clock TOYOTA RAV4 1996 Service Repair Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 1996, Model line: RAV4, Model: TOYOTA RAV4 1996Pages: 1632, PDF Size: 41.64 MB

Page 37 of 1632

The air bag sensor, which deploys air bags, contains a back-up power supply, safing sensor and diagnostic code

memory. Spiral cable (clockspring) maintains a complete circuit to the steering wheel pad.

SYSTEM OPERATION CHECK

Turn ignition switch to ACC or ON position. Air bag warning light in instrument cluster should come on for

about 6 seconds and then go out. If light does not respond as specified, SRS is malfunctioning and needs repair.

See DIAGNOSIS

.

SERVICE PRECAUTIONS

Observe the following precautions when working on SRS:

Before servicing any SRS or steering column component, disable SRS. See DISABLING &

ACTIVATING AIR BAG SYSTEM . Failure to disable system could result in accidental air bag

deployment and personal injury.

When diagnosing SRS, always check for diagnostic codes before disconnecting battery.

After ignition switch is turned to LOCK position and negative battery cable is disconnected, wait at least

90 seconds before working on SRS. SRS is equipped with a back-up power source that may allow air bag

to deploy within 90 seconds of disconnecting negative battery cable.

In a minor collision in which air bags do not deploy, steering wheel pad must be inspected.

NEVER use air bag parts from another vehicle. Replace air bag parts with new parts.

Air bag sensor assembly contains mercury. After replacement, DO NOT destroy the old part. When

scrapping vehicle or replacing air bag sensor assembly, remove air bag sensor assembly and dispose of as

toxic waste.

Never disassemble or repair system components. Replace cracked, dented or otherwise damaged system

components.

Remove air bag sensor if shocks are likely to be applied to the sensor during repairs.

When diagnosing electrical circuits, use a Digital Volt/Ohmmeter (DVOM) with high impedance (10,000

ohms minimum).

Information labels are attached to air bag components. Follow all notices on labels.

After servicing SRS, check air bag warning light to ensure system is functioning properly. See SYSTEM

OPERATION CHECK .

Always wear safety glasses when servicing or handling an air bag.

When placing a live air bag on a bench or other surface, always face air bag and trim cover up, away from

surface. This will reduce motion of module if accidentally deployed.

After deployment, air bag surface may contain deposits of sodium hydroxide which irritates skin. During

clean-up, always wear safety glasses, rubber gloves and long-sleeved shirt. After clean-up, wash hands

using mild soap and water.

When carrying a live air bag module, trim cover must be pointed away from your body to minimize

injury in case of accidental deployment.

If SRS is not fully functional for any reason, vehicle should not be driven until system is repaired and

a

gain becomes operational. DO NOTremove bulbs, modules, sensors or other components or in any way

1996 Toyota 4Runner

AIR BAG RESTRAINT SYSTEM 1996 ACCESSORIES/SAFETY EQUIPMENT Toyota Air Bag Restraint System

Microsoft

Tuesday, August 18, 2009 7:33:32 PMPage 3 © 2005 Mitchell Repair Information Company, LLC.

Page 43 of 1632

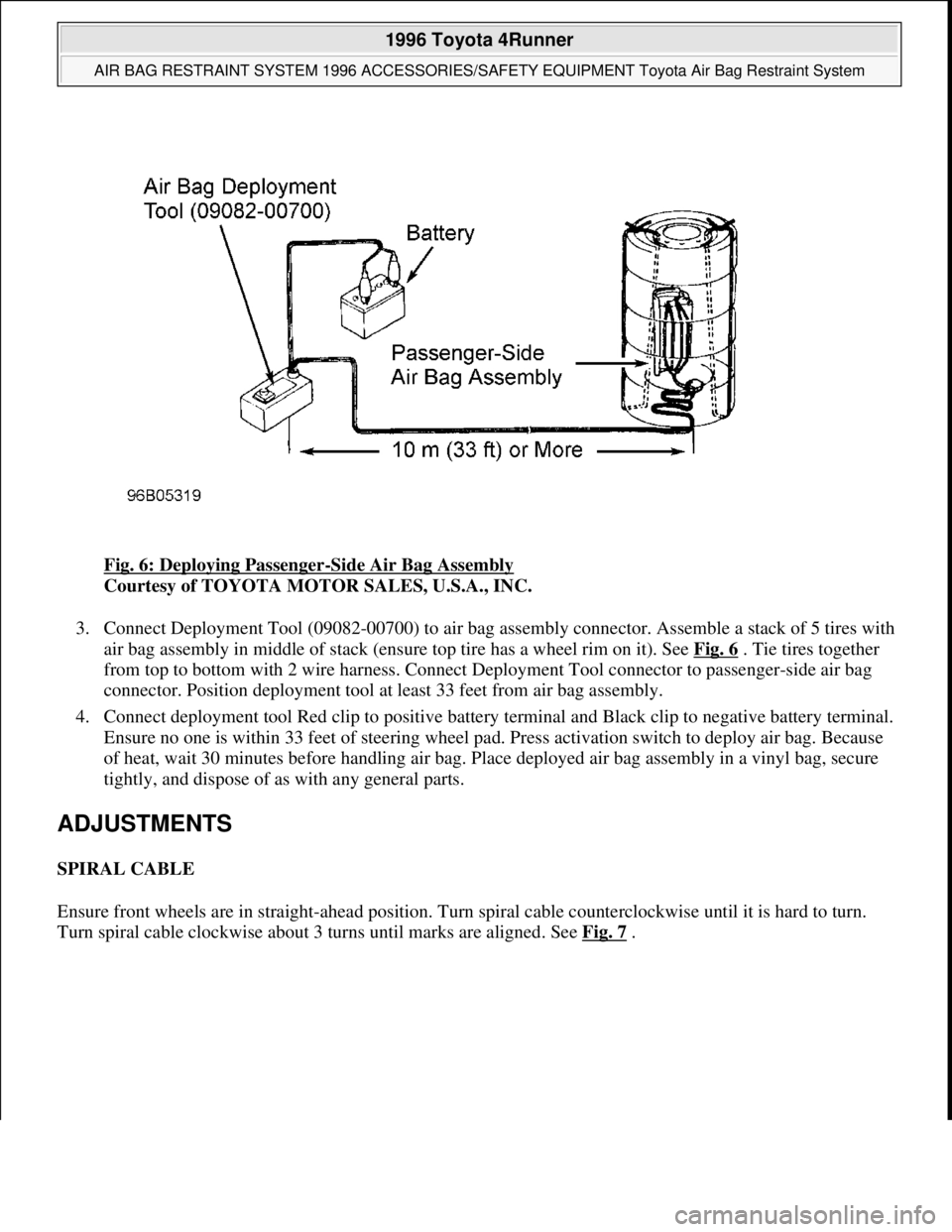

Fig. 6: Deploying Passenger-Side Air Bag Assembly

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

3. Connect Deployment Tool (09082-00700) to air bag assembly connector. Assemble a stack of 5 tires with

air bag assembly in middle of stack (ensure top tire has a wheel rim on it). See Fig. 6

. Tie tires together

from top to bottom with 2 wire harness. Connect Deployment Tool connector to passenger-side air bag

connector. Position deployment tool at least 33 feet from air bag assembly.

4. Connect deployment tool Red clip to positive battery terminal and Black clip to negative battery terminal.

Ensure no one is within 33 feet of steering wheel pad. Press activation switch to deploy air bag. Because

of heat, wait 30 minutes before handling air bag. Place deployed air bag assembly in a vinyl bag, secure

tightly, and dispose of as with any general parts.

ADJUSTMENTS

SPIRAL CABLE

Ensure front wheels are in straight-ahead position. Turn spiral cable counterclockwise until it is hard to turn.

Turn spiral cable clockwise about 3 turns until marks are ali

gned. See Fig. 7.

1996 Toyota 4Runner

AIR BAG RESTRAINT SYSTEM 1996 ACCESSORIES/SAFETY EQUIPMENT Toyota Air Bag Restraint System

Microsoft

Tuesday, August 18, 2009 7:33:32 PMPage 9 © 2005 Mitchell Repair Information Company, LLC.

Page 65 of 1632

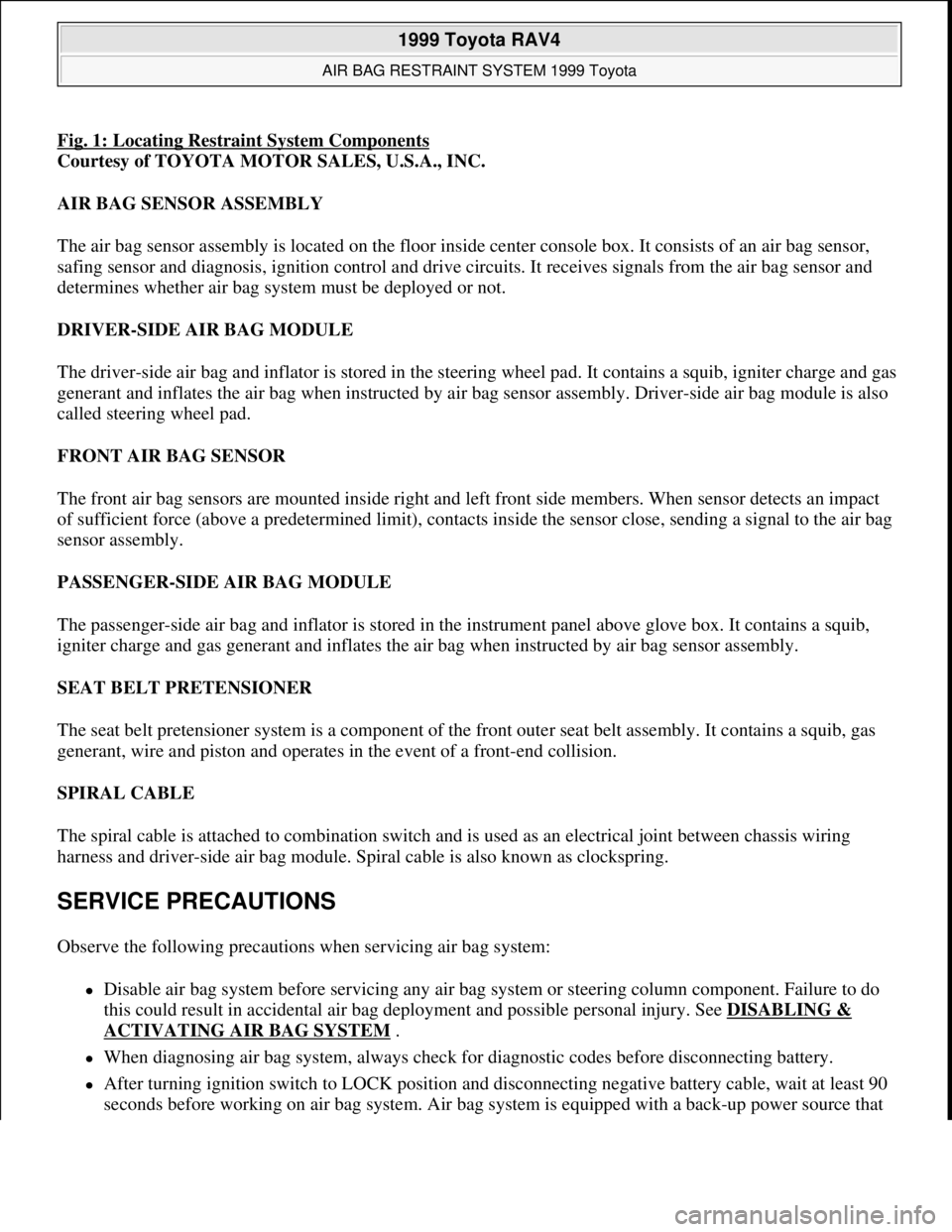

Fig. 1: Locating Restraint System Components

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

AIR BAG SENSOR ASSEMBLY

The air bag sensor assembly is located on the floor inside center console box. It consists of an air bag sensor,

safing sensor and diagnosis, ignition control and drive circuits. It receives signals from the air bag sensor and

determines whether air bag system must be deployed or not.

DRIVER-SIDE AIR BAG MODULE

The driver-side air bag and inflator is stored in the steering wheel pad. It contains a squib, igniter charge and gas

generant and inflates the air bag when instructed by air bag sensor assembly. Driver-side air bag module is also

called steering wheel pad.

FRONT AIR BAG SENSOR

The front air bag sensors are mounted inside right and left front side members. When sensor detects an impact

of sufficient force (above a predetermined limit), contacts inside the sensor close, sending a signal to the air bag

sensor assembly.

PASSENGER-SIDE AIR BAG MODULE

The passenger-side air bag and inflator is stored in the instrument panel above glove box. It contains a squib,

igniter charge and gas generant and inflates the air bag when instructed by air bag sensor assembly.

SEAT BELT PRETENSIONER

The seat belt pretensioner system is a component of the front outer seat belt assembly. It contains a squib, gas

generant, wire and piston and operates in the event of a front-end collision.

SPIRAL CABLE

The spiral cable is attached to combination switch and is used as an electrical joint between chassis wiring

harness and driver-side air bag module. Spiral cable is also known as clockspring.

SERVICE PRECAUTIONS

Observe the following precautions when servicing air bag system:

Disable air bag system before servicing any air bag system or steering column component. Failure to do

this could result in accidental air bag deployment and possible personal injury. See DISABLING &

ACTIVATING AIR BAG SYSTEM .

When diagnosing air bag system, always check for diagnostic codes before disconnecting battery.

After turning ignition switch to LOCK position and disconnecting negative battery cable, wait at least 90

seconds before workin

g on air bag system. Air bag system is equipped with a back-up power source that

1999 Toyota RAV4

AIR BAG RESTRAINT SYSTEM 1999 Toyota

Microsoft

Sunday, November 22, 2009 10:33:22 AMPage 2 © 2005 Mitchell Repair Information Company, LLC.

Page 66 of 1632

may allow air bag to deploy until 90 seconds after disconnecting negative battery cable.

If vehicle was in a minor collision but air bags did not deploy, inspect all system components for any sign

of damage, and replace as necessary.

Never use air bag system components from another vehicle. Replace air bag system components with new

parts.

Remove air bag sensor assembly if repairing the vehicle requires impacting (shocking) the vehicle.

Air bag sensor assembly contains mercury. After replacement, DO NOT destroy old part. When

scrapping vehicle or replacing air bag sensor assembly, remove air bag sensor assembly and dispose of it

as toxic waste.

Never disassemble and repair air bag sensor assembly, front air bag sensors, passenger-side or driver-side

air bag modules or seat belt pretensioners.

Replace dropped, cracked, dented or otherwise damaged components.

DO NOT expose air bag sensor assembly, front air bag sensors or air bag modules directly to heat or

flame.

When diagnosing electrical circuits, use a volt/ohm meter with high impedance (10,000 ohms minimum).

Information labels are attached to air bag components. Follow all notices on labels.

After work on air bag system is complete, check AIR BAG warning light to ensure system is functioning

properly. See SYSTEM OPERATION CHECK

.

Always wear safety glasses when servicing or handling an air bag.

When placing a live air bag on a bench or other surface, always face air bag and trim cover up and away

from surface. This will reduce motion of module if it is accidentally deployed.

After deployment, air bag surface may contain deposits of sodium hydroxide, which irritates skin. Always

wear safety glasses, rubber gloves, and long-sleeved shirt during clean-up. After clean-up, wash hands

using mild soap and water.

Carry a live air bag module with trim cover (air bag) pointed away from your body to minimize injury in

case accidental deployment.

If air bag system is not fully functional for any reason, vehicle should not be driven until system is

repaired and again becomes operational. DO NOT remove bulbs, modules, sensors or other components,

or in any way disable system from operating normally. If air bag system is not functional, park vehicle

until it is repaired and functions properly.

ADJUSTMENTS

SPIRAL CABLE

Ensure front wheels are in straight-ahead position. Turn spiral cable counterclockwise until it becomes difficult

to turn. Turn spiral cable clockwise about 2 1/2 turns to align match marks. See Fig. 2

. Install steering wheel.

1999 Toyota RAV4

AIR BAG RESTRAINT SYSTEM 1999 Toyota

Microsoft

Sunday, November 22, 2009 10:33:22 AMPage 3 © 2005 Mitchell Repair Information Company, LLC.

Page 151 of 1632

SUPRA

TORQUE SPECIFICATIONS (SUPRA)

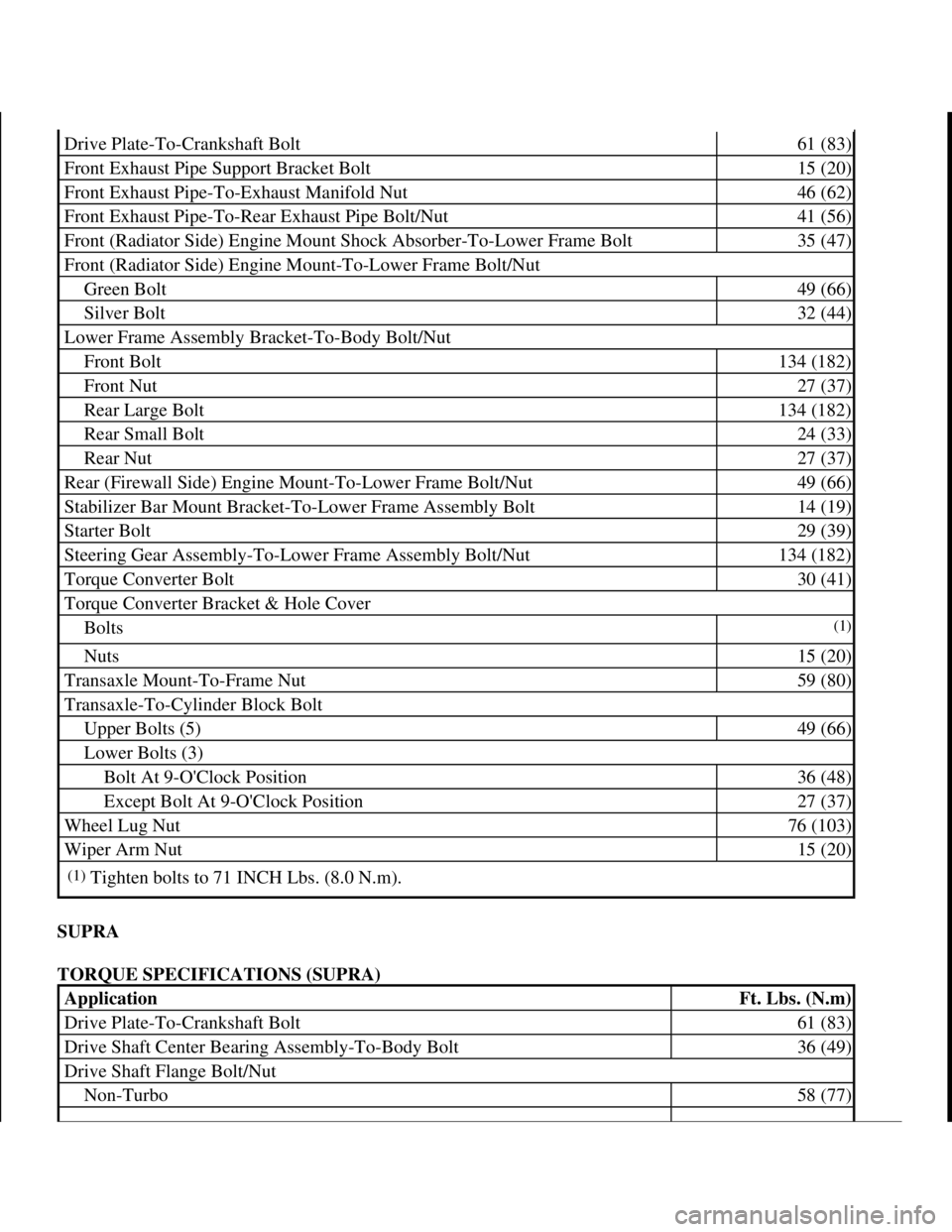

Drive Plate-To-Crankshaft Bolt61 (83)

Front Exhaust Pipe Support Bracket Bolt15 (20)

Front Exhaust Pipe-To-Exhaust Manifold Nut46 (62)

Front Exhaust Pipe-To-Rear Exhaust Pipe Bolt/Nut41 (56)

Front (Radiator Side) Engine Mount Shock Absorber-To-Lower Frame Bolt35 (47)

Front (Radiator Side) Engine Mount-To-Lower Frame Bolt/Nut

Green Bolt49 (66)

Silver Bolt32 (44)

Lower Frame Assembly Bracket-To-Body Bolt/Nut

Front Bolt134 (182)

Front Nut27 (37)

Rear Large Bolt134 (182)

Rear Small Bolt24 (33)

Rear Nut27 (37)

Rear (Firewall Side) Engine Mount-To-Lower Frame Bolt/Nut49 (66)

Stabilizer Bar Mount Bracket-To-Lower Frame Assembly Bolt14 (19)

Starter Bolt29 (39)

Steering Gear Assembly-To-Lower Frame Assembly Bolt/Nut134 (182)

Torque Converter Bolt30 (41)

Torque Converter Bracket & Hole Cover

Bolts(1)

Nuts15 (20)

Transaxle Mount-To-Frame Nut59 (80)

Transaxle-To-Cylinder Block Bolt

Upper Bolts (5)49 (66)

Lower Bolts (3)

Bolt At 9-O'Clock Position36 (48)

Except Bolt At 9-O'Clock Position27 (37)

Wheel Lug Nut76 (103)

Wiper Arm Nut15 (20)

(1)Tighten bolts to 71 INCH Lbs. (8.0 N.m).

ApplicationFt. Lbs. (N.m)

Drive Plate-To-Crankshaft Bolt61 (83)

Drive Shaft Center Bearing Assembly-To-Body Bolt36 (49)

Drive Shaft Flange Bolt/Nut

Non-Turbo58 (77)

1998 Toyota Avalon XLS

TRANSMISSION SERVICING - A/T 1997-98 TRANSMISSION SERVICING Toyota - Transmission Removal &

Installation

Helpmelearn

November-03-08 10:30:29 AMPage 39 © 2005 Mitchell Repair Information Company, LLC.

Page 174 of 1632

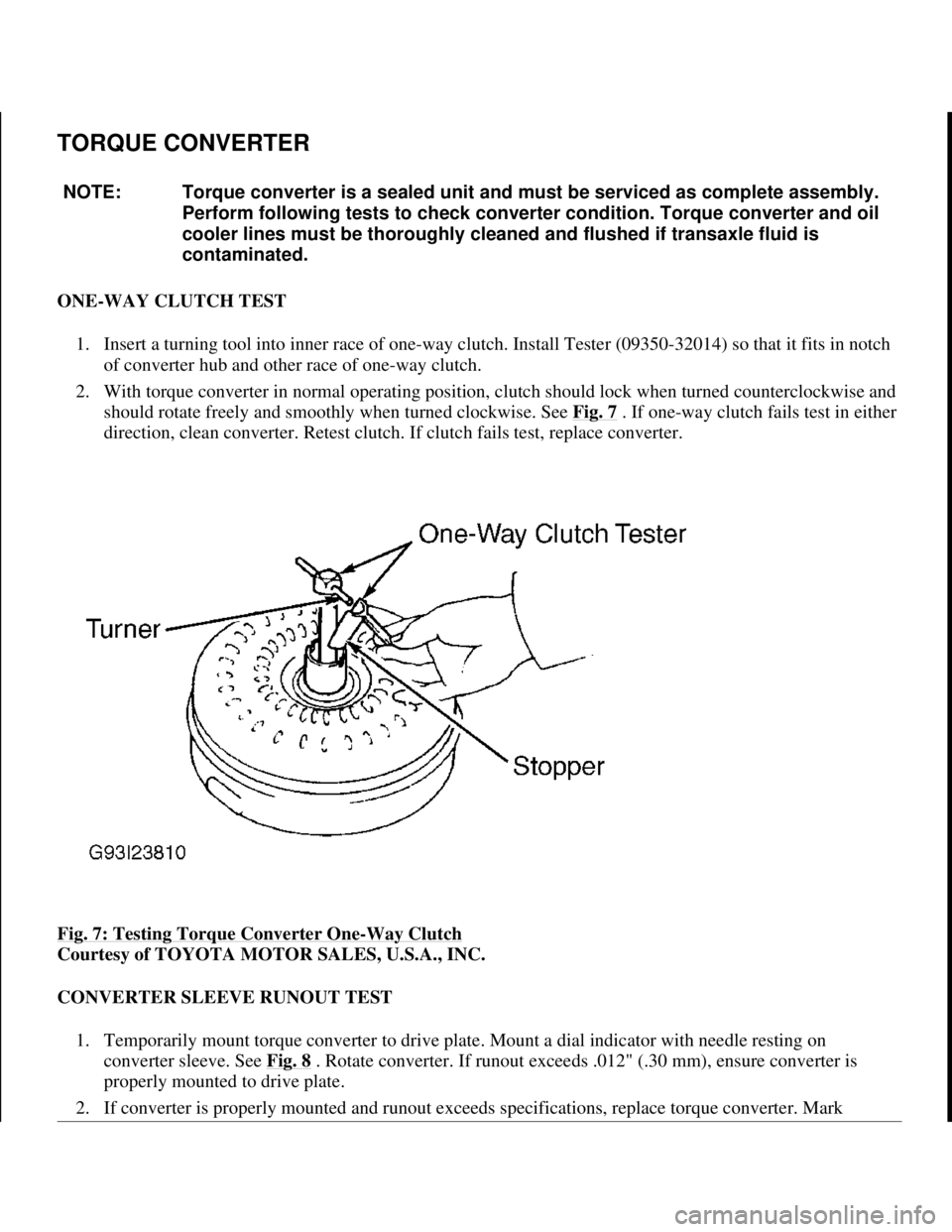

TORQUE CONVERTER

ONE-WAY CLUTCH TEST

1. Insert a turning tool into inner race of one-way clutch. Install Tester (09350-32014) so that it fits in notch

of converter hub and other race of one-way clutch.

2. With torque converter in normal operating position, clutch should lock when turned counterclockwise and

should rotate freely and smoothly when turned clockwise. See Fig. 7

. If one-way clutch fails test in either

direction, clean converter. Retest clutch. If clutch fails test, replace converter.

Fig. 7: Testing Torque Converter One

-Way Clutch

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

CONVERTER SLEEVE RUNOUT TEST

1. Temporarily mount torque converter to drive plate. Mount a dial indicator with needle resting on

converter sleeve. See Fig. 8

. Rotate converter. If runout exceeds .012" (.30 mm), ensure converter is

properly mounted to drive plate.

2. If converter is properl

y mounted and runout exceeds specifications, replace torque converter. Mark NOTE: Torque converter is a sealed unit and must be serviced as complete assembly.

Perform following tests to check converter condition. Torque converter and oil

cooler lines must be thoroughly cleaned and flushed if transaxle fluid is

contaminated.

1998 Toyota Avalon XLS

1997-99 AUTOMATIC TRANSMISSIONS Toyota A-540E, A-540H & A-541E Overhaul

Helpmelearn

November-03-08 10:28:17 AMPage 20 © 2005 Mitchell Repair Information Company, LLC.

Page 192 of 1632

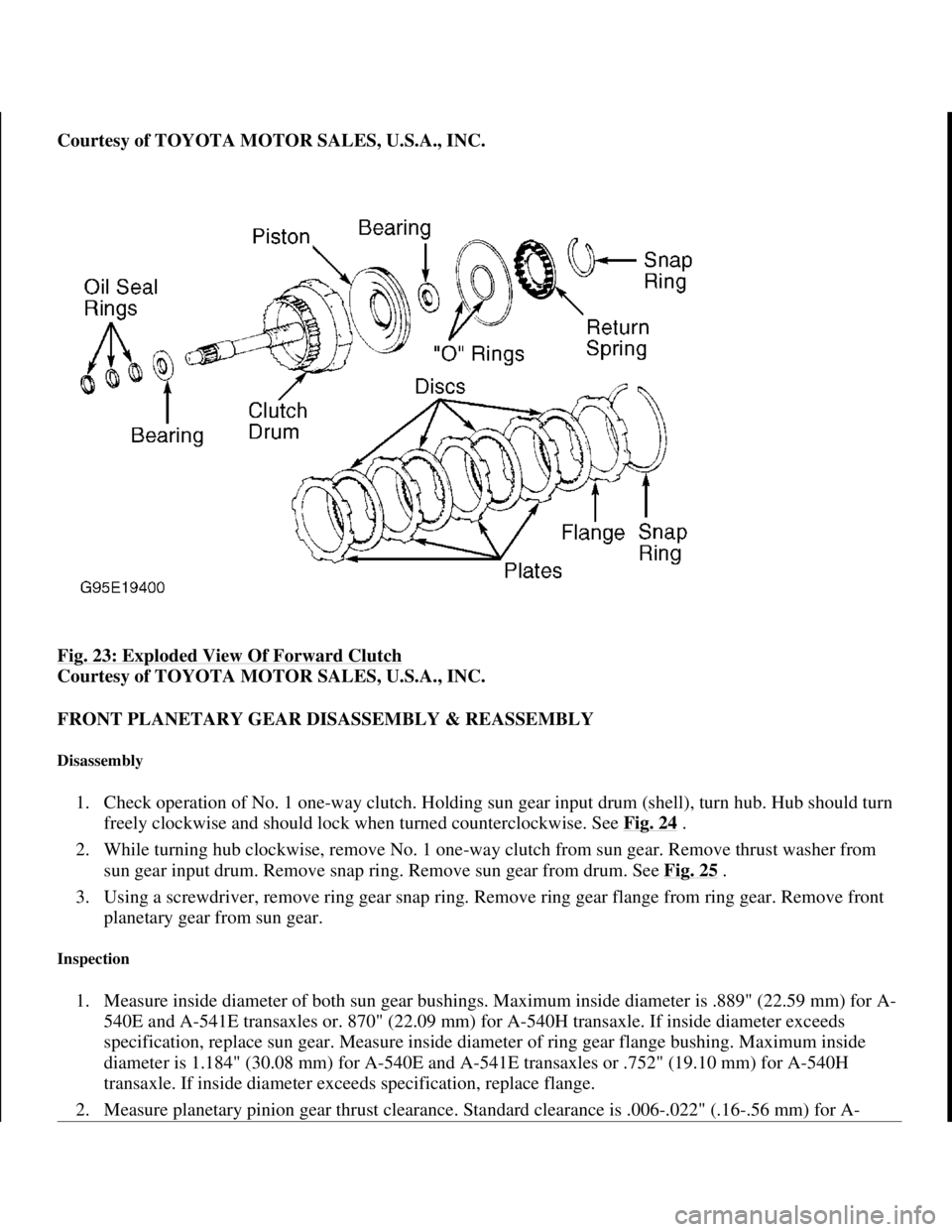

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

Fig. 23: Exploded View Of Forward Clutch

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

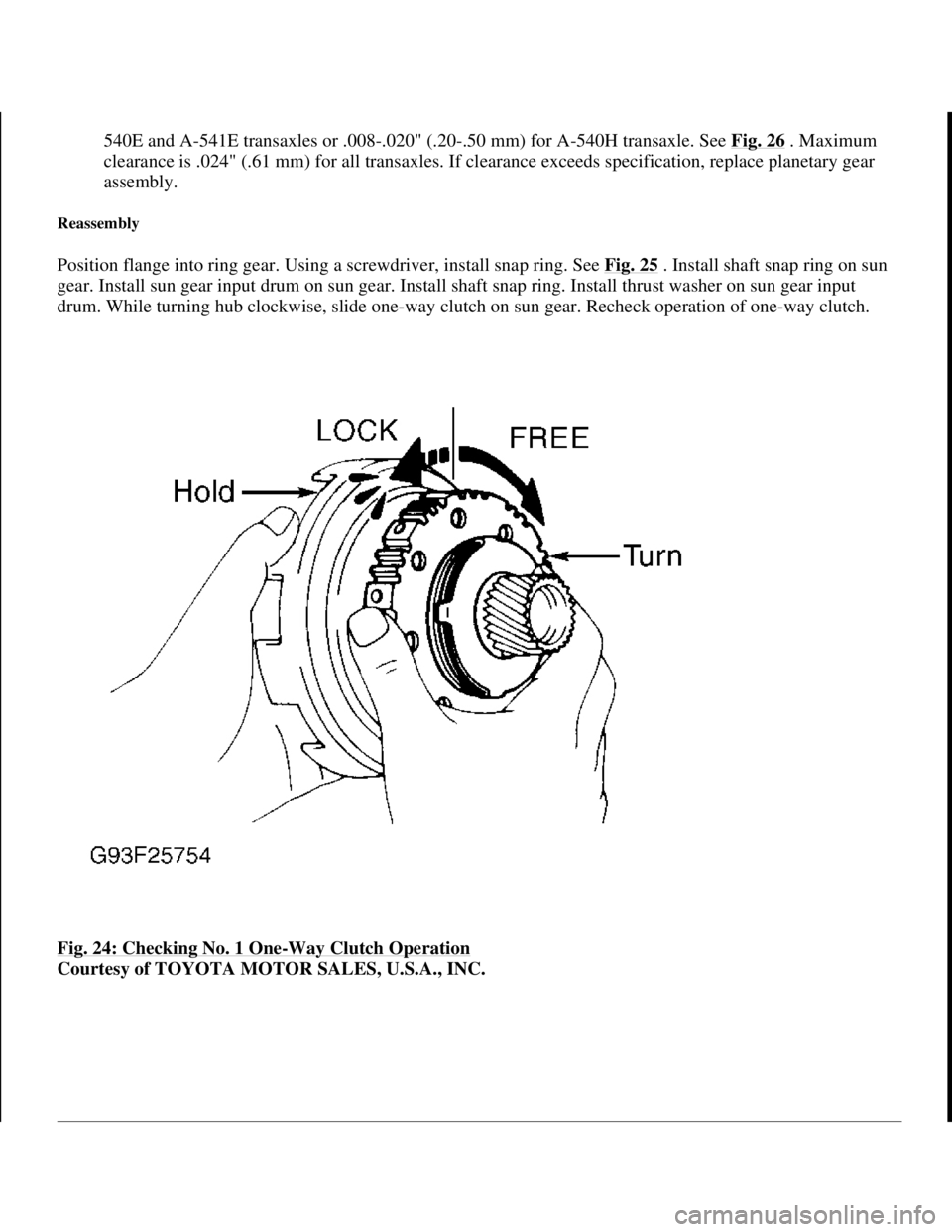

FRONT PLANETARY GEAR DISASSEMBLY & REASSEMBLY

Disassembly

1. Check operation of No. 1 one-way clutch. Holding sun gear input drum (shell), turn hub. Hub should turn

freely clockwise and should lock when turned counterclockwise. See Fig. 24

.

2. While turning hub clockwise, remove No. 1 one-way clutch from sun gear. Remove thrust washer from

sun gear input drum. Remove snap ring. Remove sun gear from drum. See Fig. 25

.

3. Using a screwdriver, remove ring gear snap ring. Remove ring gear flange from ring gear. Remove front

planetary gear from sun gear.

Inspection

1. Measure inside diameter of both sun gear bushings. Maximum inside diameter is .889" (22.59 mm) for A-

540E and A-541E transaxles or. 870" (22.09 mm) for A-540H transaxle. If inside diameter exceeds

specification, replace sun gear. Measure inside diameter of ring gear flange bushing. Maximum inside

diameter is 1.184" (30.08 mm) for A-540E and A-541E transaxles or .752" (19.10 mm) for A-540H

transaxle. If inside diameter exceeds specification, replace flange.

2. Measure planetar

y pinion gear thrust clearance. Standard clearance is .006-.022" (.16-.56 mm) for A-

1998 Toyota Avalon XLS

1997-99 AUTOMATIC TRANSMISSIONS Toyota A-540E, A-540H & A-541E Overhaul

Helpmelearn

November-03-08 10:28:18 AMPage 38 © 2005 Mitchell Repair Information Company, LLC.

Page 193 of 1632

540E and A-541E transaxles or .008-.020" (.20-.50 mm) for A-540H transaxle. See Fig. 26. Maximum

clearance is .024" (.61 mm) for all transaxles. If clearance exceeds specification, replace planetary gear

assembly.

Reassembly

Position flange into ring gear. Using a screwdriver, install snap ring. See Fig. 25 . Install shaft snap ring on sun

gear. Install sun gear input drum on sun gear. Install shaft snap ring. Install thrust washer on sun gear input

drum. While turning hub clockwise, slide one-way clutch on sun gear. Recheck operation of one-way clutch.

Fig. 24: Checking No. 1 One

-Way Clutch Operation

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

1998 Toyota Avalon XLS

1997-99 AUTOMATIC TRANSMISSIONS Toyota A-540E, A-540H & A-541E Overhaul

Helpmelearn

November-03-08 10:28:18 AMPage 39 © 2005 Mitchell Repair Information Company, LLC.

Page 195 of 1632

REAR PLANETARY GEAR DISASSEMBLY & REASSEMBLY

Disassembly

1. Check operation of No. 2 one-way clutch. Hold outer race and turn rear planetary gear. Gear should turn

freely counterclockwise and should lock when turned clockwise. See Fig. 27

. Separate No. 2 one-way

clutch and rear planetary gear.

2. Remove thrust washer(s) from rear side of planetary gear. Remove snap rings and retainers from both

sides. Remove No. 2 one-way clutch from outer race. See Fig. 28

.

Inspection

Measure rear planetary pinion gear thrust clearance. Standard clearance is .006-.022" (.16-.56 mm) for A-540E

and A-541E transaxles or .008-.020" (.20-.50 mm) for A-540H transaxle. Maximum clearance is .024" (.61

mm) for all transaxles. Replace planetary gear assembly if clearance is excessive.

Reassembly

1. Install No. 2 one-way clutch into outer race. Face No. 2 one-way clutch flanged side toward outer race

shiny side. Install retainers and snap rings to both sides of No. 2 one-way clutch.

2. Install planetary gear into No. 2 one-way clutch facing inner race of planetary gear inward toward Black

side of outer race. Check operation of No. 2 one-way clutch. Coat thrust washers with petroleum jelly.

Install thrust washer on both sides of carrier. Ali

gn tab of washers with hollow of carrier.

1998 Toyota Avalon XLS

1997-99 AUTOMATIC TRANSMISSIONS Toyota A-540E, A-540H & A-541E Overhaul

Helpmelearn

November-03-08 10:28:18 AMPage 41 © 2005 Mitchell Repair Information Company, LLC.

Page 223 of 1632

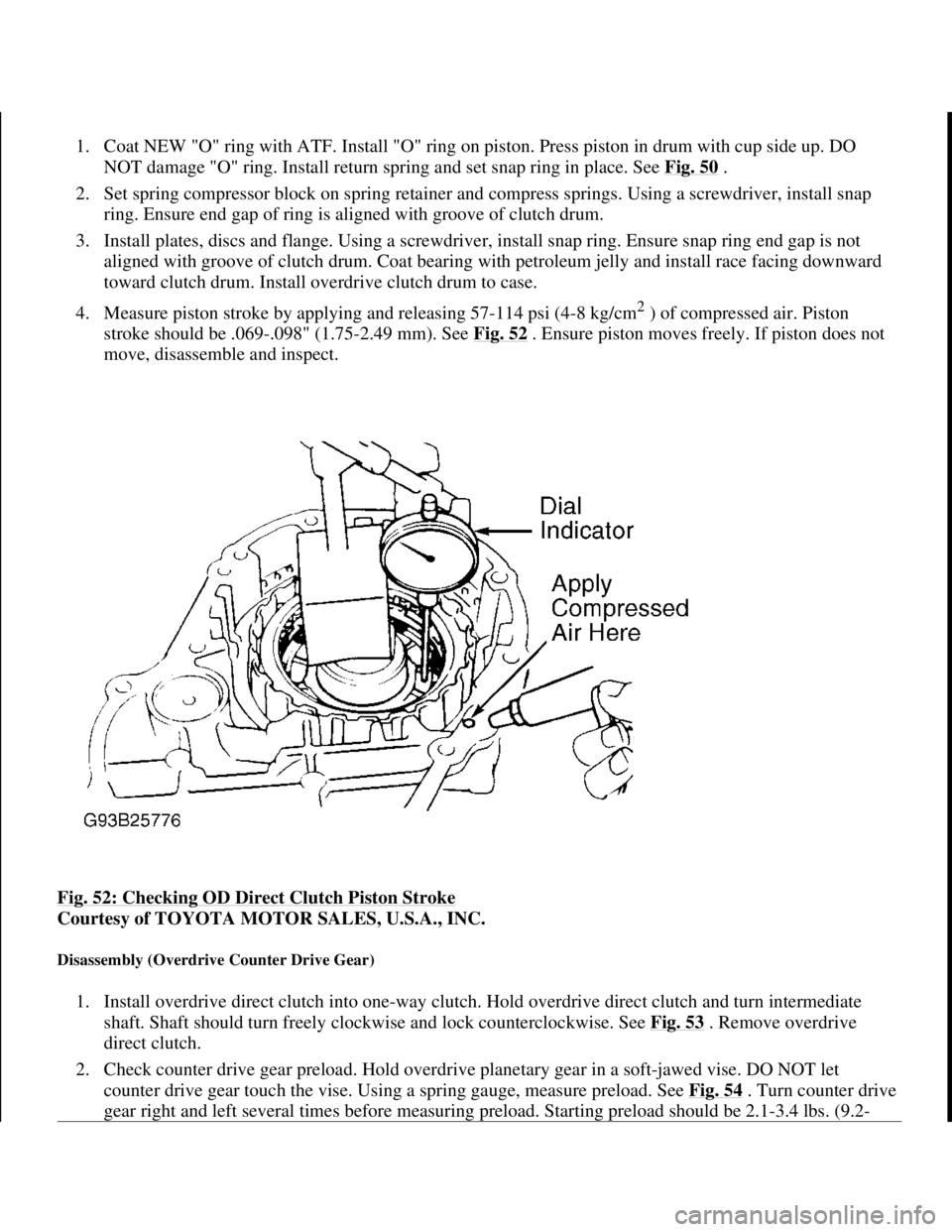

1. Coat NEW "O" ring with ATF. Install "O" ring on piston. Press piston in drum with cup side up. DO

NOT damage "O" ring. Install return spring and set snap ring in place. See Fig. 50

.

2. Set spring compressor block on spring retainer and compress springs. Using a screwdriver, install snap

ring. Ensure end gap of ring is aligned with groove of clutch drum.

3. Install plates, discs and flange. Using a screwdriver, install snap ring. Ensure snap ring end gap is not

aligned with groove of clutch drum. Coat bearing with petroleum jelly and install race facing downward

toward clutch drum. Install overdrive clutch drum to case.

4. Measure piston stroke by applying and releasing 57-114 psi (4-8 kg/cm

2 ) of compressed air. Piston

stroke should be .069-.098" (1.75-2.49 mm). See Fig. 52

. Ensure piston moves freely. If piston does not

move, disassemble and inspect.

Fig. 52: Checking OD Direct Clutch Piston Stroke

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

Disassembly (Overdrive Counter Drive Gear)

1. Install overdrive direct clutch into one-way clutch. Hold overdrive direct clutch and turn intermediate

shaft. Shaft should turn freely clockwise and lock counterclockwise. See Fig. 53

. Remove overdrive

direct clutch.

2. Check counter drive gear preload. Hold overdrive planetary gear in a soft-jawed vise. DO NOT let

counter drive gear touch the vise. Using a spring gauge, measure preload. See Fig. 54

. Turn counter drive

gear right and left several times before measuring preload. Starting preload should be 2.1-3.4 lbs. (9.2-

1998 Toyota Avalon XLS

1997-99 AUTOMATIC TRANSMISSIONS Toyota A-540E, A-540H & A-541E Overhaul

Helpmelearn

November-03-08 10:28:19 AMPage 69 © 2005 Mitchell Repair Information Company, LLC.