change wheel TOYOTA RAV4 1996 Service Repair Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 1996, Model line: RAV4, Model: TOYOTA RAV4 1996Pages: 1632, PDF Size: 41.64 MB

Page 15 of 1632

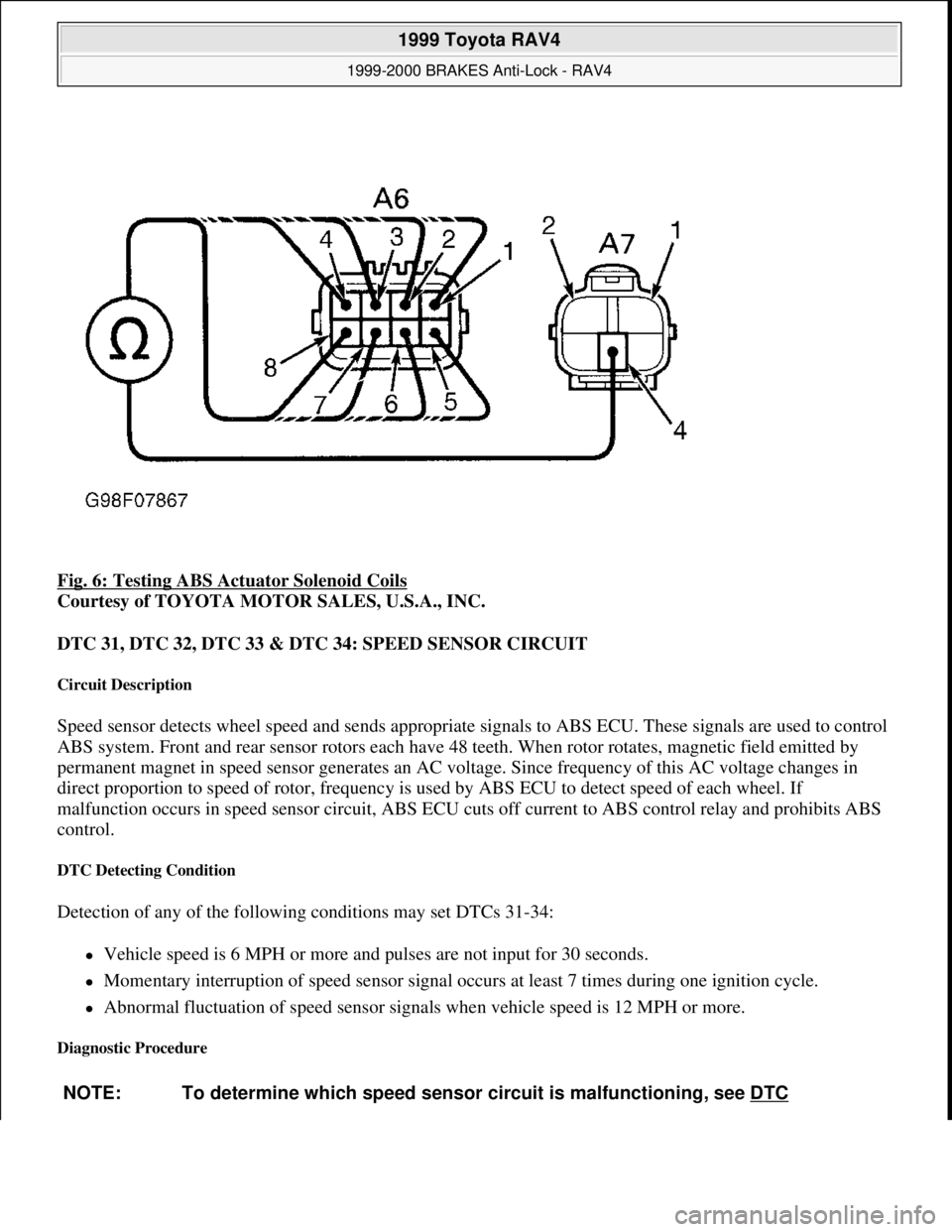

Fig. 6: Testing ABS Actuator Solenoid Coils

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

DTC 31, DTC 32, DTC 33 & DTC 34: SPEED SENSOR CIRCUIT

Circuit Description

Speed sensor detects wheel speed and sends appropriate signals to ABS ECU. These signals are used to control

ABS system. Front and rear sensor rotors each have 48 teeth. When rotor rotates, magnetic field emitted by

permanent magnet in speed sensor generates an AC voltage. Since frequency of this AC voltage changes in

direct proportion to speed of rotor, frequency is used by ABS ECU to detect speed of each wheel. If

malfunction occurs in speed sensor circuit, ABS ECU cuts off current to ABS control relay and prohibits ABS

control.

DTC Detecting Condition

Detection of any of the following conditions may set DTCs 31-34:

Vehicle speed is 6 MPH or more and pulses are not input for 30 seconds.

Momentary interruption of speed sensor signal occurs at least 7 times during one ignition cycle.

Abnormal fluctuation of speed sensor signals when vehicle speed is 12 MPH or more.

Diagnostic Procedure

NOTE: To determine which speed sensor circuit is malfunctioning, see DTC

1999 Toyota RAV4

1999-2000 BRAKES Anti-Lock - RAV4

Microsoft

Sunday, November 22, 2009 10:06:17 AMPage 15 © 2005 Mitchell Repair Information Company, LLC.

Page 17 of 1632

DTC Detecting Condition

Detection of the following condition may set DTC 41:

At vehicle speed of about 2 MPH or more, if voltage at ABS ECU terminal IG1 is less than 9.5 volts for

10 seconds or more, DTC 41 may set.

Diagnostic Procedure

1. Check charging system voltage. If voltage is 10-14 volts, system is okay. Go to next step. If voltage is not

10-14 volts, repair charging system. Ensure system fuses are okay.

2. Turn ignition off. Remove ABS ECU. Do not disconnect electrical connectors. Turn ignition switch to

ON position. Measure voltage between terminals IG1 and GND at ABS ECU harness connector. See Fig.

3 . If voltage is 10-14 volts, turn ignition off. Condition may be intermittent. Check ABS ECU connectors

for poor connection or damage. Repair as necessary. If connectors are okay, replace ABS ECU. If voltage

is not as specified, go to next step.

3. Measure resistance between ground and GND terminals at ABS ECU harness connector. See Fig. 3

. If

resistance is one ohm or less, go to next step. If resistance is more than one ohm, repair ground circuit

wiring. See WIRING DIAGRAMS

.

4. Remove ECU-IG fuse from instrument panel junction block. If fuse is blown, check for short circuit in all

wiring harnesses and components connected to ECU-IG fuse (ECM, A/C, cruise control, deceleration

sensor, combination meter, sun roof, shift lock, transmission pattern select switch). See WIRING

DIAGRAMS . Repair as necessary. If fuse is not blown, check for open circuit in wiring harness between

battery and ABS ECU. Repair as necessary.

DTC 43 & DTC 45: DECELERATION SENSOR MALFUNCTION (4WD MODELS ONLY)

DTC Detecting Conditions

Detection of the following conditions may set DTCs 43 or 45:

On 2-door models, if output voltage from deceleration sensor does not change for 16 consecutive times or

more when vehicle speed is decreased from 19 MPH to zero MPH, DTC 43 will set.

On 4-door models, after battery cables are connected, if input from deceleration sensor does not change at

one cycle (zero MPH to 19 MPH or more, then back to zero) for 16 consecutive times, DTC 43 will set.

When brake pedal is not depressed at vehicle speed of 3 MPH or more, and forward and backward force

(force of more than 0.4 "G") is detected for 30 seconds or more, DTC 43 will set.

On 2-door models, at vehicle speed of 19 MPH or more, if deceleration sensor output and vehicle

acceleration from wheel speed remains abnormally different for one minute or more, DTC 45 will set.

Diagnostic Procedure

1. Check deceleration sensor. See DECELERATION SENSOR CHECK under COMPONENT TESTS.

Replace sensor as necessary. If sensor is okay, go to next step.

2. Check for open or short circuit in wiring harness between deceleration sensor and ABS ECU. See

WIRING DIAGRAMS

. Repair as necessary. If wiring harness is okay, replace ABS ECU.

1999 Toyota RAV4

1999-2000 BRAKES Anti-Lock - RAV4

Microsoft

Sunday, November 22, 2009 10:06:17 AMPage 17 © 2005 Mitchell Repair Information Company, LLC.

Page 344 of 1632

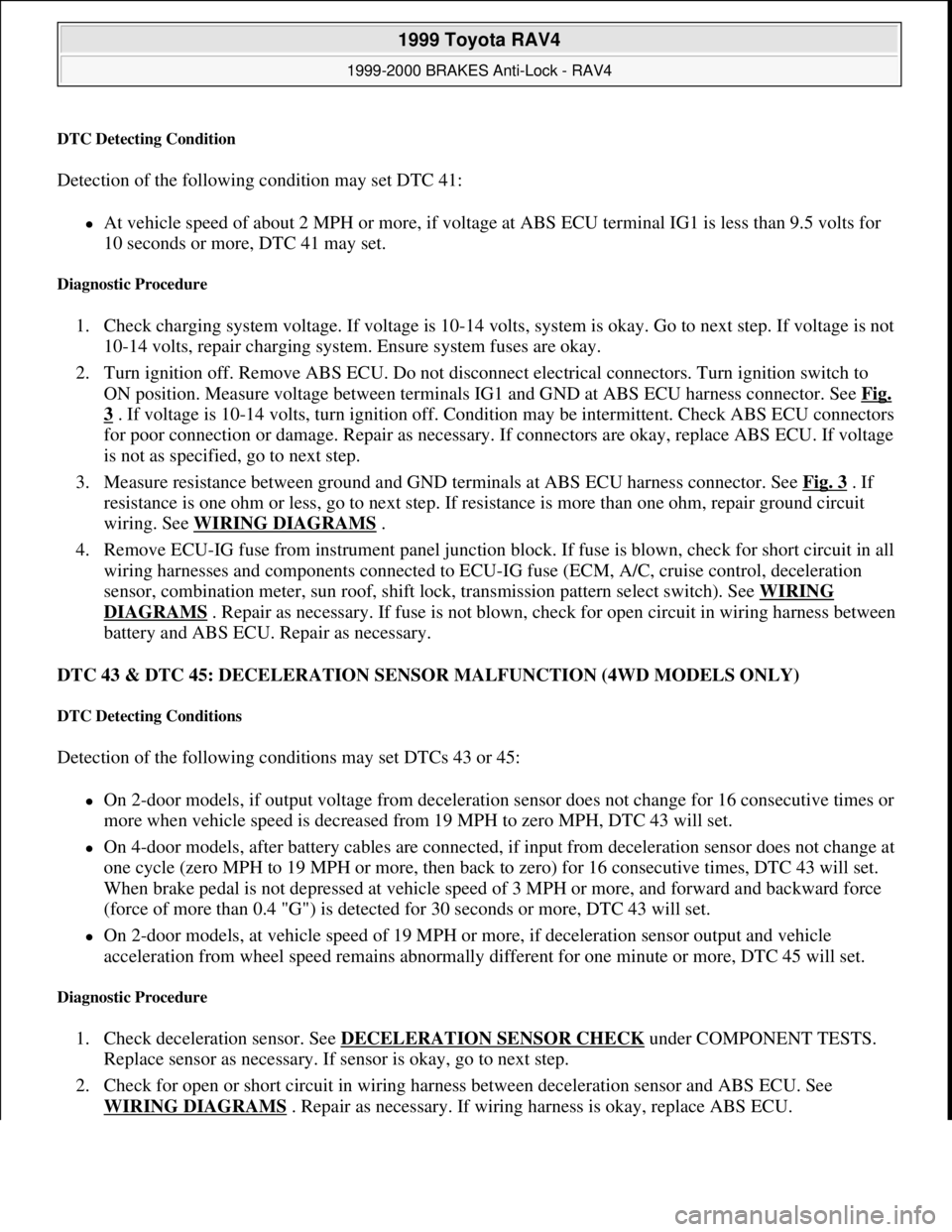

Fig. 2: Adjusting Brake Booster Push Rod

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

REAR DRUM BRAKE SHOES

To set initial lining-to-drum clearance, raise and support rear of vehicle. Release parking brake. Remove rear

wheels and brake drums. Measure brake drum inside diameter and brake lining diameter. Measured clearance

between linings and braking surface of drum should be .024" (.60 mm) on RAV4 and Tacoma, or .020" (.50

mm) on all other models. Turn brake adjuster to obtain specified clearance. Install brake drum and wheel and

adjust brakes (if necessary).

STOPLIGHT SWITCH

Remove lower instrument panel and air duct (if necessary). Loosen lock nuts. Turn switch until clearance

between threaded end of switch and pedal stop is .02-.09" (.5-2.3 mm), on all models except Land Cruiser.

Clearance should be .039" (1.0 mm) on Land Cruiser. See Fig. 1

. Check brake pedal height and brakelight

operation.

TESTING

POWER BRAKE UNIT (EXCEPT LAND CRUISER)

Operational Check

Depress brake pedal several times with engine off. There should be no change in pedal reserve distance.

NOTE: All rear drum brakes have a self-adjuster which is activated when brake pedal is

applied with vehicle traveling in reverse.

1999 Toyota RAV4

1999-2000 BRAKES Disc & Drum - Trucks & Vans

Microsoft

Sunday, November 22, 2009 10:07:28 AMPage 5 © 2005 Mitchell Repair Information Company, LLC.

Page 347 of 1632

6. If pressures cannot be adjusted to specification, check valve housing. Position valve body in uppermost

position. Apply brakes and record rear brake pressures. See VALVE BODY ADJUSTMENT

PRESSURE SPECIFICATIONS (TACOMA & TUNDRA) table. If measured value does not meet

specification, replace valve assembly.

VALVE BODY ADJUSTMENT PRESSURE SPECIFICATIONS (TACOMA & TUNDRA)

4Runner

1. For testing purposes, rear axle is loaded to a specified weight. Set total rear axle weight to specified

amount. See LSPV REAR AXLE TEST WEIGHT

table.

2. Attach pressure gauge set to front caliper and rear wheel cylinder. Bleed air from system. See

BLEEDING BRAKE SYSTEM

. Depress brake pedal until front pressure is as specified. See LSPV

PRESSURE SPECIFICATIONS table. Wait 2 seconds and record rear pressure reading.

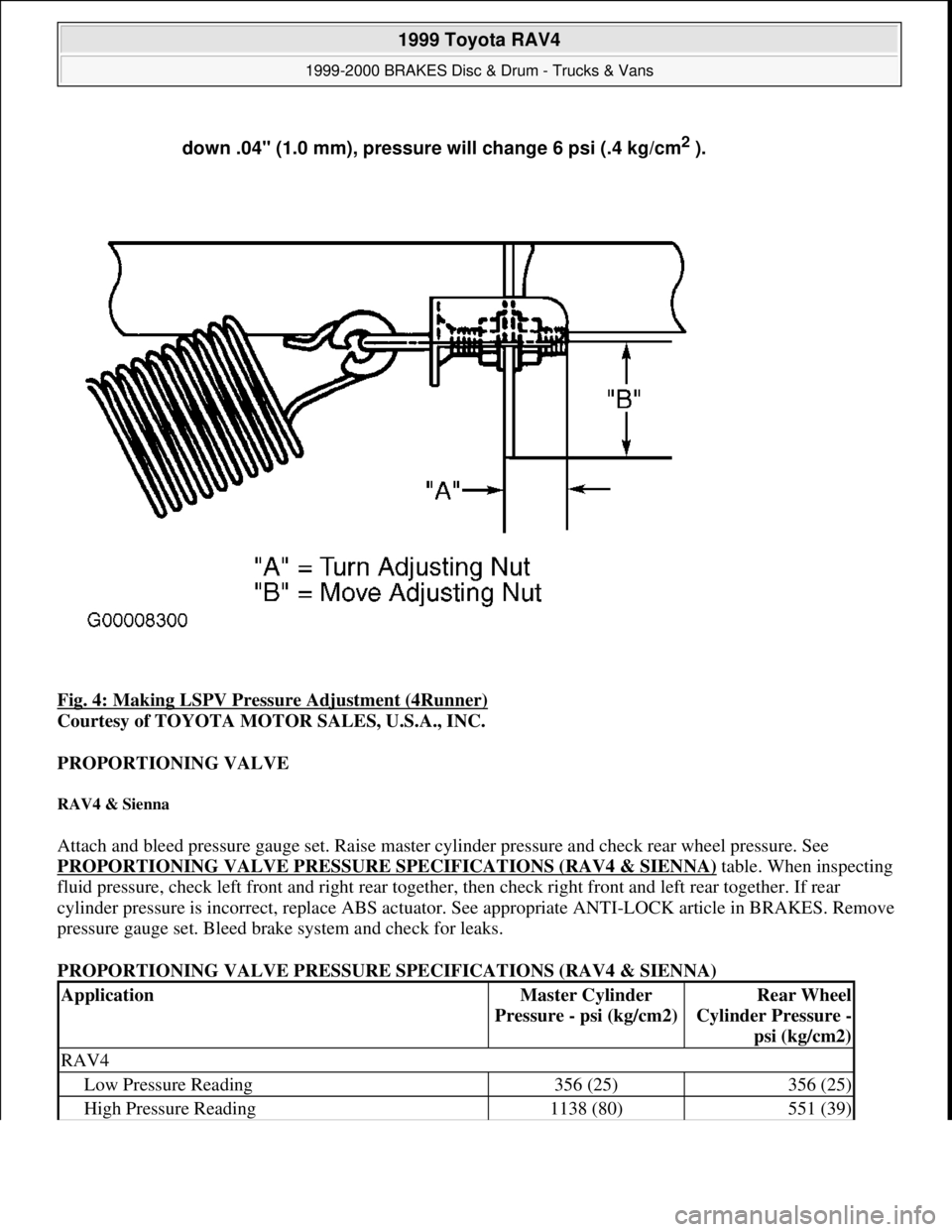

3. Adjust rear pressure by changing length "A" or "B". See Fig. 4

. To increase rear pressure reading,

decrease distance "A" or "B". To decrease rear pressure reading, increase distance "A" or "B". If valve

cannot be adjusted to specification, replace valve assembly.

2WD3.07 (78)2.83-3.31 (72-84)

4WD4.72 (120)4.49-4.96 (114-126)

Tundra4.72 (120)4.41-5.04 (112-128)

Application

Front Pressure - psi

(kg/cm

2 )

Rear Pressure - psi

(kg/cm

2 )

Tacoma

2WD

1st Reading285 (20)285 (20)

2nd Reading570 (40)327-384 (23-27)

3rd Reading998 (70)412-512 (29-36)

4WD

1st Reading213 (15)213 (15)

2nd Reading570 (40)256-313 (18-22)

3rd Reading998 (70)320-420 (23-30)

Tundra

1st Reading213 (15)213 (15)

2nd Reading569 (40)263-377 (19-27)

3rd Reading1990 (140)682-852 (48-60)

NOTE: DO NOT depress brake pedal more than once or release pedal while

setting pressure on front gauge.

NOTE: To adjust pressure, turning adjusting nut one complete turn (360 degrees) will

change pressure 14 psi (1.0 kg/cm

2 ). If adjusting nut is moved up or

1999 Toyota RAV4

1999-2000 BRAKES Disc & Drum - Trucks & Vans

Microsoft

Sunday, November 22, 2009 10:07:28 AMPage 8 © 2005 Mitchell Repair Information Company, LLC.

Page 348 of 1632

Fig. 4: Making LSPV Pressure Adjustment (4Runner)

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

PROPORTIONING VALVE

RAV4 & Sienna

Attach and bleed pressure gauge set. Raise master cylinder pressure and check rear wheel pressure. See

PROPORTIONING VALVE PRESSURE SPECIFICATIONS (RAV4 & SIENNA)

table. When inspecting

fluid pressure, check left front and right rear together, then check right front and left rear together. If rear

cylinder pressure is incorrect, replace ABS actuator. See appropriate ANTI-LOCK article in BRAKES. Remove

pressure gauge set. Bleed brake system and check for leaks.

PROPORTIONING VALVE PRESSURE SPECIFICATIONS (RAV4 & SIENNA) down .04" (1.0 mm), pressure will change 6 psi (.4 kg/cm

2 ).

ApplicationMaster Cylinder

Pressure - psi (kg/cm2)Rear Wheel

Cylinder Pressure -

psi (kg/cm2)

RAV4

Low Pressure Reading356 (25)356 (25)

High Pressure Reading1138 (80)551 (39)

1999 Toyota RAV4

1999-2000 BRAKES Disc & Drum - Trucks & Vans

Microsoft

Sunday, November 22, 2009 10:07:28 AMPage 9 © 2005 Mitchell Repair Information Company, LLC.

Page 353 of 1632

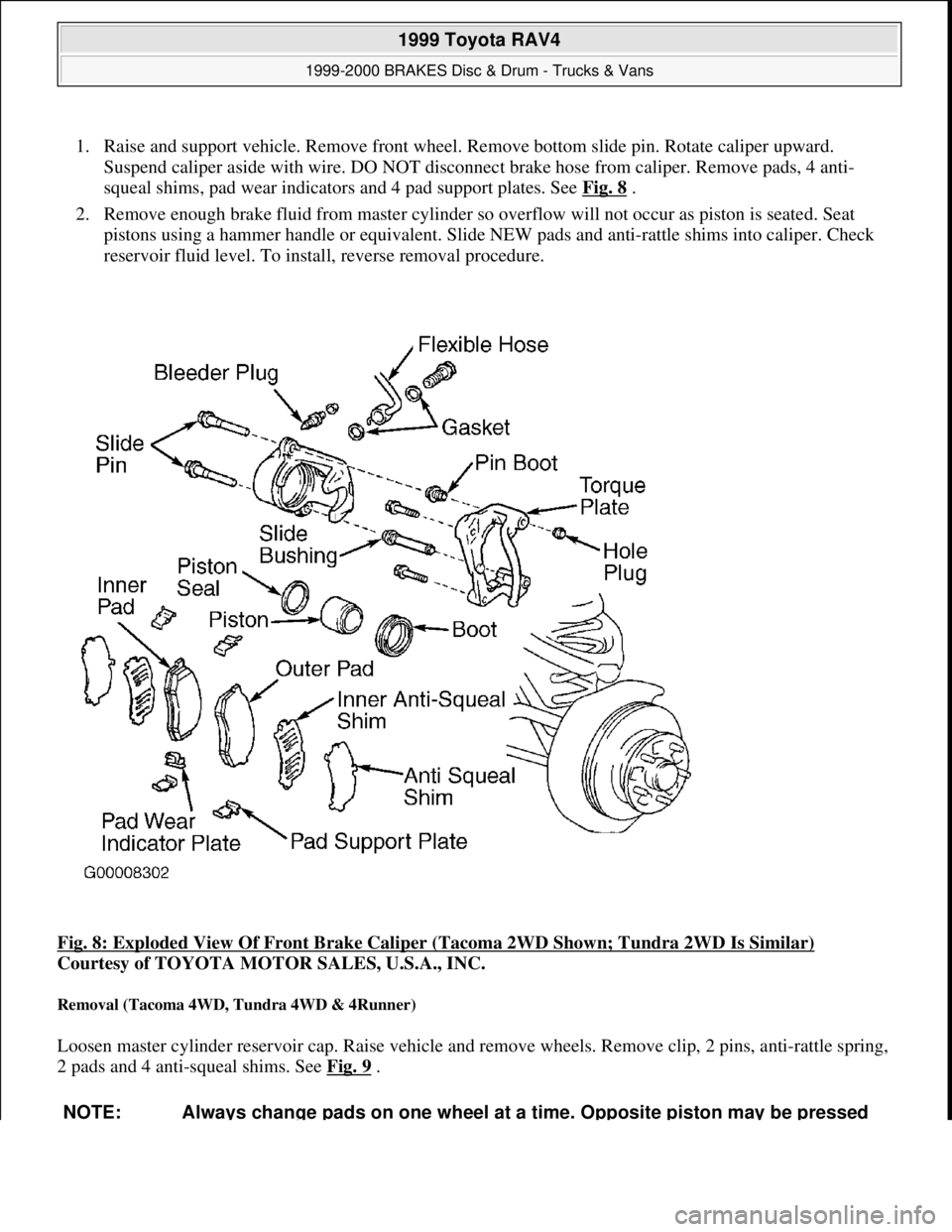

1. Raise and support vehicle. Remove front wheel. Remove bottom slide pin. Rotate caliper upward.

Suspend caliper aside with wire. DO NOT disconnect brake hose from caliper. Remove pads, 4 anti-

squeal shims, pad wear indicators and 4 pad support plates. See Fig. 8

.

2. Remove enough brake fluid from master cylinder so overflow will not occur as piston is seated. Seat

pistons using a hammer handle or equivalent. Slide NEW pads and anti-rattle shims into caliper. Check

reservoir fluid level. To install, reverse removal procedure.

Fig. 8: Exploded View Of Front Brake Caliper (Tacoma 2WD Shown; Tundra 2WD Is Similar)

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

Removal (Tacoma 4WD, Tundra 4WD & 4Runner)

Loosen master cylinder reservoir cap. Raise vehicle and remove wheels. Remove clip, 2 pins, anti-rattle spring,

2 pads and 4 anti-squeal shims. See Fig. 9

.

NOTE: Always change pads on one wheel at a time. Opposite piston may be pressed

1999 Toyota RAV4

1999-2000 BRAKES Disc & Drum - Trucks & Vans

Microsoft

Sunday, November 22, 2009 10:07:28 AMPage 14 © 2005 Mitchell Repair Information Company, LLC.

Page 945 of 1632

Normal Service

Driven More Than 10 Miles Daily

No Operating Conditions From Severe Service Schedule

Severe Service (Unique Driving Conditions)

CAMSHAFT TIMING BELT

Inspect timing belt at 60,000 miles or 48 months and thereafter inspect timing belt every 15,000 miles, or 12

months. Replace belt as necessary.

The condition of camshaft drive belts should always be checked on vehicles which have more than 50,000

miles. Although some manufacturers do not recommend belt replacement at a specified mileage, others require

it at 60,000-100,000 miles. A camshaft drive belt failure may cause extensive damage to internal engine

components on most engines, although some designs do not allow piston-to-valve contact. These designs are

often called Free Wheeling.

Many manufacturers changed their maintenance and warranty schedules in the mid-1980's to reflect timing belt

inspection and/or replacement at 50,000-60,000 miles. Most service interval schedules in this manual reflect

these changes.

Belts or components should be inspected and replaced if any of the following conditions exist:

Cracks Or Tears In Belt Surface

Missing, Damaged, Cracked Or Rounded Teeth

Oil Contamination

Damaged Or Faulty Tensioners

Incorrect Tension Adjustment NOTE: Use the Severe Service schedule if the vehicle to be serviced is operated under

ANY (one or more) of these conditions:

Towing a trailer or using a camper or car-top carrier.

Repeated short trips of less than 5 miles in temperatures below freezing.

Extensive idling or low-speed driving for long distances as in heavy

commercial use such as delivery, taxi or patrol car.

Operating on rough, muddy or salt covered roads.

Operating on unpaved or dusty roads.

CAUTION: Failure to replace a faulty camshaft timing belt may result in serious

engine damage.

1999 Toyota RAV4

MAINTENANCE INFORMATION 1997-99 MAINTENANCE Toyota Maintenance Information

Microsoft

Sunday, November 22, 2009 10:32:41 AMPage 3 © 2005 Mitchell Repair Information Company, LLC.

Page 949 of 1632

If battery is replaced, it should be of the same group number as shown on original battery label.

CAUTIONS & WARNINGS

SUPPLEMENTAL RESTRAINT SYSTEM (AIR BAG)

Modifications or improper maintenance, including incorrect removal and installation of the Supplemental

Restraint System (SRS), can adversely affect system performance. DO NOT cover, obstruct or change the

steering wheel horn pad in any way, as such action could cause improper function of the system. Use only plain

water when cleaning the horn pad. Solvents or cleaners could adversely affect the air bag cover and cause

improper deployment of the system.

AIR CONDITIONING SERVICING

ANTI-LOCK BRAKE SYSTEM CAUTION: When battery is disconnected, vehicles equipped with computers may lose

memory data. When battery power is restored, driveability problems may

exist on some vehicles. These vehicles may require a relearn procedure.

See COMPUTER RELEARN PROCEDURES article in the GENERAL

INFORMATION section.

WARNING:To avoid injury from accidental air bag deployment, read and carefully

follow all warnings and service precautions. See appropriate AIR BAG

RESTRAINT SYSTEM article in ACCESSORIES/SAFETY EQUIPMENT.

CAUTION: Disconnect negative battery cable before servicing any air bag system,

steering column or passenger side dash component. After any repair, turn

ignition key to the ON position from passenger's side of vehicle in case of

accidental air bag inflation

NOTE: See the AIR BAG RESTRAINT SYSTEM article in the ACCESSORIES/SAFETY

EQUIPMENT Section.

CAUTION: Avoid breathing R-134a refrigerant and PAG lubricant vapors, exposure

may irritate eyes, nose and throat. To remove R-134a from system use R-

134a recycling equipment that meets SAE J2210 specifications. If

accidental system discharge occurs, ventilate work area before resuming

service.

WARNING:R-134a service equipment or vehicle A/C systems SHOULD NOT be

pressure tested or leak tested with compressed air. Some mixtures of

air/R134a have shown to be combustible at elevated pressures. These

mixtures are dangerous and may cause fire and/or explosions. See AIR

CONDITIONING SERVICE article in GENERAL INFORMATION section.

1999 Toyota RAV4

MAINTENANCE INFORMATION 1997-99 MAINTENANCE Toyota Maintenance Information

Microsoft

Sunday, November 22, 2009 10:32:42 AMPage 7 © 2005 Mitchell Repair Information Company, LLC.