engine oil TOYOTA RAV4 2006 Service Repair Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 2006, Model line: RAV4, Model: TOYOTA RAV4 2006Pages: 2000, PDF Size: 45.84 MB

Page 883 of 2000

2GR-FE LUBRICATION – OIL PUMPLU–23

LU

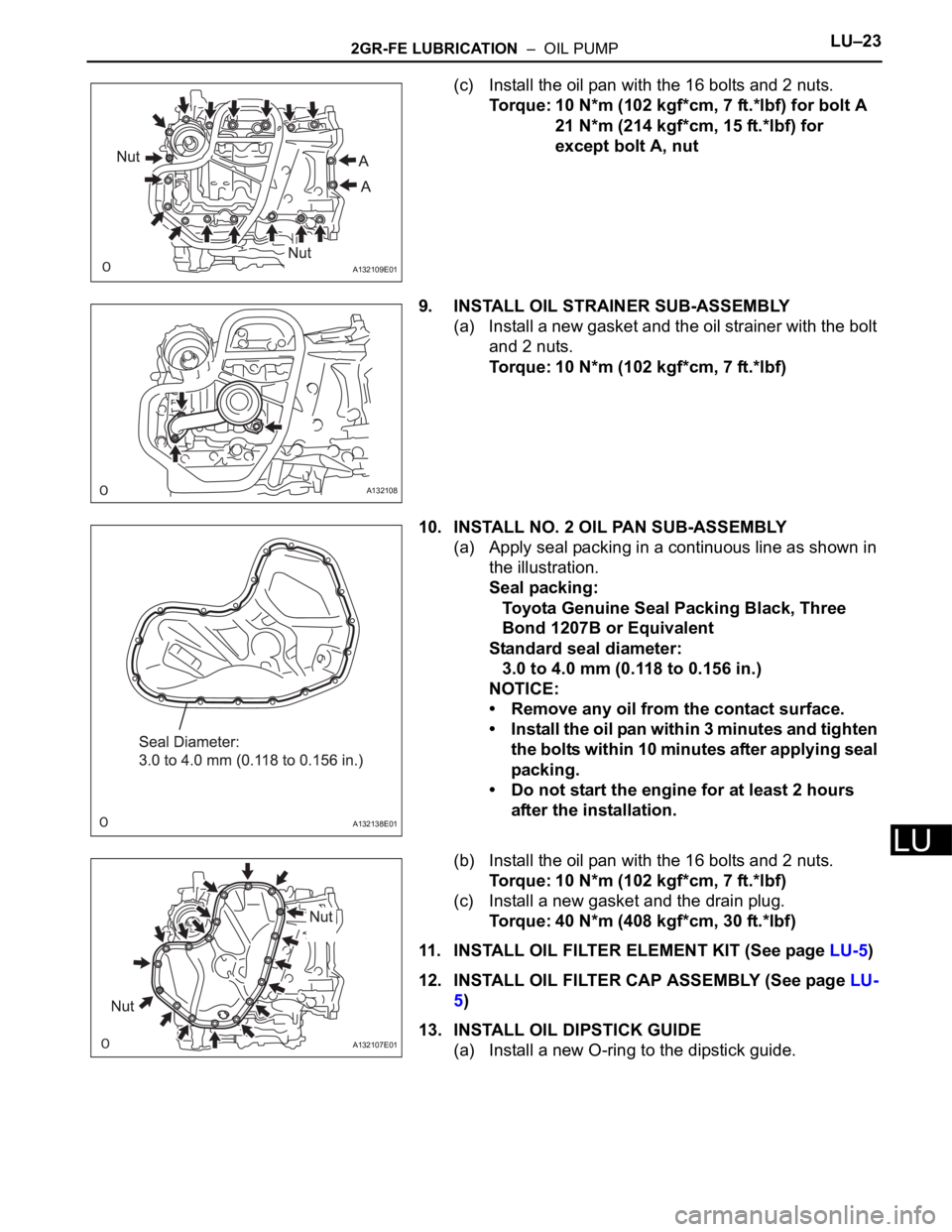

(c) Install the oil pan with the 16 bolts and 2 nuts.

Torque: 10 N*m (102 kgf*cm, 7 ft.*lbf) for bolt A

21 N*m (214 kgf*cm, 15 ft.*lbf) for

except bolt A, nut

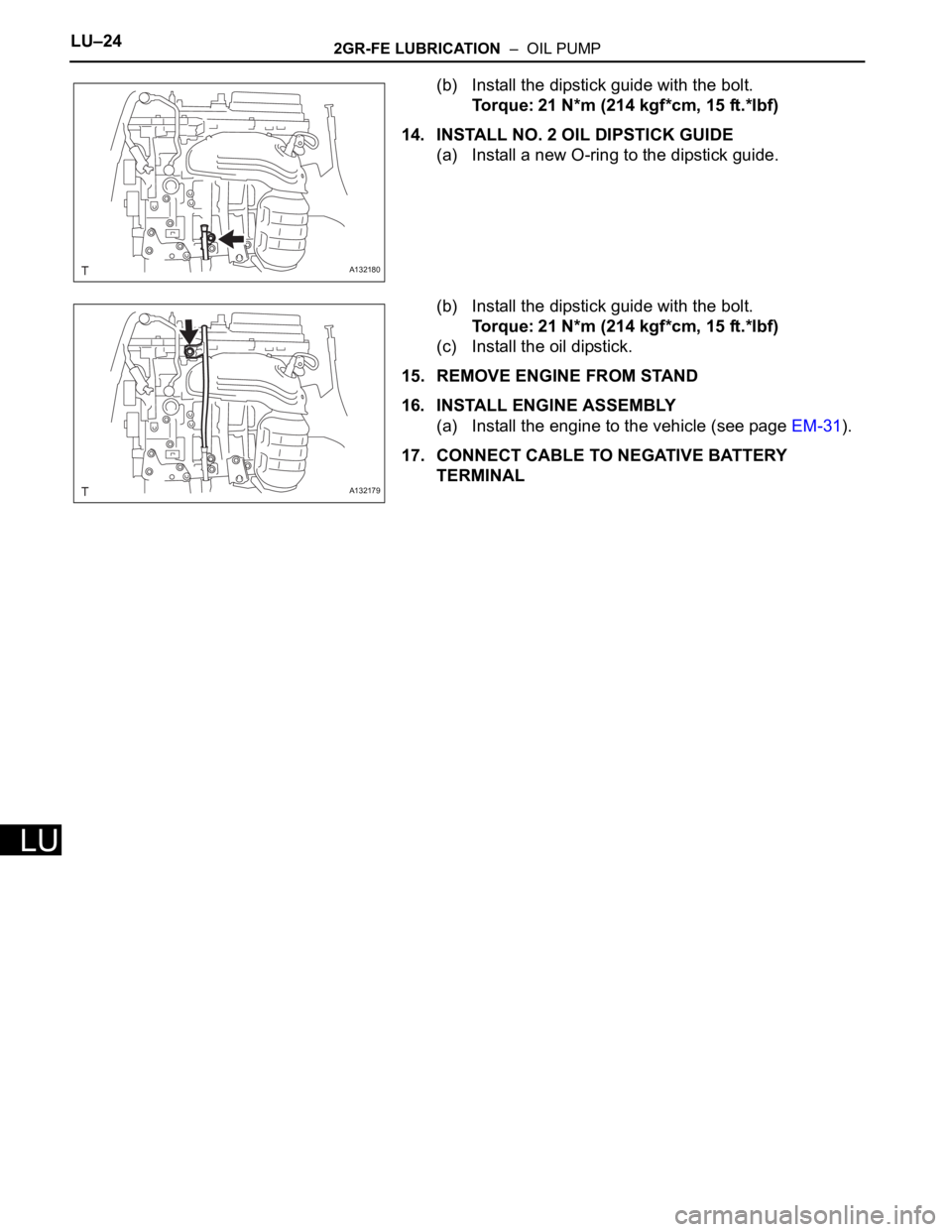

9. INSTALL OIL STRAINER SUB-ASSEMBLY

(a) Install a new gasket and the oil strainer with the bolt

and 2 nuts.

Torque: 10 N*m (102 kgf*cm, 7 ft.*lbf)

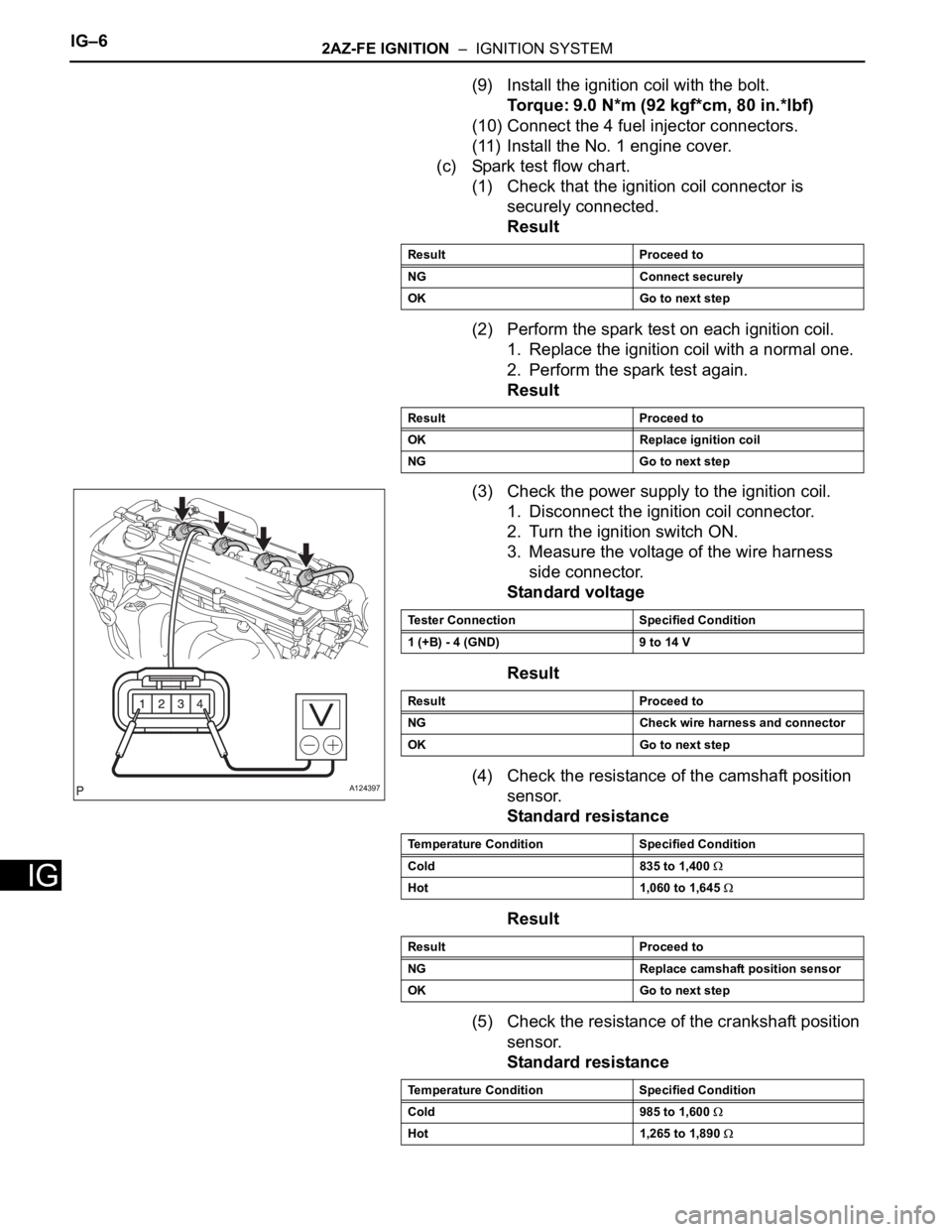

10. INSTALL NO. 2 OIL PAN SUB-ASSEMBLY

(a) Apply seal packing in a continuous line as shown in

the illustration.

Seal packing:

Toyota Genuine Seal Packing Black, Three

Bond 1207B or Equivalent

Standard seal diameter:

3.0 to 4.0 mm (0.118 to 0.156 in.)

NOTICE:

• Remove any oil from the contact surface.

• Install the oil pan within 3 minutes and tighten

the bolts within 10 minutes after applying seal

packing.

• Do not start the engine for at least 2 hours

after the installation.

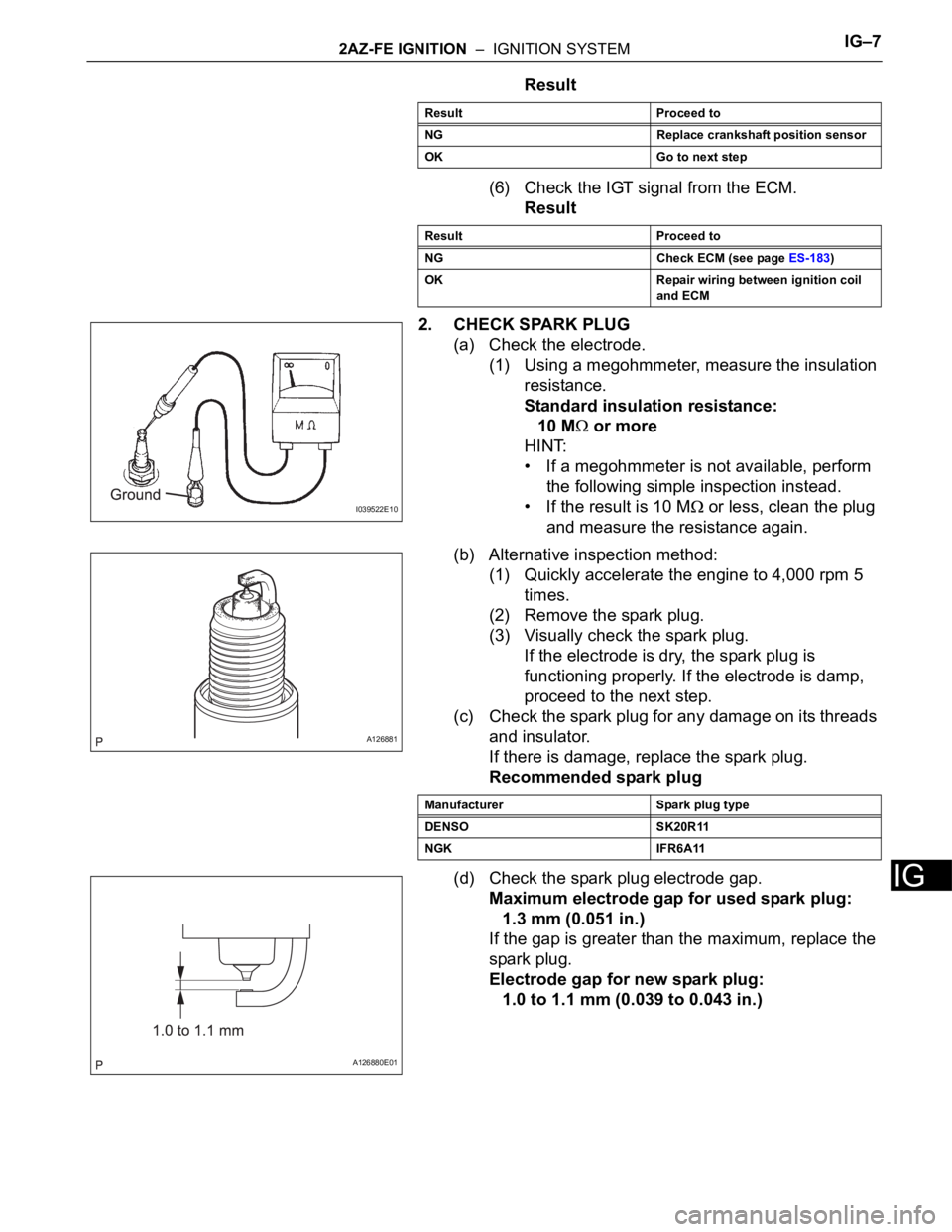

(b) Install the oil pan with the 16 bolts and 2 nuts.

Torque: 10 N*m (102 kgf*cm, 7 ft.*lbf)

(c) Install a new gasket and the drain plug.

Torque: 40 N*m (408 kgf*cm, 30 ft.*lbf)

11. INSTALL OIL FILTER ELEMENT KIT (See page LU-5)

12. INSTALL OIL FILTER CAP ASSEMBLY (See page LU-

5)

13. INSTALL OIL DIPSTICK GUIDE

(a) Install a new O-ring to the dipstick guide.

A132109E01

A132108

A132138E01

A132107E01

Page 884 of 2000

LU–242GR-FE LUBRICATION – OIL PUMP

LU

(b) Install the dipstick guide with the bolt.

Torque: 21 N*m (214 kgf*cm, 15 ft.*lbf)

14. INSTALL NO. 2 OIL DIPSTICK GUIDE

(a) Install a new O-ring to the dipstick guide.

(b) Install the dipstick guide with the bolt.

Torque: 21 N*m (214 kgf*cm, 15 ft.*lbf)

(c) Install the oil dipstick.

15. REMOVE ENGINE FROM STAND

16. INSTALL ENGINE ASSEMBLY

(a) Install the engine to the vehicle (see page EM-31).

17. CONNECT CABLE TO NEGATIVE BATTERY

TERMINAL

A132180

A132179

Page 885 of 2000

2AZ-FE IGNITION – IGNITION SYSTEMIG–5

IG

ON-VEHICLE INSPECTION

1. CHECK IGNITION COIL ASSEMBLY AND PERFORM

SPARK TEST

NOTICE:

In this section, the terms "cold" and "hot" refer to

the temperature of the coils. "Cold" means

approximately -10 to 50

C (14 to 122F). "Hot" means

approximately 50 to 100

C (122 to 212F).

(a) Check the DTCs.

NOTICE:

If a DTC is present, perform troubleshooting in

accordance with the procedure for that DTC.

(b) Check that sparks occur.

(1) Remove the No. 1 engine cover.

(2) Remove the bolt and ignition coil.

(3) Using a 16 mm spark plug wrench, remove the

spark plug.

(4) Disconnect the 4 fuel injector connectors.

(5) Install the spark plug into the ignition coil, and

then connect the ignition coil connectors.

(6) Ground the spark plug.

(7) Check that sparks occur at the spark plug while

the engine is being cranked.

NOTICE:

• Be sure to ground the spark plugs when

checking them.

• If the ignition coil has been struck or

dropped, replace it.

• Do not crank the engine for more than 2

seconds.

If sparks do not occur, Perform the spark test.

(8) Using a 16 mm plug wrench, install the spark

plug.

Torque: 25 N*m (254 kgf*cm, 18 ft.*lbf)

A124849E01

A097448E01

A124396

Page 886 of 2000

IG–62AZ-FE IGNITION – IGNITION SYSTEM

IG

(9) Install the ignition coil with the bolt.

Torque: 9.0 N*m (92 kgf*cm, 80 in.*lbf)

(10) Connect the 4 fuel injector connectors.

(11) Install the No. 1 engine cover.

(c) Spark test flow chart.

(1) Check that the ignition coil connector is

securely connected.

Result

(2) Perform the spark test on each ignition coil.

1. Replace the ignition coil with a normal one.

2. Perform the spark test again.

Result

(3) Check the power supply to the ignition coil.

1. Disconnect the ignition coil connector.

2. Turn the ignition switch ON.

3. Measure the voltage of the wire harness

side connector.

Standard voltage

Result

(4) Check the resistance of the camshaft position

sensor.

Standard resistance

Result

(5) Check the resistance of the crankshaft position

sensor.

Standard resistance

Result Proceed to

NG Connect securely

OK Go to next step

Result Proceed to

OK Replace ignition coil

NG Go to next step

A124397

Tester Connection Specified Condition

1 (+B) - 4 (GND) 9 to 14 V

Result Proceed to

NG Check wire harness and connector

OK Go to next step

Temperature Condition Specified Condition

Cold 835 to 1,400

Hot 1,060 to 1,645

Result Proceed to

NG Replace camshaft position sensor

OK Go to next step

Temperature Condition Specified Condition

Cold 985 to 1,600

Hot 1,265 to 1,890

Page 887 of 2000

2AZ-FE IGNITION – IGNITION SYSTEMIG–7

IG

Result

(6) Check the IGT signal from the ECM.

Result

2. CHECK SPARK PLUG

(a) Check the electrode.

(1) Using a megohmmeter, measure the insulation

resistance.

Standard insulation resistance:

10 M

or more

HINT:

• If a megohmmeter is not available, perform

the following simple inspection instead.

• If the result is 10 M

or less, clean the plug

and measure the resistance again.

(b) Alternative inspection method:

(1) Quickly accelerate the engine to 4,000 rpm 5

times.

(2) Remove the spark plug.

(3) Visually check the spark plug.

If the electrode is dry, the spark plug is

functioning properly. If the electrode is damp,

proceed to the next step.

(c) Check the spark plug for any damage on its threads

and insulator.

If there is damage, replace the spark plug.

Recommended spark plug

(d) Check the spark plug electrode gap.

Maximum electrode gap for used spark plug:

1.3 mm (0.051 in.)

If the gap is greater than the maximum, replace the

spark plug.

Electrode gap for new spark plug:

1.0 to 1.1 mm (0.039 to 0.043 in.)

Result Proceed to

NG Replace crankshaft position sensor

OK Go to next step

Result Proceed to

NG Check ECM (see page ES-183)

OK Repair wiring between ignition coil

and ECM

I039522E10

A126881

Manufacturer Spark plug type

DENSO SK20R11

NGK IFR6A11

A126880E01

Page 895 of 2000

2GR-FE IGNITION – IGNITION SYSTEMIG–5

IG

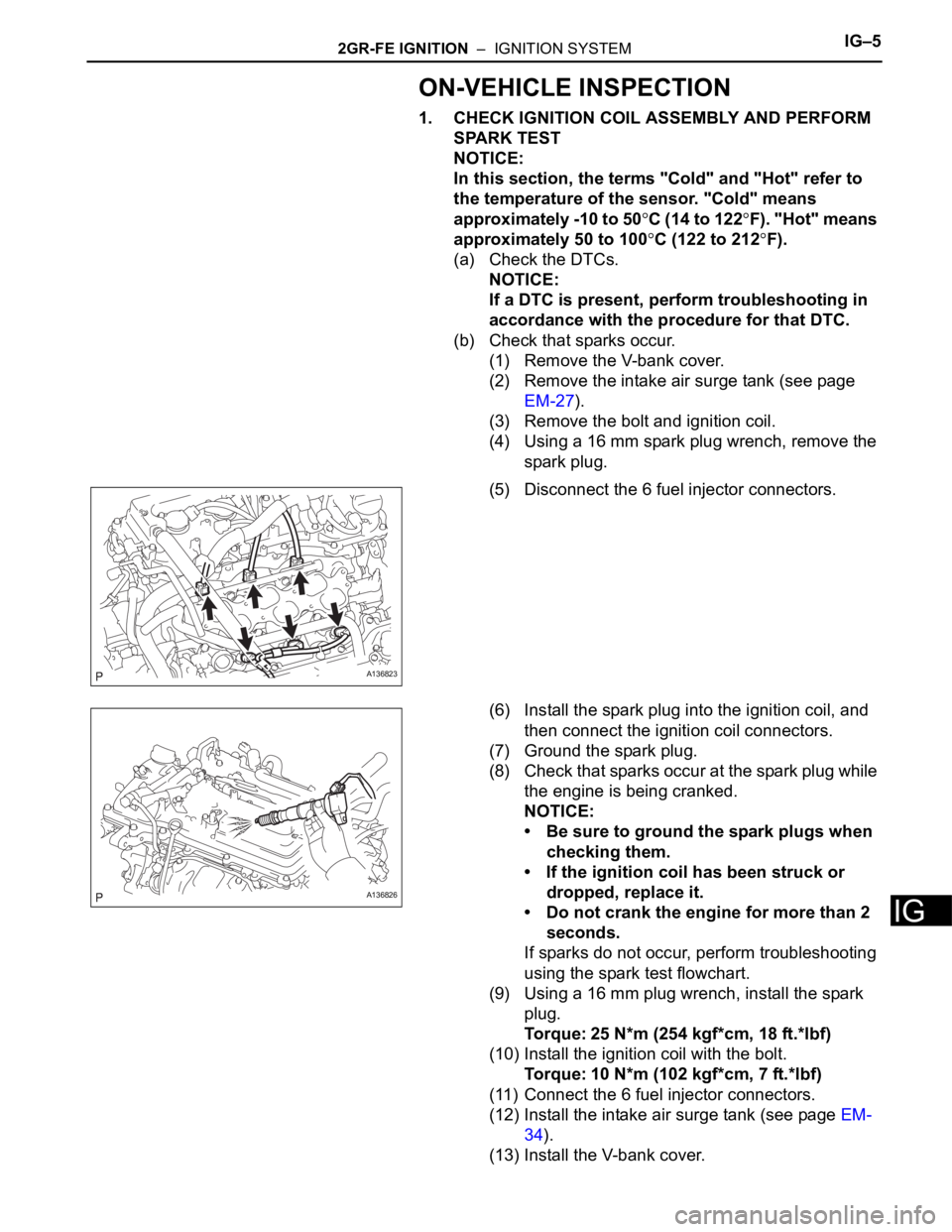

ON-VEHICLE INSPECTION

1. CHECK IGNITION COIL ASSEMBLY AND PERFORM

SPARK TEST

NOTICE:

In this section, the terms "Cold" and "Hot" refer to

the temperature of the sensor. "Cold" means

approximately -10 to 50

C (14 to 122F). "Hot" means

approximately 50 to 100

C (122 to 212F).

(a) Check the DTCs.

NOTICE:

If a DTC is present, perform troubleshooting in

accordance with the procedure for that DTC.

(b) Check that sparks occur.

(1) Remove the V-bank cover.

(2) Remove the intake air surge tank (see page

EM-27).

(3) Remove the bolt and ignition coil.

(4) Using a 16 mm spark plug wrench, remove the

spark plug.

(5) Disconnect the 6 fuel injector connectors.

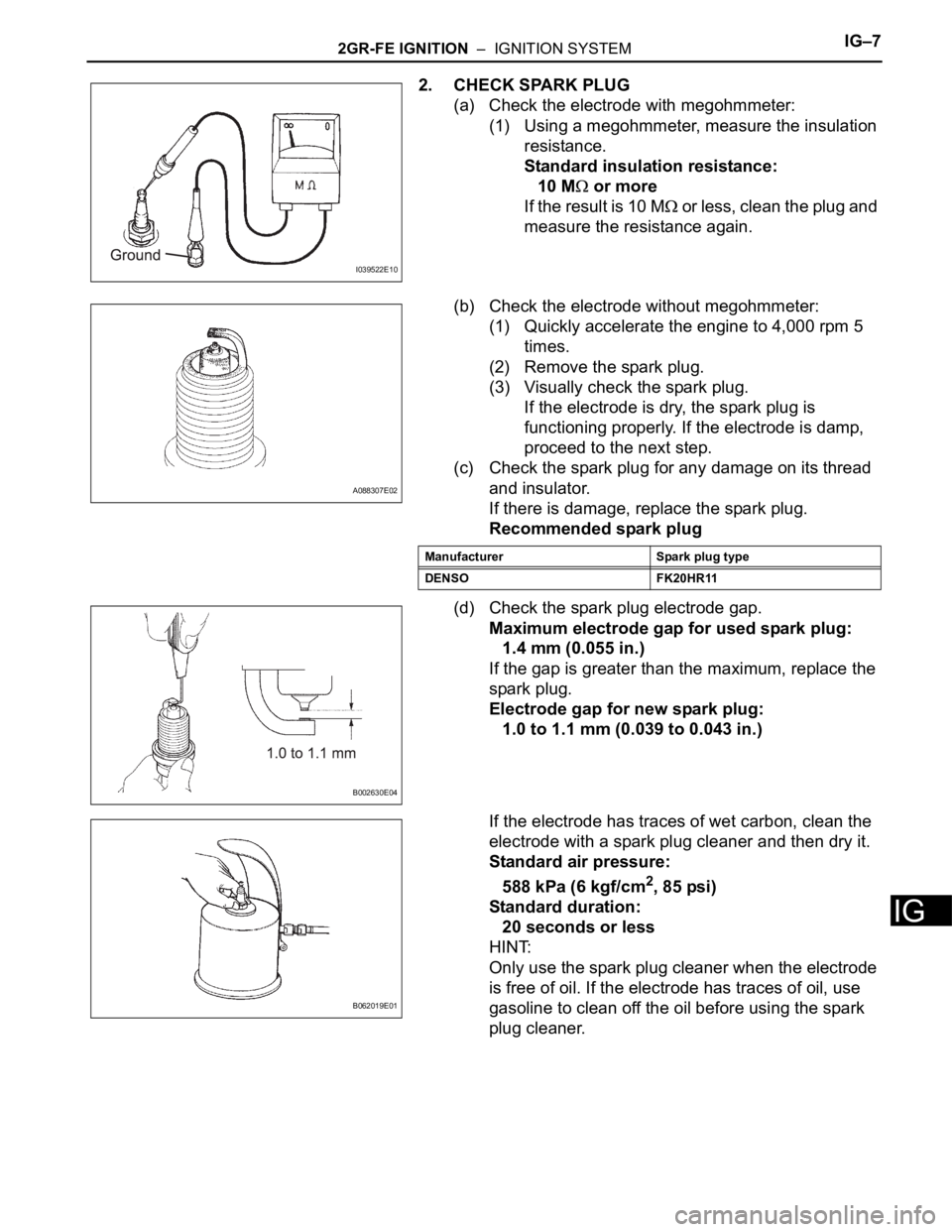

(6) Install the spark plug into the ignition coil, and

then connect the ignition coil connectors.

(7) Ground the spark plug.

(8) Check that sparks occur at the spark plug while

the engine is being cranked.

NOTICE:

• Be sure to ground the spark plugs when

checking them.

• If the ignition coil has been struck or

dropped, replace it.

• Do not crank the engine for more than 2

seconds.

If sparks do not occur, perform troubleshooting

using the spark test flowchart.

(9) Using a 16 mm plug wrench, install the spark

plug.

Torque: 25 N*m (254 kgf*cm, 18 ft.*lbf)

(10) Install the ignition coil with the bolt.

Torque: 10 N*m (102 kgf*cm, 7 ft.*lbf)

(11) Connect the 6 fuel injector connectors.

(12) Install the intake air surge tank (see page EM-

34).

(13) Install the V-bank cover.

A136823

A136826

Page 897 of 2000

2GR-FE IGNITION – IGNITION SYSTEMIG–7

IG

2. CHECK SPARK PLUG

(a) Check the electrode with megohmmeter:

(1) Using a megohmmeter, measure the insulation

resistance.

Standard insulation resistance:

10 M

or more

If the result is 10 M

or less, clean the plug and

measure the resistance again.

(b) Check the electrode without megohmmeter:

(1) Quickly accelerate the engine to 4,000 rpm 5

times.

(2) Remove the spark plug.

(3) Visually check the spark plug.

If the electrode is dry, the spark plug is

functioning properly. If the electrode is damp,

proceed to the next step.

(c) Check the spark plug for any damage on its thread

and insulator.

If there is damage, replace the spark plug.

Recommended spark plug

(d) Check the spark plug electrode gap.

Maximum electrode gap for used spark plug:

1.4 mm (0.055 in.)

If the gap is greater than the maximum, replace the

spark plug.

Electrode gap for new spark plug:

1.0 to 1.1 mm (0.039 to 0.043 in.)

If the electrode has traces of wet carbon, clean the

electrode with a spark plug cleaner and then dry it.

Standard air pressure:

588 kPa (6 kgf/cm

2, 85 psi)

Standard duration:

20 seconds or less

HINT:

Only use the spark plug cleaner when the electrode

is free of oil. If the electrode has traces of oil, use

gasoline to clean off the oil before using the spark

plug cleaner.

I039522E10

A088307E02

Manufacturer Spark plug type

DENSO FK20HR11

B002630E04

B062019E01

Page 954 of 2000

AX–20U140F AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEM

AX

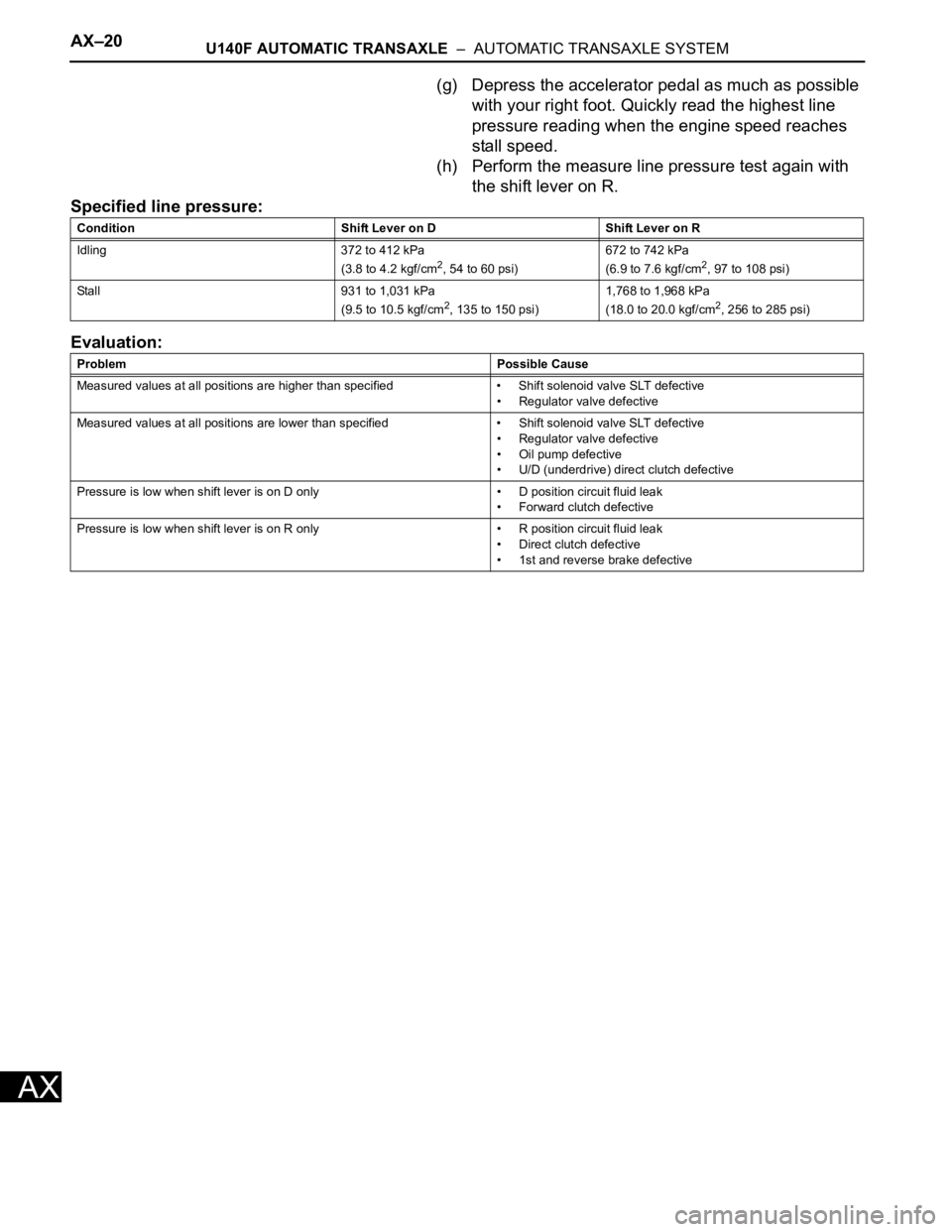

(g) Depress the accelerator pedal as much as possible

with your right foot. Quickly read the highest line

pressure reading when the engine speed reaches

stall speed.

(h) Perform the measure line pressure test again with

the shift lever on R.

Specified line pressure:

Evaluation:

Condition Shift Lever on D Shift Lever on R

Idling 372 to 412 kPa

(3.8 to 4.2 kgf/cm

2, 54 to 60 psi)672 to 742 kPa

(6.9 to 7.6 kgf/cm2, 97 to 108 psi)

Stall 931 to 1,031 kPa

(9.5 to 10.5 kgf/cm

2, 135 to 150 psi)1,768 to 1,968 kPa

(18.0 to 20.0 kgf/cm2, 256 to 285 psi)

Problem Possible Cause

Measured values at all positions are higher than specified • Shift solenoid valve SLT defective

• Regulator valve defective

Measured values at all positions are lower than specified • Shift solenoid valve SLT defective

• Regulator valve defective

• Oil pump defective

• U/D (underdrive) direct clutch defective

Pressure is low when shift lever is on D only • D position circuit fluid leak

• Forward clutch defective

Pressure is low when shift lever is on R only • R position circuit fluid leak

• Direct clutch defective

• 1st and reverse brake defective

Page 961 of 2000

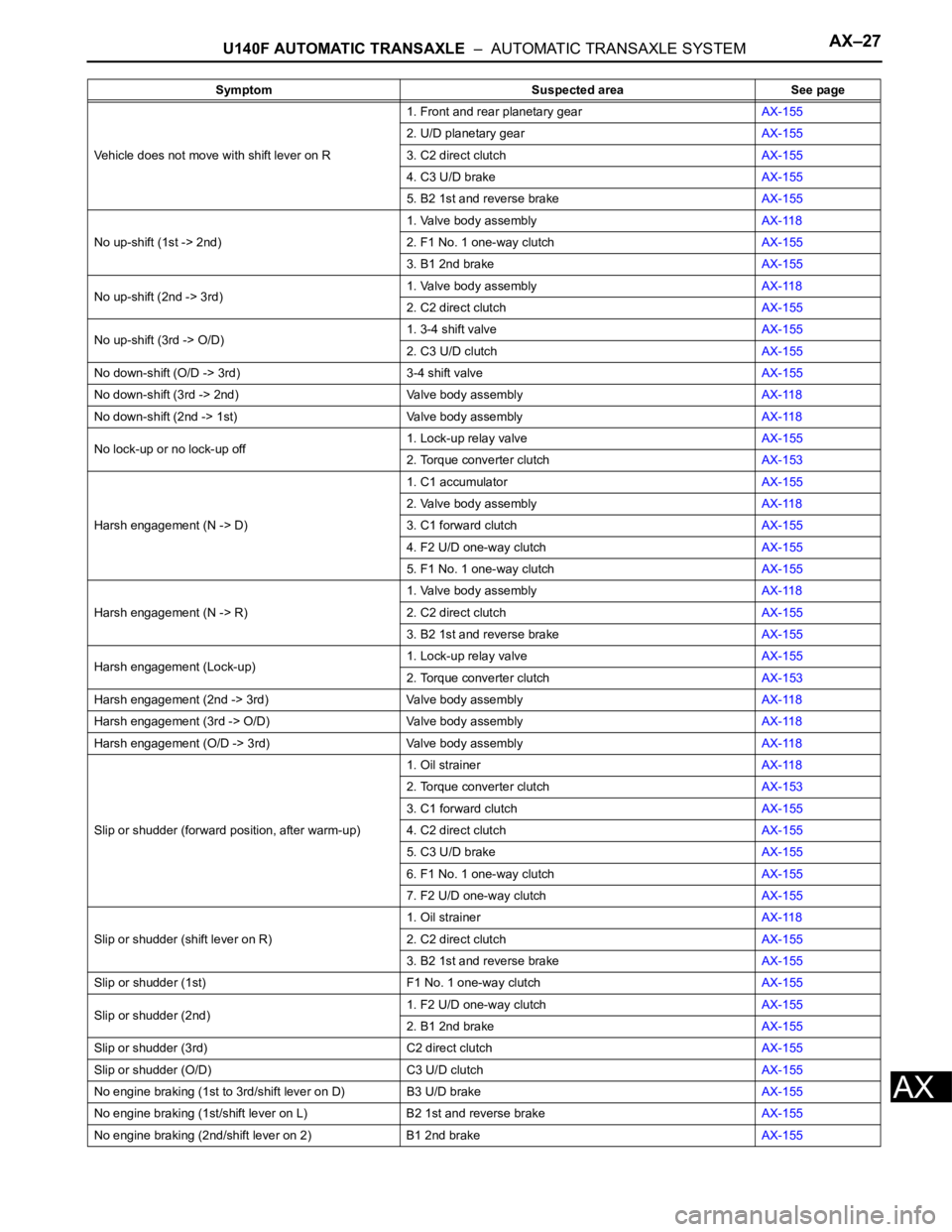

U140F AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEMAX–27

AX

Vehicle does not move with shift lever on R1. Front and rear planetary gearAX-155

2. U/D planetary gearAX-155

3. C2 direct clutchAX-155

4. C3 U/D brakeAX-155

5. B2 1st and reverse brakeAX-155

No up-shift (1st -> 2nd)1. Valve body assemblyAX-118

2. F1 No. 1 one-way clutchAX-155

3. B1 2nd brakeAX-155

No up-shift (2nd -> 3rd)1. Valve body assemblyAX-118

2. C2 direct clutchAX-155

No up-shift (3rd -> O/D)1. 3-4 shift valveAX-155

2. C3 U/D clutchAX-155

No down-shift (O/D -> 3rd) 3-4 shift valveAX-155

No down-shift (3rd -> 2nd) Valve body assemblyAX-118

No down-shift (2nd -> 1st) Valve body assemblyAX-118

No lock-up or no lock-up off1. Lock-up relay valveAX-155

2. Torque converter clutchAX-153

Harsh engagement (N -> D)1. C1 accumulatorAX-155

2. Valve body assemblyAX-118

3. C1 forward clutchAX-155

4. F2 U/D one-way clutchAX-155

5. F1 No. 1 one-way clutchAX-155

Harsh engagement (N -> R)1. Valve body assemblyAX-118

2. C2 direct clutchAX-155

3. B2 1st and reverse brakeAX-155

Harsh engagement (Lock-up)1. Lock-up relay valveAX-155

2. Torque converter clutchAX-153

Harsh engagement (2nd -> 3rd) Valve body assemblyAX-118

Harsh engagement (3rd -> O/D) Valve body assemblyAX-118

Harsh engagement (O/D -> 3rd) Valve body assemblyAX-118

Slip or shudder (forward position, after warm-up)1. Oil strainerAX-118

2. Torque converter clutchAX-153

3. C1 forward clutchAX-155

4. C2 direct clutchAX-155

5. C3 U/D brakeAX-155

6. F1 No. 1 one-way clutchAX-155

7. F2 U/D one-way clutchAX-155

Slip or shudder (shift lever on R)1. Oil strainerAX-118

2. C2 direct clutchAX-155

3. B2 1st and reverse brakeAX-155

Slip or shudder (1st) F1 No. 1 one-way clutchAX-155

Slip or shudder (2nd)1. F2 U/D one-way clutchAX-155

2. B1 2nd brakeAX-155

Slip or shudder (3rd) C2 direct clutchAX-155

Slip or shudder (O/D) C3 U/D clutchAX-155

No engine braking (1st to 3rd/shift lever on D) B3 U/D brakeAX-155

No engine braking (1st/shift lever on L) B2 1st and reverse brakeAX-155

No engine braking (2nd/shift lever on 2) B1 2nd brakeAX-155 Symptom Suspected area See page

Page 976 of 2000

AX–144U140F AUTOMATIC TRANSAXLE – DIFFERENTIAL OIL SEAL

AX

REPLACEMENT

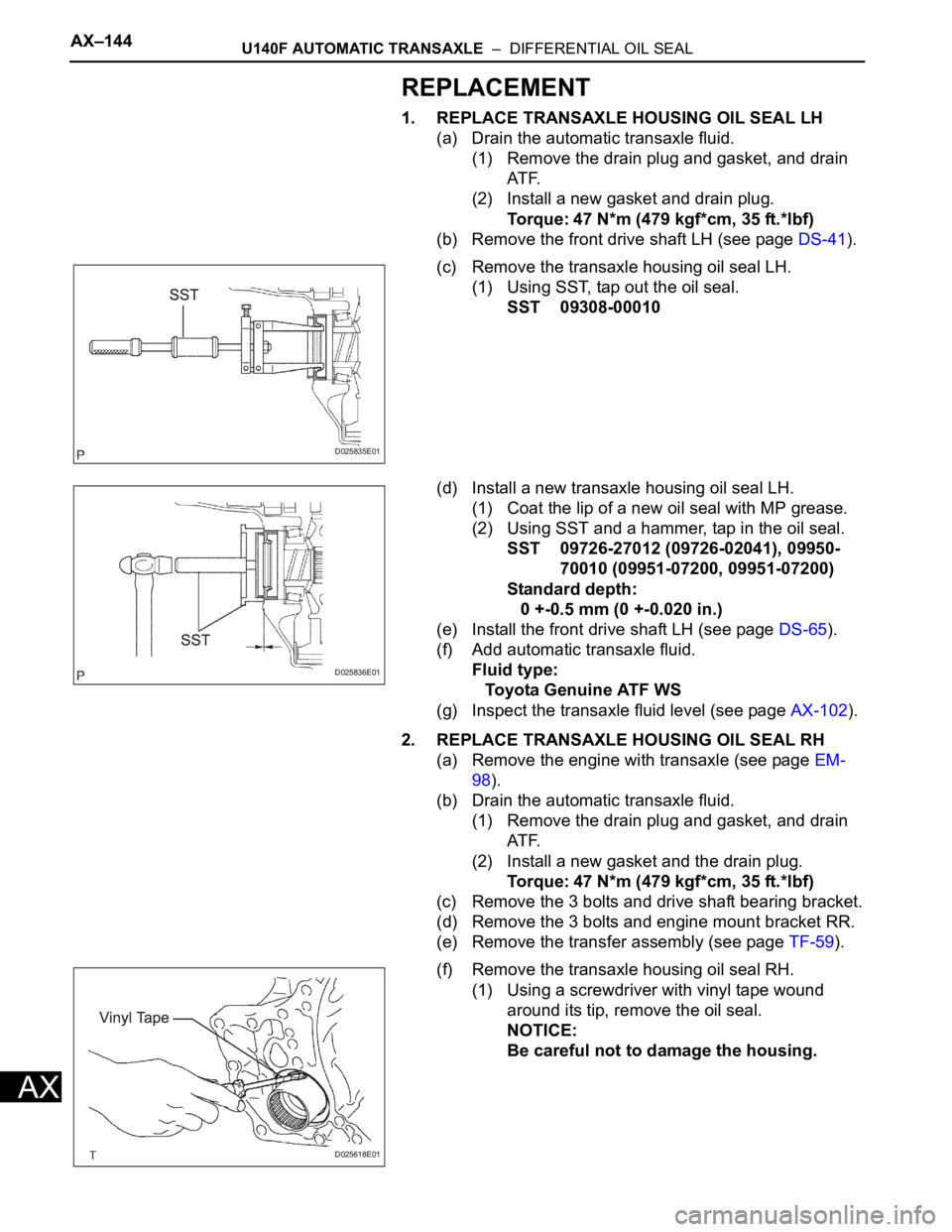

1. REPLACE TRANSAXLE HOUSING OIL SEAL LH

(a) Drain the automatic transaxle fluid.

(1) Remove the drain plug and gasket, and drain

AT F.

(2) Install a new gasket and drain plug.

Torque: 47 N*m (479 kgf*cm, 35 ft.*lbf)

(b) Remove the front drive shaft LH (see page DS-41).

(c) Remove the transaxle housing oil seal LH.

(1) Using SST, tap out the oil seal.

SST 09308-00010

(d) Install a new transaxle housing oil seal LH.

(1) Coat the lip of a new oil seal with MP grease.

(2) Using SST and a hammer, tap in the oil seal.

SST 09726-27012 (09726-02041), 09950-

70010 (09951-07200, 09951-07200)

Standard depth:

0 +-0.5 mm (0 +-0.020 in.)

(e) Install the front drive shaft LH (see page DS-65).

(f) Add automatic transaxle fluid.

Fluid type:

Toyota Genuine ATF WS

(g) Inspect the transaxle fluid level (see page AX-102).

2. REPLACE TRANSAXLE HOUSING OIL SEAL RH

(a) Remove the engine with transaxle (see page EM-

98).

(b) Drain the automatic transaxle fluid.

(1) Remove the drain plug and gasket, and drain

AT F.

(2) Install a new gasket and the drain plug.

Torque: 47 N*m (479 kgf*cm, 35 ft.*lbf)

(c) Remove the 3 bolts and drive shaft bearing bracket.

(d) Remove the 3 bolts and engine mount bracket RR.

(e) Remove the transfer assembly (see page TF-59).

(f) Remove the transaxle housing oil seal RH.

(1) Using a screwdriver with vinyl tape wound

around its tip, remove the oil seal.

NOTICE:

Be careful not to damage the housing.

D025835E01

D025836E01

D025618E01