check engine light TOYOTA RAV4 1996 Service Repair Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 1996, Model line: RAV4, Model: TOYOTA RAV4 1996Pages: 1632, PDF Size: 41.64 MB

Page 1 of 1632

1999-2000 BRAKES

Anti-Lock - RAV4

DESCRIPTION

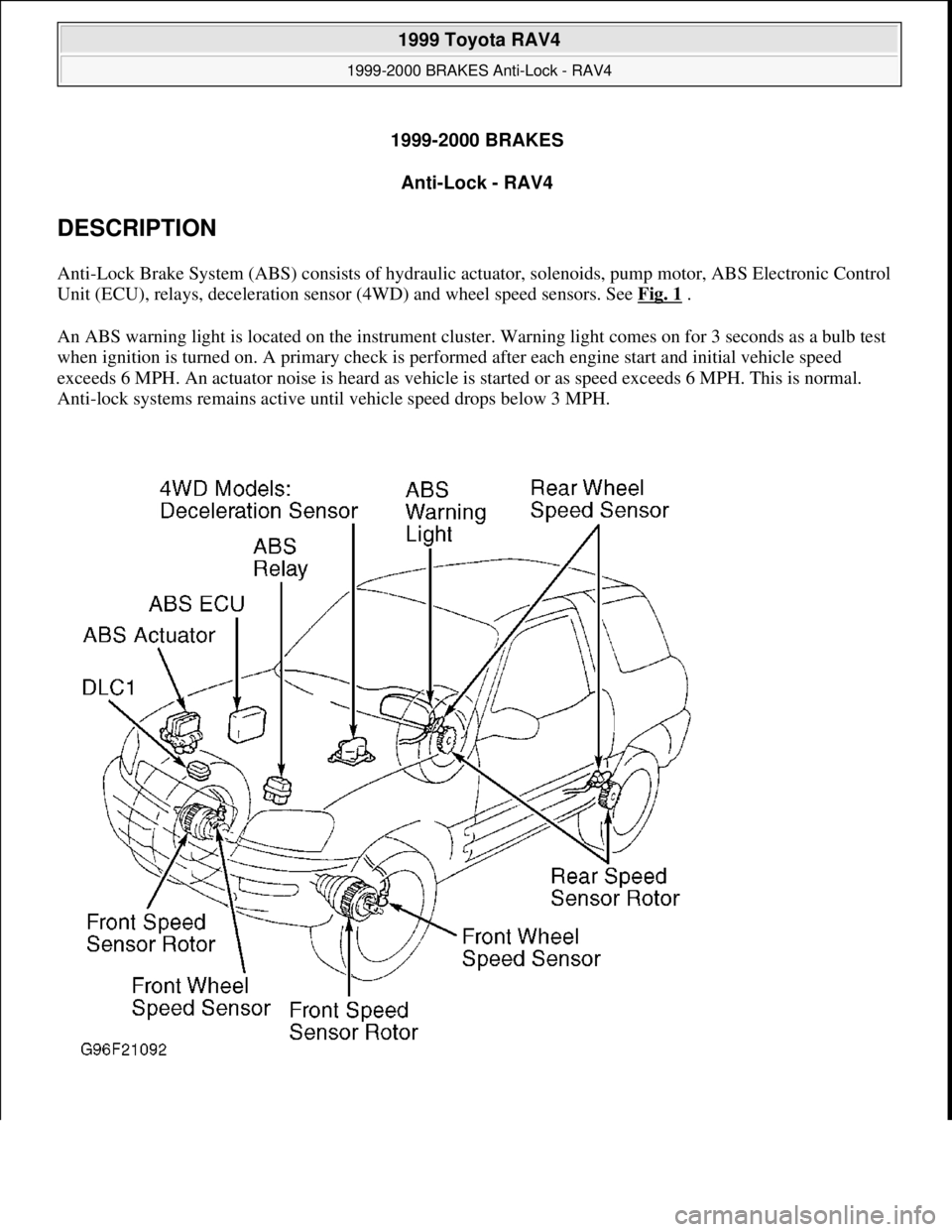

Anti-Lock Brake System (ABS) consists of hydraulic actuator, solenoids, pump motor, ABS Electronic Control

Unit (ECU), relays, deceleration sensor (4WD) and wheel speed sensors. See Fig. 1

.

An ABS warning light is located on the instrument cluster. Warning light comes on for 3 seconds as a bulb test

when ignition is turned on. A primary check is performed after each engine start and initial vehicle speed

exceeds 6 MPH. An actuator noise is heard as vehicle is started or as speed exceeds 6 MPH. This is normal.

Anti-lock systems remains active until vehicle speed drops below 3 MPH.

1999 Toyota RAV4

1999-2000 BRAKES Anti-Lock - RAV4

1999 Toyota RAV4

1999-2000 BRAKES Anti-Lock - RAV4

Microsoft

Sunday, November 22, 2009 10:06:17 AMPage 1 © 2005 Mitchell Repair Information Company, LLC.

Microsoft

Sunday, November 22, 2009 10:06:21 AMPage 1 © 2005 Mitchell Repair Information Company, LLC.

Page 3 of 1632

If cause of faulty operation cannot be located with basic diagnosis, ABS electronic control system must be

checked. See DIAGNOSIS & TESTING

.

When ignition is turned on, ABS warning light should come on, then go out after 3 seconds. If ABS warning

light does not operate as specified, go to ABS WARNING LIGHT under DIAGNOSIS & TESTING

.

DIAGNOSIS & TESTING

RETRIEVING DIAGNOSTIC TROUBLE CODES

ABS Warning Light Diagnostics

1. Ensure battery voltage is 12 volts. Turn ignition switch to ON position. ABS warning light should

illuminate, then go out after 3 seconds. If ABS warning light does not illuminate, check fuse, bulb, and

wiring harness. See ABS WARNING LIGHT

.

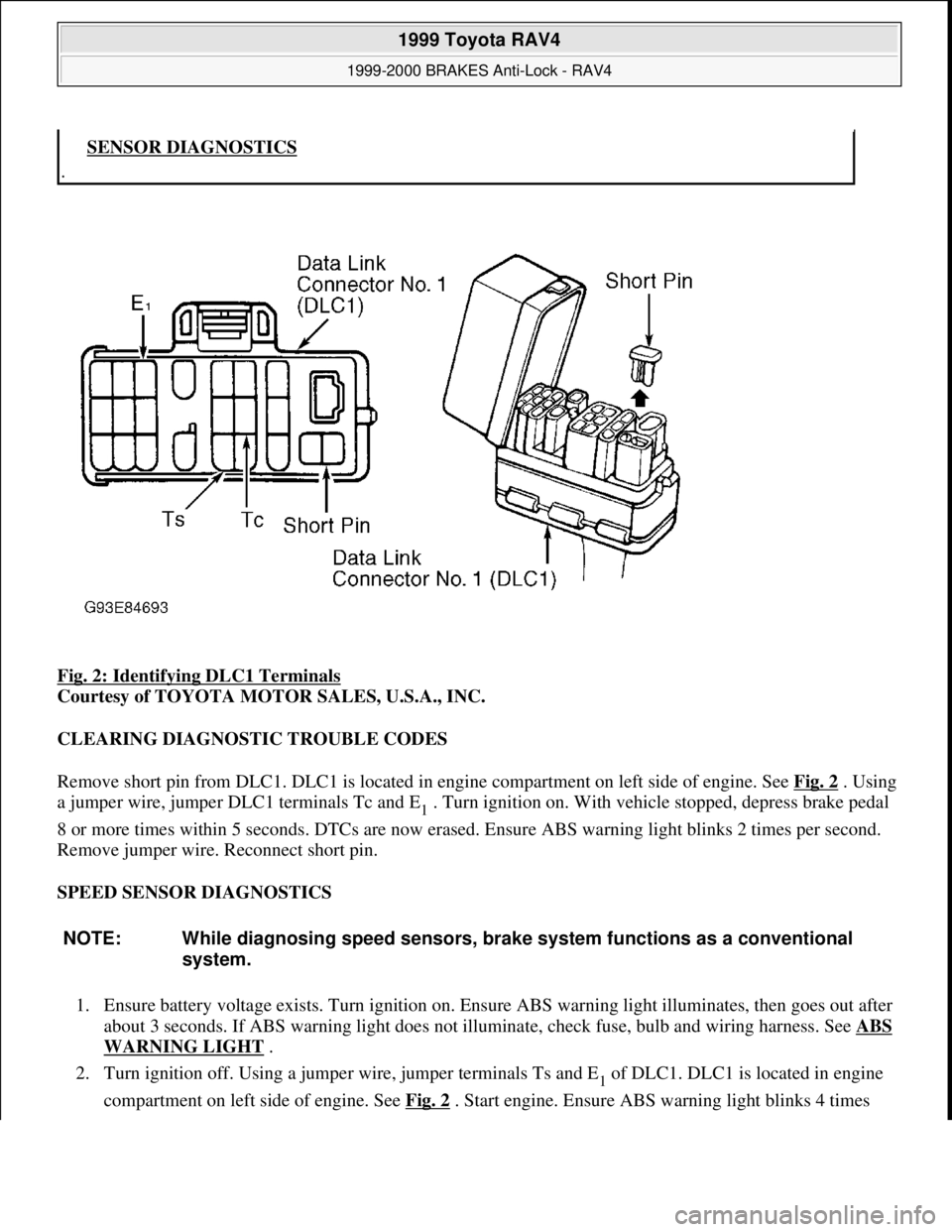

2. Remove short pin from DLC1. DLC1 is located in engine compartment, on left side of engine. See Fig.

2 . Using a jumper wire, jumper DLC1 terminals Tc and E1 . If a malfunction is detected, ABS warning

light will begin to flash a 2-digit Diagnostic Trouble Code (DTC). First number of blinks will equal first

digit in DTC. After a 1.5-second pause, second number of blinks will equal second digit in DTC.

3. If 2 or more DTCs are stored, there will be a 2.5-second pause between each DTC. After all DTCs are

flashed, there will be a 4 second pause and all DTCs will repeat. If ABS system is functioning properly,

ABS warning light will blink 2 times per second. For code definitions, see DTC DEFINITIONS

. For

DTC diagnosis, see DIAGNOSTIC TESTS

.

4. After replacing or repairing components, clear DTCs. If battery cables were disconnected during repairs,

all DTCs will be erased. If battery cables were not disconnected during repairs, see CLEARING DTCS

.

DTC DEFINITIONS NOTE: DO NOT start engine when retrieving DTCs.

NOTE: Speed sensor diagnostics and code retrieval use different DLC1 terminals to

access DTCs. If a speed sensor or speed sensor circuit problem is suspected,

see SPEED SENSOR DIAGNOSTICS

.

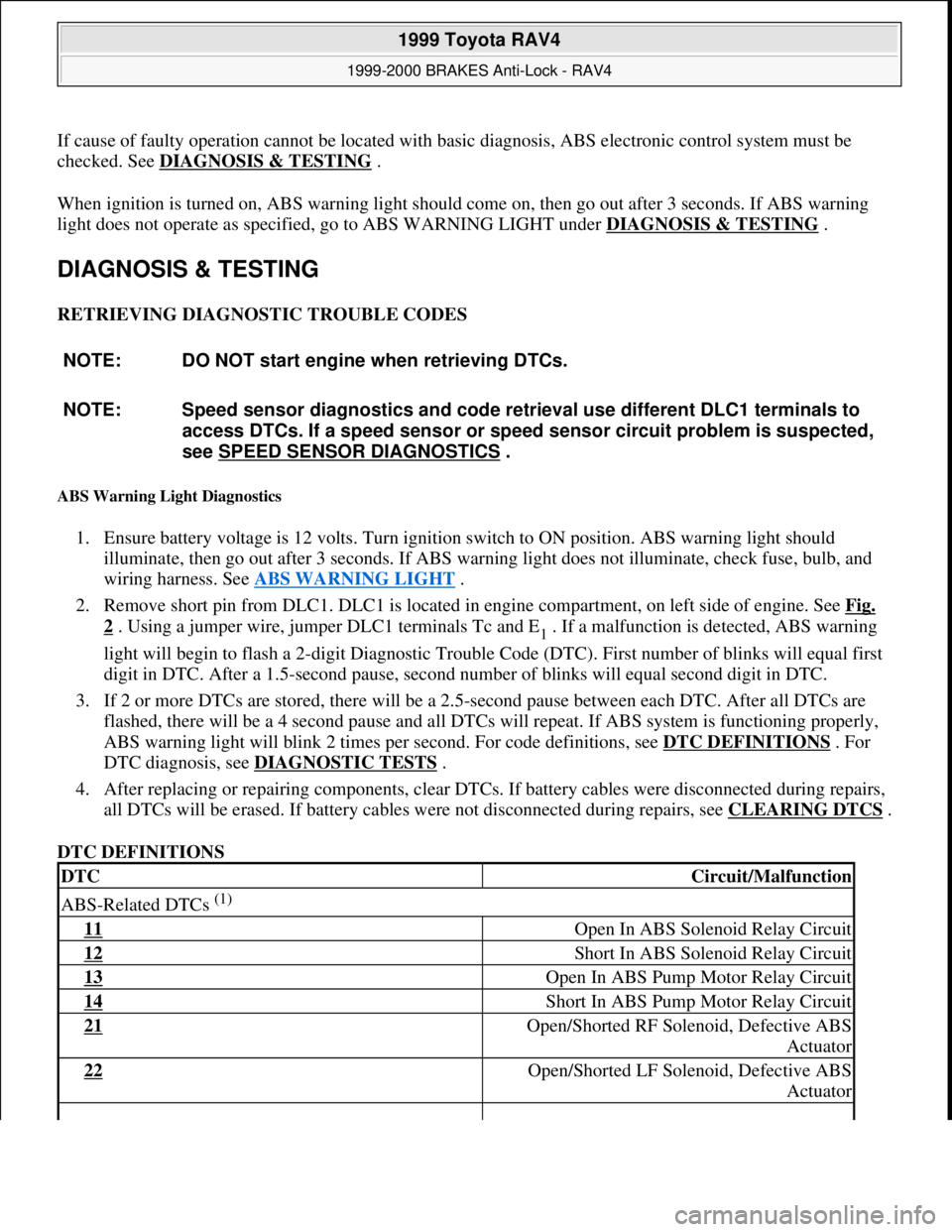

DTCCircuit/Malfunction

ABS-Related DTCs (1)

11 Open In ABS Solenoid Relay Circuit

12 Short In ABS Solenoid Relay Circuit

13 Open In ABS Pump Motor Relay Circuit

14 Short In ABS Pump Motor Relay Circuit

21 Open/Shorted RF Solenoid, Defective ABS

Actuator

22 Open/Shorted LF Solenoid, Defective ABS

Actuator

1999 Toyota RAV4

1999-2000 BRAKES Anti-Lock - RAV4

Microsoft

Sunday, November 22, 2009 10:06:17 AMPage 3 © 2005 Mitchell Repair Information Company, LLC.

Page 5 of 1632

Fig. 2: Identifying DLC1 Terminals

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

CLEARING DIAGNOSTIC TROUBLE CODES

Remove short pin from DLC1. DLC1 is located in engine compartment on left side of engine. See Fig. 2

. Using

a jumper wire, jumper DLC1 terminals Tc and E

1 . Turn ignition on. With vehicle stopped, depress brake pedal

8 or more times within 5 seconds. DTCs are now erased. Ensure ABS warning light blinks 2 times per second.

Remove jumper wire. Reconnect short pin.

SPEED SENSOR DIAGNOSTICS

1. Ensure battery voltage exists. Turn ignition on. Ensure ABS warning light illuminates, then goes out after

about 3 seconds. If ABS warning light does not illuminate, check fuse, bulb and wiring harness. See ABS

WARNING LIGHT .

2. Turn ignition off. Using a jumper wire, jumper terminals Ts and E

1 of DLC1. DLC1 is located in engine

compartment on left side of en

gine. See Fig. 2. Start engine. Ensure ABS warning light blinks 4 times

.SENSOR DIAGNOSTICS

NOTE: While diagnosing speed sensors, brake system functions as a conventional

system.

1999 Toyota RAV4

1999-2000 BRAKES Anti-Lock - RAV4

Microsoft

Sunday, November 22, 2009 10:06:17 AMPage 5 © 2005 Mitchell Repair Information Company, LLC.

Page 7 of 1632

Turn ignition on. Measure voltage between terminals Tc and E1of DLC1. If voltage is 10-14 volts, circuit is

okay. If ABS warning light does not blink even after terminals are connected, malfunction may exist in ABS

ECU. If voltage is not 10-14 volts, check for open or short circuit in wiring harness between ABS actuator and

DLC1, or between ground and DLC1. See WIRING DIAGRAMS

. Repair as necessary. If wiring harness is

okay, replace ABS ECU.

TS TERMINAL

Circuit Description

Sensor check circuit detects abnormalities in speed sensor signal which cannot be detected when checking for

DTCs. Connecting terminals Ts and E

1 of DLC1 in engine compartment starts DTC check. See Fig. 2 .

Diagnostic Procedure

Turn ignition on. Measure voltage between terminals Ts and E1 of DLC1. If voltage is 10-14 volts, circuit is

okay. If ABS warning light does not blink even after terminals are connected, malfunction may exist in ABS

ECU. If voltage is not 10-14 volts, check for open or short circuit in wiring harness between ABS ECU and

DLC1, or between ground and DLC1. See WIRING DIAGRAMS

. Repair as necessary. If wiring harness is

okay, replace ABS ECU.

ABS ECU PIN VOLTAGES

ABS circuits and harness can be tested by backprobing ABS ECU connectors and comparing measured voltages

with ABS ECU standard values chart. See Fig. 3

.

1999 Toyota RAV4

1999-2000 BRAKES Anti-Lock - RAV4

Microsoft

Sunday, November 22, 2009 10:06:17 AMPage 7 © 2005 Mitchell Repair Information Company, LLC.

Page 10 of 1632

wiring harness between ABS control relay and DLC1. Repair or replace as necessary. See WIRING

DIAGRAMS .

2. If ABS warning light is on, go to next step. If ABS warning light is off, check for open or short circuit in

wiring harness between ECU-IG fuse and ABS ECU. Repair as necessary. See WIRING DIAGRAMS

.

3. Start engine and check charging system voltage. If voltage is 10-16 volts, go to next step. If voltage is not

10-16 volts, diagnose charging system. Repair as necessary.

4. Turn ignition off. Disconnect appropriate ABS ECU connector supporting IG1 terminal. See Fig. 3

. Turn

ignition switch to ON position. Ensure ABS warning light turns off. If light turns off, replace ABS ECU.

If light does not turn off, check for short circuit in wiring harness between combination meter (instrument

panel) and ABS ECU, or between combination meter and DLC1. Repair as necessary. See WIRING

DIAGRAMS .

DIAGNOSTIC TESTS

DTC 11 & DTC 12: ABS CONTROL (SOLENOID) RELAY CIRCUIT

Circuit Description

This relay supplies power to each ABS solenoid. After ignition switch is turned to ON position, if initial check

is okay, this relay turns on. If malfunction occurs in ABS control relay circuit, ABS ECU cuts off current to

ABS control relay and prohibits ABS control.

DTC Detecting Condition

Detection of following conditions may set DTC 11 or DTC 12 if condition occurs for .2 seconds or more:

If voltage at ABS control relay connector terminal A9-1 is less than 1.5 volts and voltage at connector

terminal A9-5 is zero volts, DTC 11 may set.

If voltage at ABS control relay connector terminal A9-1 is 10-14 volts and voltage at connector terminal

A9-5 is 10-14 volts, DTC 12 may set.

Diagnostic Procedure

1. Disconnect ABS control relay 6-pin connector A9, located in engine compartment at front of vehicle. See

Fig. 1

. Measure voltage between connector terminals A9-2 and A9-6. See Fig. 4 . If voltage is 10-14

volts, go to next step. If voltage is not 10-14 volts, repair wiring harness between ground, battery and

ABS control relay.

2. Measure resistance between ABS control relay terminal A9-5 and appropriate ABS ECU terminals. See

ABS ECU

-TO-ACTUATOR CIRCUIT IDENTIFICATION/RESISTANCE VALUES . See Fig. 3 .

If resistance on every circuit is between 26-40 ohms, go to next step. If resistance is not as specified,

check for open or short circuit in appropriate wiring between ABS control relay, ABS actuator and ABS

ECU. See WIRING DIAGRAMS

. Repair as necessary. If wiring is okay, replace ABS actuator.

ABS ECU-TO-ACTUATOR CIRCUIT IDENTIFICATION/RESISTANCE VALUES

CircuitABS ECU

Connector/TerminalWire Color

1999 Toyota RAV4

1999-2000 BRAKES Anti-Lock - RAV4

Microsoft

Sunday, November 22, 2009 10:06:17 AMPage 10 © 2005 Mitchell Repair Information Company, LLC.

Page 26 of 1632

1. Check charging system voltage. Ensure 10-14 volts is present. If charging system voltage is okay, go to

next step. If charging system voltage is not okay, check and repair charging system.

2. Turn ignition switch to ON position. Ensure ABS warning light comes on, then goes out after 3 seconds.

If ABS warning light does not illuminate, check fuse, bulb, and wiring harness. See ABS WARNING

LIGHT under DIAGNOSIS & TESTING. Turn ignition off.

3. Using a jumper wire, jumper terminals Ts and E

1 of DLC1. DLC1 is located in engine compartment on

left side of engine. See Fig. 2

. Ensure ABS warning light blinks 4 times per second. If ABS light does

not blink, go to ABS WARNING LIGHT

under DIAGNOSIS & TESTING. If ABS warning light

blinks, go to next step.

4. Using a floor jack, slowly jack up rear of vehicle. On vehicles with 215/70R16 tires, raise vehicle to a

height of 25.59-27.95" (650-710 mm). On vehicles with 235/60R16 tires, raise vehicle to a height of

26.38-28.74" (670-730 mm). If ABS warning light illuminates at specified height, check deceleration

sensor installation. If installation is okay, replace deceleration sensor. Lower vehicle.

5. Using a floor jack, slowly jack up front of vehicle. On vehicles with 215/70R16 tires, raise vehicle to a

height of 21.20-23.56" (550-610 mm). On vehicles with 235/60R16 tires, raise vehicle to a height of

22.44-24.80" (570-630 mm). If ABS warning light illuminates at specified height, check deceleration

sensor installation. If installation is okay, replace deceleration sensor. Lower vehicle.

6. Drive vehicle straight ahead at speed of 13 MPH or more. Lightly depress brake pedal. Ensure ABS

warning light pattern is normal (light blinks 4 times per second).

7. While driving vehicle straight ahead at speed of 13 MPH or more, moderately depress brake pedal.

Ensure ABS warning light illuminates in a solid pattern (light does not blink) while braking.

8. While driving vehicle straight ahead at speed of 13 MPH or more, firmly depress brake pedal. Ensure

ABS warning light illumination pattern changes from a solid pattern (light does not blink) to a normal

pattern (light blinks 4 times per second), then back to a solid pattern while braking.

9. If ABS warning light does not illuminate as described in steps 6 -8 , check deceleration sensor

installation. If installation is okay, replace deceleration sensor. Stop vehicle and turn ignition off. Remove

jumper wire from DLC1.

REMOVAL & INSTALLATION

ACTUATOR

Removal & Installation

Turn ignition off. Disconnect brakelines attached to actuator. Remove power steering hose retaining bracket

bolt and power steering reservoir. Disconnect actuator electrical connectors. Remove bolts, nuts and washers.

Remove actuator assembly. Remove actuator from actuator bracket. Remove cushions and holders from NOTE: When measuring vehicle height in following steps, measure at center of

lower body of vehicle.

WARNING:Hydraulic system may be under high pressure. Use caution when opening

hydraulic system.

1999 Toyota RAV4

1999-2000 BRAKES Anti-Lock - RAV4

Microsoft

Sunday, November 22, 2009 10:06:17 AMPage 26 © 2005 Mitchell Repair Information Company, LLC.

Page 31 of 1632

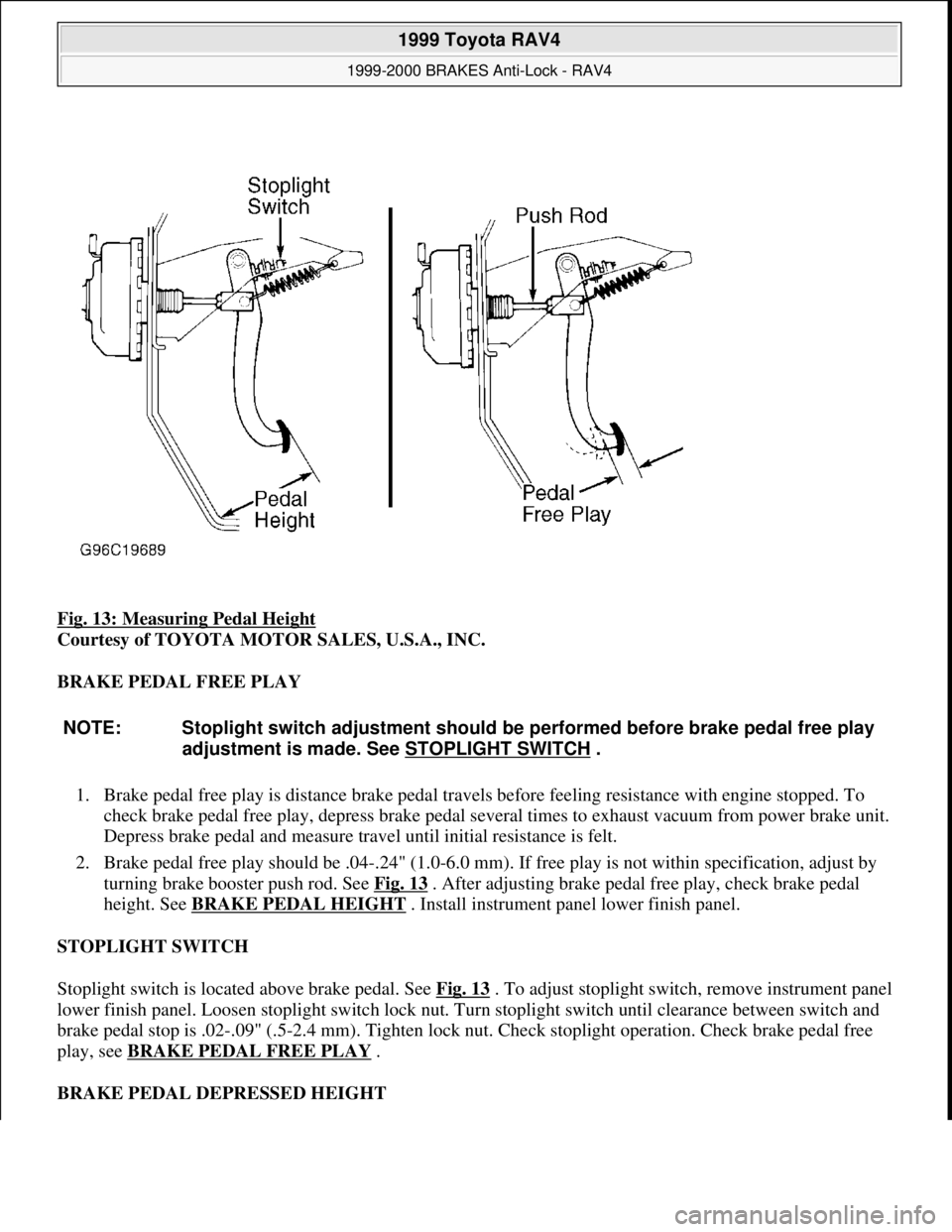

Fig. 13: Measuring Pedal Height

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

BRAKE PEDAL FREE PLAY

1. Brake pedal free play is distance brake pedal travels before feeling resistance with engine stopped. To

check brake pedal free play, depress brake pedal several times to exhaust vacuum from power brake unit.

Depress brake pedal and measure travel until initial resistance is felt.

2. Brake pedal free play should be .04-.24" (1.0-6.0 mm). If free play is not within specification, adjust by

turning brake booster push rod. See Fig. 13

. After adjusting brake pedal free play, check brake pedal

height. See BRAKE PEDAL HEIGHT

. Install instrument panel lower finish panel.

STOPLIGHT SWITCH

Stoplight switch is located above brake pedal. See Fig. 13

. To adjust stoplight switch, remove instrument panel

lower finish panel. Loosen stoplight switch lock nut. Turn stoplight switch until clearance between switch and

brake pedal stop is .02-.09" (.5-2.4 mm). Tighten lock nut. Check stoplight operation. Check brake pedal free

play, see BRAKE PEDAL FREE PLAY .

BRAKE PEDAL DEPRESSED HEIGHT

NOTE: Stoplight switch adjustment should be performed before brake pedal free play

adjustment is made. See STOPLIGHT SWITCH

.

1999 Toyota RAV4

1999-2000 BRAKES Anti-Lock - RAV4

Microsoft

Sunday, November 22, 2009 10:06:17 AMPage 31 © 2005 Mitchell Repair Information Company, LLC.

Page 137 of 1632

exceeds .0079" (.200 mm).

2. Install torque converter on transmission. To ensure torque converter is fully seated, torque converter

depth should be checked. Using straightedge and caliper, measure torque converter depth from torque

converter bolt lug on torque converter to the surface on transmission. See Fig. 1

.

3. Torque converter depth should be more than .707" (17.95 mm). If torque converter depth is less than

specified, check for improperly seated torque converter.

4. To install, reverse removal procedure. Tighten all bolts/nuts to specification. See TORQUE

SPECIFICATIONS When installing torque converter bolts, apply Loctite to torque converter bolt

threads before installing. Ensure the Green torque converter bolt is installed first before installing the

remaining torque converter bolts.

5. Once engine and transmission are installed, adjust all cables and fill with ATF. See appropriate

TRANSMISSION SERVICING article.

Removal (Tacoma 4WD)

1. Disconnect negative battery cable. Remove transmission oil dipstick. Disconnect throttle valve cable from

throttle body.

2. Raise and support vehicle. Remove lower engine cover. Remove fan shroud from radiator. Remove rear

console box, located between the seats. Remove screws from front console, located near transfer case and

transmission shift levers.

3. Remove front console with transfer case shift lever knob. Disconnect electrical connectors for removal of

transmission shift lever assembly. Disconnect shift linkage at transmission shift lever assembly. Remove

transmission shift lever assembly.

4. Remove snap ring and transfer case shift lever from transfer case. Remove transmission oil dipstick tube

and "O" ring. Place reference marks on drive shaft flanges for reassembly reference. Remove drive shafts.

5. Remove exhaust pipes as necessary for access to transmission and transfer case. Disconnect speedometer

cable and necessary electrical connectors for transmission and transfer case removal. Remove

transmission oil cooler pipes and brackets as necessary.

6. Remove starter and stabilizer bar. Remove torque converter cover from front of transmission. Remove

torque converter bolts. Front differential assembly rear mount must be removed for transmission removal.

Rear mount is located on front differential assembly, just behind the drive shaft flange.

7. Support front differential assembly with jack. Remove front differential assembly rear mount-to-

crossmember nut. Slightly raise front differential assembly. Remove the 2 front differential assembly rear

mount bolts.

8. Support transmission with transmission jack. Remove transmission mount-to-transmission crossmember

bolts. Remove transmission crossmember, located below transmission and transfer case. Remove

transmission-to-cylinder block bolts. Lower transmission with transfer case from vehicle.

Installation

1. Before installing transmission, use dial indicator to check drive plate runout. Drive plate runout should be

checked right next to the starter ring gear on the drive plate. Replace drive plate if runout

exceeds .0079" (.200 mm).

2. Install torque converter on transmission. To ensure torque converter is full

y seated, torque converter

1998 Toyota Avalon XLS

TRANSMISSION SERVICING - A/T 1997-98 TRANSMISSION SERVICING Toyota - Transmission Removal &

Installation

Helpmelearn

November-03-08 10:30:29 AMPage 25 © 2005 Mitchell Repair Information Company, LLC.

Page 161 of 1632

clutch.

Vehicle Does Not Move In Reverse ("R")

Check 1-2 shift valve, 2-3 shift valve, 2nd coast brake, front planetary gear, rear planetary gear, direct clutch,

OD direct clutch and 1st and reverse brake.

No 1-2 &/Or 2-3 Upshift

Check Throttle Position (TP) sensor circuit, No. 1 and No. 2 shift solenoid circuit, Vehicle Speed Sensor (VSS)

circuit, Electronic Control Transmission Electronic Control Module (ECT ECM), 1-2 shift valve, 2-3 shift

valve, 2nd brake, direct clutch and No. 1 one-way clutch.

No 3-O/D Upshift

Check OD switch and OD OFF indicator switch circuit, OD cancel signal circuit, No. 1 and No. 2 shift solenoid

circuit, VSS, Engine Coolant Temperature (ECT) circuit, ECT ECM, 3-4 shift valve and OD brake.

No O/D-3 Downshift

Check No. 1 and No. 2 shift solenoid valve, VSS circuit, OD cancel signal circuit, ECT ECM and 3-4 shift

valve.

No 3-2 &/Or 2-1 Downshift

Check No. 1 and No. 2 shift solenoid valve, VSS circuit, TP sensor circuit, ECT ECM, 2-3 shift valve, 1-2 shift

valve and 2nd coast brake.

No Torque Converter Lock-Up

Check shift solenoid valve SL circuit, TP sensor circuit, VSS circuit, OD cancel circuit, brakelight circuit, ECT

circuit, ECT ECM, lock-up relay valve and torque converter clutch.

Torque Converter Lock-Up Will Not Release

Check shift solenoid valve SL circuit, TP sensor circuit, brakelight circuit, ECT ECM circuit, lock-up relay

valve and torque converter clutch.

Shift Speeds Too High Or Too Low

Check TP sensor circuit, VSS circuit, shift solenoid valve SL circuit, OD cancel signal circuit, pattern select

switch circuit and ECT ECM.

Harsh Engagement Neutral To Reverse

Check direct clutch accumulator, direct clutch, throttle valve and 1st and reverse brake.

Harsh Engagement Neutral To Drive

1998 Toyota Avalon XLS

1997-99 AUTOMATIC TRANSMISSIONS Toyota A-540E, A-540H & A-541E Overhaul

Helpmelearn

November-03-08 10:28:16 AMPage 7 © 2005 Mitchell Repair Information Company, LLC.

Page 165 of 1632

steady at 43 MPH for 1997 Avalon, 47 MPH for RAV4 and 37 MPH for all other models. Lightly depress

accelerator pedal. Ensure engine RPM does not change abruptly. Large increase in engine RPM indicates

lock-up function is faulty.

"2" Range Test

1. Shift into "2" range and fully depress accelerator pedal to full throttle. Ensure 1-2 upshift takes place and

shift point conforms to specifications. See appropriate table under SHIFT SPEED SPECIFICATIONS

.

2. While driving in "2" range, 2nd gear, release accelerator pedal and check engine braking effect. If there is

no engine braking effect, 2nd coast brake is faulty. Check for abnormal noise and shock at acceleration

and deceleration.

"L" Range Test

While running in "L" range, ensure there is no upshift to 2nd gear. While running in "L" range, release

accelerator pedal. If there is no engine braking effect, 1st and reverse brake is faulty. Check for abnormal noise

at acceleration and deceleration.

"R" Range Test

Shift into "R" range. Accelerate vehicle from a stop at full throttle. Ensure slipping does not occur.

"P" Range Test

Stop vehicle on 5 degree or more gradient. Shift transaxle into "P" range. Release parking brake. Ensure parking

pawl holds vehicle.

SHIFT SPEED SPECIFICATIONS

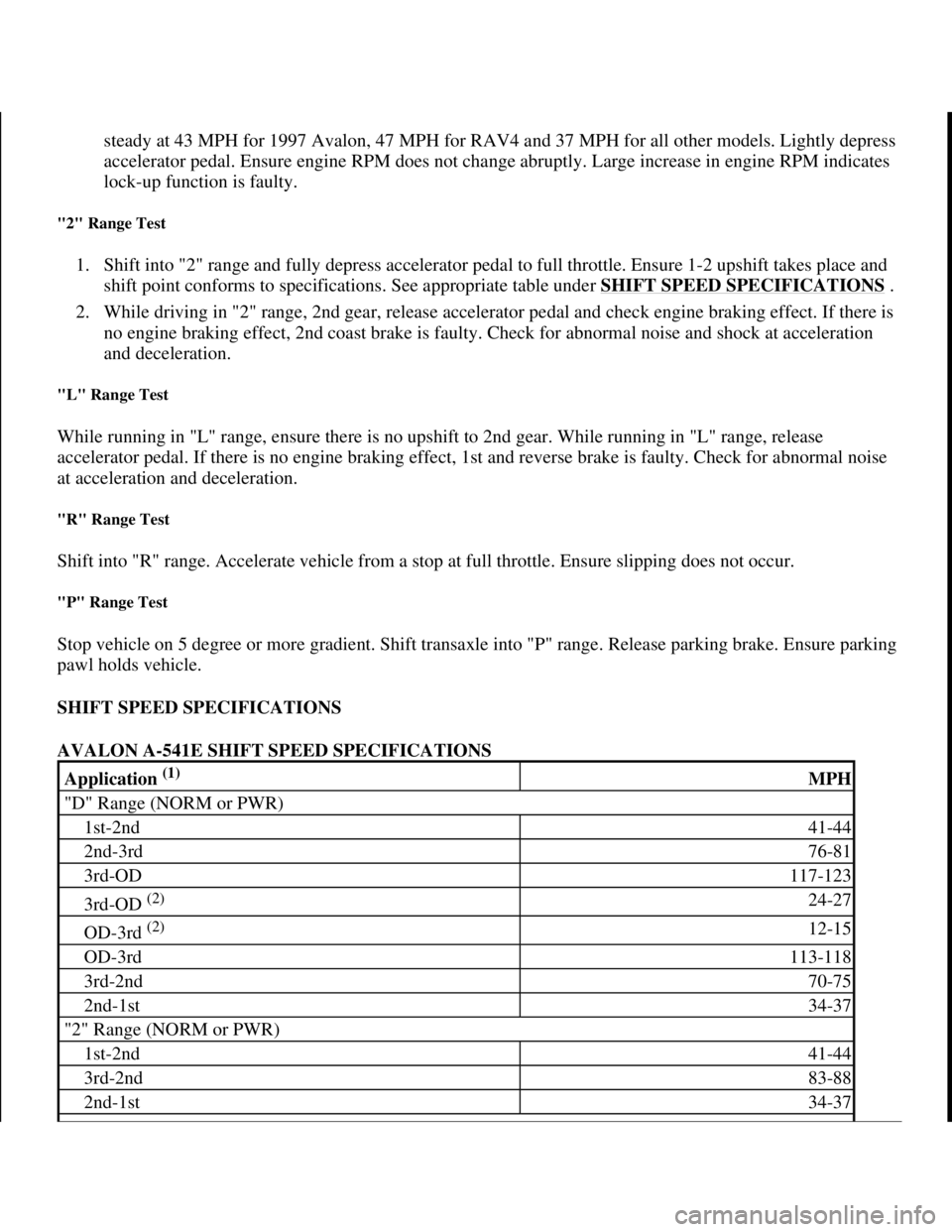

AVALON A-541E SHIFT SPEED SPECIFICATIONS

Application (1)MPH

"D" Range (NORM or PWR)

1st-2nd41-44

2nd-3rd76-81

3rd-OD117-123

3rd-OD (2)24-27

OD-3rd (2)12-15

OD-3rd113-118

3rd-2nd70-75

2nd-1st34-37

"2" Range (NORM or PWR)

1st-2nd41-44

3rd-2nd83-88

2nd-1st34-37

1998 Toyota Avalon XLS

1997-99 AUTOMATIC TRANSMISSIONS Toyota A-540E, A-540H & A-541E Overhaul

Helpmelearn

November-03-08 10:28:17 AMPage 11 © 2005 Mitchell Repair Information Company, LLC.