sensor TOYOTA RAV4 1996 Service Manual PDF

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 1996, Model line: RAV4, Model: TOYOTA RAV4 1996Pages: 1632, PDF Size: 41.64 MB

Page 148 of 1632

LAND CRUISER - 1998

TORQUE SPECIFICATIONS (LAND CRUISER - 1998)

Front Drive Shaft54 (73)

Rear Drive Shaft65 (88)

Front Exhaust Pipe-To-Exhaust Manifold Nut46 (62)

Front Exhaust Pipe-To-Rear Catalytic Converter Bolt/Nut29 (39)

Front Exhaust Support Bracket Bolt14 (19)

Oil Cooler Line Bolt25 (34)

Stabilizer Bar-To-Frame Mounting Bracket Bolt13 (18)

Starter Bolt29 (39)

Torque Converter Bolt40 (54)

Transfer Case Shift Lever Assembly Bolt13 (18)

Transmission Crossmember Bolt/Nut

Bolt45 (61)

Nut54 (73)

Transmission-To-Cylinder Block Bolt53 (72)

INCH Lbs. (N.m)

Transmission Shift Lever Assembly Bolt48 (5.4)

ApplicationFt. Lbs. (N.m)

Drive Plate-To-Crankshaft Bolt

First Step36 (49)

Second StepTurn Additional 90 Degrees

Drive Shaft Flange Bolt/Nut

Front Drive Shaft59 (80)

Rear Drive Shaft78 (106)

Front Exhaust Pipe-To-Exhaust Manifold Nut46 (62)

Front Exhaust Pipe-To-Rear Catalytic Converter Bolt/Nut30 (40)

Oil Cooler Pipe Nut51 (69)

Oxygen Sensor Bolt14 (19)

Radiator Bracket Bolt/Nut15 (20)

Torque Converter Bolt36 (48)

Torque Converter Cover Bolt13 (18)

Transmission Crossmember Bolt/Nut

Bolt37 (50)

Nut54 (73)

Transmission-To-Cylinder Block Bolt53 (72)

INCH Lbs. (N.m)

Dipstick Tube Bolt102 (11.5)

Fan Shroud Bolt44 (5.0)

1998 Toyota Avalon XLS

TRANSMISSION SERVICING - A/T 1997-98 TRANSMISSION SERVICING Toyota - Transmission Removal &

Installation

Helpmelearn

November-03-08 10:30:29 AMPage 36 © 2005 Mitchell Repair Information Company, LLC.

Page 161 of 1632

clutch.

Vehicle Does Not Move In Reverse ("R")

Check 1-2 shift valve, 2-3 shift valve, 2nd coast brake, front planetary gear, rear planetary gear, direct clutch,

OD direct clutch and 1st and reverse brake.

No 1-2 &/Or 2-3 Upshift

Check Throttle Position (TP) sensor circuit, No. 1 and No. 2 shift solenoid circuit, Vehicle Speed Sensor (VSS)

circuit, Electronic Control Transmission Electronic Control Module (ECT ECM), 1-2 shift valve, 2-3 shift

valve, 2nd brake, direct clutch and No. 1 one-way clutch.

No 3-O/D Upshift

Check OD switch and OD OFF indicator switch circuit, OD cancel signal circuit, No. 1 and No. 2 shift solenoid

circuit, VSS, Engine Coolant Temperature (ECT) circuit, ECT ECM, 3-4 shift valve and OD brake.

No O/D-3 Downshift

Check No. 1 and No. 2 shift solenoid valve, VSS circuit, OD cancel signal circuit, ECT ECM and 3-4 shift

valve.

No 3-2 &/Or 2-1 Downshift

Check No. 1 and No. 2 shift solenoid valve, VSS circuit, TP sensor circuit, ECT ECM, 2-3 shift valve, 1-2 shift

valve and 2nd coast brake.

No Torque Converter Lock-Up

Check shift solenoid valve SL circuit, TP sensor circuit, VSS circuit, OD cancel circuit, brakelight circuit, ECT

circuit, ECT ECM, lock-up relay valve and torque converter clutch.

Torque Converter Lock-Up Will Not Release

Check shift solenoid valve SL circuit, TP sensor circuit, brakelight circuit, ECT ECM circuit, lock-up relay

valve and torque converter clutch.

Shift Speeds Too High Or Too Low

Check TP sensor circuit, VSS circuit, shift solenoid valve SL circuit, OD cancel signal circuit, pattern select

switch circuit and ECT ECM.

Harsh Engagement Neutral To Reverse

Check direct clutch accumulator, direct clutch, throttle valve and 1st and reverse brake.

Harsh Engagement Neutral To Drive

1998 Toyota Avalon XLS

1997-99 AUTOMATIC TRANSMISSIONS Toyota A-540E, A-540H & A-541E Overhaul

Helpmelearn

November-03-08 10:28:16 AMPage 7 © 2005 Mitchell Repair Information Company, LLC.

Page 177 of 1632

washer. Remove nut and washer. Remove Park/Neutral Position (PNP) switch.

3. Remove throttle cable retaining bolt. Remove solenoid harness connector retaining bolt (if applicable).

Remove vehicle speed sensor mounted in differential cover. Remove sensor adapter. Remove direct

clutch speed (T/M revolution) sensor mounted to upper case cover (if equipped). Remove upper case

cover. Remove transaxle oil pan. Examine any contamination in pan to aid in diagnosis.

4. Remove oil stainer (filter) and oil pipe hold-down bracket. Remove manual valve body including detent

spring. Gently remove all oil pipes by prying up on end of pipe with screwdriver.

5. Disconnect solenoid harness connectors. Remove connector clamp and apply pipe retainer. Remove 1st

and reverse apply pipe. Remove valve body bolts. Remove wiring harness clamp. Disconnect throttle

cable from cam and remove valve body.

6. Remove throttle cable and solenoid wiring harness. Remove 2nd brake apply gasket. Loosen accumulator

cover bolts in crisscross pattern. Remove cover and gasket. Remove forward clutch accumulator. See Fi

g.

10 .

7. Remove remaining accumulators by applying 14 psi (1kg/cm

2 ) of air pressure to apply hole. See Fig.

11 . Cover accumulator bores with a rag when applying air.

8. Mark 2nd coast brake servo apply piston rod where it meets case. Apply 57-114 psi (4-8 kg/cm

2 ) of air

pressure to apply hole and measure piston rod travel (stroke). See Fig. 12

. Piston rod travel should

be .079-.138" (2.0-3.5 mm). If rod travel is not within specification, further inspect band during

disassembly.

9. Remove 2nd coast brake piston cover snap ring. Apply air to oil hole and remove cover and piston

assembly. See Fig. 12

. Remove oil pump bolts. Using appropriate puller, remove oil pump.

10. Remove direct clutch and forward clutch. Separate components and remove thrust washer. Remove thrust

bearings from front and rear of forward clutch. Push out 2nd coast brake band anchor pin. Remove band

and inspect.

11. Remove front planetary ring gear. Remove front planetary gear with thrust bearings on either side.

Remove thrust bearings. Remove sun gear shell with thrust washer.

12. Apply compressed air to 2nd brake piston port and check operation of 2nd brake. See Fig. 13

. Remove

2nd coast brake band guide. DO NOT separate band guide and bolt. Remove snap ring securing 2nd

brake drum. Remove drum.

13. Remove 2nd brake piston return spring. Remove No. 1 one-way clutch. Remove 2nd brake clutch discs,

plates and flange. Note number and location of components. Remove snap ring securing No. 2 one-way

clutch and rear planetary gear. See Fig. 14

. Remove components.

14. Remove thrust washer from rear planetary gear. Remove rear planetary ring gear with thrust bearing.

Apply air into appropriate passage to check 1st and reverse brake operation. See Fig. 15

.

15. Using feeler gauge, check pack clearance of 1st and reverse brake assembly. Clearance should be .033-

.081" (.85-2.05 mm) for A-540E transaxle, .041-.085" (1.04-2.16 mm) for A-540H transaxle, or .076-

.106" (1.92-2.68 mm) for A-541E transaxle. Remove snap ring securing 1st and reverse brake. Remove

1st and reverse brake discs, plates and flange. Note number and location of components.

16. From back of transaxle, remove 13 bolts securing overdrive unit. Using soft-faced hammer, tap around

outside of case until overdrive unit loosens and can be removed.

17. Remove overdrive (OD) planetary gear from transaxle case. Remove OD brake drum. See Fig. 14

.

Remove gaskets for OD clutch apply and OD brake apply ports.

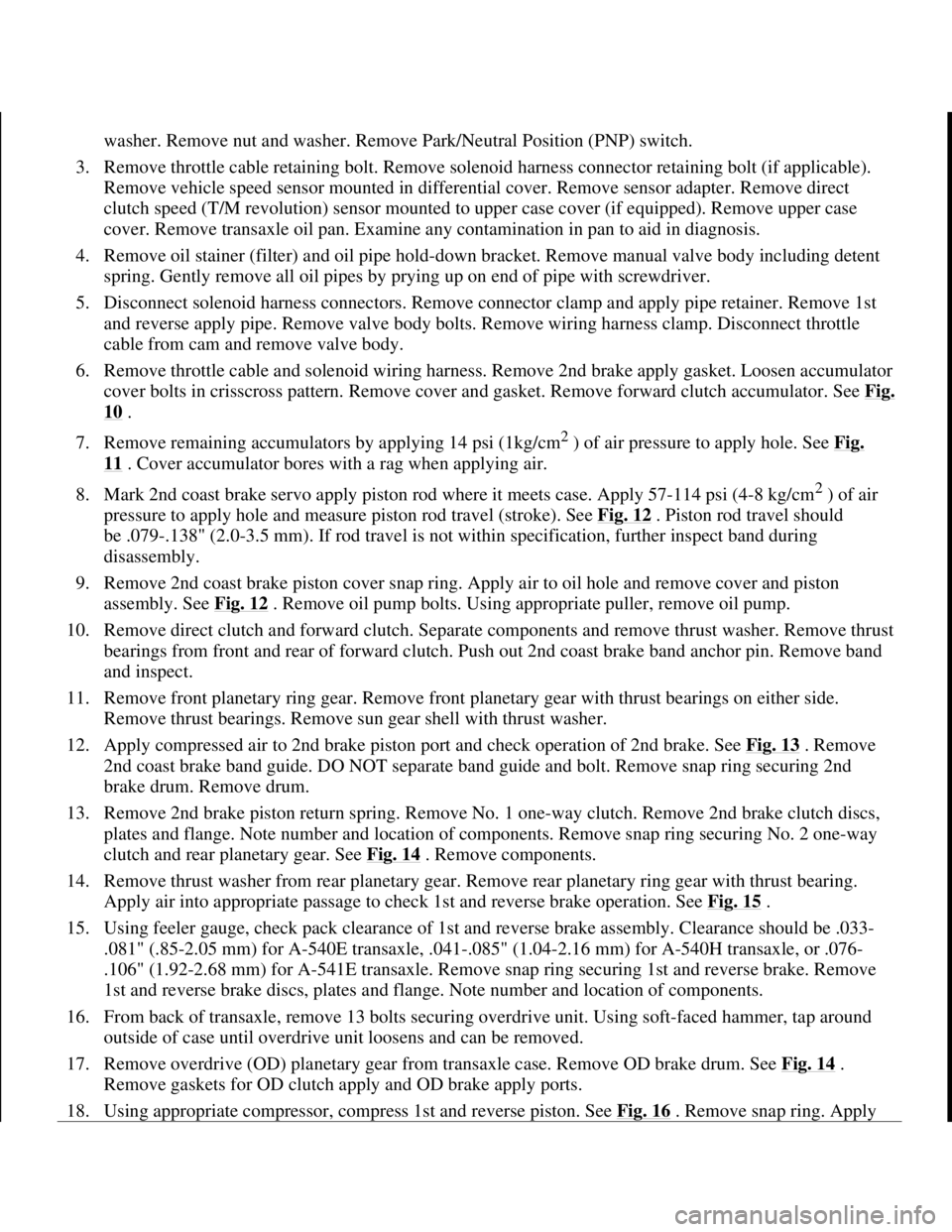

18. Usin

g appropriate compressor, compress 1st and reverse piston. See Fig. 16 . Remove snap ring. Apply

1998 Toyota Avalon XLS

1997-99 AUTOMATIC TRANSMISSIONS Toyota A-540E, A-540H & A-541E Overhaul

Helpmelearn

November-03-08 10:28:17 AMPage 23 © 2005 Mitchell Repair Information Company, LLC.

Page 183 of 1632

Fig. 16: Compressing 1st & Reverse Brake Piston Springs

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

Differential & Drive Pinion Removal

1. Using INCH-lb. torque wrench, measure and record differential total preload. See Fig. 17 . Remove left

differential bearing retainer. Ensure case or retainer is not damaged if prying is necessary.

2. On A-540E and A-541E transaxles, remove right bearing retainer. On all transaxles, remove carrier cover

bolts in crisscross pattern. Remove cover. Remove apply port gasket at lower portion of case. Remove

differential assembly.

3. From converter side of case, remove drive pinion cap. Using INCH-lb. torque wrench, measure drive

pinion preload. See Fig. 17

. Starting preload should be 4.3-6.9 INCH lbs. (.5-.8 N.m). Subtract drive

pinion preload from total preload.

4. If difference is not 1.1-1.7 INCH lbs. (about .1 N.m), differential side bearing preload may not have been

within specification. Carefully inspect condition of all bearings and replace as needed. See appropriate

component disassembly and reassembly procedure under OVERHAUL.

5. Bend back locking washer securing nut on drive pinion shaft. Secure driven gear and remove nut. Using

appropriate puller, remove driven gear and bearing. Using appropriate 2-jaw puller, remove outer race,

spacer and oil slinger. On A-540E transaxle, remove sensor rotor.

6. On all transaxles, remove snap ring. Turn transaxle case, converter side facing up. Install appropriate bar

into hole in drive pinion. Press out drive pinion shaft. Remove bearing cage from drive pinion. Press off

bearing if replacement is needed.

1998 Toyota Avalon XLS

1997-99 AUTOMATIC TRANSMISSIONS Toyota A-540E, A-540H & A-541E Overhaul

Helpmelearn

November-03-08 10:28:17 AMPage 29 © 2005 Mitchell Repair Information Company, LLC.

Page 238 of 1632

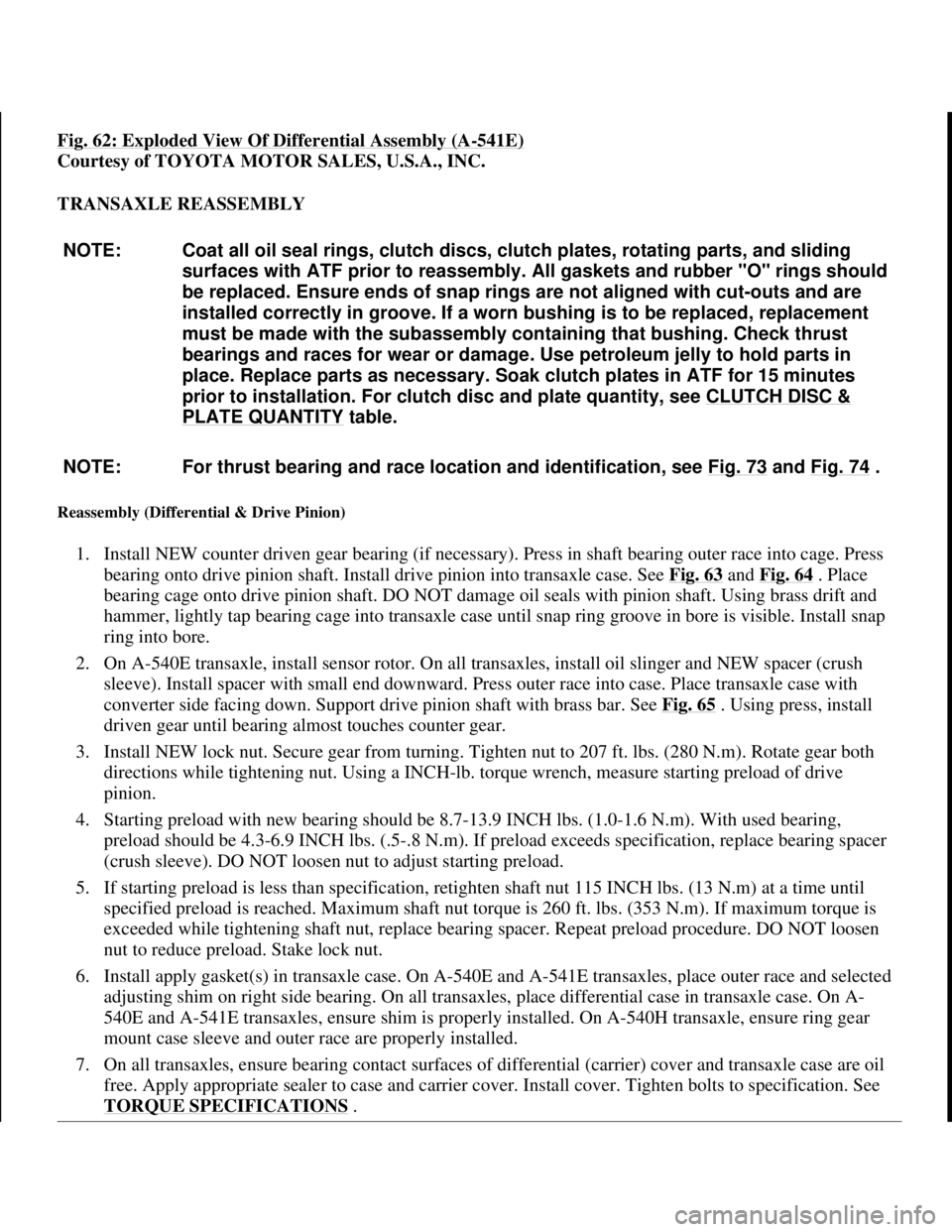

Fig. 62: Exploded View Of Differential Assembly (A-541E)

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

TRANSAXLE REASSEMBLY

Reassembly (Differential & Drive Pinion)

1. Install NEW counter driven gear bearing (if necessary). Press in shaft bearing outer race into cage. Press

bearing onto drive pinion shaft. Install drive pinion into transaxle case. See Fig. 63

and Fig. 64 . Place

bearing cage onto drive pinion shaft. DO NOT damage oil seals with pinion shaft. Using brass drift and

hammer, lightly tap bearing cage into transaxle case until snap ring groove in bore is visible. Install snap

ring into bore.

2. On A-540E transaxle, install sensor rotor. On all transaxles, install oil slinger and NEW spacer (crush

sleeve). Install spacer with small end downward. Press outer race into case. Place transaxle case with

converter side facing down. Support drive pinion shaft with brass bar. See Fig. 65

. Using press, install

driven gear until bearing almost touches counter gear.

3. Install NEW lock nut. Secure gear from turning. Tighten nut to 207 ft. lbs. (280 N.m). Rotate gear both

directions while tightening nut. Using a INCH-lb. torque wrench, measure starting preload of drive

pinion.

4. Starting preload with new bearing should be 8.7-13.9 INCH lbs. (1.0-1.6 N.m). With used bearing,

preload should be 4.3-6.9 INCH lbs. (.5-.8 N.m). If preload exceeds specification, replace bearing spacer

(crush sleeve). DO NOT loosen nut to adjust starting preload.

5. If starting preload is less than specification, retighten shaft nut 115 INCH lbs. (13 N.m) at a time until

specified preload is reached. Maximum shaft nut torque is 260 ft. lbs. (353 N.m). If maximum torque is

exceeded while tightening shaft nut, replace bearing spacer. Repeat preload procedure. DO NOT loosen

nut to reduce preload. Stake lock nut.

6. Install apply gasket(s) in transaxle case. On A-540E and A-541E transaxles, place outer race and selected

adjusting shim on right side bearing. On all transaxles, place differential case in transaxle case. On A-

540E and A-541E transaxles, ensure shim is properly installed. On A-540H transaxle, ensure ring gear

mount case sleeve and outer race are properly installed.

7. On all transaxles, ensure bearing contact surfaces of differential (carrier) cover and transaxle case are oil

free. Apply appropriate sealer to case and carrier cover. Install cover. Tighten bolts to specification. See

TORQUE SPECIFICATIONS

. NOTE: Coat all oil seal rings, clutch discs, clutch plates, rotating parts, and sliding

surfaces with ATF prior to reassembly. All gaskets and rubber "O" rings should

be replaced. Ensure ends of snap rings are not aligned with cut-outs and are

installed correctly in groove. If a worn bushing is to be replaced, replacement

must be made with the subassembly containing that bushing. Check thrust

bearings and races for wear or damage. Use petroleum jelly to hold parts in

place. Replace parts as necessary. Soak clutch plates in ATF for 15 minutes

prior to installation. For clutch disc and plate quantity, see CLUTCH DISC &

PLATE QUANTITY table.

NOTE: For thrust bearing and race location and identification, see Fig. 73

and Fig. 74 .

1998 Toyota Avalon XLS

1997-99 AUTOMATIC TRANSMISSIONS Toyota A-540E, A-540H & A-541E Overhaul

Helpmelearn

November-03-08 10:28:19 AMPage 84 © 2005 Mitchell Repair Information Company, LLC.

Page 250 of 1632

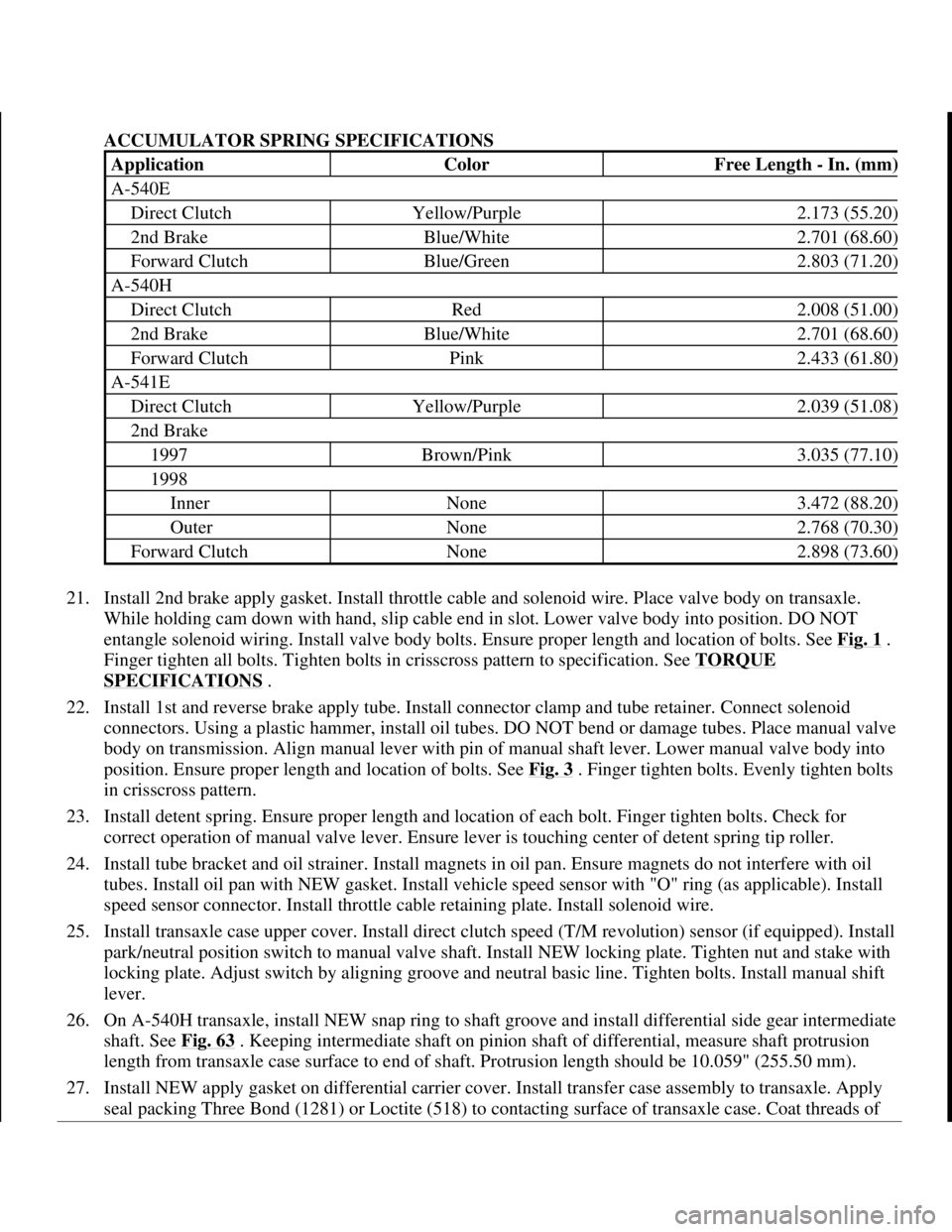

ACCUMULATOR SPRING SPECIFICATIONS

21. Install 2nd brake apply gasket. Install throttle cable and solenoid wire. Place valve body on transaxle.

While holding cam down with hand, slip cable end in slot. Lower valve body into position. DO NOT

entangle solenoid wiring. Install valve body bolts. Ensure proper length and location of bolts. See Fig. 1

.

Finger tighten all bolts. Tighten bolts in crisscross pattern to specification. See TORQUE

SPECIFICATIONS .

22. Install 1st and reverse brake apply tube. Install connector clamp and tube retainer. Connect solenoid

connectors. Using a plastic hammer, install oil tubes. DO NOT bend or damage tubes. Place manual valve

body on transmission. Align manual lever with pin of manual shaft lever. Lower manual valve body into

position. Ensure proper length and location of bolts. See Fig. 3

. Finger tighten bolts. Evenly tighten bolts

in crisscross pattern.

23. Install detent spring. Ensure proper length and location of each bolt. Finger tighten bolts. Check for

correct operation of manual valve lever. Ensure lever is touching center of detent spring tip roller.

24. Install tube bracket and oil strainer. Install magnets in oil pan. Ensure magnets do not interfere with oil

tubes. Install oil pan with NEW gasket. Install vehicle speed sensor with "O" ring (as applicable). Install

speed sensor connector. Install throttle cable retaining plate. Install solenoid wire.

25. Install transaxle case upper cover. Install direct clutch speed (T/M revolution) sensor (if equipped). Install

park/neutral position switch to manual valve shaft. Install NEW locking plate. Tighten nut and stake with

locking plate. Adjust switch by aligning groove and neutral basic line. Tighten bolts. Install manual shift

lever.

26. On A-540H transaxle, install NEW snap ring to shaft groove and install differential side gear intermediate

shaft. See Fig. 63

. Keeping intermediate shaft on pinion shaft of differential, measure shaft protrusion

length from transaxle case surface to end of shaft. Protrusion length should be 10.059" (255.50 mm).

27. Install NEW apply gasket on differential carrier cover. Install transfer case assembly to transaxle. Apply

seal packing Three Bond (1281) or Loctite (518) to contacting surface of transaxle case. Coat threads of

ApplicationColorFree Length - In. (mm)

A-540E

Direct ClutchYellow/Purple2.173 (55.20)

2nd BrakeBlue/White2.701 (68.60)

Forward ClutchBlue/Green2.803 (71.20)

A-540H

Direct ClutchRed2.008 (51.00)

2nd BrakeBlue/White2.701 (68.60)

Forward ClutchPink2.433 (61.80)

A-541E

Direct ClutchYellow/Purple2.039 (51.08)

2nd Brake

1997Brown/Pink3.035 (77.10)

1998

InnerNone3.472 (88.20)

OuterNone2.768 (70.30)

Forward ClutchNone2.898 (73.60)

1998 Toyota Avalon XLS

1997-99 AUTOMATIC TRANSMISSIONS Toyota A-540E, A-540H & A-541E Overhaul

Helpmelearn

November-03-08 10:28:20 AMPage 96 © 2005 Mitchell Repair Information Company, LLC.

Page 255 of 1632

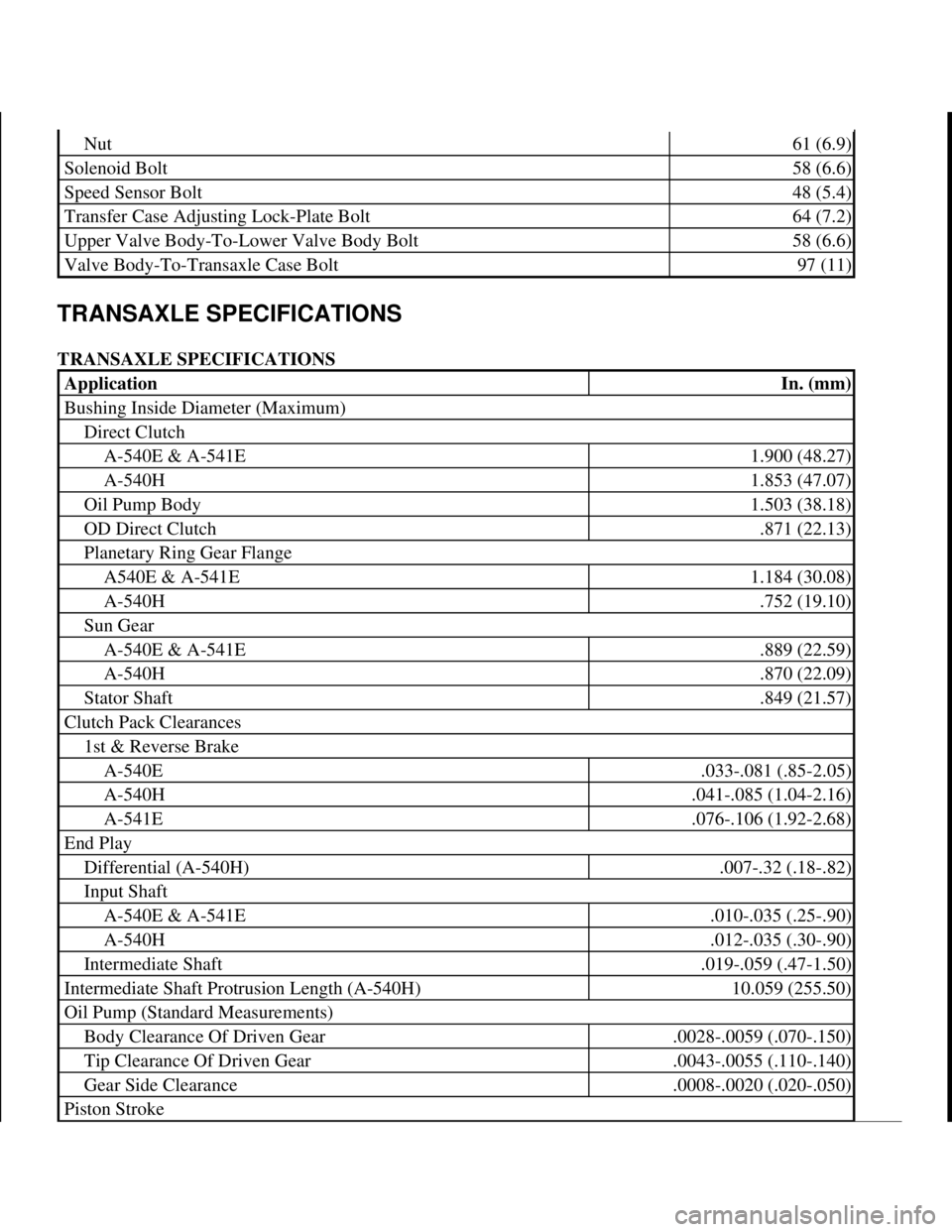

TRANSAXLE SPECIFICATIONS

TRANSAXLE SPECIFICATIONS

Nut61 (6.9)

Solenoid Bolt58 (6.6)

Speed Sensor Bolt48 (5.4)

Transfer Case Adjusting Lock-Plate Bolt64 (7.2)

Upper Valve Body-To-Lower Valve Body Bolt58 (6.6)

Valve Body-To-Transaxle Case Bolt97 (11)

ApplicationIn. (mm)

Bushing Inside Diameter (Maximum)

Direct Clutch

A-540E & A-541E1.900 (48.27)

A-540H1.853 (47.07)

Oil Pump Body1.503 (38.18)

OD Direct Clutch.871 (22.13)

Planetary Ring Gear Flange

A540E & A-541E1.184 (30.08)

A-540H.752 (19.10)

Sun Gear

A-540E & A-541E.889 (22.59)

A-540H.870 (22.09)

Stator Shaft.849 (21.57)

Clutch Pack Clearances

1st & Reverse Brake

A-540E.033-.081 (.85-2.05)

A-540H.041-.085 (1.04-2.16)

A-541E.076-.106 (1.92-2.68)

End Play

Differential (A-540H).007-.32 (.18-.82)

Input Shaft

A-540E & A-541E.010-.035 (.25-.90)

A-540H.012-.035 (.30-.90)

Intermediate Shaft.019-.059 (.47-1.50)

Intermediate Shaft Protrusion Length (A-540H)10.059 (255.50)

Oil Pump (Standard Measurements)

Body Clearance Of Driven Gear.0028-.0059 (.070-.150)

Tip Clearance Of Driven Gear.0043-.0055 (.110-.140)

Gear Side Clearance.0008-.0020 (.020-.050)

Piston Stroke

1998 Toyota Avalon XLS

1997-99 AUTOMATIC TRANSMISSIONS Toyota A-540E, A-540H & A-541E Overhaul

Helpmelearn

November-03-08 10:28:20 AMPage 101 © 2005 Mitchell Repair Information Company, LLC.

Page 322 of 1632

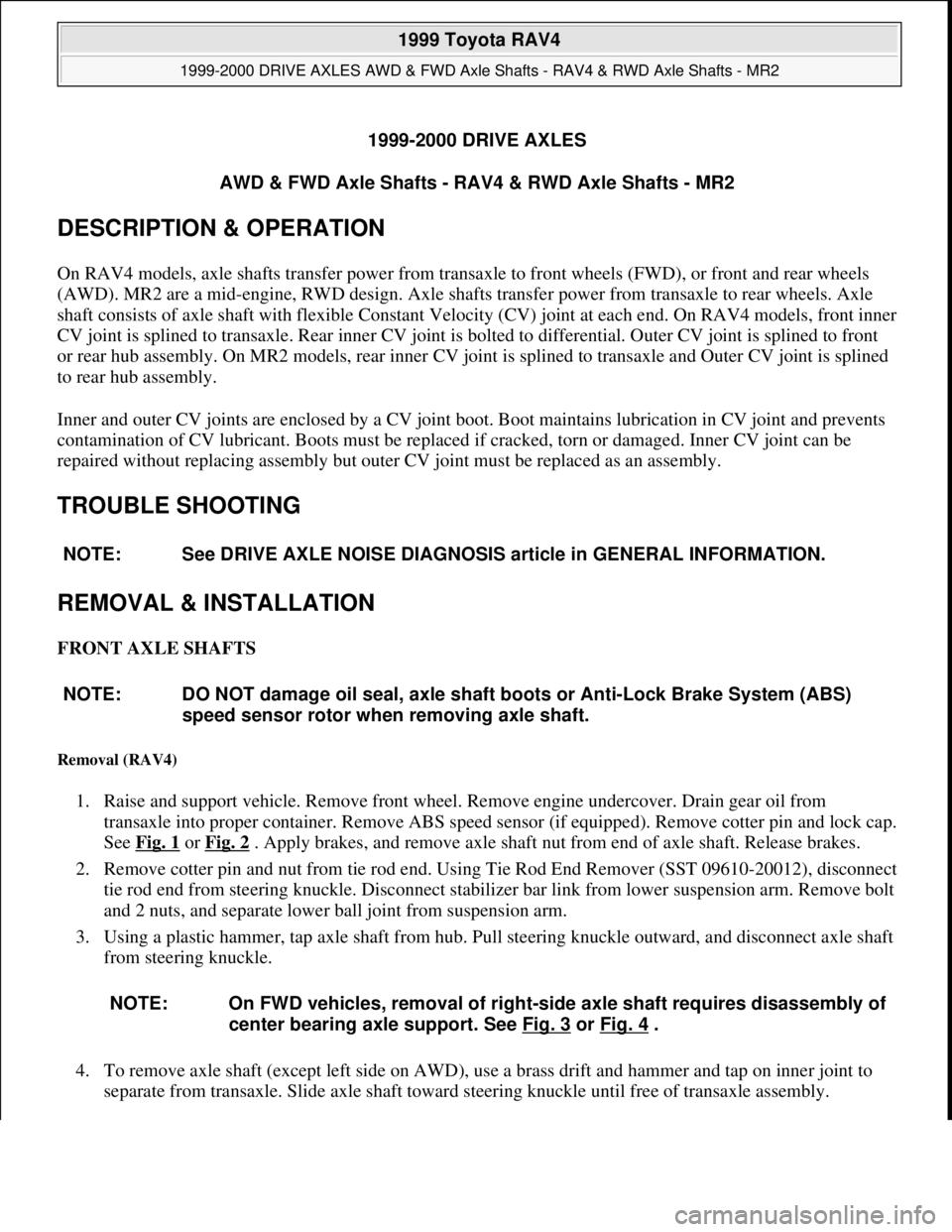

1999-2000 DRIVE AXLES

AWD & FWD Axle Shafts - RAV4 & RWD Axle Shafts - MR2

DESCRIPTION & OPERATION

On RAV4 models, axle shafts transfer power from transaxle to front wheels (FWD), or front and rear wheels

(AWD). MR2 are a mid-engine, RWD design. Axle shafts transfer power from transaxle to rear wheels. Axle

shaft consists of axle shaft with flexible Constant Velocity (CV) joint at each end. On RAV4 models, front inner

CV joint is splined to transaxle. Rear inner CV joint is bolted to differential. Outer CV joint is splined to front

or rear hub assembly. On MR2 models, rear inner CV joint is splined to transaxle and Outer CV joint is splined

to rear hub assembly.

Inner and outer CV joints are enclosed by a CV joint boot. Boot maintains lubrication in CV joint and prevents

contamination of CV lubricant. Boots must be replaced if cracked, torn or damaged. Inner CV joint can be

repaired without replacing assembly but outer CV joint must be replaced as an assembly.

TROUBLE SHOOTING

REMOVAL & INSTALLATION

FRONT AXLE SHAFTS

Removal (RAV4)

1. Raise and support vehicle. Remove front wheel. Remove engine undercover. Drain gear oil from

transaxle into proper container. Remove ABS speed sensor (if equipped). Remove cotter pin and lock cap.

See Fig. 1

or Fig. 2 . Apply brakes, and remove axle shaft nut from end of axle shaft. Release brakes.

2. Remove cotter pin and nut from tie rod end. Using Tie Rod End Remover (SST 09610-20012), disconnect

tie rod end from steering knuckle. Disconnect stabilizer bar link from lower suspension arm. Remove bolt

and 2 nuts, and separate lower ball joint from suspension arm.

3. Using a plastic hammer, tap axle shaft from hub. Pull steering knuckle outward, and disconnect axle shaft

from steering knuckle.

4. To remove axle shaft (except left side on AWD), use a brass drift and hammer and tap on inner joint to

separate from transaxle. Slide axle shaft toward steering knuckle until free of transaxle assembly. NOTE: See DRIVE AXLE NOISE DIAGNOSIS article in GENERAL INFORMATION.

NOTE: DO NOT damage oil seal, axle shaft boots or Anti-Lock Brake System (ABS)

speed sensor rotor when removing axle shaft.

NOTE: On FWD vehicles, removal of right-side axle shaft requires disassembly of

center bearing axle support. See Fig. 3

or Fig. 4 .

1999 Toyota RAV4

1999-2000 DRIVE AXLES AWD & FWD Axle Shafts - RAV4 & RWD Axle Shafts - MR2

1999 Toyota RAV4

1999-2000 DRIVE AXLES AWD & FWD Axle Shafts - RAV4 & RWD Axle Shafts - MR2

Microsoft

Sunday, November 22, 2009 10:08:21 AMPage 1 © 2005 Mitchell Repair Information Company, LLC.

Microsoft

Sunday, November 22, 2009 10:08:25 AMPage 1 © 2005 Mitchell Repair Information Company, LLC.

Page 332 of 1632

1. To install, reverse removal procedure. Before installing axle shafts, install NEW snap ring on end of axle

shaft (except right side). Coat axle shaft seals in transaxle with grease. Coat axle shaft splines and sliding

surfaces with Dexron-II. Position snap ring on end of axle shaft, with opening facing downward.

2. Install axle shaft by lightly tapping axle shaft into transaxle. Ensure axle shaft will move inward and

outward approximately .079-.120" (2.00-3.00 mm), and cannot be pulled from transaxle.

3. To install remaining components, reverse removal procedure. Tighten fasteners to specification. See

TORQUE SPECIFICATIONS

. Fill transaxle with 75W-90 gear oil with API GL-3, GL-4 or GL-5

rating.

REAR AXLE SHAFTS

Removal (MR2)

1. Raise and support vehicle. Remove rear wheels. Remove engine undercovers. Drain differential oil into

proper container. Unstake drive shaft lock nut. Apply brakes and remove nut. Remove bolt and brake flex

hose bracket from shock absorber. Loosen 2 lower shock absorber bolts and nuts.

2. Remove mounting bolts/nuts and disconnect strut rod from axle carrier. Remove mounting bolts/nuts

from No. 1 lower suspension arm. Remove nut and No. 2 lower suspension arm. Remove 2 lower shock

absorber bolts and nuts. See Fig. 8

. Using plastic hammer, remove drive shaft from axle hub. DO NOT

damage oil seal, boots or dust seal. NOTE: DO NOT damage oil seal, axle shaft boots or Anti-Lock Brake System (ABS)

speed sensor rotor when removing axle shaft.

1999 Toyota RAV4

1999-2000 DRIVE AXLES AWD & FWD Axle Shafts - RAV4 & RWD Axle Shafts - MR2

Microsoft

Sunday, November 22, 2009 10:08:21 AMPage 11 © 2005 Mitchell Repair Information Company, LLC.

Page 335 of 1632

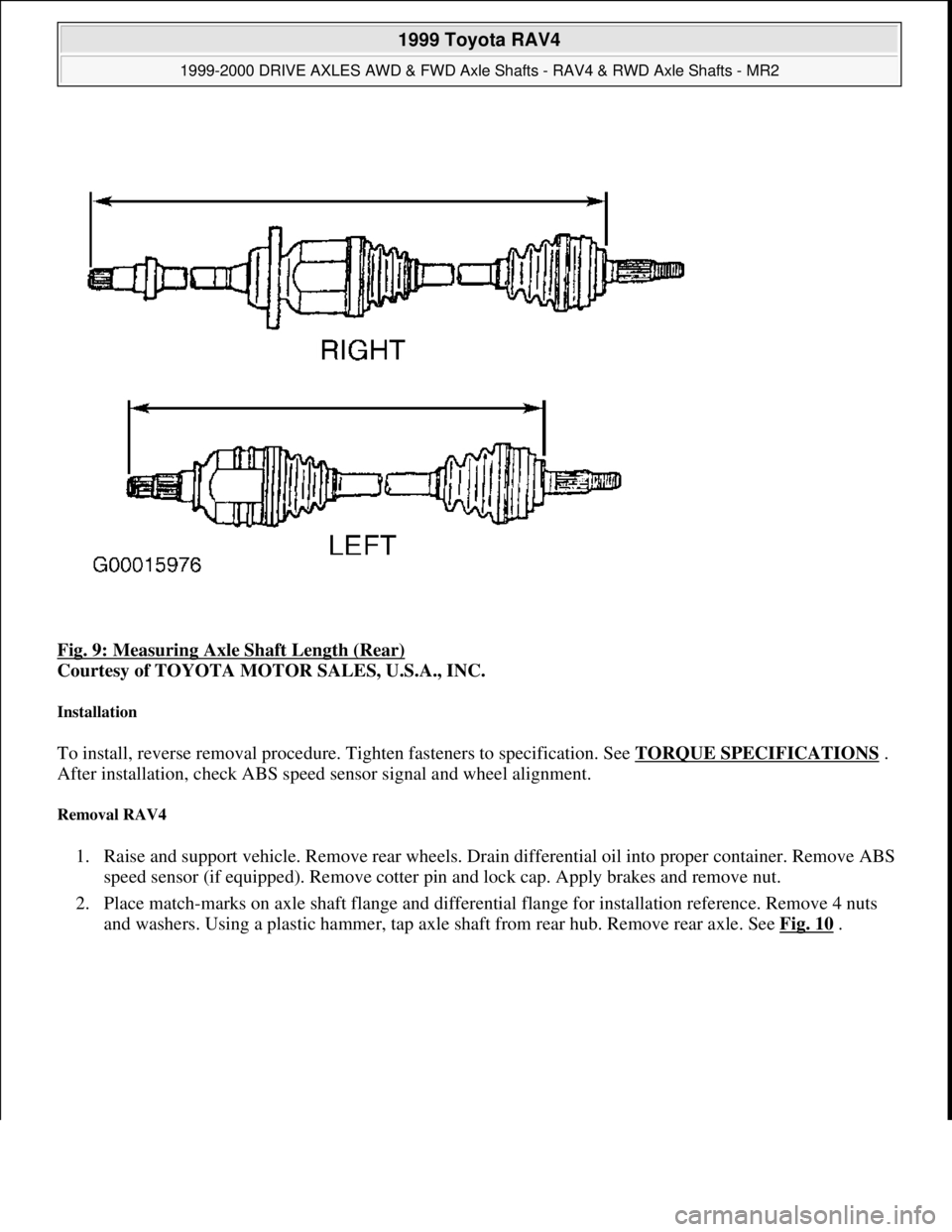

Fig. 9: Measuring Axle Shaft Length (Rear)

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

Installation

To install, reverse removal procedure. Tighten fasteners to specification. See TORQUE SPECIFICATIONS .

After installation, check ABS speed sensor signal and wheel alignment.

Removal RAV4

1. Raise and support vehicle. Remove rear wheels. Drain differential oil into proper container. Remove ABS

speed sensor (if equipped). Remove cotter pin and lock cap. Apply brakes and remove nut.

2. Place match-marks on axle shaft flange and differential flange for installation reference. Remove 4 nuts

and washers. Using a plastic hammer, tap axle shaft from rear hub. Remove rear axle. See Fig. 10

.

1999 Toyota RAV4

1999-2000 DRIVE AXLES AWD & FWD Axle Shafts - RAV4 & RWD Axle Shafts - MR2

Microsoft

Sunday, November 22, 2009 10:08:21 AMPage 14 © 2005 Mitchell Repair Information Company, LLC.