check engine light TOYOTA RAV4 1996 Service User Guide

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 1996, Model line: RAV4, Model: TOYOTA RAV4 1996Pages: 1632, PDF Size: 41.64 MB

Page 269 of 1632

step 2). If throttle valve is not fully open, adjust throttle linkage or cable so throttle valve is fully open and

then go to step 2).

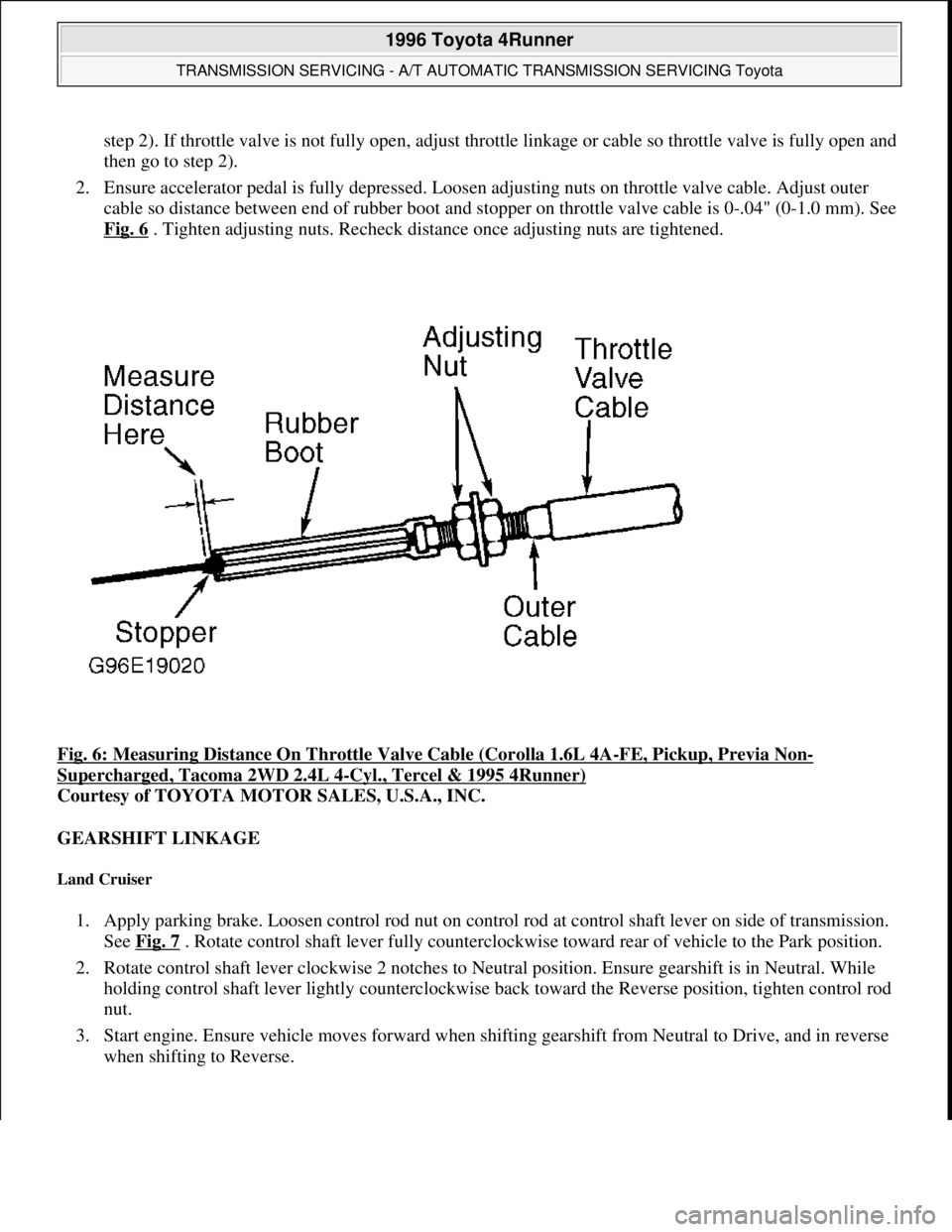

2. Ensure accelerator pedal is fully depressed. Loosen adjusting nuts on throttle valve cable. Adjust outer

cable so distance between end of rubber boot and stopper on throttle valve cable is 0-.04" (0-1.0 mm). See

Fig. 6

. Tighten adjusting nuts. Recheck distance once adjusting nuts are tightened.

Fig. 6: Measuring Distance On Throttle Valve Cable (Corolla 1.6L 4A

-FE, Pickup, Previa Non-

Supercharged, Tacoma 2WD 2.4L 4-Cyl., Tercel & 1995 4Runner)

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

GEARSHIFT LINKAGE

Land Cruiser

1. Apply parking brake. Loosen control rod nut on control rod at control shaft lever on side of transmission.

See Fig. 7

. Rotate control shaft lever fully counterclockwise toward rear of vehicle to the Park position.

2. Rotate control shaft lever clockwise 2 notches to Neutral position. Ensure gearshift is in Neutral. While

holding control shaft lever lightly counterclockwise back toward the Reverse position, tighten control rod

nut.

3. Start engine. Ensure vehicle moves forward when shifting gearshift from Neutral to Drive, and in reverse

when shiftin

g to Reverse.

1996 Toyota 4Runner

TRANSMISSION SERVICING - A/T AUTOMATIC TRANSMISSION SERVICING Toyota

Microsoft

Tuesday, August 18, 2009 7:18:46 PMPage 13 © 2005 Mitchell Repair Information Company, LLC.

Page 344 of 1632

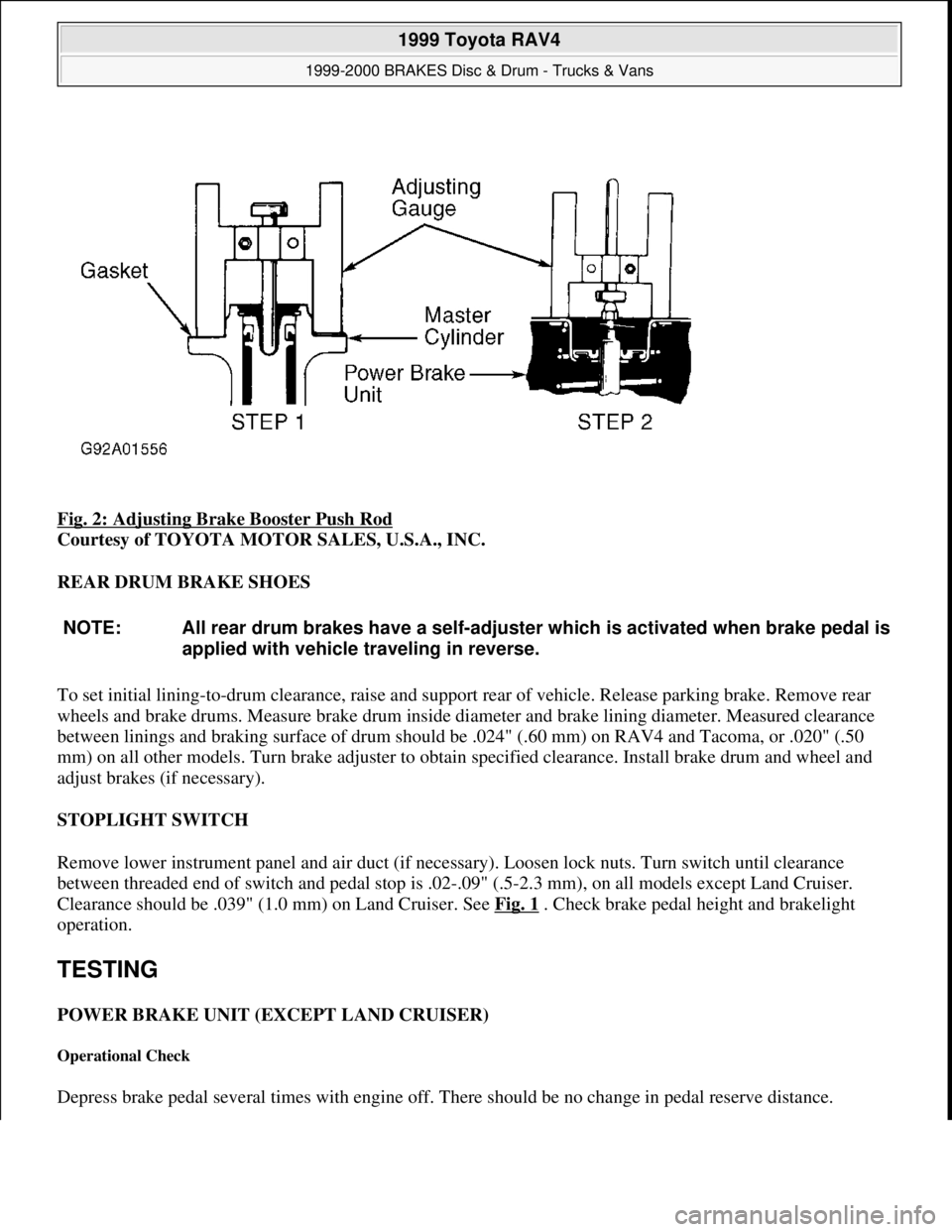

Fig. 2: Adjusting Brake Booster Push Rod

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

REAR DRUM BRAKE SHOES

To set initial lining-to-drum clearance, raise and support rear of vehicle. Release parking brake. Remove rear

wheels and brake drums. Measure brake drum inside diameter and brake lining diameter. Measured clearance

between linings and braking surface of drum should be .024" (.60 mm) on RAV4 and Tacoma, or .020" (.50

mm) on all other models. Turn brake adjuster to obtain specified clearance. Install brake drum and wheel and

adjust brakes (if necessary).

STOPLIGHT SWITCH

Remove lower instrument panel and air duct (if necessary). Loosen lock nuts. Turn switch until clearance

between threaded end of switch and pedal stop is .02-.09" (.5-2.3 mm), on all models except Land Cruiser.

Clearance should be .039" (1.0 mm) on Land Cruiser. See Fig. 1

. Check brake pedal height and brakelight

operation.

TESTING

POWER BRAKE UNIT (EXCEPT LAND CRUISER)

Operational Check

Depress brake pedal several times with engine off. There should be no change in pedal reserve distance.

NOTE: All rear drum brakes have a self-adjuster which is activated when brake pedal is

applied with vehicle traveling in reverse.

1999 Toyota RAV4

1999-2000 BRAKES Disc & Drum - Trucks & Vans

Microsoft

Sunday, November 22, 2009 10:07:28 AMPage 5 © 2005 Mitchell Repair Information Company, LLC.

Page 345 of 1632

Depress brake pedal and start engine. If pedal goes down slightly, operation is normal.

Air Tightness Check

1. Start engine and run for 1-2 minutes, then turn engine off. Depress brake pedal several times slowly. If

pedal goes down farthest on first time, but gradually rises after second or third time, power brake unit is

airtight.

2. With engine stopped, depress brake pedal several times using normal pressure. Pedal should be low when

first depressed. On consecutive applications, pedal height should gradually rise. If pedal height does not

increase, check for air leaks.

LOAD-SENSING PROPORTIONING VALVE (LSPV) & BY-PASS VALVE (BPV)

Tacoma & Tundra

1. For testing purposes, rear axle is loaded to a specified weight. Set total rear axle weight to specified

amount. See LSPV REAR AXLE TEST WEIGHT

table.

2. Attach pressure gauge set to front caliper and rear wheel cylinder or caliper. Bleed air from system. See

BLEEDING BRAKE SYSTEM

. Depress brake pedal until front pressure is as specified. See LSPV

PRESSURE SPECIFICATIONS table. Wait 2 seconds and record rear pressure reading.

LSPV REAR AXLE TEST WEIGHT

LSPV PRESSURE SPECIFICATIONS NOTE: DO NOT depress brake pedal more than once or release pedal while

setting pressure on front gauge.

ApplicationLbs. (kg)

Tacoma

2WD1543 (700)

4WD1874 (850)

Tundra

V6

Engine

(5UZ-

FE)2205 (1000)

V8

Engine

(2UZ-

FE)2315 (1050)

4Runner2033 (922)

Application

Front Pressure - psi

(kg/cm

2 )

Rear Pressure - psi

(kg/cm

2 )

Tacoma

1999 Toyota RAV4

1999-2000 BRAKES Disc & Drum - Trucks & Vans

Microsoft

Sunday, November 22, 2009 10:07:28 AMPage 6 © 2005 Mitchell Repair Information Company, LLC.

Page 407 of 1632

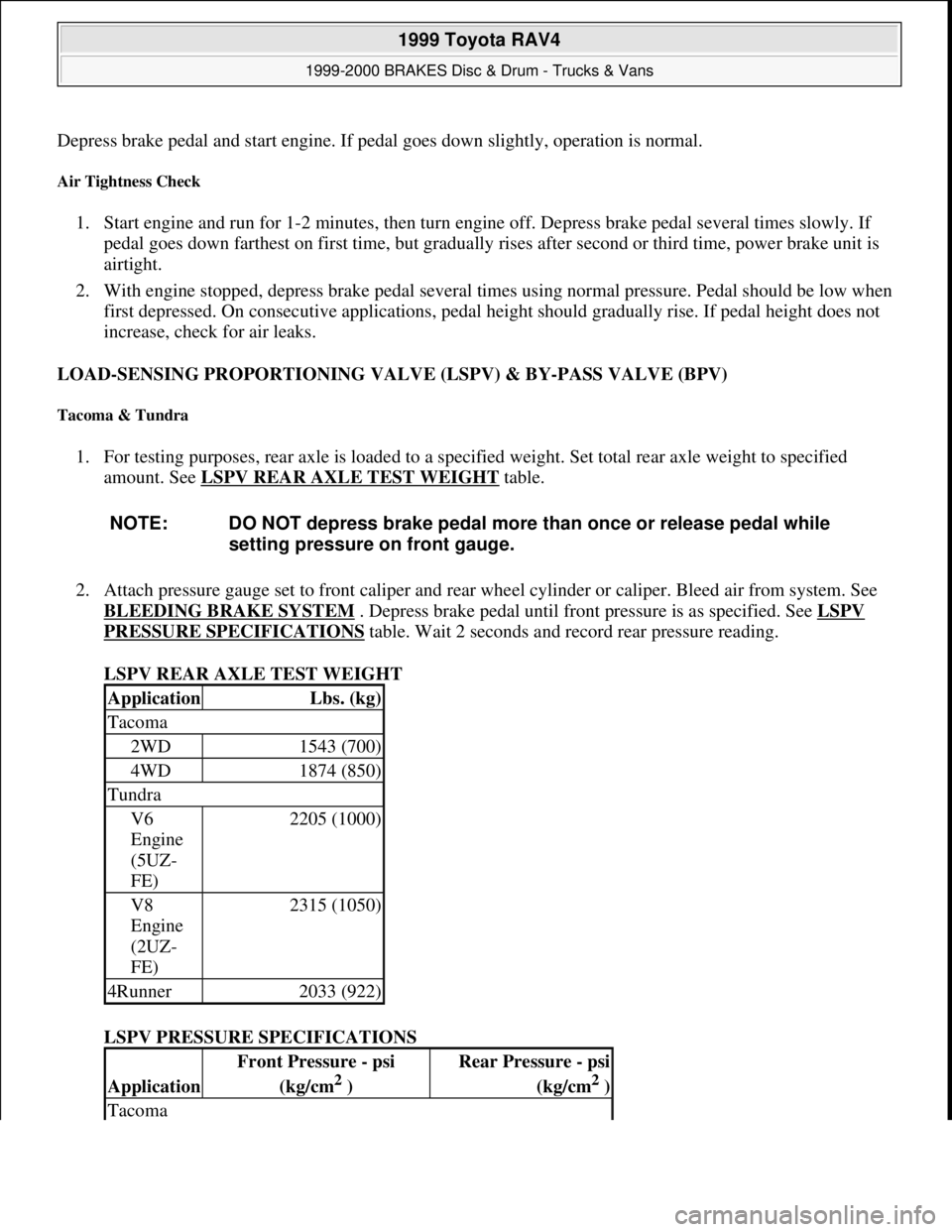

Fig. 3: Testing Generator Full Field Output (Typical)

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

LOAD TEST

1. Connect an ammeter as described in NO

-LOAD TEST , step 1) . See Fig. 2 . Start engine. Turn on high

beam headlights and place heater blower control on HI. Increase engine speed to 2000 RPM.

2. Check ammeter reading. Ammeter should read 30 amps or more. If amperage is less than specified, repair

or replace generator.

BENCH TESTING

BRUSHES

1. Brushes should slide smoothly in holders. Replace brushes if damaged or worn. On Tundra and 4Runner,

new brush exposed length should be .374-.453" (9.5-11.5 mm). On all other models, new brush exposed

length should be .413" (10.5 mm).

2. On all models, minimum exposed length should be more than .059" (1.5 mm). There are 2 different brush

holders used. One brush holder is replaced as an assembl

y, and the other has replaceable brushes. If

NOTE: If battery is fully charged, disable ignition system. Crank engine for about 15

seconds to partially discharge battery.

NOTE: If battery is fully charged, generator load test results may be less than 30 amps.

1999 Toyota RAV4

1999-2000 STARTING & CHARGING SYSTEMS Generators & Regulators

Microsoft

Sunday, November 22, 2009 10:13:07 AMPage 6 © 2005 Mitchell Repair Information Company, LLC.

Page 530 of 1632

M/T models, depress and release clutch pedal. On all models, if CRUISE control indicator light comes on when

switch is in OFF position and goes off when switch is in ON position, circuit for that switch being activated is

okay. Go to next step. If CRUISE control indicator does not function as indicated, see SYMPTOM

DIAGNOSIS and perform appropriate test(s).

Vehicle Speed Sensor

1. Raise vehicle and support vehicle with drive wheels off ground. Start engine and slowly depress

accelerator pedal until vehicle speed is 25 MPH or more. Turn cruise ON-OFF switch to ON position. If

CRUISE control indicator light flashes on and off every .25 second, go to next step. If CRUISE control

indicator light does not flash on and off every .25 second, see SYMPTOM DIAGNOSIS

and perform

appropriate test(s).

2. Slow vehicle speed to 25 MPH or less. If CRUISE control indicator light comes on and stays on, vehicle

speed sensor circuit is okay. Go to next step. If CRUISE control indicator light does not come on, see

SYMPTOM DIAGNOSIS

and perform appropriate test(s).

3. Cruise control function test is now complete. No problems are indicated at this time. If cruise control

system still does not function properly and no trouble codes are present, see SYMPTOM DIAGNOSIS

and perform appropriate test(s). Problem may also be intermittent.

SYMPTOM DIAGNOSIS

Symptom diagnosis should only be performed if no Diagnostic Trouble Codes (DTCs) are present. If symptom

is unknown, perform CRUISE CONTROL FUNCTION TEST

to identify problem area. Identify symptom

and perform appropriate test. Perform tests in order listed.

SET Not Occurring Or CANCEL Occurring (No DTCs Present)

Check the following components and/or circuits:

Perform CRUISE CONTROL SWITCH CIRCUIT test under SYSTEM TESTS.

Perform DTC 21: VEHICLE SPEED SENSOR CIRCUIT test under DIAGNOSTIC TESTS.

Perform STOPLIGHT SWITCH CIRCUIT test under SYSTEM TESTS.

Perform PARK/NEUTRAL POSITION SWITCH CIRCUIT test under SYSTEM TESTS.

Perform CLUTCH SWITCH CIRCUIT test under SYSTEM TESTS.

Perform DTC 11 OR DTC 15: ACTUATOR MOTOR CIRCUIT test under DIAGNOSTIC TESTS.

Check actuator control cable adjustment. See ADJUSTMENTS .

Replace cruise control ECU with a known-good ECU and retest. If symptom is no longer present, replace

ECU.

SET Not Occurring Or CANCEL Occurring (DTC Is Not Output)

Check the following components and/or circuits:

Perform CRUISE CONTROL ECU POWER SOURCE CIRCUIT test under SYSTEM TESTS.

Replace cruise control ECU with a known-good ECU and retest. If symptom is no longer present, replace

1999 Toyota RAV4

1999 ACCESSORIES & EQUIPMENT Cruise Control Systems - RAV4

Microsoft

Sunday, November 22, 2009 10:52:01 AMPage 6 © 2005 Mitchell Repair Information Company, LLC.

Page 535 of 1632

1. Check stoplight operation. If stoplight operation is okay, go to next step. If stoplights DO NOT operate

correctly, check and repair stoplight system as necessary. See WIRING DIAGRAMS

.

2. Perform CANCEL SWITCHES test under CRUISE CONTROL FUNCTION TEST

under TROUBLE

SHOOTING. If stoplight input signal is not as specified, go to next step. If stoplight input signal is as

specified, no problem is indicated at this time. Fault may be intermittent. If sent here from SYMPTOM

DIAGNOSIS, perform next test listed.

3. Remove cruise control ECU with connector attached. See Fig. 1

. Turn ignition switch to ON position.

Backprobing cruise control ECU connector, measure voltage between ground and cruise control ECU

connector terminal No. 2 (Green/White wire). With brake pedal depressed, battery voltage should exist.

With brake pedal released, voltage should be less than one volt. If voltage is not as specified, go to next

step. If voltage is as specified, no problem is indicated at this time. Fault may be intermittent. If sent here

from SYMPTOM DIAGNOSIS, perform next test listed.

4. Check for open circuit in wiring harness and connectors between cruise control ECU and stoplight switch.

Repair as necessary and retest system. If wiring harness and connectors are okay, replace cruise control

ECU and retest system.

IDLE SIGNAL CIRCUIT

1. Remove cruise control ECU with connector attached. Disconnect Engine Control Module (ECM) 16-pin

connector. ECM is located behind bottom center of instrument panel, in front of console. Turn ignition

switch to ON position. Backprobing connector, measure voltage between ground and cruise control ECU

connector terminal No. 13 (Blue wire).

2. With throttle valve fully open, battery voltage should exist. With throttle valve fully closed, voltage

should be less than 2 volts. If voltage is not as specified, go to next step. If voltage is as specified, no

problem is indicated at this time. Fault may be intermittent. If sent here from SYMPTOM DIAGNOSIS,

perform next test listed.

3. Check wiring harness and connectors between ECM and TP sensor. Repair as necessary and retest

system. If wiring harness and connectors are okay, go to next step.

4. Disconnect TP sensor 3-pin Black connector. Measure resistance between TP sensor connector terminals

No. 2 (Brown wire) and No. 3 (Blue/Red wire). Resistance should be 2000-10,200 ohms with throttle

valve fully opened, and 200-6300 ohms with throttle valve fully closed. If resistance is as specified, go to

next step. If resistance is not as specified, replace TP sensor and retest system.

5. Check wiring harness and connectors between cruise control ECU and TP sensor, and between TP sensor

and ground. Repair as necessary and retest system. If wiring harness and connectors are okay, replace

cruise control ECU and retest system.

ELECTRONICALLY CONTROLLED TRANSMISSION (ECT) CIRCUIT

1. Start engine and bring to operating temperature. Drive vehicle and ensure overdrive operation is turned on

and off when overdrive ON-OFF switch is operated. If overdrive switch is okay, go to next step. If

overdrive switch is not okay, see appropriate ELECTRONIC CONTROLS article in AUTOMATIC NOTE: Ensure Throttle Position (TP) sensor circuit is operating as designed, and no

fault codes are present for TP sensor circuit. See appropriate ON-VEHICLE

ADJUSTMENTS article in ENGINE PERFORMANCE.

1999 Toyota RAV4

1999 ACCESSORIES & EQUIPMENT Cruise Control Systems - RAV4

Microsoft

Sunday, November 22, 2009 10:52:01 AMPage 11 © 2005 Mitchell Repair Information Company, LLC.

Page 537 of 1632

FUNCTION TEST under TROUBLE SHOOTING. If clutch switch input signal is not as specified, go to

next step. If clutch switch input signal is as specified, no problem is indicated at this time. Fault may be

intermittent. If sent here from SYMPTOM DIAGNOSIS, perform next test listed.

3. Remove cruise control ECU with connector attached. See Fig. 1

. Turn ignition switch to ON position.

Using voltmeter positive lead, backprobe cruise control ECU connector terminal No. 3 (Blue/Black wire)

with negative lead to ground. With clutch pedal depressed, battery voltage should exist. With clutch pedal

released, voltage should be less than one volt. If voltage is not as specified, go to next step. If voltage is

as specified, no problem is indicated at this time. Fault may be intermittent. If sent here from SYMPTOM

DIAGNOSIS, perform next test listed.

4. Check wiring harness and connectors between cruise control ECU and TURN & GAUGE fuses in

instrument panel junction block. Repair as necessary. If wiring harness and connectors are okay, replace

cruise control ECU and retest system.

CRUISE CONTROL ECU POWER SOURCE CIRCUIT

1. Locate ECU-IG (10-amp) fuse in instrument panel junction block. See Fig. 1

. Remove ECU-IG fuse and

ensure fuse continuity. If fuse is okay, go to next step. If fuse is not okay, check for short between cruise

control ECU connector terminal No. 9 (Black/Yellow wire) and ECU-IG fuse.

2. Remove cruise control ECU with connector attached. See Fig. 1

. Turn ignition switch to ON position.

Using voltmeter, backprobe between cruise control ECU connector terminals No. 9 (Black/Yellow wire)

and No. 16 (White/Black wire). If battery voltage is not present, go to next step. If battery voltage is

present, no problem is indicated at this time. Fault may be intermittent. If sent here from SYMPTOM

DIAGNOSIS, perform next test listed.

3. Turn ignition switch to OFF position. Backprobing connector, measure resistance between ground and

terminal No. 16 (White/Black wire) at cruise control ECU connector. If resistance is less than one ohm,

check wiring harness or connector between cruise control ECU connector and battery. Repair as

necessary and retest system. If resistance is one ohm or more, repair wiring harness or connector between

cruise control ECU connector terminal No. 16 (White/Black wire) and ground. Retest system.

CRUISE CONTROL INDICATOR LIGHT CIRCUIT

1. Turn ignition switch to ON position. Backprobing connector, measure voltage between ground and

terminal No. 4 (Green/Red wire) at cruise control ECU connector. With cruise control switch in OFF

position, battery voltage should be present. With cruise control switch in ON position, voltage should be

less than 1.2 volts.

2. If voltage is as specified, no problem is indicated at this time. Fault may be intermittent. If sent here from

SYMPTOM DIAGNOSIS, perform next test listed. If voltage is not as specified, check instrument

cluster. See appropriate INSTRUMENT PANELS article. Repair as necessary. If instrument cluster is

okay, replace cruise control ECU and retest system.

DIAGNOSTIC CIRCUIT

1. Locate Data Link Connector (DLC) No. 1 in right side of engine compartment, near shock tower.

Connect voltmeter positive lead to terminal Tc and negative lead to terminal E1. See Fig. 2

. Turn

ignition switch to ON position. If battery voltage is not present, go to next step. If battery voltage is

present, no problem is indicated at this time. Fault ma

y be intermittent. If sent here from SYMPTOM

1999 Toyota RAV4

1999 ACCESSORIES & EQUIPMENT Cruise Control Systems - RAV4

Microsoft

Sunday, November 22, 2009 10:52:01 AMPage 13 © 2005 Mitchell Repair Information Company, LLC.

Page 540 of 1632

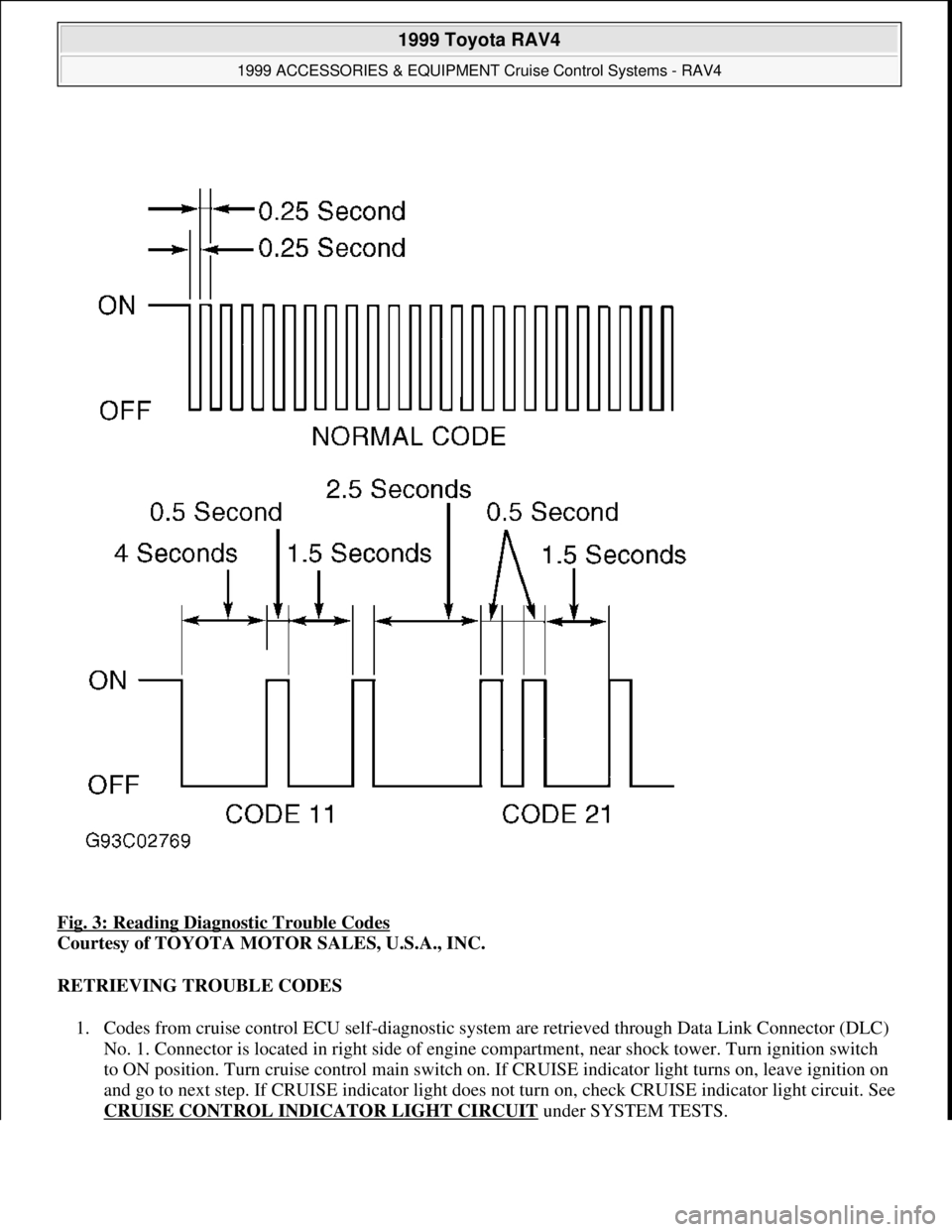

Fig. 3: Reading Diagnostic Trouble Codes

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

RETRIEVING TROUBLE CODES

1. Codes from cruise control ECU self-diagnostic system are retrieved through Data Link Connector (DLC)

No. 1. Connector is located in right side of engine compartment, near shock tower. Turn ignition switch

to ON position. Turn cruise control main switch on. If CRUISE indicator light turns on, leave ignition on

and go to next step. If CRUISE indicator light does not turn on, check CRUISE indicator light circuit. See

CRUISE CONTROL INDICATOR LIGHT CIRCUIT

under SYSTEM TESTS.

1999 Toyota RAV4

1999 ACCESSORIES & EQUIPMENT Cruise Control Systems - RAV4

Microsoft

Sunday, November 22, 2009 10:52:01 AMPage 16 © 2005 Mitchell Repair Information Company, LLC.

Page 704 of 1632

Inspection

1. Inspect cylinder head warpage at cylinder block, exhaust manifold and intake manifold surfaces. Replace

cylinder head if warpage exceeds specification. See CYLINDER HEAD

table under ENGINE

SPECIFICATIONS.

2. Inspect cylinder block deck surface for warpage. Replace cylinder block if deck surface warpage exceeds

specification. See CYLINDER BLOCK

table under ENGINE SPECIFICATIONS.

3. Inspect intake and exhaust manifold machined surfaces for warpage. Replace component if warpage

exceeds .0118" (.300 mm). Inspect camshaft and components. See CAMSHAFT

.

4. Measure valve lifter diameter and bore diameter. Ensure oil clearance is within specification. Replace

components if not within specification. See VALVE LIFTERS

table under ENGINE

SPECIFICATIONS.

Installation

1. Apply adhesive to 2 or 3 threads of oil pressure switch, and install switch. Install NEW insulator at

bottom of fuel injector and NEW grommet on top of fuel injector. Coat NEW "O" rings with gasoline and

install on fuel injector.

2. Install 2 spacers on cylinder head. Install fuel injectors on cylinder head. Install fuel delivery pipe on fuel

injectors. Using twisting motion, push fuel injectors into fuel delivery pipe.

3. Install and slightly tighten fuel delivery pipe-to-cylinder head bolts. Ensure all fuel injectors rotate

smoothly. If fuel injector fails to rotate smoothly, check for improperly installed or damaged "O" rings.

4. Position electrical connector on fuel injector facing toward top of engine. Tighten fuel delivery pipe-to-

cylinder head bolts to specification. See TORQUE SPECIFICATIONS

.

5. Using NEW gasket, install intake manifold. Install and tighten bolts/nuts to specification. See TORQUE

SPECIFICATIONS . Install air tube on side of intake manifold.

6. Install adjusting shims and valve lifters in original location on cylinder head (if removed). Ensure valve

lifters rotate smoothly in cylinder head.

7. Install NEW gasket for cylinder head on cylinder block. Ensure all holes in gasket align with holes in

cylinder block.

8. Install cylinder head. Coat threads and bolt-to-cylinder contact surfaces on cylinder head bolts with

engine oil. Install and tighten cylinder head bolts in several steps, to specification in sequence. See Fig.

15 . See TORQUE SPECIFICATIONS .

9. If removed, install spark plug tubes. Install camshafts using proper procedure. See CAMSHAFT

. Install

No. 3 timing belt cover. Install and tighten bolts to specification. See TORQUE SPECIFICATIONS

.

10. To install remaining components, reverse removal procedure. If camshaft or cylinder head components

are serviced, adjust valve clearance. See VALVE CLEARANCE ADJUSTMENT

under

ADJUSTMENTS.

11. Before installing gasket and valve cover, apply sealant at front and rear valve cover areas on cylinder

head. See Fig. 6

. Using NEW gasket, install valve cover.

12. Install grommets in original location with marking on grommet aligned in designated area. See Fig. 7

.

Install and tighten valve cover nuts to specification. See TORQUE SPECIFICATIONS

.

13. Install VSV for EGR. Connect ground cable to intake manifold with bolt. Connect knock sensor

connector. Connect power steerin

g idle-up air hoses to air tube. On A/T models, connect A/T throttle

1999 Toyota RAV4

1999-2000 ENGINES 2.0L 4-Cylinder

Microsoft

Sunday, November 22, 2009 10:22:26 AMPage 21 © 2005 Mitchell Repair Information Company, LLC.

Page 769 of 1632

1. Install NEW insulator at bottom of fuel injector and NEW grommet on top of fuel injector. Coat NEW

"O" rings with gasoline and install on fuel injector.

2. Install 2 spacers on cylinder head. Install fuel injectors on cylinder head. Install fuel delivery pipe on fuel

injectors. Using twisting motion, push fuel injectors into fuel delivery pipe.

3. Install and slightly tighten fuel delivery pipe-to-cylinder head bolts. Ensure all fuel injectors rotate

smoothly. If fuel injector fails to rotate smoothly, check for improperly installed or damaged "O" rings.

4. Position electrical connector on fuel injector facing toward top of engine. Tighten fuel delivery pipe-to-

cylinder head bolts to specification. See TORQUE SPECIFICATIONS

.

5. Using NEW gasket, install intake manifold. Install and tighten bolts/nuts to specification. See TORQUE

SPECIFICATIONS . Install air tube on side of intake manifold.

6. Install adjusting shims and valve lifters in original location on cylinder head (if removed). Ensure valve

lifters rotate smoothly in cylinder head.

7. Install NEW gasket for cylinder head on cylinder block. Ensure all holes in gasket align with holes in

cylinder block.

8. Install cylinder head. Coat threads and bolt-to-cylinder contact surfaces on cylinder head bolts with

engine oil. Install and tighten cylinder head bolts to specification in sequence. See Fig. 15

. See

TORQUE SPECIFICATIONS

.

9. Install camshafts using proper procedure. See CAMSHAFTS. Install No. 3 timing belt cover. Install and

tighten bolts to specification. See TORQUE SPECIFICATIONS

.

10. To install remaining components, reverse removal procedure. If camshaft or cylinder head components

are serviced, adjust valve clearance. See VALVE CLEARANCE ADJUSTMENT

under

ADJUSTMENTS.

11. Before installing gasket and valve cover, apply sealant at front and rear valve cover areas on cylinder

head. See Fig. 4

. Using NEW gasket, install valve cover.

12. Install grommets in original location with marking on grommet aligned in designated area. See Fig. 5

.

Install and tighten valve cover nuts to specification. See TORQUE SPECIFICATIONS

.

13. Install NEW throttle body gasket with protruding area on gasket facing toward bottom of throttle body.

On throttle bodies using 4 mounting bolts, ensure longer bolts are installed in 2 lower bolt holes.

14. Install NEW "O" ring on coolant by-pass pipe and NEW gasket on water pump cover before installing

coolant by-pass pipe. Apply soapy water solution on "O" ring before installing coolant by-pass pipe. Use

NEW gasket when installing catalytic converter on exhaust manifold.

15. Use NEW gasket and NEW nuts when installing front exhaust pipe on front catalytic converter. Ensure

all bolts/nuts are loosely installed on front exhaust pipe before tightening to specification. See TORQUE

SPECIFICATIONS .

16. Install NEW "O" ring on distributor. Coat "O" ring with engine oil. Rotate crankshaft clockwise, as

viewed from timing belt end of engine, so cylinder No. 1 is at TDC on compression stroke and timing

mark on crankshaft pulley aligns with "0" mark on timing belt cover. Cylinder No. 1 is front cylinder at

timing belt end of engine.

17. Ensure slot area on intake camshaft is positioned vertically. Rotate drive coupling on distributor so cutout

aligns with alignment mark on distributor housing. See Fig. 16

.

18. Install distributor so center of flange on distributor is aligned with bolt hole on cylinder head. Install

distributor hol

d-down bolt. Adjust control cables and ignition timing. Fill cooling system.

1997 Toyota RAV4

2.0L 4-CYL 1997-98 ENGINES Toyota 2.0L 4-Cylinder

Microsoft

Sunday, November 22, 2009 10:23:31 AMPage 21 © 2005 Mitchell Repair Information Company, LLC.