TOYOTA COROLLA HATCHBACK 2022 Owners Manual (in English)

Manufacturer: TOYOTA, Model Year: 2022, Model line: COROLLA HATCHBACK, Model: TOYOTA COROLLA HATCHBACK 2022Pages: 758, PDF Size: 155.26 MB

Page 531 of 758

529

8

8-2. Steps to take in an emergency

When trouble arises

11 Connect the power plug to the

power outlet socket. ( P.451)

12 Check the specified tire inflation

pressure.

Tire inflation pressure is specified on the label as shown. ( P.573)

13Start the vehicle's engine.

14 To inject the sealant and inflate

the tire, turn the compressor

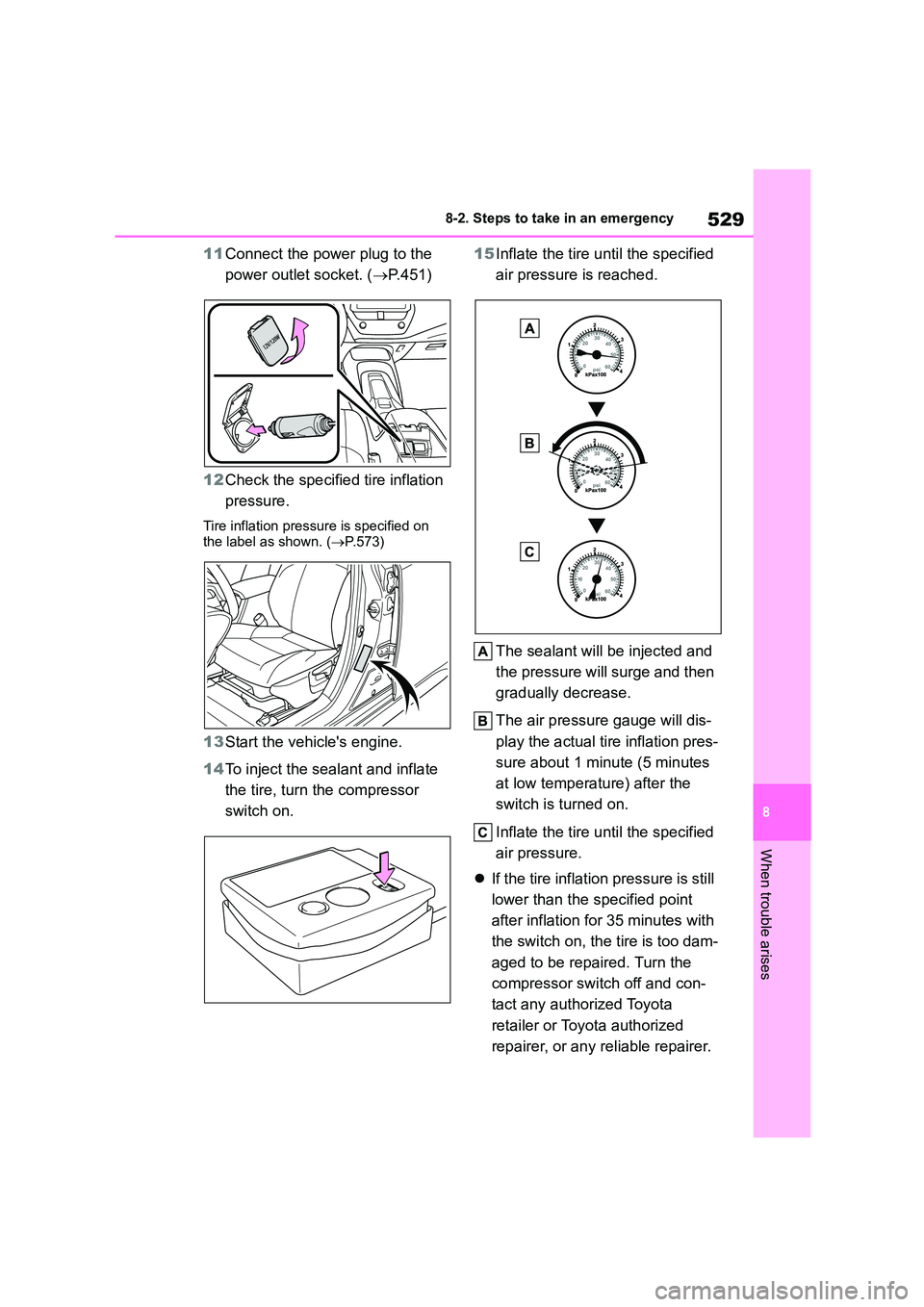

switch on.

15 Inflate the tire until the specified

air pressure is reached.

The sealant will be injected and

the pressure will surge and then

gradually decrease.

The air pressure gauge will dis-

play the actual tire inflation pres-

sure about 1 minute (5 minutes

at low temperature) after the

switch is turned on.

Inflate the tire until the specified

air pressure.

If the tire inflation pressure is still

lower than the specified point

after inflation for 35 minutes with

the switch on, the tire is too dam-

aged to be repaired. Turn the

compressor switch off and con-

tact any authorized Toyota

retailer or Toyota authorized

repairer, or any reliable repairer.

Page 532 of 758

5308-2. Steps to take in an emergency

If the tire inflation pressure

exceeds the specified air pres-

sure, let out some air to adjust

the tire inflation pressure.

( P.536, 573)

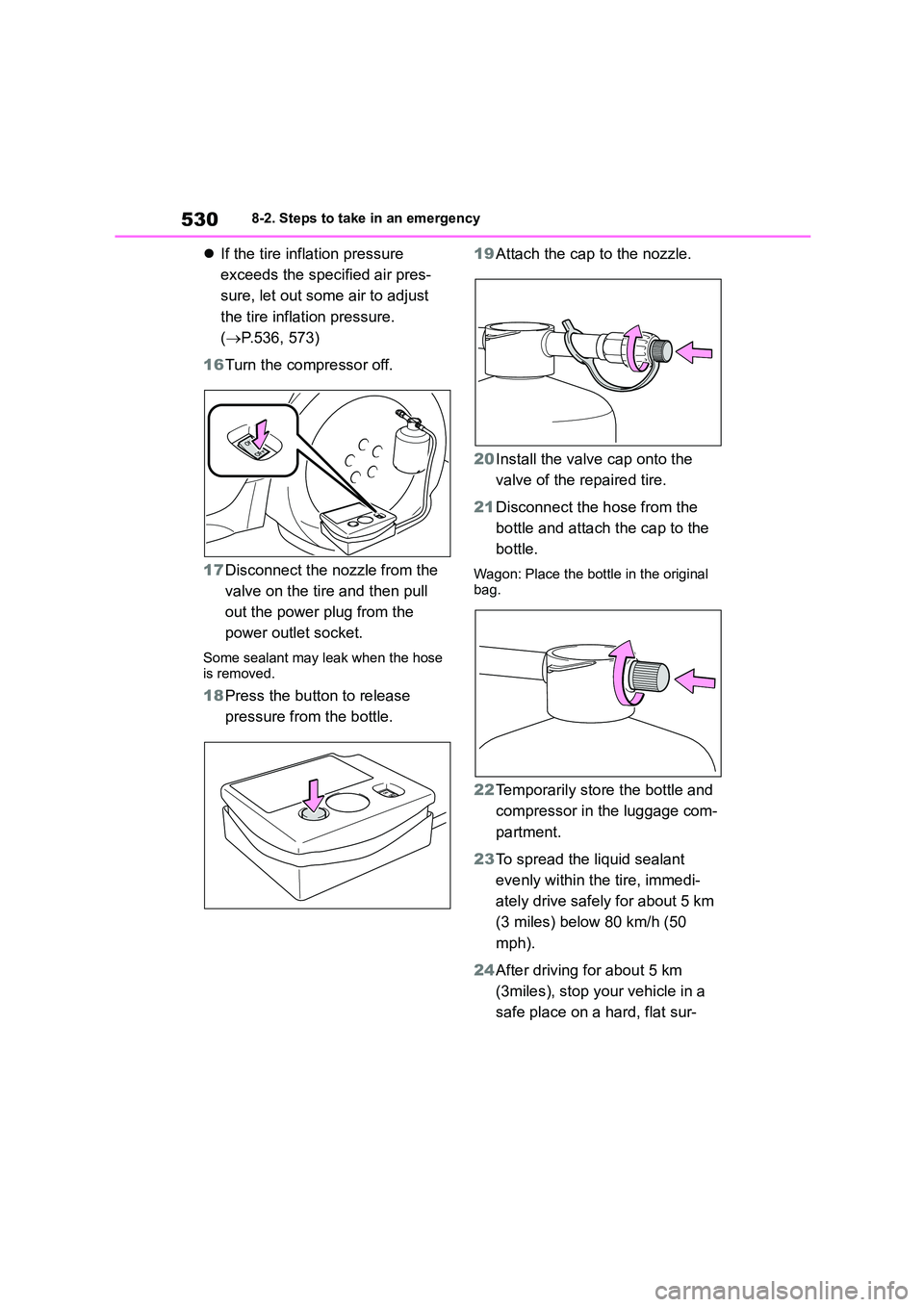

16 Turn the compressor off.

17 Disconnect the nozzle from the

valve on the tire and then pull

out the power plug from the

power outlet socket.

Some sealant may leak when the hose

is removed.

18 Press the button to release

pressure from the bottle.

19 Attach the cap to the nozzle.

20 Install the valve cap onto the

valve of the repaired tire.

21 Disconnect the hose from the

bottle and attach the cap to the

bottle.

Wagon: Place the bottle in the original

bag.

22 Temporarily store the bottle and

compressor in the luggage com-

partment.

23 To spread the liquid sealant

evenly within the tire, immedi-

ately drive safely for about 5 km

(3 miles) below 80 km/h (50

mph).

24 After driving for about 5 km

(3miles), stop your vehicle in a

safe place on a hard, flat sur-

Page 533 of 758

531

8

8-2. Steps to take in an emergency

When trouble arises

face and connect the compres-

sor.

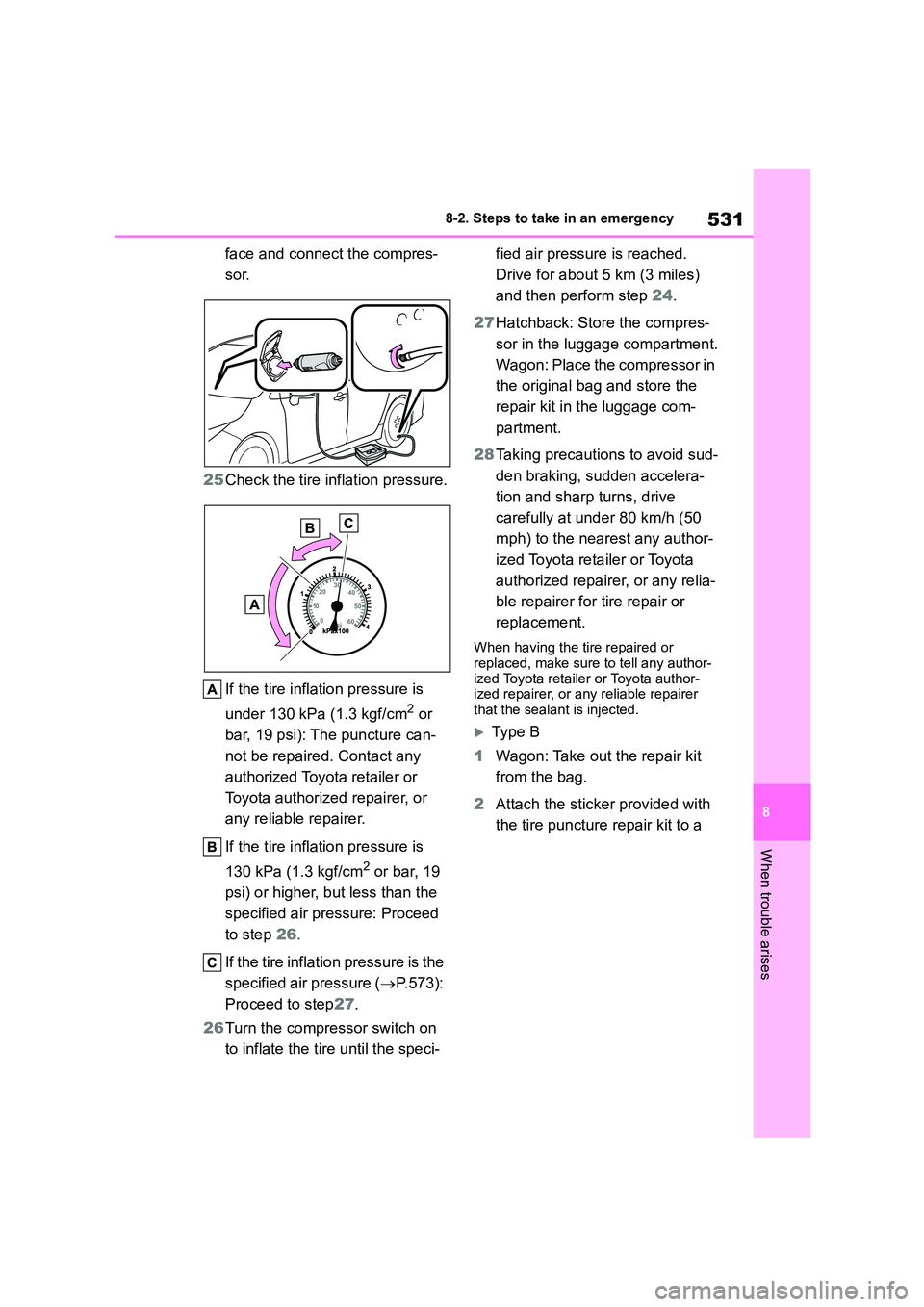

25 Check the tire inflation pressure.

If the tire inflat ion pressure is

under 130 kPa (1.3 kgf/cm2 or

bar, 19 psi): The puncture can-

not be repaired. Contact any

authorized Toyota retailer or

Toyota authorized repairer, or

any reliable repairer.

If the tire inflat ion pressure is

130 kPa (1.3 kgf/cm2 or bar, 19

psi) or higher, but less than the

specified air pressure: Proceed

to step 26.

If the tire inflatio n pressure is the

specified air pressure ( P.573):

Proceed to step 27.

26 Turn the compressor switch on

to inflate the tire until the speci-

fied air pressure is reached.

Drive for about 5 km (3 miles)

and then perform step 24.

27 Hatchback: Store the compres-

sor in the luggage compartment.

Wagon: Place the compressor in

the original bag and store the

repair kit in the luggage com-

partment.

28 Taking precautions to avoid sud-

den braking, sudden accelera-

tion and sharp turns, drive

carefully at under 80 km/h (50

mph) to the nearest any author-

ized Toyota reta iler or Toyota

authorized repairer, or any relia-

ble repairer for tire repair or

replacement.

When having the tire repaired or

replaced, make sure to tell any author-

ized Toyota retailer or Toyota author- ized repairer, or any reliable repairer

that the sealant is injected.

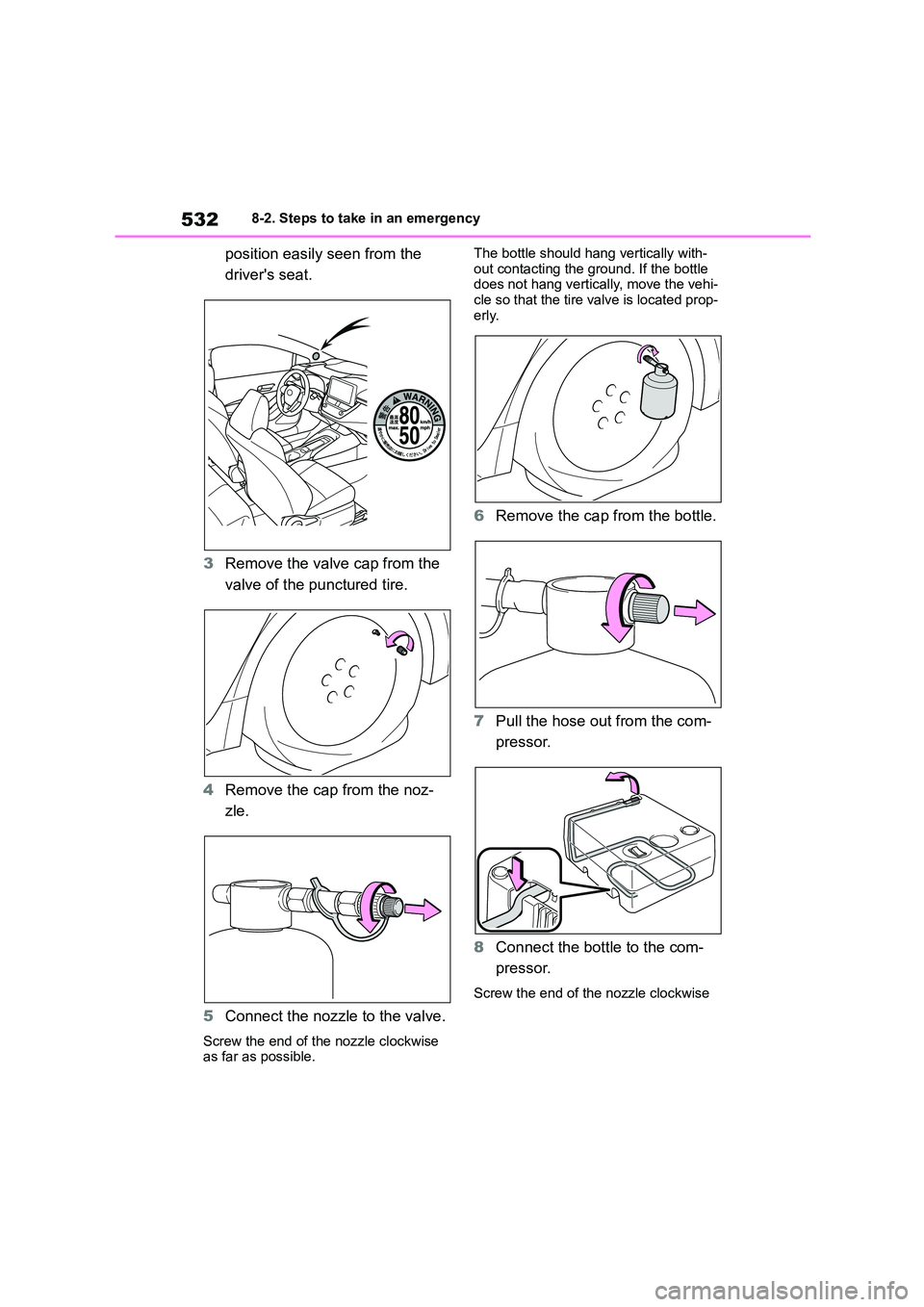

Ty p e B

1 Wagon: Take out the repair kit

from the bag.

2 Attach the sticker provided with

the tire puncture repair kit to a

Page 534 of 758

5328-2. Steps to take in an emergency

position easily seen from the

driver's seat.

3 Remove the valve cap from the

valve of the punctured tire.

4 Remove the cap from the noz-

zle.

5 Connect the nozzle to the valve.

Screw the end of the nozzle clockwise as far as possible.

The bottle should hang vertically with-

out contacting the ground. If the bottle does not hang vertically, move the vehi-

cle so that the tire valve is located prop-

erly.

6 Remove the cap from the bottle.

7 Pull the hose out from the com-

pressor.

8 Connect the bottle to the com-

pressor.

Screw the end of the nozzle clockwise

Page 535 of 758

533

8

8-2. Steps to take in an emergency

When trouble arises

as far as possible.

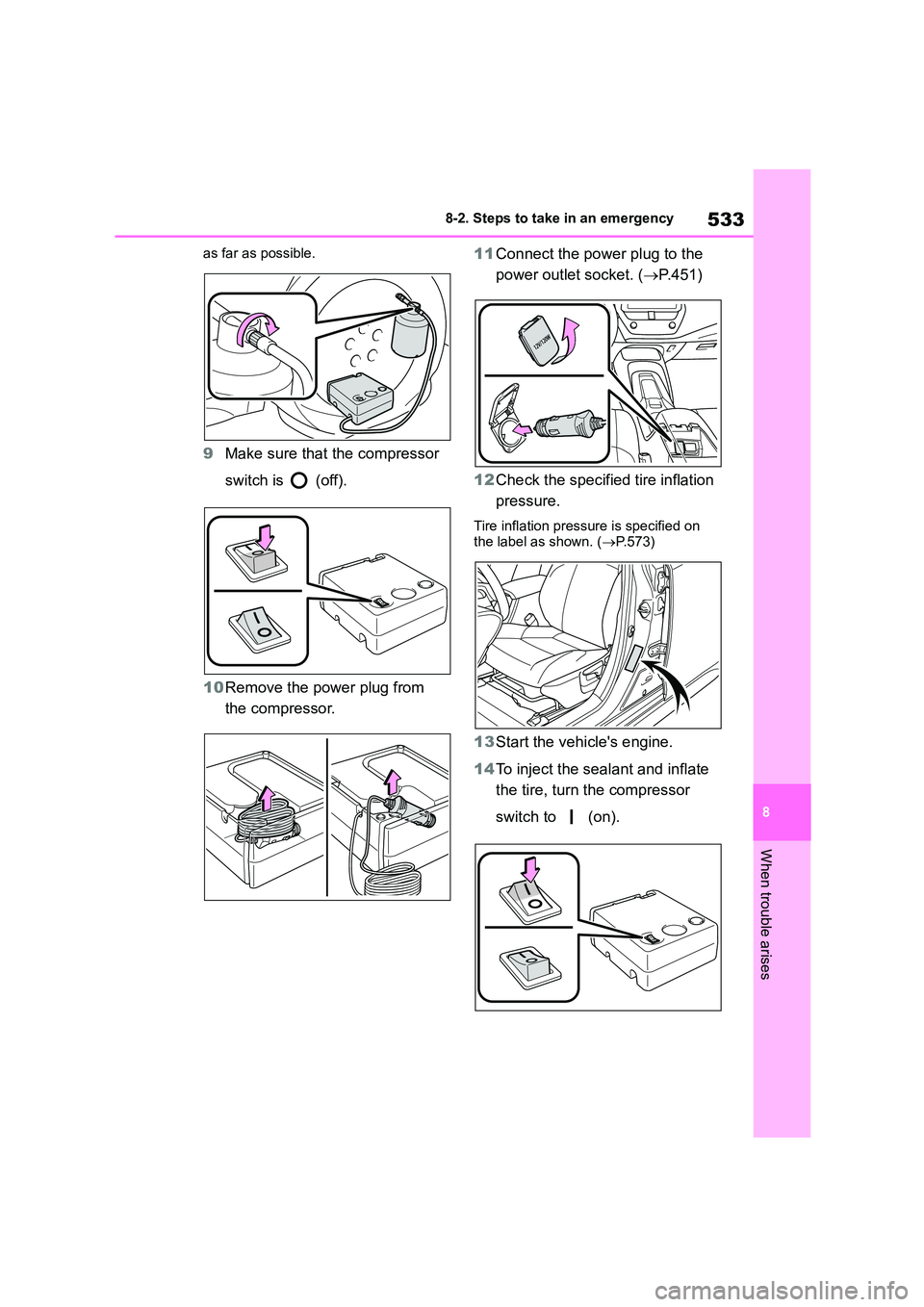

9 Make sure that the compressor

switch is (off).

10 Remove the power plug from

the compressor.

11 Connect the power plug to the

power outlet socket. ( P.451)

12 Check the specified tire inflation

pressure.

Tire inflation pressure is specified on the label as shown. ( P.573)

13Start the vehicle's engine.

14 To inject the sealant and inflate

the tire, turn the compressor

switch to (on).

Page 536 of 758

5348-2. Steps to take in an emergency

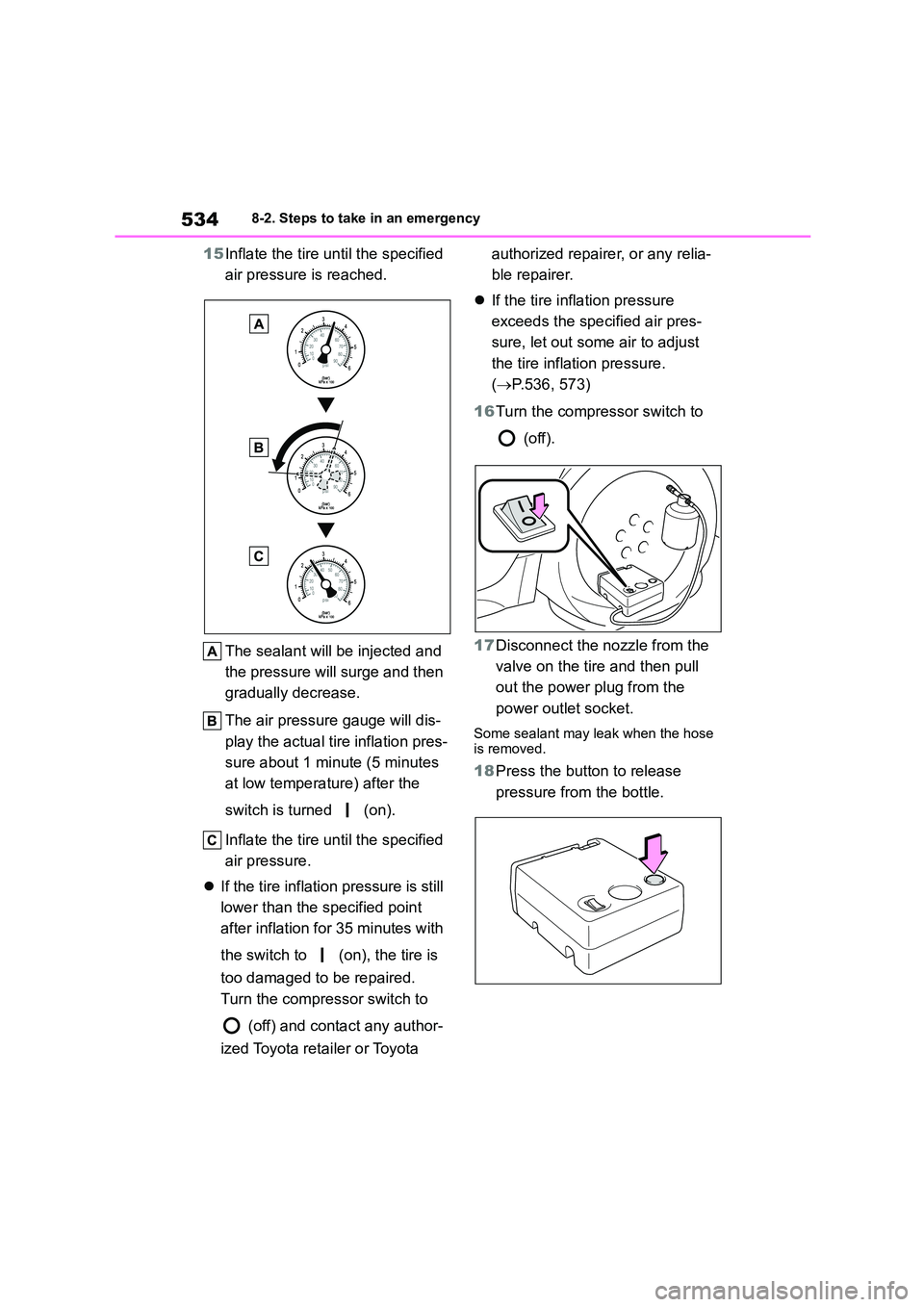

15Inflate the tire until the specified

air pressure is reached.

The sealant will be injected and

the pressure will surge and then

gradually decrease.

The air pressure gauge will dis-

play the actual tire inflation pres-

sure about 1 minute (5 minutes

at low temperature) after the

switch is turned (on).

Inflate the tire until the specified

air pressure.

If the tire inflation pressure is still

lower than the specified point

after inflation for 35 minutes with

the switch to (on), the tire is

too damaged to be repaired.

Turn the compressor switch to

(off) and contact any author-

ized Toyota reta iler or Toyota

authorized repairer, or any relia-

ble repairer.

If the tire inflation pressure

exceeds the specified air pres-

sure, let out some air to adjust

the tire inflation pressure.

( P.536, 573)

16 Turn the compressor switch to

(off).

17 Disconnect the nozzle from the

valve on the tire and then pull

out the power plug from the

power outlet socket.

Some sealant may leak when the hose is removed.

18 Press the button to release

pressure from the bottle.

Page 537 of 758

535

8

8-2. Steps to take in an emergency

When trouble arises

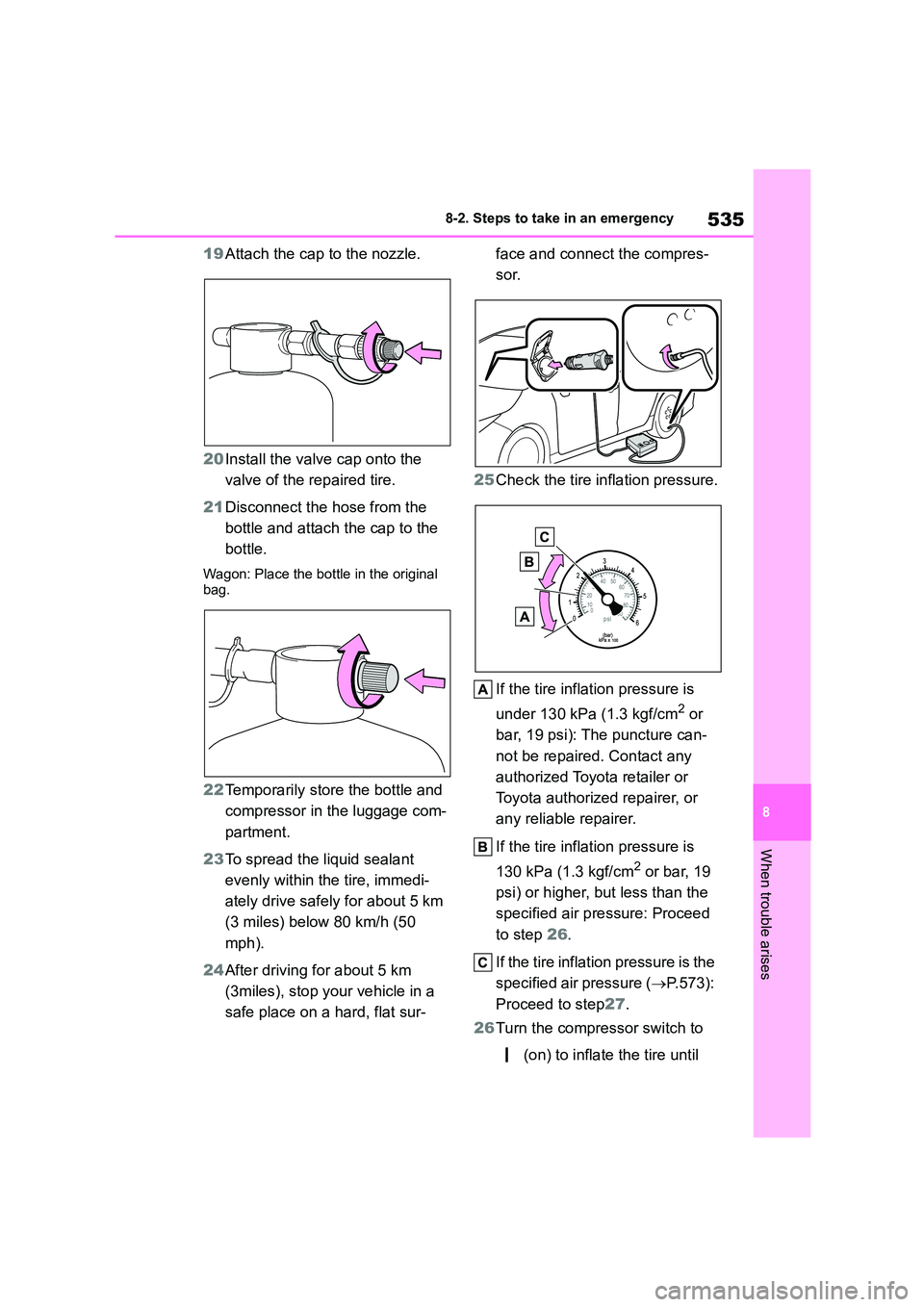

19 Attach the cap to the nozzle.

20 Install the valve cap onto the

valve of the repaired tire.

21 Disconnect the hose from the

bottle and attach the cap to the

bottle.

Wagon: Place the bottle in the original

bag.

22 Temporarily store the bottle and

compressor in the luggage com-

partment.

23 To spread the liquid sealant

evenly within the tire, immedi-

ately drive safely for about 5 km

(3 miles) below 80 km/h (50

mph).

24 After driving for about 5 km

(3miles), stop your vehicle in a

safe place on a hard, flat sur-

face and connect the compres-

sor.

25 Check the tire inflation pressure.

If the tire inflation pressure is

under 130 kPa (1.3 kgf/cm2 or

bar, 19 psi): The puncture can-

not be repaired. Contact any

authorized Toyota retailer or

Toyota authorized repairer, or

any reliable repairer.

If the tire inflation pressure is

130 kPa (1.3 kgf/cm2 or bar, 19

psi) or higher, but less than the

specified air pressure: Proceed

to step 26.

If the tire inflation pressure is the

specified air pressure ( P.573):

Proceed to step 27.

26 Turn the compressor switch to

(on) to inflate the tire until

Page 538 of 758

5368-2. Steps to take in an emergency

the specified air pressure is

reached. Drive for about 5 km (3

miles) and then perform step

24 .

27 Hatchback: Store the compres-

sor in the luggage compartment.

Wagon: Place the compressor in

the original bag and store the

repair kit in the luggage com-

partment.

28 Taking precautions to avoid sud-

den braking, sudden accelera-

tion and sharp turns, drive

carefully at under 80 km/h (50

mph) to the nearest any author-

ized Toyota reta iler or Toyota

authorized repairer, or any relia-

ble repairer for tire repair or

replacement.

When having the tire repaired or

replaced, make sure to tell any author-

ized Toyota retailer or Toyota author- ized repairer, or any reliable repairer

that the sealant is injected.

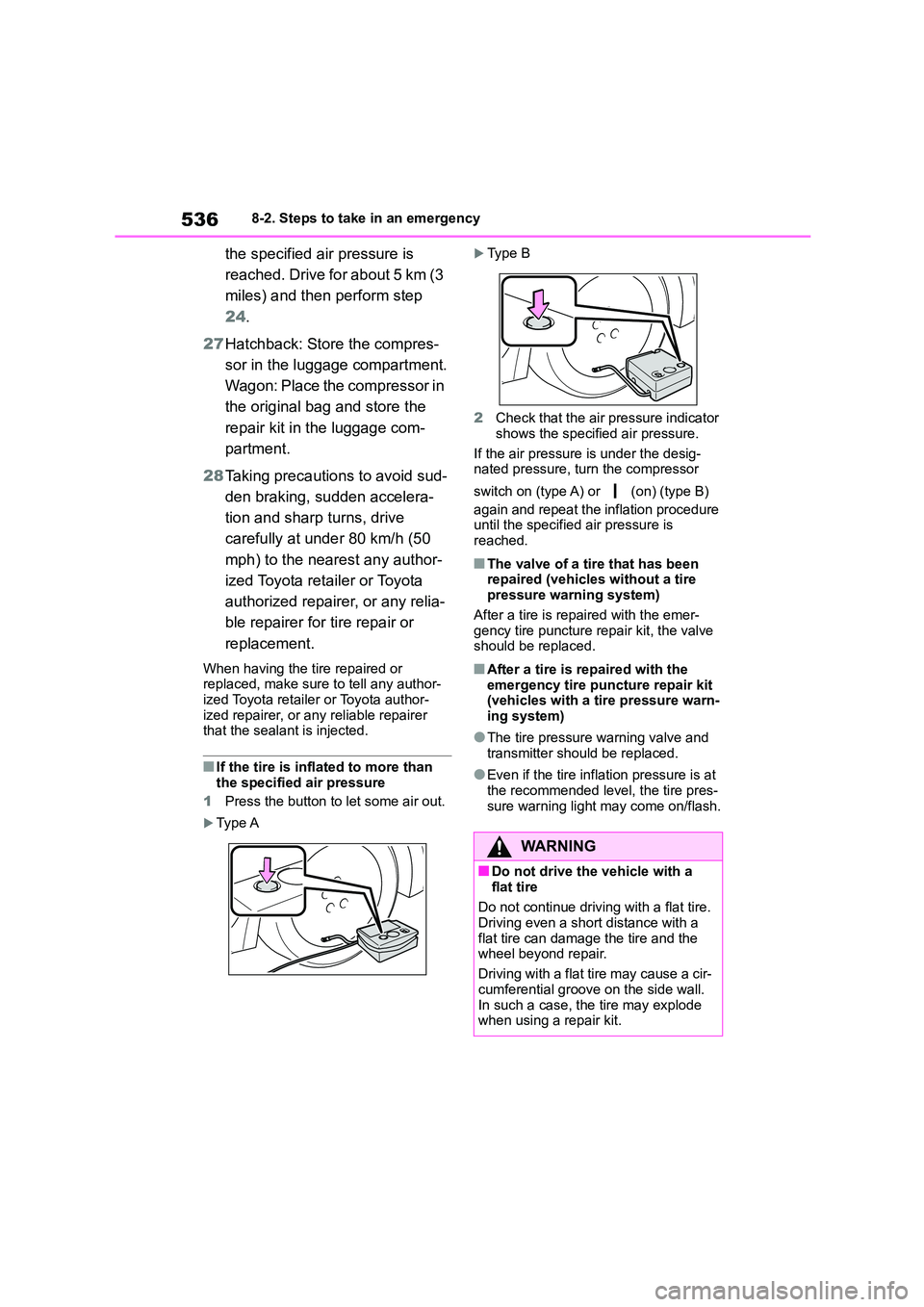

■If the tire is infl ated to more than

the specified air pressure

1 Press the button to let some air out.

Ty p e A

Ty p e B

2 Check that the air pressure indicator

shows the specified air pressure.

If the air pressure is under the desig- nated pressure, turn the compressor

switch on (type A) or (on) (type B)

again and repeat the inflation procedure until the specified air pressure is

reached.

■The valve of a tire that has been

repaired (vehicles without a tire pressure warning system)

After a tire is repaired with the emer-

gency tire puncture repair kit, the valve should be replaced.

■After a tire is repaired with the

emergency tire puncture repair kit

(vehicles with a tire pressure warn- ing system)

●The tire pressure warning valve and transmitter should be replaced.

●Even if the tire inflation pressure is at the recommended level, the tire pres-

sure warning light may come on/flash.

WA R N I N G

■Do not drive the vehicle with a

flat tire

Do not continue driving with a flat tire.

Driving even a short distance with a

flat tire can damage the tire and the wheel beyond repair.

Driving with a flat tire may cause a cir-

cumferential groove on the side wall. In such a case, the tire may explode

when using a repair kit.

Page 539 of 758

537

8

8-2. Steps to take in an emergency

When trouble arises

WA R N I N G

■When fixing the flat tire

●Stop your vehicle in a safe and flat

area.

●Do not touch the wheels or the area

around the brakes immediately after the vehicle has been driven.

After the vehicle has been driven,

the wheels and the area around the

brakes may be extremely hot. Touching these areas with hands,

feet or other body parts may result

in burns.

●Connect the valve and hose

securely with the tire installed on the vehicle. If the hose is not prop-

erly connected to the valve, air

leakage may occur as sealant may be sprayed out.

●If the hose comes off the valve while inflating the tire, there is a risk

that the hose will move abruptly due

to air pressure.

●After inflation of the tire has com-

pleted, the sealant may splatter when the hose is disconnected or

some air is let out of the tire.

●Follow the operation procedure to

repair the tire. If the procedures not

followed, the sealant may spray out.

●Keep back from the tire while it is

being repaired, as there is a chance of it bursting while the repair opera-

tion is being performed. If you

notice any cracks or deformation of

the tire, turn off (type A) or (off)

(type B) the compressor switch and

stop the repair operation immedi- ately.

●The repair kit may overheat if oper-ated for a long period of time. Do

not operate the repair kit continu-

ously for more than 40 minutes.

●Parts of the repair kit become hot during operation. Be careful when

handling the repair kit during and

after operation. Do not touch the metal part around the connecting

area between the bottle and com-

pressor. It will be extremely hot.

●Do not attach the vehicle speed

warning sticker to an area other than the one indicated. If the sticker

is attached to an area where an

SRS airbag is located, such as the pad of the steering wheel, it may

prevent the SRS airbag from oper-

ating properly.

●To avoid risk of burst or severe

leakage, do not drop or damage the bottle. Visually inspect the bottle

before use. Do not use a bottle with

shock, crack, scratch, leakage or any other damage. In such case,

immediately replace.

■Driving to spread the liquid seal-

ant evenly

Observe the following precautions to reduce the risk of accidents.

Failing to do so may result in a loss of

vehicle control and cause death or serious injury.

●Drive the vehicle carefully at a low speed. Be especially careful when

turning and cornering.

●If the vehicle does not drive straight

or you feel a pull through the steer-

ing wheel, stop the vehicle and check the following.

• Tire condition. The tire may have

separated from the wheel.

• Tire inflation pressure. If the tire

inflation pressure is 130 kPa (1.3

kgf/cm2 or bar, 19 psi) or less, the tire may be severely damaged.

Page 540 of 758

5388-2. Steps to take in an emergency

NOTICE

■When performing an emergency

repair

●A tire should only be repaired with the emergency tire puncture repair

kit if the damage is caused by a

sharp object such as nail or screw passing through the tire tread.

Do not remove the sharp object

from the tire. Removing the object

may widen the opening and disenable emergency repair with

the repair kit.

●The repair kit is not waterproof.

Make sure that the repair kit is not

exposed to water, such as when it is being used in the rain.

●Do not put the repair kit directly onto dusty ground such as sand at

the side of the road. If the repair kit

vacuums up dust etc., a malfunc- tion may occur.

●Do not turn the bottle upside down when using it, as doing so may

cause damage to the compressor.

■Precautions for the emergency

tire puncture repair kit

●The repair kit power source should be 12 V DC suitable for vehicle use.

Do not connect the repair kit to any

other source.

●If fuel splatters on the repair kit, the

repair kit may deteriorate. Take care not to allow fuel to contact it.

●Place the repair kit in a storage to prevent it from being exposed to dirt

or water.

●Store the repair kit in the luggage

compartment out of reach of chil-

dren.

●Do not disassemble or modify the

repair kit. Do not subject parts such as the air pressure indicator to

impacts. This may cause a malfunc-

tion.

■To avoid damage to the tire pres- sure warning valves and trans-

mitters (vehicles with a tire

pressure warning system)

When a tire is repaired with liquid

sealants, the tire pressure warning

valve and transmitter may not operate properly. If a liquid sealant is used,

contact any authorized Toyota retailer

or Toyota authorized repairer, or any reliable repairer or other qualified ser-

vice shop as soon as possible. After

use of liquid sealant, make sure to replace the tire pressure warning

valve and transmitter when repairing

or replacing the tire. ( P.482)