sensor TOYOTA RAV4 1996 Service Repair Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 1996, Model line: RAV4, Model: TOYOTA RAV4 1996Pages: 1632, PDF Size: 41.64 MB

Page 882 of 1632

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

IDLE AIR CONTROL (IAC) VALVE

Start engine and bring to normal operating temperature. Turn A/C switch on, set blower switch to high position

and adjust temperature control lever to maximum cooling. Ensure compressor clutch is engaged. Using

tachometer, ensure when compressor clutch engages, idle RPM increases 100-200 RPM and decreases a similar

amount when clutch is disengaged. If idle does not react as specified, check IAC valve and air intake system.

COMPRESSOR CLUTCH & COMPRESSOR LOCK SENSOR

Inspect pressure plate and rotor for signs of oil contamination. Check clutch bearing for noisy operation and

grease leakage. Check compressor lock sensor resistance. Disconnect compressor clutch/lock sensor 3-pin

connector. Measure resistance between terminals No. 1 (White wire) and No. 2 (Blue wire). Resistance should

be 65-125 ohms at 68°F (20°C). Replace as necessary. Check magnetic clutch operation. Apply battery voltage

to compressor clutch connector terminal No. 3 (Black wire). Connect negative battery lead to ground. Ensure

compressor clutch is energized. If compressor clutch is not energized, replace compressor clutch.

THERMISTOR

1. Disconnect negative battery cable and wait at least 90 seconds. Remove lower trim panel and glove box.

Disconnect thermistor 2-pin connector from top of evaporator case. See Fig. 6

. Measure resistance of

thermistor while still installed.

2. Resistance should be 1500 ohms at 77°F (25°C) ambient temperature. If resistance is not within

specification, replace thermistor. If resistance is as specified, go to next step.

3. Remove evaporator case. See EVAPORATOR ASSEMBLY

under REMOVAL & INSTALLATION.

Disassemble evaporator case and remove thermistor. Check thermistor operation. Submerge thermistor at

least 3.94" (100 mm) deep in cold water. See Fig. 7

.

4. Place thermometer in water and measure resistance of thermistor at various temperatures. Use ice or hot

water to vary water temperature. If readings are not within specification, replace thermistor. See

THERMISTOR RESISTANCE VALUES

table.

THERMISTOR RESISTANCE VALUES

Water Temperature °F (°C)Ohms

77 (25)1300-1800

68 (20)1700-2200

59 (15)2200-2600

50 (10)2800-3300

41 (5)3700-4200

32 (0)4600-5300

1999 Toyota RAV4

1999 MANUAL A/C-HEATER SYSTEMS RAV4

Microsoft

Sunday, November 22, 2009 10:29:28 AMPage 9 © 2005 Mitchell Repair Information Company, LLC.

Page 894 of 1632

2. Turn ignition switch to ON position. Test light should be on and temperature gauge should slowly move

to HOT. If gauge functions as specified, replace sending unit. If gauge does not function as specified,

perform TEMPERATURE GAUGE RESISTANCE TEST

.

Engine Coolant Temperature (ECT) Sender

1. Turn ignition switch to OFF position. Disconnect ECT sender 1-pin connector. See ENGINE

COOLANT TEMPERATURE SENDER LOCATION table. Drain cooling system and remove ECT

sender. Place probe end of ECT sender and thermometer in a container of water. Connect an ohmmeter

between ECT sender terminal and ECT sender body.

2. Heat water and note resistance reading. See ENGINE COOLANT TEMPERATURE SENDER

RESISTANCE table. If resistance is not as specified, replace ECT sender.

ENGINE COOLANT TEMPERATURE SENDER LOCATION

ENGINE COOLANT TEMPERATURE SENDER RESISTANCE

Temperature Gauge Resistance Test

Turn ignition switch to OFF position. Remove instrument cluster. Using ohmmeter, check gauge resistance

between appropriate terminals on back of instrument cluster. See TEMPERATURE GAUGE RESISTANCE

SPECIFICATIONS table. See Fig. 2 -Fig. 8 . If resistance is not as specified, replace temperature gauge. If

resistance is as specified, repair open or short circuit in wiring harness.

TEMPERATURE GAUGE RESISTANCE SPECIFICATIONS

ApplicationLocation

Land CruiserTop Front Of Engine

SiennaTop Of Engine

RAV4Rear Of Cylinder Head, Exhaust Side

Tacoma & 4Runner

4-Cyl.Right Side Of Engine, Under Intake

Manifold

V6Left Cylinder Head

Tundra

V6In Rear Of Intake Manifold

V8In Front Water By-Pass Joint, Next To

ECT Sensor

Application & Water Temp. °F (°C)Ohms

Land Cruiser, Sienna, RAV4 & Tundra

122 (50)160-240

248 (120)17-21

Tacoma & 4Runner

122 (50)234-314

248 (120)24-31

1999 Toyota RAV4

1999-2000 ACCESSORIES & EQUIPMENT Instrument Panels - Trucks

Microsoft

Sunday, November 22, 2009 10:54:09 AMPage 4 © 2005 Mitchell Repair Information Company, LLC.

Page 906 of 1632

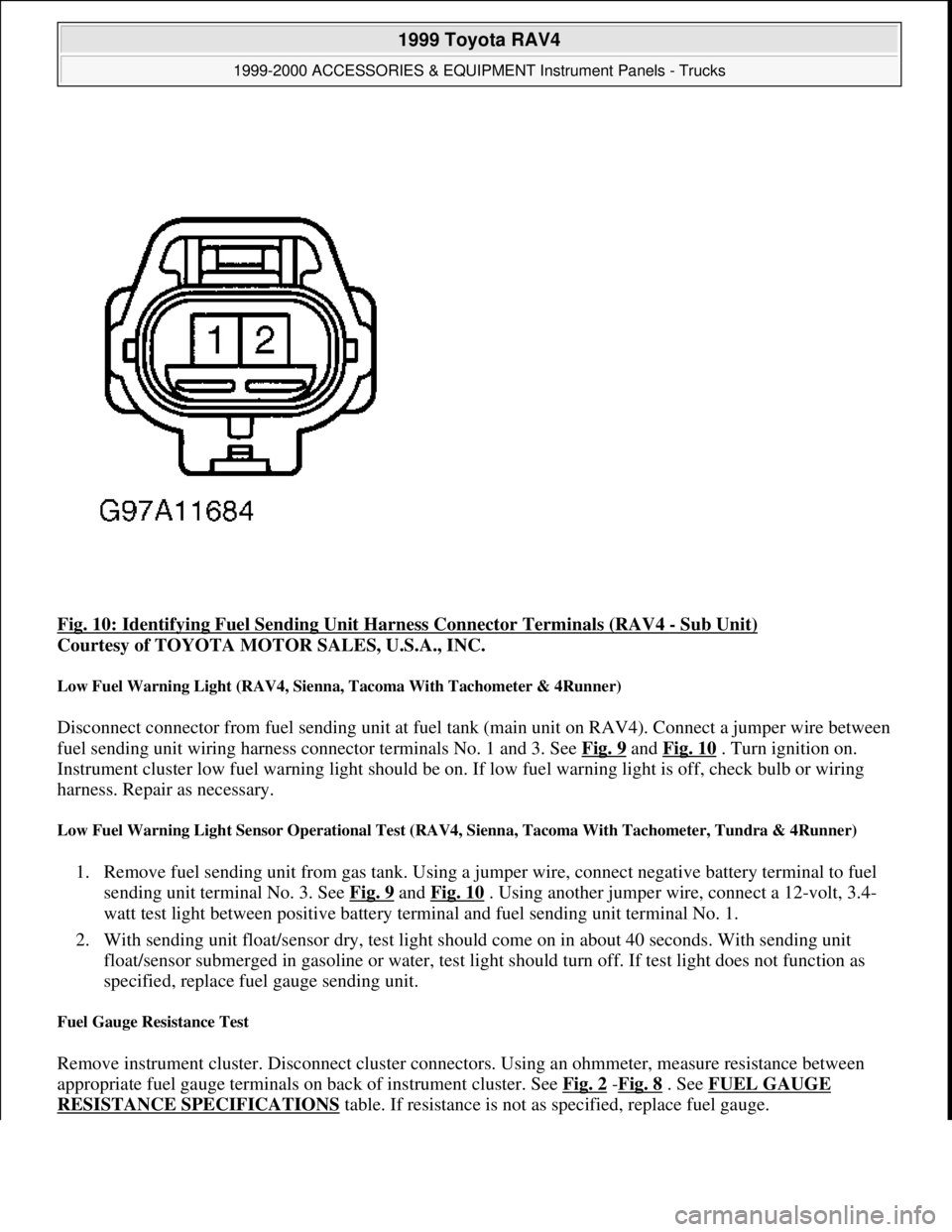

Fig. 10: Identifying Fuel Sending Unit Harness Connector Terminals (RAV4 - Sub Unit)

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

Low Fuel Warning Light (RAV4, Sienna, Tacoma With Tachometer & 4Runner)

Disconnect connector from fuel sending unit at fuel tank (main unit on RAV4). Connect a jumper wire between

fuel sending unit wiring harness connector terminals No. 1 and 3. See Fig. 9

and Fig. 10 . Turn ignition on.

Instrument cluster low fuel warning light should be on. If low fuel warning light is off, check bulb or wiring

harness. Repair as necessary.

Low Fuel Warning Light Sensor Operational Test (RAV4, Sienna, Tacoma With Tachometer, Tundra & 4Runner)

1. Remove fuel sending unit from gas tank. Using a jumper wire, connect negative battery terminal to fuel

sending unit terminal No. 3. See Fig. 9

and Fig. 10 . Using another jumper wire, connect a 12-volt, 3.4-

watt test light between positive battery terminal and fuel sending unit terminal No. 1.

2. With sending unit float/sensor dry, test light should come on in about 40 seconds. With sending unit

float/sensor submerged in gasoline or water, test light should turn off. If test light does not function as

specified, replace fuel gauge sending unit.

Fuel Gauge Resistance Test

Remove instrument cluster. Disconnect cluster connectors. Using an ohmmeter, measure resistance between

appropriate fuel gauge terminals on back of instrument cluster. See Fig. 2

-Fig. 8 . See FUEL GAUGE

RESISTANCE SPECIFICATIONS table. If resistance is not as specified, replace fuel gauge.

1999 Toyota RAV4

1999-2000 ACCESSORIES & EQUIPMENT Instrument Panels - Trucks

Microsoft

Sunday, November 22, 2009 10:54:10 AMPage 16 © 2005 Mitchell Repair Information Company, LLC.

Page 914 of 1632

LOW OIL PRESSURE WARNING LIGHT

RAV4, Sienna, Tacoma, Tundra Without Tachometer & 4Runner

Disconnect low oil pressure switch connector. See OIL PRESSURE SWITCH LOCATION table. Using a

jumper wire, connect low oil pressure switch connector terminal to ground. Turn ignition switch to ON position.

Low oil pressure warning light should turn on. If low oil pressure warning light is off, check bulb or inspect

wiring harness.

OCCUPANT DETECTION SENSOR

Land Cruiser & Tundra

Disconnect occupant detection sensor connector, located under passenger seat. Check continuity between sensor

connector terminals. Continuity should exist only when pressing on sensor. If continuity is not as specified,

replace occupant detection sensor.

OIL PRESSURE GAUGE & SENDER

Oil Pressure Gauge & Harness Operational Test (Land Cruiser & Tundra With Tachometer)

1. Disconnect oil pressure sender connector. See OIL PRESSURE SENDER LOCATION table. Turn

ignition switch to ON position. Oil gauge should indicate LOW. Turn ignition switch to OFF position.

Connect a 12-volt, 3.4-watt test light between oil sending unit harness connector terminal and ground.

2. Turn ignition switch to ON position. Test light should be on and oil pressure gauge should slowly move

to HIGH. If gauge functions as specified, perform OIL PRESSURE SENDER OPERATIONAL

TEST . If gauge does not function as specified, perform OIL PRESSURE GAUGE RESISTANCE

TEST .

Oil Pressure Sender Operational Test (Land Cruiser & Tundra With Tachometer)

Disconnect oil pressure sender connector. See OIL PRESSURE SENDER LOCATION table. Using 12-volt

source, connect an LED tester between positive battery terminal and oil pressure sender terminal. With engine

off, LED should be off. With engine running, LED should flash. LED flashes will vary with engine speed and

oil pressure. Replace oil pressure sender if LED does not operate as specified.

OIL PRESSURE SENDER LOCATION

Oil Pressure Gauge Resistance Test (Land Cruiser & Tundra With Tachometer)

Remove instrument cluster. See INSTRUMENT CLUSTER under REMOVAL & INSTALLATION. Using

an ohmmeter, check resistance between oil gauge terminals on rear of instrument cluster. See Fig. 16

or Fig.

17 . See OIL PRESSURE GAUGE RESISTANCE SPECIFICATIONS table. If resistance is not as

specified, replace oil pressure

gauge.

ApplicationLocation

Land Cruiser & TundraOn Oil Filter Housing

1999 Toyota RAV4

1999-2000 ACCESSORIES & EQUIPMENT Instrument Panels - Trucks

Microsoft

Sunday, November 22, 2009 10:54:10 AMPage 24 © 2005 Mitchell Repair Information Company, LLC.

Page 920 of 1632

Ensure tires are correct size and inflated properly. Place vehicle on standard speedometer tester. Compare tester

with speedometer readings. See SPEEDOMETER TEST

table. If vehicle speedometer readings are not within

allowable range, replace speedometer. If speedometer does not operate at all, check speedometer resistance. If

speedometer resistance is okay, check vehicle speed sensor. See appropriate SYSTEM & COMPONENT

TESTING article in ENGINE PERFORMANCE.

Speedometer Operational Test (Except Land Cruiser)

Ensure tires are correct size and inflated properly. Place vehicle on standard speedometer tester. Compare tester

with speedometer readings. See SPEEDOMETER TEST

table. If vehicle speedometer readings are not within

allowable range, replace speedometer. If speedometer does not operate at all, check vehicle speed sensor. See

SYSTEM & COMPONENT TESTING article in ENGINE PERFORMANCE.

SPEEDOMETER TEST

Speedometer Resistance (Land Cruiser & Tundra)

Remove instrument cluster. See INSTRUMENT CLUSTER under REMOVAL & INSTALLATION. Using

an ohmmeter, check resistance between speedometer terminals on rear of instrument cluster. See Fig. 6

and Fig.

20 . See SPEEDOMETER RESISTANCE table. If resistance is not as specified, replace speedometer.

SPEEDOMETER RESISTANCE

Standard Indication (MPH)Allowable Range (MPH)

2018-24

4038-44

6056-66

8078-88

10098-110

120118-132

ApplicationOhms

Land Cruiser & Tundra

Terminals "A" & "B"160

Terminals "C" & "D"160

1999 Toyota RAV4

1999-2000 ACCESSORIES & EQUIPMENT Instrument Panels - Trucks

Microsoft

Sunday, November 22, 2009 10:54:10 AMPage 30 © 2005 Mitchell Repair Information Company, LLC.

Page 923 of 1632

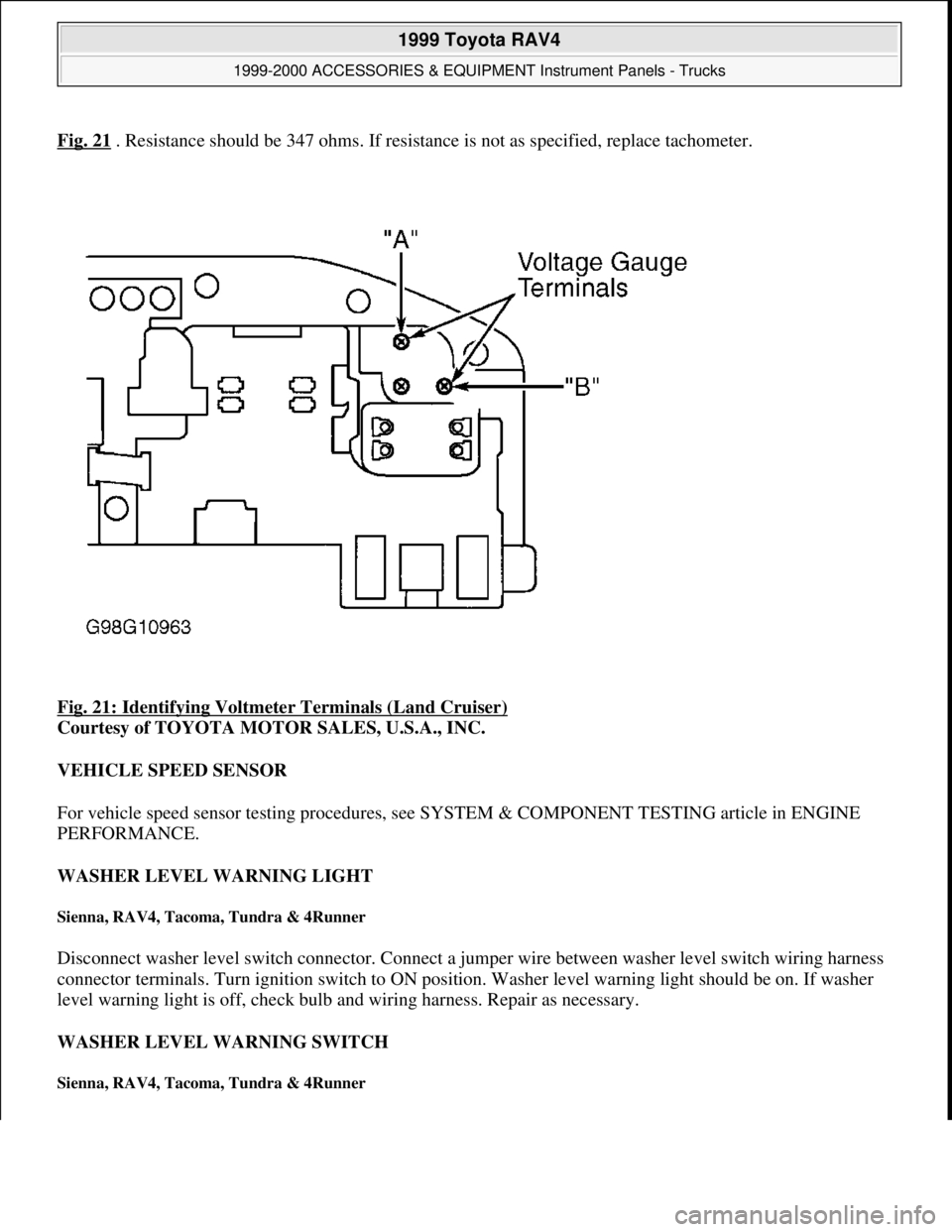

Fig. 21 . Resistance should be 347 ohms. If resistance is not as specified, replace tachometer.

Fig. 21: Identifying Voltmeter Terminals (Land Cruiser)

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

VEHICLE SPEED SENSOR

For vehicle speed sensor testing procedures, see SYSTEM & COMPONENT TESTING article in ENGINE

PERFORMANCE.

WASHER LEVEL WARNING LIGHT

Sienna, RAV4, Tacoma, Tundra & 4Runner

Disconnect washer level switch connector. Connect a jumper wire between washer level switch wiring harness

connector terminals. Turn ignition switch to ON position. Washer level warning light should be on. If washer

level warning light is off, check bulb and wiring harness. Repair as necessary.

WASHER LEVEL WARNING SWITCH

Sienna, RAV4, Tacoma, Tundra & 4Runner

1999 Toyota RAV4

1999-2000 ACCESSORIES & EQUIPMENT Instrument Panels - Trucks

Microsoft

Sunday, November 22, 2009 10:54:10 AMPage 33 © 2005 Mitchell Repair Information Company, LLC.

Page 972 of 1632

REMOVAL & INSTALLATION

See appropriate MANUAL TRANSMISSION REMOVAL article in TRANSMISSION SERVICING.

TRANSAXLE DISASSEMBLY

1. Unbolt transfer case from transaxle housing. Using a plastic hammer, remove transfer case from

transaxle. Screw appropriate bolt and washer into differential side gear intermediate shaft. Using slide

hammer type puller, remove shaft. Remove snap ring from shaft.

2. Remove clutch release fork and bearing. Remove back-up light switch. Remove speedometer adapter.

Remove speedometer driven gear or speed sensor, if equipped. Remove gear selecting bellcrank. Remove

shift and select lever lock bolt. Remove control shaft cover. Remove shift and select lever shaft assembly.

See Fig. 1

.

3. Remove case cover. Unstake output shaft lock nut. Lock transmission in 2 gears. Remove output shaft

lock nut. Unlock transmission. See Fig. 2

.

4. Remove No. 3 shift fork set bolt. Remove No. 3 hub sleeve and No. 3 shift fork. Using puller, remove 5th

driven gear. See Fig. 2

. Measure 5th gear clearances. Record for reassembly reference. Using dial

indicator, measure 5th gear thrust clearance. See Fig. 3

and Fig. 4 . Standard clearance should be .004-

.022" (.10-.57 mm). Service limit is .026" (.65 mm). Remount dial indicator to measure lateral movement

(oil clearance) of 5th gear. Standard clearance should be .0004-.002" (.009-.05 mm). Service limit

is .0028" (.070 mm).

5. Remove input shaft snap ring. Using puller, remove No. 3 clutch hub with synchronizer ring and 5th gear.

Remove needle bearing and spacer. Remove 7 Torx (T45) screws and rear bearing retainer. Remove

adjusting shim.

6. Remove input shaft rear bearing snap ring. Remove shift fork shaft snap rings. Remove plug. Remove

seat, spring and detent ball with a magnet. Remove reverse idler gear shaft retaining bolt.

7. Remove transmission housing. Remove output shaft rear bearing outer race. Remove No. 2 oil pipe.

Remove reverse shift arm bracket. Remove reverse idler gear, thrust washer and shaft. Remove all

remaining plugs, seats, springs and detent balls with magnet.

8. To remove No. 1 shift fork shaft, pull up No. 3 shift fork shaft. Using magnetic finger, remove interlock

roller. Remove No. 2 shift fork shaft, shift head and No. 1 shift fork. Pull out No. 3 shift fork shaft along

with the reverse shift fork. Remove No. 2 shift fork. Remove snap rings from shift fork shafts.

9. Remove output and input shaft assemblies. Remove oil pump drive gear. Remove differential case

assembly. Remove oil pipe and oil pump. See Fig. 1

.

1999 Toyota RAV4

1999 MANUAL TRANSMISSIONS Toyota E250 & E250F 5-Speed Overhaul

Microsoft

Sunday, November 22, 2009 10:48:07 AMPage 2 © 2005 Mitchell Repair Information Company, LLC.

Page 987 of 1632

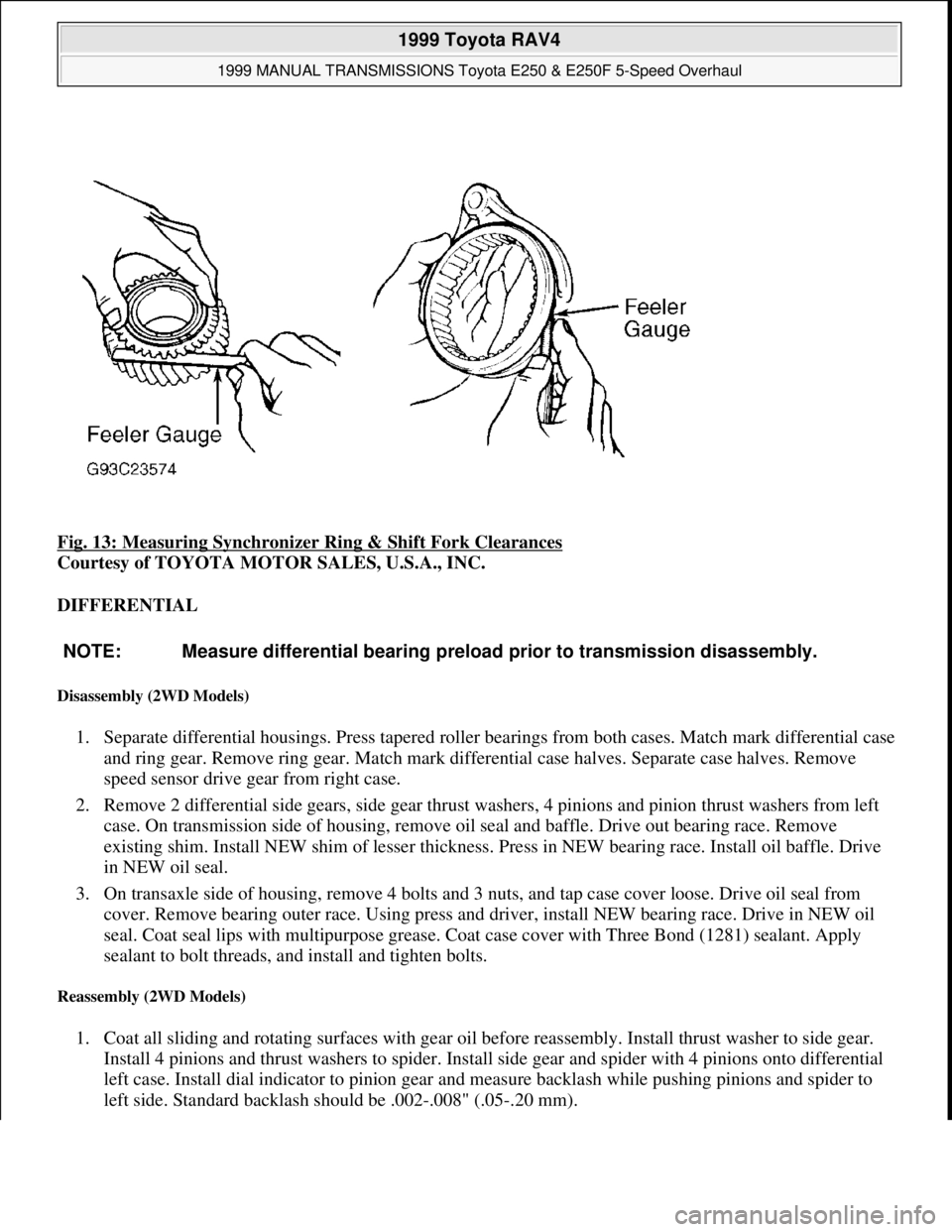

Fig. 13: Measuring Synchronizer Ring & Shift Fork Clearances

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

DIFFERENTIAL

Disassembly (2WD Models)

1. Separate differential housings. Press tapered roller bearings from both cases. Match mark differential case

and ring gear. Remove ring gear. Match mark differential case halves. Separate case halves. Remove

speed sensor drive gear from right case.

2. Remove 2 differential side gears, side gear thrust washers, 4 pinions and pinion thrust washers from left

case. On transmission side of housing, remove oil seal and baffle. Drive out bearing race. Remove

existing shim. Install NEW shim of lesser thickness. Press in NEW bearing race. Install oil baffle. Drive

in NEW oil seal.

3. On transaxle side of housing, remove 4 bolts and 3 nuts, and tap case cover loose. Drive oil seal from

cover. Remove bearing outer race. Using press and driver, install NEW bearing race. Drive in NEW oil

seal. Coat seal lips with multipurpose grease. Coat case cover with Three Bond (1281) sealant. Apply

sealant to bolt threads, and install and tighten bolts.

Reassembly (2WD Models)

1. Coat all sliding and rotating surfaces with gear oil before reassembly. Install thrust washer to side gear.

Install 4 pinions and thrust washers to spider. Install side gear and spider with 4 pinions onto differential

left case. Install dial indicator to pinion gear and measure backlash while pushing pinions and spider to

left side. Standard backlash should be .002-.008" (.05-.20 mm).

NOTE: Measure differential bearing preload prior to transmission disassembly.

1999 Toyota RAV4

1999 MANUAL TRANSMISSIONS Toyota E250 & E250F 5-Speed Overhaul

Microsoft

Sunday, November 22, 2009 10:48:07 AMPage 17 © 2005 Mitchell Repair Information Company, LLC.

Page 988 of 1632

2. Push side gear and pinions to right side of case. Measure side gear backlash. Select thrust washer which

will ensure backlash is within limits. Thrust washers are available in thicknesses of .031" (.80 mm)

to .055" (1.40 mm), in .004" (.10 mm) increments.

3. Install vehicle speed sensor drive gear. Align match marks on differential cases and carefully tap together.

Install and tighten attaching screws. Clean contact surface of differential case and threads of ring gear.

Heat ring gear in water to 212°F (100°C). Quickly clean ring gear contact surface with solvent, then

install on differential case.

4. Allow ring gear to cool. Tighten ring gear bolts to 91 ft. lbs. (124 N.m). Press NEW bearings onto

differential cases. Adjust output shaft bearing preload. See OUTPUT SHAFT BEARING PRELOAD

under TRANSAXLE REASSEMBLY. Install differential case assembly into transaxle case half. Install

output shaft assembly. Install transmission case half. Tighten bolts.

5. Install output shaft bearing outer race. Install shim. Install rear bearing retainer, and tighten bolts. Install

NEW lock nut onto output shaft. Rotate output shaft 2-3 times to set bearings. Install torque wrench, and

measure side bearing preload. If preload is not 1.6-3.0 INCH lbs. (1.8-3.5 kg) for NEW bearings, or 1.0-.9

INCH lbs. (1.1-2.2 kg) for used bearings, select appropriate adjusting shim. Adjusting shims are available

in thicknesses of .079" (2.0 mm) to .112" (2.85 mm) in .002" (.05 mm) increments. Shims are stamped

"1"-"9", and "A"-"H".

Disassembly (4WD Models)

1. Remove No. 2 differential case. Match mark differential case and ring gear. Remove ring gear. Remove

No. 2 differential side gear thrust washer and conical spring washer. See Fig. 14

.

2. Remove front differential case assembly. Remove front differential side gear and thrust washer. Remove

snap ring and spacer.

Remove front differential pinion shafts, No. 2 front pinion shaft, shaft holder, pinions, pinion thrust

washers, front differential side gear and front differential thrust washer. Remove snap ring, spacer and

vehicle speed sensor drive gear. Remove tapered roller bearing.

3. From No. 1 differential case, remove pinion shafts, shaft holder, pinions and thrust washers, differential

side gear subassembly, conical spring washer and side gear thrust washer. Remove tapered roller bearing.

See Fig. 14

. NOTE: Total preload will change approximately 1.7 lbs. (1 kg) for every .002" (.05

mm) change in adjusting shim thickness.

NOTE: Wrap vinyl tape around case to prevent damage.

1999 Toyota RAV4

1999 MANUAL TRANSMISSIONS Toyota E250 & E250F 5-Speed Overhaul

Microsoft

Sunday, November 22, 2009 10:48:07 AMPage 18 © 2005 Mitchell Repair Information Company, LLC.

Page 993 of 1632

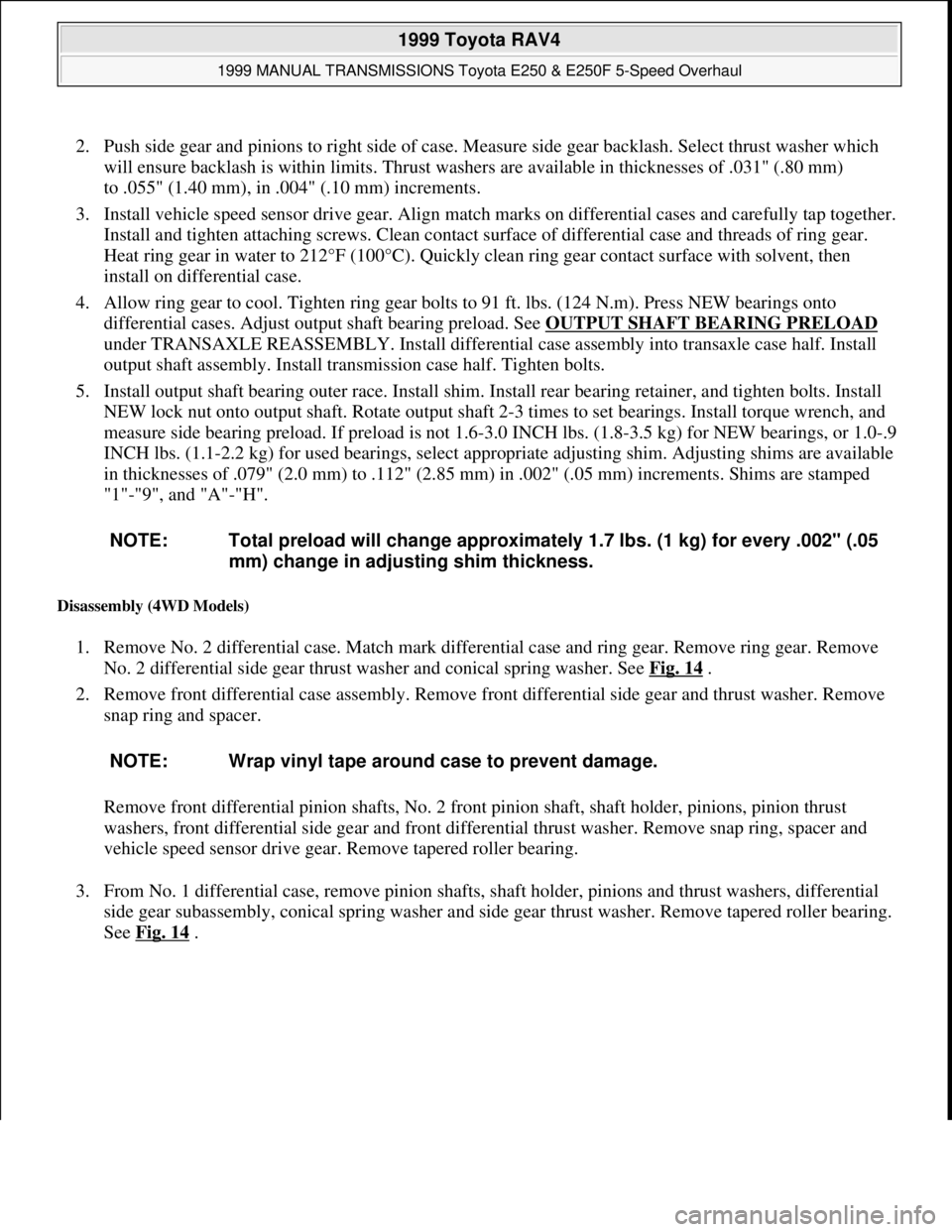

Fig. 17: Identifying Front Differential Case Measuring Point

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

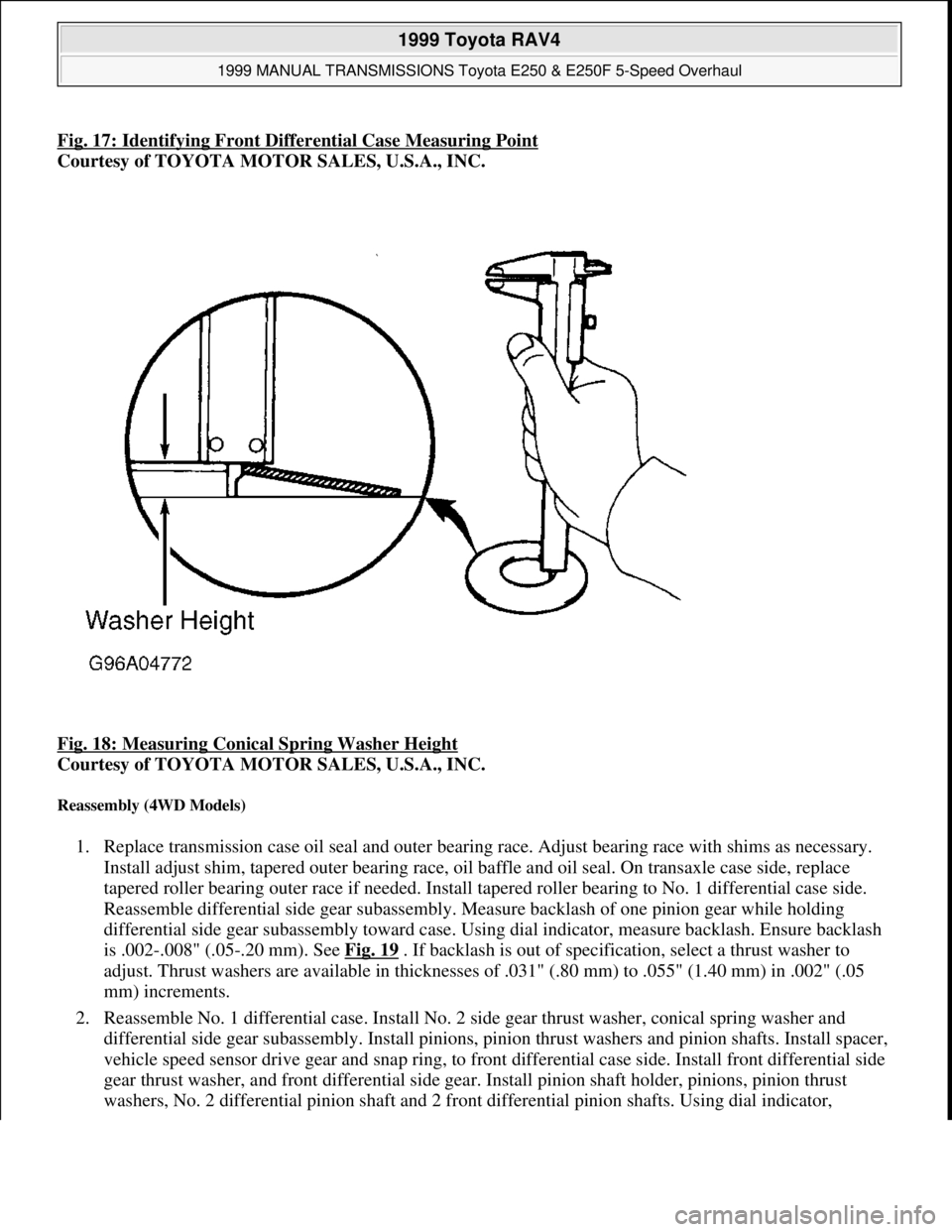

Fig. 18: Measuring Conical Spring Washer Height

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

Reassembly (4WD Models)

1. Replace transmission case oil seal and outer bearing race. Adjust bearing race with shims as necessary.

Install adjust shim, tapered outer bearing race, oil baffle and oil seal. On transaxle case side, replace

tapered roller bearing outer race if needed. Install tapered roller bearing to No. 1 differential case side.

Reassemble differential side gear subassembly. Measure backlash of one pinion gear while holding

differential side gear subassembly toward case. Using dial indicator, measure backlash. Ensure backlash

is .002-.008" (.05-.20 mm). See Fig. 19

. If backlash is out of specification, select a thrust washer to

adjust. Thrust washers are available in thicknesses of .031" (.80 mm) to .055" (1.40 mm) in .002" (.05

mm) increments.

2. Reassemble No. 1 differential case. Install No. 2 side gear thrust washer, conical spring washer and

differential side gear subassembly. Install pinions, pinion thrust washers and pinion shafts. Install spacer,

vehicle speed sensor drive gear and snap ring, to front differential case side. Install front differential side

gear thrust washer, and front differential side gear. Install pinion shaft holder, pinions, pinion thrust

washers, No. 2 differential pinion shaft and 2 front differential pinion shafts. Using dial indicator,

1999 Toyota RAV4

1999 MANUAL TRANSMISSIONS Toyota E250 & E250F 5-Speed Overhaul

Microsoft

Sunday, November 22, 2009 10:48:07 AMPage 23 © 2005 Mitchell Repair Information Company, LLC.