bulb TOYOTA RAV4 1996 Service Repair Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 1996, Model line: RAV4, Model: TOYOTA RAV4 1996Pages: 1632, PDF Size: 41.64 MB

Page 1 of 1632

1999-2000 BRAKES

Anti-Lock - RAV4

DESCRIPTION

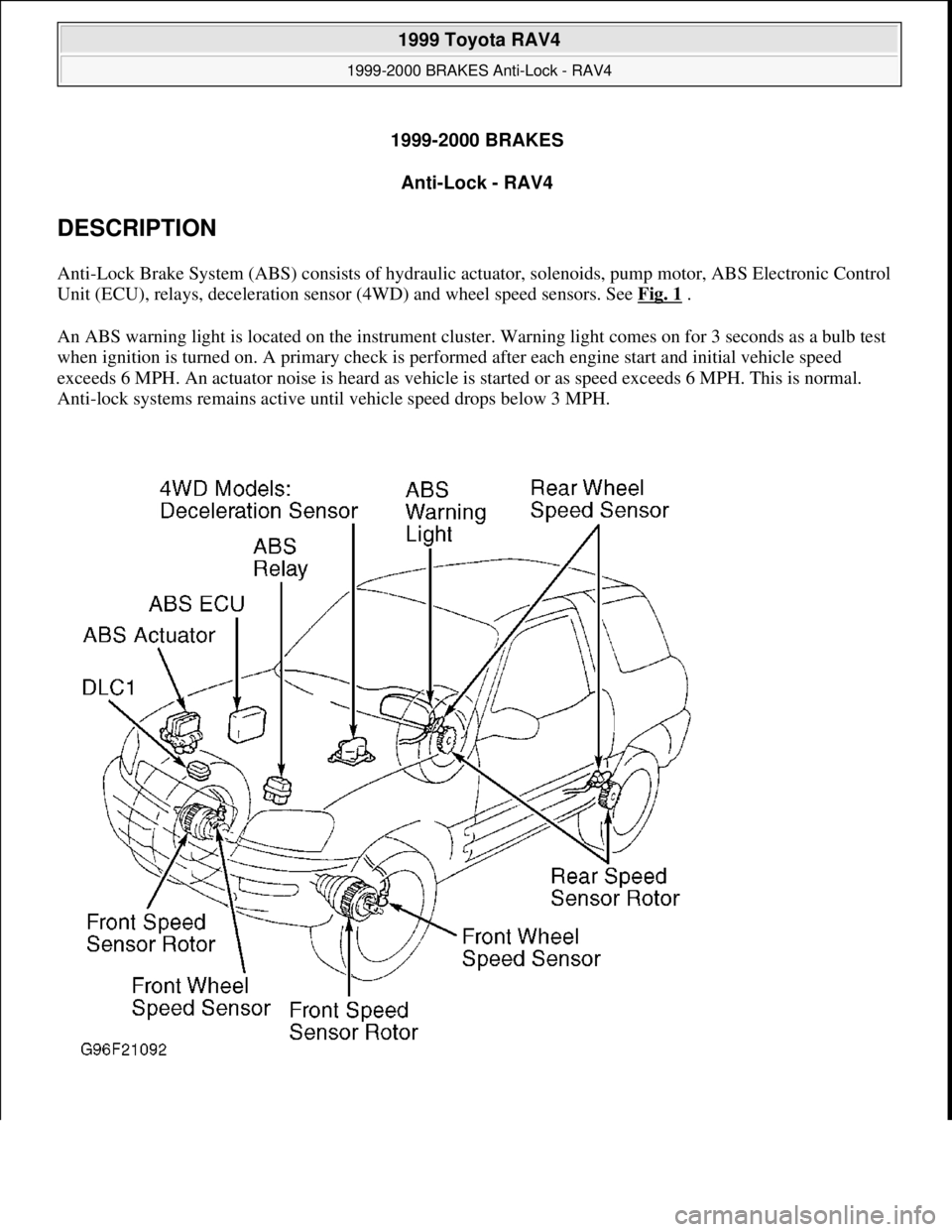

Anti-Lock Brake System (ABS) consists of hydraulic actuator, solenoids, pump motor, ABS Electronic Control

Unit (ECU), relays, deceleration sensor (4WD) and wheel speed sensors. See Fig. 1

.

An ABS warning light is located on the instrument cluster. Warning light comes on for 3 seconds as a bulb test

when ignition is turned on. A primary check is performed after each engine start and initial vehicle speed

exceeds 6 MPH. An actuator noise is heard as vehicle is started or as speed exceeds 6 MPH. This is normal.

Anti-lock systems remains active until vehicle speed drops below 3 MPH.

1999 Toyota RAV4

1999-2000 BRAKES Anti-Lock - RAV4

1999 Toyota RAV4

1999-2000 BRAKES Anti-Lock - RAV4

Microsoft

Sunday, November 22, 2009 10:06:17 AMPage 1 © 2005 Mitchell Repair Information Company, LLC.

Microsoft

Sunday, November 22, 2009 10:06:21 AMPage 1 © 2005 Mitchell Repair Information Company, LLC.

Page 3 of 1632

If cause of faulty operation cannot be located with basic diagnosis, ABS electronic control system must be

checked. See DIAGNOSIS & TESTING

.

When ignition is turned on, ABS warning light should come on, then go out after 3 seconds. If ABS warning

light does not operate as specified, go to ABS WARNING LIGHT under DIAGNOSIS & TESTING

.

DIAGNOSIS & TESTING

RETRIEVING DIAGNOSTIC TROUBLE CODES

ABS Warning Light Diagnostics

1. Ensure battery voltage is 12 volts. Turn ignition switch to ON position. ABS warning light should

illuminate, then go out after 3 seconds. If ABS warning light does not illuminate, check fuse, bulb, and

wiring harness. See ABS WARNING LIGHT

.

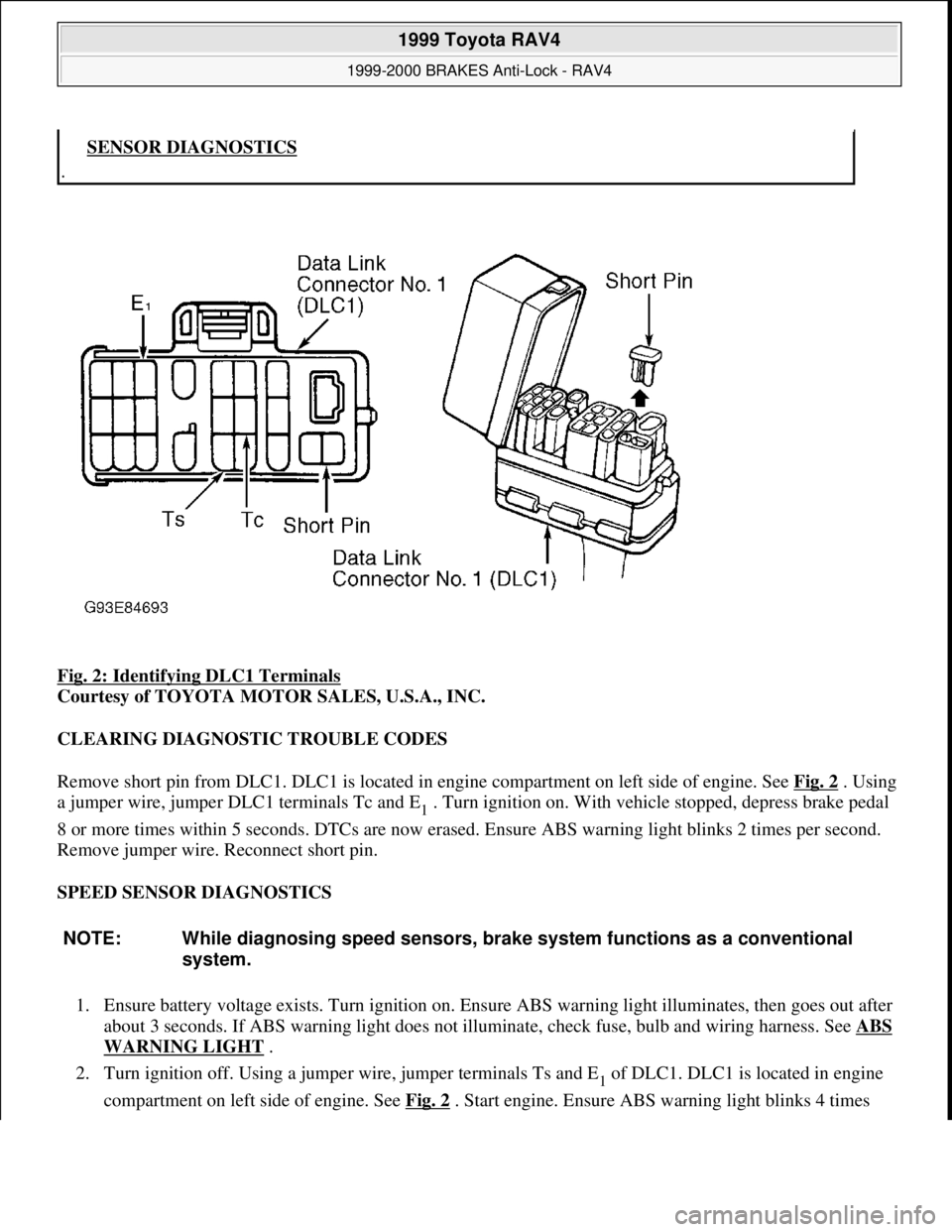

2. Remove short pin from DLC1. DLC1 is located in engine compartment, on left side of engine. See Fig.

2 . Using a jumper wire, jumper DLC1 terminals Tc and E1 . If a malfunction is detected, ABS warning

light will begin to flash a 2-digit Diagnostic Trouble Code (DTC). First number of blinks will equal first

digit in DTC. After a 1.5-second pause, second number of blinks will equal second digit in DTC.

3. If 2 or more DTCs are stored, there will be a 2.5-second pause between each DTC. After all DTCs are

flashed, there will be a 4 second pause and all DTCs will repeat. If ABS system is functioning properly,

ABS warning light will blink 2 times per second. For code definitions, see DTC DEFINITIONS

. For

DTC diagnosis, see DIAGNOSTIC TESTS

.

4. After replacing or repairing components, clear DTCs. If battery cables were disconnected during repairs,

all DTCs will be erased. If battery cables were not disconnected during repairs, see CLEARING DTCS

.

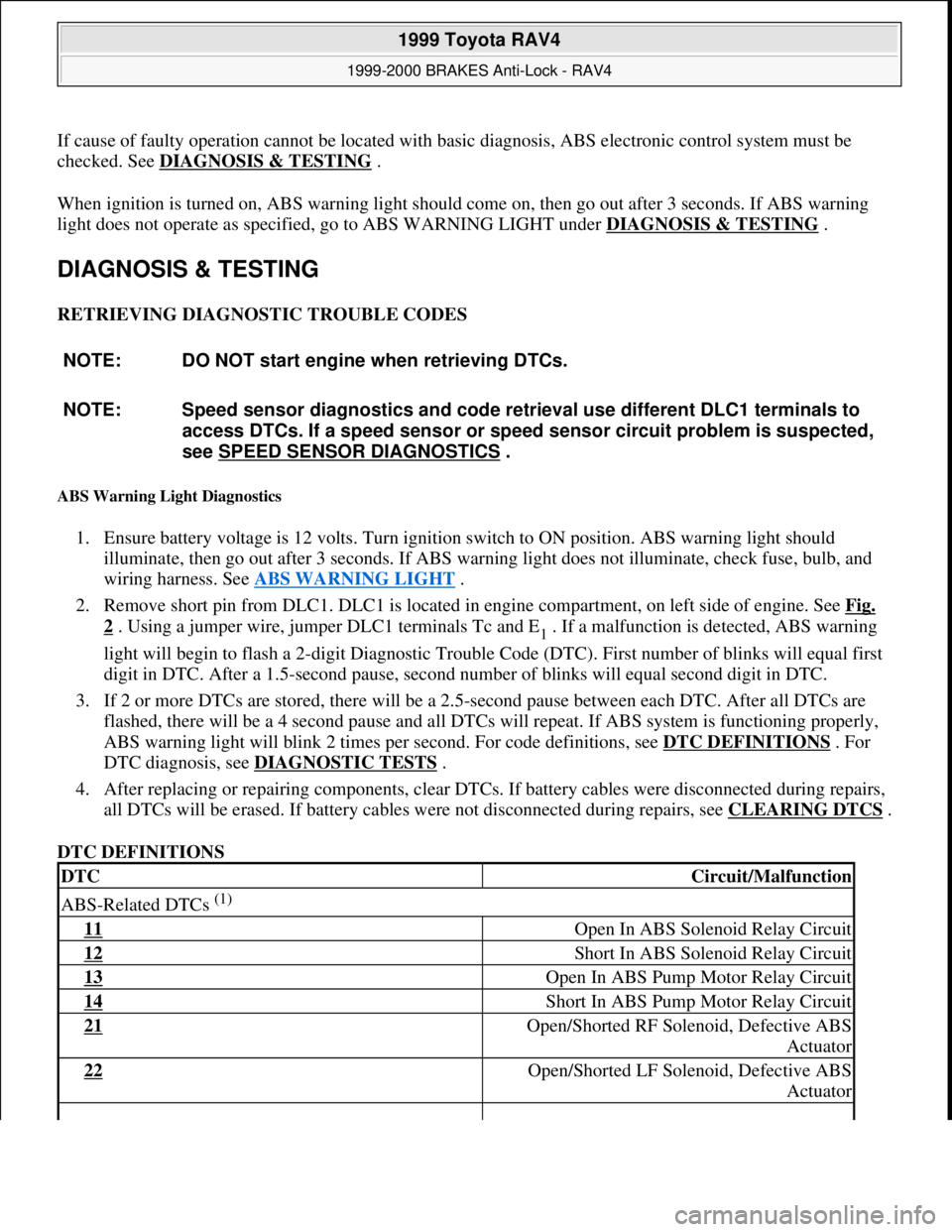

DTC DEFINITIONS NOTE: DO NOT start engine when retrieving DTCs.

NOTE: Speed sensor diagnostics and code retrieval use different DLC1 terminals to

access DTCs. If a speed sensor or speed sensor circuit problem is suspected,

see SPEED SENSOR DIAGNOSTICS

.

DTCCircuit/Malfunction

ABS-Related DTCs (1)

11 Open In ABS Solenoid Relay Circuit

12 Short In ABS Solenoid Relay Circuit

13 Open In ABS Pump Motor Relay Circuit

14 Short In ABS Pump Motor Relay Circuit

21 Open/Shorted RF Solenoid, Defective ABS

Actuator

22 Open/Shorted LF Solenoid, Defective ABS

Actuator

1999 Toyota RAV4

1999-2000 BRAKES Anti-Lock - RAV4

Microsoft

Sunday, November 22, 2009 10:06:17 AMPage 3 © 2005 Mitchell Repair Information Company, LLC.

Page 5 of 1632

Fig. 2: Identifying DLC1 Terminals

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

CLEARING DIAGNOSTIC TROUBLE CODES

Remove short pin from DLC1. DLC1 is located in engine compartment on left side of engine. See Fig. 2

. Using

a jumper wire, jumper DLC1 terminals Tc and E

1 . Turn ignition on. With vehicle stopped, depress brake pedal

8 or more times within 5 seconds. DTCs are now erased. Ensure ABS warning light blinks 2 times per second.

Remove jumper wire. Reconnect short pin.

SPEED SENSOR DIAGNOSTICS

1. Ensure battery voltage exists. Turn ignition on. Ensure ABS warning light illuminates, then goes out after

about 3 seconds. If ABS warning light does not illuminate, check fuse, bulb and wiring harness. See ABS

WARNING LIGHT .

2. Turn ignition off. Using a jumper wire, jumper terminals Ts and E

1 of DLC1. DLC1 is located in engine

compartment on left side of en

gine. See Fig. 2. Start engine. Ensure ABS warning light blinks 4 times

.SENSOR DIAGNOSTICS

NOTE: While diagnosing speed sensors, brake system functions as a conventional

system.

1999 Toyota RAV4

1999-2000 BRAKES Anti-Lock - RAV4

Microsoft

Sunday, November 22, 2009 10:06:17 AMPage 5 © 2005 Mitchell Repair Information Company, LLC.

Page 6 of 1632

per second. If ABS light does not blink, go to ABS WARNING LIGHT. If ABS warning light blinks,

go to next step.

3. Drive vehicle straight ahead above 28 MPH for several seconds. Stop vehicle. Jumper terminals Tc and

E

1 of DLC1. See Fig. 2 . If all sensors are okay, a normal DTC is displayed (ABS warning light blinks 2

times a second). If a malfunction is detected, ABS warning light will begin to flash a 2-digit DTC. First

number of blinks will equal first digit in a DTC. After a 1.5-second pause, second number of blinks will

equal second digit in a DTC.

4. If 2 or more DTCs are stored, there will be a 2.5-second pause between each DTC. After all DTCs are

flashed, there will be a 4 second pause and all DTCs will repeat.

5. Record DTCs. Turn ignition off. Repair as necessary. See DTC DEFINITIONS

. Remove jumper wire

from DLC1. Clear DTCs. See CLEARING DTCS

.

ABS WARNING LIGHT

Circuit Description

If ABS ECU detects a system malfunction, ABS ECU illuminates ABS warning light while at the same time

prohibiting ABS control. At this time, ABS ECU records a DTC in memory. After removing short pin from

DLC1, connecting terminals Tc and E

1 of DLC1 causes ABS warning light to blink and output a DTC. See Fig.

2 .

Diagnostic Procedure

1. If ABS warning light stays on, go to step 3 . If ABS warning light does not illuminate, check fuse, light

bulb and wiring. Repair or replace as necessary. If bulb is okay, diagnose combination meter (instrument

panel). See appropriate INSTRUMENT PANELS article in ACCESSORIES & EQUIPMENT. If no

problems were found, go to next step.

2. Check ABS control relay. See SOLENOID RELAY SECTION

under ABS CONTROL RELAY under

COMPONENT TESTS. Replace as necessary. If ABS control relay is okay, go to next step.

3. Retrieve DTCs. See RETRIEVING DTCS

under DIAGNOSIS & TESTING. If DTC is present, perform

appropriate test under DIAGNOSTIC TESTS. If DTC is not present, and ABS warning light goes off

when short pin is removed, go to next step. If ABS warning light does not turn off, check for short circuit

in wiring harness between ABS warning light, DLC1 and ABS ECU. Repair as necessary. See WIRING

DIAGRAMS .

4. Check ABS control relay. See SOLENOID RELAY SECTION

under ABS CONTROL RELAY under

COMPONENT TESTS. Replace relay as necessary. If relay is okay, check for short circuit in wiring

harness between DLC1 and ABS control relay. Repair as necessary. See WIRING DIAGRAMS

.

TC TERMINAL

Circuit Description

Connecting terminals Tc and E1 of DLC1 causes ABS warning light to blink and output a DTC. See Fig. 2 .

Diagnostic Procedure

1999 Toyota RAV4

1999-2000 BRAKES Anti-Lock - RAV4

Microsoft

Sunday, November 22, 2009 10:06:17 AMPage 6 © 2005 Mitchell Repair Information Company, LLC.

Page 26 of 1632

1. Check charging system voltage. Ensure 10-14 volts is present. If charging system voltage is okay, go to

next step. If charging system voltage is not okay, check and repair charging system.

2. Turn ignition switch to ON position. Ensure ABS warning light comes on, then goes out after 3 seconds.

If ABS warning light does not illuminate, check fuse, bulb, and wiring harness. See ABS WARNING

LIGHT under DIAGNOSIS & TESTING. Turn ignition off.

3. Using a jumper wire, jumper terminals Ts and E

1 of DLC1. DLC1 is located in engine compartment on

left side of engine. See Fig. 2

. Ensure ABS warning light blinks 4 times per second. If ABS light does

not blink, go to ABS WARNING LIGHT

under DIAGNOSIS & TESTING. If ABS warning light

blinks, go to next step.

4. Using a floor jack, slowly jack up rear of vehicle. On vehicles with 215/70R16 tires, raise vehicle to a

height of 25.59-27.95" (650-710 mm). On vehicles with 235/60R16 tires, raise vehicle to a height of

26.38-28.74" (670-730 mm). If ABS warning light illuminates at specified height, check deceleration

sensor installation. If installation is okay, replace deceleration sensor. Lower vehicle.

5. Using a floor jack, slowly jack up front of vehicle. On vehicles with 215/70R16 tires, raise vehicle to a

height of 21.20-23.56" (550-610 mm). On vehicles with 235/60R16 tires, raise vehicle to a height of

22.44-24.80" (570-630 mm). If ABS warning light illuminates at specified height, check deceleration

sensor installation. If installation is okay, replace deceleration sensor. Lower vehicle.

6. Drive vehicle straight ahead at speed of 13 MPH or more. Lightly depress brake pedal. Ensure ABS

warning light pattern is normal (light blinks 4 times per second).

7. While driving vehicle straight ahead at speed of 13 MPH or more, moderately depress brake pedal.

Ensure ABS warning light illuminates in a solid pattern (light does not blink) while braking.

8. While driving vehicle straight ahead at speed of 13 MPH or more, firmly depress brake pedal. Ensure

ABS warning light illumination pattern changes from a solid pattern (light does not blink) to a normal

pattern (light blinks 4 times per second), then back to a solid pattern while braking.

9. If ABS warning light does not illuminate as described in steps 6 -8 , check deceleration sensor

installation. If installation is okay, replace deceleration sensor. Stop vehicle and turn ignition off. Remove

jumper wire from DLC1.

REMOVAL & INSTALLATION

ACTUATOR

Removal & Installation

Turn ignition off. Disconnect brakelines attached to actuator. Remove power steering hose retaining bracket

bolt and power steering reservoir. Disconnect actuator electrical connectors. Remove bolts, nuts and washers.

Remove actuator assembly. Remove actuator from actuator bracket. Remove cushions and holders from NOTE: When measuring vehicle height in following steps, measure at center of

lower body of vehicle.

WARNING:Hydraulic system may be under high pressure. Use caution when opening

hydraulic system.

1999 Toyota RAV4

1999-2000 BRAKES Anti-Lock - RAV4

Microsoft

Sunday, November 22, 2009 10:06:17 AMPage 26 © 2005 Mitchell Repair Information Company, LLC.

Page 37 of 1632

The air bag sensor, which deploys air bags, contains a back-up power supply, safing sensor and diagnostic code

memory. Spiral cable (clockspring) maintains a complete circuit to the steering wheel pad.

SYSTEM OPERATION CHECK

Turn ignition switch to ACC or ON position. Air bag warning light in instrument cluster should come on for

about 6 seconds and then go out. If light does not respond as specified, SRS is malfunctioning and needs repair.

See DIAGNOSIS

.

SERVICE PRECAUTIONS

Observe the following precautions when working on SRS:

Before servicing any SRS or steering column component, disable SRS. See DISABLING &

ACTIVATING AIR BAG SYSTEM . Failure to disable system could result in accidental air bag

deployment and personal injury.

When diagnosing SRS, always check for diagnostic codes before disconnecting battery.

After ignition switch is turned to LOCK position and negative battery cable is disconnected, wait at least

90 seconds before working on SRS. SRS is equipped with a back-up power source that may allow air bag

to deploy within 90 seconds of disconnecting negative battery cable.

In a minor collision in which air bags do not deploy, steering wheel pad must be inspected.

NEVER use air bag parts from another vehicle. Replace air bag parts with new parts.

Air bag sensor assembly contains mercury. After replacement, DO NOT destroy the old part. When

scrapping vehicle or replacing air bag sensor assembly, remove air bag sensor assembly and dispose of as

toxic waste.

Never disassemble or repair system components. Replace cracked, dented or otherwise damaged system

components.

Remove air bag sensor if shocks are likely to be applied to the sensor during repairs.

When diagnosing electrical circuits, use a Digital Volt/Ohmmeter (DVOM) with high impedance (10,000

ohms minimum).

Information labels are attached to air bag components. Follow all notices on labels.

After servicing SRS, check air bag warning light to ensure system is functioning properly. See SYSTEM

OPERATION CHECK .

Always wear safety glasses when servicing or handling an air bag.

When placing a live air bag on a bench or other surface, always face air bag and trim cover up, away from

surface. This will reduce motion of module if accidentally deployed.

After deployment, air bag surface may contain deposits of sodium hydroxide which irritates skin. During

clean-up, always wear safety glasses, rubber gloves and long-sleeved shirt. After clean-up, wash hands

using mild soap and water.

When carrying a live air bag module, trim cover must be pointed away from your body to minimize

injury in case of accidental deployment.

If SRS is not fully functional for any reason, vehicle should not be driven until system is repaired and

a

gain becomes operational. DO NOTremove bulbs, modules, sensors or other components or in any way

1996 Toyota 4Runner

AIR BAG RESTRAINT SYSTEM 1996 ACCESSORIES/SAFETY EQUIPMENT Toyota Air Bag Restraint System

Microsoft

Tuesday, August 18, 2009 7:33:32 PMPage 3 © 2005 Mitchell Repair Information Company, LLC.

Page 52 of 1632

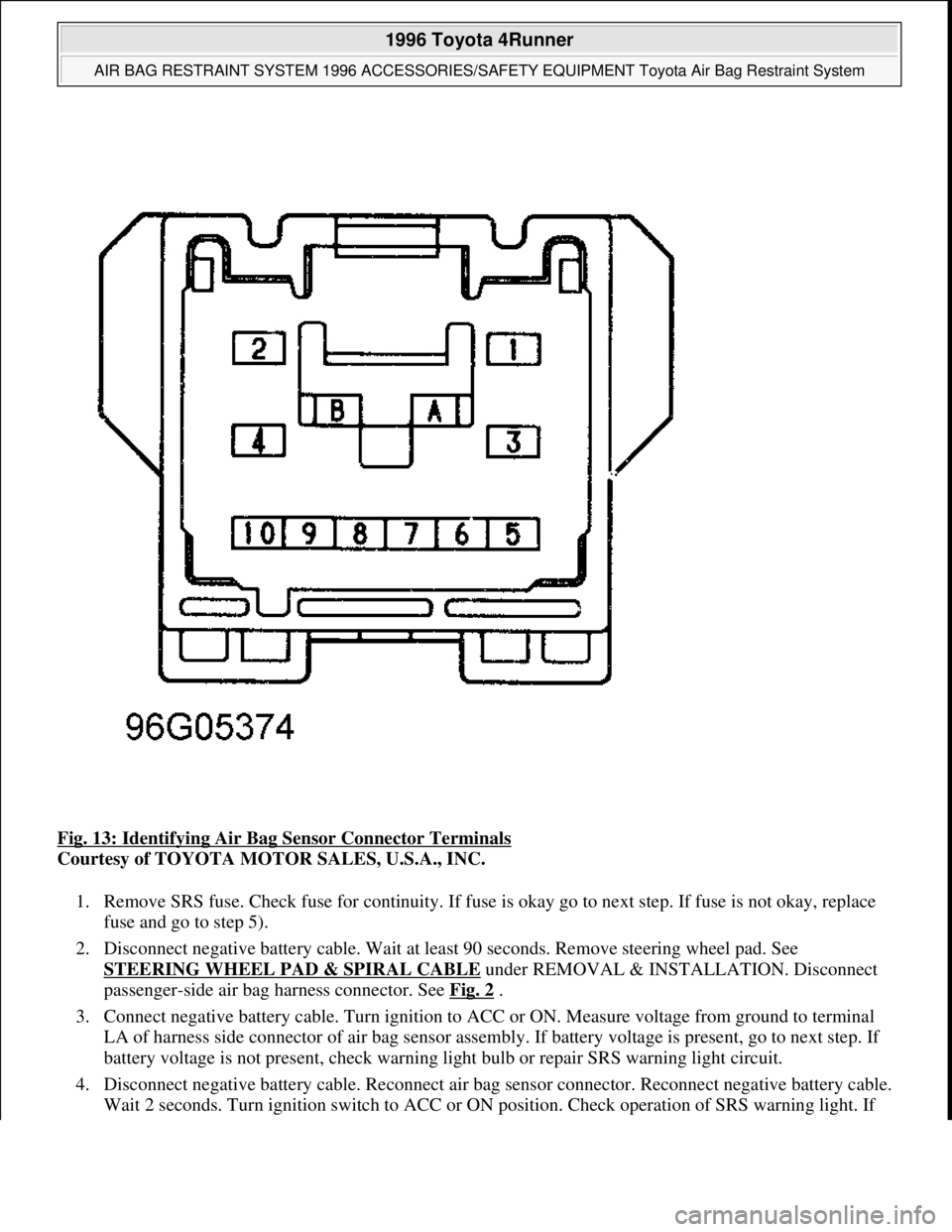

Fig. 13: Identifying Air Bag Sensor Connector Terminals

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

1. Remove SRS fuse. Check fuse for continuity. If fuse is okay go to next step. If fuse is not okay, replace

fuse and go to step 5).

2. Disconnect negative battery cable. Wait at least 90 seconds. Remove steering wheel pad. See

STEERING WHEEL PAD & SPIRAL CABLE

under REMOVAL & INSTALLATION. Disconnect

passenger-side air bag harness connector. See Fig. 2

.

3. Connect negative battery cable. Turn ignition to ACC or ON. Measure voltage from ground to terminal

LA of harness side connector of air bag sensor assembly. If battery voltage is present, go to next step. If

battery voltage is not present, check warning light bulb or repair SRS warning light circuit.

4. Disconnect negative battery cable. Reconnect air bag sensor connector. Reconnect negative battery cable.

Wait 2 seconds. Turn i

gnition switch to ACC or ON position. Check operation of SRS warning light. If

1996 Toyota 4Runner

AIR BAG RESTRAINT SYSTEM 1996 ACCESSORIES/SAFETY EQUIPMENT Toyota Air Bag Restraint System

Microsoft

Tuesday, August 18, 2009 7:33:32 PMPage 18 © 2005 Mitchell Repair Information Company, LLC.

Page 66 of 1632

may allow air bag to deploy until 90 seconds after disconnecting negative battery cable.

If vehicle was in a minor collision but air bags did not deploy, inspect all system components for any sign

of damage, and replace as necessary.

Never use air bag system components from another vehicle. Replace air bag system components with new

parts.

Remove air bag sensor assembly if repairing the vehicle requires impacting (shocking) the vehicle.

Air bag sensor assembly contains mercury. After replacement, DO NOT destroy old part. When

scrapping vehicle or replacing air bag sensor assembly, remove air bag sensor assembly and dispose of it

as toxic waste.

Never disassemble and repair air bag sensor assembly, front air bag sensors, passenger-side or driver-side

air bag modules or seat belt pretensioners.

Replace dropped, cracked, dented or otherwise damaged components.

DO NOT expose air bag sensor assembly, front air bag sensors or air bag modules directly to heat or

flame.

When diagnosing electrical circuits, use a volt/ohm meter with high impedance (10,000 ohms minimum).

Information labels are attached to air bag components. Follow all notices on labels.

After work on air bag system is complete, check AIR BAG warning light to ensure system is functioning

properly. See SYSTEM OPERATION CHECK

.

Always wear safety glasses when servicing or handling an air bag.

When placing a live air bag on a bench or other surface, always face air bag and trim cover up and away

from surface. This will reduce motion of module if it is accidentally deployed.

After deployment, air bag surface may contain deposits of sodium hydroxide, which irritates skin. Always

wear safety glasses, rubber gloves, and long-sleeved shirt during clean-up. After clean-up, wash hands

using mild soap and water.

Carry a live air bag module with trim cover (air bag) pointed away from your body to minimize injury in

case accidental deployment.

If air bag system is not fully functional for any reason, vehicle should not be driven until system is

repaired and again becomes operational. DO NOT remove bulbs, modules, sensors or other components,

or in any way disable system from operating normally. If air bag system is not functional, park vehicle

until it is repaired and functions properly.

ADJUSTMENTS

SPIRAL CABLE

Ensure front wheels are in straight-ahead position. Turn spiral cable counterclockwise until it becomes difficult

to turn. Turn spiral cable clockwise about 2 1/2 turns to align match marks. See Fig. 2

. Install steering wheel.

1999 Toyota RAV4

AIR BAG RESTRAINT SYSTEM 1999 Toyota

Microsoft

Sunday, November 22, 2009 10:33:22 AMPage 3 © 2005 Mitchell Repair Information Company, LLC.

Page 88 of 1632

Fig. 15: Releasing Shorting Spring

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

DIAGNOSTIC TESTS

AIR BAG WARNING LIGHT DOES NOT ILLUMINATE

Description

AIR BAG warning light is located in instrument cluster. When air bag system is normal, AIR BAG warning

light illuminates for about 6 seconds after ignition switch is turned from LOCK to ACC or ON position, and

turns off automatically. If a malfunction is present in air bag system, AIR BAG warning light illuminates to

inform operator of malfunction. When Data Link Connector 1 (DLC1) terminals Tc and E1 are connected

together, a Diagnostic Trouble Code (DTC) is displayed by flashing AIR BAG warning light.

Diagnostic Procedure

1. Remove SRS-B fuse and check continuity across fuse blades. SRS-B fuse is located in instrument panel

fuse block under left side of instrument panel. If fuse is faulty, go to step 4). If fuse is okay, reinstall fuse

and go to next step.

2. Disable air bag system. See DISABLING SYSTEM

under DISABLING & ACTIVATING AIR BAG

SYSTEM. Reconnect negative battery cable. Turn ignition switch to ACC or ON position. Measure

voltage between ground and harness side of air bag sensor assembly connector C20, terminal No. 3

(circuit LA, Black/Yellow wire). See Fig. 16

. If 10-14 volts is not present, repair AIR BAG warning

light bulb or circuit. If 10-14 volts is present, go to next step.

3. Turn ignition switch to LOCK position. Disconnect negative battery cable. Reconnect 3 air bag sensor

assembly connectors. Leave air bag modules, pretensioners and front air bag sensors disconnected.

Reconnect negative battery cable and wait at least 2 seconds. Turn ignition switch to ACC or ON

position. If AIR BAG warning light illuminates, system operation is normal. If AIR BAG warning light

does not come on, check for poor connection at air bag sensor assembly connector C20, terminal No. 3

(Black/Yellow wire). If connection is oka

y, replace air bag sensor assembly. WARNING:Failure to follow service precautions may result in air bag deployment and

personal injury. See SERVICE PRECAUTIONS

. After component

replacement, check system operation. See SYSTEM OPERATION CHECK

.

CAUTION: Ensure ignition switch is in LOCK position before disconnecting or

connecting negative battery cable. If ignition switch is in ACC or ON

position when negative battery cable is disconnected or connected, air

bag sensor may be damaged. To prevent damage to connector terminals,

DO NOT probe terminal ends. Instead, backprobe terminals (probe

terminal where wire enters harness connector).

NOTE: In the following tests, the term squib connector and module connector may be

used interchangeably.

1999 Toyota RAV4

AIR BAG RESTRAINT SYSTEM 1999 Toyota

Microsoft

Sunday, November 22, 2009 10:33:23 AMPage 25 © 2005 Mitchell Repair Information Company, LLC.

Page 388 of 1632

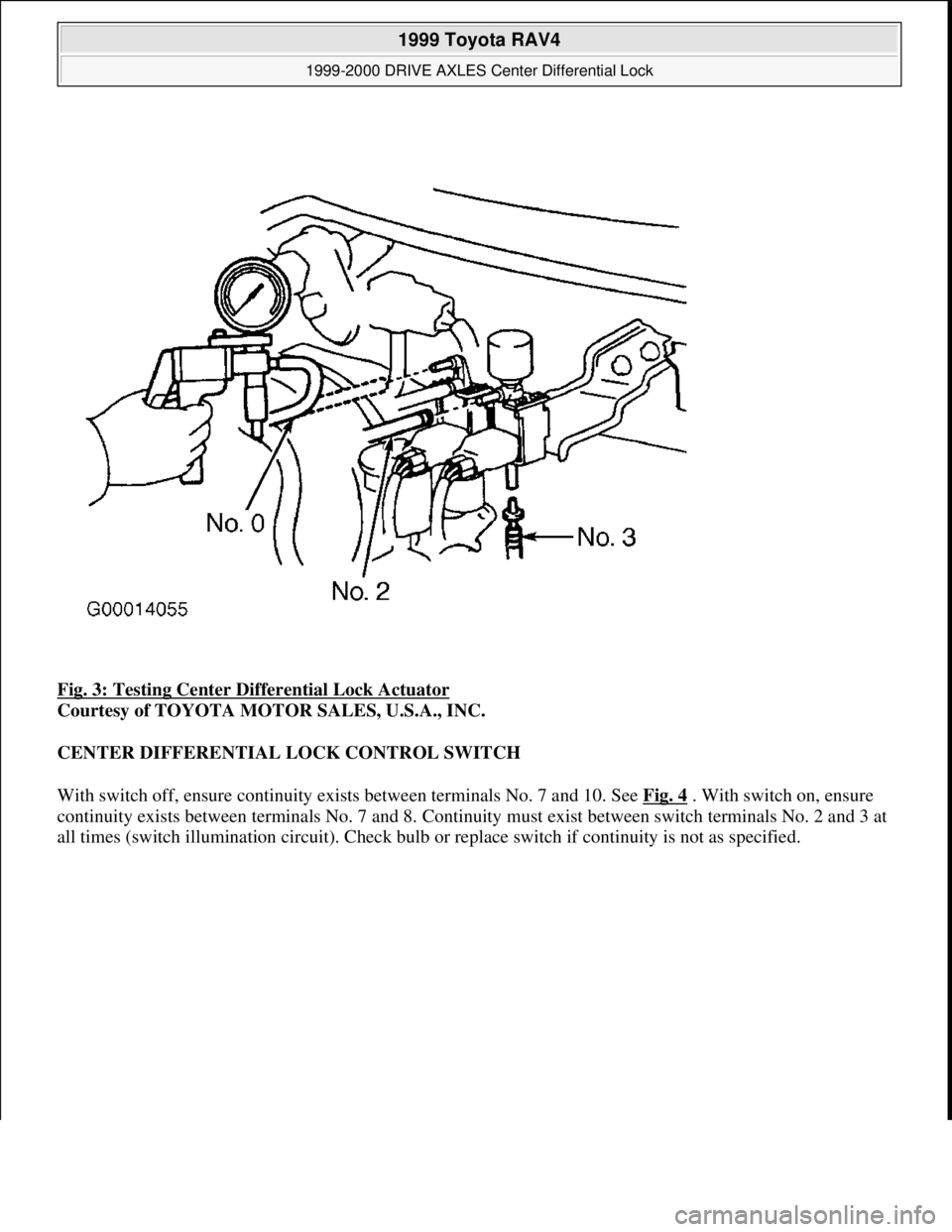

Fig. 3: Testing Center Differential Lock Actuator

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

CENTER DIFFERENTIAL LOCK CONTROL SWITCH

With switch off, ensure continuity exists between terminals No. 7 and 10. See Fig. 4

. With switch on, ensure

continuity exists between terminals No. 7 and 8. Continuity must exist between switch terminals No. 2 and 3 at

all times (switch illumination circuit). Check bulb or replace switch if continuit

y is not as specified.

1999 Toyota RAV4

1999-2000 DRIVE AXLES Center Differential Lock

Microsoft

Sunday, November 22, 2009 10:08:59 AMPage 5 © 2005 Mitchell Repair Information Company, LLC.