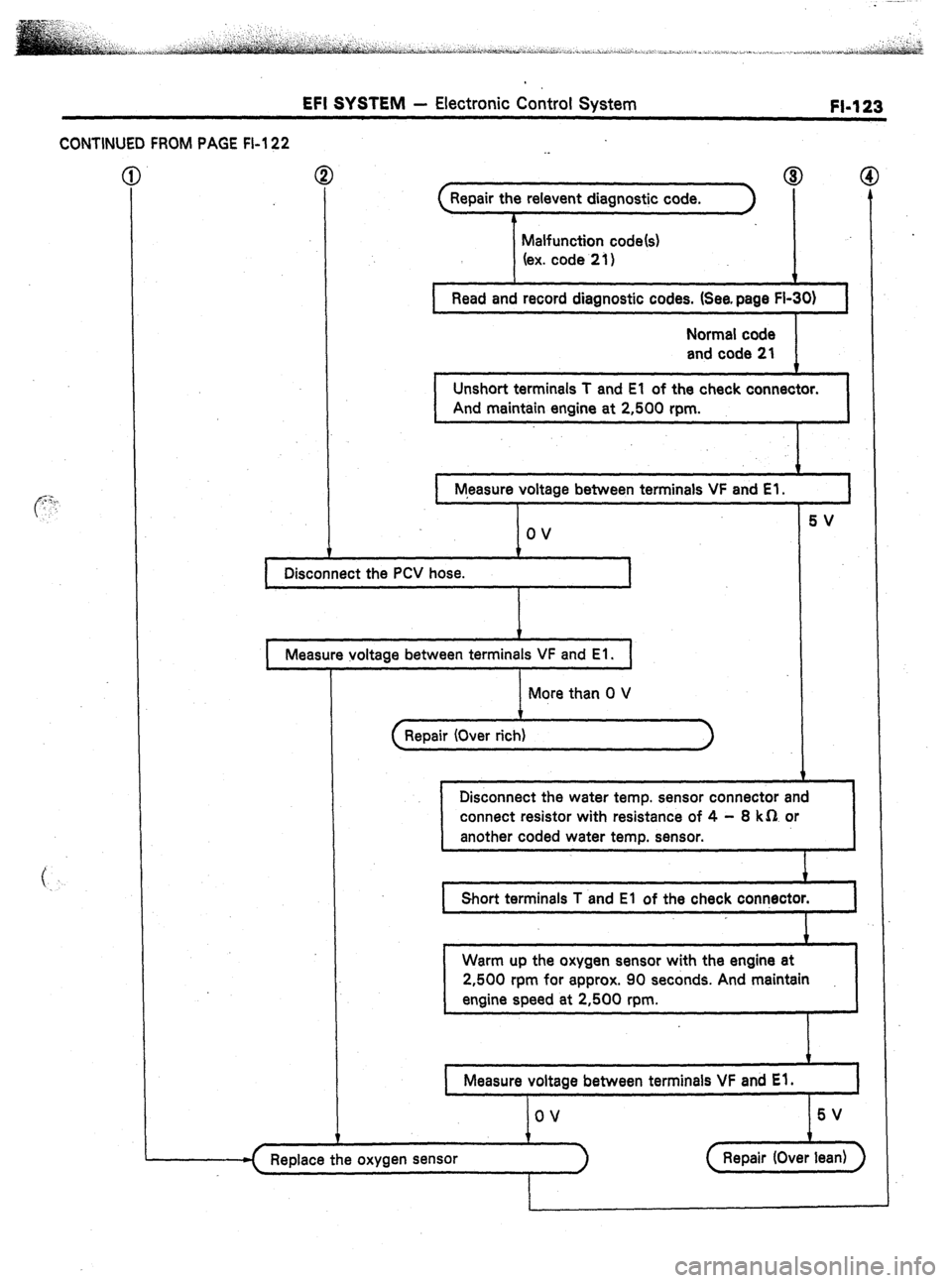

EFI SYSTEM - Electronic Control System FI-123

CONTINUED FROM PAGE FI-122

. .

t

8 (

epair the relevent diagnostic code.

Malfunction code(s)

(ex. code 21)

Read and record diagnostic codes. (See.page FL30)

Normal code

and code 21

t

Unshort terminals T and El of the check connector.

And maintain engine at 2,500 rpm.

I

I

M,easure voltage between terminals VF and El.

ov

t

1

Disconnect the PCV hose.

.

1 Measure voltage between terminals VF and El. 1

t

Replace the oxygen sensor Repair (Over lean) 5V

Disconnect the water temp. sensor connector and

connect resistor with resistance of 4 - 8 kS1 or

another coded water temp. sensor.

1

Short terminals T and El of the check connector.

I

I

Warm up the oxygen sensor with the engine at

I

1 2,500 rpm for approx. 90 seconds. And maintain 1

engine speed at 2,500 rpm.

Measure voltage between terminals VF and El.

I

I 5V

Page 158 of 346

FI-124 EFI SYSTEM - Electronic Control System

-.

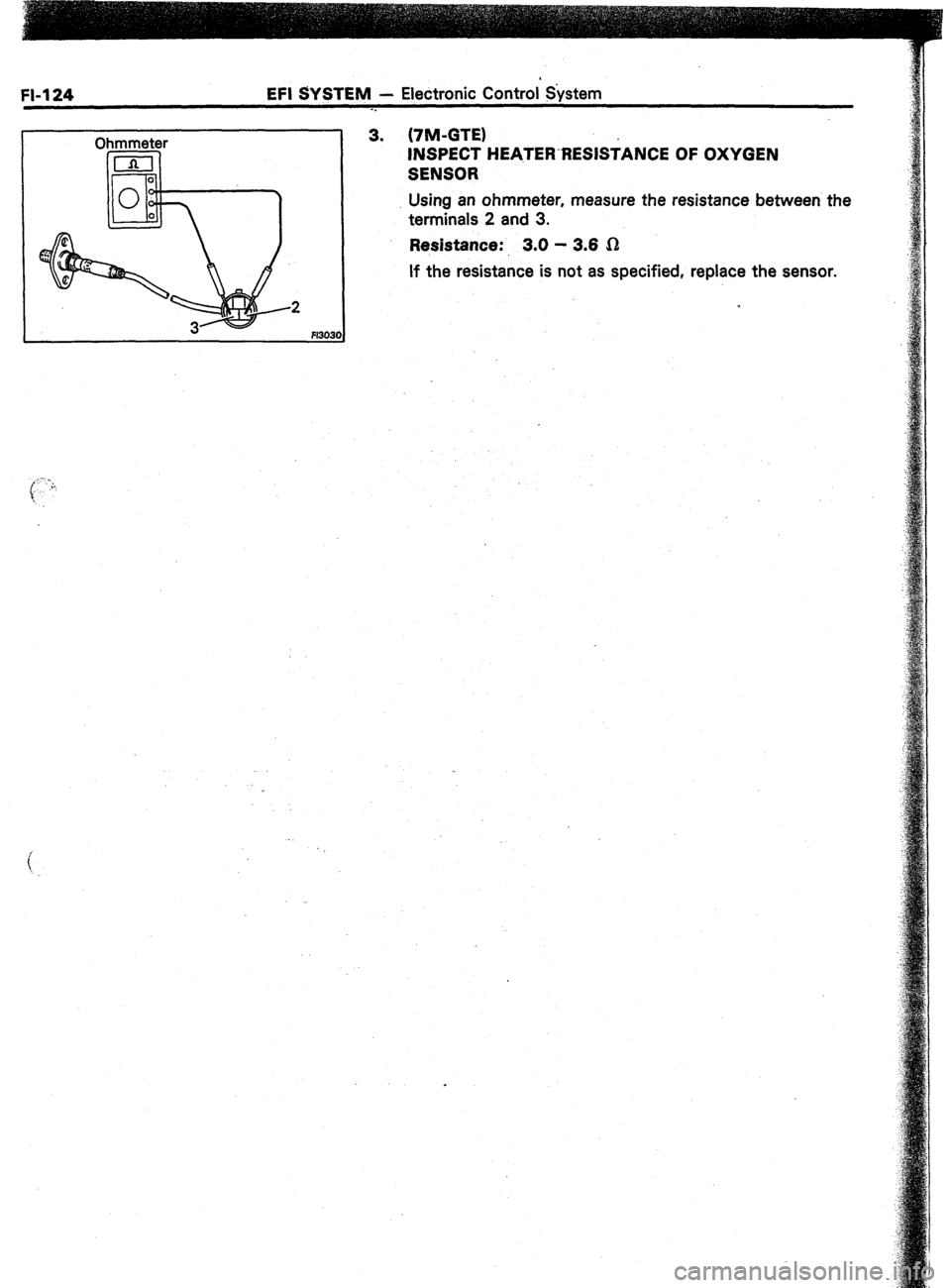

Ohmmeter 3. (‘IM-GTE)

INSPECT HEATERAESISiANCE OF OXYGEN

SENSOR

Using an ohmmeter, measure the resistance between the

terminals 2 and 3.

R8SiStaflC8:, 3.0 - 3.6 n

If the resistance is not as specified, replace the sensor.

Page 162 of 346

Fl-128 EFI SYSTEM - Electronic Contpl SyStem

c

’ FlO54

Tachometer Fl114:

Fuel Cut RPM--

;INSPECTION OF FUEL CUT RPM

I.

2. WARM UP ENGINE

Allow the engine to reach normal operating temperature.

INSPECT FUEL CUT RPM

(a) Disconnect the connector from the throttle position

sensor.

(b) Short circuit terminals IDL and El on the wire con-

nector side.

(c) Gradually raise the engine rpm and check that there

is fluctuation the fuel cut and fuel return points.

NOTE: The vehicle should be stopped.

Fuel cut rpm:

1,800 rpm

Fuel return rpm: 1,200 rpm