sensor TOYOTA RAV4 1996 Service Manual Online

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 1996, Model line: RAV4, Model: TOYOTA RAV4 1996Pages: 1632, PDF Size: 41.64 MB

Page 337 of 1632

retaining inboard tripod joint. Paint reference marks on tripod joint and axle shaft for reassembly

reference.

3. Using a hammer and brass drift, tap inboard tripod joint from axle shaft. DO NOT tap on roller of tripod

joint during removal. Remove boots from axle shaft. Using a screwdriver and hammer, remove dust

deflector from axle shaft.

Reassembly

1. Using a press, install NEW dust deflector on axle shaft. Wrap splines on axle shaft with tape to prevent

damaging boots during installation.

2. Install NEW boots and NEW boot clamps on axle shaft. Install NEW snap ring on axle shaft. Install

inboard tripod joint on axle shaft, with small diameter side facing outboard joint. Ensure reference mark

on inboard joint and axle shaft are aligned. Install NEW snap ring that retains inboard tripod joint on axle

shaft.

3. Apply grease supplied with overhaul kit to inner joint and boot. Install outer joint tulip on inner joint.

Ensure match-marks are aligned.

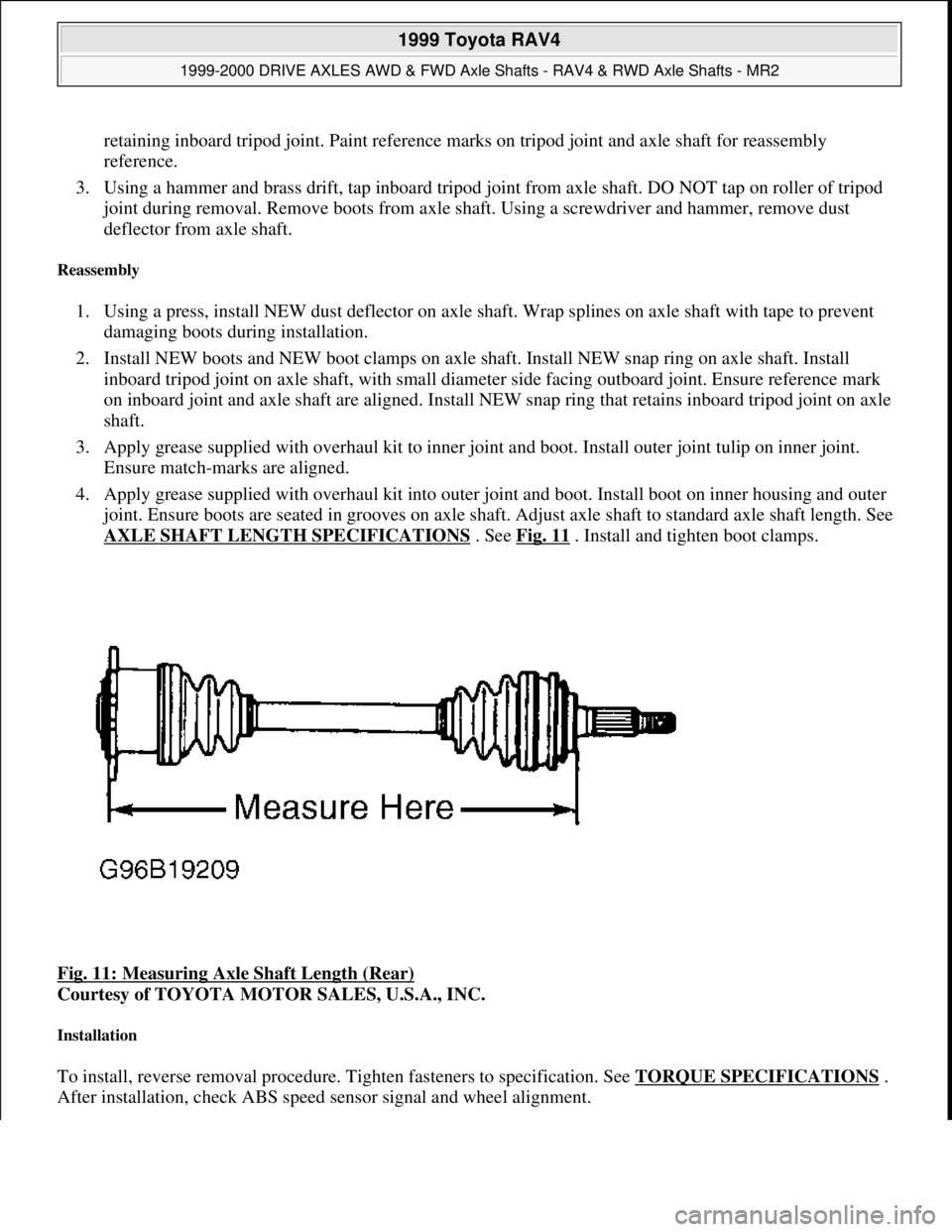

4. Apply grease supplied with overhaul kit into outer joint and boot. Install boot on inner housing and outer

joint. Ensure boots are seated in grooves on axle shaft. Adjust axle shaft to standard axle shaft length. See

AXLE SHAFT LENGTH SPECIFICATIONS

. See Fig. 11 . Install and tighten boot clamps.

Fig. 11: Measuring Axle Shaft Length (Rear)

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

Installation

To install, reverse removal procedure. Tighten fasteners to specification. See TORQUE SPECIFICATIONS .

After installation, check ABS speed sensor si

gnal and wheel alignment.

1999 Toyota RAV4

1999-2000 DRIVE AXLES AWD & FWD Axle Shafts - RAV4 & RWD Axle Shafts - MR2

Microsoft

Sunday, November 22, 2009 10:08:21 AMPage 16 © 2005 Mitchell Repair Information Company, LLC.

Page 338 of 1632

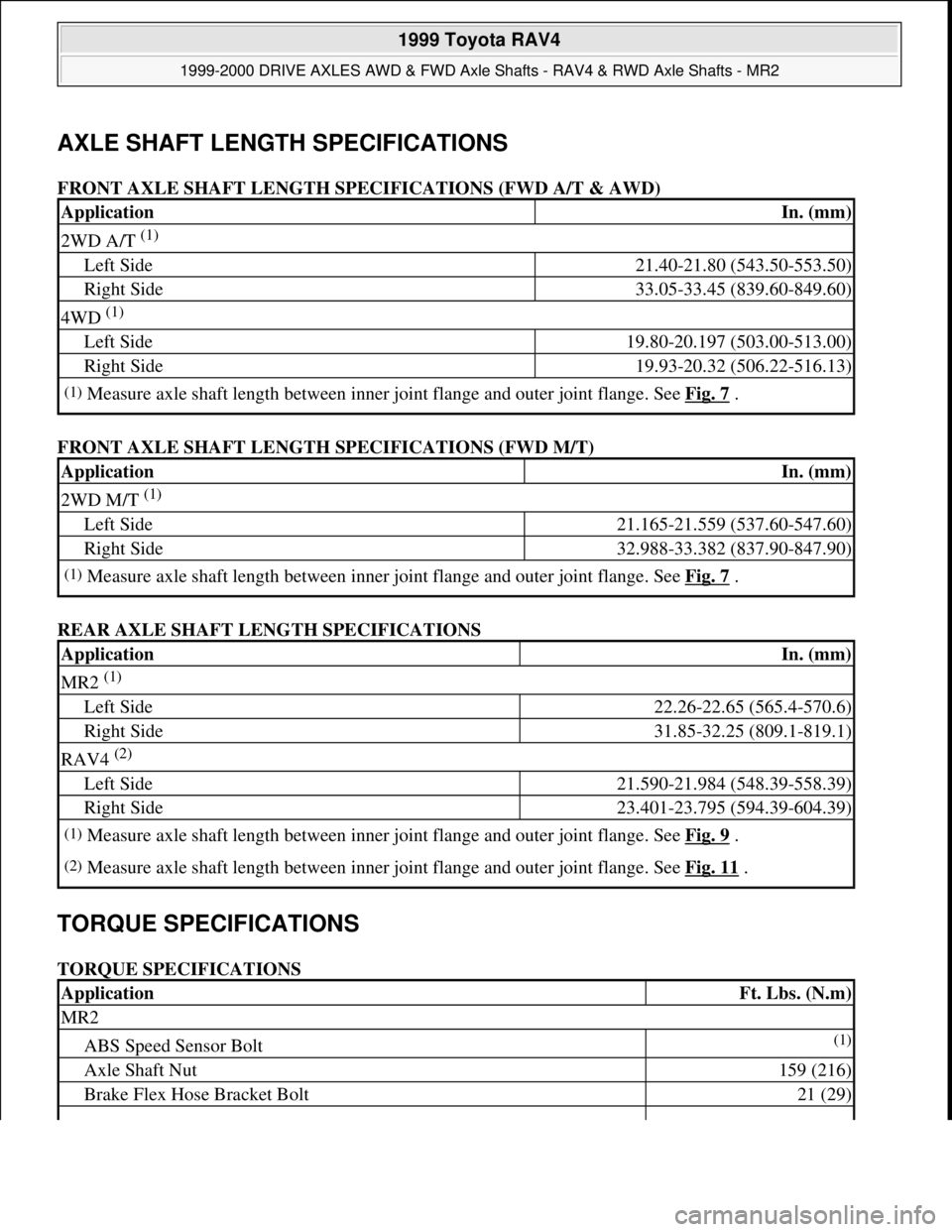

AXLE SHAFT LENGTH SPECIFICATIONS

FRONT AXLE SHAFT LENGTH SPECIFICATIONS (FWD A/T & AWD)

FRONT AXLE SHAFT LENGTH SPECIFICATIONS (FWD M/T)

REAR AXLE SHAFT LENGTH SPECIFICATIONS

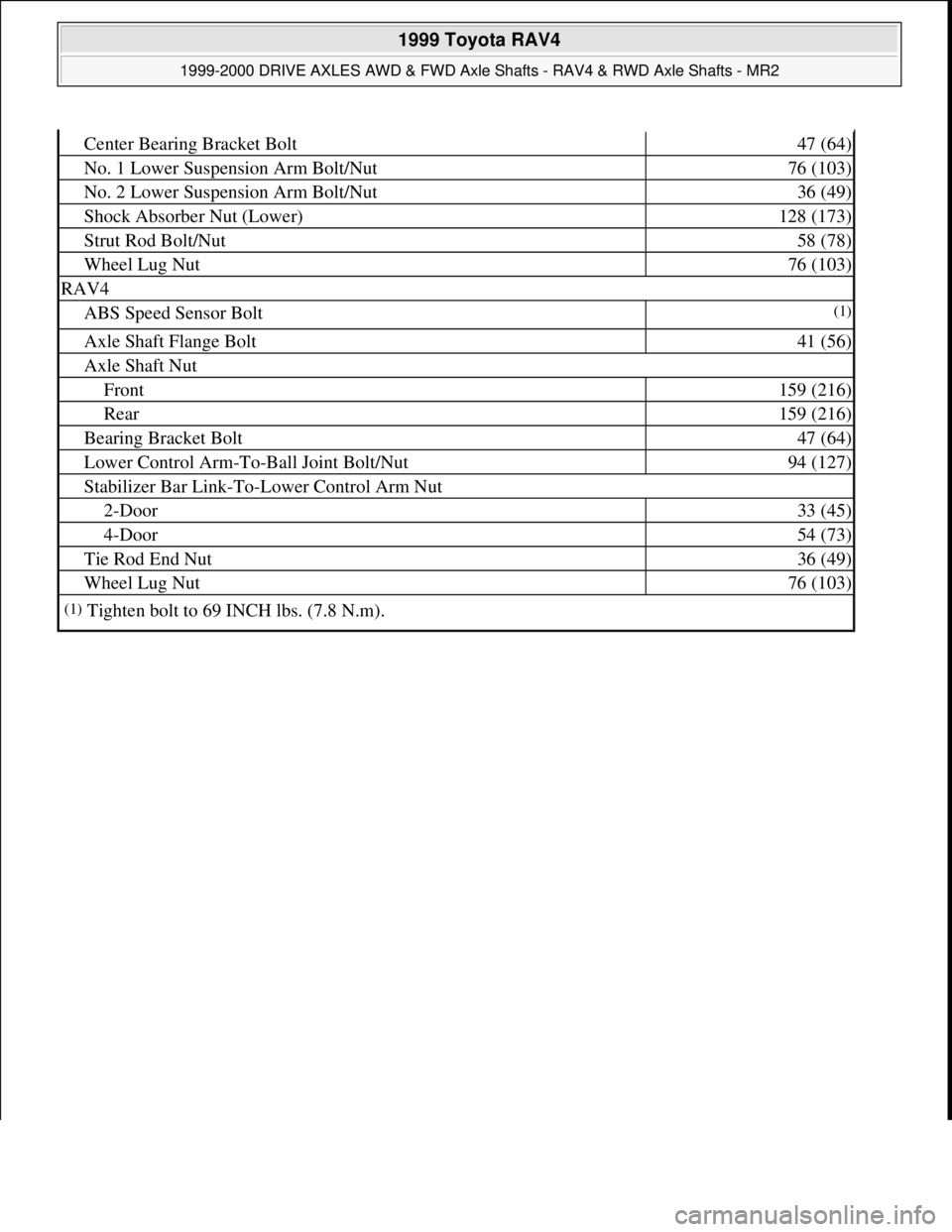

TORQUE SPECIFICATIONS

TORQUE SPECIFICATIONS

ApplicationIn. (mm)

2WD A/T (1)

Left Side21.40-21.80 (543.50-553.50)

Right Side33.05-33.45 (839.60-849.60)

4WD (1)

Left Side19.80-20.197 (503.00-513.00)

Right Side19.93-20.32 (506.22-516.13)

(1)Measure axle shaft length between inner joint flange and outer joint flange. See Fig. 7 .

ApplicationIn. (mm)

2WD M/T (1)

Left Side21.165-21.559 (537.60-547.60)

Right Side32.988-33.382 (837.90-847.90)

(1)Measure axle shaft length between inner joint flange and outer joint flange. See Fig. 7 .

ApplicationIn. (mm)

MR2 (1)

Left Side22.26-22.65 (565.4-570.6)

Right Side31.85-32.25 (809.1-819.1)

RAV4 (2)

Left Side21.590-21.984 (548.39-558.39)

Right Side23.401-23.795 (594.39-604.39)

(1)Measure axle shaft length between inner joint flange and outer joint flange. See Fig. 9 .

(2)Measure axle shaft length between inner joint flange and outer joint flange. See Fig. 11 .

ApplicationFt. Lbs. (N.m)

MR2

ABS Speed Sensor Bolt(1)

Axle Shaft Nut159 (216)

Brake Flex Hose Bracket Bolt21 (29)

1999 Toyota RAV4

1999-2000 DRIVE AXLES AWD & FWD Axle Shafts - RAV4 & RWD Axle Shafts - MR2

Microsoft

Sunday, November 22, 2009 10:08:21 AMPage 17 © 2005 Mitchell Repair Information Company, LLC.

Page 339 of 1632

Center Bearing Bracket Bolt47 (64)

No. 1 Lower Suspension Arm Bolt/Nut76 (103)

No. 2 Lower Suspension Arm Bolt/Nut36 (49)

Shock Absorber Nut (Lower)128 (173)

Strut Rod Bolt/Nut58 (78)

Wheel Lug Nut76 (103)

RAV4

ABS Speed Sensor Bolt(1)

Axle Shaft Flange Bolt41 (56)

Axle Shaft Nut

Front159 (216)

Rear159 (216)

Bearing Bracket Bolt47 (64)

Lower Control Arm-To-Ball Joint Bolt/Nut94 (127)

Stabilizer Bar Link-To-Lower Control Arm Nut

2-Door33 (45)

4-Door54 (73)

Tie Rod End Nut36 (49)

Wheel Lug Nut76 (103)

(1)Tighten bolt to 69 INCH lbs. (7.8 N.m).

1999 Toyota RAV4

1999-2000 DRIVE AXLES AWD & FWD Axle Shafts - RAV4 & RWD Axle Shafts - MR2

Microsoft

Sunday, November 22, 2009 10:08:21 AMPage 18 © 2005 Mitchell Repair Information Company, LLC.

Page 364 of 1632

1. Disconnect fluid level warning switch connector. Remove fluid from master cylinder with syringe.

Remove 2 bolts, and move relay box aside. Remove air cleaner housing and hose.

2. Disconnect brake lines and 3-way line connector from master cylinder. If equipped with M/T, disconnect

clutch reservoir hose. On all models, remove 2 bolts and master cylinder.

3. Prior to installation, adjust length of brake booster push rod if necessary. See POWER BRAKE UNIT

PUSH ROD under ADJUSTMENTS.

4. Install master cylinder in reverse of removal procedure. Use NEW gasket. Fill and bleed system. Check

for leaks and adjust pedal, if needed. Bleed clutch system, if equipped.

Removal & Installation (Sienna)

1. Remove air cleaner assembly. Disconnect fluid level warning switch connector. Remove fluid from

master cylinder with syringe. Remove fluid reservoir tank and bracket (2 bolts).

2. Disconnect brake lines from master cylinder. Remove 2 bolts and master cylinder.

3. Prior to installation, adjust length of brake booster push rod if necessary. See POWER BRAKE UNIT

PUSH ROD under ADJUSTMENTS.

4. Install master cylinder in reverse of removal procedure. Use NEW gasket. Fill and bleed system. Check

for leaks and adjust pedal, if needed. Bleed clutch system, if equipped.

Removal & Installation (Tacoma, Tundra & 4Runner)

1. Unplug fluid level sensor lead. Drain brake fluid from reservoir. Disconnect and plug hydraulic lines.

Remove master cylinder-to-power brake unit nuts. Remove master cylinder.

2. If master cylinder has been overhauled or replaced, check and adjust power brake unit push rod. See

POWER BRAKE UNIT PUSH ROD

under ADJUSTMENTS. To install, reverse removal procedure.

Bleed brake system. See BLEEDING BRAKE SYSTEM

.

POWER BRAKE UNIT

Removal & Installation (RAV4, Tacoma, Tundra & 4Runner)

1. Remove master cylinder. See MASTER CYLINDER . On RAV4, remove charcoal canister. On all

models, disconnect vacuum hose. On Tundra, remove scuff plate LH, cowl side trim LH, lower finish

panel and No. 2 heater to register duct. On all models, remove brake pedal return spring, clip and clevis

pin. On Tundra, remove 4 nuts, clevis, brake booster and gasket. Remove 2 stopper rings, brake booster

bracket and gasket from brake booster. Remove power brake unit.

2. Install power brake unit. On Tundra, install NEW gasket to power brake unit. Install bracket and stopper

rings. Install clevis to operating rod. On all models, attach clevis pin, clip and return spring. Adjust push

rod length. See POWER BRAKE UNIT PUSH ROD

under ADJUSTMENTS.

3. Install master cylinder with NEW gasket. Connect vacuum hose. Fill master cylinder. Bleed system and

check for leaks. Adjust brake pedal, if necessary.

Removal & Installation (Sienna)

1. Remove 2 cowl top vent louvers and outer front cowl top panel. See Fig. 16 . Remove master cylinder.

1999 Toyota RAV4

1999-2000 BRAKES Disc & Drum - Trucks & Vans

Microsoft

Sunday, November 22, 2009 10:07:28 AMPage 25 © 2005 Mitchell Repair Information Company, LLC.

Page 471 of 1632

1999-2000 ENGINE COOLING

Electric Cooling Fans

IDENTIFICATION

ELECTRIC COOLING FAN IDENTIFICATION

DESCRIPTION & OPERATION

Land Cruiser, Tacoma, Tundra and 4Runner use a belt-driven cooling fan attached to the water pump. All other

models use 2 electric cooling fans located directly behind the radiator. Fans are controlled via Engine Coolant

Temperature (ECT) switches/sensors, and turn on when engine coolant temperature is above 208°F (98°C) on

Avalon, Camry with 3.0L, Camry Solara with 3.0L and Sienna. On Camry with 2.2L, Camry Solara with 2.2L,

Celica, Corolla, ECHO, MR2 and RAV4, ECT turns cooling fans on above 199°F (93°C). On Avalon, Camry

with 3.0L, Camry Solara with 3.0L and Sienna, fans will turn off when engine coolant temperature falls below

190°F (88°C). On Camry with 2.2L, Camry Solara with 2.2L, Celica, Corolla and RAV4, fans will turn off

below 181°F (83°C).

SYSTEM TESTS

ELECTRIC COOLING FAN

Avalon (1999), Camry 3.0L, Camry Solara 3.0L & Sienna

1. With engine coolant temperature below 190°F (88°C), turn ignition switch to ON position (engine off).

Ensure fans stop.

2. If fan do not stop, test cooling fan relay and ECT switch. See COOLING FAN RELAYS

and ECT

SWITCH . Check for loose or broken connector or wiring between relay and ECT switch. Repair as

necessary.

3. Disconnect No. 1 ECT switch connector. See ECT SWITCH LOCATIONS

table. With ignition still in

ON position, ensure cooling fan turns on. If not, check fuses, engine main relay, cooling fan relay and

cooling fan motor. Check for short between cooling fan relay and ECT switch.

4. Start engine and raise temperature above 208°F (98°C). Ensure cooling fan turns. If not, replace No. 1

ECT switch.

5. Stop engine and disconnect cooling fan 2-pin connector. With battery connected to ammeter (positive

battery terminal to positive ammeter terminal and negative battery and negative ammeter terminals to

each connector pin), test amperage readings. See Fig. 1

. If readings are not as specified, replace cooling

fan. See COOLING FAN AMPERAGE READINGS

table. Reconnect fan connector.

Avalon (2000)

ApplicationCooling Fan Location

All Models

Condenser Cooling FanPassenger's Side, Rear Of Radiator

Radiator Cooling FanDriver's Side, Rear Of Radiator

1999 Toyota RAV4

1999-2000 ENGINE COOLING Electric Cooling Fans

1999 Toyota RAV4

1999-2000 ENGINE COOLING Electric Cooling Fans

Microsoft

Sunday, November 22, 2009 10:21:41 AMPage 1 © 2005 Mitchell Repair Information Company, LLC.

Microsoft

Sunday, November 22, 2009 10:21:45 AMPage 1 © 2005 Mitchell Repair Information Company, LLC.

Page 474 of 1632

Fig. 1: Testing Amperage At Fan Connectors (Corolla Shown; Other Models Similar)

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

Camry 2.2L, Camry Solara 2.2L, Celica, Corolla, ECHO, MR2 & RAV4

1. With engine coolant temperature below 181°F (83°C), turn ignition switch to ON position (engine off).

Ensure fan stops.

2. If fan does not stop, test cooling fan relay and ECT switch/sensor. See COOLING FAN RELAYS

and

ECT SWITCH

or ECT SENSOR . Check for loose or broken connector or wiring between relay and

ECT switch. Repair as necessary.

3. Disconnect ECT switch/sensor connector. See ECT SWITCH LOCATIONS

table. With ignition still in

ON position, ensure cooling fan turns on. If not, check fuses, engine main relay (if equipped), cooling fan

relay, and cooling fan motor. On MR2, check ECM. On all models, check for short between cooling fan

relay and ECT switch.

4. Start engine and raise temperature above 199°F (93°C). Ensure cooling fan turns. If not, replace ECT

switch/sensor.

5. Stop engine and disconnect cooling fan 2-pin connector. With battery connected to ammeter (positive

battery terminal to positive ammeter terminal and negative battery and negative ammeter terminals to

each connector pin), test amperage readings. See Fig. 1

. If readings are not as specified, replace cooling

fan. See COOLING FAN AMPERAGE READINGS

table. Reconnect fan connector.

ECT SWITCH LOCATIONS

COOLING FAN AMPERAGE READINGS

ApplicationECT Switch Location

All Models

Condenser Cooling FanPassenger's Side, Rear Of Radiator

Radiator Cooling FanDriver's Side, Rear Of Radiator

ApplicationAmps @ 68°F (20°C)

Avalon

19999.2-11.0

20008.5-11.5

Camry & Camry Solara

5S-FE4.9-8.5

1MZ-FE8.3-11.3

Celica

19996.4-7.4

20005.2-8.2

Corolla5.2-8.2

ECHO (1) 7.8-11.8

MR25.7-7.7

RAV49.1-11.1

Sienna

1999 Toyota RAV4

1999-2000 ENGINE COOLING Electric Cooling Fans

Microsoft

Sunday, November 22, 2009 10:21:41 AMPage 4 © 2005 Mitchell Repair Information Company, LLC.

Page 492 of 1632

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

ENGINE COOLANT TEMPERATURE (ECT) SWITCH

Avalon, Camry 3.0L, Camry Solara 3.0L, & Sienna

1. Drain engine coolant. Remove ECT switches. See ECT SWITCH LOCATION table. Place ECT switch

thermal sensor into a water bath.

2. Using an ohmmeter, check that there is no continuity between ECT switch terminals when coolant

temperature is above 208°F (98°C) on No. 1 ECT switch or below 181°F (83°C) on No. 2 ECT switch. If

there is continuity, replace switch.

3. Cool water and check that there is continuity between the switch terminals when coolant temperature is

below 190°F (88°C) or above 199°F (93°C), on Avalon, or above 201°F (94°C), on Camry with 3.0L,

Camry Solara with 3.0L and Sienna. If there is no continuity, replace switch.

4. Reinstall switches. Fill with engine coolant.

Camry 2.2L, Camry Solara 2.2L, Celica (1999), Corolla, ECHO & RAV4

1. Drain engine coolant. Remove ECT switch. See ECT SWITCH LOCATION table. Place ECT switch

thermal sensor into a water bath.

2. Using an ohmmeter, check that there is no continuity between ECT switch terminals when coolant

temperature is above 199°F (93°C). If continuity exists, replace ECT switch.

3. Cool water and check that there is continuity when coolant temperature is below 181°F (83°C). If there is

no continuity, replace ECT switch.

4. Reinstall switches. Fill with engine coolant.

ENGINE COOLANT TEMPERATURE (ECT) SENSOR

MR2 & 2000 Celica

1. Drain engine coolant. On 2000 Celica, remove No. 2 cylinder head cover. On all models, remove ECT

sensor. See ECT SENSOR LOCATIONS

. Place ECT sensor and thermometer into a water bath.

ECT SENSOR LOCATIONS

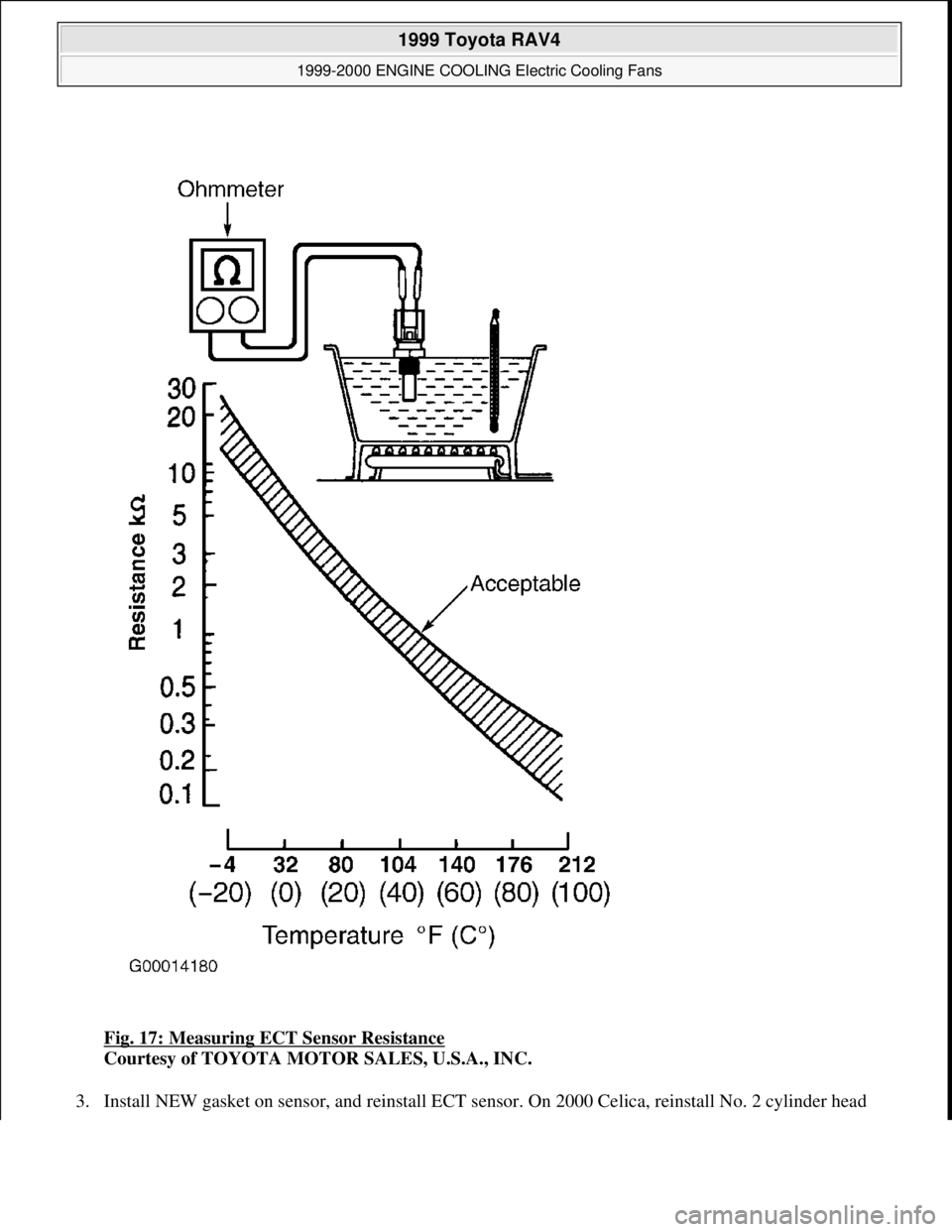

2. Measure resistance between terminal Nos. 1 and 2. See Fig. 17

. If resistance is not as specified, replace

ECT sensor.

ApplicationSensor Location

Celica (2000)Driver's Side, Rear Of Radiator

MR2Passenger's Side, Rear Of Radiator

1999 Toyota RAV4

1999-2000 ENGINE COOLING Electric Cooling Fans

Microsoft

Sunday, November 22, 2009 10:21:41 AMPage 22 © 2005 Mitchell Repair Information Company, LLC.

Page 493 of 1632

Fig. 17: Measuring ECT Sensor Resistance

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

3. Install NEW

gasket on sensor, and reinstall ECT sensor. On 2000 Celica, reinstall No. 2 cylinder head

1999 Toyota RAV4

1999-2000 ENGINE COOLING Electric Cooling Fans

Microsoft

Sunday, November 22, 2009 10:21:41 AMPage 23 © 2005 Mitchell Repair Information Company, LLC.

Page 525 of 1632

1999 ACCESSORIES & EQUIPMENT

Cruise Control Systems - RAV4

DESCRIPTION

Cruise control system consists of cruise control Electronic Control Unit (ECU), actuator and cables, speed

sensor, cruise control switch, stoplight switch, clutch switch (M/T), park/neutral position switch (A/T) and

related wirin

g. See Fig. 1 . The system allows vehicle to cruise at a desired speed greater than 25 MPH. WARNING:Deactivate air bag system before performing any service operation. See

AIR BAG RESTRAINT SYSTEMS article. DO NOT apply electrical power to

any component on steering column without first deactivating air bag

system. Air bag may deploy.

1999 Toyota RAV4

1999 ACCESSORIES & EQUIPMENT Cruise Control Systems - RAV4

1999 Toyota RAV4

1999 ACCESSORIES & EQUIPMENT Cruise Control Systems - RAV4

Microsoft

Sunday, November 22, 2009 10:52:01 AMPage 1 © 2005 Mitchell Repair Information Company, LLC.

Microsoft

Sunday, November 22, 2009 10:52:04 AMPage 1 © 2005 Mitchell Repair Information Company, LLC.

Page 527 of 1632

OPERATION

Cruise control system functions can be performed from cruise control switch, located on lever on right side of

steering column. Pressing cruise ON-OFF (main) switch at end of lever turns system on. CRUISE indicator

light in instrument cluster comes on when desired cruising speed is set. To set desired speed, move control lever

downward in SET/COAST direction and release it. Desired speed should be maintained. Press cruise ON-OFF

(main) switch again to turn cruise control system off.

Cancel set speed by moving cruise control lever in CANCEL direction, pressing brake pedal, or pressing clutch

pedal (M/T) or placing shift lever in Neutral (A/T). If vehicle speed drops to less than 25 MPH, set speed will

automatically cancel. If vehicle speed decreases 10 MPH less than set speed, set speed will also cancel. If cruise

control ECU detects a system malfunction, set speed will automatically cancel and CRUISE indicator light will

flash several times.

Moving cruise control lever in RES/ACC (resume/accelerate) direction allows vehicle to return to speed set

before cancellation. Holding cruise control lever in RES/ACC (resume/accelerate) direction gradually increases

vehicle speed. Holding cruise control lever in SET/COAST direction gradually decreases vehicle speed.

ACTUATOR

Actuator consists of a motor, safety magnetic clutch, position sensor, pulley and a cable connected to engine

throttle valve. When actuator receives a signal from cruise control ECU, it engages safety magnetic clutch and

activates motor. Motor causes pulley and cable to move, which will open or close engine throttle valve.

When motor rotates forward, pulley also rotates (via safety magnetic clutch, gears and drive shaft). A cable

connected to engine throttle valve and opens valve accordingly. When motor rotates in a reverse direction,

pulley and cable also rotate in a reverse direction and engine throttle valve closes.

CRUISE CONTROL SWITCH

ON-OFF (Main Switch)

Cruise ON-OFF switch is power switch for cruise control system. When ignition is turned off, cruise ON-OFF

switch is also turned off. The switch remains off even when ignition is turned on again.

SET/COAST Position

When cruise control switch is moved to SET/COAST position with cruise ON-OFF switch turned to ON

position and vehicle speed greater than 25 MPH, cruise control ECU stores vehicle speed and maintains that

speed via actuator.

When cruise control switch is moved to SET/COAST position while in cruise control mode, actuator motor is

energized to close engine throttle valve. Vehicle decelerates until switch is released. From then on, cruise

control ECU stores new vehicle speed and maintains that speed.

RES/ACC Position

1999 Toyota RAV4

1999 ACCESSORIES & EQUIPMENT Cruise Control Systems - RAV4

Microsoft

Sunday, November 22, 2009 10:52:01 AMPage 3 © 2005 Mitchell Repair Information Company, LLC.