sensor TOYOTA RAV4 1996 Service Repair Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 1996, Model line: RAV4, Model: TOYOTA RAV4 1996Pages: 1632, PDF Size: 41.64 MB

Page 1000 of 1632

Output Shaft Lock Nut90 (123)

Rear Bearing Retainer Bolt31 (42)

Reverse Idler Shaft Lock Bolt22 (29)

Reverse Shaft Arm Bracket Bolt13 (17)

Selecting Bellcrank Support Set Bolt14 (20)

Selector Shaft Lock Bolt36 (49)

Shift Forks & Head Set Bolts17 (24)

Stiffener Plate-To-Transaxle Bolt27 (37)

Straight Screw Plug18 (25)

Transaxle Case Cover Bolt22 (29)

Transmission Case Cover Bolt22 (29)

Vehicle Speed Sensor Bolt13 (17)

INCH Lbs. (N.m)

Oil Pump-To-Cover Bolt89 (10)

Oil Tube108 (12)

Reverse Restrict Pin Holder115 (13)

1999 Toyota RAV4

1999 MANUAL TRANSMISSIONS Toyota E250 & E250F 5-Speed Overhaul

Microsoft

Sunday, November 22, 2009 10:48:07 AMPage 30 © 2005 Mitchell Repair Information Company, LLC.

Page 1087 of 1632

1. Start engine and warm engine to normal operating temperature. Shut engine off. Remove cover (if

equipped) and connect scan tool to data link connector No. 3. See Fig. 19

-Fig. 25 . Scan tool is used to

read engine RPM.

2. Apply parking brake. Place transmission/transaxle in Neutral. Start engine and maintain engine at 2500

RPM for 90 seconds and then allow engine to idle. Ensure idle speed is within specification. See IDLE

SPEED SPECIFICATIONS table.

3. If idle speed is not within specification, check air intake system, Idle Air Control (IAC) valve, wiring and

Engine Control Module (ECM). See IDLE CONTROL SYSTEM in SYSTEM & COMPONENT

TESTING - 4-CYLINDER article. Shut engine off. Remove scan tool.

IDLE SPEED SPECIFICATIONS

(1)

THROTTLE POSITION SENSOR

4-CYLINDER THROTTLE POSITION SENSOR

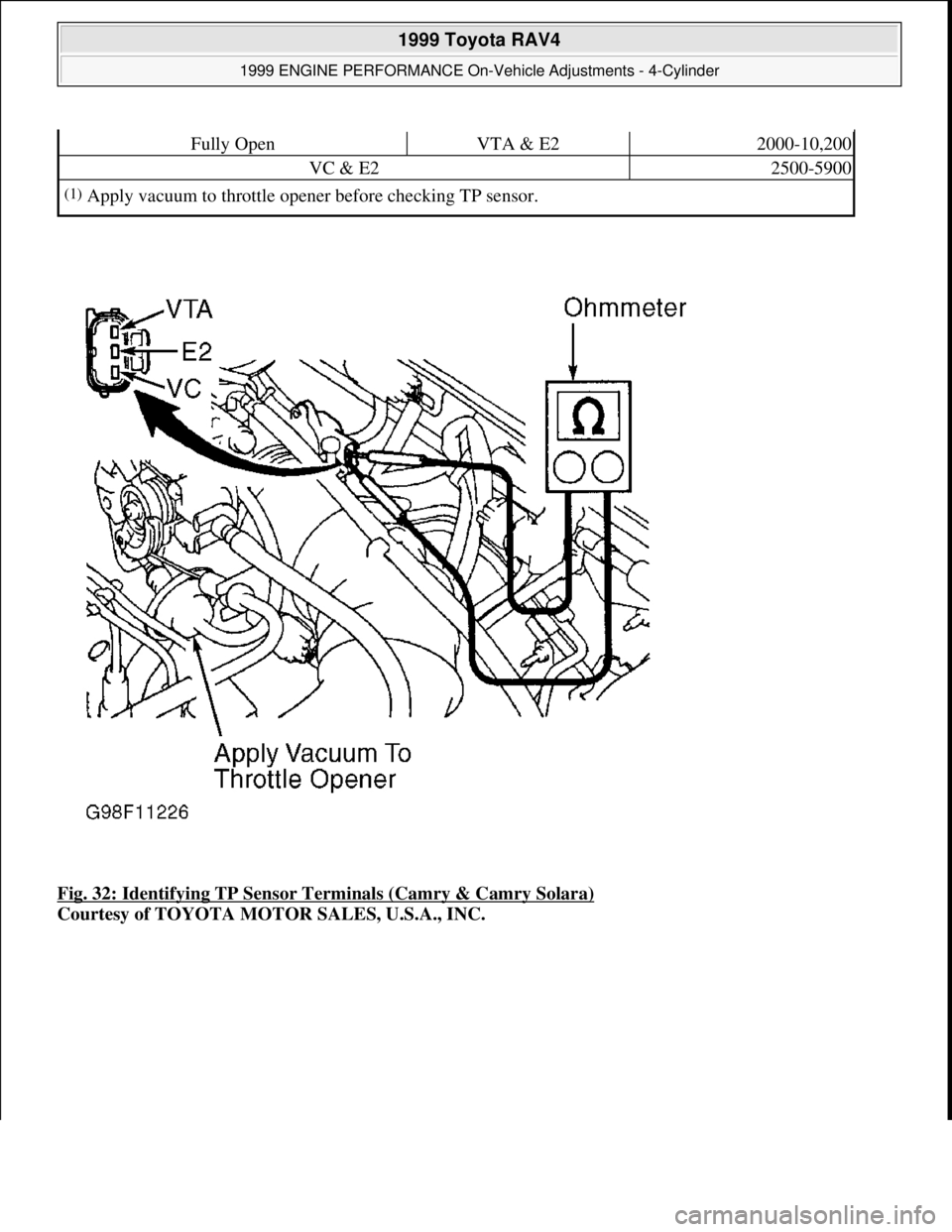

Camry & Camry Solara

1. Manufacturer does not list procedure for Throttle Position (TP) sensor adjustment. Only information

available is for checking resistance of TP sensor.

2. Disconnect electrical connector from TP sensor. Note electrical terminals on TP sensor. See Fig. 32

.

Apply vacuum to throttle opener.

3. Using ohmmeter, check resistance between specified terminals in relation to throttle position. See

THROTTLE POSITION SENSOR RESISTANCE

table. Replace components as necessary if

resistance is not within specification.

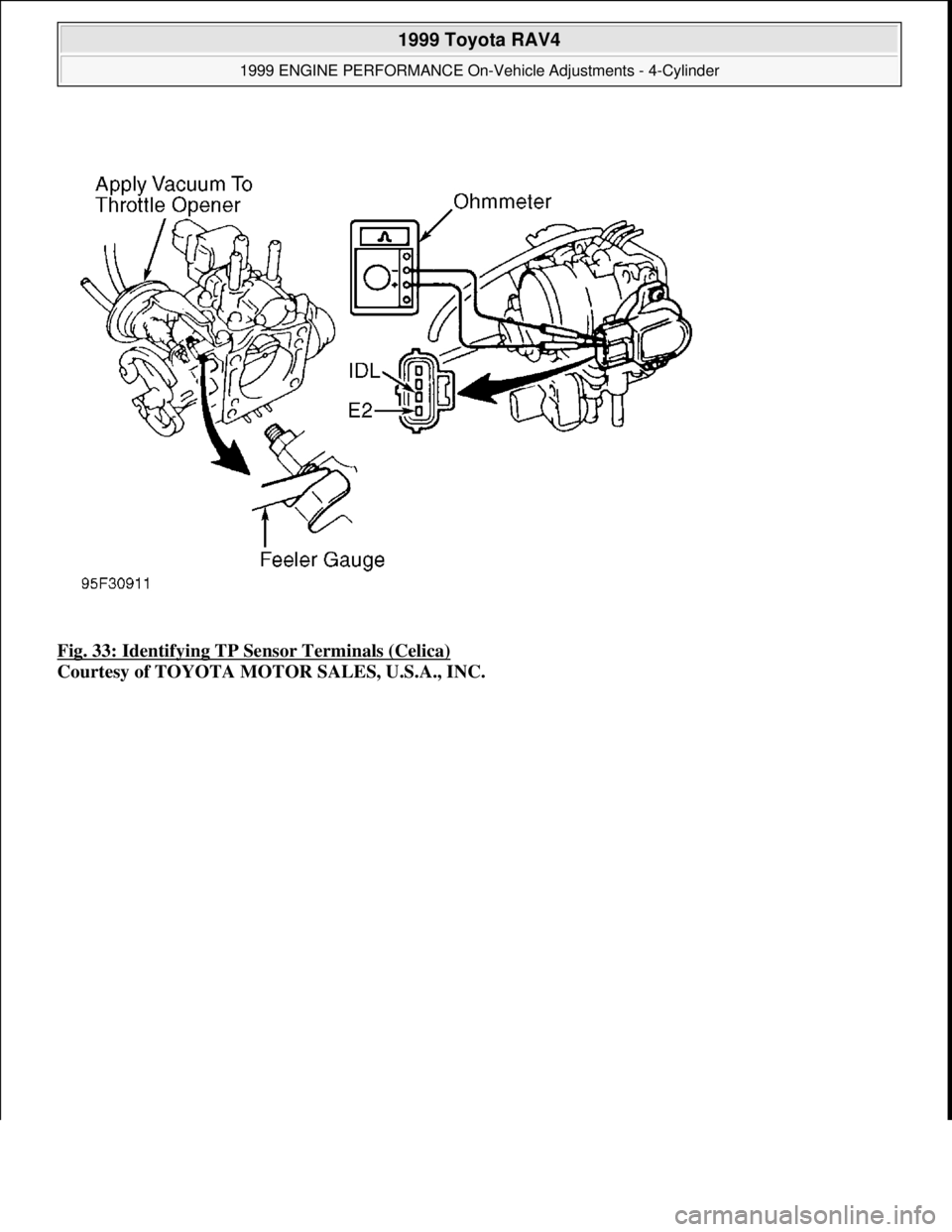

Celica

1. Disconnect electrical connector from Throttle Position (TP) sensor. Loosen TP sensor mounting screws.

Connect ohmmeter between terminals IDL and E2. See Fig. 33

.

2. Apply vacuum to throttle opener. To set initial clearance, insert .024" (.60 mm) feeler gauge between

throttle stop screw and throttle lever.

3. Gradually rotate TP sensor clockwise until ohmmeter deflects. Tighten TP sensor mounting screws.

Remove feeler

gauge. Reinsert a .020" (.50 mm) feeler gauge. Continuity should exist between terminals

ApplicationRPM

Camry, Camry Solara, Celica &

Corolla650-750

RAV4700-800

Tacoma & 4Runner650-750

(1)Check with engine at normal operating temperature, transmission/transaxle

in Neutral, parking brake applied, air cleaner and all vacuum hoses

installed, electronic fuel injection system wiring connectors properly

installed, ignition timing properly set, electric cooling fan off (if

equipped), and A/C and all accessories off.

1999 Toyota RAV4

1999 ENGINE PERFORMANCE On-Vehicle Adjustments - 4-Cylinder

Microsoft

Sunday, November 22, 2009 10:25:31 AMPage 36 © 2005 Mitchell Repair Information Company, LLC.

Page 1088 of 1632

IDL and E2. Remove feeler gauge.

4. Reinsert a .028" (.70 mm) feeler gauge. No continuity should exist between terminals IDL and E2.

Remove feeler gauge and ohmmeter. Install electrical connector on TP sensor.

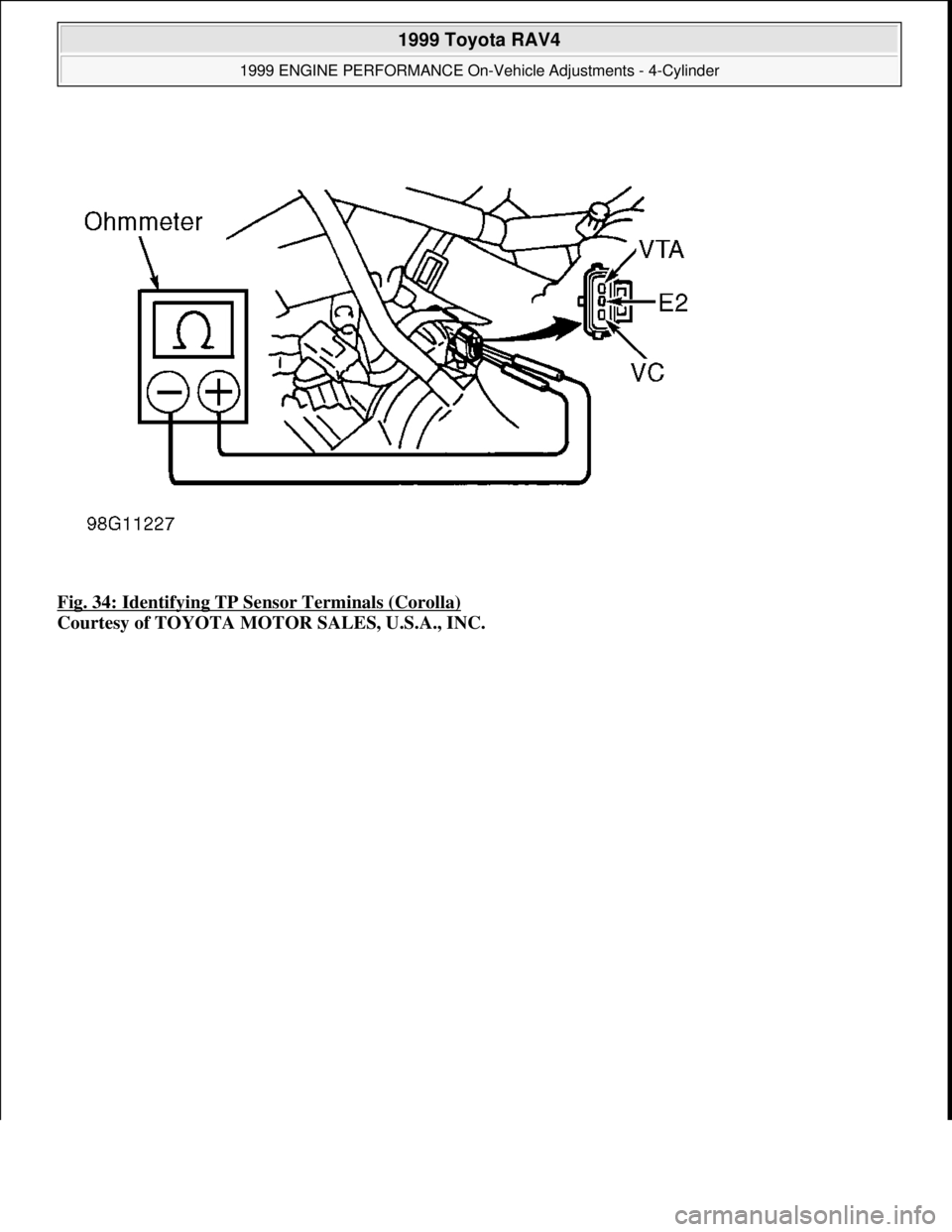

Corolla

1. Manufacturer does not list procedure for Throttle Position (TP) sensor adjustment. Only information

available is for checking resistance of TP sensor.

2. Disconnect electrical connector from TP sensor. Note electrical terminals on TP sensor. See Fig. 34

.

3. Using ohmmeter, check resistance between specified terminals in relation to throttle position. See

THROTTLE POSITION SENSOR RESISTANCE

table. Replace components as necessary if

resistance is not within specification.

RAV4

1. Manufacturer does not list procedure for Throttle Position (TP) sensor adjustment. Only information

available is for checking resistance of TP sensor.

2. Note location of E2 terminal (Brown wire), VC terminal (Yellow wire) and VTA terminal (Blue/Red

wire) on TP sensor. Disconnect electrical connector from TP sensor. Apply vacuum to throttle opener.

3. Using ohmmeter, check resistance between specified terminals in relation to throttle position. See

THROTTLE POSITION SENSOR RESISTANCE

table. Replace components as necessary if

resistance is not within specification.

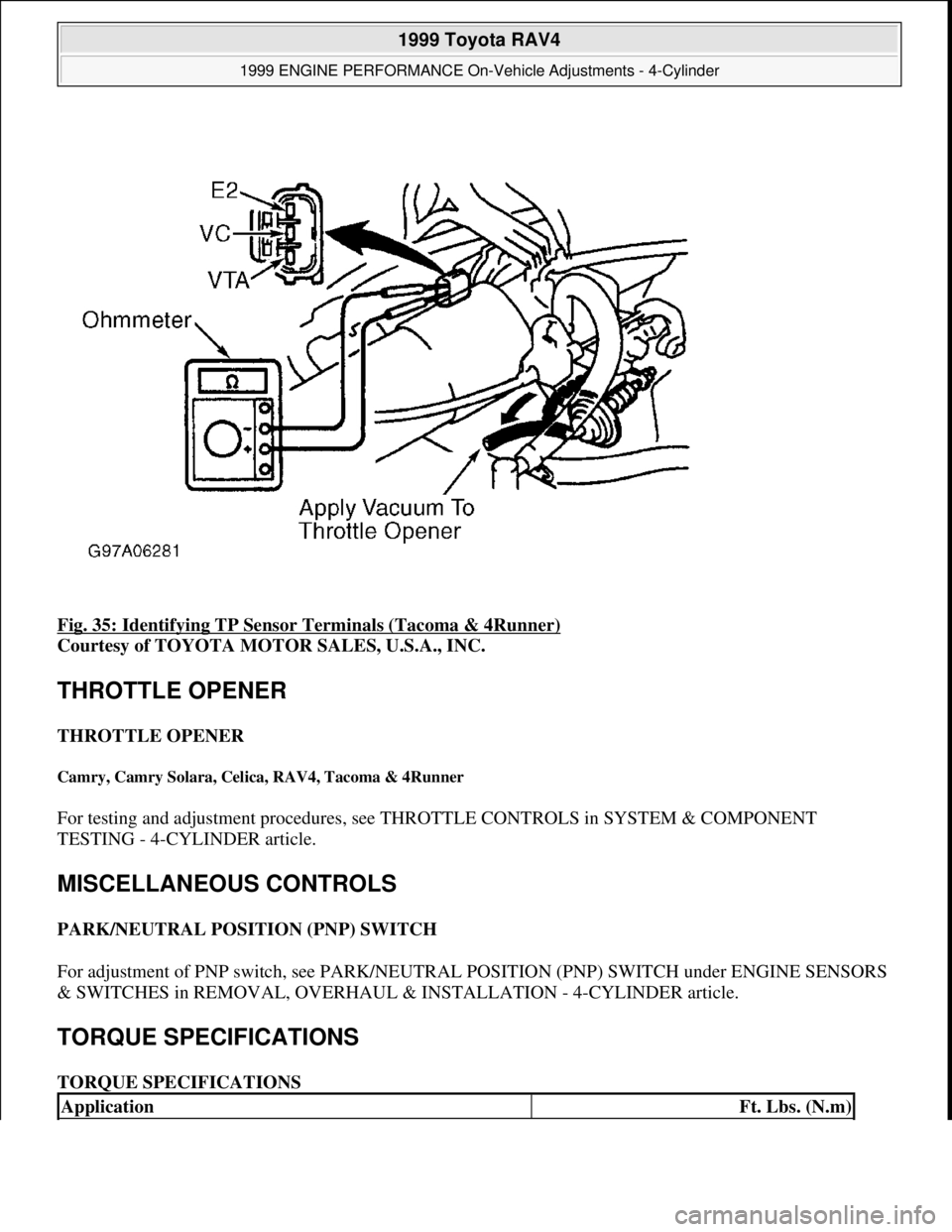

Tacoma & 4Runner

1. Manufacturer does not list procedure for Throttle Position (TP) sensor adjustment. Only information

available is for checking resistance of TP sensor.

2. Disconnect electrical connector from TP sensor. Note electrical terminals on TP sensor. See Fig. 35

.

Apply vacuum to throttle opener.

3. Using ohmmeter, check resistance between specified terminals in relation to throttle position. See

THROTTLE POSITION SENSOR RESISTANCE

table. Replace components as necessary if

resistance is not within specification.

THROTTLE POSITION SENSOR RESISTANCE

ApplicationThrottle PositionTerminalsOhms

Camry & Camry

Solara

(1)

Fully ClosedVTA & E2200-5700

Fully OpenVTA & E22000-10,200

VC & E22500-5900

CorollaFully ClosedVTA & E2200-5700

Fully OpenVTA & E22000-10,200

VC & E22500-5900

RAV4, Tacoma &

4Runner

(1)

Fully ClosedVTA & E2200-5700

1999 Toyota RAV4

1999 ENGINE PERFORMANCE On-Vehicle Adjustments - 4-Cylinder

Microsoft

Sunday, November 22, 2009 10:25:31 AMPage 37 © 2005 Mitchell Repair Information Company, LLC.

Page 1089 of 1632

Fig. 32: Identifying TP Sensor Terminals (Camry & Camry Solara)

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

Fully OpenVTA & E22000-10,200

VC & E22500-5900

(1)Apply vacuum to throttle opener before checking TP sensor.

1999 Toyota RAV4

1999 ENGINE PERFORMANCE On-Vehicle Adjustments - 4-Cylinder

Microsoft

Sunday, November 22, 2009 10:25:31 AMPage 38 © 2005 Mitchell Repair Information Company, LLC.

Page 1090 of 1632

Fig. 33: Identifying TP Sensor Terminals (Celica)

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

1999 Toyota RAV4

1999 ENGINE PERFORMANCE On-Vehicle Adjustments - 4-Cylinder

Microsoft

Sunday, November 22, 2009 10:25:31 AMPage 39 © 2005 Mitchell Repair Information Company, LLC.

Page 1091 of 1632

Fig. 34: Identifying TP Sensor Terminals (Corolla)

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

1999 Toyota RAV4

1999 ENGINE PERFORMANCE On-Vehicle Adjustments - 4-Cylinder

Microsoft

Sunday, November 22, 2009 10:25:31 AMPage 40 © 2005 Mitchell Repair Information Company, LLC.

Page 1092 of 1632

Fig. 35: Identifying TP Sensor Terminals (Tacoma & 4Runner)

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

THROTTLE OPENER

THROTTLE OPENER

Camry, Camry Solara, Celica, RAV4, Tacoma & 4Runner

For testing and adjustment procedures, see THROTTLE CONTROLS in SYSTEM & COMPONENT

TESTING - 4-CYLINDER article.

MISCELLANEOUS CONTROLS

PARK/NEUTRAL POSITION (PNP) SWITCH

For adjustment of PNP switch, see PARK/NEUTRAL POSITION (PNP) SWITCH under ENGINE SENSORS

& SWITCHES in REMOVAL, OVERHAUL & INSTALLATION - 4-CYLINDER article.

TORQUE SPECIFICATIONS

TORQUE SPECIFICATIONS

ApplicationFt. Lbs. (N.m)

1999 Toyota RAV4

1999 ENGINE PERFORMANCE On-Vehicle Adjustments - 4-Cylinder

Microsoft

Sunday, November 22, 2009 10:25:31 AMPage 41 © 2005 Mitchell Repair Information Company, LLC.

Page 1143 of 1632

WHEEL BEARING INSPECTION

Raise and support vehicle. Remove wheel and brake drum, or rotor (if equipped). Position dial indicator with

stem against center of axle hub. Move axle hub in and out while observing dial indicator. Replace hub if axial

play exceeds .002" (.05 mm). Measure hub axial runout. Replace hub if runout exceeds .0028" (.07 mm).

WHEEL BEARING ADJUSTMENT

Hubs must be replaced if axle end play or runout are not within specification. No adjustment is available. See

WHEEL BEARINGS (HUBS)

under REMOVAL & INSTALLATION

REMOVAL & INSTALLATION

AXLE BEAM

Removal (ECHO)

1. Raise and support vehicle. Remove rear wheels and brake drums. Disconnect brakelines from flex hoses,

remove retaining clips from shock absorbers and plug openings. Disconnect ABS sensor and remove

harness clamp from axle beam. Disconnect parking brake cable from backing plate and remove cable

clamp from axle beam. Remove axle hub assemblies. Remove backing plate assemblies, with brake shoes

still attached.

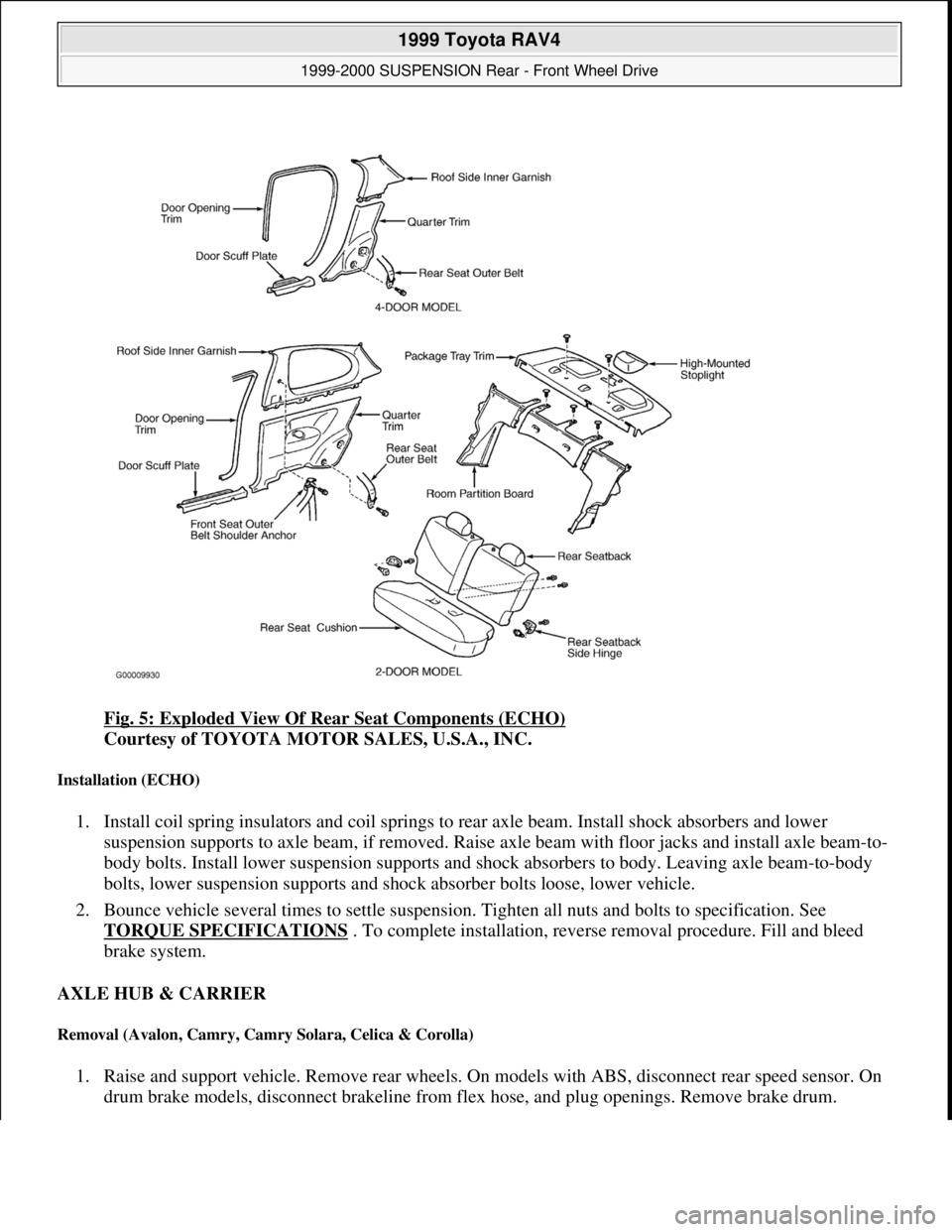

2. Remove high-mounted stop light from rear package tray. Remove 2 clips and remove package tray.

Remove rear seat. Remove door scuff plate and door opening trim. See Fig. 5

. Remove rear seat outer

seat belts and remove quarter trim panels. On 2 door models, remove outer anchor for front seat shoulder

belt and remove roof side inner garnish. On all models, remove room partition board.

3. Using 2 floor jacks, support rear axle beam under each coil spring. While holding shock absorber shaft,

remove the 2 upper nuts, disconnecting lower suspension supports from body. Lower jacks slowly.

Remove coil springs and insulators. Remove axle beam-to-

body bolts. Remove axle beam. NOTE: See SPECIFICATIONS & PROCEDURES

in WHEEL ALIGNMENT article.

1999 Toyota RAV4

1999-2000 SUSPENSION Rear - Front Wheel Drive

Microsoft

Sunday, November 22, 2009 10:37:21 AMPage 5 © 2005 Mitchell Repair Information Company, LLC.

Page 1144 of 1632

Fig. 5: Exploded View Of Rear Seat Components (ECHO)

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

Installation (ECHO)

1. Install coil spring insulators and coil springs to rear axle beam. Install shock absorbers and lower

suspension supports to axle beam, if removed. Raise axle beam with floor jacks and install axle beam-to-

body bolts. Install lower suspension supports and shock absorbers to body. Leaving axle beam-to-body

bolts, lower suspension supports and shock absorber bolts loose, lower vehicle.

2. Bounce vehicle several times to settle suspension. Tighten all nuts and bolts to specification. See

TORQUE SPECIFICATIONS

. To complete installation, reverse removal procedure. Fill and bleed

brake system.

AXLE HUB & CARRIER

Removal (Avalon, Camry, Camry Solara, Celica & Corolla)

1. Raise and support vehicle. Remove rear wheels. On models with ABS, disconnect rear speed sensor. On

drum brake models, disconnect brakeline from flex hose, and plu

g openings. Remove brake drum.

1999 Toyota RAV4

1999-2000 SUSPENSION Rear - Front Wheel Drive

Microsoft

Sunday, November 22, 2009 10:37:21 AMPage 6 © 2005 Mitchell Repair Information Company, LLC.

Page 1145 of 1632

2. On disc brake models, remove rotor and caliper. Leaving flex hose attached, suspend caliper aside. On all

models, remove 4 axle hub-to-axle carrier bolts, axle hub and "O" ring.

3. Note position of nuts on suspension arms and strut rods for installation reference. Disconnect strut rod

from axle carrier. Disconnect No. 1 and No. 2 lower suspension arms from axle carrier. Remove 2 bolts

and nuts, and remove axle carrier.

Installation (Avalon, Camry, Camry Solara, Celica & Corolla)

To install, reverse removal procedure. Coat NEW "O" ring with grease and install hub. Tighten all fasteners to

specification. See TORQUE SPECIFICATIONS

. Bleed brake system. Check rear wheel alignment.

Removal (RAV4)

1. Raise and support vehicle. Remove rear wheel and brake drum. On 4WD models, remove drive axle.

Remove ABS speed sensor (if equipped). Remove drive axle lock nut. Place matchmarks on drive axle

and differential gear shaft. Remove the 4 nuts and remove drive axle from differential side gear. On FWD

models, disconnect ABS sensor and remove harness clamp (if equipped). On all models, remove 2

brakeline clamps from rear No. 1 suspension arm. Remove parking brake cable clamp. See Fig. 4

.

2. Remove 4 bolts and remove axle hub and backing plate, leaving brake shoes attached. Disconnect lower

end of shock absorber. Using Ball Joint Puller (09628-62011), disconnect upper and lower suspension

arms from rear No. 1 suspension arm. Place matchmarks on camber adjusting cam and suspension

member and remove bolt. See Fig. 6

. Place matchmarks on toe adjusting cam and body and loosen bolt.

See Fig. 7

. Remove coil spring and upper insulator. Remove loosened toe adjusting cam bolt. Remove

rear No. 1 suspension arm. NOTE: Bounce vehicle several times to stabilize suspension. Tighten axle carrier-to-

shock absorber assembly and suspension arm bolts to specification with

vehicle at normal operating height.

1999 Toyota RAV4

1999-2000 SUSPENSION Rear - Front Wheel Drive

Microsoft

Sunday, November 22, 2009 10:37:21 AMPage 7 © 2005 Mitchell Repair Information Company, LLC.