bulb TOYOTA RAV4 1996 Service Owner's Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 1996, Model line: RAV4, Model: TOYOTA RAV4 1996Pages: 1632, PDF Size: 41.64 MB

Page 911 of 1632

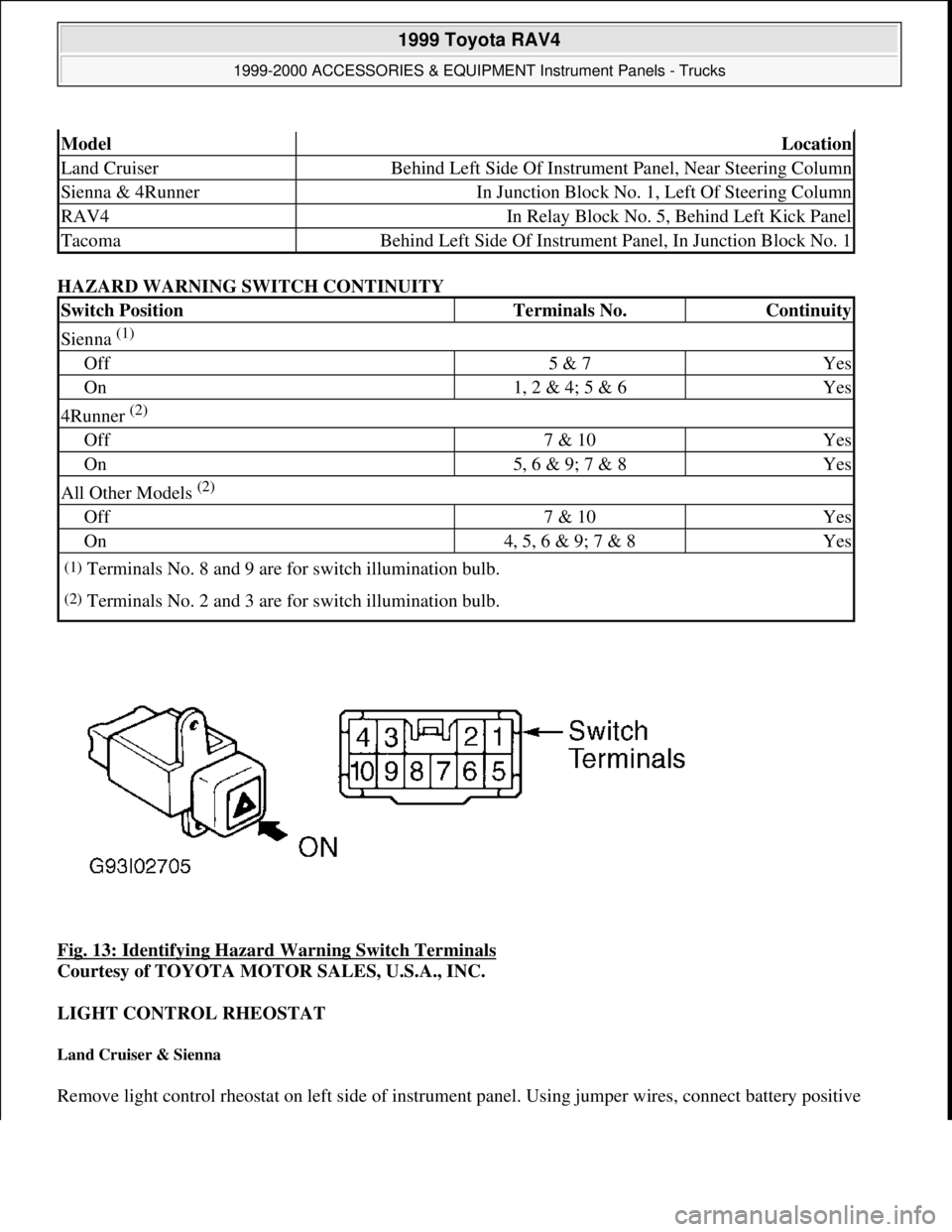

HAZARD WARNING SWITCH CONTINUITY

Fig. 13: Identifying Hazard Warning Switch Terminals

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

LIGHT CONTROL RHEOSTAT

Land Cruiser & Sienna

Remove light control rheostat on left side of instrument panel. Using jumper wires, connect battery positive

ModelLocation

Land CruiserBehind Left Side Of Instrument Panel, Near Steering Column

Sienna & 4RunnerIn Junction Block No. 1, Left Of Steering Column

RAV4In Relay Block No. 5, Behind Left Kick Panel

TacomaBehind Left Side Of Instrument Panel, In Junction Block No. 1

Switch PositionTerminals No.Continuity

Sienna (1)

Off5 & 7Yes

On1, 2 & 4; 5 & 6Yes

4Runner (2)

Off7 & 10Yes

On5, 6 & 9; 7 & 8Yes

All Other Models (2)

Off7 & 10Yes

On4, 5, 6 & 9; 7 & 8Yes

(1)Terminals No. 8 and 9 are for switch illumination bulb.

(2)Terminals No. 2 and 3 are for switch illumination bulb.

1999 Toyota RAV4

1999-2000 ACCESSORIES & EQUIPMENT Instrument Panels - Trucks

Microsoft

Sunday, November 22, 2009 10:54:10 AMPage 21 © 2005 Mitchell Repair Information Company, LLC.

Page 914 of 1632

LOW OIL PRESSURE WARNING LIGHT

RAV4, Sienna, Tacoma, Tundra Without Tachometer & 4Runner

Disconnect low oil pressure switch connector. See OIL PRESSURE SWITCH LOCATION table. Using a

jumper wire, connect low oil pressure switch connector terminal to ground. Turn ignition switch to ON position.

Low oil pressure warning light should turn on. If low oil pressure warning light is off, check bulb or inspect

wiring harness.

OCCUPANT DETECTION SENSOR

Land Cruiser & Tundra

Disconnect occupant detection sensor connector, located under passenger seat. Check continuity between sensor

connector terminals. Continuity should exist only when pressing on sensor. If continuity is not as specified,

replace occupant detection sensor.

OIL PRESSURE GAUGE & SENDER

Oil Pressure Gauge & Harness Operational Test (Land Cruiser & Tundra With Tachometer)

1. Disconnect oil pressure sender connector. See OIL PRESSURE SENDER LOCATION table. Turn

ignition switch to ON position. Oil gauge should indicate LOW. Turn ignition switch to OFF position.

Connect a 12-volt, 3.4-watt test light between oil sending unit harness connector terminal and ground.

2. Turn ignition switch to ON position. Test light should be on and oil pressure gauge should slowly move

to HIGH. If gauge functions as specified, perform OIL PRESSURE SENDER OPERATIONAL

TEST . If gauge does not function as specified, perform OIL PRESSURE GAUGE RESISTANCE

TEST .

Oil Pressure Sender Operational Test (Land Cruiser & Tundra With Tachometer)

Disconnect oil pressure sender connector. See OIL PRESSURE SENDER LOCATION table. Using 12-volt

source, connect an LED tester between positive battery terminal and oil pressure sender terminal. With engine

off, LED should be off. With engine running, LED should flash. LED flashes will vary with engine speed and

oil pressure. Replace oil pressure sender if LED does not operate as specified.

OIL PRESSURE SENDER LOCATION

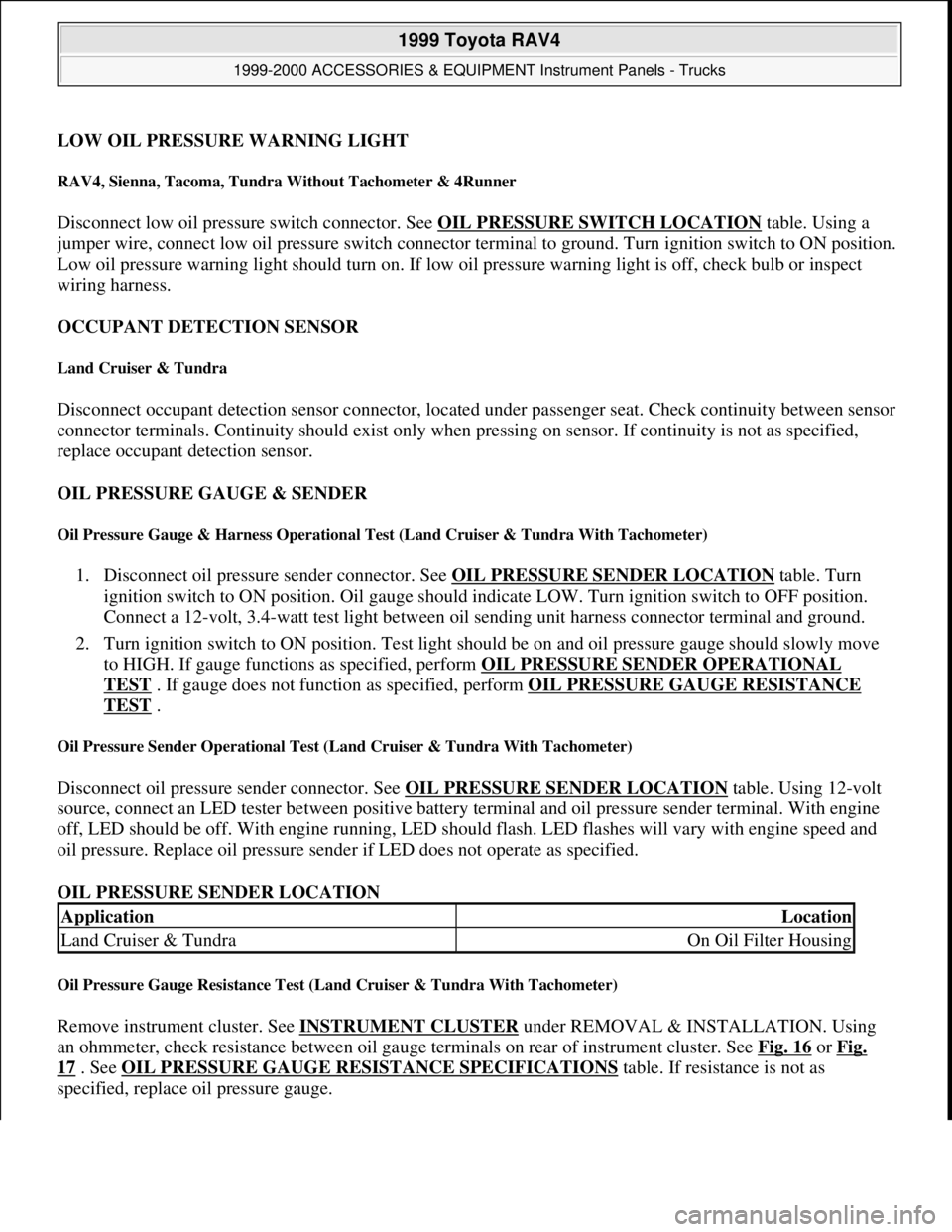

Oil Pressure Gauge Resistance Test (Land Cruiser & Tundra With Tachometer)

Remove instrument cluster. See INSTRUMENT CLUSTER under REMOVAL & INSTALLATION. Using

an ohmmeter, check resistance between oil gauge terminals on rear of instrument cluster. See Fig. 16

or Fig.

17 . See OIL PRESSURE GAUGE RESISTANCE SPECIFICATIONS table. If resistance is not as

specified, replace oil pressure

gauge.

ApplicationLocation

Land Cruiser & TundraOn Oil Filter Housing

1999 Toyota RAV4

1999-2000 ACCESSORIES & EQUIPMENT Instrument Panels - Trucks

Microsoft

Sunday, November 22, 2009 10:54:10 AMPage 24 © 2005 Mitchell Repair Information Company, LLC.

Page 916 of 1632

Fig. 17: Identifying Oil Pressure Gauge Terminals (Tundra)

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

OPEN DOOR WARNING LIGHT

Land Cruiser, Sienna, RAV4 & 4Runner

Locate door courtesy switch in door jamb. Disconnect door courtesy switch 1-pin connector. Ground door

courtesy switch wiring harness connector terminal. Open door warning light should be on. If open door warning

light is off, check bulb and wiring harness. Repair as necessary.

PARKING BRAKE SWITCH

Land Cruiser, Sienna, Tacoma, Tundra & 4Runner

Disconnect parking brake switch, located at base of parking brake handle. Ensure continuity exists between

switch terminals when switch is ON (pin released). Ensure continuity does not exist between switch terminals

when switch is OFF (pin pushed in). If continuity is not as specified, replace switch.

RAV4

1999 Toyota RAV4

1999-2000 ACCESSORIES & EQUIPMENT Instrument Panels - Trucks

Microsoft

Sunday, November 22, 2009 10:54:10 AMPage 26 © 2005 Mitchell Repair Information Company, LLC.

Page 918 of 1632

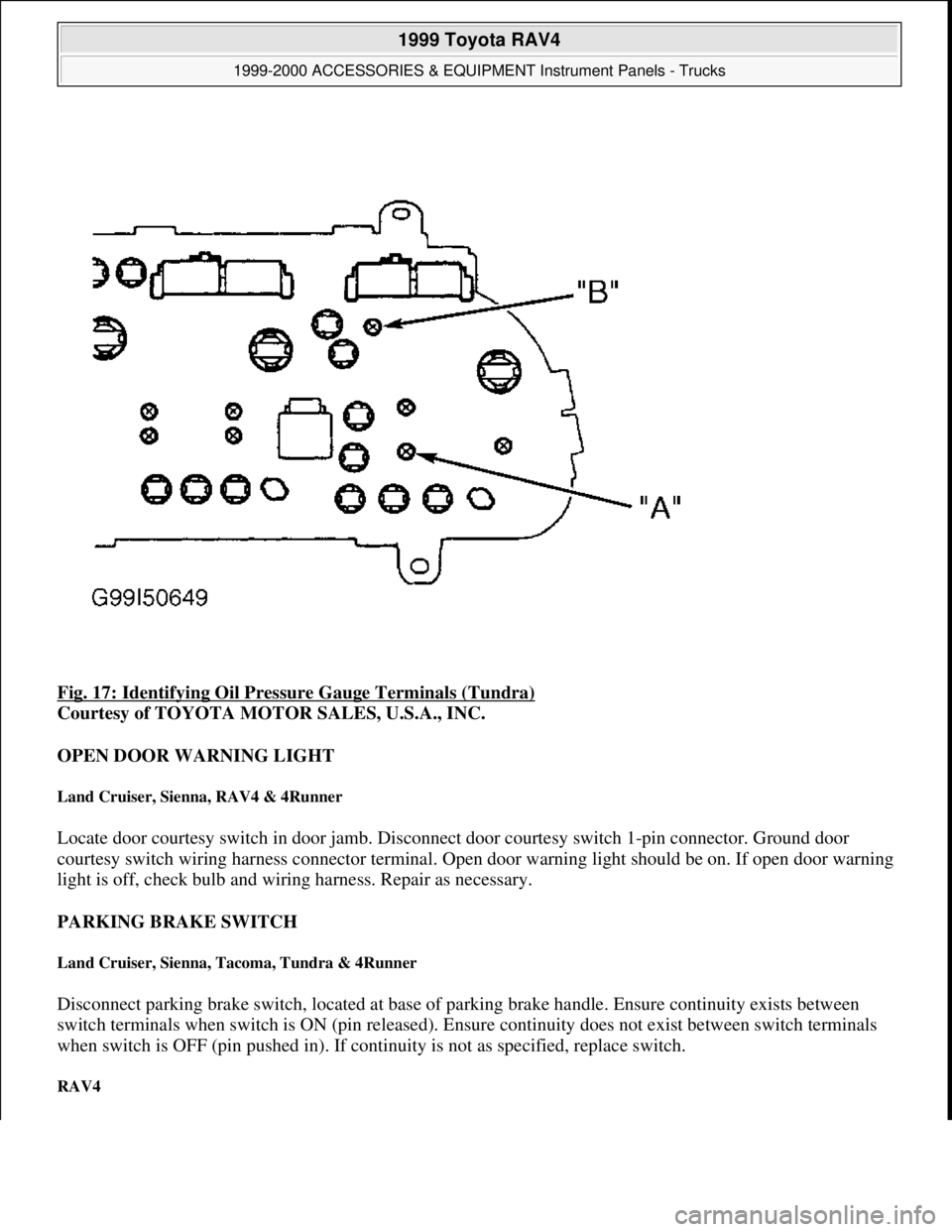

Fig. 18: Testing Seat Belt Retractor Switch (RAV4 & Sienna)

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

SEAT BELT WARNING LIGHT

Land Cruiser

Turn ignition switch to OFF position. Disconnect seat belt buckle switch connector at bottom of inner seat belt.

Connect a jumper wire between seat belt buckle switch wiring harness connector terminals. Turn ignition on.

Seat belt warning light should be on. If seat belt warning light is off, check bulb and wiring harness. Repair as

necessary.

Sienna

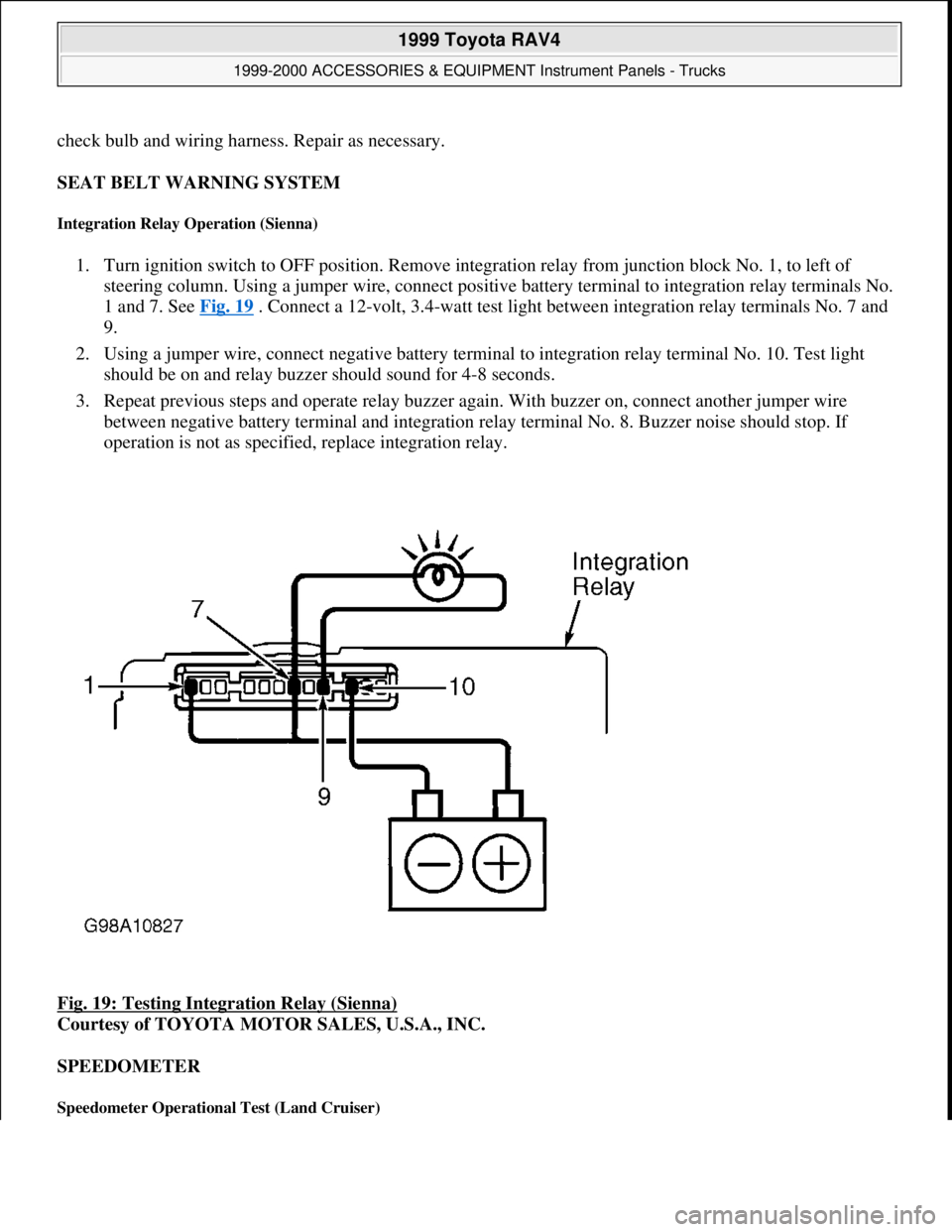

Turn ignition switch to OFF position. Remove integration relay from instrument panel junction block No. 1, to

left of steering column. Using a jumper wire, ground integration relay terminal No. 9 in junction block. See Fi

g.

19 . Turn ignition switch to ON position. Seat belt warning light should be on. If seat belt warning light is off,

1999 Toyota RAV4

1999-2000 ACCESSORIES & EQUIPMENT Instrument Panels - Trucks

Microsoft

Sunday, November 22, 2009 10:54:10 AMPage 28 © 2005 Mitchell Repair Information Company, LLC.

Page 919 of 1632

check bulb and wiring harness. Repair as necessary.

SEAT BELT WARNING SYSTEM

Integration Relay Operation (Sienna)

1. Turn ignition switch to OFF position. Remove integration relay from junction block No. 1, to left of

steering column. Using a jumper wire, connect positive battery terminal to integration relay terminals No.

1 and 7. See Fig. 19

. Connect a 12-volt, 3.4-watt test light between integration relay terminals No. 7 and

9.

2. Using a jumper wire, connect negative battery terminal to integration relay terminal No. 10. Test light

should be on and relay buzzer should sound for 4-8 seconds.

3. Repeat previous steps and operate relay buzzer again. With buzzer on, connect another jumper wire

between negative battery terminal and integration relay terminal No. 8. Buzzer noise should stop. If

operation is not as specified, replace integration relay.

Fig. 19: Testing Integration Relay (Sienna)

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

SPEEDOMETER

Speedometer Operational Test (Land Cruiser)

1999 Toyota RAV4

1999-2000 ACCESSORIES & EQUIPMENT Instrument Panels - Trucks

Microsoft

Sunday, November 22, 2009 10:54:10 AMPage 29 © 2005 Mitchell Repair Information Company, LLC.

Page 923 of 1632

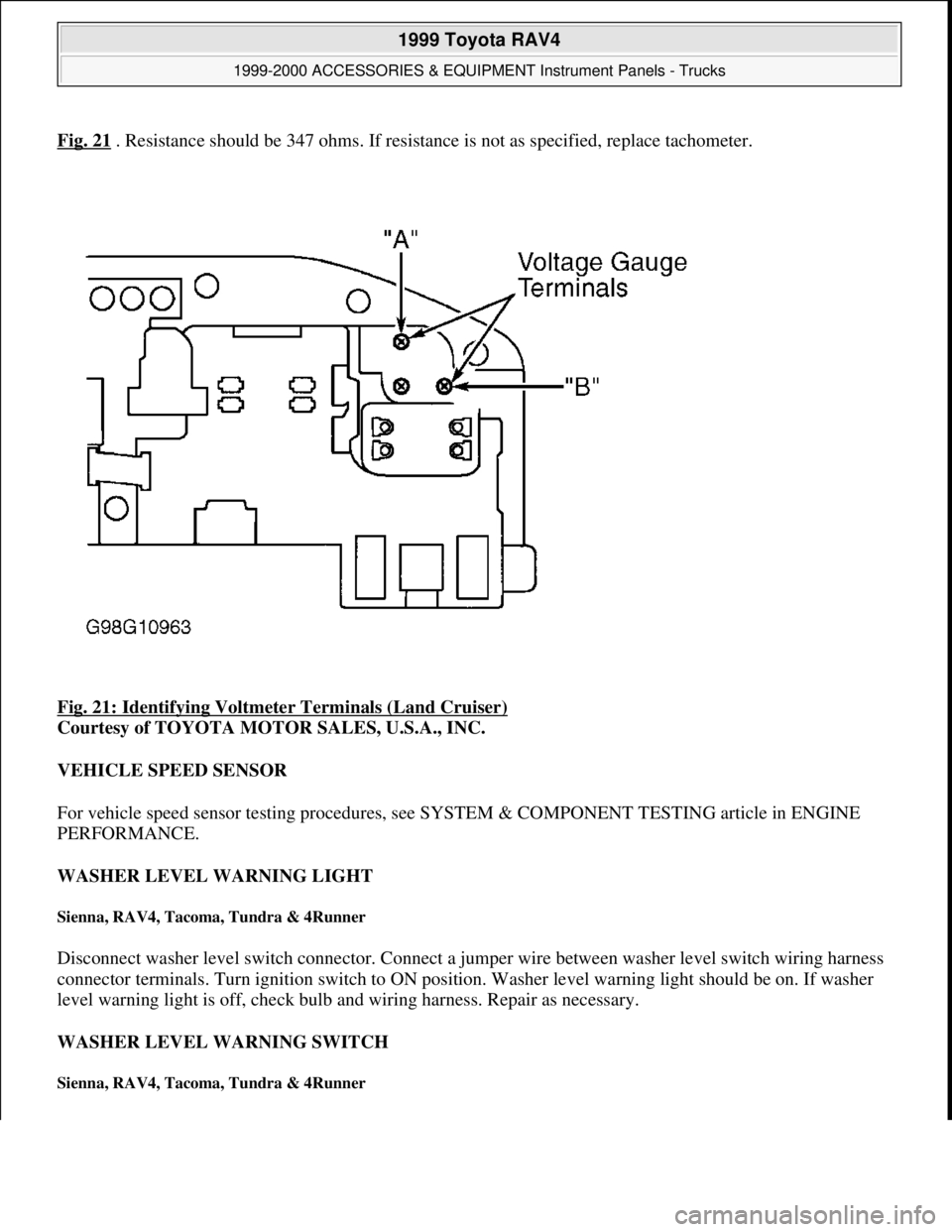

Fig. 21 . Resistance should be 347 ohms. If resistance is not as specified, replace tachometer.

Fig. 21: Identifying Voltmeter Terminals (Land Cruiser)

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

VEHICLE SPEED SENSOR

For vehicle speed sensor testing procedures, see SYSTEM & COMPONENT TESTING article in ENGINE

PERFORMANCE.

WASHER LEVEL WARNING LIGHT

Sienna, RAV4, Tacoma, Tundra & 4Runner

Disconnect washer level switch connector. Connect a jumper wire between washer level switch wiring harness

connector terminals. Turn ignition switch to ON position. Washer level warning light should be on. If washer

level warning light is off, check bulb and wiring harness. Repair as necessary.

WASHER LEVEL WARNING SWITCH

Sienna, RAV4, Tacoma, Tundra & 4Runner

1999 Toyota RAV4

1999-2000 ACCESSORIES & EQUIPMENT Instrument Panels - Trucks

Microsoft

Sunday, November 22, 2009 10:54:10 AMPage 33 © 2005 Mitchell Repair Information Company, LLC.

Page 951 of 1632

ELECTROSTATIC DISCHARGE SENSITIVE (ESD) PARTS

ENGINE OIL

FUEL SYSTEM SERVICE

HALOGEN BULBS

RADIATOR CAP

RADIATOR FAN

WARRANTY INFORMATION

NEW VEHICLE LIMITED WARRANTY WARNING:Many solid state electrical components can be damaged by static

electricity (ESD). Some will display a warning label, but many will not.

Discharge personal static electricity by touching a metal ground point on

the vehicle prior to servicing any ESD sensitive component.

CAUTION: Never use non-detergent or straight mineral oil.

WARNING:Relieve fuel system pressure prior to servicing any fuel system

component (fuel injection models).

WARNING:Halogen bulbs contain pressurized gas which may explode if overheated.

DO NOT touch glass portion of bulb with bare hands. Eye protection

should be worn when handling or working around halogen bulbs.

CAUTION: Always disconnect the fan motor when working near the radiator fan. The

fan is temperature controlled and could start at any time even when the

ignition key is in the OFF position. DO NOT loosen or remove radiator cap

when cooling system is hot.

WARNING:Keep hands away from radiator fan. Fan is controlled by a thermostatic

switch which may come on or run for up to 15 minutes even after engine

is turned off.

CAUTION: Due to the different warranties offered in various regions and the variety of

after-market extended warranties available, please refer to the warranty

package that came with the vehicle to verify all warranty options.

1999 Toyota RAV4

MAINTENANCE INFORMATION 1997-99 MAINTENANCE Toyota Maintenance Information

Microsoft

Sunday, November 22, 2009 10:32:42 AMPage 9 © 2005 Mitchell Repair Information Company, LLC.

Page 1208 of 1632

1999-2000 STEERING

Steering Columns - Standard

DESCRIPTION & OPERATION

Steering column is a collapsible 2-piece design. Columns use shear pins to absorb collision impact. Steering

shaft is connected directly to steering gear with either a flexible coupling or "U" joint. Some models have an air

bag integral with the steering wheel pad.

SERVICE PRECAUTIONS

Observe the following precautions when servicing Supplemental Restraint System (SRS):

Disable SRS before servicing any SRS or steering column component. Failure to do this could result in

accidental air bag deployment and possible personal injury. See DISABLING & ACTIVATING AIR

BAG SYSTEM .

Remove air bag sensor assembly/center air bag sensor and front air bag sensors if repairing the vehicle

requires impacting (shocking) the vehicle.

Replace dropped, cracked, dented or otherwise damaged components.

DO NOT expose front air bag sensors, air bag sensor assembly/center air bag sensor or steering wheel

pad (air bag module) directly to heat or flame.

Information labels are attached to air bag components. Follow all notices on labels.

After work on SRS is completed, check air bag warning light to ensure system is functioning properly.

See appropriate AIR BAG RESTRAINT SYSTEMS article in ACCESSORIES & EQUIPMENT.

Always wear safety glasses when servicing or handling an air bag.

When placing a live air bag on a bench or other surface, always face air bag and trim cover upward, away

from surface. This will reduce motion of module if it is accidentally deployed.

Carry a live air bag module with trim cover (air bag) pointed away from your body to minimize injury in

case of accidental deployment.

If SRS is not fully functional for any reason, vehicle should not be driven until system is repaired and

becomes operational. DO NOT remove bulbs, modules, sensors or other components or in any way

disable system from operating normally. If SRS is not functional, park vehicle until it is repaired and

functions properl

y. NOTE: For models with tilt wheel steering columns, see appropriate STEERING

COLUMNS - TILT WHEEL article.

WARNING:To avoid injury from accidental air bag deployment, read and carefully

follow all SERVICE PRECAUTIONS. Deactivate air bag system before

performing any repairs. See DISABLING & ACTIVATING AIR BAG

SYSTEM .

1999 Toyota RAV4

1999-2000 STEERING Steering Columns - Standard

1999 Toyota RAV4

1999-2000 STEERING Steering Columns - Standard

Microsoft

Sunday, November 22, 2009 10:34:51 AMPage 1 © 2005 Mitchell Repair Information Company, LLC.

Microsoft

Sunday, November 22, 2009 10:34:55 AMPage 1 © 2005 Mitchell Repair Information Company, LLC.

Page 1236 of 1632

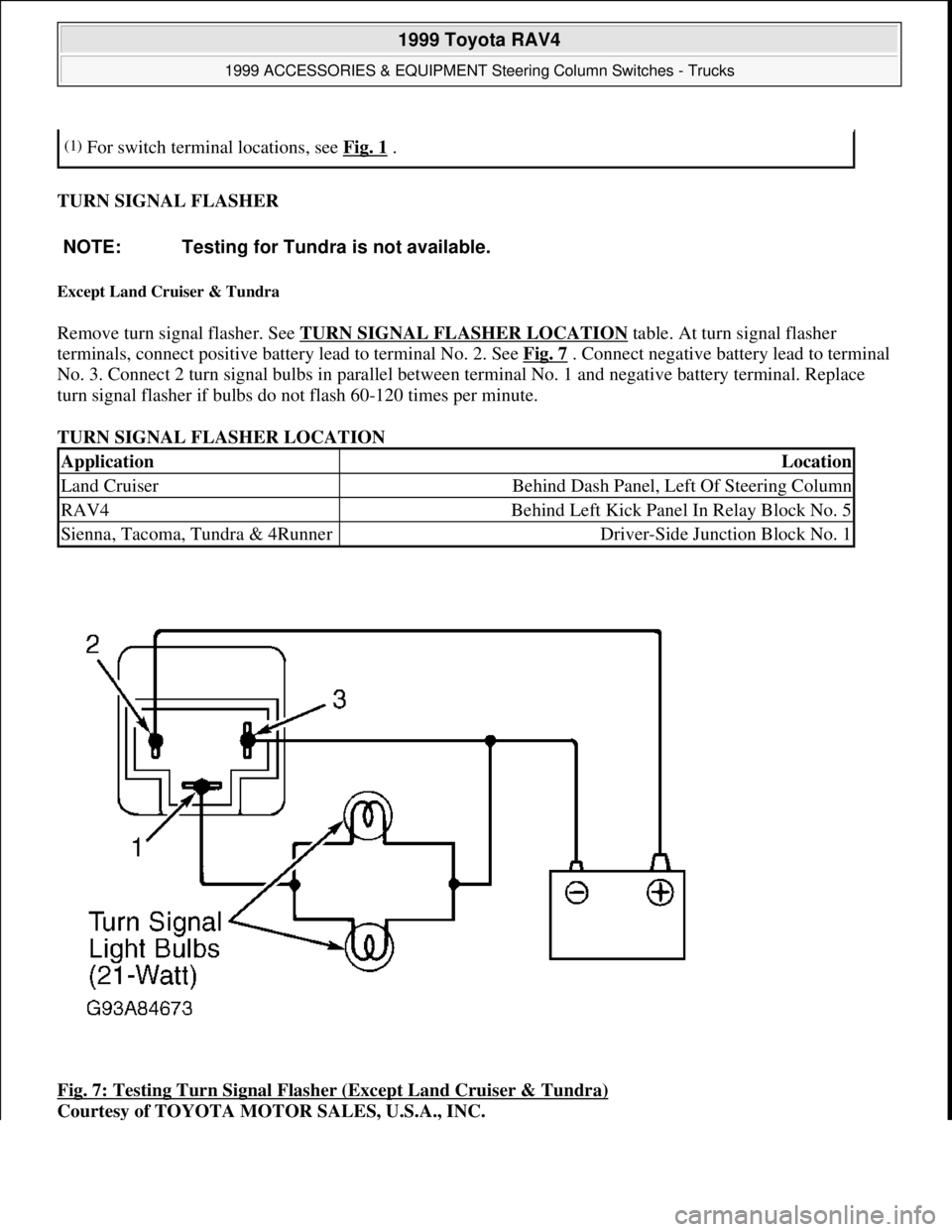

TURN SIGNAL FLASHER

Except Land Cruiser & Tundra

Remove turn signal flasher. See TURN SIGNAL FLASHER LOCATION table. At turn signal flasher

terminals, connect positive battery lead to terminal No. 2. See Fig. 7

. Connect negative battery lead to terminal

No. 3. Connect 2 turn signal bulbs in parallel between terminal No. 1 and negative battery terminal. Replace

turn signal flasher if bulbs do not flash 60-120 times per minute.

TURN SIGNAL FLASHER LOCATION

Fig. 7: Testing Turn Signal Flasher (Except Land Cruiser & Tundra)

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

(1)For switch terminal locations, see Fig. 1 .

NOTE: Testing for Tundra is not available.

ApplicationLocation

Land CruiserBehind Dash Panel, Left Of Steering Column

RAV4Behind Left Kick Panel In Relay Block No. 5

Sienna, Tacoma, Tundra & 4RunnerDriver-Side Junction Block No. 1

1999 Toyota RAV4

1999 ACCESSORIES & EQUIPMENT Steering Column Switches - Trucks

Microsoft

Sunday, November 22, 2009 10:56:55 AMPage 8 © 2005 Mitchell Repair Information Company, LLC.

Page 1255 of 1632

1999-2000 STEERING

Steering Columns - Tilt Wheel - Trucks & Vans

DESCRIPTION & OPERATION

Tilt steering columns incorporate a main shaft, attached by a "U" joint to an intermediate steering shaft. Shafts

are held in place by upper and lower column tubes. Column tubes are pinned together so upper column can

move up or down. Upper column is locked in place by pawl attached to lever. Steering columns are collapsible.

SERVICE PRECAUTIONS

Observe the following precautions when servicing SRS:

Disable SRS before servicing any SRS or steering column component. Failure to do this could result in

accidental air bag deployment and possible personal injury. See DISABLING & ACTIVATING AIR

BAG SYSTEM .

Remove air bag sensor assembly/center air bag sensor and front air bag sensors if repairing the vehicle

requires impacting (shocking) the vehicle.

Replace dropped, cracked, dented or otherwise damaged components.

DO NOT expose front air bag sensors, air bag sensor assembly/center air bag sensor or steering wheel

pad (air bag module) directly to heat or flame.

Information labels are attached to air bag components. Follow all notices on labels.

After work on SRS is completed, check air bag warning light to ensure system is functioning properly.

See appropriate AIR BAG RESTRAINT SYSTEMS article in ACCESSORIES & EQUIPMENT.

Always wear safety glasses when servicing or handling an air bag.

When placing a live air bag on a bench or other surface, always face air bag and trim cover upward, away

from surface. This will reduce motion of module if it is accidentally deployed.

Carry a live air bag module with trim cover (air bag) pointed away from your body to minimize injury in

case of accidental deployment.

If SRS is not fully functional for any reason, vehicle should not be driven until system is repaired and

becomes operational. DO NOT remove bulbs, modules, sensors or other components or in any way

disable system from operating normally. If SRS is not functional, park vehicle until it is repaired and

functions properly.

DISABLING & ACTIVATING AIR BAG SYSTEM

WARNING:To avoid injury from accidental air bag deployment, read and carefully

follow all SERVICE PRECAUTIONS

. Deactivate air bag system before

performing any repairs. See DISABLING & ACTIVATING AIR BAG

SYSTEM .

WARNING:Back-up power supply maintains SRS voltage for about 90 seconds after

1999 Toyota RAV4

1999-2000 STEERING Steering Columns - Tilt Wheel - Trucks & Vans

1999 Toyota RAV4

1999-2000 STEERING Steering Columns - Tilt Wheel - Trucks & Vans

Microsoft

Sunday, November 22, 2009 10:34:02 AMPage 1 © 2005 Mitchell Repair Information Company, LLC.

Microsoft

Sunday, November 22, 2009 10:34:07 AMPage 1 © 2005 Mitchell Repair Information Company, LLC.