battery location TOYOTA RAV4 1996 Service Repair Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 1996, Model line: RAV4, Model: TOYOTA RAV4 1996Pages: 1632, PDF Size: 41.64 MB

Page 142 of 1632

1. Before installing transmission, use dial indicator to check drive plate runout. Drive plate runout should be

checked right next to the starter ring gear on the drive plate. Replace drive plate if runout

exceeds .0079" (.200 mm).

2. Install torque converter on transmission. To ensure torque converter is fully seated, torque converter

depth should be checked. Using straightedge and caliper, measure torque converter depth from torque

converter bolt lug on torque converter to the surface on transmission. See Fig. 1

.

3. Torque converter depth should be more than .707" (17.95 mm). If torque converter depth is less than

specified, check for improperly seated torque converter.

4. To install, reverse removal procedure. Tighten all bolts/nuts to specification. See TORQUE

SPECIFICATIONS . When installing torque converter bolts, apply Loctite to torque converter bolt

threads before installing.

5. Apply grease to transfer case shift lever before installing. Use NEW gasket when installing front exhaust

pipe. Adjust all cables, shift linkages and fill with ATF. See appropriate TRANSMISSION SERVICING

article.

Removal (4Runner 2WD)

1. Disconnect negative battery cable. Remove transmission oil dipstick, dipstick tube and "O" ring.

Disconnect throttle valve cable from throttle body.

2. Raise and support vehicle. Remove lower engine cover. Disconnect shift linkage for transmission at

gearshift. Remove front exhaust pipe, located between exhaust manifold and catalytic converter on rear

exhaust pipe.

3. Place reference marks on drive shaft flange for reassembly reference. Remove drive shaft. Disconnect

necessary electrical connectors for transmission removal. Remove transmission oil cooler pipes and

brackets as necessary.

4. Support transmission with floor jack. Remove transmission crossmember, located below transmission.

Remove starter.

5. Remove cover from front of transmission for access to torque converter bolts. On 3.4L, note location of

Green torque converter bolt for reassembly reference. Remove torque converter bolts. Remove

transmission-to-cylinder block bolts. Lower transmission from vehicle.

Installation

1. Before installing transmission, use dial indicator to check drive plate runout. Drive plate runout should be

checked right next to the starter ring gear on the drive plate. Replace drive plate if runout

exceeds .0079" (.200 mm).

2. Install torque converter on transmission. To ensure torque converter is fully seated, torque converter

depth should be checked. Using straightedge and caliper, measure torque converter depth from torque

converter bolt lug on torque converter to the surface on transmission. See Fig. 1

.

3. Torque converter depth should be more than 1.250" (31.75 mm) for 2.7L 4-cylinder or .707" (17.95 mm)

for 3.4L V6. If torque converter depth is less than specified, check for improperly seated torque converter.

4. To install, reverse removal procedure. Tighten all bolts/nuts to specification. See TORQUE

SPECIFICATIONS . When installing torque converter bolts, apply Loctite to torque converter bolt

threads before installin

g. On 3.4L V6, ensure the Green torque converter bolt is installed first before

1998 Toyota Avalon XLS

TRANSMISSION SERVICING - A/T 1997-98 TRANSMISSION SERVICING Toyota - Transmission Removal &

Installation

Helpmelearn

November-03-08 10:30:29 AMPage 30 © 2005 Mitchell Repair Information Company, LLC.

Page 143 of 1632

installing the remaining torque converter bolts.

5. Use NEW gasket when installing front exhaust pipe. Adjust all cables, shift linkages and fill with ATF.

See appropriate TRANSMISSION SERVICING article.

Removal (4Runner 4WD)

1. Disconnect negative battery cable. Remove rear console upper panel and disconnect electrical connectors.

Rear console upper panel is located on the top of the console, near emergency brake lever.

2. Remove heater control knobs from instrument panel. Using screwdriver, pry heater control plate from

center finish panel on instrument panel. Center finish panel is the panel that fits around the radio and air

outlet ducts, located at center of instrument panel.

3. Remove screws and disconnect electrical connectors from center finish panel from instrument panel.

Remove center finish panel.

4. On models without 2-4 selector button on side of transfer case shift lever, unscrew knob from transfer

case shift lever. On models with2-4 selector button on side of transfer case shift lever, remove screw from

knob on transfer case shift lever. Remove knob from transfer case shift lever and lay aside with wire

attached.

5. On all models, remove upper console panel which contains boot for transfer case shift lever and is located

on center console. On models with 2-4 selector button on side of transfer case shift lever, disconnect

electrical connector for 2-4 selector button and remove knob on transfer case shift lever.

6. On all models, remove screws, clips and front console box, located around transmission shift lever

assembly and transfer case shift lever. Raise and support vehicle. Disconnect shift linkage at transmission

shift lever.

7. Disconnect electrical connectors for removal of transmission shift lever assembly. Remove transmission

shift lever assembly. Remove snap ring and transfer case shift lever.

8. Remove transmission oil dipstick, dipstick tube and "O" ring. Remove lower engine covers. Place

reference marks on drive shaft flanges for reassembly reference. Remove drive shafts.

9. Remove front exhaust pipe, located between exhaust manifold and catalytic converter on rear exhaust

pipe. Disconnect and necessary electrical connectors for transmission and transfer case removal. Separate

wiring harness from transmission and transfer case.

10. Remove starter. Remove transmission oil cooler pipes and brackets as necessary. On 3.4L V6, it may be

necessary to remove stabilizer bar.

11. On all models, support transmission with floor jack. Remove rear transmission mount-to-transmission

crossmember bolts. Remove transmission crossmember, located below transmission and transfer case.

12. Remove torque converter cover from front of transmission. On 3.4L, note location of Green torque

converter bolt for re-installation reference. Remove torque converter bolts. Remove transmission-to-

cylinder block bolts. Lower transmission with transfer case from vehicle.

Installation

1. Before installing transmission, use dial indicator to check drive plate runout. Drive plate runout should be

checked right next to the starter ring gear on the drive plate. Replace drive plate if runout

exceeds .0079" (.200 mm).

2. Install torque converter on transmission. To ensure torque converter is fully seated, torque converter

1998 Toyota Avalon XLS

TRANSMISSION SERVICING - A/T 1997-98 TRANSMISSION SERVICING Toyota - Transmission Removal &

Installation

Helpmelearn

November-03-08 10:30:29 AMPage 31 © 2005 Mitchell Repair Information Company, LLC.

Page 471 of 1632

1999-2000 ENGINE COOLING

Electric Cooling Fans

IDENTIFICATION

ELECTRIC COOLING FAN IDENTIFICATION

DESCRIPTION & OPERATION

Land Cruiser, Tacoma, Tundra and 4Runner use a belt-driven cooling fan attached to the water pump. All other

models use 2 electric cooling fans located directly behind the radiator. Fans are controlled via Engine Coolant

Temperature (ECT) switches/sensors, and turn on when engine coolant temperature is above 208°F (98°C) on

Avalon, Camry with 3.0L, Camry Solara with 3.0L and Sienna. On Camry with 2.2L, Camry Solara with 2.2L,

Celica, Corolla, ECHO, MR2 and RAV4, ECT turns cooling fans on above 199°F (93°C). On Avalon, Camry

with 3.0L, Camry Solara with 3.0L and Sienna, fans will turn off when engine coolant temperature falls below

190°F (88°C). On Camry with 2.2L, Camry Solara with 2.2L, Celica, Corolla and RAV4, fans will turn off

below 181°F (83°C).

SYSTEM TESTS

ELECTRIC COOLING FAN

Avalon (1999), Camry 3.0L, Camry Solara 3.0L & Sienna

1. With engine coolant temperature below 190°F (88°C), turn ignition switch to ON position (engine off).

Ensure fans stop.

2. If fan do not stop, test cooling fan relay and ECT switch. See COOLING FAN RELAYS

and ECT

SWITCH . Check for loose or broken connector or wiring between relay and ECT switch. Repair as

necessary.

3. Disconnect No. 1 ECT switch connector. See ECT SWITCH LOCATIONS

table. With ignition still in

ON position, ensure cooling fan turns on. If not, check fuses, engine main relay, cooling fan relay and

cooling fan motor. Check for short between cooling fan relay and ECT switch.

4. Start engine and raise temperature above 208°F (98°C). Ensure cooling fan turns. If not, replace No. 1

ECT switch.

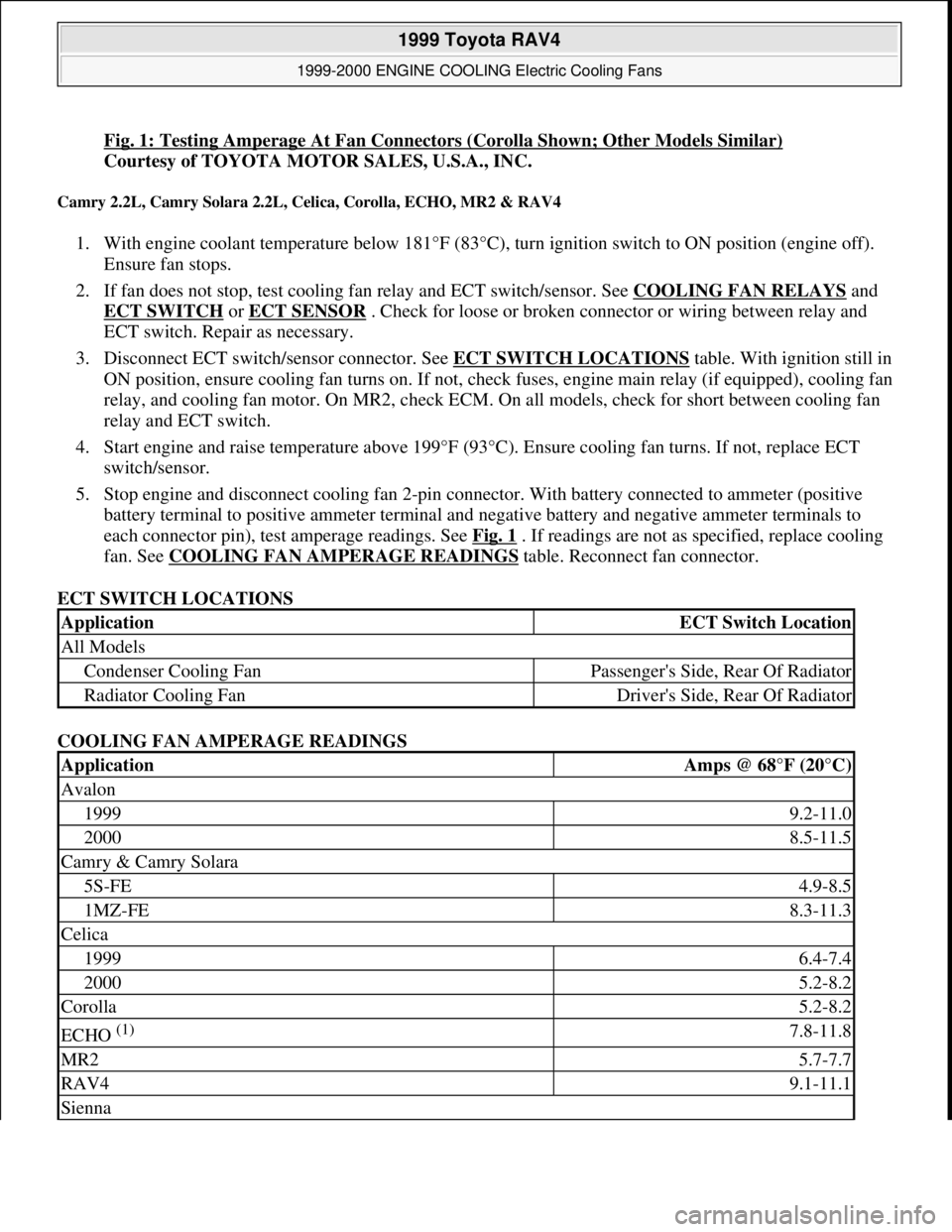

5. Stop engine and disconnect cooling fan 2-pin connector. With battery connected to ammeter (positive

battery terminal to positive ammeter terminal and negative battery and negative ammeter terminals to

each connector pin), test amperage readings. See Fig. 1

. If readings are not as specified, replace cooling

fan. See COOLING FAN AMPERAGE READINGS

table. Reconnect fan connector.

Avalon (2000)

ApplicationCooling Fan Location

All Models

Condenser Cooling FanPassenger's Side, Rear Of Radiator

Radiator Cooling FanDriver's Side, Rear Of Radiator

1999 Toyota RAV4

1999-2000 ENGINE COOLING Electric Cooling Fans

1999 Toyota RAV4

1999-2000 ENGINE COOLING Electric Cooling Fans

Microsoft

Sunday, November 22, 2009 10:21:41 AMPage 1 © 2005 Mitchell Repair Information Company, LLC.

Microsoft

Sunday, November 22, 2009 10:21:45 AMPage 1 © 2005 Mitchell Repair Information Company, LLC.

Page 474 of 1632

Fig. 1: Testing Amperage At Fan Connectors (Corolla Shown; Other Models Similar)

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

Camry 2.2L, Camry Solara 2.2L, Celica, Corolla, ECHO, MR2 & RAV4

1. With engine coolant temperature below 181°F (83°C), turn ignition switch to ON position (engine off).

Ensure fan stops.

2. If fan does not stop, test cooling fan relay and ECT switch/sensor. See COOLING FAN RELAYS

and

ECT SWITCH

or ECT SENSOR . Check for loose or broken connector or wiring between relay and

ECT switch. Repair as necessary.

3. Disconnect ECT switch/sensor connector. See ECT SWITCH LOCATIONS

table. With ignition still in

ON position, ensure cooling fan turns on. If not, check fuses, engine main relay (if equipped), cooling fan

relay, and cooling fan motor. On MR2, check ECM. On all models, check for short between cooling fan

relay and ECT switch.

4. Start engine and raise temperature above 199°F (93°C). Ensure cooling fan turns. If not, replace ECT

switch/sensor.

5. Stop engine and disconnect cooling fan 2-pin connector. With battery connected to ammeter (positive

battery terminal to positive ammeter terminal and negative battery and negative ammeter terminals to

each connector pin), test amperage readings. See Fig. 1

. If readings are not as specified, replace cooling

fan. See COOLING FAN AMPERAGE READINGS

table. Reconnect fan connector.

ECT SWITCH LOCATIONS

COOLING FAN AMPERAGE READINGS

ApplicationECT Switch Location

All Models

Condenser Cooling FanPassenger's Side, Rear Of Radiator

Radiator Cooling FanDriver's Side, Rear Of Radiator

ApplicationAmps @ 68°F (20°C)

Avalon

19999.2-11.0

20008.5-11.5

Camry & Camry Solara

5S-FE4.9-8.5

1MZ-FE8.3-11.3

Celica

19996.4-7.4

20005.2-8.2

Corolla5.2-8.2

ECHO (1) 7.8-11.8

MR25.7-7.7

RAV49.1-11.1

Sienna

1999 Toyota RAV4

1999-2000 ENGINE COOLING Electric Cooling Fans

Microsoft

Sunday, November 22, 2009 10:21:41 AMPage 4 © 2005 Mitchell Repair Information Company, LLC.

Page 674 of 1632

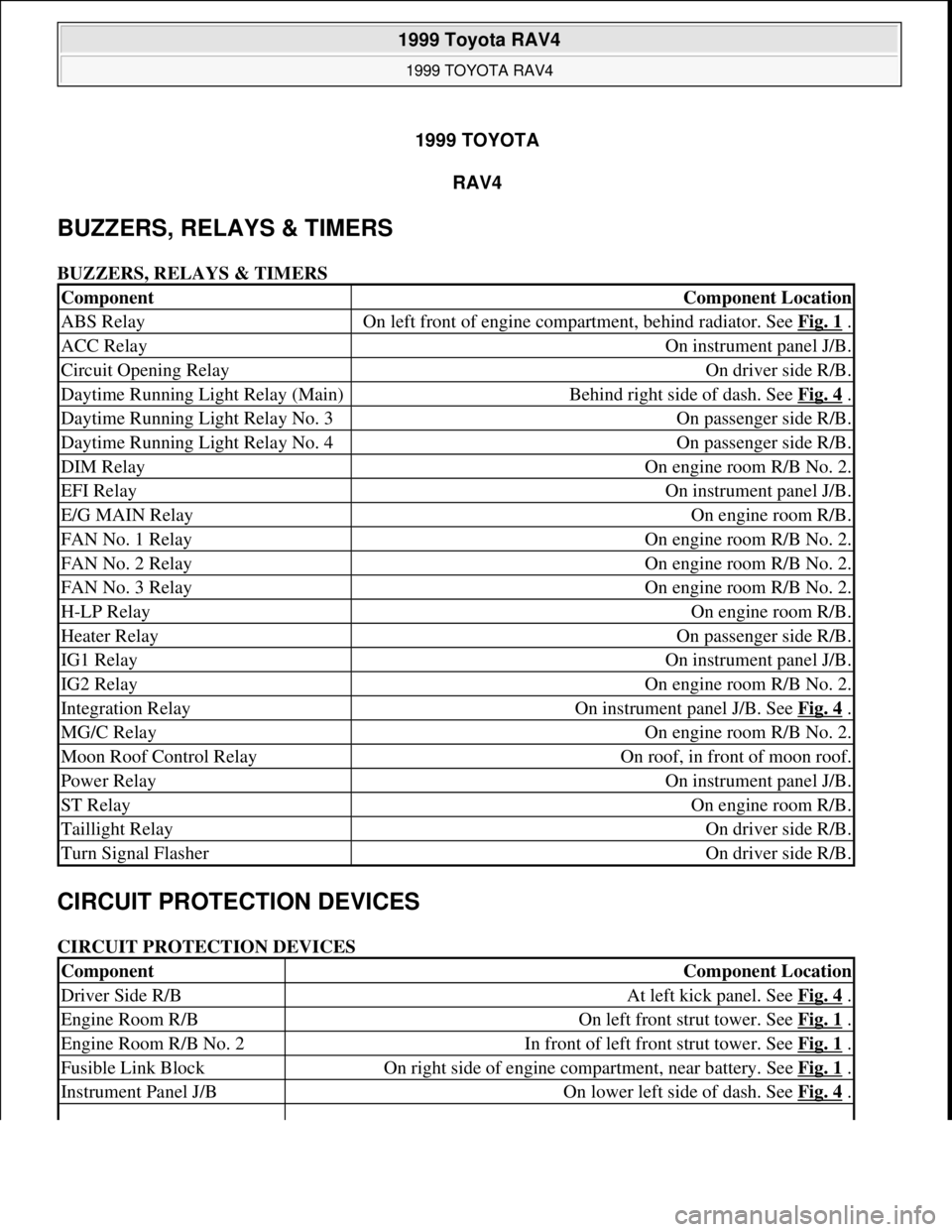

1999 TOYOTA

RAV4

BUZZERS, RELAYS & TIMERS

BUZZERS, RELAYS & TIMERS

CIRCUIT PROTECTION DEVICES

CIRCUIT PROTECTION DEVICES

ComponentComponent Location

ABS RelayOn left front of engine compartment, behind radiator. See Fig. 1 .

ACC RelayOn instrument panel J/B.

Circuit Opening RelayOn driver side R/B.

Daytime Running Light Relay (Main)Behind right side of dash. See Fig. 4 .

Daytime Running Light Relay No. 3On passenger side R/B.

Daytime Running Light Relay No. 4On passenger side R/B.

DIM RelayOn engine room R/B No. 2.

EFI RelayOn instrument panel J/B.

E/G MAIN RelayOn engine room R/B.

FAN No. 1 RelayOn engine room R/B No. 2.

FAN No. 2 RelayOn engine room R/B No. 2.

FAN No. 3 RelayOn engine room R/B No. 2.

H-LP RelayOn engine room R/B.

Heater RelayOn passenger side R/B.

IG1 RelayOn instrument panel J/B.

IG2 RelayOn engine room R/B No. 2.

Integration RelayOn instrument panel J/B. See Fig. 4 .

MG/C RelayOn engine room R/B No. 2.

Moon Roof Control RelayOn roof, in front of moon roof.

Power RelayOn instrument panel J/B.

ST RelayOn engine room R/B.

Taillight RelayOn driver side R/B.

Turn Signal FlasherOn driver side R/B.

ComponentComponent Location

Driver Side R/BAt left kick panel. See Fig. 4 .

Engine Room R/BOn left front strut tower. See Fig. 1 .

Engine Room R/B No. 2In front of left front strut tower. See Fig. 1 .

Fusible Link BlockOn right side of engine compartment, near battery. See Fig. 1 .

Instrument Panel J/BOn lower left side of dash. See Fig. 4 .

1999 Toyota RAV4

1999 TOYOTA RAV4

1999 Toyota RAV4

1999 TOYOTA RAV4

Microsoft

Sunday, November 22, 2009 10:17:32 AMPage 1 © 2005 Mitchell Repair Information Company, LLC.

Microsoft

Sunday, November 22, 2009 10:17:35 AMPage 1 © 2005 Mitchell Repair Information Company, LLC.

Page 851 of 1632

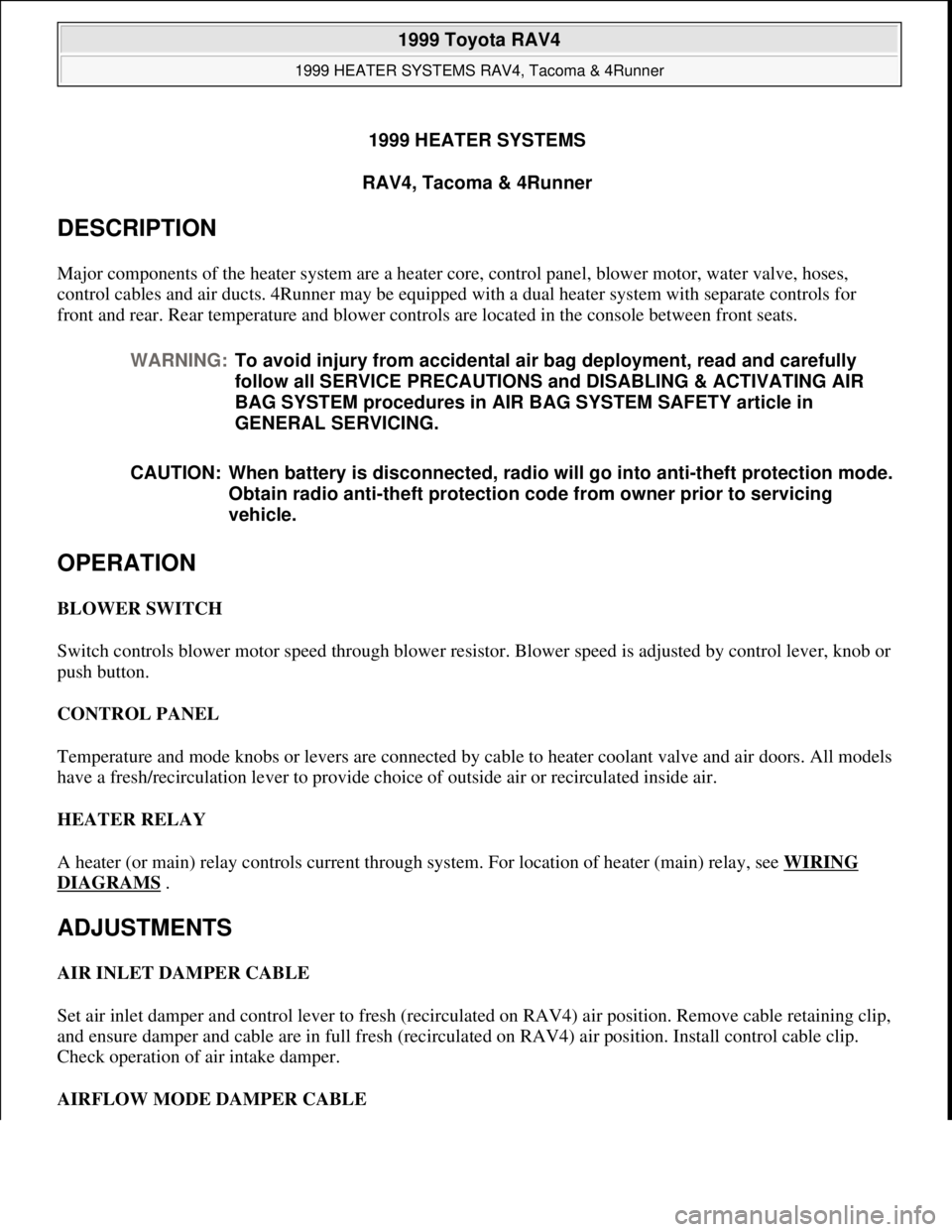

1999 HEATER SYSTEMS

RAV4, Tacoma & 4Runner

DESCRIPTION

Major components of the heater system are a heater core, control panel, blower motor, water valve, hoses,

control cables and air ducts. 4Runner may be equipped with a dual heater system with separate controls for

front and rear. Rear temperature and blower controls are located in the console between front seats.

OPERATION

BLOWER SWITCH

Switch controls blower motor speed through blower resistor. Blower speed is adjusted by control lever, knob or

push button.

CONTROL PANEL

Temperature and mode knobs or levers are connected by cable to heater coolant valve and air doors. All models

have a fresh/recirculation lever to provide choice of outside air or recirculated inside air.

HEATER RELAY

A heater (or main) relay controls current through system. For location of heater (main) relay, see WIRING

DIAGRAMS .

ADJUSTMENTS

AIR INLET DAMPER CABLE

Set air inlet damper and control lever to fresh (recirculated on RAV4) air position. Remove cable retaining clip,

and ensure damper and cable are in full fresh (recirculated on RAV4) air position. Install control cable clip.

Check operation of air intake damper.

AIRFLOW MODE DAMPER CABLE WARNING:To avoid injury from accidental air bag deployment, read and carefully

follow all SERVICE PRECAUTIONS and DISABLING & ACTIVATING AIR

BAG SYSTEM procedures in AIR BAG SYSTEM SAFETY article in

GENERAL SERVICING.

CAUTION: When battery is disconnected, radio will go into anti-theft protection mode.

Obtain radio anti-theft protection code from owner prior to servicing

vehicle.

1999 Toyota RAV4

1999 HEATER SYSTEMS RAV4, Tacoma & 4Runner

1999 Toyota RAV4

1999 HEATER SYSTEMS RAV4, Tacoma & 4Runner

Microsoft

Sunday, November 22, 2009 10:30:50 AMPage 1 © 2005 Mitchell Repair Information Company, LLC.

Microsoft

Sunday, November 22, 2009 10:30:55 AMPage 1 © 2005 Mitchell Repair Information Company, LLC.

Page 910 of 1632

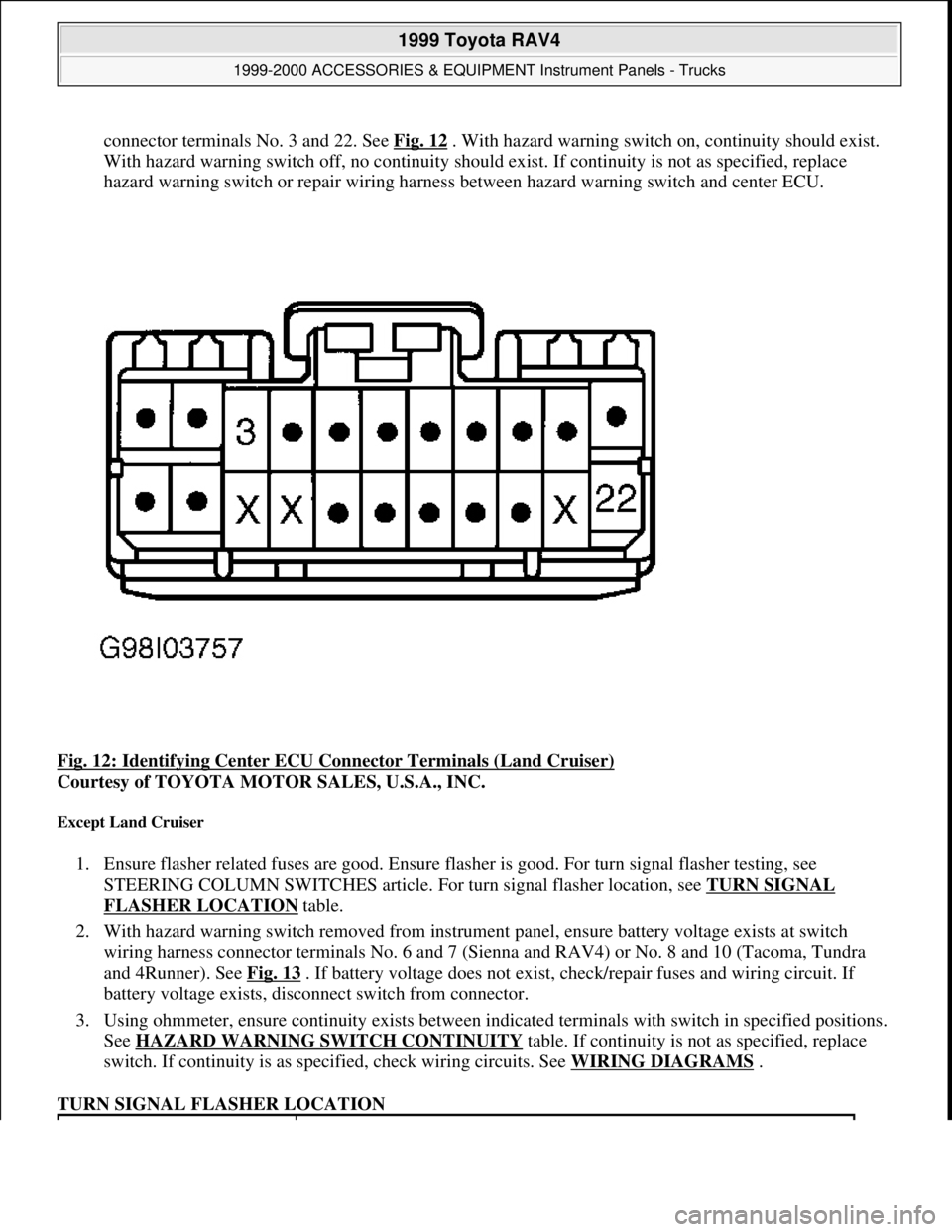

connector terminals No. 3 and 22. See Fig. 12. With hazard warning switch on, continuity should exist.

With hazard warning switch off, no continuity should exist. If continuity is not as specified, replace

hazard warning switch or repair wiring harness between hazard warning switch and center ECU.

Fig. 12: Identifying Center ECU Connector Terminals (Land Cruiser)

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

Except Land Cruiser

1. Ensure flasher related fuses are good. Ensure flasher is good. For turn signal flasher testing, see

STEERING COLUMN SWITCHES article. For turn signal flasher location, see TURN SIGNAL

FLASHER LOCATION table.

2. With hazard warning switch removed from instrument panel, ensure battery voltage exists at switch

wiring harness connector terminals No. 6 and 7 (Sienna and RAV4) or No. 8 and 10 (Tacoma, Tundra

and 4Runner). See Fig. 13

. If battery voltage does not exist, check/repair fuses and wiring circuit. If

battery voltage exists, disconnect switch from connector.

3. Using ohmmeter, ensure continuity exists between indicated terminals with switch in specified positions.

See HAZARD WARNING SWITCH CONTINUITY

table. If continuity is not as specified, replace

switch. If continuity is as specified, check wiring circuits. See WIRING DIAGRAMS

.

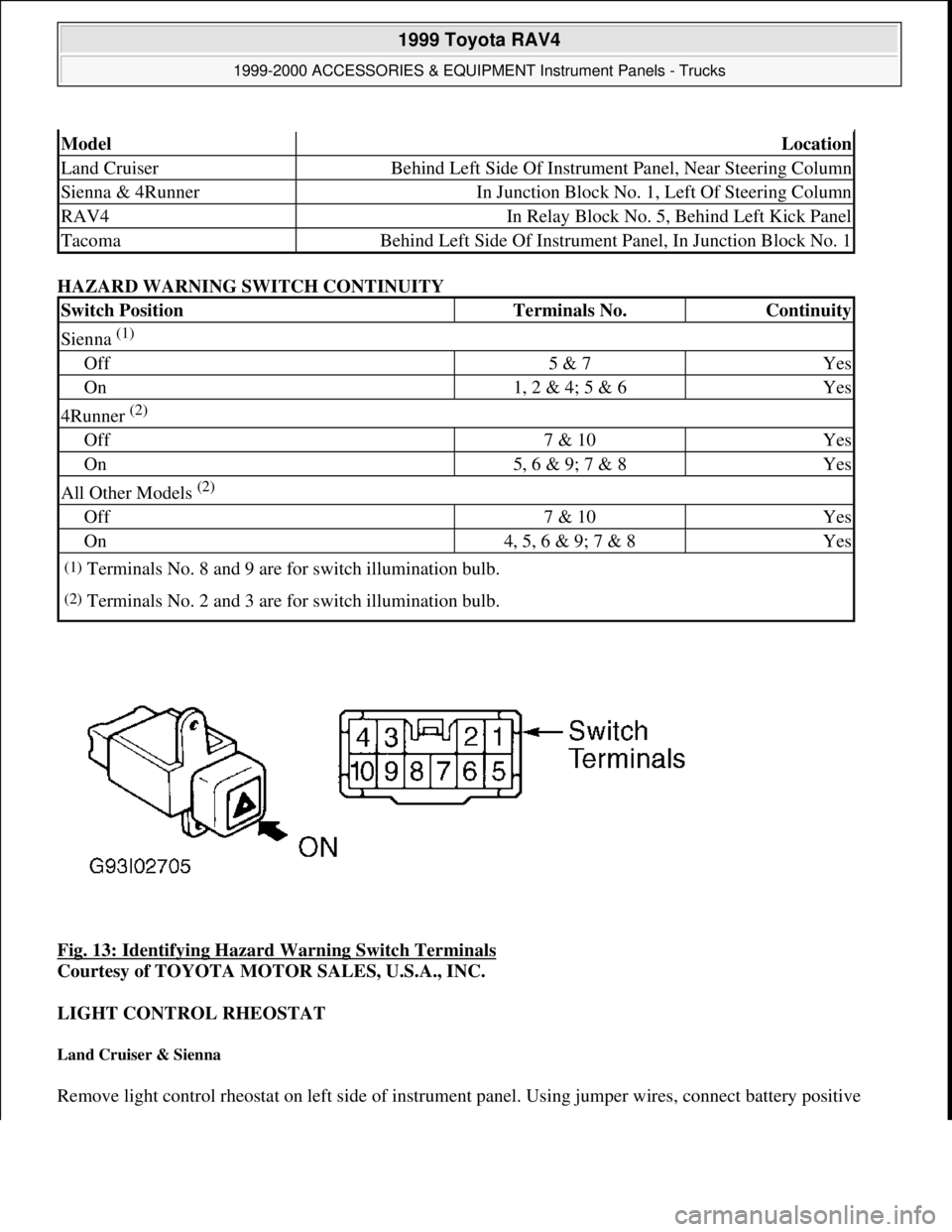

TURN SIGNAL FLASHER LOCATION

1999 Toyota RAV4

1999-2000 ACCESSORIES & EQUIPMENT Instrument Panels - Trucks

Microsoft

Sunday, November 22, 2009 10:54:10 AMPage 20 © 2005 Mitchell Repair Information Company, LLC.

Page 911 of 1632

HAZARD WARNING SWITCH CONTINUITY

Fig. 13: Identifying Hazard Warning Switch Terminals

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

LIGHT CONTROL RHEOSTAT

Land Cruiser & Sienna

Remove light control rheostat on left side of instrument panel. Using jumper wires, connect battery positive

ModelLocation

Land CruiserBehind Left Side Of Instrument Panel, Near Steering Column

Sienna & 4RunnerIn Junction Block No. 1, Left Of Steering Column

RAV4In Relay Block No. 5, Behind Left Kick Panel

TacomaBehind Left Side Of Instrument Panel, In Junction Block No. 1

Switch PositionTerminals No.Continuity

Sienna (1)

Off5 & 7Yes

On1, 2 & 4; 5 & 6Yes

4Runner (2)

Off7 & 10Yes

On5, 6 & 9; 7 & 8Yes

All Other Models (2)

Off7 & 10Yes

On4, 5, 6 & 9; 7 & 8Yes

(1)Terminals No. 8 and 9 are for switch illumination bulb.

(2)Terminals No. 2 and 3 are for switch illumination bulb.

1999 Toyota RAV4

1999-2000 ACCESSORIES & EQUIPMENT Instrument Panels - Trucks

Microsoft

Sunday, November 22, 2009 10:54:10 AMPage 21 © 2005 Mitchell Repair Information Company, LLC.

Page 914 of 1632

LOW OIL PRESSURE WARNING LIGHT

RAV4, Sienna, Tacoma, Tundra Without Tachometer & 4Runner

Disconnect low oil pressure switch connector. See OIL PRESSURE SWITCH LOCATION table. Using a

jumper wire, connect low oil pressure switch connector terminal to ground. Turn ignition switch to ON position.

Low oil pressure warning light should turn on. If low oil pressure warning light is off, check bulb or inspect

wiring harness.

OCCUPANT DETECTION SENSOR

Land Cruiser & Tundra

Disconnect occupant detection sensor connector, located under passenger seat. Check continuity between sensor

connector terminals. Continuity should exist only when pressing on sensor. If continuity is not as specified,

replace occupant detection sensor.

OIL PRESSURE GAUGE & SENDER

Oil Pressure Gauge & Harness Operational Test (Land Cruiser & Tundra With Tachometer)

1. Disconnect oil pressure sender connector. See OIL PRESSURE SENDER LOCATION table. Turn

ignition switch to ON position. Oil gauge should indicate LOW. Turn ignition switch to OFF position.

Connect a 12-volt, 3.4-watt test light between oil sending unit harness connector terminal and ground.

2. Turn ignition switch to ON position. Test light should be on and oil pressure gauge should slowly move

to HIGH. If gauge functions as specified, perform OIL PRESSURE SENDER OPERATIONAL

TEST . If gauge does not function as specified, perform OIL PRESSURE GAUGE RESISTANCE

TEST .

Oil Pressure Sender Operational Test (Land Cruiser & Tundra With Tachometer)

Disconnect oil pressure sender connector. See OIL PRESSURE SENDER LOCATION table. Using 12-volt

source, connect an LED tester between positive battery terminal and oil pressure sender terminal. With engine

off, LED should be off. With engine running, LED should flash. LED flashes will vary with engine speed and

oil pressure. Replace oil pressure sender if LED does not operate as specified.

OIL PRESSURE SENDER LOCATION

Oil Pressure Gauge Resistance Test (Land Cruiser & Tundra With Tachometer)

Remove instrument cluster. See INSTRUMENT CLUSTER under REMOVAL & INSTALLATION. Using

an ohmmeter, check resistance between oil gauge terminals on rear of instrument cluster. See Fig. 16

or Fig.

17 . See OIL PRESSURE GAUGE RESISTANCE SPECIFICATIONS table. If resistance is not as

specified, replace oil pressure

gauge.

ApplicationLocation

Land Cruiser & TundraOn Oil Filter Housing

1999 Toyota RAV4

1999-2000 ACCESSORIES & EQUIPMENT Instrument Panels - Trucks

Microsoft

Sunday, November 22, 2009 10:54:10 AMPage 24 © 2005 Mitchell Repair Information Company, LLC.

Page 1163 of 1632

1. Locate and remove starter relay. Starter relay is marked "ST". See STARTER RELAY LOCATION

table. Using ohmmeter, verify continuity exists between relay terminals No. 3 and 4. See STEP 1. See

Fig. 6

. Continuity should not exist between terminals No. 1 and 2. If continuity is not as specified,

replace relay.

2. Check relay operation by applying battery voltage to terminals No. 3 and 4. See STEP 2. See Fig. 6

.

Continuity should now exist between terminals No. 1 and 2. If relay does not test as indicated, replace

relay.

All Others

1. Locate and remove starter relay. Starter relay is marked "ST". See STARTER RELAY LOCATION

table. Using ohmmeter, verify continuity between relay terminals No. 1 and 2. See Fig. 7

. Continuity

should not exist between terminals No. 3 and 5. If continuity is not as specified, replace relay.

2. Check relay operation by applying battery voltage through terminals No. 1 and 2. See Fig. 7

. Continuity

should now exist between terminals No. 3 and 5. If relay does not test as indicated, replace relay.

STARTER RELAY LOCATION

ApplicationLocation

Avalon & CorollaIn Engine Compartment Junction Block

Camry, Camry Solara & SiennaIn Engine Compartment Junction Block No. 2

CelicaIn Engine Compartment Junction/Relay Block No. 2

Land CruiserIn Engine Compartment Junction Block

RAV4, Tundra & 4RunnerIn Engine Compartment Relay Block

TacomaIn Engine Compartment Relay Block No. 2

1999 Toyota RAV4

1999-2000 STARTING & CHARGING SYSTEMS Starters

Microsoft

Sunday, November 22, 2009 10:19:18 AMPage 8 © 2005 Mitchell Repair Information Company, LLC.